Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Cordless Cutter

Scie Diamant sans Fil

Cortador Inalámbrico

CC301D

IMPORTANT: Read Before Using.

IMPORTANT : Lire avant usage.

IMPORTANTE: Lea antes de usar.

Page 2

ENGLISH (Original instructions)

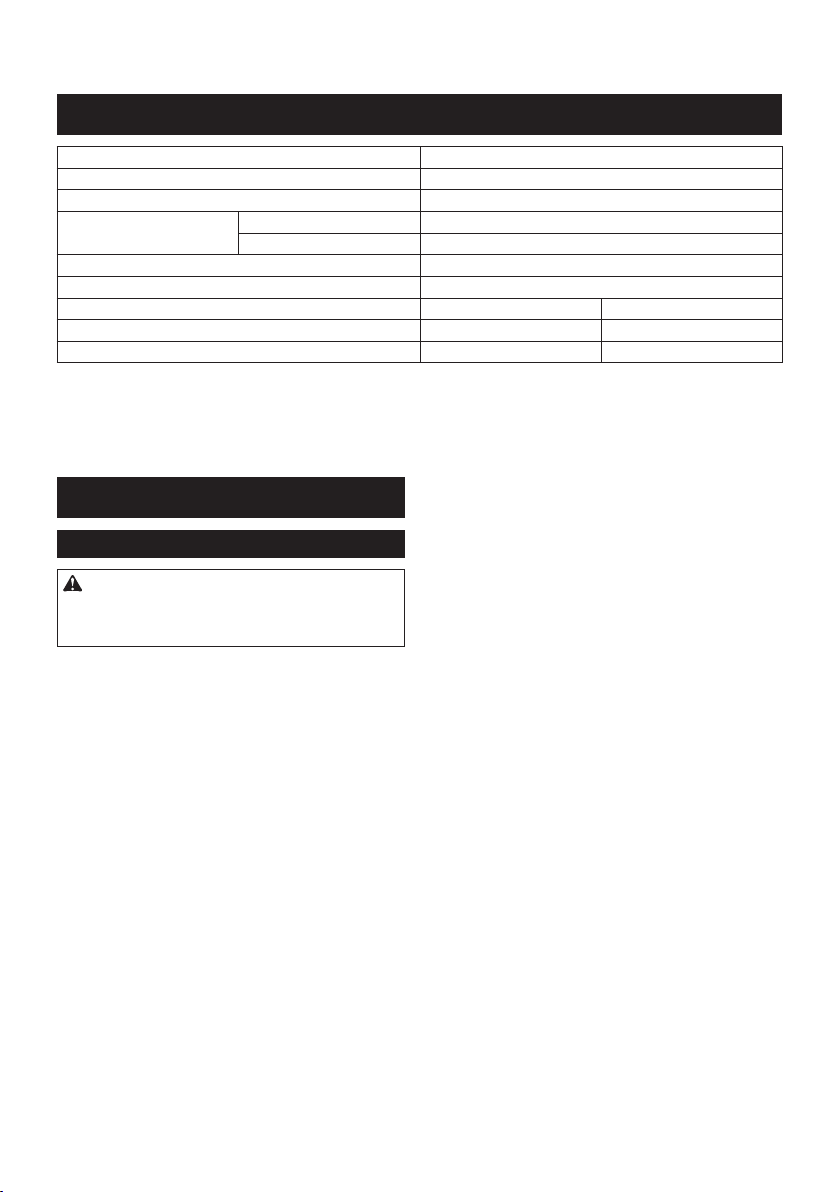

SPECIFICATIONS

Model: CC301D

Diamond wheel diameter 85 mm (3-3/8″)

Max. wheel thickness 0.8 mm (1/32″)

Max. Cutting depth at 0° bevel 25.5 mm (1″)

at 45° bevel 16.5 mm (5/8″)

Rated speed 1,600 /min

Rated voltage D.C. 10.8 V - 12 V max

Standard battery cartridge BL1016, BL1021B BL1041B

Overall length 313 mm (12-3/8″) 331 mm (13″)

Net weight 1.8 kg (4.0 lbs) 1.9 kg (4.2 lbs)

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications and battery cartridge may differ from country to country.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

3. Do not expose power tools to rain or wet con-

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

2. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

ditions. Water entering a power tool will increase

the risk of electric shock.

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electric shock.

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

2. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

3. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools

that have the switch on invites accidents.

4. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

2 ENGLISH

Page 3

5. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

Power tool use and care

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

2.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting

the power tool accidentally.

4. Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

5. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

2. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

4.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact acci-

dentally occurs, ush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected

from the battery may cause irritation or burns.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2. Follow instruction for lubricating and chang-

ing accessories.

3. Keep handles dry, clean and free from oil and

grease.

Cordless cutter safety warnings

1. The guard provided with the tool must be

securely attached to the power tool and

positioned for maximum safety, so the least

amount of wheel is exposed towards the operator. Position yourself and bystanders away

from the plane of the rotating wheel. The guard

helps to protect operator from broken wheel fragments and accidental contact with wheel.

2.

Use only diamond cut-off wheels for your power

tool. Just because an accessory can be attached to

your power tool, it does not assure safe operation.

3. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and y apart.

4.

Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

5. Always use undamaged wheel anges that are

of correct diameter for your selected wheel.

Proper wheel anges support the wheel thus

reducing the possibility of wheel breakage.

6. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

7. The arbour size of wheels and anges must

properly t the spindle of the power tool.

Wheels and anges with arbour holes that do not

match the mounting hardware of the power tool

will run out of balance, vibrate excessively and

may cause loss of control.

8.

Do not use damaged wheels. Before each use,

inspect the wheels for chips and cracks. If power

tool or wheel is dropped, inspect for damage or

install an undamaged wheel. After inspecting

and installing the wheel, position yourself and

bystanders away from the plane of the rotating

wheel and run the power tool at maximum no

load speed for one minute. Damaged wheels will

normally break apart during this test time.

9.

Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appro

priate, wear dust mask, hearing protectors,

gloves and shop apron capable of stopping

small abrasive or workpiece fragments. The eye

protection must be capable of stopping ying debris

generated by various operations. The dust mask

or respirator must be capable of ltrating particles

generated by your operation. Prolonged exposure

to high intensity noise may cause hearing loss.

3 ENGLISH

-

Page 4

10. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken wheel may

y away and cause injury beyond immediate area

of operation.

11. Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power

tool “live” and could give the operator an electric

shock.

12. Position the cord clear of the spinning acces-

sory. If you lose control, the cord may be cut or

snagged and your hand or arm may be pulled into

the spinning wheel.

13. Never lay the power tool down until the acces-

sory has come to a complete stop. The spinning

wheel may grab the surface and pull the power

tool out of your control.

14. Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

15. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

16. Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel. Pinching or snagging causes rapid

stalling of the rotating wheel which in turn causes the

uncontrolled power tool to be forced in the direction

opposite of the wheel’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of

the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the

operator, depending on direction of the wheel’s move-

ment at the point of pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

1. Maintain a rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating acces-

sory. Accessory may kickback over your hand.

3. Do not position your body in line with the

rotating wheel. Kickback will propel the tool in

direction opposite to the wheel’s movement at the

point of snagging.

4. Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

5. Do not attach a saw chain, woodcarving blade,

segmented diamond wheel with a peripheral

gap greater than 10 mm or toothed saw blade.

Such blades create frequent kickback and loss of

control.

6. Do not “jam” the wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases

the loading and susceptibility to twisting or binding

of the wheel in the cut and the possibility of kickback or wheel breakage.

7. When wheel is binding or when interrupting

a cut for any reason, switch off the power

tool and hold the power tool motionless until

the wheel comes to a complete stop. Never

attempt to remove the wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

8. Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted in

the workpiece.

9. Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

10. Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, elec-

trical wiring or objects that can cause kickback.

Additional Safety Warnings:

1. Before using a segmented diamond wheel,

make sure that the diamond wheel has the

peripheral gap between segments of 10 mm or

less, only with a negative rake angle.

2. Never attempt to cut with the tool held upside

down in a vise. This can lead to serious accidents, because it is extremely dangerous.

3. Some material contains chemicals which may

be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier

safety data.

4. Store wheels as per manufacturer recommendations. Improper storage may damage the

wheels.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

4 ENGLISH

Page 5

Symbols

The followings show the symbols used for tool.

volts

direct current

rated speed

revolutions or reciprocation per minute

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consult-

ing an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3. Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery

cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

12

3

► 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

5 ENGLISH

Page 6

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

Battery protection system

The tool is equipped with a battery protection system.

This system automatically cuts off power to the motor to

extend battery life.

The tool will automatically stop during operation if the

tool and/or battery are placed under one of the following

conditions:

Overloaded:

The tool is operated in a manner that causes it to draw

an abnormally high current.

In this situation, turn the tool off and stop the application

that caused the tool to become overloaded. Then turn

the tool on to restart.

If the tool does not start, the battery is overheated. In

this situation, let the battery cool before turning the tool

on again.

Low battery voltage:

The remaining battery capacity is too low and the tool

will not operate. If you turn the tool on, the motor runs

again but stops soon. In this situation, remove and

recharge the battery.

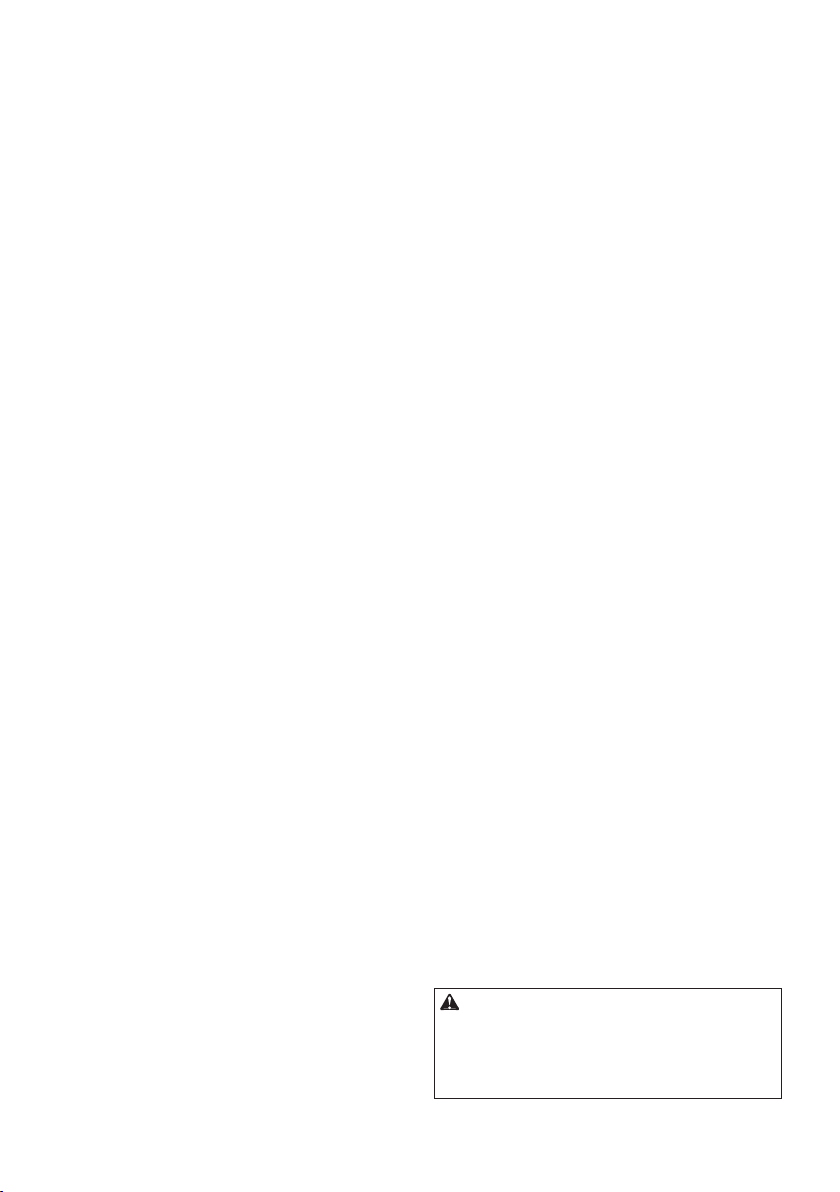

Indicating the remaining battery

capacity

Only for battery cartridges with "B" at the end of the

model number

Indicator lamps Remaining

Lighted Off

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

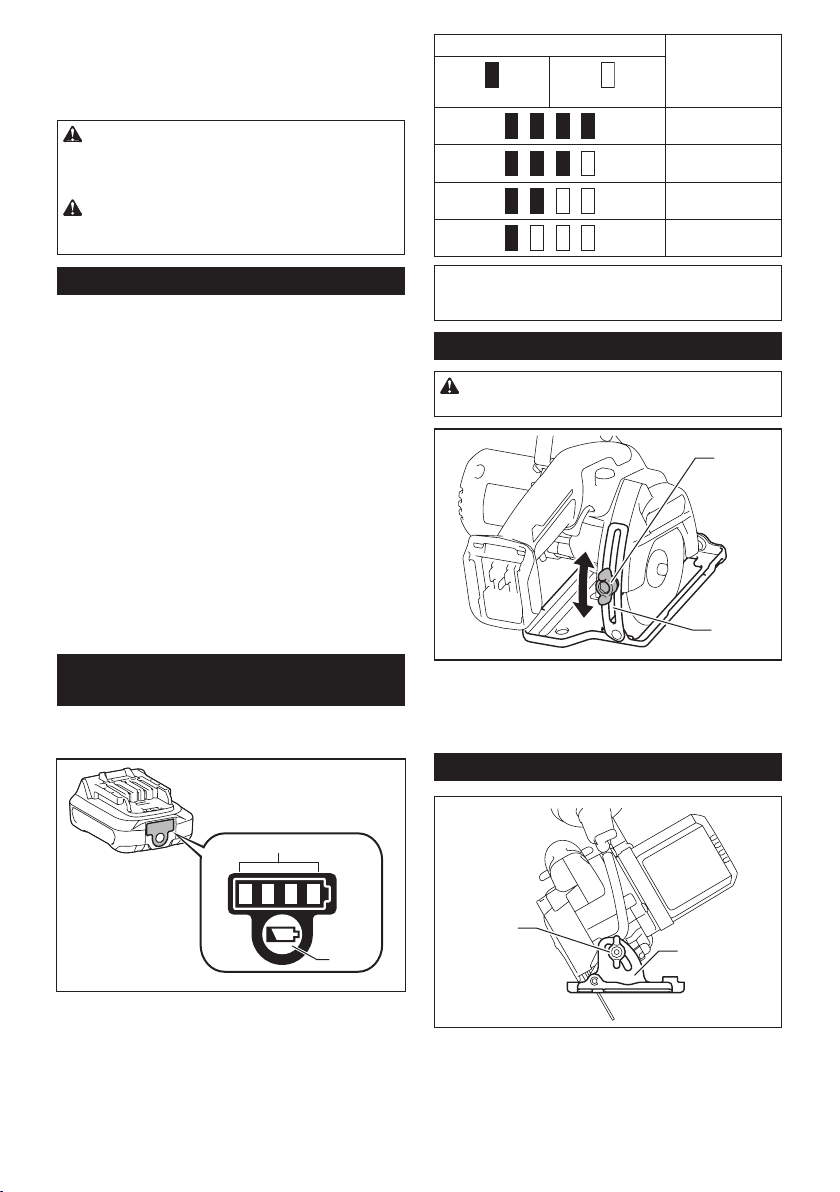

Adjusting depth of cut

CAUTION: After adjusting the depth of cut,

always tighten the clamping screw securely.

1

2

► 1. Clamping screw 2. Depth guide

Loosen the clamping screw on the depth guide and

move the base up or down. At the desired depth of cut,

secure the base by tightening the clamping screw.

Bevel cutting

1

2

► 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for few seconds.

1

2

► 1. Clamping screw 2. Bevel scale plate

Loosen the clamping screw on the bevel scale plate on

the front of the base. Set for the desired angle (0° - 45°)

by tilting accordingly, then tighten the clamping screw

securely.

6 ENGLISH

Page 7

Sighting

1

A

B

► 1. Cutting line

For straight cuts, align the A position on the front of the

base with your cutting line. For 45° bevel cuts, align the

B position with it.

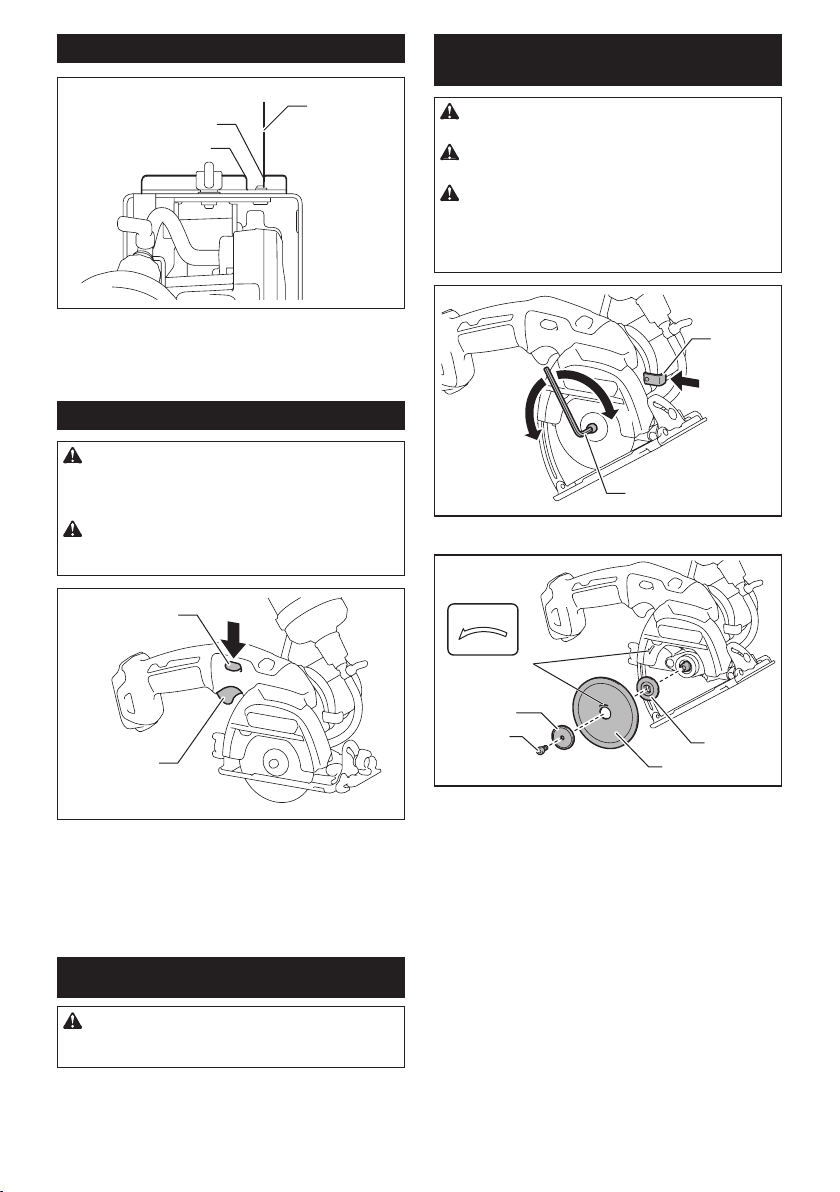

Switch action

CAUTION: Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

CAUTION: Do not pull the switch trigger

hard without pressing the lock-off lever. This can

cause switch breakage.

1

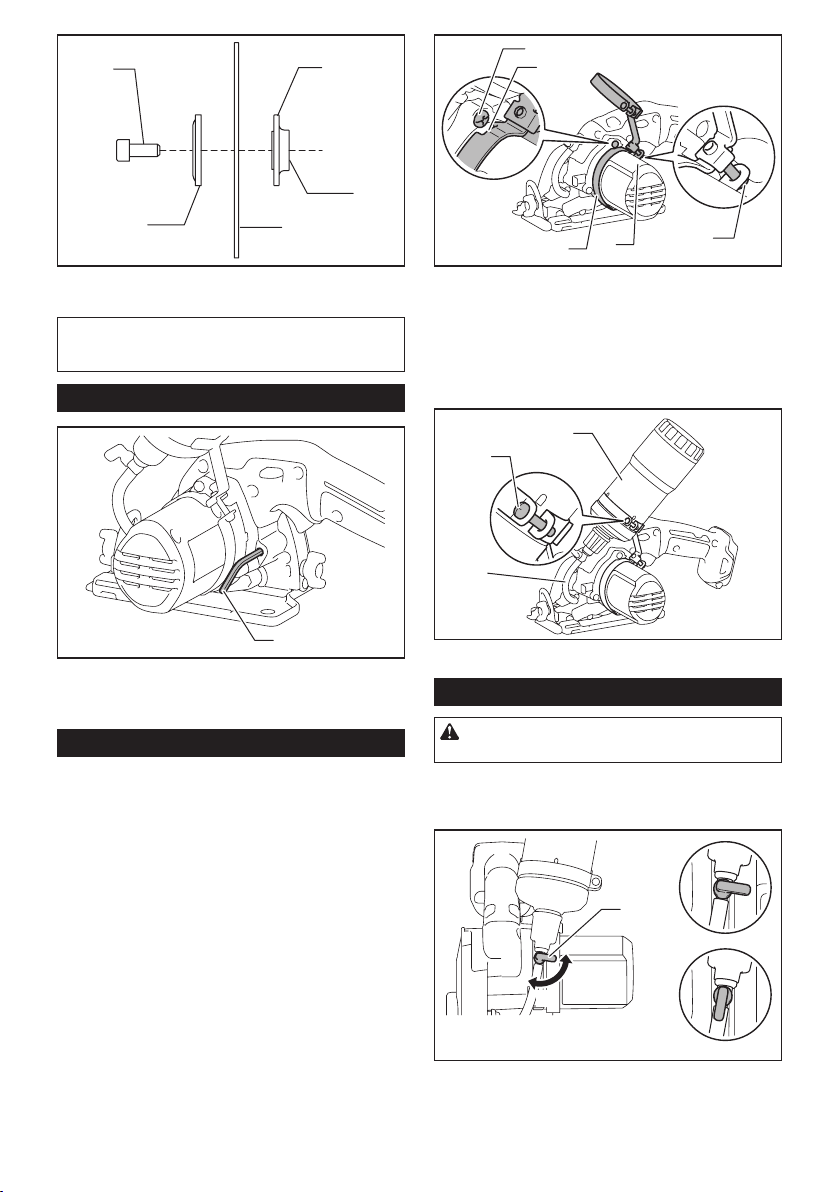

Installing or removing diamond

wheel

CAUTION: Use only the Makita wrench to

install or remove the diamond wheel.

CAUTION: When installing the diamond

wheel, be sure to tighten the bolt securely.

CAUTION: Always install the diamond wheel

so that the arrow on the diamond wheel points in

the same direction as the arrow on the diamond

wheel case. Otherwise the wheel rotates in reverse,

it may cause personal injury.

1

3

4

2

► 1. Shaft lock 2. Hex wrench 3. Tighten 4. Loosen

2

► 1. Lock-off lever 2. Switch trigger

To prevent the switch trigger from being accidentally

pulled, a lock-off lever is provided. To start the tool, slide

the lock-off lever and pull the switch trigger. Release the

switch trigger to stop.

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

5

2

1

3

► 1. Hex bolt 2. Outer ange 3. Diamond wheel

4. Inner ange 5. Arrow

To remove the diamond wheel, press the shaft lock fully

so that the diamond wheel cannot revolve and use the

hex wrench to loosen the hex bolt counterclockwise.

Then remove the hex bolt, outer ange and diamond

wheel.

To install the diamond wheel, follow the removal pro-

cedure in reverse. Make sure the diamond wheel is

installed so that the arrow on the wheel points in the

same direction as the arrow on the diamond wheel

case.

BE SURE TO TIGHTEN THE HEX BOLT SECURELY.

7 ENGLISH

4

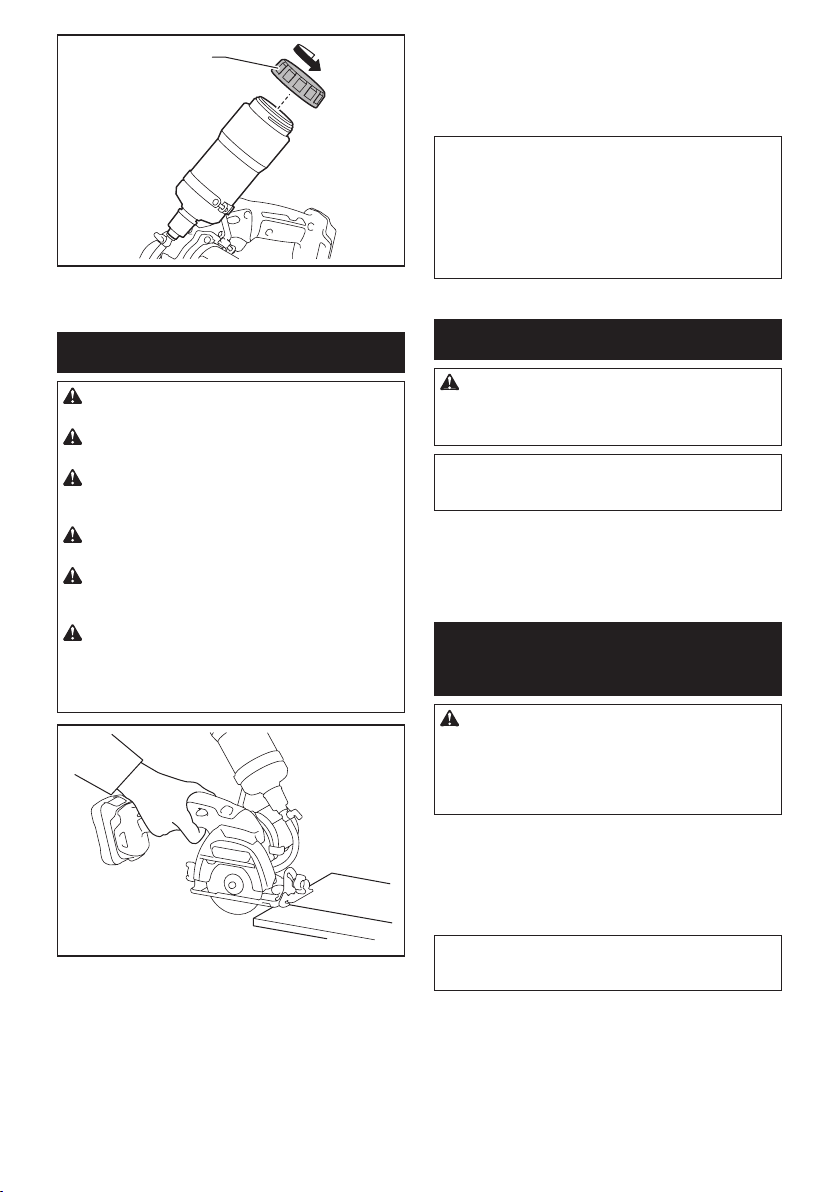

Page 8

1

2

► 1. Hex bolt 2. Outer ange 3. Diamond wheel

4. Inner ange 5. Protrusion (bigger side)

NOTE: If an inner ange is removed by chance,

install the inner ange so that its protrusion (bigger

side) faces inside as shown in the gure.

4

3

Hex wrench storage

5

4

5

3

2

► 1. Screw A 2. Tank holder 3. Motor housing 4. Notch

of the band (part of the tank holder) 5. Screw head

of the tool

Attach the tank on the tank holder so that the tank

holder ts between the step and dots. Connect the cap

on the tube end to the mouth of the tank. Turn the tank

clockwise. Then tighten the screw B.

1

3

2

1

1

► 1. Hex wrench

When not in use, store the hex wrench as shown in the

gure to keep it from being lost.

Installing water supply

Loosen the screw A.

Slide the tank holder all the way over the motor housing

so that the notch of the band (part of the tank holder)

is positioned just below the screw head of the tool as

illustrated.

Then tighten the screw A.

► 1. Tank 2. Tube 3. Screw B

Water supply

CAUTION: When lling the tank with water, be

careful not to let the tool get wet.

Be sure that the water supply cock is closed before

lling the tank with water. Open the cap on the tank and

ll the water. Recap the tank.

2

1

2

3

► 1. Water supply cock 2. Close 3. Open

8 ENGLISH

3

Page 9

► 1. Cap 2. Open

11

2

For ne, clean cuts, cut slowly. (When cutting glass

plate 5 mm (3/16") thick, cut at about 250 mm/min

(9-7/8"/min). When cutting tile 10 mm (3/8") thick, cut

at about 300 mm/min (11-13/16"/min).) Also slow down

as you complete a cut to avoid breaking or cracking the

workpiece being cut.

NOTE: When the battery cartridge temperature is

low, the tool may not work to its full capacity. At this

time, for example, use the tool for a light-duty cut for

a while until the battery cartridge warms up as high

as room temperature. Then, the tool can work to its

full capacity.

NOTE: Make sure that the water supply cock is

closed before operation.

OPERATION

CAUTION: This tool should only be used on

horizontal surfaces.

CAUTION:

down on a stable bench or table during operation.

CAUTION: Do not twist or force the tool in the

cut, or the motor may be overloaded or the workpiece may break.

CAUTION: Do not use the tool with the dia-

mond wheel in an upward or sideways position.

CAUTION:

diamond wheel for glass and tile applications. Be sure

to feed water to the diamond wheel during operation.

CAUTION:

wheel begins to diminish, dress the cutting edge of

the wheel using an old discarded coarse grit bench

grinder wheel or concrete block. Dress by pressing

lightly on the outer edge of the diamond wheel.

Hold the tool rmly. Set the base plate on the workpiece

to be cut without the wheel making any contact.

Then turn the tool on and wait until the wheel attains

full speed.

Feed water to the wheel by adjusting the water supply

cock to obtain a gentle ow of water.

Move the tool forward over the workpiece surface,

keeping it at and advancing smoothly until the cutting

is completed. Keep your cutting line straight and your

speed of advance uniform.

Be sure to hold the workpiece rmly

The wheel for this tool is a wet-type

If the cutting action of the diamond

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

OPTIONAL

ACCESSORIES

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Diamond wheels

• Hex wrench

• Makita genuine battery and charger

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

9 ENGLISH

Page 10

MAKITA LIMITED ONE YEAR

WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one

of Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specic legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or lim-

itation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

10 ENGLISH

Page 11

FRANÇAIS (Mode d’emploi original)

SPÉCIFICATIONS

Modèle : CC301D

Diamètre de la meule diamant 85 mm (3-3/8″)

Épaisseur max. de la meule 0,8 mm (1/32″)

Profondeur de coupe max. avec biseau de 0° 25,5 mm (1″)

avec biseau de 45° 16,5 mm (5/8″)

Vitesse nominale 1 600 /min

Tension nominale C.C. 10,8 V - 12 V max.

Batterie standard BL1016, BL1021B BL1041B

Longueur totale 313 mm (12-3/8″) 331 mm (13″)

Poids net 1,8 kg (4,0 lbs) 1,9 kg (4,2 lbs)

• Étant donné l’évolution constante de notre programme de recherche et développement, les spécications

contenues dans ce manuel sont sujettes à modication sans préavis.

• Les spécications et la batterie peuvent varier suivant les pays.

• Poids, batterie comprise, conforme à la procédure EPTA 01/2003

CONSIGNES DE

SÉCURITÉ

Consignes de sécurité générales

pour outils électriques

MISE EN GARDE : Lisez toutes les

consignes de sécurité et toutes les instructions.

L’ignorance des mises en garde et des instructions

comporte un risque de choc électrique, d’incendie et/

ou de blessure grave.

Conservez toutes les mises en

garde et instructions pour référence future.

Le terme « outil électrique » qui gure dans les avertissements fait référence à un outil électrique branché sur

une prise de courant (par un cordon d’alimentation) ou

alimenté par batterie (sans l).

Sécurité de la zone de travail

1. Maintenez la zone de travail propre et bien

éclairée. Les zones de travail encombrées ou

sombres ouvrent grande la porte aux accidents.

2. N’utilisez pas les outils électriques dans les

atmosphères explosives, par exemple en présence de liquides, gaz ou poussières inammables. Les outils électriques produisent des

étincelles au contact desquelles la poussière ou

les vapeurs peuvent s’enammer.

3. Assurez-vous qu’aucun enfant ou curieux ne

s’approche pendant que vous utilisez un outil

électrique. Vous risquez de perdre la maîtrise de

l’outil si votre attention est détournée.

Sécurité en matière d’électricité

1. Les ches d’outil électrique sont conçues pour

s’adapter parfaitement aux prises de courant.

Ne modiez jamais la che de quelque façon

que ce soit. N’utilisez aucun adaptateur de

che sur les outils électriques avec mise à

la terre. En ne modiant pas les ches et en les

insérant dans des prises de courant pour lesquelles elles ont été conçues, vous réduirez les

risques de choc électrique.

2. Évitez tout contact corporel avec les surfaces

mises à la terre, telles que tuyaux, radiateurs,

cuisinières et réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps se trouve

mis à la terre.

3. N’exposez pas les outils électriques à la pluie

ou à l’eau. La présence d’eau dans un outil élec-

trique augmente le risque de choc électrique.

4. Ne maltraitez pas le cordon. N’utilisez jamais

le cordon pour transporter, tirer ou débrancher

l’outil électrique. Maintenez le cordon à l’écart

des sources de chaleur, de l’huile, des objets à

bords tranchants et des pièces en mouvement.

Le risque de choc électrique est plus élevé lorsque

les cordons sont endommagés ou enchevêtrés.

5. Lorsque vous utilisez un outil électrique à l’extérieur, utilisez un cordon prolongateur conçu

pour l’usage extérieur. Les risque de choc électrique est moindre lorsqu’un cordon conçu pour

l’usage extérieur est utilisé.

6. Si vous devez utiliser un outil électrique dans

un endroit humide, utilisez une source d’alimentation protégée par un disjoncteur de fuite

à la terre. L’utilisation d’un disjoncteur de fuite à la

terre réduit le risque de choc électrique.

Sécurité personnelle

1. Restez alerte, attentif à vos mouvements et

faites preuve de bon sens lorsque vous utilisez un outil électrique. N’utilisez pas les outils

11 FRANÇAIS

Page 12

électriques si vous êtes fatigué ou avez pris

une drogue, de l’alcool ou un médicament. Un

moment d’inattention pendant l’utilisation d’un

outil électrique peut entraîner une grave blessure.

2. Portez des dispositifs de protection personnelle. Portez toujours une protection oculaire.

Les risques de blessure seront moins élevés si

vous utilisez des dispositifs de protection tels

qu’un masque anti-poussière, des chaussures à

semelle antidérapante, une coiffure résistante ou

une protection d’oreilles.

3. Évitez les démarrages accidentels. Assurez-

vous que l’interrupteur est en position d’arrêt

avant de brancher l’outil à la prise de courant

et/ou au bloc-piles, et avant de prendre ou

de transporter l’outil. Vous ouvrez la porte aux

accidents si vous transportez les outils électriques

avec le doigt sur l’interrupteur ou si vous les bran-

chez alors que l’interrupteur est en position de

marche.

4. Retirez toute clé de réglage ou de serrage

avant de mettre l’outil électrique sous tension.

Toute clé laissée en place sur une pièce rotative

de l’outil électrique peut entraîner une blessure.

5. Ne vous étirez pas exagérément. Assurez-vous

d’une bonne prise au sol et d’un bon équilibre

en tout temps. Cela vous permettra d’avoir une

meilleure maîtrise de l’outil électrique dans les

situations imprévues.

6. Portez des vêtements adéquats. Ne portez ni

vêtements amples ni bijoux. Vous devez main-

tenir cheveux, vêtements et gants à l’écart des

pièces en mouvement. Les pièces en mouve-

ment peuvent happer les vêtements amples, les

bijoux et les cheveux longs.

7. Si des accessoires sont fournis pour raccorder

un appareil d’aspiration et de collecte de la

poussière, assurez-vous qu’ils sont correctement raccordés et qu’ils sont utilisés de

manière adéquate. L’utilisation d’un appareil de

collecte permet de réduire les risques liés à la

présence de poussière dans l’air.

Utilisation et entretien des outils électriques

1. Ne forcez pas l’outil électrique. Utilisez l’outil

électrique adéquat suivant le type de travail à

effectuer. Si vous utilisez l’outil électrique adéquat et respectez le régime pour lequel il a été

conçu, il effectuera un travail de meilleure qualité

et plus sécuritaire.

2. N’utilisez pas l’outil électrique s’il n’est pas

possible de l’allumer et de l’éteindre avec son

interrupteur. Un outil électrique dont l’interrupteur

est défectueux représente un danger et doit être

réparé.

3. Débranchez la che de la source d’alimen-

tation et/ou retirez le bloc-piles de l’outil

électrique avant d’effectuer tout réglage, de

remplacer un accessoire ou de ranger l’outil électrique. De telles mesures préventives

réduisent les risques de démarrage accidentel de

l’outil électrique.

4. Après l’utilisation d’un outil électrique,

rangez-le hors de portée des enfants et ne

laissez aucune personne l’utiliser si elle n’est

pas familiarisée avec l’outil électrique ou les

présentes instructions d’utilisation. Les outils

électriques représentent un danger entre les

mains de personnes qui n’en connaissent pas le

mode d’utilisation.

5. Veillez à l’entretien des outils électriques.

Assurez-vous que les pièces mobiles ne sont

pas désalignées ou coincées, qu’aucune pièce

n’est cassée et que l’outil électrique n’a subi

aucun dommage affectant son bon fonctionnement. Le cas échéant, faites réparer l’outil

électrique avant de l’utiliser. De nombreux

accidents sont causés par des outils électriques

mal entretenus.

6. Maintenez les outils tranchants bien aiguisés

et propres. Un outil tranchant dont l’entretien est

effectué correctement et dont les bords sont bien

aiguisés risquera moins de se coincer et sera plus

facile à maîtriser.

7. Utilisez l’outil électrique, ses accessoires, ses

embouts, etc., en respectant les présentes

instructions, en tenant compte des conditions

de travail et du type de travail à effectuer.

L’utilisation d’un outil électrique pour d’autres

usages que ceux prévus peut entraîner une situa-

tion dangereuse.

Utilisation et entretien des outils alimentés par

batterie

1. Pour recharger, utilisez uniquement le char-

geur spécié par le fabricant. L’utilisation d’un

chargeur conçu pour un type donné de bloc-piles

comporte un risque d’incendie lorsqu’il est utilisé

avec un autre type de bloc-piles.

2. N’utilisez un outil électrique qu’avec le bloc-

piles conçu spéciquement pour cet outil. Il y a

risque de blessure ou d’incendie si un autre blocpiles est utilisé.

3. Lorsque vous n’utilisez pas le bloc-piles, ran-

gez-le à l’écart des objets métalliques tels que

trombones, pièces de monnaie, clés, clous,

vis ou autres petits objets métalliques qui

risqueraient d’établir une connexion entre les

bornes. La mise en court-circuit des bornes de

batterie peut causer des brûlures ou un incendie.

4. Dans des conditions d’utilisation inadéquates

de la batterie, il peut y avoir fuite d’électrolyte;

évitez tout contact avec ce liquide. En cas

de contact accidentel, rincez avec beaucoup

d’eau. Si le liquide pénètre dans vos yeux, il

faut aussi consulter un médecin. L’électrolyte

qui s’échappe de la batterie peut causer des

irritations ou des brûlures.

Réparation

1. Faites réparer votre outil électrique par un

réparateur qualié qui utilise des pièces de

rechange identiques aux pièces d’origine. Le

maintien de la sûreté de l’outil électrique sera ainsi

assuré.

2. Suivez les instructions de lubrication et de

remplacement des accessoires.

3. Maintenez les poignées de l’outil sèches,

propres et exemptes d’huile ou de graisse.

12 FRANÇAIS

Page 13

Consignes de sécurité pour scie

diamant sans l

1. La protection fournie avec l’outil doit être

solidement attachée à l’outil électrique et

positionnée pour un maximum de sécurité,

an qu’un minimum de meule soit exposé

vers l’utilisateur. Tenez l’outil de façon que la

meule en rotation se trouve loin de vous et de

toute personne présente. La protection permet

de protéger l’utilisateur des fragments cassés de

meule et d’un contact accidentel avec la meule.

2. N’utilisez que les meules tronçonneuses

diamant conçues pour votre outil électrique.

Même si un accessoire peut être xé à votre outil

électrique, cela ne garantit pas son fonctionnement sécuritaire.

3. La vitesse nominale de l’accessoire doit

être au moins égale à la vitesse maximale

inscrite sur l’outil électrique. Les accessoires

qui tournent plus vite que leur vitesse nominale

peuvent casser et voler en éclats.

4. Les meules ne doivent être utilisées que pour

des applications recommandées. Exemple :

ne meulez pas avec le côté de la meule tron-

çonneuse. Les meules tronçonneuses abrasives

sont conçues pour le meulage périphérique. Elles

peuvent voler en éclats sous l’effet d’une force

latérale.

5. Utilisez toujours des asques de meule en

parfait état et dont le diamètre correspond à la

meule sélectionnée. Les asques adéquats, en

soutenant la meule, réduisent les risques de rup-

ture de la meule.

6. Le diamètre extérieur et l’épaisseur de

votre accessoire ne doivent pas dépasser la

capacité nominale de votre outil électrique.

Il est impossible de protéger ou de contrôler

adéquatement les accessoires d’une dimension

inappropriée.

7. Le diamètre intérieur des meules et des

asques doit être bien adapté à l’axe de l’outil

électrique. Les meules et asques dont l’alésage

ne correspond pas au support de montage de

l’outil électrique se déséquilibreront, vibreront trop

et risqueront de causer une perte de maîtrise de

l’outil.

8. N’utilisez pas de meules endommagées.

Avant chaque utilisation, vériez l’absence

de copeaux et ssures sur la meule. Si vous

échappez l’outil électrique ou la meule, assurez-vous que la meule n’a subi aucun dommage ou remplacez-la par une meule en bon

état. Après avoir vérié et installé la meule,

tenez l’outil de façon que la meule en rotation

se trouve loin de vous et de toute personne

présente, et faites tourner l’outil électrique à

vide pendant une minute à vitesse maximale.

Si la meule est endommagée, elle devrait normalement se casser lors de ce test.

9. Portez des dispositifs de sécurité personnelle.

Suivant le type d’utilisation, portez un écran

facial, des lunettes à coques ou des lunettes

de sécurité. Au besoin, portez un masque

antipoussières, des protections d’oreilles,

des gants et un tablier de travail résistant aux

petites pièces abrasives et aux fragments de

pièce. La protection oculaire utilisée doit pou-

voir protéger contre les débris projetés lors des

diverses opérations. Le masque antipoussières

ou le respirateur doit pouvoir ltrer les particules

générées par votre travail. L’exposition trop

longue à un bruit très intense peut entraîner des

lésions de l’ouïe.

10. Tenez toutes les personnes présentes à une

distance sécuritaire de votre zone de travail.

Toute personne pénétrant dans votre zone de

travail doit porter des dispositifs de protection

personnelle. Des fragments de pièce ou une

meule cassée peuvent être projetés et blesser

quelqu’un même s’il ne se trouve pas tout près de

vous.

11. Tenez l’outil électrique uniquement par ses

surfaces de prise isolées pendant toute opération où l’accessoire de coupe pourrait venir en

contact avec un câblage dissimulé. En cas de

contact de l’accessoire de coupe avec un l sous

tension, les pièces métalliques à découvert de

l’outil électrique risqueraient de transmettre une

décharge électrique à l’utilisateur.

12. Positionnez le cordon loin de l’accessoire

en rotation. Si vous perdez le contrôle, vous

risquez de sectionner ou d’accrocher le cordon,

et il est possible que votre main ou votre bras soit

entraîné vers la meule en rotation.

13. Ne reposez jamais l’outil électrique tant que

l’accessoire ne s’est pas complètement immobilisé. La meule en rotation pourrait s’agripper à

la surface et rendre l’outil électrique incontrôlable.

14. Ne faites pas fonctionner l’outil électrique

lorsque vous le transportez. Un contact acci-

dentel avec l’accessoire en rotation pourrait accro-

cher vos vêtements et entraîner l’accessoire vers

votre corps.

15. Nettoyez régulièrement les orices d’aération

de l’outil électrique. Le ventilateur du moteur

aspire les poussières à l’intérieur du boîtier, et

l’accumulation excessive de métal en poudre peut

entraîner un risque électrique.

16. N’utilisez pas l’outil électrique près de maté-

riaux inammables. Les étincelles risqueraient

de faire prendre en feu ces matériaux.

Recul et mises en gardes connexes

Le recul est une réaction brusque qui se produit lorsqu’une meule en rotation se coince ou accroche. Le

coincement ou l’accrochage provoque un arrêt soudain

de la meule en rotation qui, à son tour, propulse l’outil

électrique hors de contrôle, dans le sens opposé à celui

de la rotation de la meule au point de grippage.

Par exemple, si une meule abrasive accroche dans la

pièce ou s’y coince, le bord de la meule, au point où elle

se coince, plongera dans le matériau, faisant du même

coup remonter ou reculer la meule hors de la pièce.

La meule peut alors bondir vers l’utilisateur ou dans

le sens opposé, selon la direction du mouvement de

la meule au point de coinçage. Les meules abrasives

peuvent également se casser dans ces conditions.

Le recul est le résultat d’une mauvaise utilisation de

l’outil électrique et/ou de mauvaises méthodes ou

conditions d’utilisation ; on peut l’éviter en prenant les

précautions adéquates indiquées ci-dessous.

13 FRANÇAIS

Page 14

1. Maintenez une prise ferme sur l’outil électrique, et placez votre corps et votre bras de

manière à pouvoir résister aux forces de recul.

Utilisez toujours la poignée auxiliaire, le cas

échéant, pour contrôler au maximum le recul

ou la réaction de couple durant le démarrage.

Si les précautions adéquates sont prises, l’utilisateur peut contrôler les réactions de couple ou les

forces de recul.

2. Ne mettez jamais votre main près de l’acces-

soire en rotation. L’accessoire pourrait reculer

sur votre main.

3. Ne vous placez pas droit derrière la meule

en rotation. Le recul propulsera l’outil dans le

sens opposé au mouvement de la meule au point

d’accrochage.

4. Soyez tout particulièrement prudent lorsque

vous travaillez dans les coins, sur les rebords

aigus, etc. Évitez de faire bondir ou accrocher

l’accessoire. Les coins, les rebords aigus ou les

rebondissements ont tendance à provoquer un

accrochage de l’accessoire en rotation et à causer

une perte de contrôle ou un recul.

5. N’attachez pas de chaîne de scie, de lame de

sculpture, de meule diamant segmentée avec

un espace périphérique de plus de 10 mm

ou une lame en dents de scie. De telles lames

créent fréquemment un recul et une perte de

contrôle.

6. Ne « bloquez » pas la meule et n’appliquez pas

de pression excessive. N’essayez pas de faire

une coupe trop profonde. Une surcharge de la

meule augmente la charge et le risque de torsion

ou coincement de la meule dans la coupe et la

possibilité de recul ou de cassure de la meule.

7. Lorsque la meule se coince ou que vous

interrompez une coupe pour une raison quelconque, éteignez l’outil électrique et mainte-

nez-le immobile jusqu’à ce que la meule s’arrête complètement. Ne cherchez jamais à sortir

la meule de l’entaille pendant que la meule est

encore en mouvement, car vous vous expo-

seriez à un recul. Si la meule a tendance à se

coincer, recherchez-en la cause et apportez les

correctifs appropriés.

8. Ne redémarrez pas le travail de coupe dans

la pièce. Laissez la meule atteindre sa pleine

vitesse et replacez avec précaution l’outil dans

l’entaille. La meule peut se coincer, remonter ou

provoquer un recul si l’outil électrique est redémarré dans la pièce.

9. Assurez un soutien aux panneaux ou à toute

pièce surdimensionnée pour réduire le risque

de coincement de la meule ou de recul. Les

grandes pièces ont tendance à s’affaisser sous

leur propre poids. Placez des points d’appui sous

la pièce près de la ligne de coupe et près des

bords de la pièce des deux côtés de la meule.

10. Soyez particulièrement prudent lorsque vous

découpez une ouverture dans une cloison

existante ou tout autre matériau dont l’arrière

n’est pas visible. En dépassant, la meule pourrait

couper une conduite de gaz ou d’eau, des ls

électriques ou des objets qui risquent de provoquer un recul.

Consignes de sécurité additionnelles :

1. Avant d’utiliser une meule diamant segmentée,

assurez-vous que la meule diamant présente

un espace périphérique de 10 mm ou moins,

avec un angle de coupe négatif seulement.

2. Ne tentez jamais de couper en bloquant l’outil

la tête en bas dans un étau. Cela est très dangereux et peut entraîner de graves accidents.

3. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez

les précautions nécessaires pour éviter l’inhalation de ces poussières ou leur contact avec

la peau. Conformez-vous aux consignes de

sécurité du fournisseur du matériau.

4. Rangez les meules conformément aux recommandations du fabricant. Un rangement inadéquat peut endommager les meules.

CONSERVEZ CE MODE

D’EMPLOI.

MISE EN GARDE : NE VOUS LAISSEZ PAS

tromper (au l d’une utilisation répétée) par un

sentiment d’aisance ou de familiarité avec le

produit en négligeant les consignes de sécurité

qui accompagnent le produit. L’UTILISATION

INCORRECTE ou l’ignorance des consignes de

sécurité du présent manuel d’instructions comporte un risque de blessure grave.

Symboles

Les symboles utilisés pour l’outil sont indiqués

ci-dessous.

volts

courant continu

vitesse nominale

tours ou alternances par minute

Consignes de sécurité importantes

pour la batterie

1. Avant d’utiliser la batterie, lisez toutes les

instructions et les mises en garde apposées

sur (1) le chargeur de batterie, (2) la batterie et

(3) le produit utilisant la batterie.

2. Ne démontez pas la batterie.

3. Cessez immédiatement l’utilisation si le temps

de fonctionnement devient excessivement

court. Il y a risque de surchauffe, de brûlures,

voire d’explosion.

4. Si l’électrolyte pénètre dans vos yeux, rincez-les à l’eau claire et consultez immédiatement un médecin. Il y a risque de perte de la

vue.

14 FRANÇAIS

Page 15

5. Ne court-circuitez pas la batterie :

(1) Ne touchez les bornes avec aucun maté-

riau conducteur.

(2) Évitez de ranger la batterie dans un

conteneur avec d’autres objets métalliques tels que clous, pièces de monnaie,

etc.

(3) Évitez d’exposer la batterie à l’eau ou à la

pluie.

Un court-circuit de la batterie pourrait provoquer un fort courant, une surchauffe, parfois

des brûlures et même une panne.

6. Ne rangez pas l’outil ou la batterie dans

des emplacements où la température peut

atteindre ou dépasser 50 °C (122 °F).

7. Ne jetez pas la batterie au feu même si elle est

sérieusement endommagée ou complètement

épuisée. La batterie peut exploser au contact

du feu.

8. Prenez garde d’échapper ou de heurter la

batterie.

9. N’utilisez pas une batterie si elle est

endommagée.

10. Les batteries lithium-ion fournies sont soumises aux exigences de la législation sur les

marchandises dangereuses.

Des exigences particulières sur l’emballage et

l’étiquetage doivent être respectées lors du transport commercial par des tiers, des transitaires, etc.

Pour préparer la marchandise à expédier, consultez un expert en matériaux dangereux si nécessaire. Respectez aussi les éventuelles réglementations nationales plus détaillées.

Recouvrez de ruban isolant les contacts exposés,

et emballez la batterie de sorte qu’elle ne puisse

pas se déplacer à l’intérieur de l’emballage.

11. Suivez la réglementation locale concernant

l’élimination de la batterie.

CONSERVEZ CES

INSTRUCTIONS.

ATTENTION : Utilisez exclusivement les bat-

teries fabriquées par Makita. Les batteries autres

que celles fabriquées par Makita ou les batteries

modiées peuvent exploser et causer un incendie,

une blessure ou des dommages. Cela annule aussi la

garantie Makita de l’outil et du chargeur Makita.

Conseils pour maintenir la

durée de service maximale de la

batterie

1. Rechargez la batterie avant qu’elle ne soit

complètement déchargée. Arrêtez toujours

l’outil et rechargez la batterie quand vous

remarquez que la puissance de l’outil diminue.

2. Ne rechargez jamais une batterie complètement chargée. La surcharge réduit la durée de

service de la batterie.

3. Chargez la batterie à une température

ambiante comprise entre 10 °C et 40 °C (50 °F

et 104 °F). Si la batterie est chaude, laissez-la

refroidir avant de la charger.

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION : Assurez-vous toujours que

l’outil est éteint et que sa batterie est retirée avant

de l’ajuster ou de vérier son fonctionnement.

Installation ou retrait de la batterie

ATTENTION : Éteignez toujours l’outil avant

d’installer ou de retirer la batterie.

ATTENTION : Tenez fermement l’outil et la

batterie lors de l’installation ou du retrait de cette

dernière. Si l’outil et la batterie ne sont pas tenus

fermement, ils risquent de vous glisser des mains et

de subir des dommages, ou encore de vous blesser.

12

3

► 1. Voyant rouge 2. Bouton 3. Batterie

Pour retirer la batterie, faites-la glisser hors de l’outil

tout en glissant le bouton qui se trouve à l’avant.

Pour installer la batterie, alignez sa languette sur la

rainure pratiquée dans le boîtier, et glissez la batterie en

place. Insérez-la à fond jusqu’à ce que vous entendiez

un léger déclic. Si vous pouvez voir le voyant rouge sur

le dessus du bouton, la batterie n’est pas complètement

verrouillée.

ATTENTION : Installez toujours la batterie à

fond jusqu’à ce que vous ne puissiez plus voir le

voyant rouge. Autrement elle risque de tomber accidentellement de l’outil et d’entraîner des blessures.

ATTENTION : Ne forcez pas sur la batterie

pour l’installer. Si la batterie ne glisse pas facile-

ment, c’est qu’elle n’est pas insérée correctement.

Dispositif de protection de la

batterie

L’outil est équipé d’un système de protection de la

batterie. Ce système coupe automatiquement l’alimentation du moteur pour augmenter la durée de vie de la

batterie.

L’outil s’arrête automatiquement pendant l’utilisation

lorsque l’outil et/ou la batterie sont dans l’une des situa-

tions suivantes :

15 FRANÇAIS

Page 16

En surcharge :

L’outil est utilisé d’une manière entraînant une consommation anormale de courant.

Dans cette situation, éteignez l’outil et arrêtez l’application qui a causé la surcharge de l’outil. Allumez ensuite

l’outil pour redémarrer.

Si l’outil ne démarre pas, c’est que la batterie est surchauffée. Dans cette situation, laissez refroidir la batte-

rie avant de rallumer l’outil.

Tension de la batterie faible :

La capacité restante de la batterie est trop faible pour

que l’outil puisse fonctionner. Si vous allumez l’outil, le

moteur tourne de nouveau mais s’arrête aussitôt. Dans

cette situation, retirez et rechargez la batterie.

Afchage de la charge restante de la

batterie

Uniquement pour les batteries dont le numéro de

modèle se termine par « B »

1

2

1

2

► 1. Vis de serrage 2. Guide de profondeur

Desserrez la vis de serrage sur le guide de profondeur,

et déplacez la base vers le haut ou le bas. À la profondeur de coupe désirée, xez la base en serrant la vis

de serrage.

Coupe en biseau

1

2

► 1. Témoins indicateurs 2. Bouton de vérication

Appuyez sur le bouton de vérication de la batterie pour

afcher la charge restante de la batterie. Les témoins

indicateurs s’allument pendant quelques secondes.

Témoins indicateurs Capacité restante

Allumé Éteint

75 % à 100 %

50 % à 75 %

25 % à 50 %

0 % à 25 %

NOTE : Suivant les conditions d’utilisation et la

température ambiante, il se peut que l’indication soit

légèrement différente de la charge réelle.

Réglage de la profondeur de coupe

ATTENTION : Après avoir ajusté la profon-

deur de coupe, serrez toujours fermement la vis

de serrage.

► 1. Vis de serrage 2. Secteur angulaire

Desserrez la vis de serrage du secteur angulaire à

l’avant de la base. Réglez sur l’angle désiré (0° à 45°)

en inclinant, puis serrez fermement la vis de serrage.

Visée

1

A

B

► 1. Ligne de coupe

Pour les coupes rectilignes, alignez sur la ligne de

coupe la position A à l’avant de la base. Pour les

coupes en biseau de 45°, alignez la position B sur la

ligne de coupe.

16 FRANÇAIS

Page 17

Interrupteur

ATTENTION : Avant d’insérer la batterie dans

l’outil, vériez toujours que la gâchette fonctionne bien et revient en position d’arrêt lorsque

libérée.

ATTENTION : N’appuyez pas fortement sur la

gâchette avant d’avoir enfoncé le levier de sécurité. Vous risqueriez de casser la gâchette.

1

2

► 1. Levier de sécurité 2. Gâchette

Un levier de sécurité est fourni pour prévenir la pression

accidentelle sur la gâchette. Pour faire démarrer l’outil,

faites glisser le levier de sécurité puis appuyez sur la

gâchette. Pour l’arrêter, relâchez la gâchette.

ASSEMBLAGE

ATTENTION : Assurez-vous toujours que

l’outil est éteint et que sa batterie est retirée avant

d’effectuer tout travail dessus.

Pose ou retrait de la meule diamant

ATTENTION : Utilisez uniquement la clé

Makita pour installer ou retirer la meule diamant.

ATTENTION : Lorsque vous installez la meule

diamant, vous devez serrer le boulon fermement.

ATTENTION : Installez toujours la meule

diamant de sorte que sa èche pointe dans le

même sens que celle du logement à meule dia-

mant. Autrement, la meule tournera en sens inverse

et risque d’entraîner une blessure.

1

3

4

2

► 1. Blocage de l’arbre 2. Clé hexagonale 3. Serrer

4. Desserrer

5

2

1

4

3

► 1. Boulon hexagonal 2. Flasque externe 3. Meule

diamant 4. Flasque interne 5. Flèche

Pour retirer la meule diamant, enfoncez complètement

le blocage de l’arbre de sorte que la meule diamant ne

puisse pas tourner, et utilisez la clé hexagonale pour

desserrer le boulon hexagonal en tournant dans le sens

contraire des aiguilles d’une montre. Retirez ensuite

le boulon hexagonal, le asque externe et la meule

diamant.

Pour installer la meule diamant, suivez la procédure

de retrait en sens inverse. Assurez-vous d’installer la

meule diamant de sorte que sa èche pointe dans le

même sens que celle du logement à meule diamant.

VOUS DEVEZ SERRER LE BOULON HEXAGONAL

FERMEMENT.

1

4

2

► 1. Boulon hexagonal 2. Flasque externe 3. Meule

diamant 4. Flasque interne 5. Partie saillante (côté

le plus gros)

17 FRANÇAIS

3

5

Page 18

NOTE : Si une bague interne est malencontreuse-

ment retirée, remettez-la en place avec sa partie

saillante (côté le plus gros) vers l’intérieur, tel qu’illustré sur la gure.

Rangement de la clé hexagonale

1

3

2

► 1. Réservoir 2. Tube 3. Vis B

Alimentation en eau

1

► 1. Clé hexagonale

Lorsque vous n’utilisez pas la clé hexagonale, rangez-la

de la façon indiquée sur la gure pour éviter de l’égarer.

Pose de l’alimentation en eau

Desserrez la vis A.

Faites glisser le support de réservoir à fond sur le carter

du moteur, de sorte que l’entaille de la bande (pièce du

support de réservoir) se trouve juste sous la tête de vis

de l’outil, tel qu’illustré.

Serrez ensuite la vis A.

5

4

3

2

► 1. Vis A 2. Support de réservoir 3. Carter du moteur

4. Entaille de la bande (pièce du support de réser-

voir) 5. Tête de vis de l’outil

Fixez le réservoir au support de réservoir de sorte

que ce dernier s’insère entre la saillie et les points.

Connectez le bouchon de l’extrémité du tube à l’ouverture du réservoir. Tournez le réservoir dans le sens des

aiguilles d’une montre. Serrez ensuite la vis B.

1

ATTENTION : Lorsque vous remplissez le

réservoir d’eau, prenez garde de mouiller l’outil.

Avant de remplir le réservoir d’eau, assurez-vous que

le robinet d’alimentation en eau est fermé. Ouvrez le

bouchon du réservoir et remplissez-le d’eau. Remettez

le bouchon sur le réservoir.

2

1

2

3

3

► 1. Robinet d’alimentation en eau 2. Fermer 3. Ouvrir

11

► 1. Bouchon 2. Ouvrir

2

18 FRANÇAIS

Page 19

UTILISATION

ATTENTION : Cet outil ne doit être utilisé que

sur des surfaces horizontales.

ATTENTION : Pendant l’exécution du travail,

vous devez immobiliser fermement la pièce sur

un établi ou une table stable.

ATTENTION : Évitez de tordre ou de forcer

l’outil pendant la coupe, autrement vous risquez

de surcharger le moteur ou de casser la pièce.

ATTENTION : N’utilisez pas l’outil avec la

meule diamant placée sur le dessus ou sur le

côté.

ATTENTION : La meule de cet outil est une

meule diamant pour coupe au mouillé du verre

et des carreaux. Vous devez alimenter la meule

diamant en eau pendant l’utilisation.

ATTENTION : Si la capacité de coupe de la

meule diamant commence à diminuer, dressez

son tranchant avec un vieux touret à gros grain

ou un bloc de béton. Dressez la meule diamant en

appuyant légèrement sur son bord extérieur.

NOTE : Il se peut que l’outil n’offre pas son plein rendement lorsque la batterie est froide. Le cas échéant,

utilisez l’outil, par exemple, pour effectuer un léger

travail de coupe pendant un moment, jusqu’à ce que

la batterie se réchauffe à la température ambiante.

L’outil pourra alors offrir son plein rendement.

NOTE : Avant d’effectuer le travail, assurez-vous que

le robinet d’alimentation en eau est fermé.

ENTRETIEN

ATTENTION : Assurez-vous toujours que

l’outil est hors tension et que la batterie est retirée avant d’y effectuer tout travail d’inspection ou

d’entretien.

AVIS : N’utilisez jamais d’essence, de benzine,

de solvant, d’alcool ou autres produits similaires.

Une décoloration, une déformation ou la forma-

tion de ssures peuvent en découler.

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit, les réparations et tout autre travail d’entretien

ou de réglage doivent être effectués dans un centre

de service après-vente autorisé ou une usine Makita,

exclusivement avec des pièces de rechange Makita.

ACCESSOIRES EN

OPTION

Tenez l’outil fermement. Posez la plaque de base sur

la pièce à couper, sans que la meule n’entre en contact

avec quoi que ce soit.

Allumez ensuite l’outil et attendez que la meule atteigne

sa pleine vitesse.

Alimentez la meule en eau en ajustant le robinet d’alimentation en eau pour obtenir un léger débit d’eau.

Déplacez l’outil vers l’avant à la surface de la pièce, en

le gardant à l’horizontale et en le faisant avancer doucement jusqu’à ce que la coupe soit terminée. Gardez

votre ligne de coupe bien droite et votre vitesse de

progression constante.

Pour obtenir des coupes nes et propres, coupez lentement. (Lorsque vous coupez une plaque de verre de 5

mm (3/16″) d’épaisseur, coupez à environ 250 mm/min

(9-7/8″/min). Lorsque vous coupez des carreaux de 10

mm (3/8″) d’épaisseur, coupez à environ 300 mm/min

(11-13/16″/min).) Ralentissez à la n de la coupe pour

éviter de casser ou ssurer la pièce que vous coupez.

ATTENTION : Ces accessoires ou pièces

complémentaires sont recommandés pour l’utili-

sation avec l’outil Makita spécié dans ce manuel.

L’utilisation de tout autre accessoire ou pièce com-

plémentaire peut comporter un risque de blessure.

N’utilisez les accessoires ou pièces complémentaires

qu’aux ns auxquelles ils ont été conçus.

Si vous désirez obtenir plus de détails sur ces acces-

soires, veuillez contacter le centre de service aprèsvente Makita le plus près.

• Meules diamant

• Clé hexagonale

• Chargeur et batterie authentiques Makita

NOTE : Certains éléments de la liste peuvent être

inclus avec l’outil comme accessoires standards. Ils

peuvent varier suivant les pays.

19 FRANÇAIS

Page 20

GARANTIE LIMITÉE D’UN AN DE

MAKITA

Politique de garantie

Tous les outils Makita sont soigneusement inspectés et

mis à l’essai avant de quitter l’usine. Ils sont garantis

contre les vices de fabrication et de matériau pour une

période d’UN AN suivant la date de l’achat original. Si

un problème survient pendant cette période d’un an,

retournez l’outil COMPLET, fret payé d’avance, à une

usine ou un centre de service après-vente autorisé

Makita. S’il ressort de l’inspection que le problème est

dû à un vice de fabrication ou de matériau, Makita réparera (ou remplacera, à son gré) l’outil gratuitement.

Cette garantie ne s’applique pas dans les cas où :

• des réparations ont été effectuées ou tentées par

un tiers;

• des réparations sont nécessaires en raison de

l’usure normale;

• l’outil a été malmené, mal utilisé ou non adéquatement entretenu;

• l’outil a subi des modications.

MAKITA NE SERA EN AUCUN CAS RESPONSABLE

DE TOUS DOMMAGES INDIRECTS, ACCESSOIRES

OU CONSÉCUTIFS DE LA VENTE OU DE

L’UTILISATION DU PRODUIT. CET AVIS DE NONRESPONSABILITÉ S’APPLIQUE PENDANT ET

APRÈS LA PÉRIODE COUVERTE PAR CETTE

GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

À TOUTES GARANTIES IMPLICITES, Y COMPRIS

LES GARANTIES DE « QUALITÉ MARCHANDE »

OU D’« ADAPTATION À UN USAGE PARTICULIER »

APRÈS LA PÉRIODE DE GARANTIE D’UN AN.

Cette garantie vous donne des droits légaux spéciques, et vous pouvez également avoir d’autres droits

qui varient d’une province à l’autre. Certaines provinces

n’autorisant pas l’exclusion ou la restriction des dom-

mages accessoires ou consécutifs, il se peut que la

restriction ou l’exclusion ci-dessus ne s’applique pas à

vous. Certaines provinces n’autorisant pas de restric-

tion quant à la durée des garanties implicites, il se peut

que la restriction ci-dessus ne s’applique pas à vous.

20 FRANÇAIS

Page 21

ESPAÑOL (Instrucciones originales)

ESPECIFICACIONES

Modelo: CC301D

Diámetro de la rueda de diamante 85 mm (3-3/8″)

Grosor máx. de la rueda 0,8 mm (1/32″)

Profundidad de corte máxima bisel a 0° 25,5 mm (1″)

bisel a 45° 16,5 mm (5/8″)

Velocidad especicada 1 600 r/min

Tensión nominal 10,8 V c.c. - 12 V (máx.) c.c.

Cartucho de batería estándar BL1016, BL1021B BL1041B

Longitud total 313 mm (12-3/8″) 331 mm (13″)

Peso neto 1,8 kg (4,0 lbs) 1,9 kg (4,2 lbs)

• Debido a nuestro continuo programa de investigación y desarrollo, las especicaciones aquí incluidas están

sujetas a cambio sin previo aviso.

• Las especicaciones y el cartucho de batería pueden variar de país a país.

• Peso de acuerdo al procedimiento de EPTA-01/2003 incluyendo el cartucho de batería

ADVERTENCIAS DE

SEGURIDAD

Advertencias generales de

seguridad para herramientas

eléctricas

ADVERTENCIA: Lea todas las advertencias

de seguridad e instrucciones. El no seguir las

advertencias e instrucciones indicadas puede ocasio-

nar una descarga eléctrica, un incendio y/o lesiones

graves.

Conserve todas las advertencias

e instrucciones como referencia

en el futuro.

En las advertencias, el término “herramienta eléctrica”

se reere a su herramienta eléctrica de funcionamiento

con conexión a la red eléctrica (con cableado eléctrico)

o herramienta eléctrica de funcionamiento a batería

(inalámbrica).

Seguridad en el área de trabajo

1. Mantenga el área de trabajo limpia y bien iluminada. Las áreas oscuras o desordenadas son

propensas a accidentes.

2. No utilice las herramientas eléctricas en

atmósferas explosivas, tal como en la presen-

cia de líquidos, gases o polvo inamables. Las

herramientas eléctricas crean chispas que pueden

prender fuego al polvo o los humos.

3. Mantenga a los niños y curiosos alejados

mientras utiliza una herramienta eléctrica. Las

distracciones le pueden hacer perder el control.

Seguridad eléctrica

1. Las clavijas de conexión de las herramientas

eléctricas deberán encajar perfectamente en la

toma de corriente. No modique nunca la clavija de conexión de ninguna forma. No utilice

ninguna clavija adaptadora con herramientas

eléctricas que tengan conexión a tierra (puesta

a tierra). La utilización de clavijas no modica-

das y que encajen perfectamente en la toma de

corriente reducirá el riesgo de que se produzca

una descarga eléctrica.

2. Evite tocar con el cuerpo supercies conec-

tadas a tierra o puestas a tierra tales como

tubos, radiadores, cocinas y refrigeradores. Si

su cuerpo es puesto a tierra o conectado a tierra

existirá un mayor riesgo de que sufra una descarga eléctrica.

3. No exponga las herramientas eléctricas a la

lluvia ni a condiciones húmedas. La entrada de

agua en una herramienta eléctrica aumentará el

riesgo de que se produzca una descarga eléctrica.

4. No maltrate el cable. Nunca utilice el cable

para transportar, jalar o desconectar la herramienta eléctrica. Mantenga el cable alejado del

calor, aceite, objetos cortantes o piezas móviles. Los cables dañados o enredados aumentan

el riesgo de sufrir una descarga eléctrica.

5. Cuando utilice una herramienta eléctrica en

exteriores, utilice un cable de extensión apropiado para uso en exteriores. La utilización de

un cable apropiado para uso en exteriores redu-

cirá el riesgo de que se produzca una descarga

eléctrica.

6. Si no es posible evitar usar una herramienta

eléctrica en condiciones húmedas, utilice un

alimentador protegido con interruptor de circuito de falla a tierra (ICFT). El uso de un ICFT

reduce el riesgo de descarga eléctrica.

21 ESPAÑOL

Page 22

Seguridad personal

1. Manténgase alerta, preste atención a lo que

está haciendo y utilice su sentido común

cuando opere una herramienta eléctrica. No

utilice una herramienta eléctrica cuando esté

cansado o bajo la inuencia de drogas, alcohol o medicamentos. Un momento de distracción

mientras opera las herramientas eléctricas puede

terminar en una lesión grave.

2. Use equipo de protección personal. Póngase

siempre protección para los ojos. El equipo

protector tal como máscara contra el polvo, zapatos de seguridad antiderrapantes, casco rígido y

protección para oídos utilizado en las condiciones

apropiadas reducirá el riesgo de lesiones.

3.

Impida el encendido accidental. Asegúrese de

que el interruptor esté en la posición de apa

gado antes de conectar a la alimentación eléctrica y/o de colocar el cartucho de batería, así

como al levantar o cargar la herramienta. Cargar

las herramientas eléctricas con su dedo en el inte

rruptor o enchufarlas con el interruptor encendido

hace que los accidentes sean comunes.

4. Retire cualquier llave de ajuste o llave de

apriete antes de encender la herramienta. Una

llave de ajuste o llave de apriete que haya sido

dejada puesta en una parte giratoria de la herramienta eléctrica puede ocasionar alguna lesión.

5.

No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo rme y el equilibrio

en todo momento. Esto permite un mejor control de

la herramienta eléctrica en situaciones inesperadas.

6.

Use vestimenta apropiada. No use ropas sueltas ni joyas. Mantenga el cabello, la ropa y los

guantes alejados de las piezas móviles. Las

prendas de vestir holgadas, las joyas y el cabello

suelto podrían engancharse en las piezas móviles.

7.

Si dispone de dispositivos para la conexión de

equipos de extracción y recolección de polvo,

asegúrese de conectarlos y utilizarlos debidamente. Hacer uso de la recolección de polvo puede

reducir los riesgos relacionados con el polvo.

Mantenimiento y uso de la herramienta eléctrica

1. No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación. La herramienta eléctrica adecuada hará un

mejor trabajo y de forma más segura a la velocidad para la que ha sido fabricada.

2. No utilice la herramienta eléctrica si el interruptor no la enciende y apaga. Cualquier

herramienta eléctrica que no pueda ser controlada con el interruptor es peligrosa y debe ser

reemplazada.

3. Desconecte la clavija de la fuente de energía

y/o la batería de la herramienta eléctrica antes