Page 1

T

Description

ECHNICAL INFORMATION

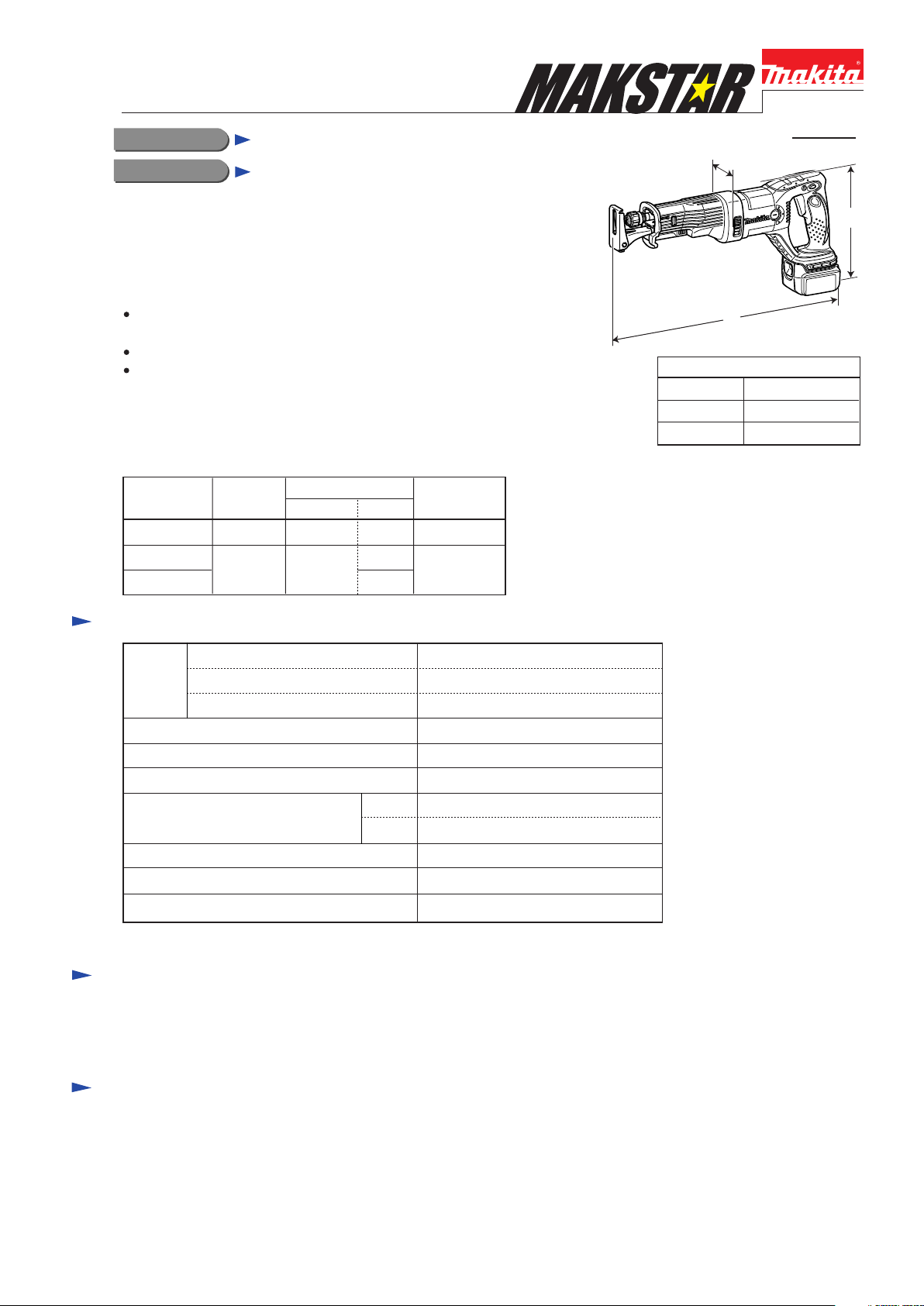

Models No.

BJR141

Cordless Recipro Saw

PRODUCT

P 1 /10

W

CONCEPT AND MAIN APPLICATIONS

Model BJR141 has been developed as the successor model to

the current Model JR140D 14.4V cordless recipro saw.

While having the same basic construction as Model JR140D,

features the following additional advantages;

Lightweight design achieved by using Li-ion battery

as a power unit instead of Ni-cd battery.

More work amount on a single full battery charge

Non-skid handle angled and contoured ergonomically for

best-fitting to reciprocating cutting

This product is available in the following variations.

Model No.

BJR141Z

BJR141RF

BJR181RFE 2

Charger

Battery

type quantity

No No

BL1430 DC18RA

No

1

Specification

Voltage: V

Battery

Max output (W) 280

Length of stroke: mm (")

No load speed: min-1=spm 0 - 2,700

Max cutting capacities: mm (")

[when cutting with a 160mm blade]

Capacity: Ah

Cell

wood 90 (3-1/2)

pipe

Plastic

carrying case

No

Yes

14.4

3.0

Li-ion

23 (7/8)

90 (3-1/2)

L

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

H

466 (18-3/8)

79 (3-1/8)

226 (8-7/8)

Variable speed Yes

Electric brake

Net weight*: kg (lbs)

*Includes battery BL1430

Yes

3.1 (6.8)

Standard equipment

Recipro saw blade for metal ............................................................... 1

Recipro saw blade for composite material (wood plus metal) ........... 1

Plastic carrying case ........................................................................... 1

Note: The standard equipment for the tool shown above may differ from country to country.

Optional accessories

Charger DC18RA

Charger DC24RC

Charger DC24SC

Li-ion battery BL1430

Assorted recipro saw blades

Page 2

P 2 /10

Repair

CAUTION: Remove recipro saw blade and battery cartridge from the machine

for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R030 Bearing setting pipe 2.5-17.2 Press-fitting Dust seal 14 in Gear housing cover complete

1R269 Removing Ball bearing 6001DDW from the drive-end of Armature

1R291 Removing/installing Retaining ring S-18 from/on Blade clamp section

--- Recipro saw blade Assembling Pin 3 to Blade clamp section

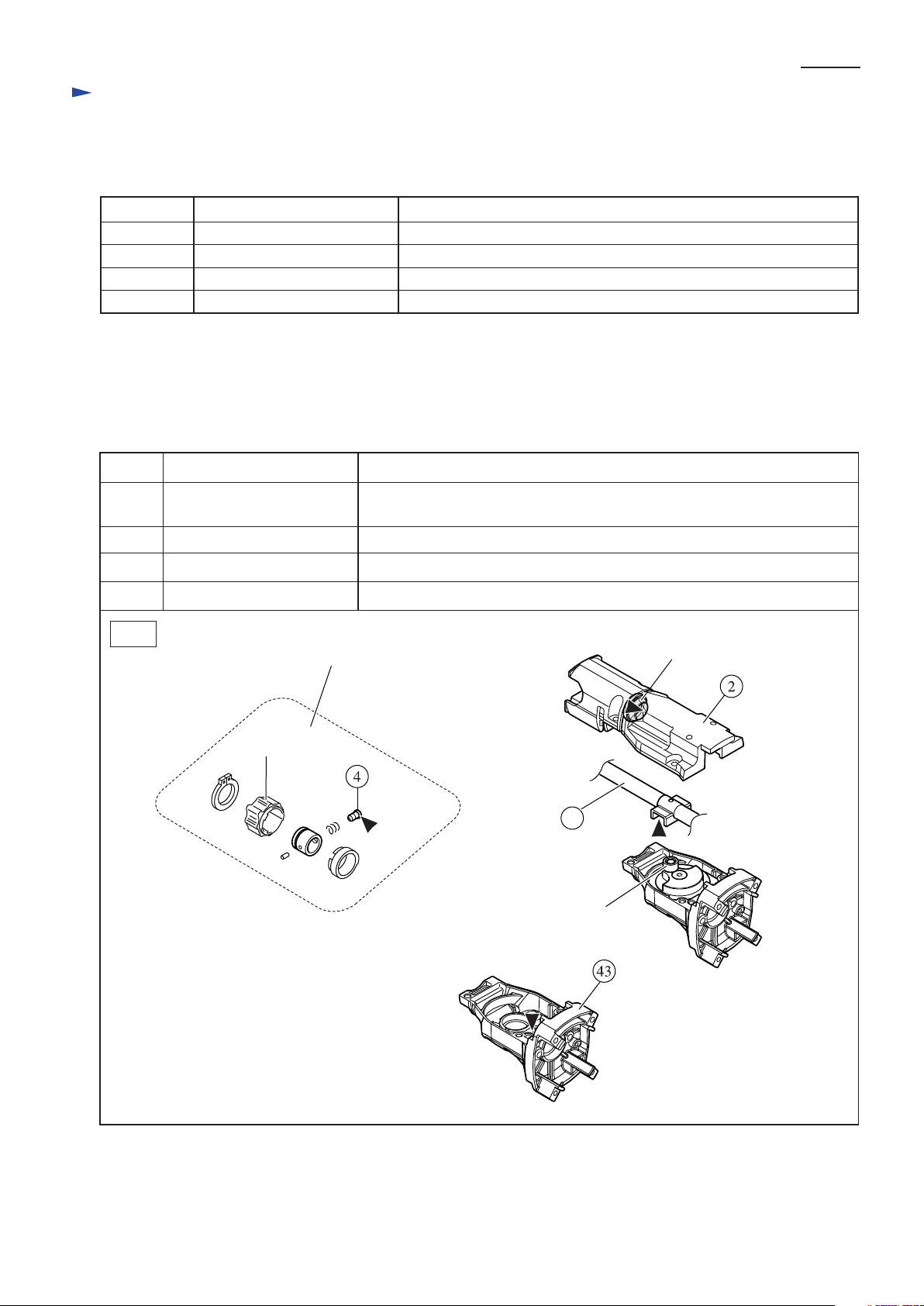

[2] LUBRICATION and ADHESIVE

Lubrication: Apply Makita grease FA No.2 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion. (Fig. 1)

Adhesive: When reusing threadlocker coated screws, be sure to apply adhesive before tightening.

Recommended adhesives are Threebond 1342 or Loctite 242.

Item No. Description Portion to be lubricate

2 Gear housing cover complete

4 Shoulder pin 5

Bearing extractor

Retaining ring S and R pliers

Inside surface of the lip portion of Dust seal 14

(Any kind of lubricating grease can be used.)

Pin head that contacts Driving sleeve

17

Slider complete Surface that contacts Needle bearing 708 (Put approx. 9g.)

43 Gear housing Gear room (Put approx. 9g.)

Fig. 1

Blade clamp section

Driving sleeve

Needle bearing 708

Dust seal 14

17

Page 3

Repair

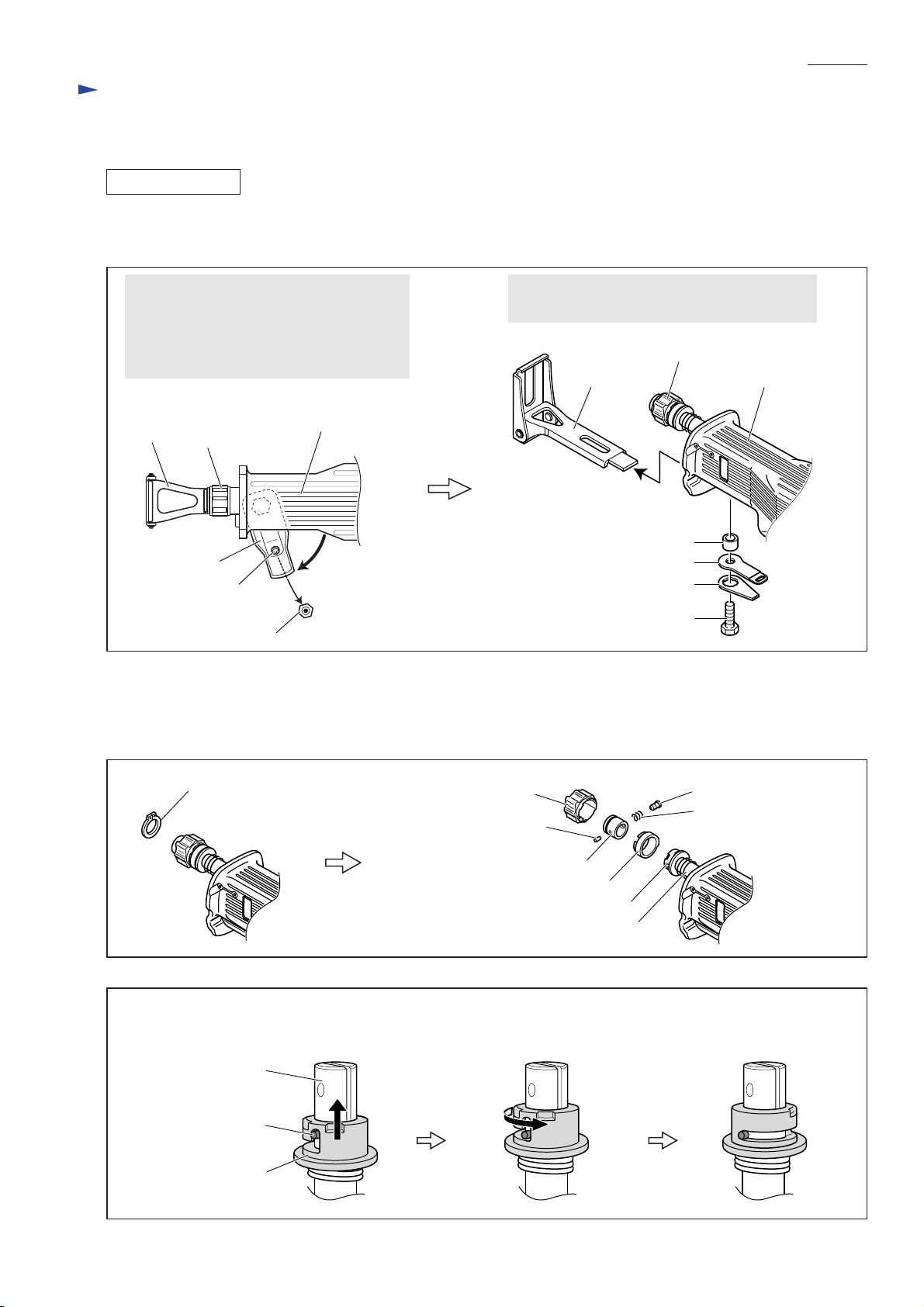

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Blade Clamp Section

DISASSEMBLING

1) Remove Shoe as illustrated in Fig. 2.

Note: If the Blade clamp section is positioned inside Gear housing, pull it out of Gear housing.

Fig. 2

P 3 /10

Turn Lever 60 in the direction of the arrow.

Remove Pan head screw M4x10.

Remove Lever 60.

Note: Hex nut M4 will be left in Lever 60.

Be careful not to lose it.

[View from top]

Shoe

Blade clamp section

Lever 60

Pam head screw

M4x10

Hex nut M4

2) Remove Retaining ring S-18 using 1R291. The following parts can now be removed (Fig. 3):

Driving sleeve, Shoulder pin 5, Compression spring 6, Pin 3 (of 6mm length), Guide sleeve, Driving sleeve guide

Note: Sleeve is still locked on Slider in this step.

3) Unlock Sleeve from Slider as illustrated in Fig. 4.

Fig. 3

Insulation cover

By unscrewing Hex bolt M8x25, Shoe can now

be removed as illustrated below.

Blade clamp section

Shoe

Sleeve 9

Inner plate

Lock plate

Hex bolt M8x25

Insulation cover

Retaining ring S-18

Fig. 4

Pull up Sleeve until it stops against

Pin 3 (of 19.8mm length).

Slider

Pin 3

(of 19.8mm length)

Sleeve

Driving sleeve

Pin 3 (of 6mm length)

Guide sleeve

Driving sleeve guide

Turn Sleeve in the direction

of the arrow.

Shoulder pin 5

Compression spring 6

Sleeve

Slider

Sleeve is now unlocked.

Page 4

P 4 /10

Repair

[3] -1. Blade Clamp Section (cont.)

4) While putting your finger on the top of Slider to close the slit of Slider, remove Pin 3 (of 19.8mm length) by pushing

with a thin bar. (Fig. 5)

Note: Be sure to put your finger on the top of Slider or Push plate will pop out from the slit of Slider.

5) Remove Sleeve and Torsion spring 17 from Slider. Take out Push plate and Compression spring 2 from the slit of

Slider. (Fig. 6)

Fig. 5 Fig. 6

Pin 3

Slider

Sleeve

thin bar

ASSEMBLING

1) Assemble Torsion spring 17 to Slider then Sleeve to Slider as illustrated in Fig. 7.

Important: Torsion spring 17 is not reversible when assembled to Slider.

2) Put Compression spring 2 into the slit of Slider by provisionally locking Sleeve with Pin 3 (of 19.8mm length). (Fig. 8)

Fig. 7

Torsion spring 17

Shoulder pin 5

insertion hole

(of 19.8mm length)

Be sure that this end is

positioned on the opposite

side to Shoulder pin 5

insertion hole.

Put this end in

the slit of Slider.

Sleeve

Torsion

spring 17

Sleeve

hole

Push plate

Compression

spring 2

Slider

Fig. 8

Turn Sleeve in the direction

of the arrow so that Pin 3

insertion hole can be seen.

Sleeve

Gear housing

cover complete

Insert Pin 3 (of 19.8mm length) into

the hole provisionally.

Note: Be sure that the top of Pin 3

is not seen in the slit of Slider.

Pin 3 (of 19.8mm length)

Put this end of

Torsion spring 17

into the hole of

Sleeve.

Put Compression spring 2 into

the slit of Slider.

Compression

spring 2

Page 5

P 5 /10

Repair

[3] -1. Blade Clamp Section (cont.)

3) Install Guide sleeve on Sleeve provisionally. Put Push plate into the slit of Slider as illustrated in Fig. 9.

Note: 1. Push plate is not reversible when installed.

2. Guide sleeve is used as a jig in this step. Do not assemble to Slider yet.

4) Insert Push plate straight into Slider using recipro saw blade until the hole of Push plate is aligned with the hole of Slider.

Insert Pin 3 (of 19.8mm length) through the holes of Push plate and Slider. (Fig. 10)

Fig. 9

Fig. 10

This protrusion must

face the blade side.

Push plate

Guide sleeve

Pin 3

(of 19.8mm length)

5) Remove Guide sleeve, and install Driving sleeve on Sleeve provisionally. Then lock Sleeve as illustrated in Fig. 11.

Note: Driving sleeve is used as a jig to lock Sleeve in this step. Do not assemble to Slider yet.

Fig. 11

Hold Driving sleeve and turn it together with Sleeve

in the direction of the arrow until Sleeve stops against

Pin 3 (of 19.8mm length).

Driving sleeve

recipro saw blade

Pin 3 (of 19.8mm length)

hole of Slider

Sleeve

Compression spring 2

Push Sleeve towards

Gear housing side.

Sleeve is now locked.

Sleeve

Pin 3

(of 19.8mm length)

[Gear housing side]

6) Remove Driving sleeve.

7) Assemble the following parts to Slider (Refer to Fig. 3.):

Driving sleeve guide, Guide sleeve, Shoulder pin 5,

Compression spring 6, Pin 3 (of 6mm length)

8) Install Driving sleeve on Guide sleeve and secure with

Retaining ring S-18 using 1R291.

Note: When installing Driving sleeve, fit its protrusions

in the notches of Sleeve and Driving sleeve guide.

(Fig. 12)

Fig. 12

protrusion

Driving sleeve

Driving sleeve guide

notch

notch

Sleeve

Page 6

Repair

[3] -2. Slider Section

DISASSEMBLING

1) Remove Shoe. (See Fig. 2 in page 3.)

2) Remove Blade clamp section. (See [3] -1. Blade Clamp Section in pages 3 and 4.)

3) Remove Insulation cover;

If replacing with new one, cut away using cutter knife.

If reusing removed Insulation cover, remove as illustrated in Fig. 13.

Fig. 13

P 6 /10

Insulation cover has two raised

portions on its inside surface to

prevent from falling off from

the machine.

Insulation cover,

viewed from rear

raised portion (B)

raised portion (A)

4) Separate Gear housing cover complete from Gear housing

by unscrewing four M5x18 Pan head screws. (Fig. 14)

5) Remove two Plates that fix Plane bearing 14 by unscrewing

four M5x16 Pan head screws.

Remove Plane bearing 14 on the Motor housing side. (Fig. 15)

6) Move Slider towards the Motor housing side.

Slider can now be removed together with Plane bearing 14 on

the blade side by pulling in the direction of the gray arrow.

(Fig. 16)

Turn Insulation cover inside out

by hand until the raised portion (A)

is reached.

Insulation cover

Pull Insulation cover in the direction

of the arrow bit by bit while levering

off from Gear housing section using

two slotted screwdrivers.

Gear housing section

Fig. 14

Pan head screw M5x18 (4pcs)

Slider section

Gear housing

cover complete

Fig. 15 Fig. 16

Pan head screw M5x16 (4pcs)

Plate (2pcs)

[blade side]

Plane bearing 14

Slider

Gear housing

cover complete

[Motor housing side]

Gear housing

Plane bearing 14,

on the blade side Slider

Page 7

P 7 /10

Repair

[3] -2. Slider Section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note 1: If replacing Dust seal 14 of Gear housing cover complete, press-fit using 1R030 as illustrated in Fig. 18.

Note 2: Plane bearing 14 is not reversible when assembled to Slider. Be sure to assemble each Plane bearing 14 to Slider

so that the stepped end of each Plane bearing is placed as illustrated in Fig. 19.

Note 3: Apply threadlocker to four M5x16 Pan head screws when fastening Slider section to Gear housing cover complete.

(Recommended adhesives: Threebond 1342, Loctite 242) (Fig. 20)

Note 4: Do not to forget to apply Makita grease FA No.2 to the crank portion of Slider. (Fig. 20)

Note 5: When assembling Gear housing cover complete to Gear housing, tighten four M5x18 Pan head screws while

pushing Gear housing cover complete against Motor housing (Fig. 21).

Note 6: Apply water or soap water to the inside surface of Insulation cover for easy installation over Gear housing section.

Fig. 18 Fig. 19

Fit the tapered end of 1R030 to Dust seal 14.

1R030

tapered end

Dust seal 14

Fig. 20 Fig. 21

: portion to apply threadlocker

: portion to apply Makita grease FA No.2

Gear housing

cover complete

Slider

Gear housing

cover complete

Pan head screw

M5x16 (4pcs)

[blade side]

stepped end

Gear housing

Plane bearing 14

Slider

Plane bearing 14

[Motor housing side]

Pan head screw M5x18 (4pcs)

Gear housing

cover complete

Motor housing

[3] -3. Spiral Bevel Gear Section

DISASSEMBLING

1) Remove Plate C from Gear housing by unscrewing two M5x12 Hex socket head bolts. Remove Spiral bevel gear section

from Gear housing by unscrewing three M5x8 Pan head screws. Remove Needle bearing 708. (Fig. 22)

Fig. 22

Hex socket head bolt

M5x12

Plate C

Gear housing

Needle bearing 708

Spiral bevel gear section

Pan head screw M5x8 (3pcs)

Page 8

P 8/10

Repair

[3] -3. Spiral Bevel Gear Section (cont.)

DISASSEMBLING

2) Fix Spiral bevel gear section in vise by clamping the flats of Gear shaft, then remove Torx socket head bolt M6x15

using Torx screwdriver applicable to T20 Torx socket. (Fig. 23)

Note: Securely fit Torx driver in the socket of Torx socket head bolt M6x15 because Threadlocker is applied to the bolt.

Spiral bevel gear section can now be disassembled as illustrated in Fig. 24.

Fig. 23 Fig. 24

Torx socket head bolt M6x15

(with T20 Torx socket)

Gear shaft

Vise

ASSEMBLING

Do the reverse of the disassembling steps.

Note: When tightening Torx socket head bolt M6x15, be sure to apply Threebond 1342 or Loctite 242 to the threaded

portion of the bolt.

Torx socket head bolt M6x15

Spiral bevel gear 48

Bearing retainer A

Ball bearing 6000LLB

Ring 10

Ball bearing 6900LLB

Gear shaft

[3] -4. Motor Section

DISASSEMBLING

1) Remove Carbon brushes. Turn Insulation cover inside out as illustrated in Fig. 25.

2) Remove Motor housing and Baffle plate by unscrewing four 5x35 Tapping screws. (Fig. 26)

3) Separate Armature from Gear housing by unscrewing two M4x12 Pan head screws. (Fig. 27)

4) Remove two E-10 Stop rings. Remove Ball bearing 6001DDW from Armature shaft using 1R269.

Bearing retainer B and Fan guide can now be removed. (Fig. 28)

Fig. 26Fig. 25

Gear housing

Insulation cover

Pan head screw M4x12

Tapping screw

5x35 (4pcs)

Fig. 28Fig. 27

Ball bearing 6001DDW

Stop ring E-10

Armature

Motor housing

Baffle plate

Bearing retainer B

Fan guide

Page 9

Repair

[3] -4. Motor Section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note: When inserting Armature into Motor housing, Armature will be pulled strong towards Motor housing

by the magnet force of Yoke unit. Be careful not to damage the copper wire of Armature or not to pinch

your fingers.

Circuit diagram

Fig. 29

Brush holder, Right

Brush holder, Left

Right side

P 9/10

Left side

(+) Terminal

Brush holder, Left Brush holder, Right

Color index of lead wires' sheath

Black

Red

Switch

(-) Terminal

Terminal

Heatsink

FET

Terminal

Left side

Right side

Switch

Page 10

Wiring diagram

1) Motor Housing

Route two Lead wires (black, red) from Brush holder as illustrated in Fig. 30.

Fig. 30

P 10/10

Fix with the lead wire holder

on Motor housing.

Do not route over the rib

on Motor housing.

Fix with the lead wire holder

on Brush holder.

lead wire holder

on Motor housing

rib on Motor housing

lead wire holder

on Bush holder

Brush holder, left

2) Handle L

Fig. 31

Route all lead wires between the rib and the boss.

boss

red

black

rib

Motor housing

Brush holder, right

Handle L

Assemble Insulated connectors to

Switch terminals at such an angle

that the Insulated connectors do not

touch the rib.

Connecting Flag Connector to Terminal

The flag connector has to be so connected that

the wire connecting portion is positioned on

the side of pole marks of Terminal.

Wire connecting portion

Pole mark

Flag connector

Switch

rib

Terminal

Terminal

Loading...

Loading...