Page 1

T

Model No.

Description

ECHNICAL INFORMATION

DDF481 (XFD07*1)

18V Cordless driver drill

*1 Model number for USA

PRODUCT

P 1/ 11

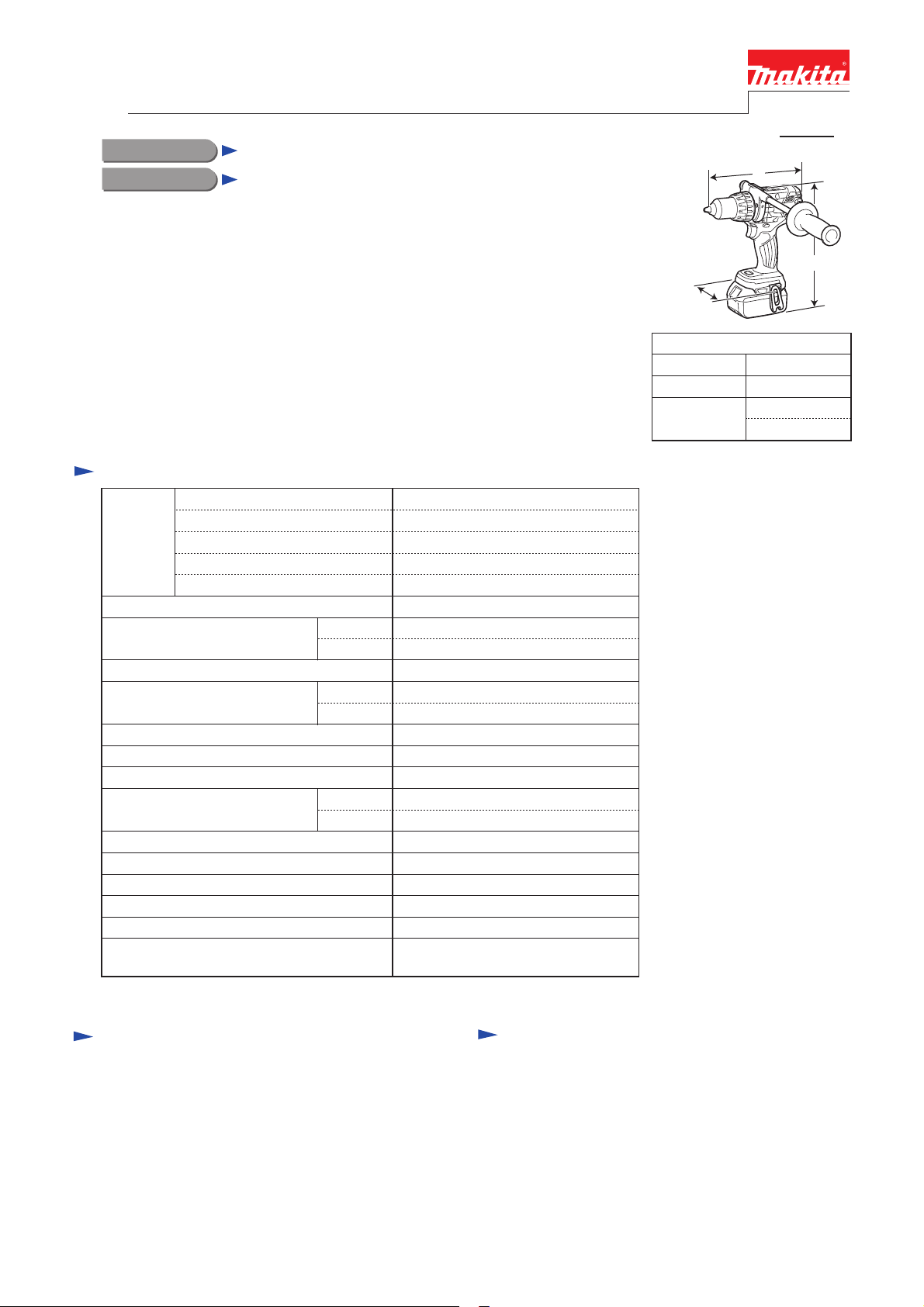

L

CONCEPT AND MAIN APPLICATIONS

Model DDF481 (XFD07*1) is a supreme class cordless driver drill

powered by 18V Li-ion battery of BL1815N (1.5Ah)/ BL1820 (2.0Ah)/

BL1830 (3.0Ah)/ BL1840 (4.0Ah)/ BL1850 (5.0Ah) .

Its main features are:

• Max lock torque: 125N.m. (1,090in.lbs)

• Compact tool size with an overall length of 205mm (8-1/8")

• Efficient Brushless DC motor provides higher power and productivity

than that of 18V Cordless driver drill model BDF458.

Note: BL1815 is not compatible.

Specification

Voltage: V

Capacity: Ah

Battery

Max output: W 640

No load speed: min.

Capacity of drill chuck: mm (")

Capacity: mm (")

Torque setting

Clutch torque setting: N.m (in.lbs) 1.0 - 10.0 (9 - 89)

Max lock torque: N.m (in.lbs)

Max fastening torque:

Electric brake

Mechanical speed control

Variable speed control

Reversing switch

LED job light

Weight according to

EPTA-Procedure 01/2003*

4

: with Grip assembly

*

Energy capacity: Wh

Cell Li-ion

Charging time (approx.): min.

High

Low

Steel

Wood

Soft joint

Hard joint

N.m (in.lbs)

ˉ¹= rpm

4

: kg (lbs)

1.5/ 2.0/ 3.0/ 4.0/ 5.0

27/ 36/ 54/ 72/ 90

15/ 24/ 22/ 36/ 45 with DC18RC

0 - 2,100

0 - 550

1.5 (1/16) - 13 (1/2)

13 (1/2)

21 stage + drill mode

125 (1,090)

60 (530)

115 (1,020)

Yes (2 speed)

2.4 (5.2)*

18

76 (3)

Yes

Yes

Yes

Yes

2

/ 2.6 (5.8)*

H

W

Dimensions: mm (")

Length (L) 205 (8-1/8)

Width (W)

Height (H)

2

: with BL1815N

*

*3: with BL1830 or BL1840

3

79 (3-1/8)

249 (9-3/4)*

266 (10-1/2)*3

2

Standard equipment

Battery ...................................................... 1 or 2*

Charger ..................................................... 1*5

Battery cover ............................................ 1*

+ – bit 2-45 ............................................... 2

Belt clip .................................................... 1

(+) Screw M4x12 ..................................... 1

Grip assembly .......................................... 1

Bit holder ................................................. 1

Plastic carrying case ................................. 1

*5: Battery and charger are not supplied with “Z” model

*6: Supplied with the same quantity of extra Battery

Note: The standard equipment for the tool shown above

may vary by country.

5

6

Optional accessories

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Quad Port Charger DC18SF

Battery BL1815N

Battery BL1820

Battery BL1830

Battery BL1840

Battery BL1850

Battery BL1840

Drill bits for wood

Drill bits for steel

Driver bits

Belt clip

Bit holder

Page 2

P 2/ 11

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R264 Torque wrench removing Drill chuck

1R291 Retaining ring S and R pliers removing Retaining ring (INT) R-15

1R298 Hex bar 10 with square socket removing Drill chuck

1R359 Chuck removing tool

1R404 Drill chuck removing tool removing Drill chuck without disassembling Gear assembly

1R404-A Frame assembly

1R404-B Frame support

1R404-C

921477-5

922127-5 M4x16 Hex socket head bolt

Pinion gear complete

M8x55 Hex bolt

---

Hex wrench 10

[2] LUBRICATION

It is not required to lubricate, because this product has gear mechanism of factory assembled.

[3] DISASSEMBLY/ASSEMBLY

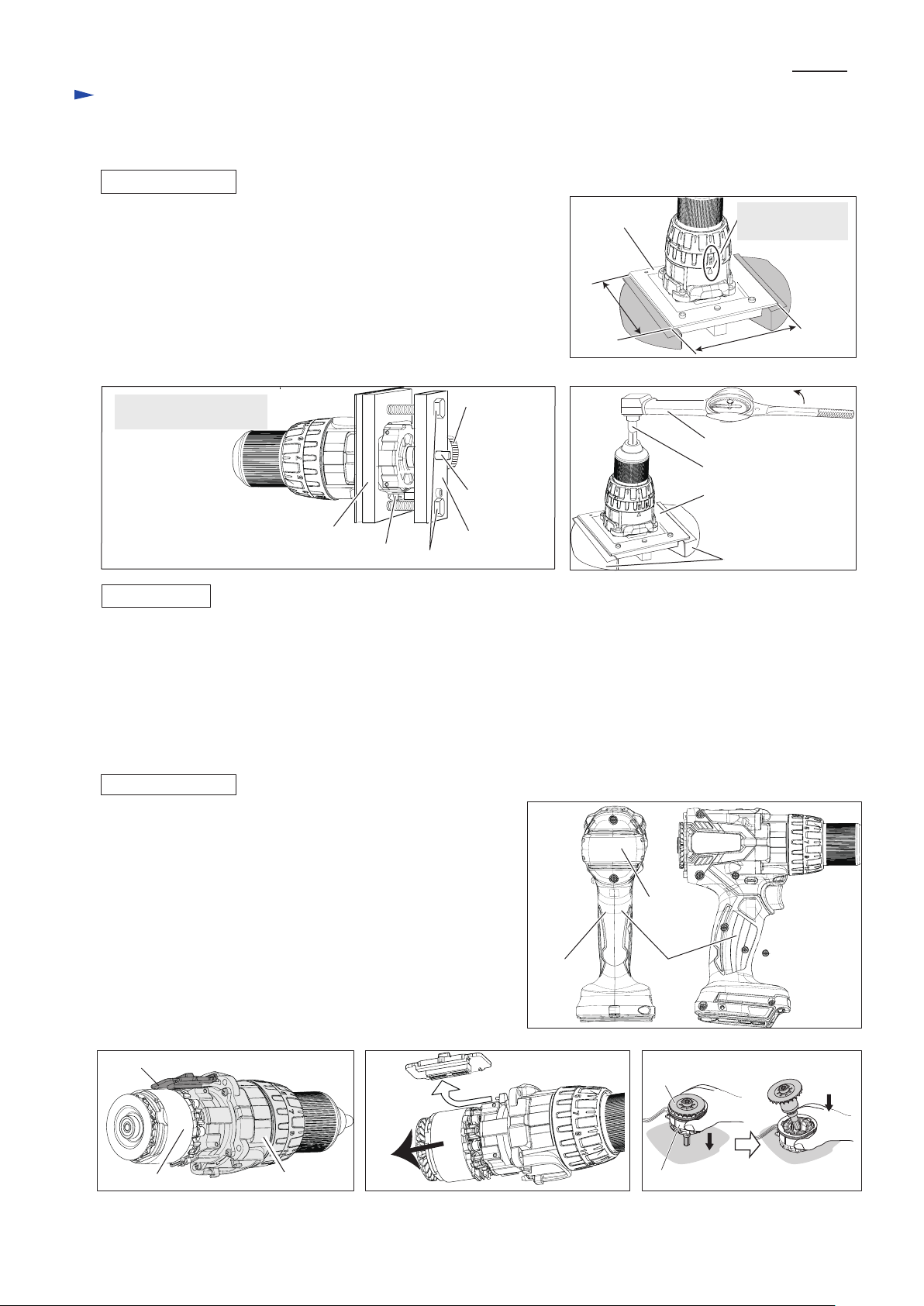

[3] -1. Drill chuck

removing Drill chuck (If it is impossible to remove Drill chuck by the steps

mentioned here)

the components of Drill chuck removing tool (1R404)

removing Drill chuck

Fig. 1

DISASSEMBLING

Note: When Gear assembly is replaced with a new one, separate Drill chuck from

Gear assembly in advance. When the repair is independent of Gear assembly,

it is not necessary to separate Drill chuck from Gear assembly.

(1) Remove four 4x18 Tapping screws, and then separate Gear assembly from

Housing set. (Fig. 1)

(2) Remove M6x22 (-) Flat head screw by turning it clockwise with Slotted

screwdriver.

Note: Use Impact driver to unscrew M6x22 (-) Flat head screw if it cannot be

removed manually. (Fig. 2)

(3) Engage 1R404-C with Gear teeth in Gear assembly. (Fig. 2)

(4) Fit two Pins 4 of 1R404-A into the holes of Gear assembly. (Fig. 3)

Secure Gear assembly to 1R404-A by tightening two 922127-5. (Fig. 3)

Be careful about each direction. (Figs. 3 and 4

(5) Assemble 1R404-B to 1R404-A so that the lever portion of Gear assembly can

be pushed toward 1st gear position. (Fig. 5)

Note: Face the flat surface of the shaft of

1R404-C to the threaded hole in

1R404-B, and pass the shaft through

the hole of 1R404-B. (Fig. 6)

Fig. 5

921477-5 (2 pcs.)

1R404-B

1R404-A

)

Fig. 3

Lever portion of Gear assembly

Pin 4 (2 pcs.) of

1R404-A

1R404

Narrow side

Fig. 6

Wide side

4x18 Tapping

screw (4 pcs.)

Fig. 2

M6x22 (-) flat head screw

Drill chuck

Gear assembly

1R404-C

Fig. 4

922127-5

(2 pcs.)

1R404

1R404-A

Lever portion of

Gear assembly

Face the flat surface to

M5x10 Thumb screw.

Shaft of

1R404-C

M5x10 Thumb screw

of 1R404-B

Page 3

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Drill chuck (cont.)

P 3/ 11

DISASSEMBLING

(6) Set the lever portion of Gear assembly to 1st gear position. (Fig. 6)

Set Gear assembly in drill mode. (Refer to Fig. 7.)

Fig. 7

1R404

Set Gear assembly

in drill mode.

Tighten two 921477-5 evenly while keeping 1R404-B parallel with

1R404-A, and then tighten M5x10 Thumb screw of 1R404-B. (Fig. 6)

(8) Hold 1R404 in Vise as drawn in Fig. 7.

Secure 1R298 to Drill chuck and attach 1R264 to 1R298. (Fig. 8)

(9) Turn 1R264 counterclockwise to remove Drill chuck. (Fig. 8)

Note: When it is impossible to remove Drill chuck, try the steps

with 1R359 mentioned in Makita repair tool list.

Fig. 6

Keep 1R404-B parallel

with 1R404-A.

M5x10

Thumb

screw

Shaft of

1R404-C

1R404-A

1R404-B

narrow

side

Fig. 8

1R404

1R404

wide side

1R264

1R298

1R404

Lever portion of Gear assembly

921477-5 (2 pcs.)

Vise

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note: • When you turn 1R264 clockwise to assemble Drill chuck to Spindle, the tightening torque should be 65 up to 72.5

N∙m (660 up to 740 kgf∙cm).

• M6x22 (-) flat head screw is thread locker type, and therefore, apply ThreeBond 1342H/ Loctite 243 to the thread

and tighten the screw using Cordless impact driver with slotted bit.

[3] -2. Gear assembly, Rotor, Stator assembly, Speed change lever assembly

DISASSEMBLING

(1) Remove nine Bind PT3x14 tapping screws and four 4x18

Tapping screw, and then separate Rear cover and Housing R

from Housing L. (Fig. 1 of the previous page and Fig. 9)

(2) Remove the following parts from Housing L at a time. (Fig. 10)

• Gear assembly with Drill chuck

• Motor section

• Speed change lever assembly

(3) Remove Speed change lever assembly from Gear assembly,

and then separate Motor section from Gear assembly. (Fig. 11)

(4) Put Rotor section on a workbench so that the drive end of Rotor

touches the workbench.

Press Stator down to separate from Rotor. (Fig. 12)

Fig. 10

Fig. 11 Fig. 12

Speed change lever assembly

Gear assemblyMotor section

Fig. 9

Rear cover

Housing RHousing L

Rotor

Stator

4x18 Tapping

screw (9 pcs.)

Page 4

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear assembly, Rotor, Stator assembly,

Speed change lever assembly (cont.)

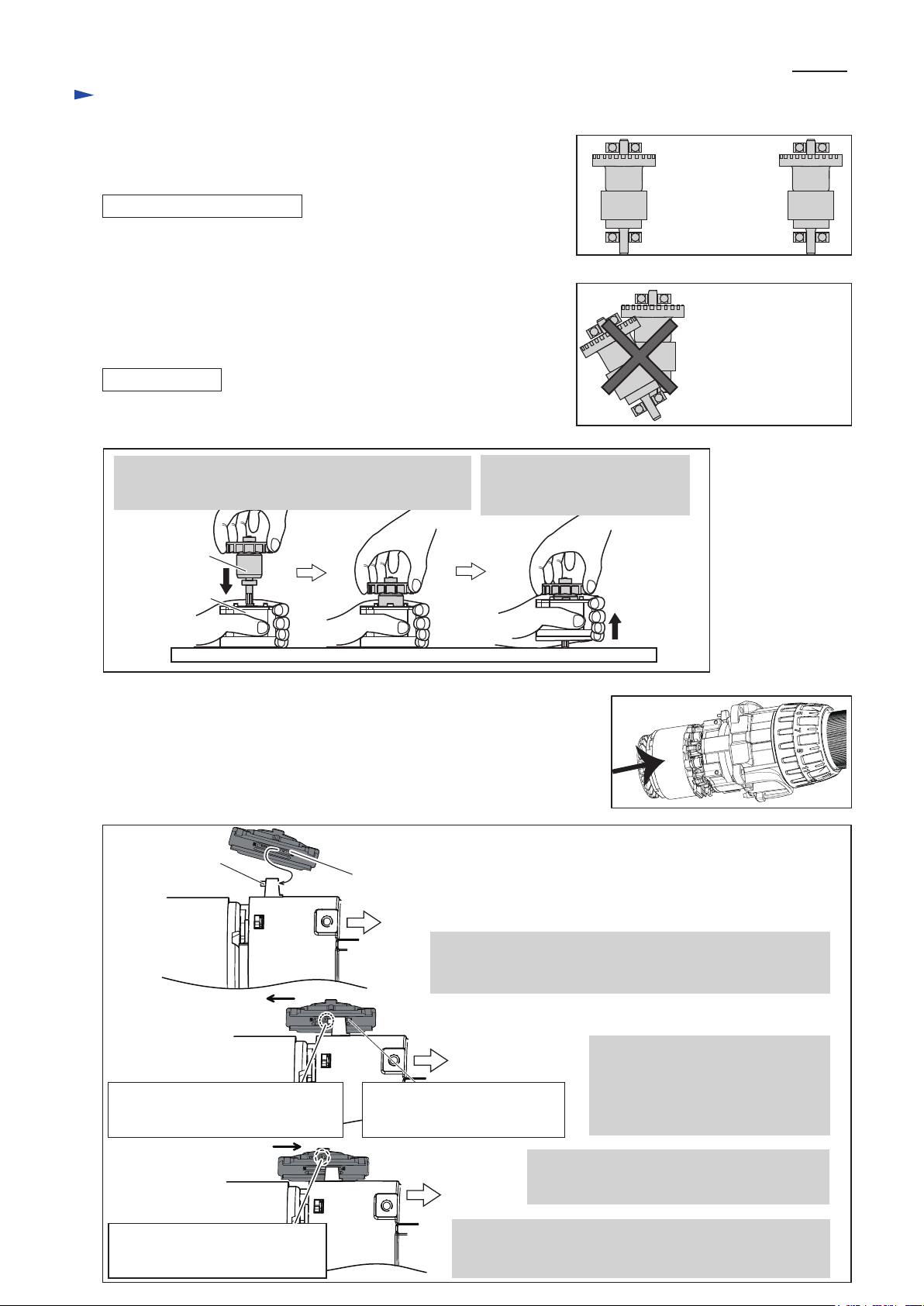

Caution for Handling of Rotor

When handling or storing multiple Rotors, be sure to keep a proper

distance between Rotors as shown in Fig. 13

because Rotor is a strong magnet, failure to follow this instruction

could result in:

• Finger injury caused by pinching between Rotors pulling each other

• Magnetic loss of Rotors or damage on the magnet portion of Rotor.

(Fig. 14)

ASSEMBLING

(1) Put Rotor into Stator complete as drawn in Fig. 15.

Fig. 15

P 4/ 11

Fig. 13

Fig. 14

* Magnetic loss of Rotors

* Damage on the magnet

portion of Rotor

1. Holding Stator complete on a workbench, insert Rotor

slowly in Stator complete until Rotor’s drive end

reaches the workbench.

Rotor

Stator complete

(2) Make sure that Rotor’s gear engages with the super gears of Gear assembly

to rotate them smoothly, and push Rotor section (Rotor and Stator) fully in

Gear assembly, (Fig. 16)

(3) Assemble Speed change lever assembly as drawn in Fig. 17.

Fig. 17

Pin on the lever

of Gear assembly

front Compression spring 4

2. When the drive end of Rotor

reaches the workbench, lift up

Stator complete slowly.

Fig. 16

Stator

Space between the rear Compression

spring 4 and the pin on the lever of

Gear assembly

Pin on the lever of Gear assembly

for fitting into the coil of the rear

Compression spring 4.

Gear

assembly

Drill chuck

side

The front Compression spring 4

compressed by the lever of

Gear assembly.

1. Apply the front Compression spring 4 of Speed change lever

assembly to the flat side (without pin) of Gear assembly

for Speed change.

Drill chuck

side

3. Fit the pin of Gear assembly to Spring’s coil

Drill chuck

side

4. Slide Speed change lever assembly to High speed mode:

(Position 2 shown on Housing: Refer to Fig. 20 in

the next page.)

with slowly returning Speed change lever

assembly toward Drill chuck side.

2. Push Speed change lever assembly

toward Rotor side until it stops to

have space between the pin of

Gear assembly and the rear

Compression spring 4.

Page 5

P 5/ 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear assembly, Rotor, Stator assembly, Speed change lever assembly (cont.)

(4) Assemble Motor section with Gear assembly and Speed change lever assembly to Housing L at a time.

And assemble Switch and F/R change lever to Housing L. (Fig. 18) Then, assemble Housing R to Housing L.

(5) Assemble Rear cover to Housing set. (Figs. 19 and 9) and tighten nine PT3x16 Tapping screws to fasten Housing L,

Housing R and Rear cover.

Fig. 18

Other side viewed from Housing L

Depressions

Make sure that two Leaf springs

are set in place in advance.

Speed change lever assembly

Leaf spring (2 pcs.)

Fit the protrusions of Housing L

into the depressions of Stator

complete

F/R Change lever

Fig. 19

Terminal of Stator must be on the center line of Motor section and Gear assembly.

Before assembling Switch to Housing L,

fit the prong of F/R change lever to

the projection of Switch.

prong portion

projection

Depression

in Rear cover

Protrusion on

Housing R

Fit the depression in Rear cover into

the protrusion on Housing R.

Page 6

/ 11

P 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear assembly, Rotor, Stator assembly, Speed change lever assembly (cont.)

Note: • Be sure to route the lead wires for LED circuit to the space between ribs of Gear assembly after setting

Gear assembly in place. (Fig. 20)

If the routing is done before assembling Gear assembly, the breakage or pinching of the lead wires will happen.

• When Housing L are fastened to Housing R, the clearance is left because of the existence of Gear assembly in

Housing L and Housing R. Therefore, clamp them with a waterpump pliers carefully. (Fig. 21.)

Fig. 20 Fig. 21

Clamp the designated positions carefully not to leave

the clearance between Housing L and R when tightening

PT3x16 Tapping screws.

Lead wires

for LED

circuit

Ribs of Gear assembly

[3] -3. Grip assembly

DISASSEMBLING

Refer to Fig. 22 for the components of Grip assembly.

(1) Remove Retaining ring (INT) R-15 with 1R291.

(2) Remove M8x65 Hex bolt from Pole complete by turning

the bolt counterclockwise.

(3) Remove Arm R complete from Arm L.

(4) Remove Arm L from Pole complete by turning the arm

clockwise.

Note: Grip assembly for DHP481 has M5x10 Thumb screw

and M5 Hex nut, and therefore, the grip is different

from that of DDF481. Loosening the thumb screw

will cause the M5 Hex nut to be removed from Arm L.

Be careful about the loss of the M5 Hex nut when

DHP481 is disassembled.

ASSEMBLING

(1) Screw Pole complete in Arm L to the full.

(2) Insert the rod of Arm complete R into the hole of Arm L. (Fig. 23)

(3) Connect the male thread of M8x65 Hex bolt with the female thread of Pole complete as drawn in Fig. 24.

(4) Set Retaining ring (INT) R-15 in place of Arm R complete.

Fig. 22

The components of Grip assembly

Arm L Arm R complete Retaining ring

M5x10

Thumb screw

(for DHP481 only)

Pole complete

M5 Hex nut

(for DHP481 only)

(INT) R-15

M8x65 Hex bolt

Fig. 23

Hole of Arm L Rod of Arm R complete

Fig. 24

Five to six turns of the thread of M8x65 Hex bolt must be

connected with Pole complete before DDF481/ DHP481

is setting in place.

Page 7

Circuit diagram

Fig. D-1

Black

White

Red

Color index of lead wires' sheath

Yellow

Orange

Blue

Purple

Brown

Gray

P 7

/ 11

Switch

Stator complete

LED circuit

Controller

Terminal

Red lead wire is used

for some country

instead of white.

Page 8

Wiring diagram

Fig. D-2

View before setting Switch and F/ R change lever in place

P 8

/ 11

Place Connector this space among Rib A,

Rib B and Boss.

Stator

Thick lead wires from Stator

must be put on the other thin

lead wires.

Rib A

A’

LED circuit

A

See the following illustration

for the cross section

between A and A’.

Front view around the lead wires for LED circuit after setting Gear assembly in place

Note:

Be sure to route the lead wires for LED circuit

to the space between ribs of Gear assembly

after setting Gear assembly in place.

If the routing is done before assembling Gear

assembly, the breakage or pinching of the lead

wires will happen.

Lead wires for LED circuit

Rib B

Boss

Ribs of Gear assembly

LED circuit

(Insert it

as drawn above,)

Page 9

Wiring diagram

Fig. D-3

Set Flag terminal to Switch

as shown above.

Switch

Lead wire

(white)

Flag terminal

P 9

/ 11

Stator complete

Thick lead wires from Stator complete

must be put on the other thin lead wires

for the designated area .

Boss A

Lead wires from Stator complete must be

routed between Boss A and Rib C.

Lead wire (Red) from Terminal must be;

• placed under Lead wires from Stator complete

• routed between Rib D and Rib E.

Rib of Controller

Rib D

The slack of Lead wire (Red) from

Terminal must not be piled on/under

Capacitor of Controller.

Rib C

Boss B

Do not put any lead wires

on these ribs.

Rib E

Controller

Rib E

Lead wires from Terminal must be

placed under Rib of Controller.

Capacitor of Controller

Terminal

Page 10

Trouble shooting

Whenever you find any trouble in your machine, first, refer to this list to check the machine for solution.

P 10/ 11

Note in Repairing

(1) Use the full charged battery which has the star mark. (Fig. D-4)

(2) When Housing is disassembled, check the conditions of the electrical parts

(Connectors, Lead wires, Switches, etc.), Armature, Stator, Gear section, etc.

(3) Do the running test in Low speed mode (when the trigger is being pulled just a little)

to check the following functions by repeating 10 times;

• F/R change lever • Operation mode change ring • High/Low speed change lever

• Variable speed control trigger

Fig. D-4

Star mark

Check List for Trouble Shooting

Check the items from the top of the following list. (Description of the item is referred to Circuit diagram in Fig. D-1.)

Change Stator complete if your problem cannot be solved although its corrective action has been carried out.

Symptom Cause Corrective action

LED indicator lamps

are on.

No

Controller is broken. Replace Stator complete.

(See the next page.)

Yes

Rotation speed can

be changed.

Forward/ Reverse

rotation are OK

Yes

Motor runs when the machine

is switched on.

In case of running inconstantly,

go to “No”.

Yes

No

Connectors are in incomplete

connection.

Lead wires are broken.

Switch is broken.

Connectors are in incomplete

connection.

Connect it firmly.

Check Lead wires,

or replace it.

Replace Switch.

Connect it firmly.

No

LED job light are on.

Yes

The machine does not

have any trouble.

LED indicator lamps

are on.

Yes

LED job light are on.

Yes

No

No

No

Lead wires are broken.

LED circuit is broken.

Switch is broken. Replace Switch.

Switch is broken.

Terminal is broken.

Controller is broken.

Connectors are in incomplete

connection.

Lead wires are broken.

Switch is broken. Replace Switch.

LED is broken.

Check Lead wires,

or replace it.

Replace LED circuit.

Replace Switch.

Check Terminal,

or replace it.

Replace Stator complete.

Connect it firmly.

Check Lead wires,

or replace it.

Replace LED.

Rotor is rubbed to

Stator.

Yes

No

Controller is broken.

Rotor is broken.

Stator is broken.

Replace Stator complete.

(See the next page.)

Replace Rotor.

Replace Stator complete.

Page 11

Trouble shooting

Test for recognizing the trouble on FET (Field effect transistor) in Controller

(1) Set Digital tester (1R402) in the diode mode ( mark on the tester: Refer to Fig. D-5.)

(2) Switch, Terminal, Controller and Stator are connected each other as drawn in Fig. D-6.

Do the following steps.

Test 1: Attach Black tester bar to the terminal of white lead wire end on B1 terminal of Switch. (Fig. D-7.)

Attach Red tester bar to one of UVW terminal connected with Red, White, Blue lead wires. (Fig. D-8)

Check the figure in the tester.

Test 2: Attach Red tester bar to minus terminal of Terminal (connected with black lead wire). (Fig. D-9)

Attach Black tester bar to one of UVW terminal connected with Red, White, Blue lead wires. (Fig. D-10)

There is no fault on FET of Controller if the tester indicates within 0.39V - 0.41V in both Test 1 and Test 2.

If either Test 1 or Test 2 results in the improper figure, Controller is broken. Change Stator complete.

P 11/ 11

Fig. D-5

Fig. D-7

Fig. D-6

Stator complete

(A modular part of Controller, lead wires and Stator)

Terminal Switch

Fig. D-8

Stator complete

Fig. D-9

Red tester bar

Black tester bar

Terminal

Switch

Red tester bar

Fig. D-10

Stator complete

Controller (the component

of Stator complete)

Black tester bar

Loading...

Loading...