Makita EB7650TH, EB7650THG, EB7650WH Technical Information

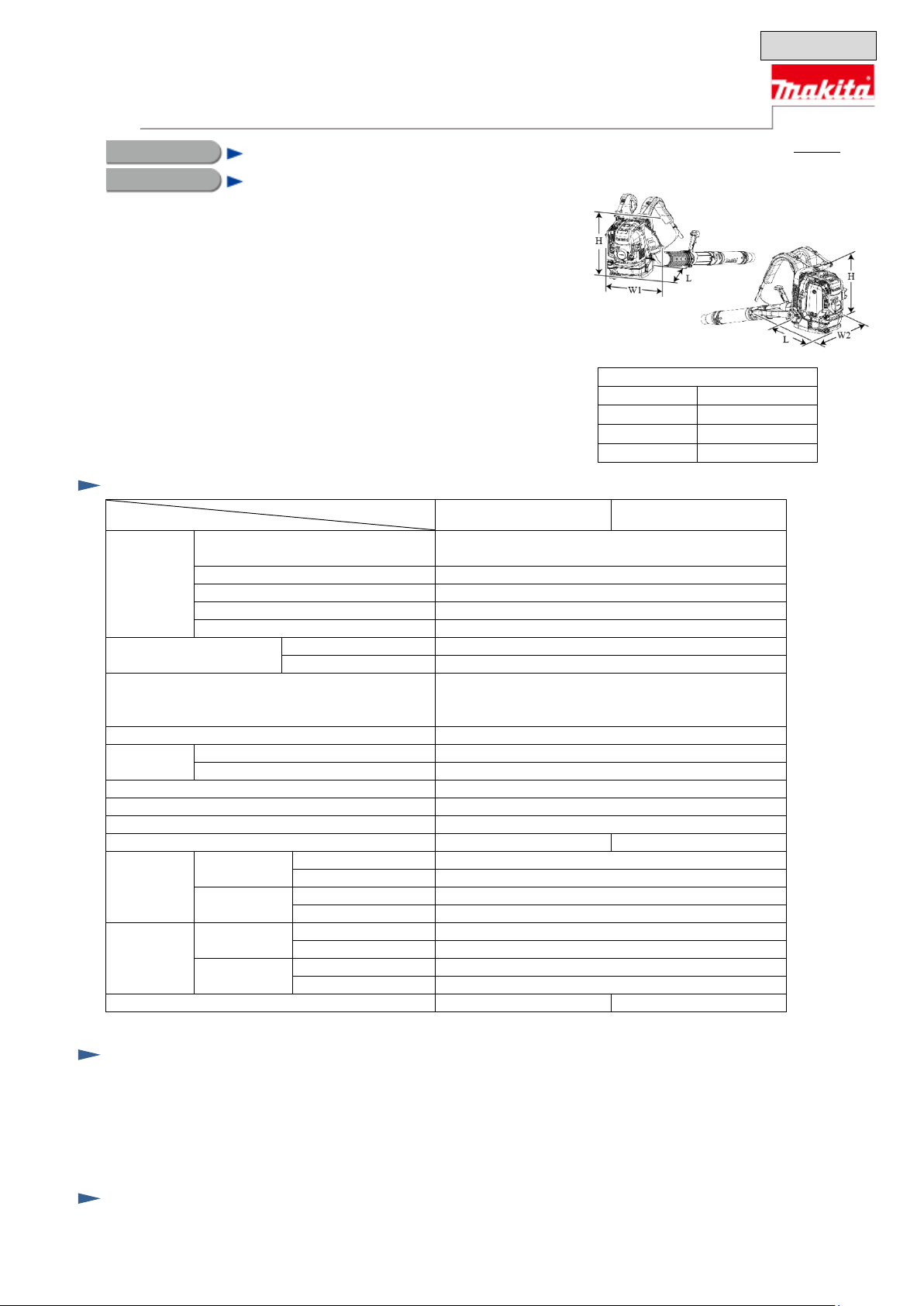

Dimensions: mm (“)

Length (L)

332 (13-1/8)

Width 1 (W1)

460 (18-1/8)

Width 2 (W2)

510 (20)

Height (H)

480 (18-7/8)

Model

Specification

4-stroke, single-cy linder, air-cooled

(Makita EH075F1)

Displacement: cm³ (cu.in)

75.6 (4.6)

Fuel

Straight u nleaded g asolin e*1 (E 0 to E10* 2)

Max output: kW (PS)

2.7 (3.7) [at 7,000 minˉ¹]

Max torque: N.m

4.4 [at 5,000 minˉ¹]

at max out put pow er

7,100

at no load

2,800

SAE10W-30,

(4-stroke eng ine oil for automobile)

Carburetor

Diaphragm

Starting

system

Easy start (Spring-assisted recoil starter)

No

Decompression valve

Yes

Spark plug

NGK CMR6A

Primer pump

Yes

Fuel tank capacity: L (US oz )

1.9 (64)

Throttle location

Tube-mounted

Hip-mounted

End nozzle 90-60

89 (200)

End nozzle 90-70

81 (181)

End nozzle 90-60

90 (201)

End nozzle 90-70

81 (182)

End nozzle 90-60

17 (607)

End nozzle 90-70

19 (682)

End nozzle 90-60

17 (611)

End nozzle 90-70

19 (682)

Dry weight: kg (lbs)

10.8 (23.8)

11.0 (24.3)

T

ECHNICAL INFORMATION

July 2015

OFFICIAL USE

for A SC & Sales Shop

P 1 /35

PRODUCT

Petrol Blower

CONCEPT AND MAIN APPLICA TIONS

Model No.

Description

S

S

O

EB7650TH/

EB7650THG

EB7650WH

EB7650TH/ EB7650THG/ EB7650WH

Models EB7650 TH/ EB7650TH G/ EB7650WH a re Petrol blow ers equip ped wit h

75.6cm³ 4-stroke engine in compliance with strict exhaust emission regulations.

These products are ideal for professional use with the following features:

• Higher air speed and larger air volume than our current model BBX7600

for excellent operation effici ency

• 4 damper springs mou nted between t he engine and the b ackpack fram e

that reduce vibration on the back of operator even during long hours

of operation t o redu ce opera tor st ress an d fatig ue

• Cushioning back padding and shoulder straps well-ventilated for effective

sweat evaporati on to provide m ore comf ort

Model EB7650TH features tube-mounted throttle while EB7650WH features

hip-mounted throttle. Model EB7650THG is E25 compatible.

pecification

EB7650TH/ EB 7650THG EB7650WH

Type

Engine

Speed: minˉ¹ = rpm

Engine oil

Max air

speed:

m/s*3

Max air

volume:

m³/min*3

*1 "Straight" means "not mixed with engine oil". *2 EB7650THG: E25 *3 Actual m easured value

tandard equi pment

Oil bottle set*4 Flexible pipe End nozzle 90-60 Long pipe 90

Box wrench 16 Swivel pipe End nozzle 90-70

Driver Hose clamp Flat nozzle 90

*4 W ith engine oil contained for some countries.

Note: The standard equipment may vary by country or model variation.

ptional accessories

Short pipe 90 Hip belt set

Long pipe 90

Short pipe 9 0

Long pipe 90

Short pipe 9 0

Class SF or higher of A PI Classification

P 2/ 35

Repair

CAUTION: R epair the mach ine in acco rdance with “Ins tructio n manual” or “Safety instructions”.

Index

[1] NECESSARY REPAIRING T OOLS P 2

[2] GASKETS AND LUBRICA TION P 3

[3] DISASSEMB LY/ASSEM BLY P 4-28

[3]-1. W arning P 4

[3]-2. Blower Section (Band Completes L and R, Frame and Fan) P 4-9

[3]-3. Throttle Lever Section P 10-12

[3]-4. Engine Section (Rocker Arm, Valve Portion, and Cam gear Portion) P 13-17

[3]-5. Air Cleaner Case P 17

[3]-6. Carburetor P 18-20

[3]-7. Flywheel P 21

[3]-8. Ignition System P 21-22

[3]-9. Crankcase P 23-27

[3]-10. Completion Inspection Che ck Poi nts P 28

[1] NECESSARY REPAIRING T OOLS

Code No. Description Use for

1R005 Retaining ring pliers R T -2N Attaching/removing Cot ter (u sed tog ether w ith 1R 389)

1R070 Tachometer Engin e speed check

1R181 Ignition checker Diagnosis of Ignition coil

1R229 1/4” hex. Shank bit for M5 Loosening/tightening M5 Hex socket head bolts

1R288 Screwdriver magnetizer Attaching/removing Cotter

1R306 Ring spring removing jig Attaching/removing Cotter

1R311 Retaining ring pliers Removing/inserting tubes

1R364 Flywheel puller Removing Flywheel

1R366 Feeler gauge set Adjusting gaps of Spark plug, Rocker arm, an d Ignition coil

1R389 Cotter removal attachment Attaching/removing Cot ter (u sed tog ether w ith 1R 005)

1R402-A Digital tester Diagnosis of Ignition coil

Makita Corporation

P 3/ 35

Tips of valves

Outer circumference of Cam lifter

Outer circumference of Push rods

Outer circumference of O-rings 17

17

20

Remove grease.

Sliding part s inside the engine

Sealing lips of Oil seals

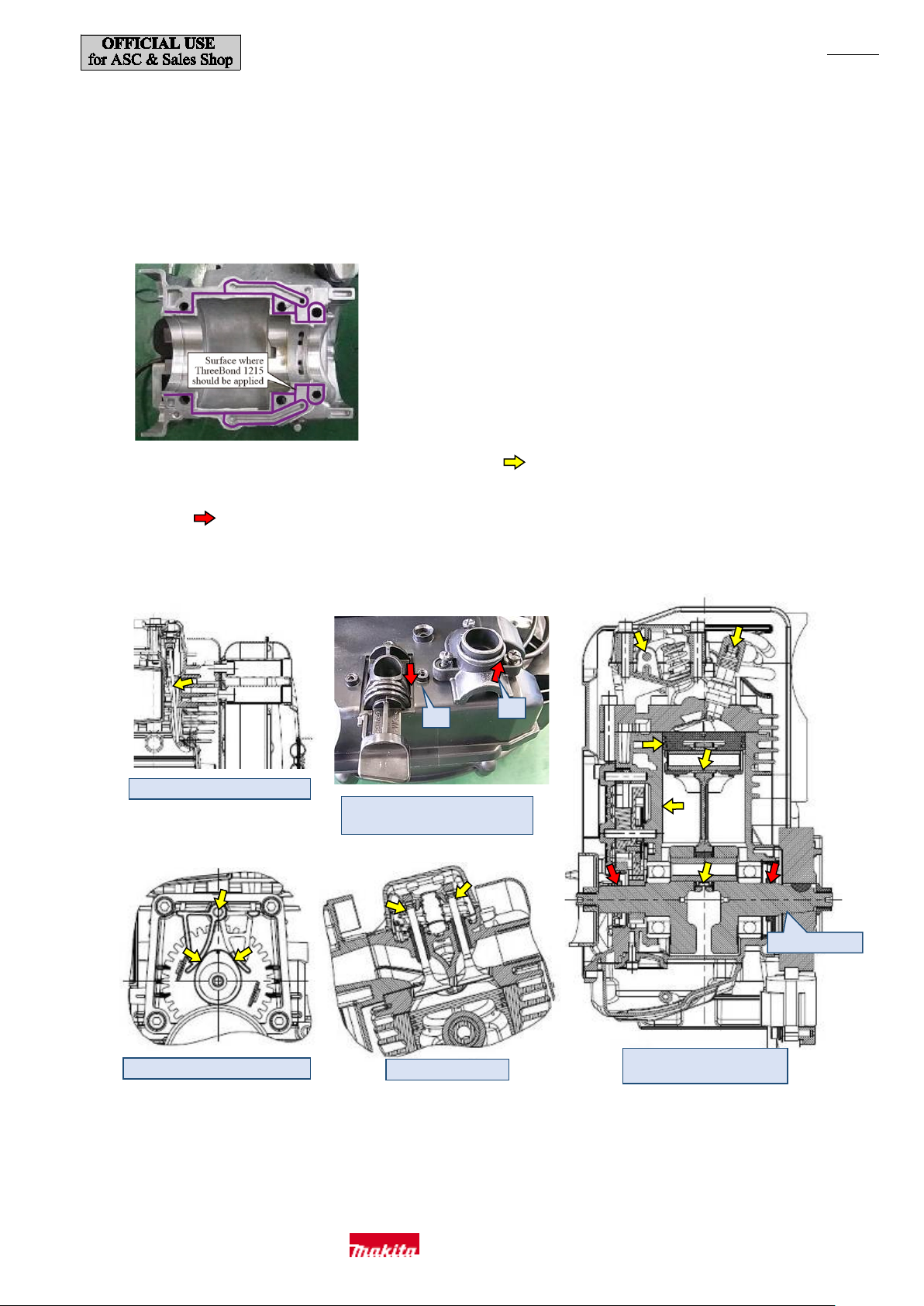

[2] GASKETS AND LUBRICA TION

・After removing the gasket s, completely remove any residue.

・When reassembling, replace the gaskets with new ones.

・Use parts cleaner or the li ke to rem ove grease from the mating surface of Cylinder and Crankcase and then apply Liqu id gasket

ThreeBond 1215 as drawn below

.

・Apply a small amount of 4-s troke engine oil to each part in dicated by in the following diagrams when assembling the parts.

・Apply Makita grease N No.2 to the sealing lips of Oil seals and outer circumf erence of O rings 17 and 20 of the anti-icing valve portion

indicated by .

・Apply Makita grease N No.2 to the outer circumferen ce of the O ring of Elbow.

・When attaching Flywheel, use parts clean er or the lik e to remov e the grease from the tapered part.

and 20 of the anti-icing valve p ortion

Makita Corporation

P 4/ 35

Fig. 1

Pull out the band as shown above.

Position the buck le vertica lly

and then remove it.

Turn t he ce nter of Lock rivet with

a Phillips scr ewdriv er to loose n it a

[3] DISASSEMB LY/ASSEM BLY

[3]-1. W arning

・There is a risk of a burn injury immediately after the engine is stopped. So wait until the engine has completely cooled

before performing the work.

・Completely remove all fuel from the inside of Fuel tank and Carburetor before performing the work. [No open flames]

・Remove the engine oil before performing the work.

・Perform the work on a solid workbench in a place where dust, dirt, etc. will not enter inside.

・Remember how and where the parts were assem bled when disas sembling th e product and take c are not to m ake a mis take

when assembling the product.

Prepare boxes so that you can store the parts in groups when disassembling the product.

・Handle the removed parts carefully and clean and w ash them properly.

・If a bolt or screw cann ot be loosened, do n ot apply excessive force. Use an impact d river or sim ilar tool.

・Be sure to tighten bolts and screws to the specified tightening torque values.

・After assembling the main parts, turn the engine by hand to check that there is no abnormality or looseness.

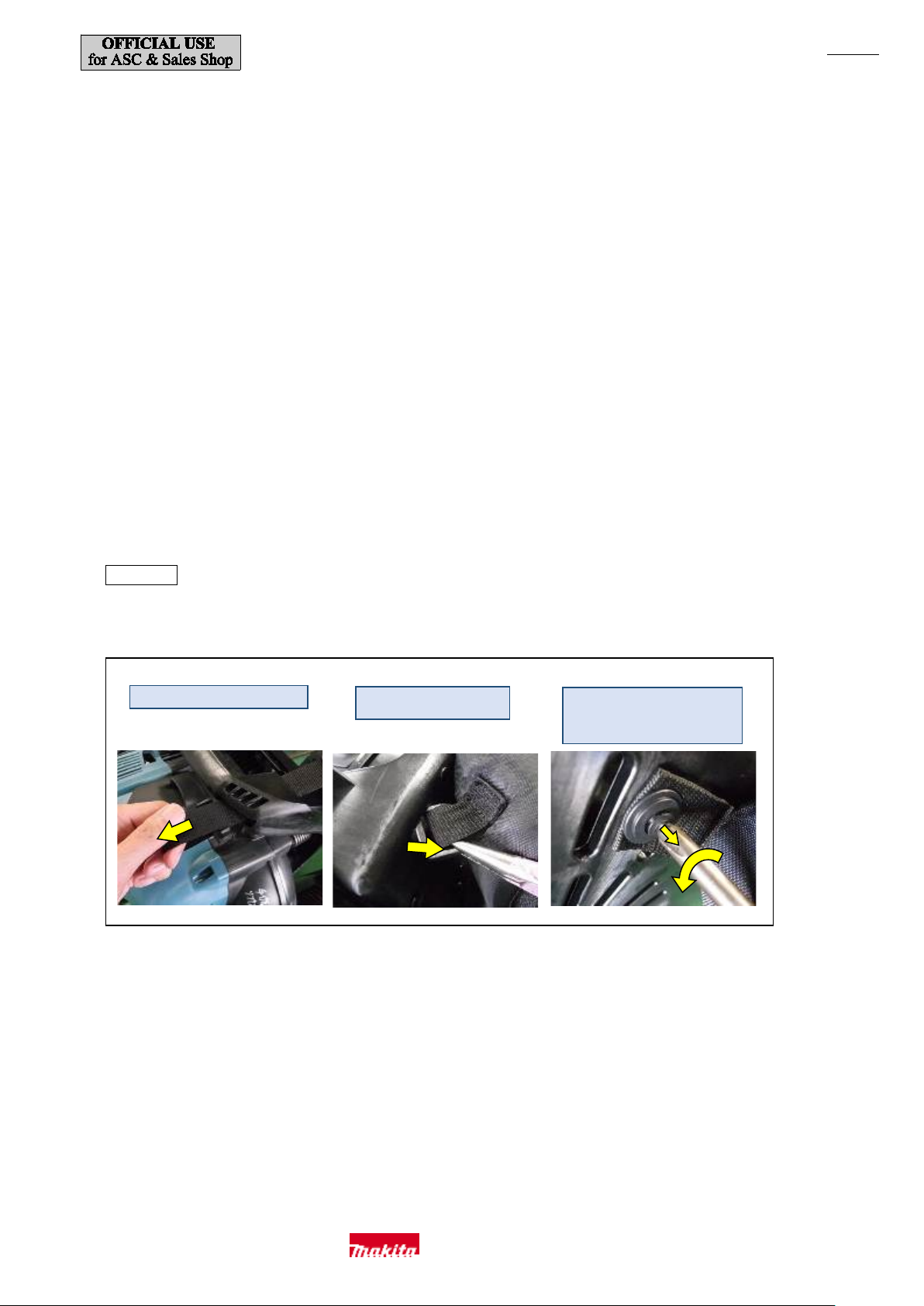

[3]-2. Blower Section (Band Completes L and R, Frame and Fan)

Disassembly

(1) Remove Band completes L and R and Hip belt. Remove each of the fixing parts as shown in Fig. 1.

little and then re move it.

Makita Corporation

P 5/ 35

Fig. 4

Fig. 2

(a)

Fig. 3

(b)

(c)

Guard

(c)

Loosen this screw

only whe n remov ing

Fig. 5

Disconnect (e) from (f ).

(e)

2. Return Throttle

position a nd rem ove

1. Pull Throttle lev er

place with a finger.

(f)

Disconnect (e) from (d) a nd (g).

(d)

For Model EB7650WH,

(g)

Disconnec t the wire f rom the

M5-10 Hex nut

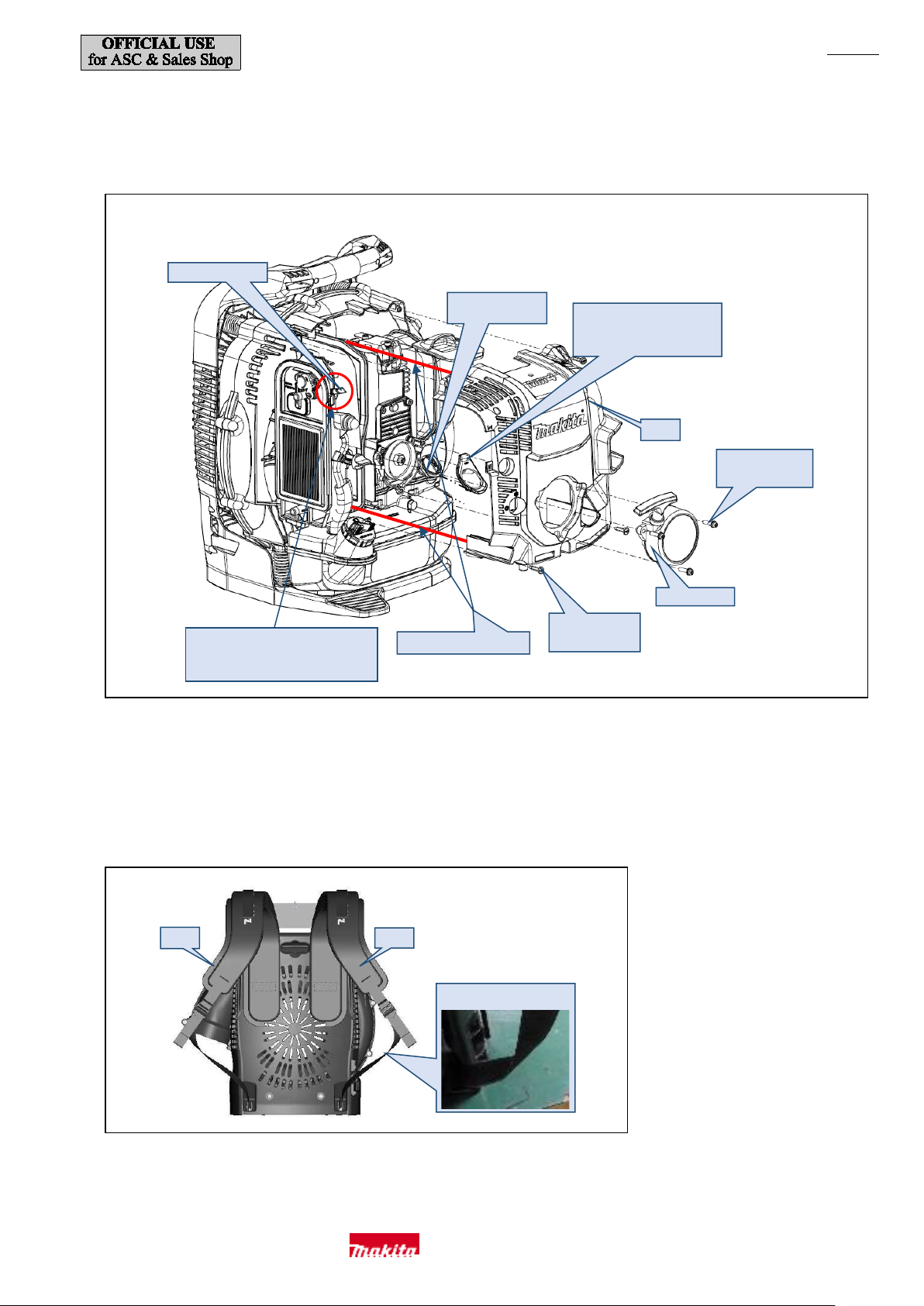

(2) Loosen three M5x20 Pan head screws and then remov e Recoil starter (a). (Fig. 2)

(3) Loosen f our 5x20 Tapping screws and then remove Engine cover (b). (Fig. 3)

(4) Remove six M5x16 Hex socket head bolts from th e bottom and front of Frame (c). (Fig. 4)

Guard.

(5) Lift up Fuel tank and disconnect the earth wire of Ignition coil from the brass M5-10 Hex nut beneath Fuel tank. (Left photo of Fig. 5)

(6) Disconnect Ignition coil at the bullet te rminals (d) (Center photo of Fig. 5), then disconnect Control cabl e (e) from Carburetor (f)

(Right photo of Fig. 5), and then rem ove the integrated Control cable (e) and Lead unit from Front volut e case (h). In th e case of

EB7650WH, remove Con trol ca ble (e) f rom Clip (g). (Center photo of Fig. 5)

earth terminal.

(7) Remove the engine, Volute case and Fuel tank together and then replace Frame (c).

lever to its or iginal

remove (e) from (g).

the wire end.

Makita Corporation

and then hold it in

P 6/ 35

(j)

(i)

Fig. 6

3

(h)

2

1

4

(k)

Upper

Lower

Fig. 7

Fig. 8

(8) Turn four Compression spri ngs 22 (the u pper tw o are sh orter than the lower two) used as vibration damper countercl ockwise and then

remove them. (Fig. 6)

(9) Loosen eleven 5x20 Tapping screws and then remove Rear volute case (i). Rem ove Elbow (j) together with it. (Fig. 7)

(10) Loosen the four M6x25 Hex socket head bolts and then remove fan (k). (Fig. 8)

Makita Corporation

P 7/ 35

Protrusion

(b)

Slide Ru bber r ing all the w ay onto each

(a)

(c)

Place the bullet te rminals and

Fig. 9

Fig. 10

Assembly

(1) Tighten the four fan fixing screws in a criss-cross pattern (the order shown in Fig. 8).

(2) Screw Compression springs 22 all the way onto Spring holders. The two shorter ones should be at the top (of Rear volute cas e) and the

two longer on es shou ld be at the bottom (of Front volute case). (Fig. 6)

If Rubber rings at the bottom h ave been removed, att ach them as shown in the photo on the right of Fig. 9 and then screw the springs

onto Spring holders.

Spring hol der w ith the flang ed e nd of the

ring facing Front volute case.

(3) Attach Elbow (a) wit h the prot rusi on position ed as s how n in Fig. 9 so that you can rotate Elbow from the front

of the machine and then secure Rear volute case (b) with eleven Tapping screws 5. (Fig. 7)

(4) Attach Frame, then connect Carburetor to Control cable, then connect the bullet terminals and earth wire of

Ignition coil and then secure Guard. (Figs. 4 and 5)

Place the bullet terminals in place as shown in Fig. 5 (d) while taking care that it w ill not become pinched

in the engine cover. Place corrugated tube (c) of Model EB7650TH in place as shown in Fig. 10.

line filter in this space, if used.

Makita Corporation

P 8/ 35

Left

Right

Twist 90 degrees

Carry out disassembly and assembly

he lever

Insert al ong the gui des

Recoil starter

Three M5x2 0

(d)

Oil guard:

Cylinder block

assembly

Choke lever

Four 5x20

Fig. 11

Fig. 12

(5) When fitting Engine cover complete (d), f ollow the instructions described in Fig. 11. Make sure that Carburetor gasket is on the inner

side of the rib inside Engine cover complete and that Plug cover is not pinched.

Align the fixing screw boss positions and then fit the cover and secure it in place with the four screws. (Fig. 3)

Attach before f itting Engine

cover complete.

Pan head screws

(6) Secure Band completes L and R with the fixing parts by reversing the disassembly procedure shown in Fig. 1 while taking care not to mix

them up.

with Choke lever raised or t

will catch on the engine cover .

Tapping screws

Twist the bands; Band complete R by 90 degrees clockwis e and Band com plete L by 90 degrees counterclo ckwise viewed from the top,

and then attach them . (Fig. 12)

Makita Corporation

P 9/ 35

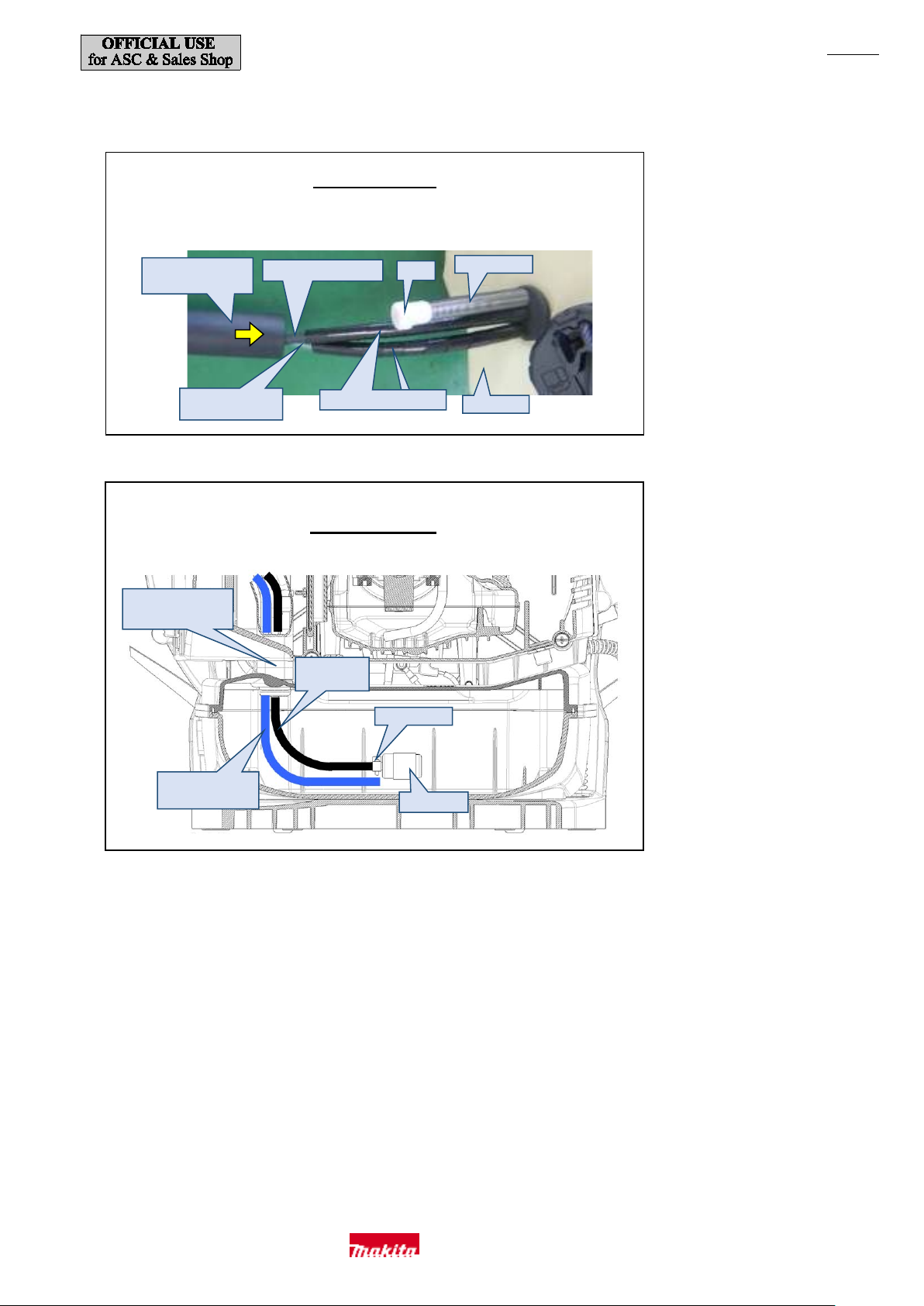

Fuel tank

Coil spring 8

(e)

Slide (f) all the way

Spiral tube 6-100

Tube 3-370

(transpare nt bl ue)

Tube 3-370 (black)

Inside of Fuel Tank

Hose clamp

Filter

Tube 3-370

(black)

Tube 3-370

Slide (f) all the way

Fig. 13

Fig. 14

(7) When the tubes have been disconn ected from Fuel tank during disassembly, connect them as shown in Figs. 13 and 14.

Cover the two tubes coming out of Fuel tank, individually, with Spiral tube 6-100, then cover

the tube of Breather (e) w ith the coil spring 8 and then slide Tube guard 20-102 (f) all the way

to cover the tubes.

to cover the tubes.

Outside of Fuel T ank

to cover the tubes.

(transpare nt bl ue)

Makita Corporation

P 10/ 35

(e)

(f) is on the back.

(a)

(b)

(d)

(c) (d)

Lever case L

Switch unit

Fig. 15

Fig. 16

[3]-3. Thr ottle Lever Section

EB7650TH

Disassembly

(1) Remove M5x30 thumb screw (a). (Fig. 15)

(2) Loosen five 4x18 Tapping screws and then remove Lever case R (b). (Fig. 15)

(3) Remove the h ead of Control cable (c) from Throttle lever A (d) and then remove the lever. (Fig. 15)

(4) Remove Throttle link (e), disconnect the connector of Switch unit, and then replace Switch unit.

(5) Loosen M 4x18 Hex socket head bolt and remove Throttle lever B (f). (Fig. 16)

Assembly

・Attach Throttle link (e) at the position shown in Fig. 16. First secure Throttle lever B (f) with the screw and then turn it counterclockwise

(viewed from the in side) to press the lever of Switch unit and then attach Throttle lever A (d).

Makita Corporation

P 11/ 35

W ave washer 20

(a)

Remove (b).

Disconnect (c).

Pull out (d).

(e)

(f)

Tw o rubber sleeves 6

(h)

(g)

T wo tors ion s prings 21

(g)

Fig. 17

Fig. 18

Fig. 19

EB7650WH

Disassembly

(1) Loosen six 4x18 Tapping screws and then remove Arm cover.

(2) Loosen M 5x25 Hex socket head bolt and remove Throttle lever (a). (Fig. 17)

(3) Remove the h ead of Control cable (b) from Throttle lever (a), then disconnect the connecto r (c) of Stop sw itch wire and then pull out

Cont rol cable (b), Lead unit, and Corrugate d tube (d). (Fig. 18)

(4) Loosen M 6x25 Hex socket head bolt and then rem ove Arm base (e).

(5) Disassemble Arm base (e) and Arm base holde r (f) by rem oving on e of two E-4 Stop rings (g) and then pushing out Rod 6 (h) fr om th ere.

(Fig. 19)

Makita Corporation

Loading...

Loading...