Page 1

T

Model No.

Description

ECHNICAL INFORMATION

DS4010, DS4011/ DS5000

Drills 13mm (1/2")/ 16mm (5/8'')

PRODUCT

P 1/ 8

CONCEPT AND MAIN APPLICATIONS

These three drills are redesigned version of models 6013B, 6013BR, 6016BR

with the same high performance as the current models.

Their main features and benefits are:

Non-skid elastomer covering main handle area for good looking impression

and sure and comfortable grip

Full 360 degree rotatable D-handle with 24 positive stops

for multi-position operation

Switch type is the main notable specification difference between

these three models:

DS4010

Trigger type, without reverse function, with variable speed control

DS4011, DS5000

Rocker type, with reverse function, without variable speed control

DS4010 is also available without Drill chuck as model DS4010M.

Specification

DS4010

Voltage (V) Cycle (Hz)

110

120

220

230

240

DS4011, DS5000

110

120

220

230

240

Current (A)

7.2

6.5

3.6

3.4

3.3

7.2

6.5

3.6

3.4

3.3

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

Continuous Rating (W)

Input

750

--750

750

750

750

--750

750

750

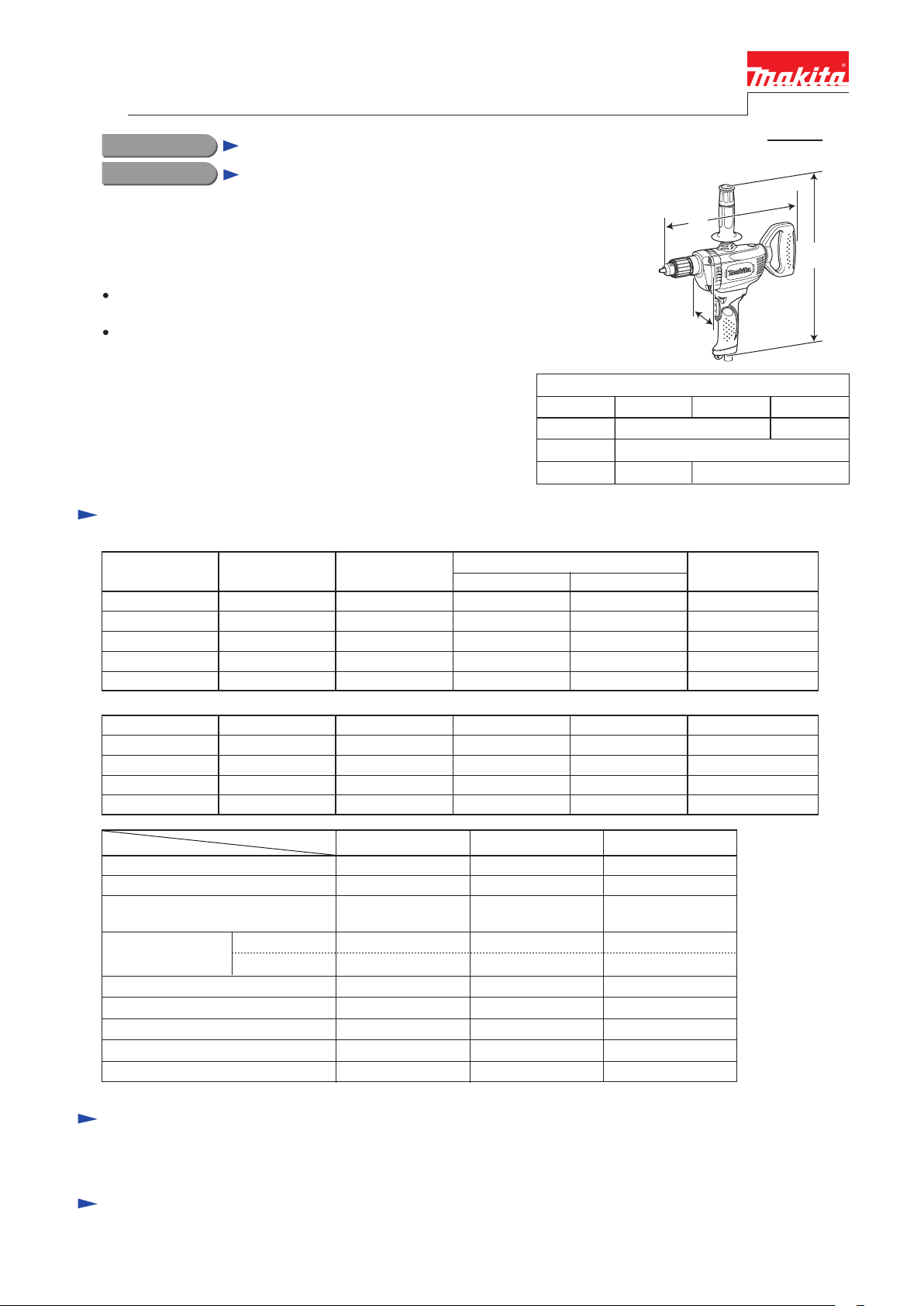

Model No.

Length (L)

Width (W)

Height (H)

L

W

Dimensions: mm (")

DS4010 DS4011 DS5000

391 (15-3/8)

Output

380

380

380

380

380

350

350

350

350

350

340 (13-3/8)

83 (3-1/4)

Max. Output (W)

348 (13-3/4)

401 (15-3/4)

540

650

650

650

650

550

550

550

550

550

H

Specification

No load speed: minDrill chuck type

Chuck capacity: mm (")

Capacities: mm (")

Reverse function

Variable speed control by trigger

Double insulation

Power supply cord

Net weight

*1 2.0m (6.6ft) for Brazil, Australia *2 Weight according to EPTA-Procedure 01/2003, with Side grip

*2: kg (lbs)

Model No.

1= rpm

Steel

Wood

*1: m (ft)

DS4010 DS4011 DS5000

0 - 600 600 600

Keyed Keyed Keyed

2 - 13

(1/16 - 1/2)

13 (1/2)

36 (1-7/16)

No

Yes

Yes

2.5 (8.2) 2.5 (8.2) 2.5 (8.2)

2.8 (6.2) 2.8 (6.3) 3.0 (6.6)

2 - 13

(1/16 - 1/2)

13 (1/2)

36 (1-7/16)

Yes

No

Yes

3 - 16

(1/8 - 5/8)

16 (5/8)

36 (1-7/16)

Yes

No

Yes

Standard equipment

Chuck key S-13 ........... 1 (for DS4010, DS4011)

Chuck key S-16 ........... 1 (for DS5000)

Note: The standard equipment for the tool shown above may vary by country.

Side grip ...................... 1

Plastic carrying case .... 1 (for DS4011, if requested)

Optional accessories

Depth gauge

Keyless Drill chuck set (for DS4010, DS4011)

Keyed drill chuck set (for DS4010, DS4011)

Bits

Hole saws

Wrench 9 (for Hole saw)

Angle attachment

Wrench 17 (for Angle attachment)

Page 2

P 2/ 8

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R139 Drill chuck extractor Removing / Assembling Drill chuck

1R223 Torque wrench shaft 20-90 N.m Removing / Assembling Drill chuck

1R224 Ratchet head 12.7 Attaching to 1R223 Torque wrench shaft 20-90 N.m

1R269 Bearing extractor Removing Ball bearings

1R291 Retaining ring S and R pliers Removing / Assembling Retaining rings

1R298 Hex. bar 10 with square socket Removing / Assembling Drill chuck

1R340 Bearing retainer wrench Removing / Assembling Bearing retainer

781024-2 Wrench 43 Removing broken Drill chuck for DS4010 and DS4011

781007-2 Wrench 14 Removing broken Drill chuck for DS5000

[2] LUBRICATIONS

Apply the following lubricant to the portion to protect parts and product from unusual abrasion.

Fig. 1

Item No.

8

Description Lubricant

Gear housing

complete

Gear room where Spur gear 47 and Gear complete 7-41

engage with Armature’ gear (Refer to Fig. 8.)

Portion to lubricate

Makita

grease N No.2

Amount

10g

[3] DISASSEMBLY/ASSEMBLY

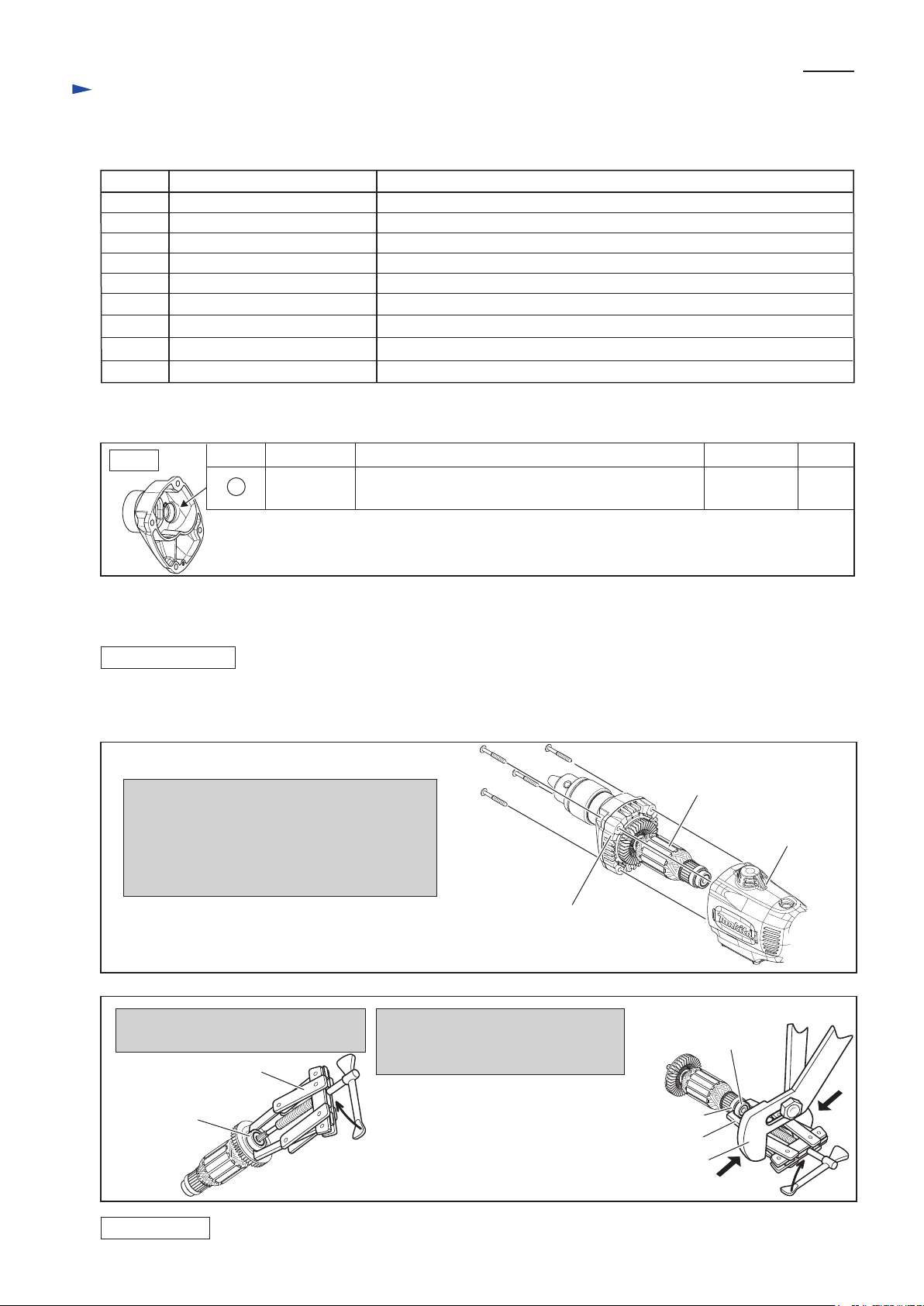

[3]-1. Armature

DISASSEMBLING

(1) Remove Armature ass’y as illustrated in Fig. 2.

(2) Disassemble Armature ass’y as illustrated in Fig. 3.

Fig. 2

1. Remove Carbon brushes.

2. Remove four 5x40 Tapping screws and then

pull off Armature together with Gear housing

cover complete from Motor housing complete.

3. Remove Armature ass’y from Gear cover

housing complete.

Fig. 3

1. Remove Ball bearing 608LLB from

Armature drive end with 1R269.

1R269

Ball bearing 608LLB

2. Remove Ball bearing 608LLB from

the commutator end of Armature

with 1R269 and Water pump pliers.

Note: Be sure to firmly grasp

the jaws of 1R269 with

Water pump pliers because

the space between

Insulation washer and Ball

bearing 608LLB is very tight.

5x40 Tapping

screw (4pcs.)

Gear cover housing complete

Insulation washer

Water pump pliers

Armature ass’y

Motor housing

complete

Ball bearing 608LLB

1R269

ASSEMBLING

Take the disassembling step in reverse.

Page 3

Repair

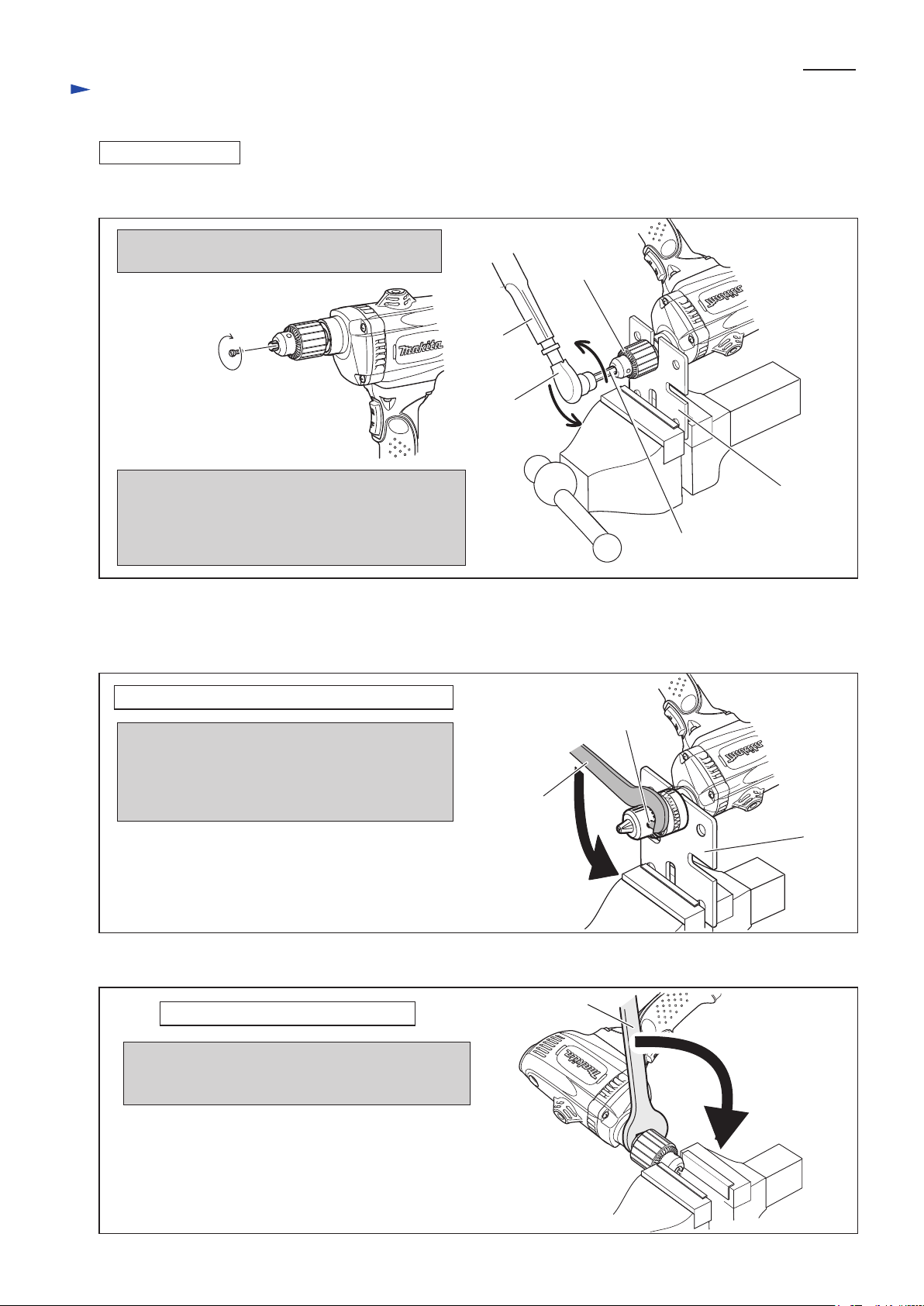

[3]-2. Drill chuck, Gear, Spindle

DISASSEMBLING

(1) Remove Drill chuck as illustrated in Fig. 4.

Fig. 4

1. Loosen the jaws of Drill chuck and then remove

M6x22 Flat head screw by turning it clockwise.

M6x22 Flat head screw

Note: It has left-hand thread.

P 3/ 8

Drill chuck

1R223

1R224

2. Fit the flats of Spindle to the notch of 1R139

and then hold 1R139 in vise.

3. Attach 1R224 and 1R298 to 1R223 and then secure

1R298 with Drill chuck.

4. Turn 1R223 counterclockwise.

(1A) When Drill chuck is broken, 1R298 can not be secured with the Drill chuck.

Therefore, separate the drill chuck from Spindle as illustrated in Fig. 5 or 6

after removing M6x22 Flat head screw.

Fig. 5

Removing Drill chuck S13 for DS4010 and DS4011

1. Fit the flats of Spindle to the notch of 1R139

and then hold 1R139 in vise.

2. Fit the pin of 781024-2 into a hole of Drill chuck,

and turn 781024-2 counterclockwise as illustrated

right.

Hole of Drill chuck

781024-2

1R139

1R298

1R139

Fig. 6

Removing Drill chuck S16 for DS5000

1. Hold Drill chuck in vise.

2. Fit the flats of 781007-2 to those of Spindle and

turn 781007-2 counterclockwise as illustrated right.

781007-2

Page 4

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Drill chuck, Gear, Spindle

DISASSEMBLING

(2) Gears can be removed as illustrated in Figs. 7 and 8.

Fig. 7

P 4/ 8

1. Hold Switch cover handle in vise.

remove Bearing retainer 22-36 by

turning it clockwise with 1R340.

Note: Use Cushion to protect

Switch cover handle in vise.

1R340

Bearing

retainer

22-36

Note:

It has a

left-hand

thread.

Fig. 8

4. Remove Retaining ring S-14

with 1R291 from Spindle.

Retaining ring S-14

Switch cover

handle

2. Separate Motor housing complete

from Gear housing cover complete

by removing four 5x70 Tapping

screws.

5x70 Tapping screw

(4pcs.)

Gear housing

cover complete

Motor housing complete

5. Strike Gear housing complete to

remove Gears as illustrated below.

Gear complete 7-41 with

Fiber washer 6

Ball bearing 626LLB

Key 5

Spur gear 47

3. After pulling off Armature,

separate Gear housing cover

complete and Gasket from

Gear housing complete.

Do not lose Pin 3.

Gear housing complete

Gasket

Pin 3

Gear housing cover complete

6. Remove Spindle together

with Ball bearing 6202LLB

from Gear housing complete.

Spindle

(3) Remove Ball bearings on Spindle and Gear complete 7-41 with 1R269 as illustrated in Fig. 9.

Fig. 9

Remove Ball bearing

6202LLB from Spindle.

1R269

Ball bearing 6202LLB

Spindle

Remove Ball bearing

626LLB from Gear

complete 7-41.

Ball bearing 626LLB

Gear complete 7-41

Ring 15

1R269

Spindle

Ball bearing

6202LLB

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Gear, Spindle

(1) Assemble Gear section as illustrated in Figs. 10 and 11.

Fig. 10

P 5/ 8

1. Assemble Ball bearing 626LLB

to Gear housing complete.

Meanwhile, assemble Ball bearing

6202LLB to Spindle, then set them

in place of Gear housing complete.

Ball bearing

626LLB

Spindle

Ball bearing

6202LLB

Fig. 9

4. Set Pin 3 in place to assemble Gasket

and Gear housing cover complete

precisely to Gear housing complete

in the next step.

Key 5

2. Fit Key 5 to Spindle’s groove.

And assemble Ring 15 and Spur

gear 47 to Spindle.

Secure their parts to Spindle with

Retaining ring S-14.

Spur gear 47

Ring 15

Retaining

ring S-14

Key 5

5. Align the holes of Gasket and those of Gear housing cover complete

and insert Pin 3 through Gasket into Gear housing complete.

3. Insert Gear complete 7-41 into Ball

bearing 626LLB with Spur gear 47

engaged.

Do not forget to assemble Fiber

washer 6 to the Gear complete 7-41.

Fiber washer 6

Gear complete 7-41

Pin 3

Gasket

Pin 3

Gear housing complete

(3) Take the disassembling step in reverse. Refer to Figs. 5 and 4.

Note: 1. Turn 1R340 counterclockwise for setting Bearing retainer 22-36 in place.

2. Preset the fastening torque of 1R223 to 68.6 - 78.4 N.m (700 - 800 Kgf.cm) and turn Drill chuck clockwise to

Spindle using 1R223 with 1R224, 1R139, 1R298 and vise.

Gear housing

cover complete

[3]-3. Leaf spring

ASSEMBLING

Two Leaf springs have to be set in place of Handle set (L) without dropping. See Fig. 10.

Fig. 10

Handle set (L)

Leaf spring

Page 6

Circuit diagram

Fig.D-1

P 6/ 8

Model DS4010 without reverse switch,

with variable speed control

Color index of lead wires' sheath

Black

Brown

Blue

Switch

(Noise suppressor

is built in.)

This Lead wire is black

for some countries.

Field viewed from

Armature fan side

This Lead wire is white

for some countries.

Line filter

Fig.D-1A

Models DS4011 and DS5000 with reverse switch,

without variable speed control

Color index of lead wires' sheath

Black

Purple

Orange

Blue

White

Field viewed from

Armature Fan side

Switch viewed from

Trigger side

4

Noise

suppressor

Terminal

block

Line filter

1

5

6

1

2

3

Resistor

2

3

Page 7

Wiring diagram

Fig.D-2

P 7/ 8

Model DS4010 without reverse switch,

with variable speed control

Motor Housing

viewed from Armature fan side

To Switch terminals

M1 and M2

Pass Field lead wires

(black) through the

hole to connect

them to Switch.

Switch handle cover set (L)

Pass field lead wires

(black) between Boss

and rib of Hole.

Put Line filter between

Ribs.

Line filter

Switch

Hole for

storing

Chuck key

Boss

Rib

Power supply cord

Pass the Lead wires

of Power supply cord

through Line filter.

Fig.D-2A

Models DS4011 and DS5000 with reverse switch,

without variable speed control

Motor Housing viewed

from Armature fan side

Pass Field lead wires

(blue, orange, black)

through this hole.

Pass Field lead wires

(black, purple, white)

through this hole.

to Switch

Page 8

Wiring diagram (cont.)

Fig.D-3A

Put Line filter here

P 8/ 8

Models DS4011 and DS5000 with reverse switch,

without variable speed control

Switch handle cover set (L)

Hole for storing Chuck key

Pass field lead wires between Boss

and Hole for storing Chuck key

Line filter

Coil Field lead wires

(orange) and (purple)

to Line filter one time.

Resistor

Noise

supperssor

Viewed from Switch cover handle (R) side

1. Connect Field lead wire (white) to

Switch terminal No. 6 and Field lead

wire (blue) to Switch terminal No.3

from Switch trigger side.

Boss

Connect Field lead wires

(white), (purple), (orange),

(blue) as illustrated in

Fig. D-SP.

Rib

Do not to put the folowing Lead wires

Terminal

block

Rib

on the Ribs and Terminal block.

* Field lead wires (black)

* Noise suppressor’s lead wire (white)

* Lead wires (brown), (blue)

of Power supply cord

Viewed from Switch cover handle (L) side

Screw head

Switch terminal end

Field lead

wire (purple)

Field lead wire

(white)

2. Inflect their Insulated connectors of

the Field lead wires until they touch

Screw heads.

Insulated terminal

3. Insulated connectors of Field lead

wires (purple) and (orange) have to

be located inside of Switch terminal

end.

Field lead wire

(blue)

Screw head

Switch terminal end

Field lead wire

(orange)

Loading...

Loading...