Makita DC9711 Technical Information

T

ECHNICAL INFORMATION

Models No.

Description

DC9711

Charger

CONCEPTION AND MAIN APPLICATIONS

This charger can charge both Ni-Cd.and Ni-MH.batteries

of which powers are 7.2V and 9.6V.

Its brief benefits and features are as follows.

* The charging time is kept in the steady level by controlling the

out put current ( current for charging battery) in spite of the changeable

input voltage (power source voltage).

* The charger can switch into trickle charge (maintenance charge) mode

to keep the full charged condition for battery left in the charger.

Specification

H

W

Width ( W )

Height ( H )

Length ( L )

PRODUCT

P 1 / 2

L

Dimensions : mm ( " )

80 (3-1/8)

63 (2-1/2)

145 (5-3/4)

Voltage (V) Cycle (Hz)

220 - 240

230 - 240

Output voltage (D/C)

Output current (D/C)

Ni-Cd. battery 2.0Ah approx. 90 min.

Charging

time

Net weight : Kg ( lbs )

Cord length : m ( ft )

Current (A)

7.2 V, 9.6 V,

1.5 A

Ni-Cd. battery 1.3Ah

Ni-MH.battery 2.2Ah

Ni-MH.battery 2.6Ah

Ni-MH.battery 3.0Ah

0.41 (0.9)

2.0 (6.6)

50 / 60

50 / 60

approx. 60 min.

approx. 100 min.

approx. 115 min.

approx. 130 min.

Continuous Rating (W)

Input Output

35

35

The chargeable batteries

Voltage

7.2 V

9.6 V

Type No.

7000 (Ni-Cd. 1.3Ah)

7002 (Ni-Cd. 2.0Ah)

7033 (Ni-MH. 2.2Ah)

9000 (Ni-Cd. 1.3Ah)

9100 (Ni-Cd. 1.3Ah)

9120 (Ni-Cd. 1.3Ah)

9002 (Ni-Cd. 2.0Ah)

9102 (Ni-Cd. 2.0Ah)

9102A (Ni-Cd. 2.0Ah)

9122 (Ni-Cd. 2.0Ah)

9033 (Ni-MH. 2.2Ah)

9133 (Ni-MH. 2.2Ah)

9134 (Ni-MH. 2.6Ah)

9135 (Ni-MH. 3.0Ah)

Max. Output(W)

Charging time

approx. 60 min.

approx. 90 min.

approx. 100 min.

approx. 60 min.

approx. 60 min.

approx. 60 min.

approx. 90 min.

approx. 90 min.

approx. 90 min.

approx. 90 min.

approx. 100 min.

approx. 100 min.

approx. 115 min.

approx. 130 min.

Repair

<1> The circuit board can not be repaired, because the circuit itself are molded on the board

with the urethane resin.

It has to be replaced completely with new one.

<2> In case of damaged varistor or fuse, they can be repaired according to the following procedure without

replacing the circuit board.

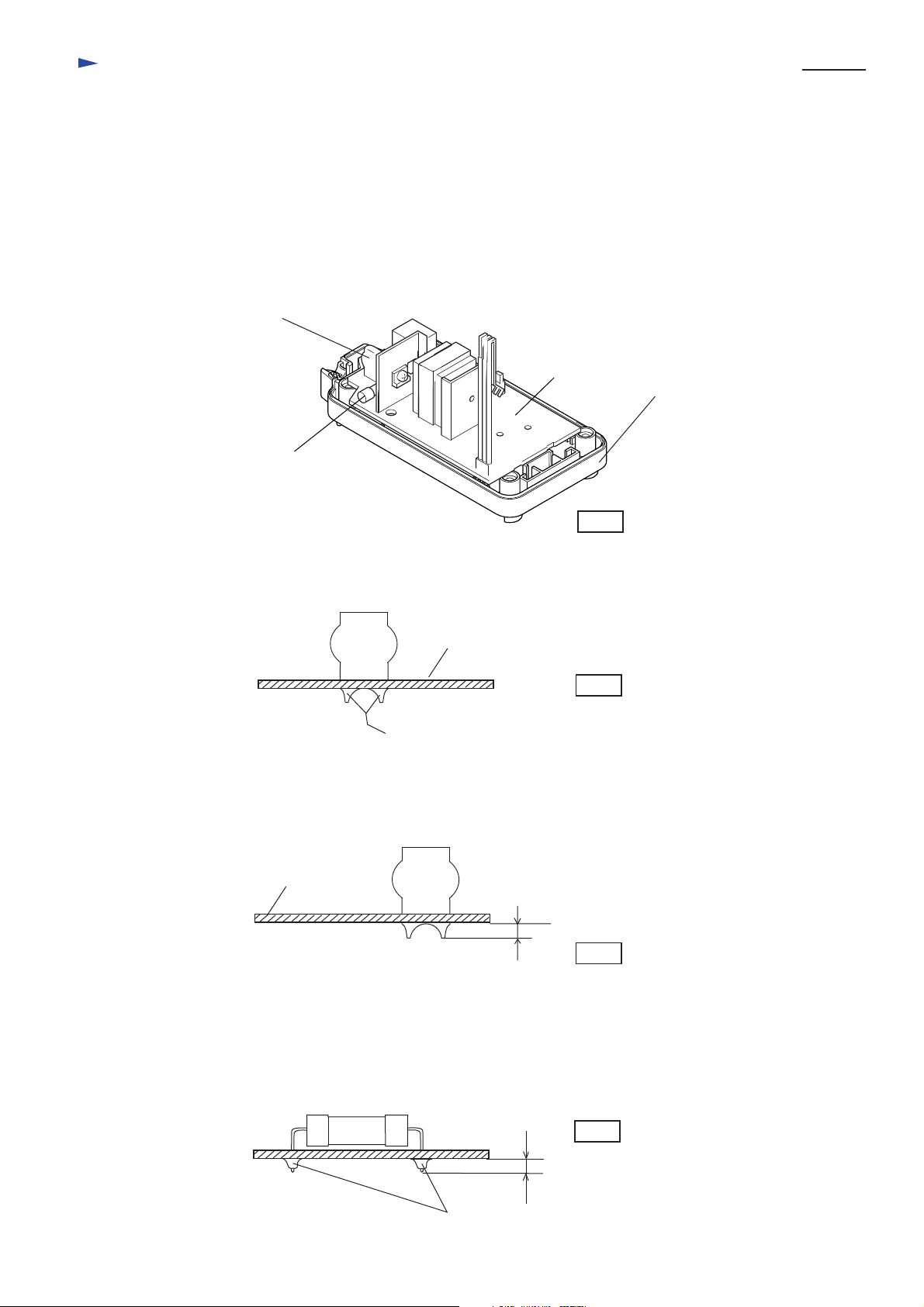

(1) How to find broken varistor

a. In case that the surface of varistor (ref. to the following illustration) has broken or has become black, and

fuse has been cut, the varistor has been damaged.

b. Varistor can be damaged easily, if the charger is plugged in a double voltage of the rating one.

c. It is considered that the varistor has been broken for other reasons, if the fuse is broken while the surface

of varistor is not damaged. In this case circuit board has to be replaced.

Varistor

Circuit board

Charger case set

Fuse

P 2 / 2

Fig.1

(2) Replacing damaged varistor

a. Varistor is assembled on circuit board with solder. Remove it from circuit board

with soldering iron.

Varistor

b. Assemble new varistor to the circuit board by soldering.

c. Cut the surplus of varistor's wire with nipper.

Circuit board

Circuit board

Fig.2

When removing varistor, melt this part with soldering iron

and remove varistor.

Varistor

Less than 3mm

Fig.3

(3) Replacing damaged fuse

a. Fuse is assembled on circuit board with solder. Remove it from circuit board with soldering iron.

b. Assemble new fuse to the circuit board by soldering.

c. Cut the surplus of fuse's wire with nipper.

Fuse

When removing fuse, melt this part with soldering iron

and remove fuse.

Fig.4

Less than 3mm

Loading...

Loading...