Makita BJR240 User Manual [en, es, fr]

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Cordless Recipro Saw

Scie récipro sans fil

Sierra de sable inalámbrico

BJR240

001660

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

ENGLISH

SPECIFICATIONS

MODEL BJR240

Length of stroke 32 mm (1-1/4”)

Strokes per minute High speed: 0 - 2,700/min. Low speed: 0 - 2,300/min.

Overall length 469 mm (18-1/2”)

Net weight 4.4 kg (9.7 lbs)

Battery Charger DC24SA DC24WA

Input A.C. only 50 Hz - 60 Hz

Output D.C. 7.2 V - 24 V

Battery Cartridge BH2420 BH2433 BH2420 BH2433

Voltage 24 V

Charging time 30 min. 60 min. 55 min. 90 min.

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

GENERAL SAFETY RULES

USA003-2

(FOR ALL BATTERY OPERATED TOOLS)

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below,

may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

4. A battery operated tool with integral batteries or

a separate battery pack must be recharged only

with the specified charger for the battery. A

charger that may be suitable for one type of battery

may create a risk of fire when used with another battery.

5. Use battery operated tool only with specifically

designated battery pack. Use of any other batter-

ies may create a risk of fire.

Personal Safety

6. Stay alert, watch what you are doing, and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

7. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

8. Avoid accidental starting. Be sure switch is in

the locked or off position before inserting battery pack. Carrying tools with your finger on the

switch or inserting the battery pack into a tool with

the switch on invites accidents.

9. Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

10. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enable better control of the tool in unexpected situations.

11. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

2

Tool Use and Care

12. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

13. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

14. Do not use tool if switch does not turn it on or

off. A tool that cannot be controlled with the switch is

dangerous and must be repaired.

15. Disconnect battery pack from tool or place the

switch in the locked or off position before making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

16. Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

17. When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal to

another. Shorting the battery terminals together

may cause sparks, burns, or a fire.

18. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edge are less likely to bind and are

easier to control.

19. Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

20. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool may create a risk of

injury when used on another tool.

SERVICE

21. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified personnel may result in a risk

of injury.

22. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow Maintenance

instructions may create a risk of shock or injury.

SPECIFIC SAFETY RULES

USB029-2

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to cordless

recipro saw safety rules. If you use this

tool unsafely or incorrectly, you can suffer serious personal injury.

1. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will make exposed metal parts of the tool “live”

and shock the operator.

2. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

3. Always use safety glasses or goggles. Ordinary

eye or sun glasses are NOT safety glasses.

4. Avoid cutting nails. Inspect workpiece for any

nails and remove them before operation.

5. Do not cut oversize workpiece.

6. Check for the proper clearance beyond the workpiece before cutting so that the blade will not

strike the floor, workbench, etc.

7. Hold the tool firmly.

8. Make sure the blade is not contacting the workpiece before the switch is turned on.

9. Keep hands away from moving parts.

10. Always switch off and wait for the blade to come

to a complete stop before removing the blade

from the workpiece.

11. Do not touch the blade or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

12. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

3

SYMBOLS

The followings show the symbols used for tool.

V............................volts

.......................direct current

.......................no load speed

.../min....................revolutions or reciprocation per

minute

USD301-1

IMPORTANT SAFETY INSTRUCTIONS FOR CHARGER & BATTERY CARTRIDGE

1. SAVE THESE INSTRUCTIONS- This manual contains important safety and operating instructions for battery charger.

2. Before using battery charger, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

3. CAUTION - To reduce risk of injury, charge only

MAKITA rechargeable batteries marked on the

USC002-3

charger label. Other types of batteries may burst

causing personal injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold

by the battery charger manufacturer may result

in a risk of fire, electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and

cord, pull by plug rather than cord when disconnecting charger.

7. Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected

to damage or stress.

8. An extension cord should not be used unless

absolutely necessary. Use of improper extension

cord could result in a risk of fire and electric

shock. If extension cord must be used, make

sure:

a. That pins on plug of extension cord are the

same number, size, and shape as those of

plug on charger;

b. That extension cord is properly wired and in

good electrical condition; and

c. That wire size is at least as large as the one

specified in the table below.

Table 1: RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS FOR BATTERY CHARGERS

Length of Cord (Feet) 25 50 100 150

AWG Size of Cord 18 18 18 16

9. Do not operate charger with damaged cord or

plug - replace them immediately.

10. Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in

any way; take it to a qualified serviceman.

11. Do not disassemble charger or battery cartridge;

take it to a qualified serviceman when service or

repair is required. Incorrect reassembly may

result in a risk of electric shock or fire.

12. To reduce risk of electric shock, unplug charger

from outlet before attempting any maintenance

or cleaning. Turning off controls will not reduce

this risk.

13. The battery charger is not intended for use by

young children or infirm persons without supervision.

14. Young children should be supervised to ensure

that they do not play with the battery charger.

15. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

16. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

ADDITIONAL SAFETY RULES

FOR CHARGER & BATTERY CARTRIDGE

1. Do not charge Battery Cartridge when temperature is BELOW 10°C (50°F) or ABOVE 40°C

(104°F).

2. Do not attempt to use a step-up transformer, an

engine generator or DC power receptacle.

3. Do not allow anything to cover or clog the

charger vents.

4. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as nails,

coins, etc.

4

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

5. Do not store the tool and Battery Cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

6. Do not incinerate the Battery Cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

7. Be careful not to drop, shake or strike battery.

8. Do not charge inside a box or container of any

kind. The battery must be placed in a well ventilated area during charging.

SAVE THESE INSTRUCTIONS

SYMBOLS

The following show the symbols used for the charger. Be

sure that you understand their meaning before use.

............Ready to charge

...............Charging

...............Charging complete

...........Delay charge (Cooling)

...........Defective battery

...........Conditioning

............Cooling abnormality

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

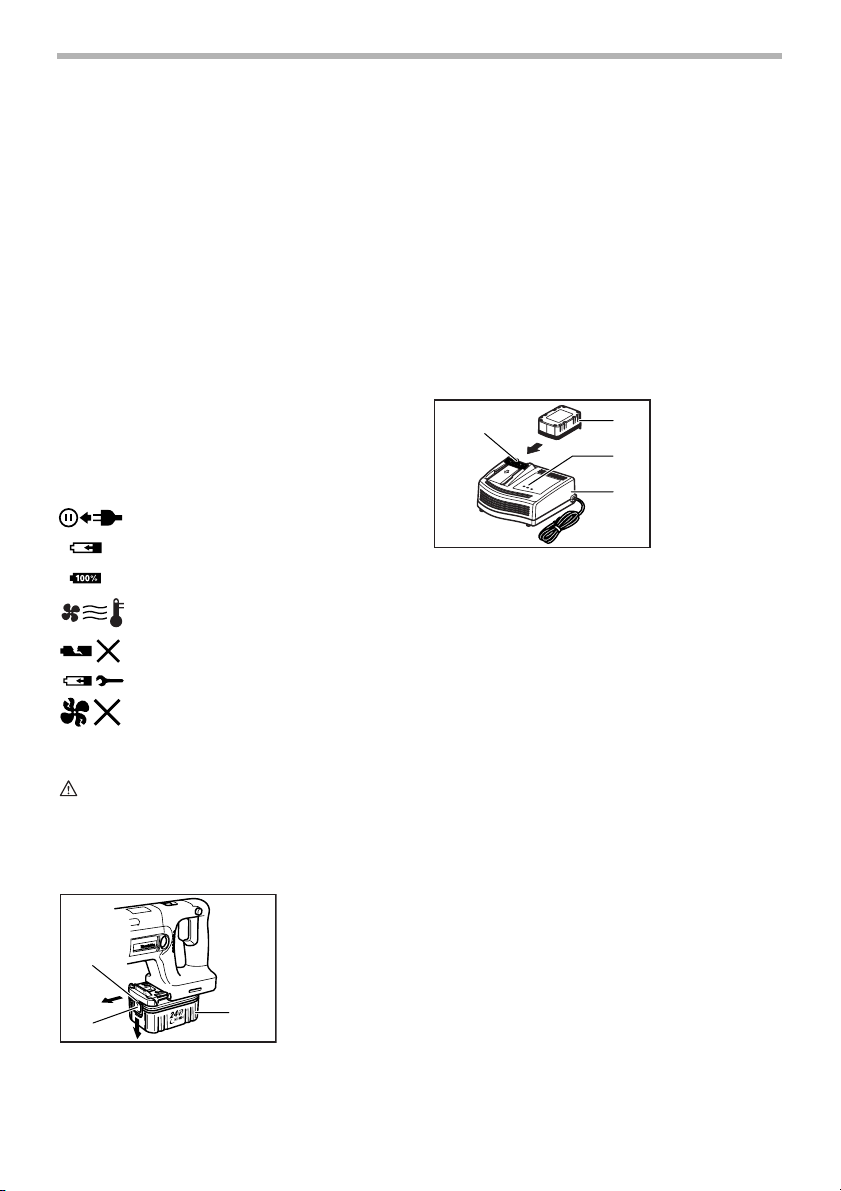

Installing or removing battery cartridge

1

2

• Always switch off the tool before insertion or

removal of the battery cartridge.

001661

3

1. Red part

2. Button

3. Battery cartridge

• To remove the battery cartridge, withdraw it from

the tool while sliding the button on the side of the

cartridge.

• To insert the battery cartridge, align the tongue on

the battery cartridge with the groove in the housing

and slip it into place. Always insert it all the way

until it locks in place with a little click. If you can see

the red part on the upper side of the button, it is not

locked completely. Insert it fully until the red part

cannot be seen. If not, it may accidentally fall out of

the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery car-

tridge. If the cartridge does not slide in easily, it is

not being inserted correctly.

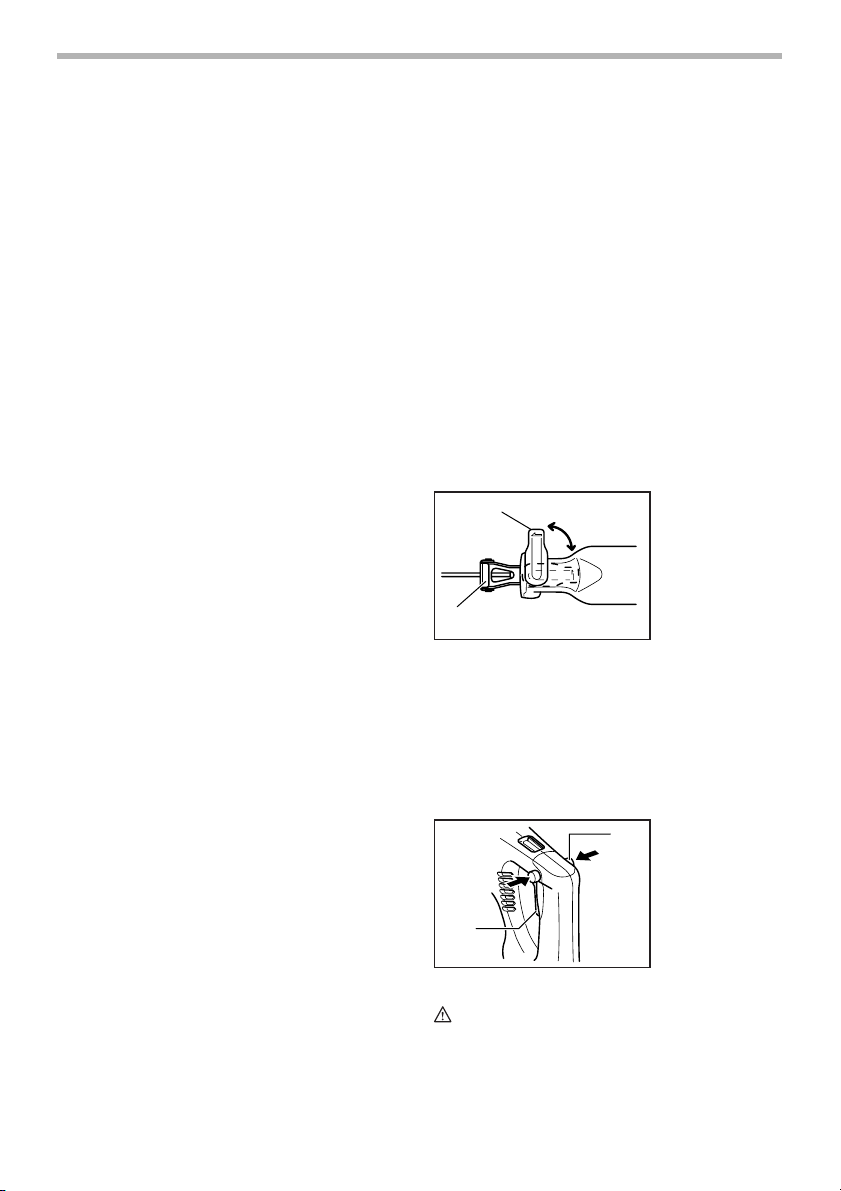

Charging

2

1. Plug the battery charger into the proper AC voltage

source. Two charging lights will flash in green color

repeatedly.

2. Insert the battery cartridge into charger until it stops

adjusting to the guide of charger. Terminal cover of

charger can be opened with inserting and closed

with pulling out the battery cartridge.

3. When the battery cartridge is inserted, the charging

light color will change from green to red and charging will begin. The charging light will keep lighting

up lit steadily during charging. One red charging

light indicates charged condition in 0 - 80% and two

red ones indicates 80 - 100%.

4. With finish of charge, the charging lights will

change from two red ones to two green ones.

5. If you leave the battery cartridge in the charger

after the charging cycle is complete, the charger

will switch into its “trickle charge (maintenance

charge)” mode which will last approximately 24

hours.

6. After charging, unplug the charger from the power

source.

NOTE:

• The battery charger is for charging Makita battery

cartridge. Never use it for other purposes or for

other manufacturer’s batteries.

• When you charge a new battery cartridge or a bat-

tery cartridge which has not been used for a long

period of time, it may not accept a full charge. This

is a normal condition and does not indicate a prob-

001662

1. Battery car-

1

2. Terminal cover

3

3. Charging lights

4. Battery charger

4

tridge

5

lem. You can recharge the battery cartridge fully

after discharging it completely and recharging a

couple of times.

• If you charge a battery cartridge from a just oper-

ated tool or battery cartridge which has been left in

a location exposed to direct sunlight for a long time,

the charging light may flash in red color. If this

occurs, wait for a while. Charging will begin after

the battery cartridge is cooled by the cooling fan

installed in the charger. (DC24SA only) When the

temperature on battery is more than approx. 70°C,

two charging lights may flash in red color, and when

approx. 50°C - 70°C, one charging light in red color.

• If the charging light flashes alternately in green and

red color, charging is not possible. The terminals on

the charger or battery cartridge are clogged with

dust or the battery cartridge is worn out or damaged.

Cooling system (DC24SA only)

• This charger is equipped with cooling fan for heated

battery in order to enable the battery to prove its

own performance. Sound of cooling air comes out

during cooling, which means no trouble on the

charger.

• Yellow light will flash for warning in the following

cases.

- Trouble on cooling fan

- Incomplete cool down of battery, such as, being

clogged with dust

The battery can be charged in spite of the yellow

warning light. But the charging time will be longer

than usual in this case.

• Check the sound of cooling fan, vent on the charger

and battery, which can be sometime clogged with

dust.

• The cooling system is in order although no sound of

cooling fan comes out, if the yellow warning light

will not flash.

• Always keep clean the vent on charger and battery

for cooling.

• The products should be sent to repair or mainte-

nance, if the yellow warning light will frequently

flash.

Conditioning charge (DC24SA only)

Conditioning charge can extend the life of battery by

automatically searching the optimum charging condition

for the batteries in every situations.

The battery employed in the following conditions repeatedly, will be worn out shortly, and yellow warning light

may flash.

1. Recharge of battery with its high temperature

2. Recharge of battery with its low temperature

3. Recharge of full charged battery

4. Over-discharge of battery (continue to discharge

battery in spite of down of power.)

The charging time of such battery is longer than usual.

Trickle charge (Maintenance charge)

If you leave the battery cartridge in the charger to prevent

spontaneous discharging after full charge, the charger

will switch into its “trickle charge (maintenance charge)”

mode and keep the battery cartridge fresh and fully

charged.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely dis-

charged.

• Always stop tool operation and charge the bat-

tery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

• Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature

at 10°C - 40°C (50°F - 104°F).

• Let a hot battery cartridge cool down before

charging it.

4. Charge the Nickel Metal Hydride battery cartridge

when you do not use it for more than six months.

Adjusting the shoe

1

001663

1. Lever

2. Shoe

2

When the blade loses its cutting efficiency in one place

along its cutting edge, reposition the shoe to utilize a

sharp, unused portion of its cutting edge. This will help to

lengthen the life of the blade. To reposition the shoe,

loosen the lever counterclockwise and slide the shoe forward or back to the desired position. Then tighten the

lever clockwise to firmly secure the shoe.

Switch action

001664

1

1. Lock-off button

2. Switch trigger

2

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

6

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided.

To start the tool, press in the lock-off button and pull the

switch trigger. The lock-off button can be pressed in from

either left or right side of the tool. Tool speed is increased

by increasing pressure on the switch trigger. Release the

switch trigger to stop.

Electric brake

This tool is equipped with an electric brake. If the tool

consistently fails to quickly stop after switch trigger

release, have tool serviced at a Makita service center.

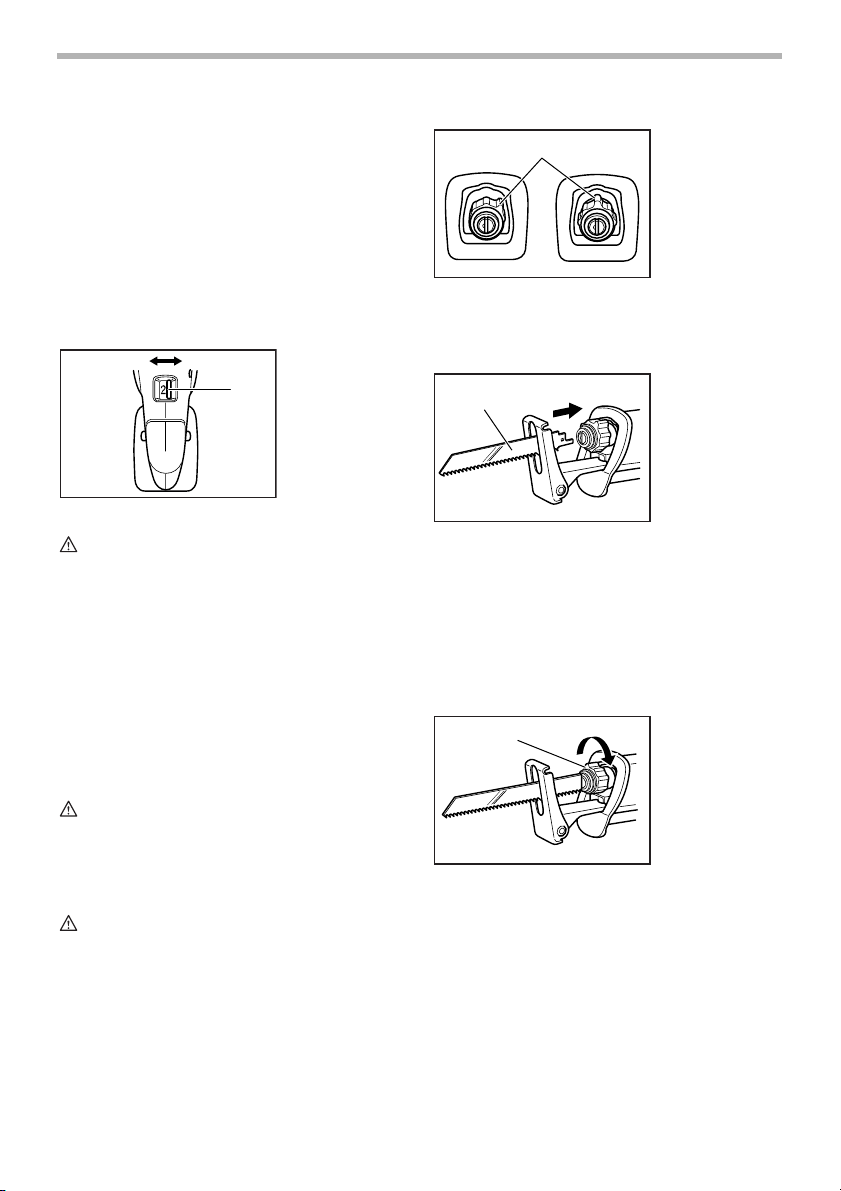

Speed change

BA

001665

1

1. Speed change

lever

001666

1

23

1. Blade clamp

sleeve

2. Released position

3. Fixed position

Insert the saw blade into the blade clamp as far as it will

go. The blade clamp sleeve rotates and the saw blade is

fixed. Make sure that the saw blade cannot be extracted

even though you try to pull it out.

001667

1. Blade

1

CAUTION:

• Always set the speed change lever fully to the cor-

rect position. If you operate the tool with the speed

change lever positioned half-way, the tool may be

damaged.

• Do not use the speed change lever while the tool is

running. The tool may be damaged.

To change the speed, first switch off the tool and then

slide the speed change lever to the A side (2) for high

speed or B side (1) for low speed. Be sure that the speed

change lever is set to the correct position before operation. Use the right speed for your job.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out

any work on the tool.

Installing or removing the saw blade

CAUTION:

• Always clean out all chips or foreign matter adher-

ing to the blade, blade clamp and/or slider. Failure

to do so may cause insufficient tightening of the

blade, resulting in a serious injury.

To install the saw blade, always make sure that the blade

clamp sleeve is in released position before inserting the

saw blade. If the blade clamp sleeve is in fixed position,

rotate the sleeve to the released position.

NOTE:

• If you do not insert the saw blade deep enough, the

saw blade may be ejected unexpectedly during

operation. This can be extremely dangerous.

To remove the saw blade, rotate the blade clamp sleeve

in the direction of the arrow fully. The saw blade is

removed and the blade clamp sleeve is fixed at the

released position.

1

001668

1. Blade clamp

sleeve

NOTE:

• If you remove the saw blade without rotating the

blade clamp sleeve fully, the sleeve may not be

fixed. In this case, rotate the blade clamp sleeve

fully, then make the sleeve fixed at the released

position.

7

OPERATION

CAUTION:

• Always press the shoe firmly against the workpiece

during operation. If the shoe is held away from the

workpiece during operation, strong vibration and/or

twisting will be produced, causing the blade to snap

dangerously.

• Always wear gloves to protect your hands from hot

flying chips when cutting metal.

• Be sure to always wear suitable eye protection

which conforms with current national standards.

• Always use a suitable coolant (cutting oil) when cut-

ting metal. Failure to do so will cause premature

blade wear.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

Press the shoe firmly against the workpiece. Do not allow

the tool to bounce. Bring the blade into light contact with

the workpiece. First, make a pilot groove using a slower

speed. Then use a faster speed to continue cutting.

001669

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

001145

1. Limit mark

1

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

1

After replacing brushes, insert the battery cartridge into

the tool and break in brushes by running tool with no load

for about 1 minute. Then check the tool while running and

electric brake operation when releasing the switch trigger. If electric brake is not working well, ask your local

Makita service center for repair.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

001670

2

1. Brush holder

cap

2. Screwdriver

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Recipro saw blades

• Various type of Makita genuine batteries and charg-

ers

• Plastic carrying case

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

8

EN0006-1

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

9

Loading...

Loading...