Page 1

Models No.

Description

PRODUCT

P 1/ 16

Model BHS630 is a 165mm (6-1/2") Cordless Circular Saw powered by

18V/3.0Ah Li-ion battery Model BL1830.

Its main features are:

• Aable to cut up to 66mm (2-5/8") thick wood with a single stroke,

which no competitors’ 18V models can do.

• In spite of compact and lightweight design, performs the same smooth

and comfortable cutting as AC circular saws.

• Compatible with 18V Li-ion battery of BL1830 equipped with the battery

protection circuit designed to protect the battery from damages due to

overdischarge, high temperature or overload current.

• High maneuverability provided by Good tool balance, Twin LED light,

Blower function and Fine parallel adjustment of base plate.

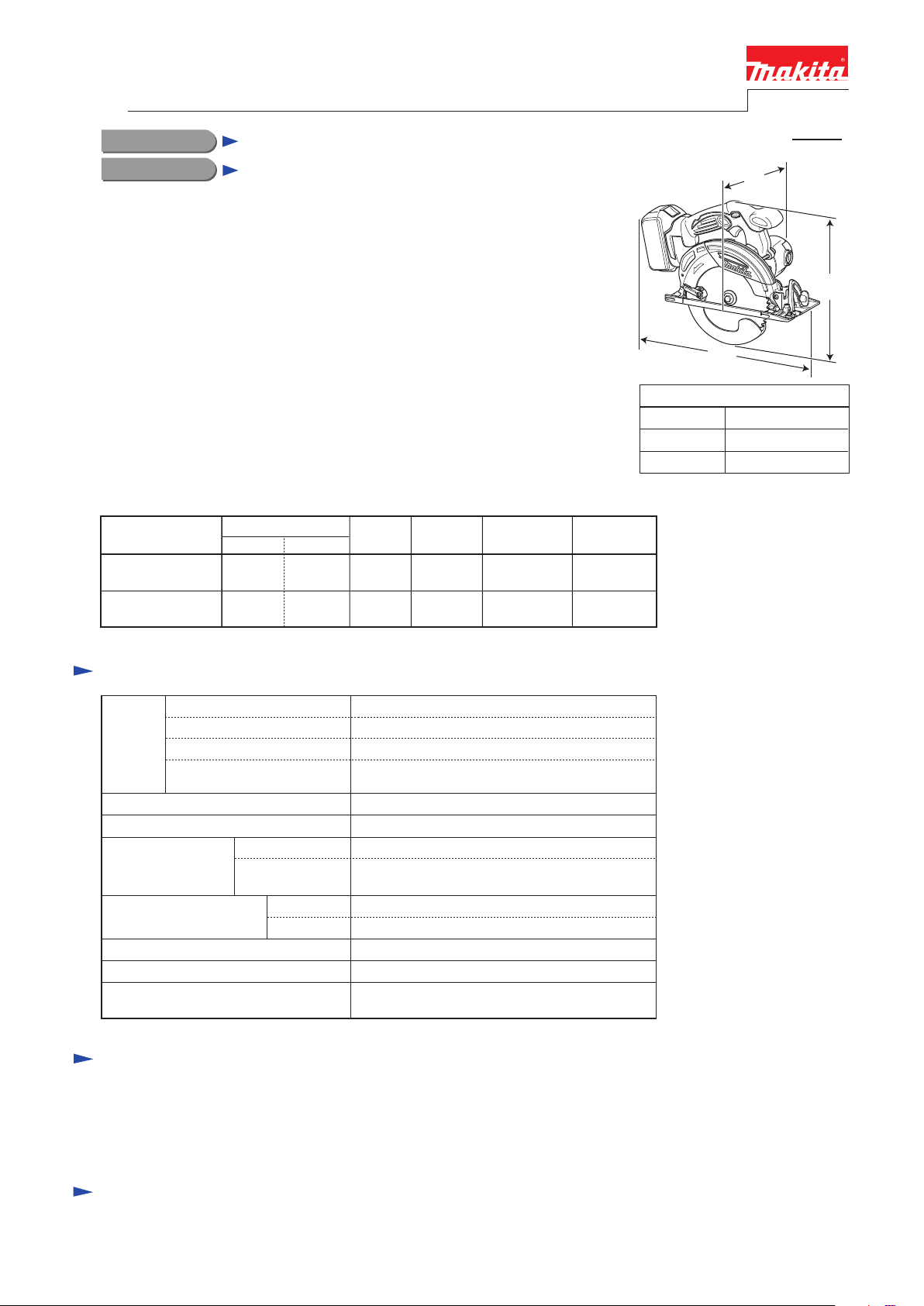

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 346 (13-5/8)

220 (8-5/8)

247 (9-3/4)

Note: The standard equipment for the tool shown above may vary from country to country.

BHS630 (LXSH01*1)

165mm (6-1/2") Cordless Circular Saw

TCT Saw blade 165mm (6-1/2") .................................. 1

Hex wrench 5 ................................................................ 1

Rip fence ....................................................................... 1

Dust nozzle (for European countries only) ................... 1

Battery

Blade size: mm (")

Electric brake

Max cutting capacities:

mm (")

Diameter

Hole diameter

at 45°

No load speed: min-1=rpm

Cell

Voltage:V

Capacity:Ah

Li-ion

18

3.0

Weight according to

EPTA-Procedure 01/2003*2: kg (lbs)

*Includes TCT Saw Blade, Battery BL1830 and Dust nozzle

3.5 (7.7)

Yes

Job light Yes (Twin LED light)

North America: 15.88 (5/8)

All countries except North America: 20

46 (1-13/16)

at 0° 66 (2-5/8)

3,100

165 (6-1/2)

Max output (W) 730

This model is available in the following variations.

Note: 1.3Ah Li-ion battery of BL1815 cannot be used for this model.

T

ECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

L

H

W

*1 Model number for North and Central American countries

All models also include the accessories listed below in "Standard equipment".

Model No.

Type Quantity

Charger

Plastic

carrying case

Battery

cover

Battery

BL1830

---

DC18RC Yes

BHS630Z

(LXSH01Z)

2 1

--- ---

Housing

color

Makita-blue

Makita-blue--- ---

BHS630RFE

(LXSH01)

Battery BL1830

165mm (6-1/2") TCT Saw Blades

Dust nozzle

Rip fences

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Safety goggles

Guide rail adapter

Various parts of guide rail

Charging time (approx.):

min.

15/ 22

with DC18RC

Page 2

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

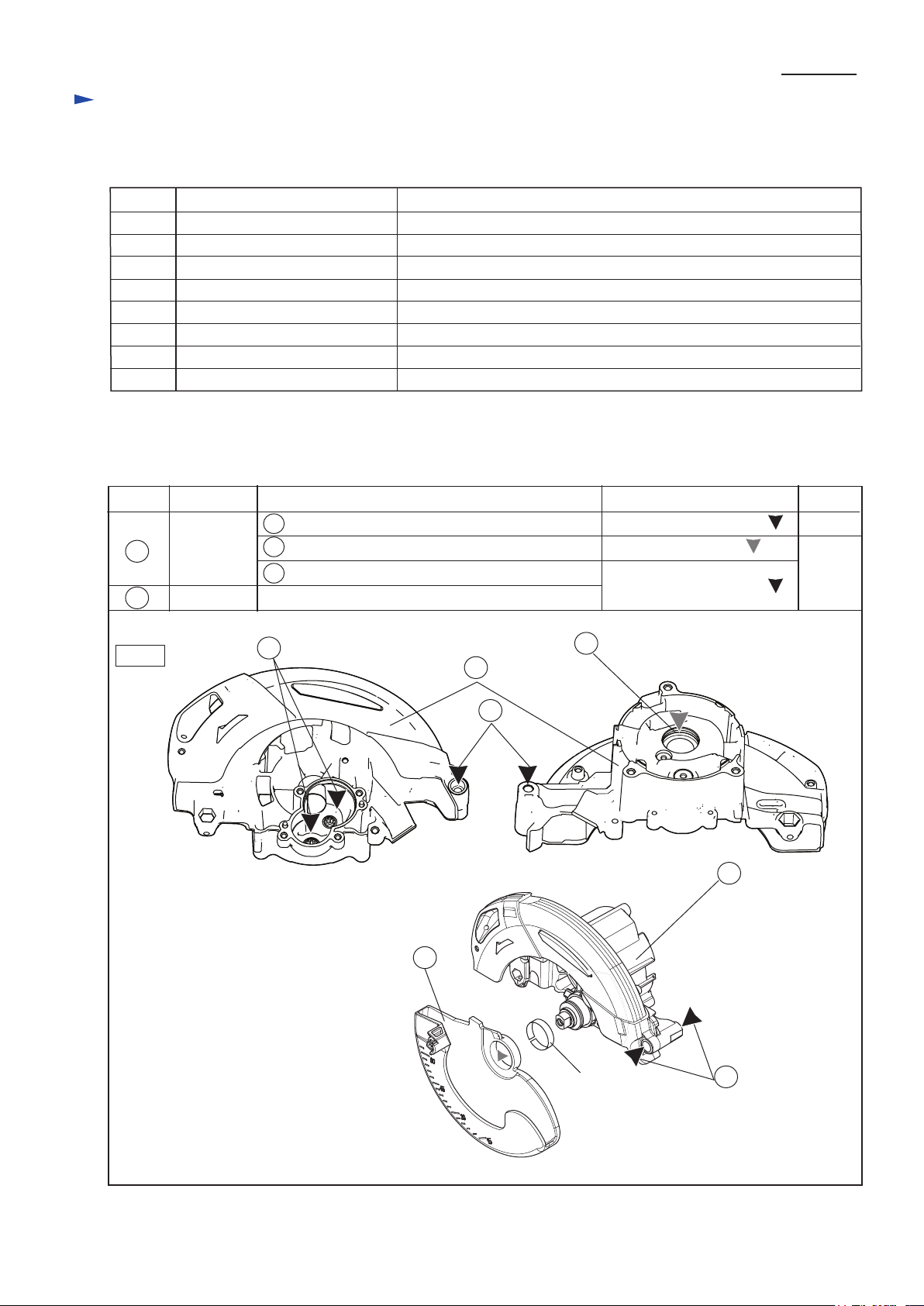

Fig. 1

Code No. Description Use for

1R003 Retaining ring S pliers ST2N removing / mounting Retaining ring WR-26

1R031 Bearing setting pipe 28-20.2 holding Bearing box when removing Helical gear 24

1R208 90 degree set square adjusting the angle of Saw blade to 90 Degrees

1R212 Tip for Retaining ring pliers attachment to 1R003

1R263 Bearing extractor removing Blade cover

1R269 Bearing extractor removing Ball bearings

1R291 Retaining ring S & R pliers removing Retaining ring S-10 from Spindle

1R361 Bearing retainer tightening tool removing / Mounting Bearing retainer 14-23

Item No.

60

A

A Gear room where Gears engage each other

B O ring 24 Lubricant VG100

a little

8 gMakita grease SG No.0

B

Apply the following grease and Lubricant to the portions pointed with triangles to protect parts and product

from unusual abrasion.

Description

Blade case

complete

Lubricant

Safety cover

AmountPortion to lubricate

Makita grease SG No.0

40

60

Thickness

Ring

C Pivot portion where Angular guide contacts

Inside of Ring portion where Thickness ring contacts

40

C

60

C

Repair

P 2/ 16

Page 3

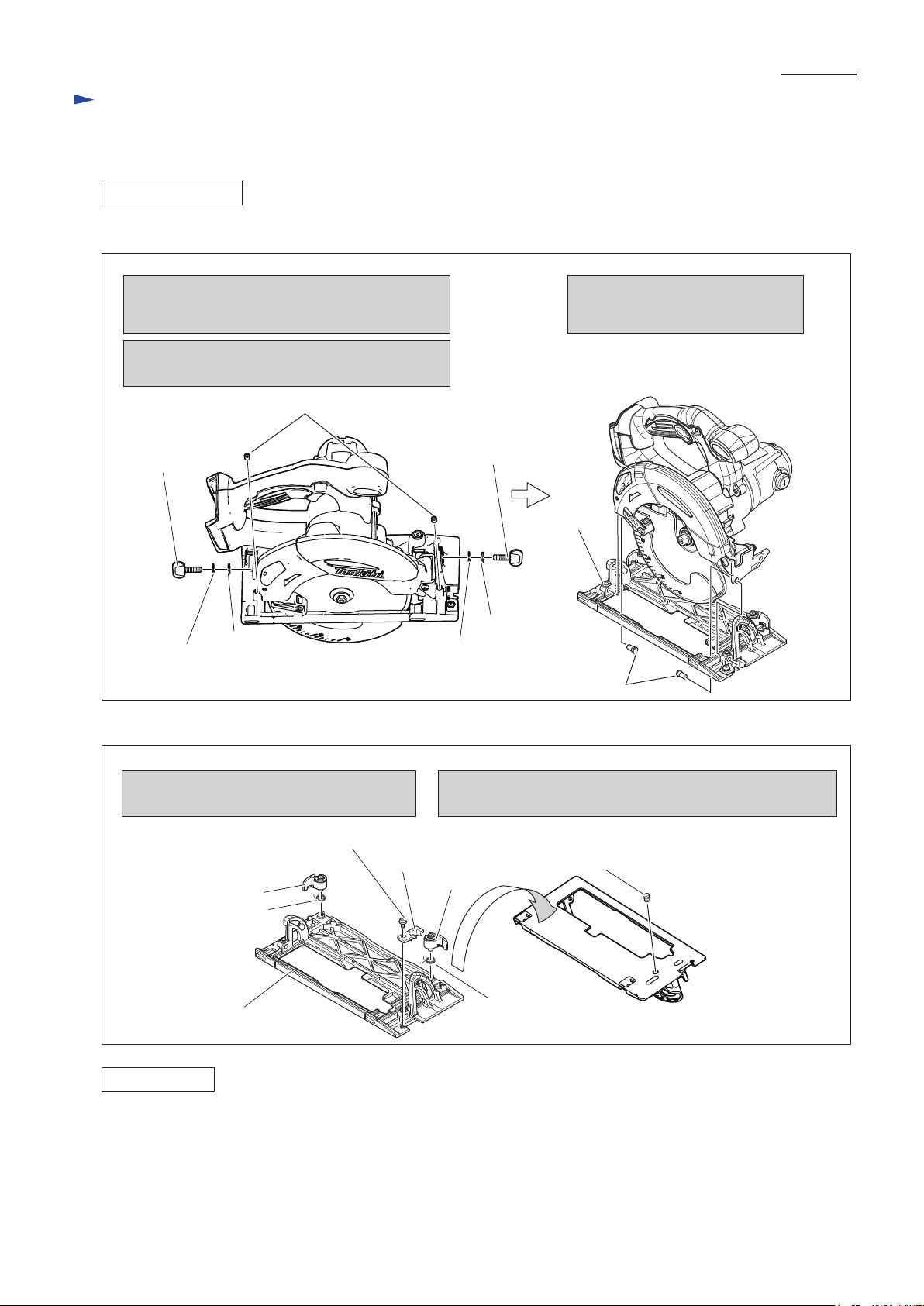

M6x8 Hex socket head

set screw

Fig. 2

Fig. 3

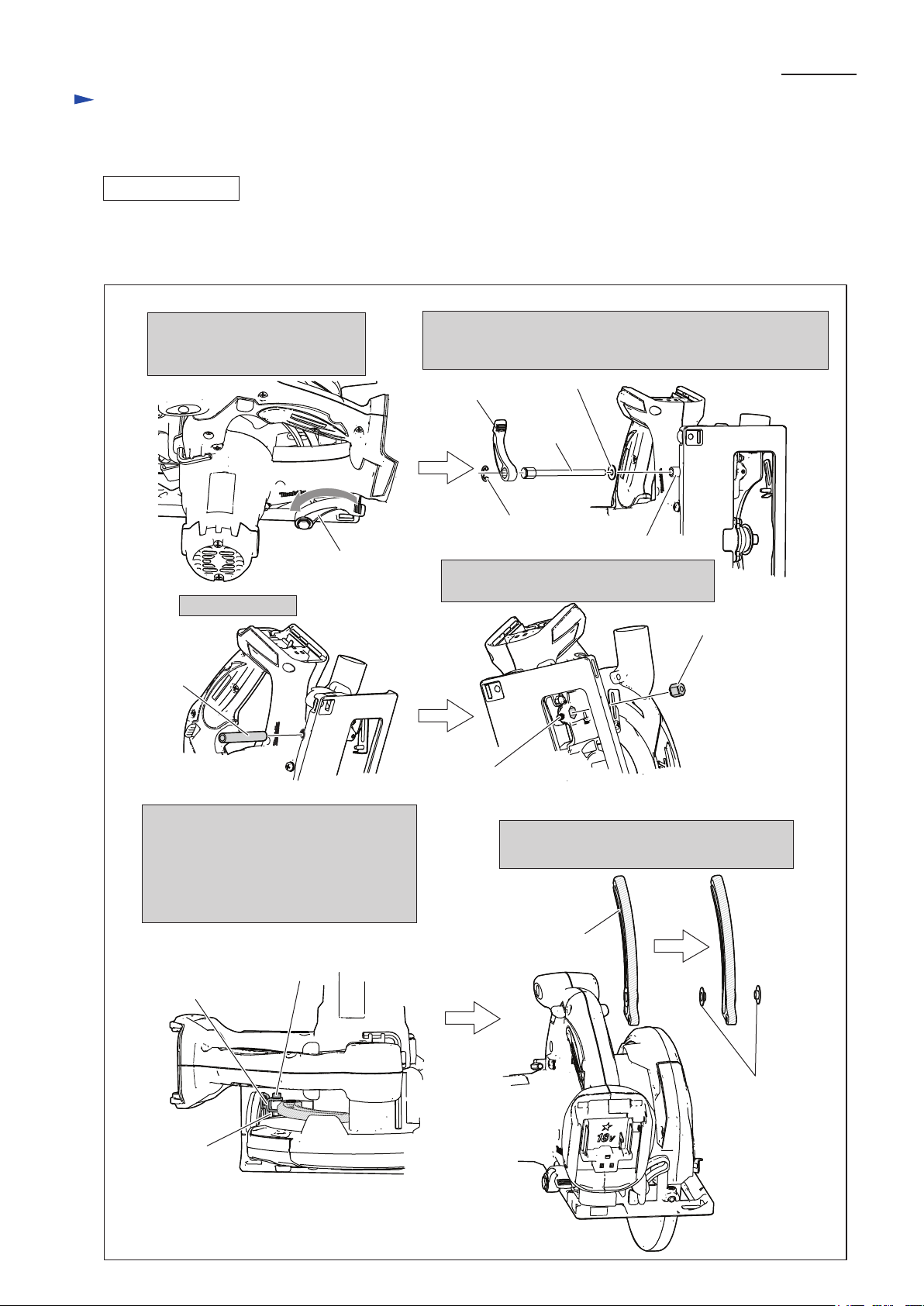

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Base

DISASSEMBLING

M6x6 Hex socket head set Screw

1. Remove M6x20 Thumb screw, Spring washer 6,

and Flat washer 6 from Angular guide side and

Depth guide side.

2. Remove M6x6 Hex Socket Head Set Screw

from Angular guide side and Depth guide side.

M6x20 Thumb

screw

Shoulder pin 6-7

Base

Remove the parts drawn below from Base.

And then, replace the Base with the new one.

Do not forget to remove M6x8 Hex socket head set screw for

adjusting the angle of saw blade from the reverse side of Base.

Base

Note in Assembling

1. After mounting Lock lever, its adjustment is required to obtain the correct lock position for guide rule, mounted.

to Base. See “[3]-2. Lock Lever” .

2. After mounting Base to the machine, adjustment of angle of saw blade to the Base is required.

See “[4] Adjustment”

Take the reverse step of Disassembling. Refer to Fig. 3, Fig. 2.

Base can be separated from the machine as drawn in Figs. 2 and 3.

3. Remove Shoulder pin 6-7.

Now Base complete is separated

from the machine.

Spring

washer 6

Flat

washer 6

Lock lever

Torsion

spring 11

Torsion spring 11

Lock lever

Spring

washer 6

Flat

washer 6

M6x20 Thumb

screw

M4x8 Pan head screw

Top guide

ASSEMBLING

Repair

P 3/ 16

Page 4

M6x10 Hex bolt

Lock lever

Lock lever

3. Set Lock lever to M6x10 Hex bolt, while hooking Torsion spring 11

with its long Arm to the Rib of Base.

4. Push the Lock lever to engage it with M6x10 Hex bolt at the

convenient position for loosening and locking.

And secure the Lock lever with Stop ring E-6.

Note:

Do not yet push Lock lever to the

position where it is in this step.

Otherwise, Lock lever engages

unintentionally with M6x10

Hex bolt, before obtaining the

convenient position for operating

Lock lever.

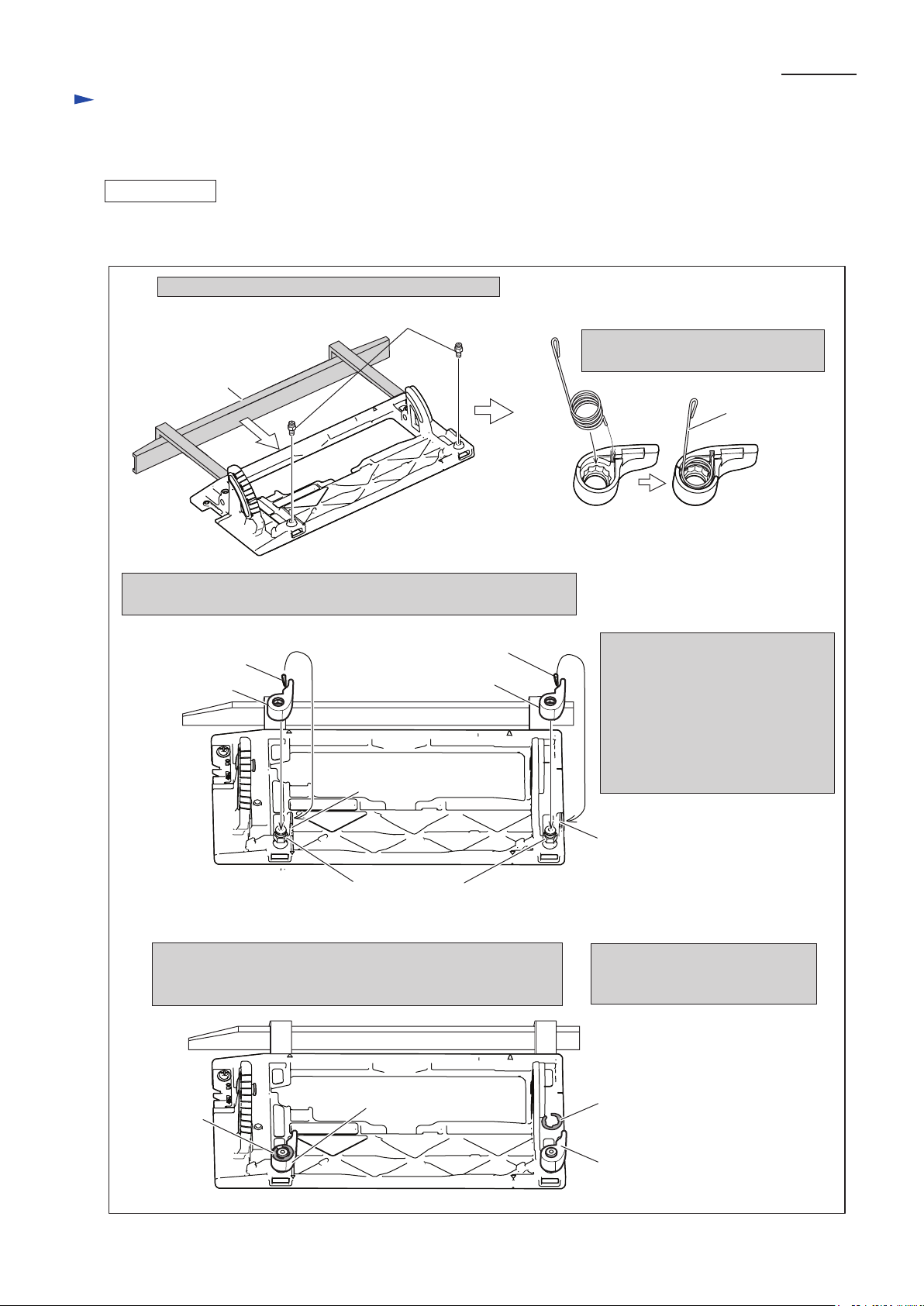

Fig. 4

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Lock Lever

ASSEMBLING

1. Tighten M6x10 Hex bolt to fix Guide rule to Base.

Guide Rule

M6x10 Hex bolt

2. Set Torsion spring 11 to Lock lever

as drawn in below.

Base

Assemble Lock lever to Base, and adjust to obtain the convenient lock position as drawn in Fig. 4.

Long arm of

Torsion spring 11

Long arm of

Torsion spring 11

Rib

Rib

long arm of

Torsion spring 11

Lock lever

Lock lever

Stop ring E-6

5. Make sure that the reassembled

Guide rule is locked with the

Lock lever at the same position.

Stop ring E-6

Repair

P 4/ 16

Page 5

Fig. 5

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Depth Guide

DISASSEMBLING

Depth guide is joined to the Machine at the Handle section, and to Base at Rear angular guide.

Separate Depth guide by disassembling from Handle section and from Rear angular guide as drawn in Fig. 5.

1. Loosen Lever 55 by turning

toward the direction designated

with arrow.

2. Take off Stop ring E-8, and remove M6x85 Hex bolt, by

employing Lever 55 as a wrench. And remove Flat washer 6.

Now, Depth guide is disjoined from the machine.

Lever 55

Lever 55

Flat washer 6

M6x85

Hex bolt

Stop ring E-8

Pipe 6

Pipe 6

M6 Hex nut

3. Remove Pipe 6.

4. Remove M6 Hex nut, loosening M5x8

Hex socket head set screw.

5. Remove M4x20 Hex socket head bolt

and M4-7 Hex lock nut, pulling down

Base to the position in which they can

be easily removed. Now, Depth guide is

disjoined both from the machine

and Rear angular guide.

Base

M5x8 Hex socket head

set screw ( No need to remove completely.)

M4x20 Hex socket

head bolt

Rear angular

guide

M4-7 Hex

lock nut

Collar

Depth guide

6. Disassemble Depth guide, and remove two

Collars from the both side of Depth guide.

Repair

P 5/ 16

Page 6

Fig. 6

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Depth Guide

ASSEMBLING

Fig. 7

1. Mount M6 Hex nut, facing its concave side to M5x8 Hex socket head set screw side.

So, the Hex nut can be fixed with M5x8 Hex socket head screw firmly in Blade case.

This concave portion

accepts the end of

M5x8 Hex socket head

set screw.

M5x8 Hex socket head set screw

45 mm

4. The distance between the bottom of Base and

the bend of Lever 55 has to be approx 45 mm,

when the machine is adjusted to obtain max.

cutting depth.

1. Insert Pipe 6 into the hole of

Motor housing complete

at the Handle portion.

2. Passing M6x85 Hex bolt through Flat

washer 6, insert the Hex bolt into the

Pipe 6, and pass through two Collars

and Depth guide.

3. Setting the machine to the

deepest position (max. cut

mode), drive the M6x85 Hex

bolt to the M6 Hex nut,

mentioned in Fig. 6

4. Proceed the assembling as drawn in Fig. 7.

1. Assemble Depth guide to Rear angular guide by tightening with M4x20 Hex socket head bolt and M4-7 Hex lock nut.

Refer to the bottom left illustration in Fig. 5.

2. Set Collar to the both side of the Depth guide. Refer to the bottom right illustration in Fig. 5.

3. Mount M6 Hex nut to Blade case as illustrated in Fig. 6.

M6 Hex nut

M6 Hex nut

Pipe 6

Flat Washer 6

M6x85 Hex bolt

Pipe 6

Repair

P 6/ 16

Page 7

Fig. 8

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Angular Guide

DISASSEMBLING

DISASSEMBLING

ASSEMBLING

1. Remove M5 Pan head screw with Screwdriver, while locking M5-8 Nut with wrench 8.

Now, Angular guide is removed from the machine.

Angular guide is fixed to the machine at the following 3 positions.

1. at the hinge portion fixed with Shoulder pin 6-7 and M6x6 Hex socket head set screw

2. at Angular plate on Base with M6x20 Thumb screw, Flat washer 6 and Spring washer 6

3. at Blade case section with M5 pan head screw and M5-8 Nut.

(1) Make Angular guide free at hinge portion and Angular plate portion as drawn in Fig. 2.

(2) Make the Angular plate free from the Blade case section as drawn in Fig. 8.

Wrench 8

M5-8 Nut

M5-8 Nut

M5 Pan head screw

Angular guide

Disassemble Cover by unscrewing 4x20 Tapping screws.

Now, Connectors and LED come into your sight. Disconnect Connectors. So, LED is replaced.

Blade case section

[3]-5. LED and Motor Section

Assemble Angular guide, referring to Fig. 2.

The machine is joined to Base at the following 2 positions.

1. at the hinge portion of Blade case ( at the front side of Blade case) with Angular guide

2. at the Handle section of Motor housing complete with Depth guide

Angular guide

M5 Pan head screw

(1) Remove Lever 55 and M6x85 Hex bolt as per the top right drawing in Fig. 5.

Now the machine is free from Depth guide.

(2) Make the machine free from Angular guide as illustrated in Fig. 8.

Now the machine is separated from Base completely. And disassemble LED as drawn in Fig. 9.

Fig. 9

Repair

P 7/ 16

Cover

LED

Connector

4x20 Tapping screw

Connector

LED

Page 8

Fig. 10

Fig. 11

[3] DISASSEMBLY/ASSEMBLY

[3]-5. LED and Motor Section

DISASSEMBLING

1. Remove Carbon brush and unscrew three M5x33

Pan head screws.

2. Separate Blade case section from Motor housing complete.

3. From Blade case section, Armature, Shaft lock and

Compression spring 6 are removed.

4. Disassemble Baffle plate and Yoke unit by unscrewing

two 4x65 Tapping screws.

(3) Armature and Yoke unit can be replaced as drawn in Fig. 10.

Carbon brush

M5x33 Pan

head screw

Armature

Compression

spring 6

Baffle plate

Yoke unit

(1) Assemble Yoke unit to Motor housing complete as illustrated in Fig. 11.

(2) Assemble Motor section by tasking the reverse step of Disassembling. Refer to Fig. 10.

4x65 Tapping screw

Shaft lock

Yoke unit

Note in Assembling:

Notch A and Notch B are reversible.

Note in Assembling:

Do not forget to assemble Shaft lock and Compression spring 6. Refer to the lower left drawing in Fig. 10.

Insert Yoke unit into Motor housing complete,

while aligning Notch A to Rib A.

So, Yoke unit is exactly mounted to Motor

housing complete, by fitting Notch B to Rib B.

Motor housing

complete

ASSEMBLING

Rib A

Rib B

Notch A

Notch B

Repair

P 8/ 16

Page 9

Fig. 12

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Blade Case Complete

DISASSEMBLING

1. Remove retaining ring WR-26 and Flat washer 26.

Use 1R003 equipped with Claw of 1R212,

when removing retaining ring WR-26.

2. Remove Safety cover, Tension spring 4 and Thickness ring.

3. Remove the parts of LED section,

Rubber sleeve 6, M5-8 Hex socket

head set screw and M6 Hex nut.

4. Remove Bearing box (Gear section)

by unscrewing four M4x16 pan head

screws.

(1) Remove Lever 55 and M6x85 Hex bolt as per the top right drawing in Fig. 5.

Now the machine is free from Depth guide.

(2) Make the machine free from Angular guide as drawn in Fig. 8.

Now the machine is separated from Base completely.

(3) Separate Blade case as per the upper left, upper right and lower left drawings in Fig. 10.

(4) Disassemble Safety cover and Gear section from Blade case as drawn in Fig. 12.

Cover

Retaining

ring WR-26

<Note in Disassembling>

Hold the Retaining ring with your gloved hand

so that it does not spring when removing.

Flat washer 26

Safety cover

Tension spring 4

Thickness ring

Connector box

Connector

LED

Gasket

Gear section

M4x16 Pan

head screw

(4pcs.)

4x20 Tapping screw

Rubber

sleeve 6

M6 Hex nut

M5-8 Hex socket

head set screw

LED section

Repair

P 9/ 16

Page 10

Fig. 14

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Blade Case Complete

ASSEMBLING

Fig. 13

(1) Take the reverse step of Disassembling. Refer to Figs. 13 and 12.

(5) Remove Blade cover and Duct from Blade case complete as drawn in Fig. 13.

1. Remove two 4x12 Tapping screws

with which Blade cover and Duct

are secured to Blade case complete.

2. Remove Blade cover from Blade

case complete by levering up with

1R263, inserted into the gap between

Blade case complete and Blade cover.

3. Remove Duct from Blade

case complete.

Note in Assembling:

Tension spring 4 has to be connected to Safety cover and Blade case as drawn in Fig. 14.

DISASSEMBLING

Blade cover

1R263

Duct

Duct

Tension spring 4

Blade case

Safety cover

Pass the Hook from Gear section side to Blade case.

Pass the Hook from Blade side to Gear section side.

Blade side

Gear section side

Repair

P 10/ 16

Page 11

[3] DISASSEMBLY/ASSEMBLY

[3]-7. Bearing Box (Gear Section)

DISASSEMBLING

ASSEMBLING

In case of repairing of Bearing box (Gear section) singly, no need to separate the machine from the Base.

(1) Remove Safety cover as per the upper left and upper right drawings in Fig. 12.

(2) Remove Bearing box (Gear section) from Blade case complete as per the lower right drawing in Fig. 12.

(3) Now the Bearing box can be disassembled as drawn in Fig. 15.

Helical gear 39

Helical gear 24

Rubber ring 10

Bearing box

Spindle

Helical gear 17

Ball bearing

606ZZ

Flat washer 7

1. Disassemble Rubber ring 10, Ball bearing 606ZZ

Helical gear 17, Helical gear 39 and Flat washer 7.

Spindle, Ball bearing 6900DDW, Helical gear 24

are still in Bearing box, which are disassembled

in the next step.

2. Disassemble Retaining ring S-10 from Spindle.

And then, remove Spindle with Arbor press,

setting Bearing box on 1R031.

The Ball bearing 6900DDW has been broken in

this step.

Spindle

Retaining ring S-10

Spindle

3. Helical gear 24, Ring 10 are removed from Bearing box.

In this step, Ball bearing 6900DDW is still in Bearing box.

1R031

Bearing retainer 14-43

for securing Ball bearing

6900DDW

Helical

gear 24

Ring 10

Spindle

5. Inserting Spindle into Ball bearing 6900DDW

as illustrated below, push the Ball bearing with

the Spindle. So, Ball bearing 6900DDW is

removed from Bearing box.

Bearing

retainer 14-43

1R361

4. Set 1R361 by fitting its Claw to the Groove of

Bearing retainer 14-43.

And turn it counter clockwise. Now Bearing

retainer 14-43 is removed from Bearing box.

Spindle

Ball bearing

6900DDW

Ball bearing

6900DDW

Ball bearing 6900DDW

Take the reverse step of Disassembling. Refer to Fig. 15 and Fig. 12.

Note in Assembling:

Assemble fresh Ball bearing 6900DDW instead of the removed one, because the Ball bearing has been broken when

removing Spindle from Bearing retainer 14-43.

Fig. 15

Repair

P 11/ 16

Page 12

[3] DISASSEMBLY/ASSEMBLY

[3]-8. Lock Off Lever, Switch Lever

ASSEMBLING

Compression spring 4

Compression spring 4

Note in Assembling:

Both Compression springs are interchangeable.

1. Compression spring 4 has to be assembled

deeply and firmly to Switch lever and Lock

off lever as drawn below.

Switch lever

Lock off lever

Lock off lever

Switch lever

2. Set Lock off lever Compression spring 4 and

Switch lever to the Handle at the position

drawn below.

Handle

Assemble Switch lever and Lock off lever to Handle as illustrated in Fig. 16.

Fig. 16

Repair

P 12/ 16

Page 13

[4] ADJUSTMENT

[4]-2. Adjusting Accuracy of Parallel of Base to Saw blade

Mounting Saw blade to the machine, set the machine to the lowest possible position to obtain the max. cut depth.

But, do not attach Battery to the machine.

Adjust accuracy of 90 degree cut as drawn in Fig. 18.

Following two kinds of adjustment screws are used in this product.

1. M6x8 Hex socket head set screw for adjusting Accuracy of 90 degrees .

2. M5x8 hex socket head set screw for adjusting Accuracy of Parallel of Base to saw blade

See the following drawing in Fig. 17.

Mounting Saw blade to the machine, set the machine to the lowest possible position to obtain the max. cut depth.

But, do not attach Battery to the machine.

Adjust accuracy of parallel of Base to saw blade as drawn in Fig. 19.

Fig. 18

Fig. 18

Fig. 17

M6x8 Hex socket

head set bolt

Apply triangular rule as per the illustration

and adjust the accuracy of right angle by turning

M6x8 Hex socket head set bolt with hex wrench,

until the two sides of the adjusting jig fit to Base

and saw blade completely.

1. M6x8 Hex socket head set screw

for adjusting accuracy of 90 degree

of Base to saw blade

2. M5x8 Hex socket head set screw

for adjusting accuracy of parallel

of Base to saw blade

Triangular rule or 1R208

Hex wrench

[4]-1. Adjusting Accuracy of 90 degree cut

Base

Rear side

of Base

1. Loosen M5x8 Hex socket head set screw

with Hex wrench a little bit.

2. Apply square to the machine as per the

illustration.

3. Adjust by moving the rear side of base,

until the Square fits both to the saw blade

and the front edge of base.

M5x8 Hex socket

head set screw

Square

Saw blade

Front edge of

Base

Repair

P 13/ 16

Page 14

Circuit diagram

P 14/ 16

White

Yellow

Color index of lead wires' sheath

Black

Red

Controller

Terminal

Handle section

Motor housing

Blade case

Brush holder

LED Job

Light

Switch for

LED job light

ON / OFF

Switch

Fig. D-1

Page 15

Fig. D-2

to ON/OFF Switch in Handle

Opening for Lead wires

Opening for Lead wire

Lead wire holder

Lead wire holder

Put Lead wires for

connecting to Connector

inside the Rib.

Brush holder

Brush holder

Fix Lead wires (black), (white) of Brush holders in

Lead wire holder here so as not to make any slacks

between Opening and the lead holder.

Fix Brush holder’s Lead wires

in Lead wire holders.

Pass the Lead wires through the opening

to Blade case side.

Lead wire

holder

Wiring of Brush holder’s Lead wires

Wiring in Handle

Fig. D-3

Fix the following Lead wires in these Lead wire holders.

* Lead wre (white) between ON/OFF switch and Switch unit of LED

* Lead wire (black) between Controller and Connector

Connector

See Fig. D-4 in

the next page.

Wiring diagram

P 15/ 16

Page 16

Fig. D-4

Put the extra portion of Lead

wires in Connector box.

Fix the Lead wires (black),

(red) from Handle in

Lead wire holder.

Do not put the lead wires on

rib and the place designated

with gray color.

Wiring of LED Lead wires

in Blade case and Connector box

Connector

Connector box

LED

Wiring diagram

P 16/ 16

Loading...

Loading...