Page 1

Spindle-Table Crash

Avoidance Function

Operation Manual

Professional 6

0847C-1610 (en)

Original instructions

MAKINO GmbH

Essener Bogen 5, 22419 Hamburg

Phone ++49 / 40 / 29 80 90

Fax ++49 / 40 / 29 80 94 00

Page 2

Page 3

Imprint I

Imprint

Editor: MAKINO GmbH

Essener Bogen 5

D-22419 Hamburg

Germany

Tel.: ++49 / 40 / 298 09 - 0

Fax: ++49 / 40 / 298 09 - 400

e-mail: documentation@makino.de

Date issued: 2016-10

MAKINO 0847C-1610 (en)

Page 4

II Imprint

0847C-1610 (en) MAKINO

Page 5

Revisions III

Revisions

Date Chapter/Page Modification

MAKINO 0847C-1610 (en)

Page 6

IV Revisions

Revisions

Date Chapter/Page Modification

0847C-1610 (en) MAKINO

Page 7

Table of contents V

Table of contents

0 GENERAL SAFETY INSTRUCTIONS ....................................................................................................... 0-1

0.1 Indicator words and their meaning .......................................................................................................... 0-1

1INTRODUCTION ............................................................................................................................................. 1-1

2OUTLINE ............................................................................................................................................................. 2-1

3 OPERATIONAL NOTES ................................................................................................................................ 3-1

4 SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE ...................................................... 4-1

4.1 M Codes .............................................................................................................................................................. 4-1

4.2 Function Button ................................................................................................................................................ 4-1

4.3 Verification of 3D Crash Avoidance State .............................................................................................. 4-2

5 CRASH CHECK ALARM AND RECOVERY ........................................................................................... 5-1

6 USE OF TOOL SHAPE DATA TRANSFER FUNCTION .................................................................... 6-1

6.1 Timing of Tool Shape Data Transfer Function ...................................................................................... 6-1

6.2 Tool Length, Tool Radius Data Handled by Tool Shape Data Transfer Function ................... 6-2

6.3 Tool Length (Check), Tool Radius/Diameter (Check) of Tool Shape

Data Transfer Function .................................................................................................................................. 6-2

6.4 Use of Tool Shape Data Transfer Function in dummy pot .............................................................. 6-3

7 Z AXIS COLLISION AVOIDANCE FUNCTION .................................................................................... 7-1

7.1 Z Axis Collision Avoidance Function Setting ......................................................................................... 7-3

7.2 Reference Position Z Setting according to M Code ........................................................................... 7-4

7.3 Cancel of the Limitation Area of Z Axis Collision Avoidance Function ....................................... 7-5

7.4 Application Example of Limitation Area of Z Axis Collision Avoidance Function ................... 7-5

7.5 Motion of the Limitation Area of Z Axis Collision Avoidance Function for Workpiece Rotation

Type Machines with 4 or 5 Axes ................................................................................................................ 7-7

7.6 Verification of Z Axis Collision Avoidance Function ........................................................................... 7-8

8 OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE ...................................................... 8-1

8.1 Use of 3DC Y position setting function (ONLY MCC2013VG) ........................................................ 8-1

8.2 About Automatic Pallet Change (APC) of a/A series-5XR machines ........................................... 8-2

8.3 About Spindle Model Change in EG3010 .............................................................................................. 8-3

8.4 About high-speed attachment specification in iQ300 ...................................................................... 8-4

9 MACHINE PARAMETERS ........................................................................................................................... 9-1

10 MACHINE ALARMS ................................................................................................................................... 10-1

MAKINO 0847C-1610 (en)

Page 8

VI Table of contents

0847C-1610 (en) MAKINO

Page 9

GENERAL SAFETY INSTRUCTIONS 0-1

0 GENERAL SAFETY INSTRUCTIONS

The hazards involved in operating the machine are identified by the following means:

- In this manual, warning notices serve to indicate aspects which are relevant to safety.

- On the machine, warning signs point out aspects which are relevant to safety.

0.1 Indicator words and their meaning

The indicator words use for warning notices are divided into the categories listed below, according to the

accepted degree of risk involved.

Consciously ignoring these warning notices can result in accidents, serious injuries or death.

Furthermore, serious damage may be caused to the machine and its auxiliary units. The warning notices

below must there be followed without fail!

DANGER!

Indicator word used to denote an immediately hazardous situation which, if not avoided,

will result in serious injury or death.

WARNING!

Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in serious injury or death.

CAUTION!

Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in slight to moderate injuries.

NOTICE! Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in damage to property.

REMARK Indicator word used to point out important or useful information.

MAKINO 0847C-1610 (en)

Page 10

0-2 GENERAL SAFETY INSTRUCTIONS

0847C-1610 (en) MAKINO

Page 11

INTRODUCTION 1-1

1INTRODUCTION

REMARK 1. Read this manual carefully before operating the machine.

2. Store this manual in a clearly marked location for easy reference.

3. All rights reserved. No part of this document may be reproduced, copied, or modified

in any form or any means without direct permission of Makino Milling Machine Co., Ltd.

The present document contains customer specific technical information concerning the “Spindle – Table

Crash Avoidance Function” (hereafter it is referred to as “3D crash avoidance function”).

This technical information describes the following:

- Function explanation

- Operational notes

- Switching ON/OFF the 3D crash avoidance mode

- Use of Tool Shape Data Transfer Function

- Use of the Z Axis Collision Avoidance Function

- Other functions different in each machine type

MAKINO 0847C-1610 (en)

Page 12

1-2 INTRODUCTION

0847C-1610 (en) MAKINO

Page 13

OUTLINE 2-1

2OUTLINE

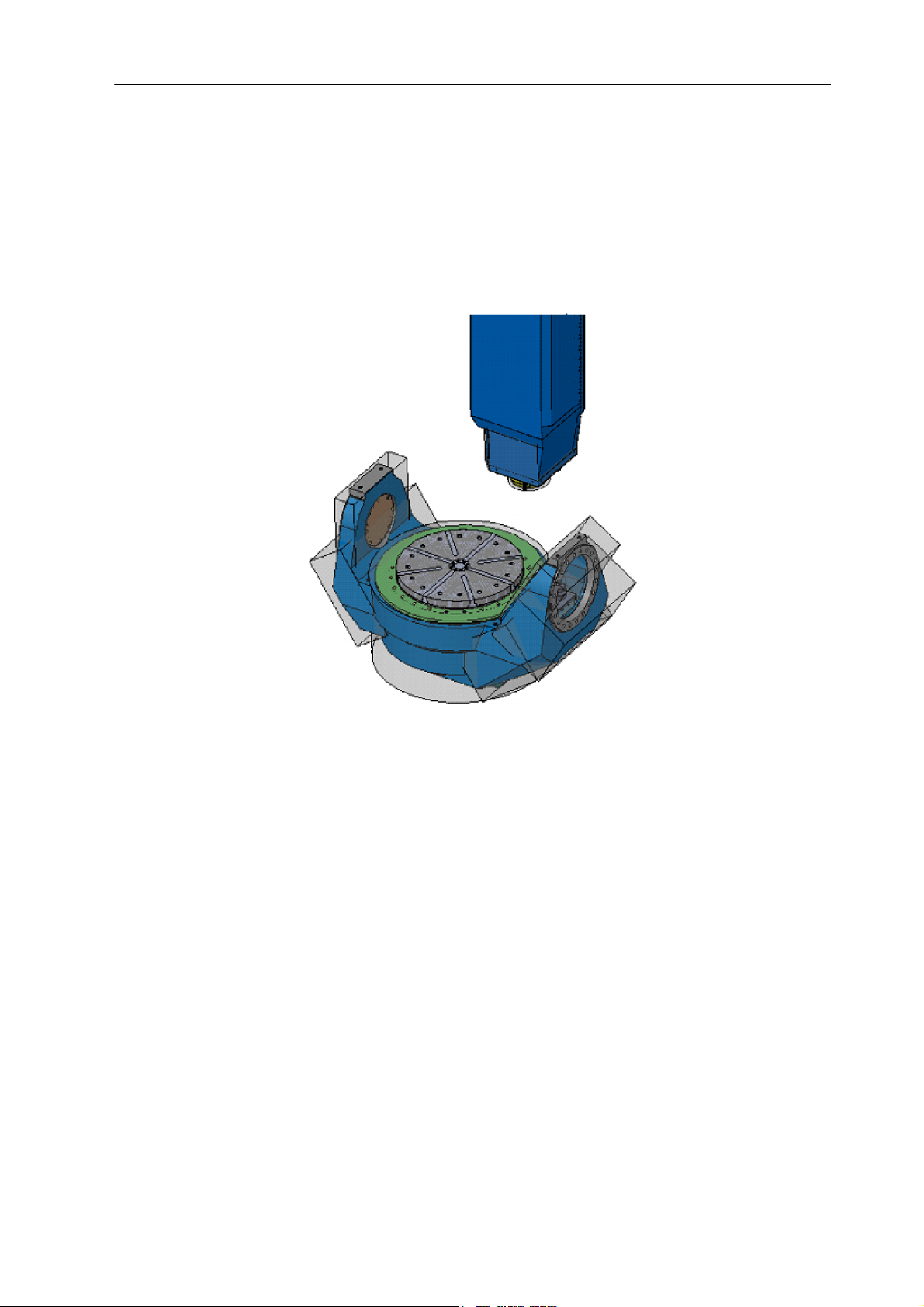

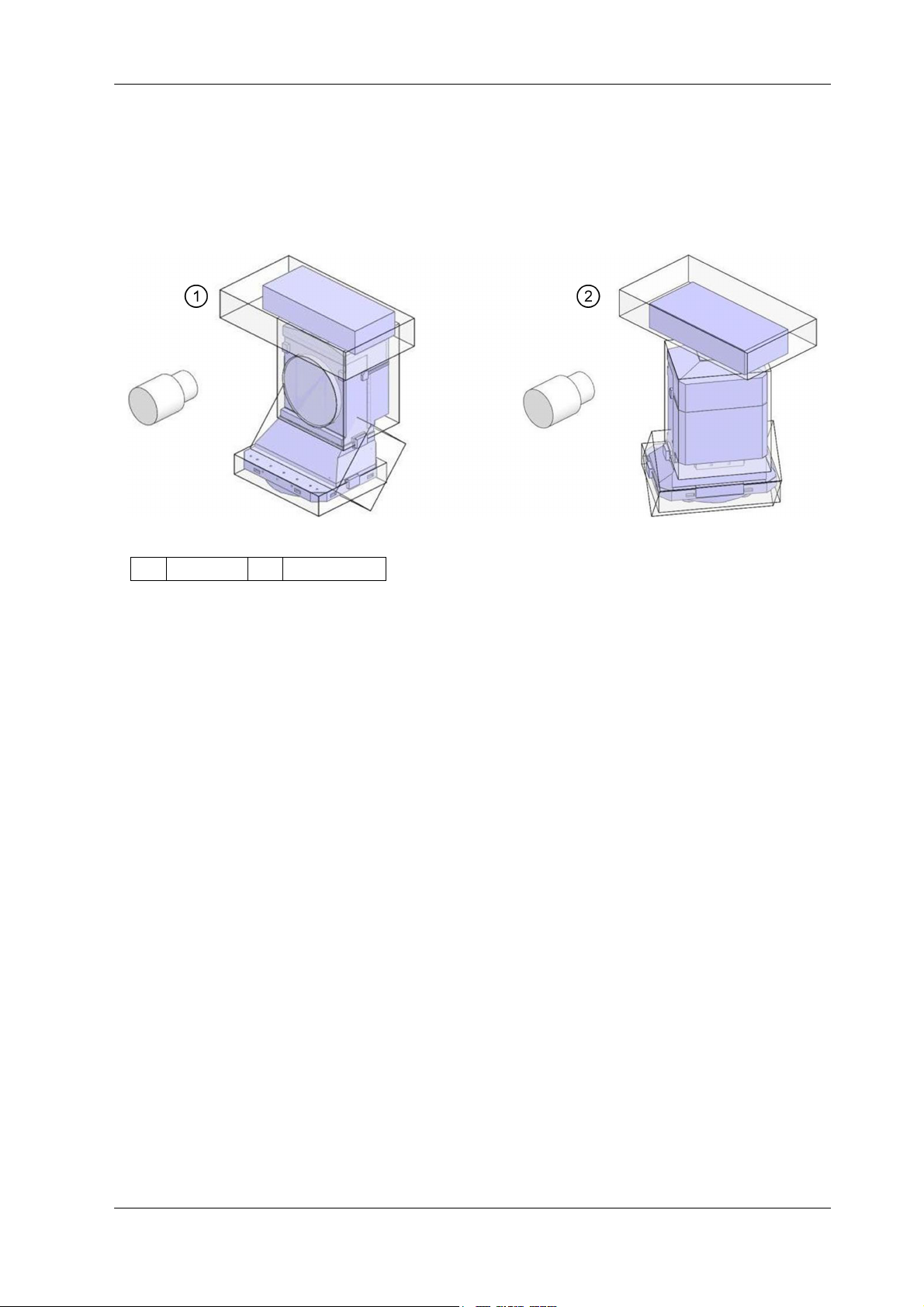

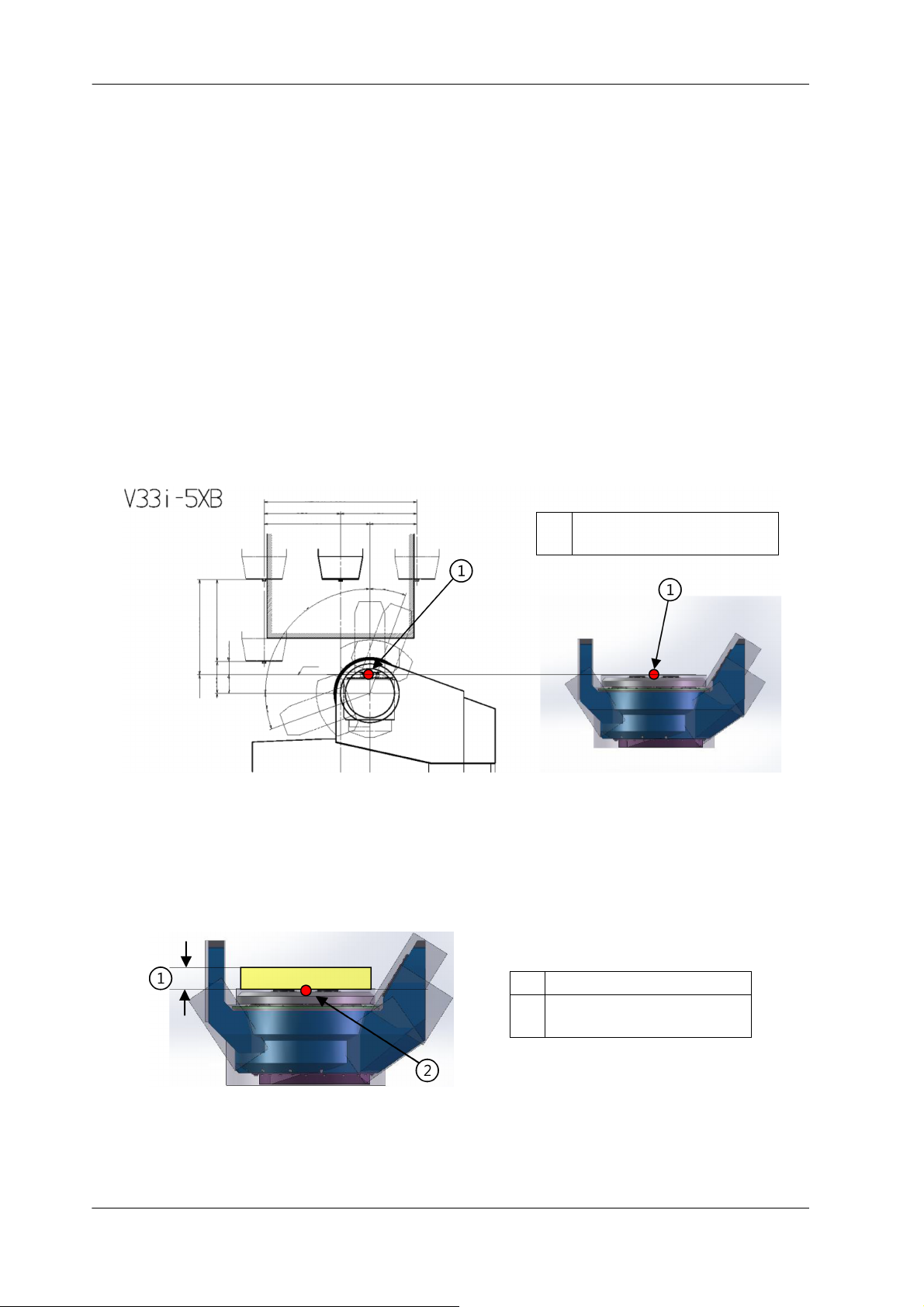

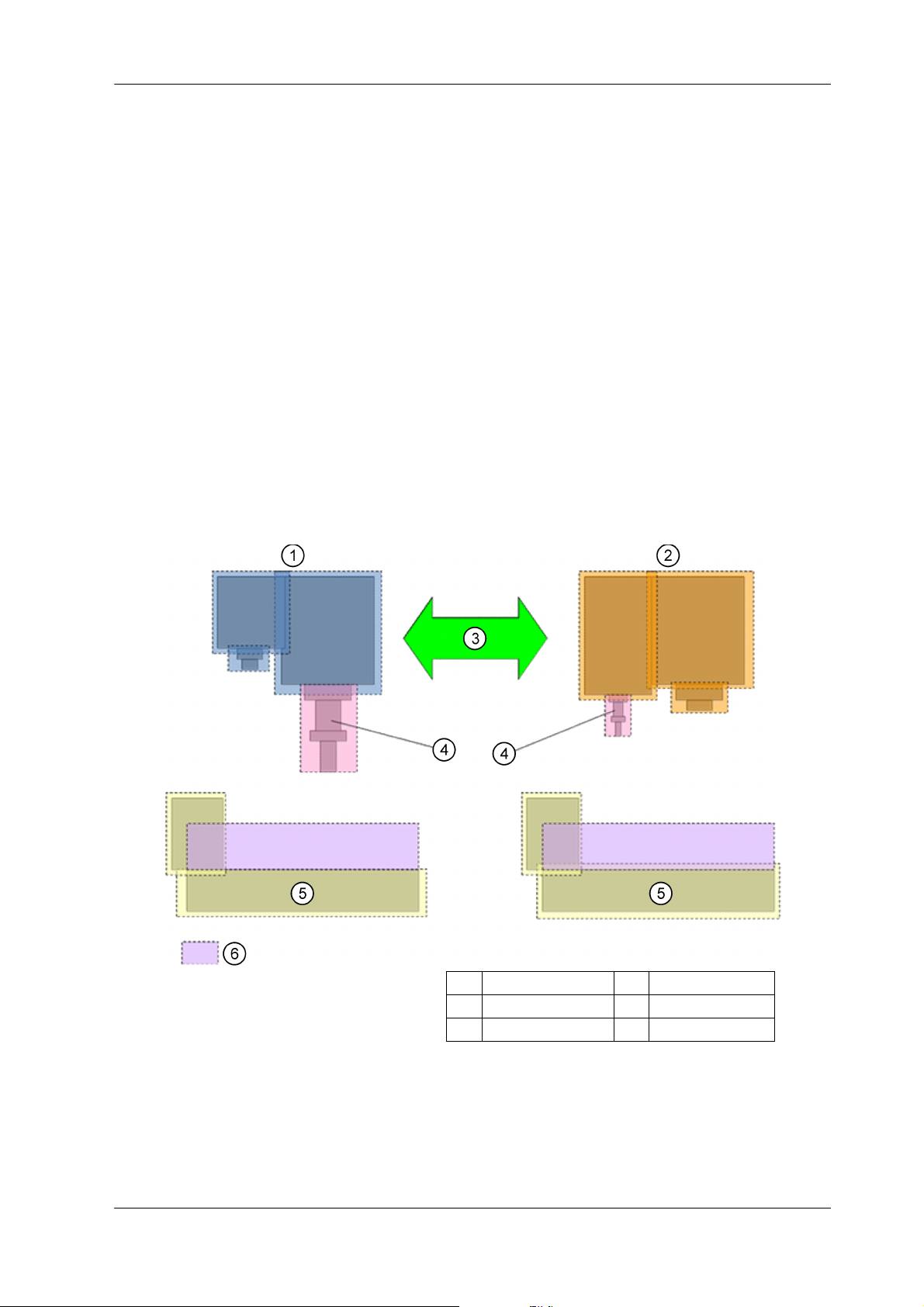

3D crash avoidance function allows stopping the machine in advance by an Crash Check Alarm when a

possible collision is detected between spindle and table which are defined by simplified factory preset geometrical configurations as shown in “Fig. 2-1: ”.

Usually this function becomes active at the machine start-up. No special handling by an operator is required.

Fig. 2-1:

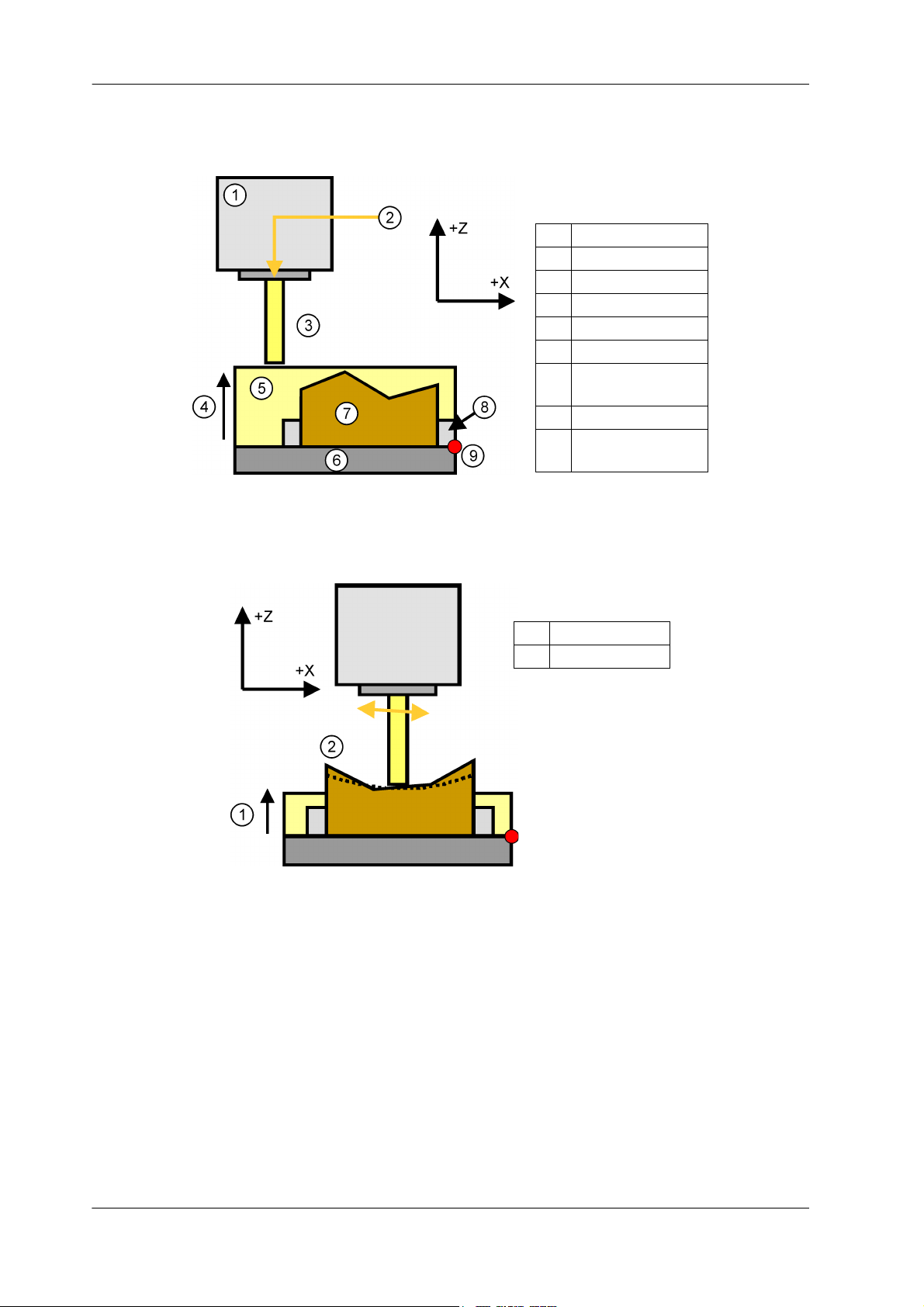

Moreover, it is possible to prevent the following accidents using the Tool Shape Data Transfer Function

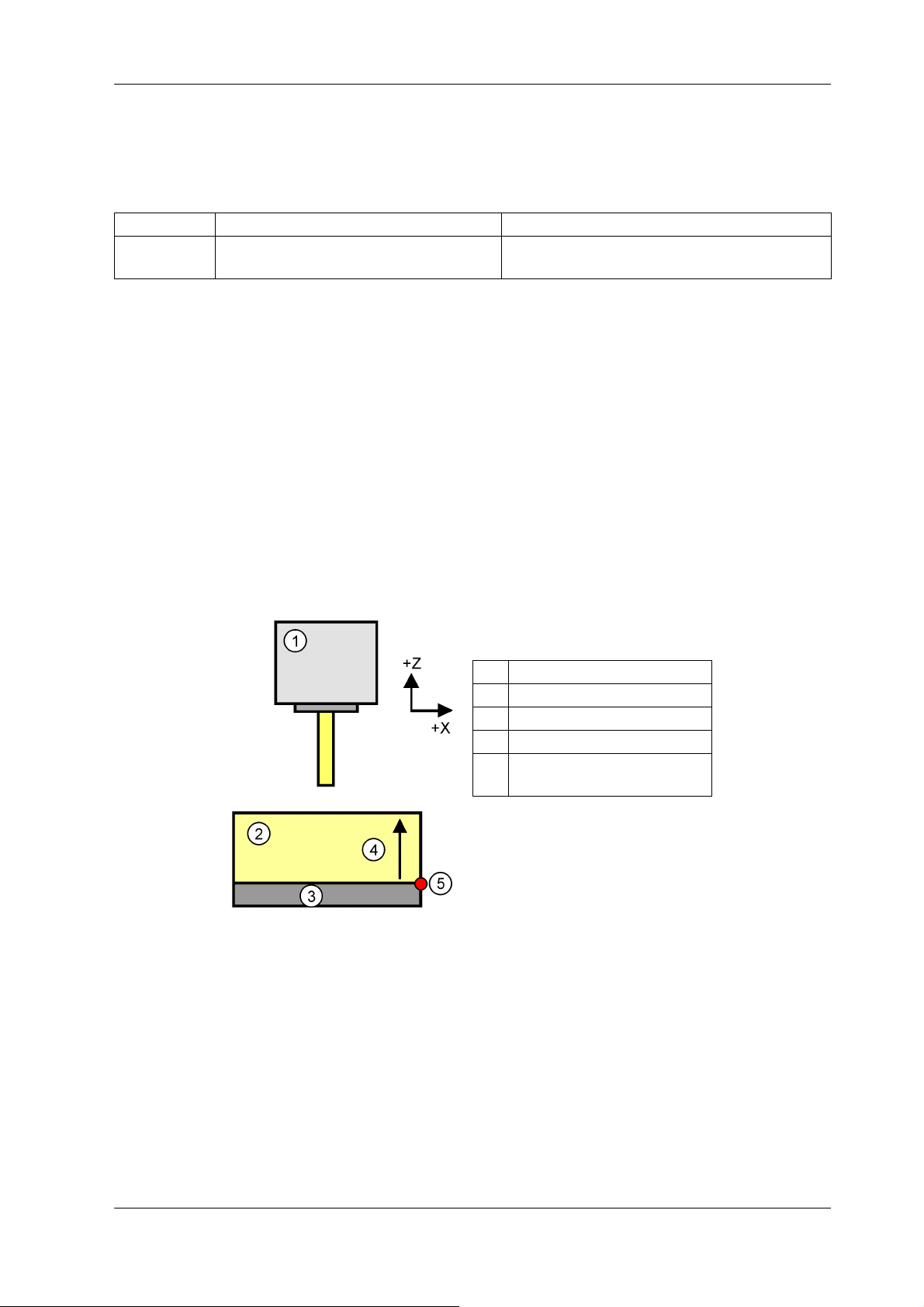

(chapter “6 USE OF TOOL SHAPE DATA TRANSFER FUNCTION”) and the Z Axis Collision Avoidance Function (chapter “7 Z AXIS COLLISION AVOIDANCE FUNCTION”).

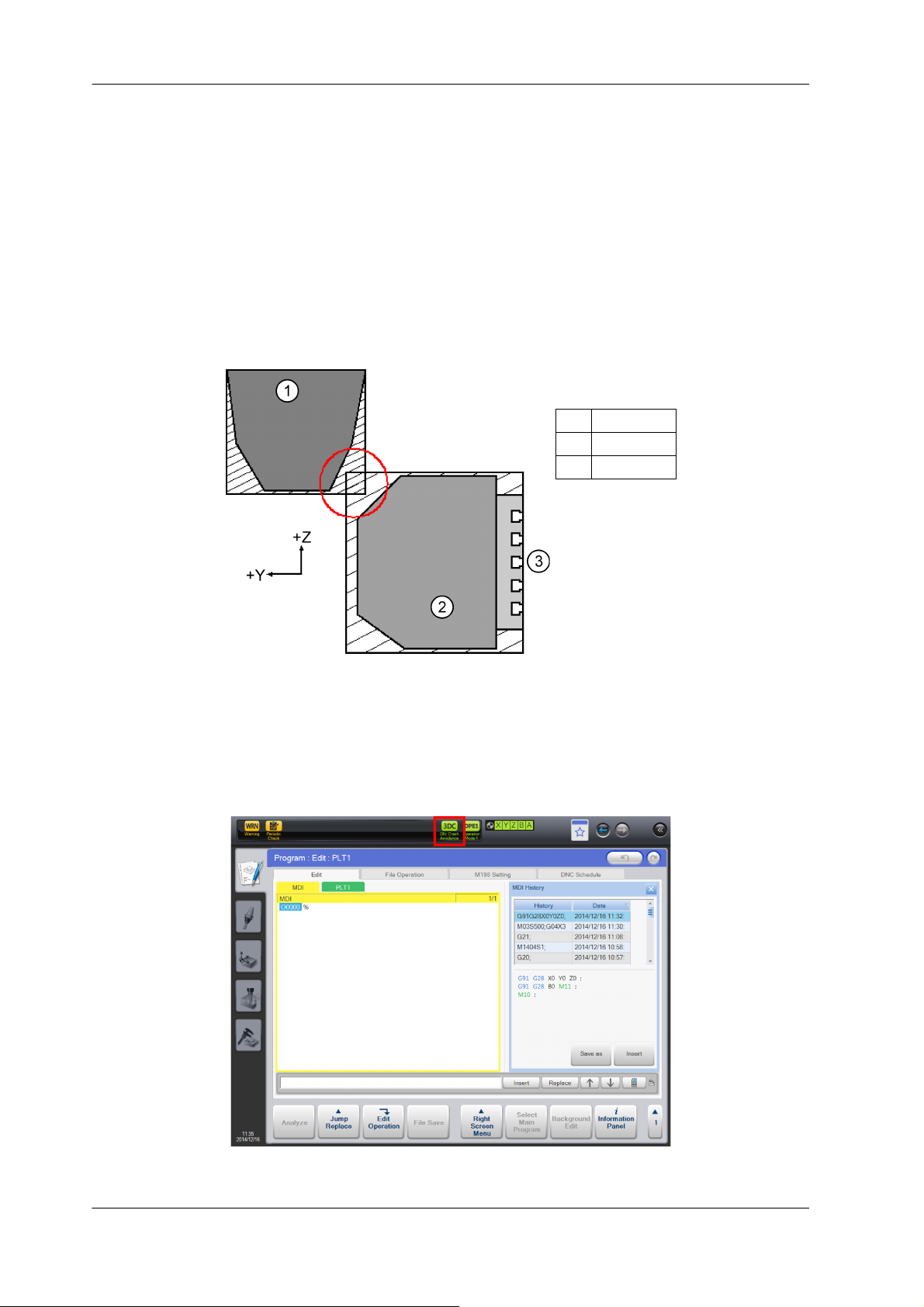

- Collision during the initial approach in Z axis direction (“Fig. 2-2: Initial approach”)

- Collision during the movement in –Z axis direction outwards machining area (“Fig. 2-3: Machining”)

MAKINO 0847C-1610 (en)

Page 14

2-2 OUTLINE

Legend

[1] Spindle

[2] Approach

[3] Tool model

[4] M code

[5] Limitation area

[6] Table

[7] Workpiece before

cutting

[8] Fixture

[9] Reference position

Z

Legend

[1] M code

[2] Machining area

Fig. 2-2: Initial approach

Fig. 2-3: Machining

0847C-1610 (en) MAKINO

Page 15

OPERATIONAL NOTES 3-1

3 OPERATIONAL NOTES

CAUTION!

Check that 3D crash avoidance function is active before starting machine operation.

Particularly, note that this function will not be active if referencing of all coordinate axes

had not been executed at least once.

NOTICE! 3D crash avoidance function may temporarily turn off during Machine Lock or while

searching for the program restart.

NOTICE! Please move axes in the opposite direction and push [NC Reset] button, when Crash

Check Alarm has been generated by this function. Movement in the direction of further

collision with [OT Release] button pushed is impossible. In order to enable movement in

the direction of further collision, first do NC reset and then turn this function OFF.

NOTICE! Except the automatic non-contact tool measuring device (separate-type) of D500, this

function is temporarily turned off and then restores during the automatic tool measurement procedure.

However, this function may remain turned off if there has been some intervention or some

alarms have been generated in the course of the measurement procedure.

Please be sure to have confirmed the status of the 3D crash avoidance mode as shown in

paragraph “4.3 Verification of 3D Crash Avoidance State” before proceeding to the next

operation execution.

NOTICE! The spindle model of the machine with the bar spindle is set with W axis at a reference

position. When the bar spindle is extended, Shape model of 3D crash avoidance func-

tion does not apply to the extension of the bar spindle.

CAUTION!

3D crash avoidance function does not apply to workpieces, jigs, tool holders, angle

plates etc.

Also note that 3D crash avoidance function does not apply to structural elements being

not in their usual positions during machining, such as advanced ATC arm or covers of auxiliary appliances in opened state etc.

Using Tool Shape Data Transfer function, tool’s cylindrical model is created so that tool

also becomes an object for 3D crash avoidance.

CAUTION!

As a general rule, 3D crash avoidance function does not apply to the chuck of WPS specifications, CPH arm, and tale stock which can be attached, removed and shifted to other

position.

And also, flexible nozzles do not apply.

CAUTION!

3D crash avoidance function does not apply to the Programmable coolant nozzle (PCN),

CD spindle in iGRINDER.

MAKINO 0847C-1610 (en)

Page 16

3-2 OPERATIONAL NOTES

Legend

[1] The pallet part

does not apply.

CAUTION!

When Center of Rotation Axis Measurement is used, the Crash Check Alarm might be generated, because the spindle approaches to the table extremely. In such case, please operate it carefully after 3D crash avoidance mode is temporarily turned off.

CAUTION!

For the table with the chuck, the pallet gripped to chuck do not apply to the 3D crash

avoidance function.

Especially, about the RWH or 1-face angle plate with clamping system D of Work Holding

Pallet System, the pallet part does not apply to the 3D crash avoidance function.

Fig. 3-1: The example for the RWH with Clamping system D with Work Holding Pallet System

0847C-1610 (en) MAKINO

Page 17

OPERATIONAL NOTES 3-3

Legend

[1] B: 0 deg [2] B: -120 deg

NOTICE! In a92-5XR, the shape model for the collision check is greatly set to include the range of

motion though Terminal box on RWH moves by rotating B axis (see “Fig. 3-2: The shape

model of terminal box on B axis in a92-5XR”).

Fig. 3-2: The shape model of terminal box on B axis in a92-5XR

NOTICE! The distance in which the collision with the object is detected is as follows for operation

safety.

These change by the part.

• Objects in machining area: 10 mm or more

• Tool and Table side object: 10 mm or more

• Limitation area(*) and Table side object: 10 mm or more

• Limitation area(*) and Tool: 0 mm or more

(*) Area where work and fixture are protected (refer to chapter “7 Z AXIS COLLISION

AVOIDANCE FUNCTION”).

It is necessary to invalidate the function temporarily when it is necessary to cut it at the

position in which the distance becomes shorter than the above-mentioned setting.The

presence of collision need to be confirmed. The machining need to be executed safely.

(Refer to chapter “4 SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE”.)

There are the following methods in the effective return of the function promptly after the

machining ends or manual interruption.

- Function button.

- M1401 command in MDI mode.

- M30 or NC reset button (machine parameter No. 2075=1).

MAKINO 0847C-1610 (en)

Page 18

3-4 OPERATIONAL NOTES

0847C-1610 (en) MAKINO

Page 19

SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE 4-1

4 SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE

Switching ON/OFF the 3D crash avoidance function can be performed either by M codes or by a function

button.

4.1 M Codes

M code Name Explanation

M1400 3D Crash Avoidance Mode Off Turns Off 3D Crash Avoidance mode

M1401 3D Crash Avoidance Mode On Turns On 3D Crash Avoidance mode

Table 4-1:

4.2 Function Button

“3D Crash Avoidance Mode” (On/Off).

Fig. 4-1:

NOTICE! The last commanded mode change becomes effective regardless of whether it was done

by an M code or by the function button.

Status of 3D Crash Avoidance Mode at Power ON can be specified by the machine parameter No. 02073.

NOTICE! It is necessary to turn On the function again either by M1401 “3D Crash Avoidance Mode

On” or by the function button at the “Function” screen, after it was turned Off either by

M1400 “3D Crash Avoidance Mode Off” or by the function button at the “Function”

screen.

MAKINO 0847C-1610 (en)

Page 20

4-2 SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE

Legend

[1] Spindle

[2] Table

[3] A–90deg.

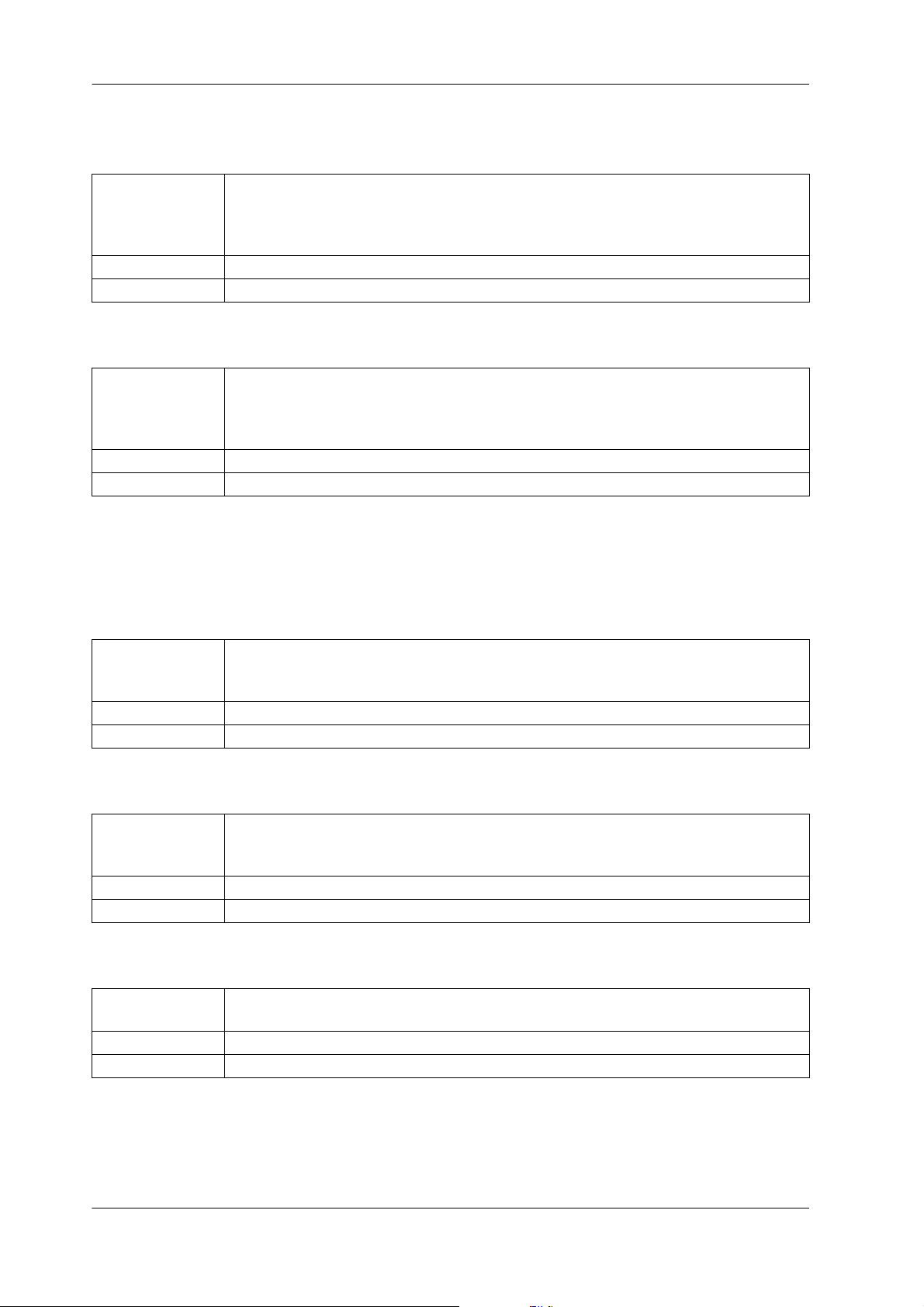

NOTICE! 3D Crash Avoidance function will not run properly if it is commanded when 3D Crash

Avoidance check areas are superposed as shown by ○ at the picture below, until superposed areas are not drawn apart.

This function should be turned On when the distance between structural elements is

200 mm or more.

This is valid during machine’s start-up as well. Machine’s power supply should be

turned Off in a position when the distance between structural elements satisfies the

aforementioned limits.

Fig. 4-2: Example of superposition of 3D Crash Avoidance check areas

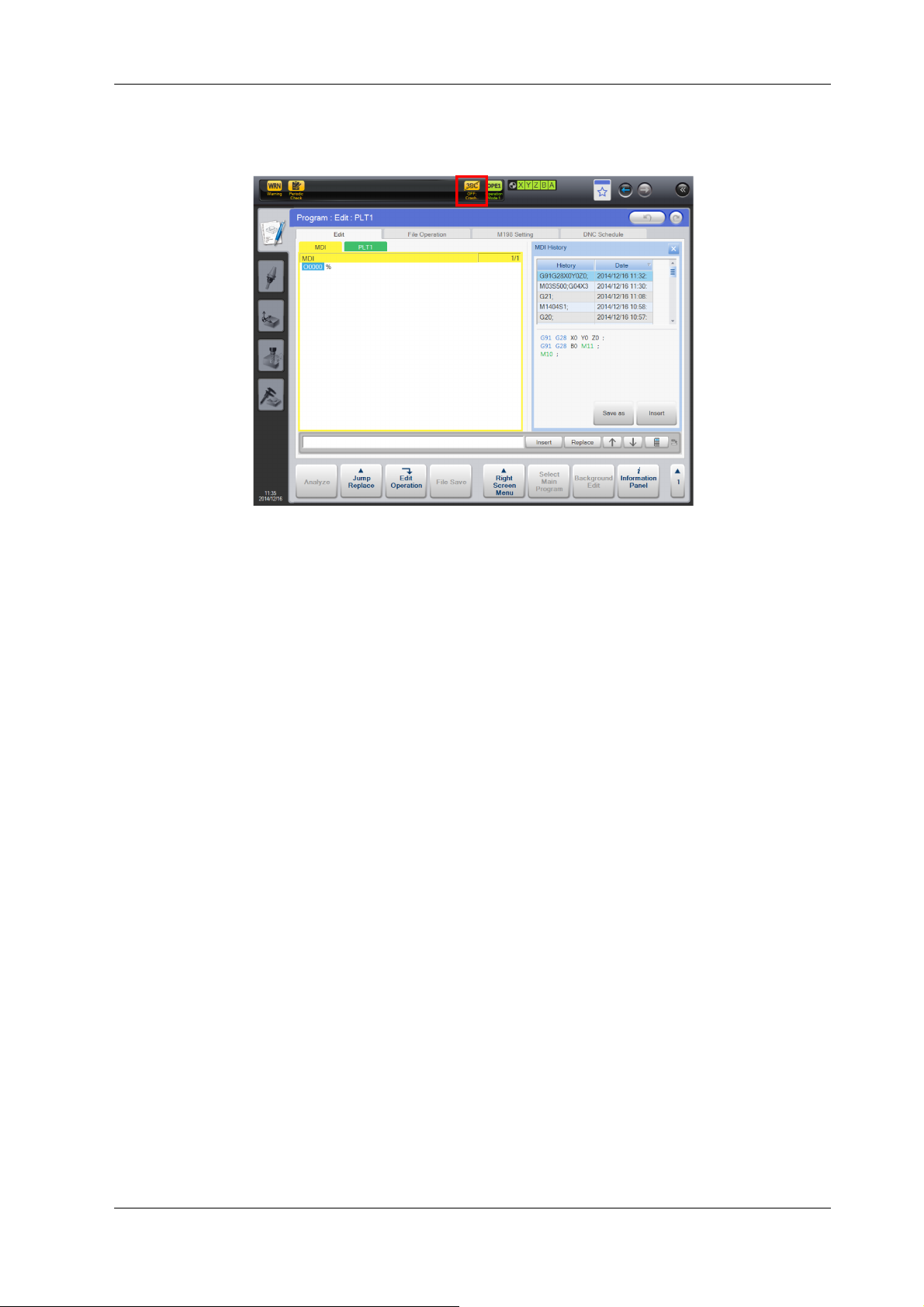

4.3 Verification of 3D Crash Avoidance State

Fig. 4-3: 3D crash avoidance active

0847C-1610 (en) MAKINO

Page 21

SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE 4-3

Fig. 4-4: 3D crash avoidance deactivated

In the above figures,

- when the 3D crash avoidance mode is On (active), [3DC] has green background color and the function

button has yellow background color;

- when the 3D crash avoidance mode is Off (deactivated), [3DC] has yellow background color and the

function button has gray background color.

MAKINO 0847C-1610 (en)

Page 22

4-4 SWITCHING ON/OFF THE 3D CRASH AVOIDANCE MODE

0847C-1610 (en) MAKINO

Page 23

CRASH CHECK ALARM AND RECOVERY 5-1

5 CRASH CHECK ALARM AND RECOVERY

When Crash Check Alarm is generated by this function, the screen in Professional 6, like “Fig. 5-1: Example

for Crash Check Alarm display”, is displayed.

After Crash Check Alarm is generated, please change handle mode, move Spindle and Table to opposite

direction of crash, and reset the Crash Check Alarm by pushing the [RESET] button.

Fig. 5-1: Example for Crash Check Alarm display

NOTICE! When Crash Check Alarm is generated, the meaning of the object displayed by the alarm

is different according to the machine type.

MAKINO 0847C-1610 (en)

Page 24

5-2 CRASH CHECK ALARM AND RECOVERY

0847C-1610 (en) MAKINO

Page 25

USE OF TOOL SHAPE DATA TRANSFER FUNCTION 6-1

6 USE OF TOOL SHAPE DATA TRANSFER FUNCTION

When an automatic tool change is performed, it is possible to attach a simplified cylindrical tool model to

the spindle configuration model using tool length and tool radius data of the “Tool data” screen of Professional 6.

Due to this function it becomes for example possible to prevent intrusion of the Z axial tool into the table.

This functional option is disabled at shipping from the factory.

NOTICE! This function is enabled to set 1 for machine parameter, No. 2081.

3D crash avoidance function is not applied to tool holders.

NOTICE! If you done dressing in G5 that this function is enabled, there is a possibility the Crash

Check Alarm is generated.

If you done dressing, please set off to Spindle-Table Crash Avoidance mode temporarily.

NOTICE! In automatic non-contact tool measuring device (separate-type) of D500, 3D crash avoid-

ance mode isn’t turned off while being measuring tool length.

Therefore, when the value of tool length or tool radius in tool data screen is larger than an

actual value or “0”, there is a possibility that Crash Check Alarm is generated while measuring it.

Please set the value of appropriate tool length or tool radius.

NOTICE! The tool model is set to the position where W axis is a reference position on the machine

attached the bar spindle.

Therefore, when the machine is used with the bar spindle extended, please add length

value of the bar spindle’s extension to the tool length data.

6.1 Timing of Tool Shape Data Transfer Function

This option can be enabled by changing the machine parameter No. 2081.

Tool geometrical model is created when there is some tool in the spindle (when pot is not the escape pot

or pot number is other than 0).

Specifically, tool shape data are renewed at the following instances:

- When an operator enters or edits either of tool length H, tool radius D, tool length wear HW, radial wear

DW values directly at the “Tool Data” screen of Professional 6.

- When tool length H or tool radius D of the spindle tool are changed by the NC tool measurement pro-

gram.

- When spindle pot number changes as a result of ATC action.

- When an operator changes spindle pot number at “Maintenance” screen of Professional 6.

- When upper level computer changes spindle tool shape data.

- When the machine power supply is turned ON.

- When emergency state is released.

- When 3D crash avoidance mode is turned ON.

NOTICE! Tool shape data is not changed at tool change done by manual tool clamp / unclamp.

Please set an appropriate value again in tool data screen.

MAKINO 0847C-1610 (en)

Page 26

6-2 USE OF TOOL SHAPE DATA TRANSFER FUNCTION

6.2 Tool Length, Tool Radius Data Handled by Tool Shape Data Transfer Function

Overall tool length transferred to CNC is calculated as tool length H plus length wear HW.

Similarly, overall tool radius transferred to CNC is calculated as tool radius D plus radial wear DW.

If calculated overall tool length turns out to be zero, it is substituted by the setting value of the machine

parameter No. 2085. Similarly, if calculated overall tool radius turns out to be zero, it is substituted by the

setting value of the machine parameter No. 2086.

Regardless of the machine specification (metric or inch), the values of the machine parameters No. 2085,

2086 are set in ten thousandths of a millimeter. At machines with inch specification their setting values are

automatically converted into inches by Professional 6.

NOTICE! When tool shape data transfer function is used, all tool length and radius values at the

“Tool Data” screen must be specified as measured from the gauge line to the farthest

point of a cutting edge as well as the largest radii respectively.

NOTICE! If there is a mismatch between the machine specification set by the machine parameter

No. 0073 and the current CNC units switched by G20/G21 codes, the tool shape data

transfer is blocked and the machine alarm No. 410011 is generated.

NOTICE! Machine parameter No. 2085 and No. 2086 need to be set more than 0 mm.

NOTICE! When negative values are input to tool length H or tool radius D, the alarm occurs.

Positive values need to be set to tool length (check) and tool diameter (check).

(The machine parameter No. 2076=1.)

REMARK More effective operation due to prevention of tool data related mistakes can be achieved

by simultaneous use of the Standard Tool Length Function.

REMARK When tool length measurement device is attached, the result of a measurement is auto-

matically input into tool data screen by setting it to “The tool data transfer is on the machine side.” just after measuring tool length.

6.3 Tool Length (Check), Tool Radius/Diameter (Check) of Tool Shape Data Transfer Function

Data used as tool offset value and data used for this function can be separately set.

In this case, set the value to the column of Tool Length (Check) and Tool Radius/Diameter (Check) displayed

on the tool data screen of Professional 6. (Hereafter, the input data is called “Collision Check Data”.)

When the value of Collision Check Data is “0”, the tool model is made by using the value of tool length H

and tool radius D displayed on the tool data screen. At this time, when the value of tool length H and tool

radius D are “0”, the tool model is made by using the value of machine parameter No. 2085 and No. 2086.

The method of inputting the tool radius/diameter of Collision Check Data can be set by machine parameter No. 76.

0847C-1610 (en) MAKINO

Page 27

USE OF TOOL SHAPE DATA TRANSFER FUNCTION 6-3

NOTICE! When machine parameter No. 2076 is “1”, this specification is effective.

When shipping it, machine parameter No. 2076 is “0” (specification of paragraph “6.2 Tool

Length, Tool Radius Data Handled by Tool Shape Data Transfer Function”).

NOTICE! When machine parameter No. 2076 is “1”, the tool data only of the tool length and tool

radius/diameter is transferred.

The tool ware data is not included in the calculation.

NOTICE! When this specification is used, tool length H and tool radius D shown in paragraph “6.1

Timing of Tool Shape Data Transfer Function” indicate Collision Check Data.

NOTICE! When the tool attaches to the attachment such as the angle head, the Collision Check

Data cannot be used.

6.4 Use of Tool Shape Data Transfer Function in dummy pot

If the actual number of tools used is the same as the available tool storage capacity, tool geometrical

model is created even if pot number of spindle tool is dummy pot number.

NOTICE! When machine parameter No. 2077 is “1”, this specification is effective.

When shipping it, machine parameter No. 2077 is “0” (tool geometrical model is none in

the dummy pot).

MAKINO 0847C-1610 (en)

Page 28

6-4 USE OF TOOL SHAPE DATA TRANSFER FUNCTION

0847C-1610 (en) MAKINO

Page 29

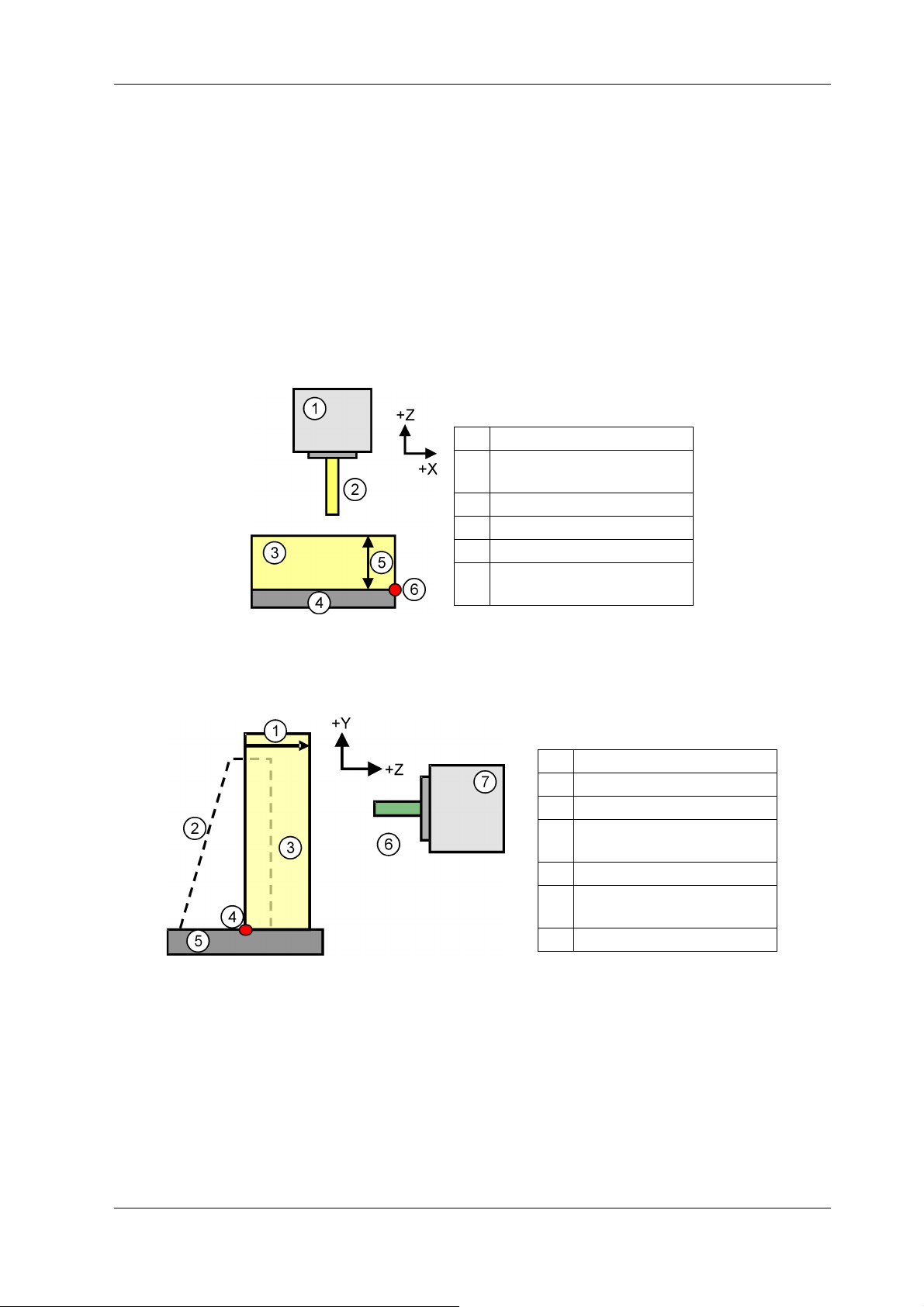

Z AXIS COLLISION AVOIDANCE FUNCTION 7-1

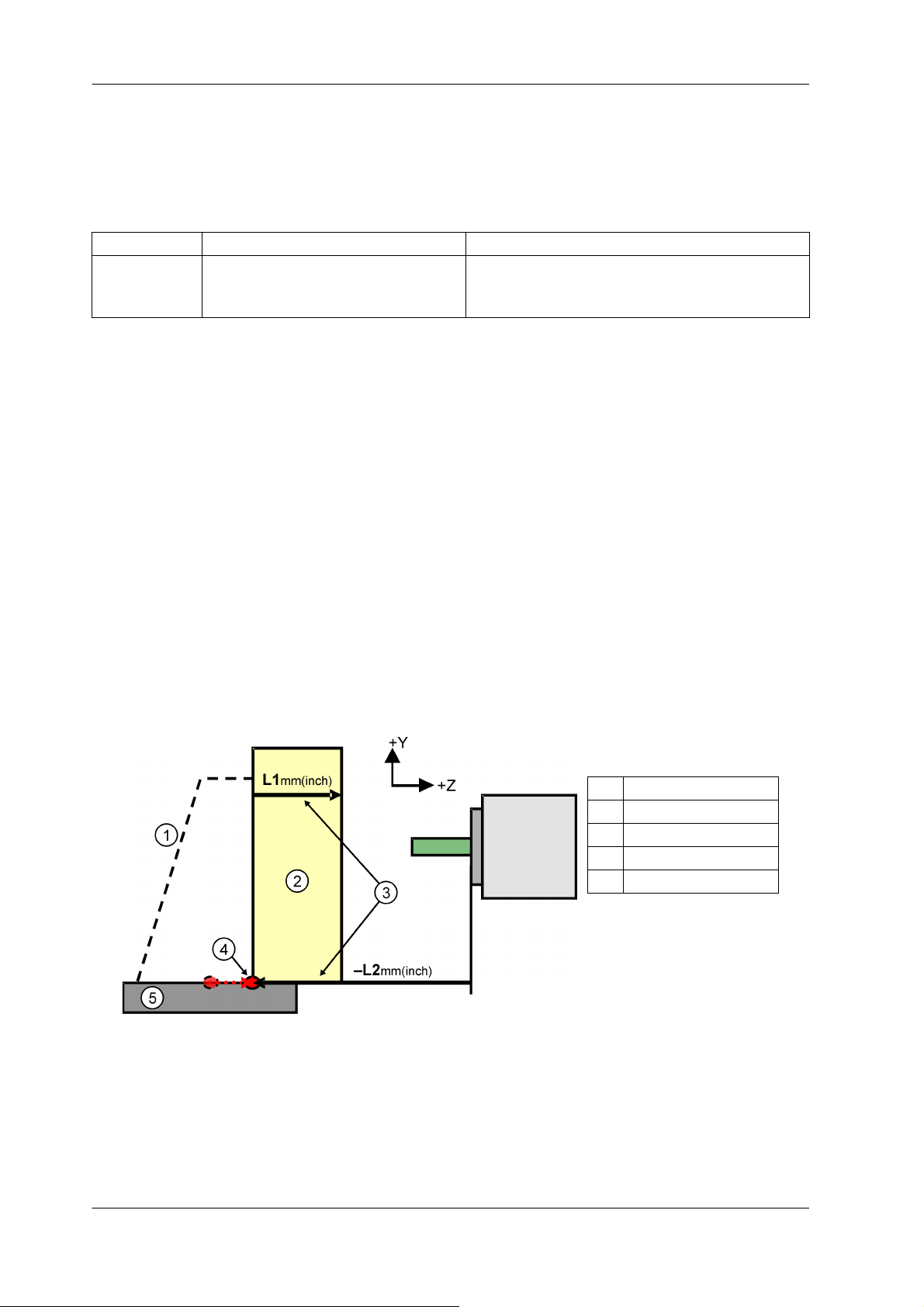

Legend

[1] Spindle

[2] Tool model (Tool shape data

transfer function)

[3] Limitation area

[4] Table

[5] Set using M code

[6] Reference postion Z

(Machine parameter N2064)

Legend

[1] Set using M code

[2] Angle plate etc.

[3] Limitation area

[4] Reference postion Z

(Machine parameter N2064)

[5] Table

[6] Tool model (Tool shape

transfer function)

[7] Spindle

7 Z AXIS COLLISION AVOIDANCE FUNCTION

Z Axis Collision Avoidance Function is a function which allows setting of a limitation area in order to avoid

collision between the tool tip and the table.

It is possible to create the limitation area with this function in order to prevent the collision through setting with an M code the area’s height, which is measured from the Z reference position, which is defined

by the machine parameter beforehand.

After the limitation area has been set, an Crash Check Alarm will be generated during machine operation

every time the tool tip is about to intrude in the range of the set Z machine coordinates. Therefore this

function allows preventing the tool tip’s piercing into the work in Z direction due to an erroneously set

workpiece origin offset values.

Fig. 7-1: Vertical type

Fig. 7-2: Horizontal type

NOTICE! Z axis collision avoidance Function cannot be used if 3D Crash Avoidance mode is not ef-

fective.

REMARK Set “0 (3DC)” to the machine parameter No. 02168 if this function is used during 3D Crash

MAKINO 0847C-1610 (en)

Avoidance mode.

Page 30

7-2 Z AXIS COLLISION AVOIDANCE FUNCTION

Legend

[1] Reference position Z

(Machine parameter N2064)

EROWA ITS CHUCK TYPE

(ER-007625)

406.2

350

Z-axis stroke

135

78.8 56.2

Contact

face

90°

20°

20°

200

325325

450

X-axis stroke 650

Legend

[1] Height of the pallet

[2] Reference position Z

(Machine parameter N2064)

REMARK More effective operation can be achieved using the Z Axis Collision Avoidance Function

together with the Tool Shape Data Transfer Function (chapter “6 USE OF TOOL SHAPE

DATA TRANSFER FUNCTION”).

REMARK If ATC is executed with Z axis collision avoidance function set, there is a possibility that the

Crash Check alarm is generated according to the tool length.

Cancel the Z axis collision avoidance function if ATC is executed.

REMARK For a series, M1404 might be executed before the axis movement is completed. Machine

alarm 311027 is generated for the above situation.

In that case, please add G53 in front of M1404.

REMARK Reference position Z (machine parameter N2064) is set to the face of the pallet at ship-

ment.

The following setting is set for V-5XB (for example, V33i-5XB, V56i-5XB, etc.), and D500

with work holding pallet specification.

Fig. 7-3: Example for reference position Z about V33i-5XB and D500 with work holding pallet

REMARK At shipment, limitation area has been set to the height of the pallet, specified from MAK-

INO.

The following setting is set for D500 with work holding pallet specification.

Fig. 7-4: Example for D500 with work holding pallet at shipment

0847C-1610 (en) MAKINO

Page 31

Z AXIS COLLISION AVOIDANCE FUNCTION 7-3

Legend

[1] Spindle

[2] Limitation area

[3] Table

[4] 100 mm (inch)

[5] Reference postion Z

(Machine parameter N2064)

7.1 Z Axis Collision Avoidance Function Setting

Switching this function ON/OFF can be performed either by M codes or by a function button.

M code Name Explanation

M1404 S_ Z Axis Collision Avoidance Setting Sets the limitation area of Z Axis Collision

Avoidance

Table 7-1:

M1404 S “L offset value from the table plane, mm or inch (depending on the mode)”

Sets the limitation area at of height L as measured from Z reference position. Positive values must be commanded.

Program example: M1404 S100;

- Limitation area’s height is 100 mm or 100 inch (“Fig. 7-5: Limitation area”)

- Additionally, by changing the machine parameter No. 2070, it is also possible to express values smaller

than 1 mm (1 inch) by multiplying the argument S by a coefficient

NOTICE! It is necessary to set the Z reference position with the machine parameter No. 2064.

Fig. 7-5: Limitation area

NOTICE! If the function is commanded in the situation when the tool model and the limitation area

overlap, the function will not perform properly until they are drawn apart.

Argument S value of the limitation area must be set about several mm more greatly.

MAKINO 0847C-1610 (en)

Page 32

7-4 Z AXIS COLLISION AVOIDANCE FUNCTION

Legend

[1] Angle plate etc.

[2] Limitation area

[3] Set using M code

[4] Reference postion Z

[5] Table

7.2 Reference Position Z Setting according to M Code

It is possible to set the reference position Z of the limitation area by M code command in paragraph “7.1

Z Axis Collision Avoidance Function Setting”.

M code Name Explanation

M1404 S_T_ Z Axis Collision Avoidance Setting Sets the limitation area of Z Axis Collision Avoid-

ance. (The command position of argument T becomes reference position.)

Table 7-2:

M1404 S “L1” T “L2 reference position Z mm or inch (depending on the mode)”

- When T is commanded, the limitation area of “L1” in width is made. At this time, reference position Z is

assumed to be machine coordinate value “–L2”.

- When T isn’t commanded or T command is “T0”, the limitation area where machine parameter No. 2064

is assumed to be reference position Z is made.

NOTICE! Reference position Z that can be set is transformed into a negative value.

At this time, when argument T is set, change reference position Z to a positive value, and

command.

REMARK The change in reference position by T code is an argument of an effective one shot until

being canceled or being commanded M1404 again.

Fig. 7-6: Example for command

Program example

M1404S100T500

- The height of the limitation area becomes 100 mm or 100 inch.

- The reference position Z becomes “machine coordinate value –500 mm or –500 inch”.

0847C-1610 (en) MAKINO

Page 33

Z AXIS COLLISION AVOIDANCE FUNCTION 7-5

- Additionally, by changing the machine parameter No. 2070, it is also possible to express values smaller

than 1 mm (1 inch) by multiplying the argument S and T by a coefficient.

M1404S0T500 or M1404T500

- Argument T is disregarded, and the limitation area is canceled.

M1404S100T0

- The machine parameter No. 2064 is assumed to be reference position Z, and the limitation area of

100 mm or 100 inch in height is generated.

7.3 Cancel of the Limitation Area of Z Axis Collision Avoidance Function

M1404........................Cancels the function. (The same is “M1404 S0”).

Function button....It is possible to cancel the limitation area of the Z Axis Collision Avoidance Function

from Professional 6 Function screen.

It is also possible to cancel the limitation area by NC reset or Power off.

Refer to the machine parameter No. 2069 (chapter “9 MACHINE PARAMETERS”) for details.

Fig. 7-7: Example of cancel button of the Z Axis Collision Avoidance Function

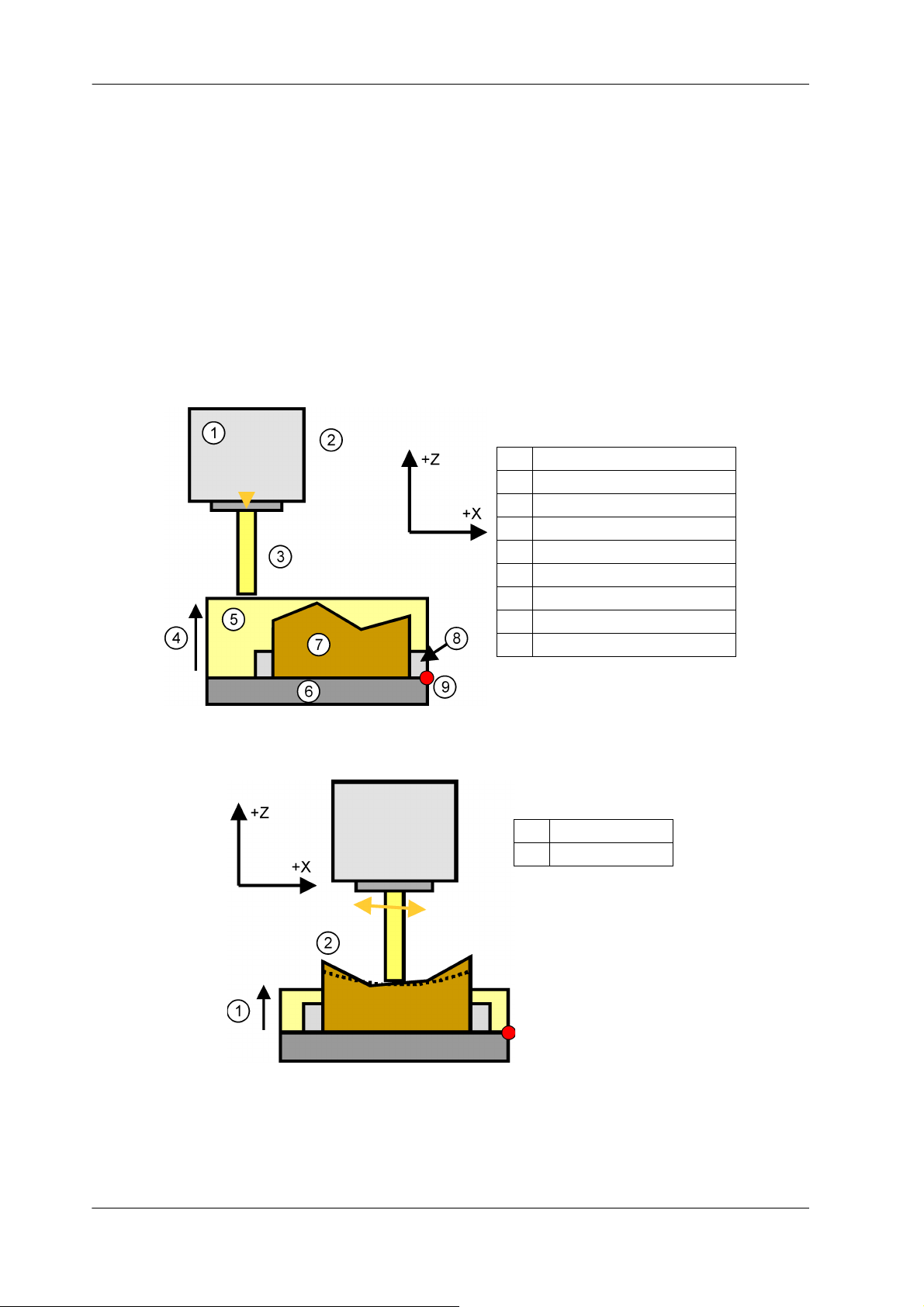

7.4 Application Example of Limitation Area of Z Axis Collision Avoid-

ance Function

The application example is shown below.

In N2, Height from the Z reference position to which the tool tip is allowed to approach is set to

argument S.

After the initial approach is finished, in N4, the height of the area which is supposed to be outside the machining area, as measured from the table, is set to prevent collision. In N7 the limitation area is cancelled.

MAKINO 0847C-1610 (en)

Page 34

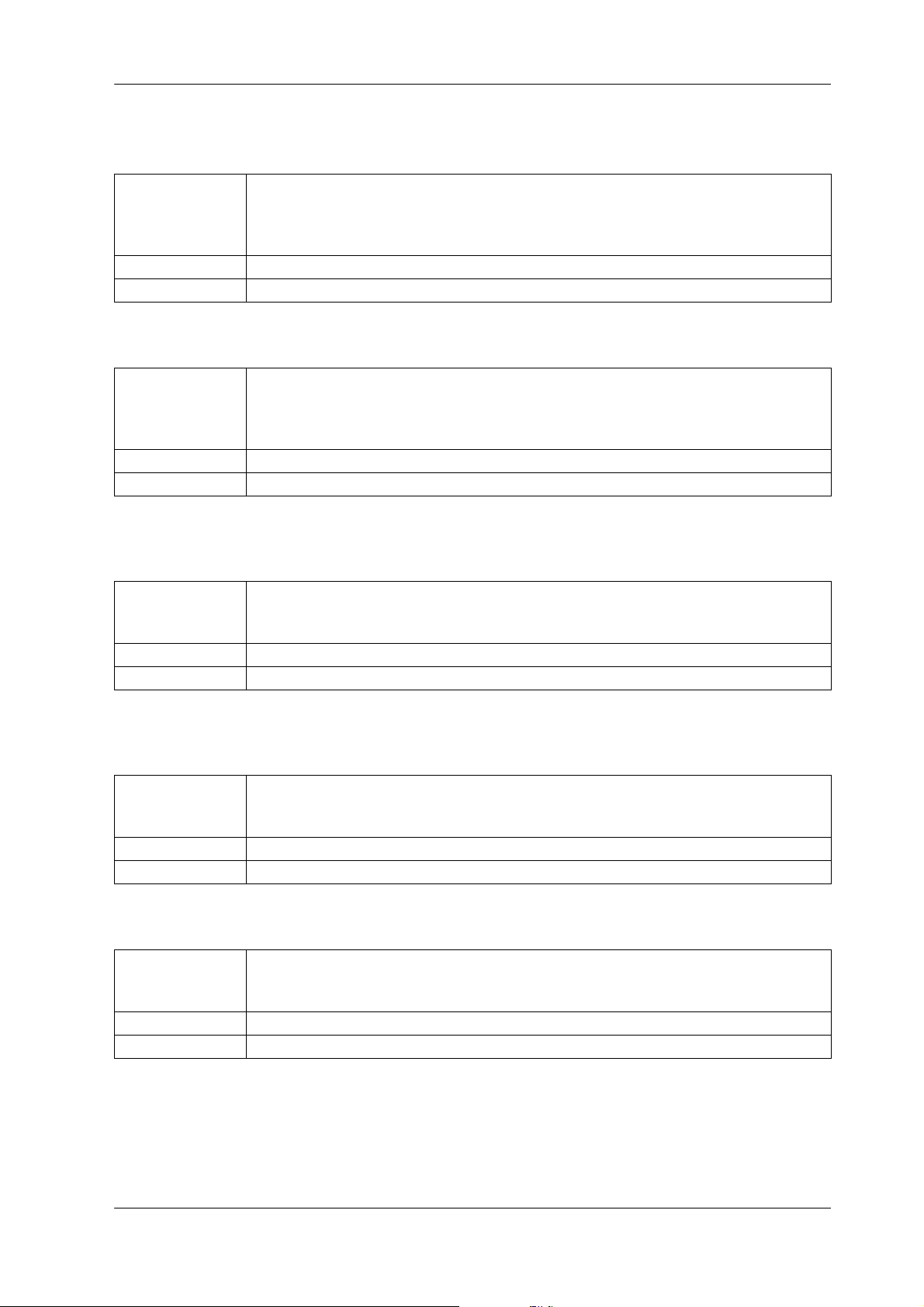

7-6 Z AXIS COLLISION AVOIDANCE FUNCTION

Legend

[1] Spindle

[2] Approach

[3] Tool model

[4] 100 mm

[5] Limitation area

[6] Table

[7] Workpiece before cutting

[8] Fixture

[9] Reference position Z

Legend

[1] Machining area

[2] 30 mm

Program example

O1000 (units are mm)

N1 T1 M6;

N2 M1404 S100; (“Fig. 7-8: N2”)

N3 G90 G43 G54 X0 Y0 Z0 H1; (initial approach)

N4 M1404 S30; (“Fig. 7-9: N4”)

M198 Pxxxx; (machining program)

N6 G91 G28 Z0;

N7 M1404; (Cancel of the Z Axis Collision Avoidance)

N8 M30;

Fig. 7-8: N2

0847C-1610 (en) MAKINO

Fig. 7-9: N4

Page 35

Z AXIS COLLISION AVOIDANCE FUNCTION 7-7

Legend

[1] Angle plate [4] B axis rotary / index

[2] Table [5] B axis rotation

[3] Limitation area

7.5 Motion of the Limitation Area of Z Axis Collision Avoidance Func-

tion for Workpiece Rotation Type Machines with 4 or 5 Axes

The limitation area does not rotate synchronously with the rotational axis at 4/5 axes machines of a/A /

MCC / MCD series.

However, the limitation area can rotate synchronously with rotational axes at five-axial workpiece rotation

type machines of D500, V-5XB, A66E-5XD, a51-5XU, G5, G10.

MAKINO 0847C-1610 (en)

Fig. 7-10: Rotation of the limitation area

Page 36

7-8 Z AXIS COLLISION AVOIDANCE FUNCTION

7.6 Verification of Z Axis Collision Avoidance Function

It is possible to verify the limitation area setting state by the color of 3DC indicator.

Fig. 7-11: Z Axis Collision Avoidance is effective

Fig. 7-12: Z Axis Collision Avoidance is disabled

In the above figures,

- when the Z Axis Collision Avoidance Function is On (active), [3DCZ] has green backcolor.

- when the Z Axis Collision Avoidance Function is Off (deactivated), [3DC] has green backcolor.

0847C-1610 (en) MAKINO

Page 37

OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE 8-1

Legend

[1] Y shift amount (No. 2093)

[2] Position of table shape be-

fore it changes

[3] Position of table shape af-

ter it changes

[4] (Y-STROKE)

8 OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE

8.1 Use of 3DC Y position setting function (ONLY MCC2013VG)

This function is that the model of the table, set beforehand, can be shifted to Y+ direction by an arbitrary

value of the operator. The height (amount) that shifts from the upper surface of the table in Y+ direction is

input to the machine parameter (No. 2093). And, you can avoid the crash of the things (nozzle and piping

etc.) on the table.

REMARK 3DC Y position setting function cannot be used if 3D Crash Avoidance Function is not ef-

NOTICE! When Y shift amount (No. 2093) of the table is set to 100 mm or more, there is a possibil-

MAKINO 0847C-1610 (en)

Fig. 8-1: Outline Figure of 3DC Y position setting function

fective.

ity that the spindle and the table crash.

Page 38

8-2 OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE

Legend

[1] Pallet No. 1

[2] Pallet No. 2

[3] APC

Legend

[1] Pallet No. 1

[2] Pallet No. 2

[3] Reference position Z

(Machine parameter 2064)

8.2 About Automatic Pallet Change (APC) of a/A series-5XR machines

After completing APC of a/A series-5XR machines, the model is changed to the shape model matched to

specifications of pallet in machining chamber automatically (“Fig. 8-2: Example for APC of a/A series-5XR

machines”).

Limitation area of the Z-Axis Collision Avoidance Function has following restrictions in this machine type.

- Limitation area is canceled automatically in working APC.

- Regardless of specifications such as RWH or WHP, Shape of limitation area is based on pallet part (“Fig.

8-3: Example for limitation area of a/A series-5XR machines”).

- The limitation area doesn’t rotate synchronously with the rotational axis (reference to paragraph “7.4

Application Example of Limitation Area of Z Axis Collision Avoidance Function”).

Fig. 8-2: Example for APC of a/A series-5XR machines

Fig. 8-3: Example for limitation area of a/A series-5XR machines

NOTICE! Initial value of reference position Z of the Z-Axis Collision Avoidance Function has been

set to distance from gauge line of spindle to the center of rotation of B-axis.

0847C-1610 (en) MAKINO

Page 39

OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE 8-3

Legend

[1] Main spindle [4] Tool

[2] Sub spindle [5] Table

[3] Change [6] Limitation area

8.3 About Spindle Model Change in EG3010

It automatically changes into the spindle model matched to an effective spindle now in EG3010 (the machine that has a sub spindle).

Limitation area of Z axis remains after the switch of the spindle model.

When the tool shape data transfer function of chapter “6 USE OF TOOL SHAPE DATA TRANSFER FUNCTION” is used, and the data of the length or diameter of the tool is empty, the machine parameter to which

it refers with the main spindle and a sub-spindle is different.

Tool shape data transfer function

1. The main spindle

When Tool Length (Check) = Tool (H) = 0, it refers to machine parameter No. 2085.

When Tool Diameter (Check) = Tool (D) = 0, it refers to machine parameter No. 2086.

2. The sub spindle

When Tool Length (Check) = Tool (H) = 0, it refers to machine parameter No. 2089.

When Tool Diameter (Check) = Tool (D) = 0, it refers to machine parameter No. 2088.

Fig. 8-4: Image of spindle model change

MAKINO 0847C-1610 (en)

Page 40

8-4 OTHER FUNCTIONS DIFFERENT IN EACH MACHINE TYPE

8.4 About high-speed attachment specification in iQ300

It automatically changes into the spindle model matched to an effective spindle now in iQ300 (the machine that has a high-speed attachment).

Limitation area of Z axis remains after the switch of the spindle model.

When the tool shape data transfer function of chapter “6 USE OF TOOL SHAPE DATA TRANSFER FUNCTION” is used, and the data of the length or diameter of the tool is empty, the machine parameters to

which it refers are same.

0847C-1610 (en) MAKINO

Page 41

MACHINE PARAMETERS 9-1

9 MACHINE PARAMETERS

The following machine parameters must be set in order to enable 3D crash avoidance function. Note that

only default setting values are listed below.

No. 00076 Tool Radius/Diameter (Check) Type

Description 0:Radius

1:Diameter

Setting Set as desired (Standard setting: 0).

Power Off Required

No. 02064 Reference position of the Z Axis Collision Avoidance Setting Function

Description Sets the Z coordinate in machine coordinates for the reference position of the Z Axis

Collision Avoidance Setting function (unit: mm).

Please set as the distance (negative value) as measured from the spindle gauge line

when machine is in auto zero reference position.

Setting For example Z-600 mm: -600.0

Power Off Not Required

No. 02069 Cancel Conditions of the Z Axis Collision Avoidance Setting Function

Description Defines whether to cancel the Z Axis Collision Avoidance Setting function at NC Reset

or M30.

0: Do Nothing

1: Cancel the function

Setting Standard setting: 0

Power Off Not Required

No. 02070 Coefficient of the Entered Values of the Z Axis Collision Avoidance Setting Function

Description Sets the coefficient of the values for the Z Axis Collision Avoidance Setting Function

entered with S code / T code of the M1404 code.

Setting values vs. coefficients.

0:1

1:0.1

2:0.01

3:0.001

4:0.0001

Setting Standard setting: 0

Power Off Not Required

MAKINO 0847C-1610 (en)

Page 42

9-2 MACHINE PARAMETERS

No. 02073 Status of 3D Crash Avoidance Mode at Power ON

Description Status of 3D Crash Avoidance Mode at Power ON

0: Mode Off

1: Mode On

2: Restore the status which was effective at the last power shut-down

Setting Set as desired (Standard setting: 1).

Power Off Required

No. 02075 Status of 3D Crash Avoidance Mode at NC reset

Description Status of 3D Crash Avoidance Mode at NC reset

0: Mode Off

1: Mode On

2: No change of mode

Setting Set as desired (Standard setting: 2).

Power Off Required

NOTICE! NC reset may be executed automatically with One touch functions etc.

No. 02076 Enable Tool Length (Check) and Radius (Check) Data for 3DC

Description Use or not Tool Length(Check) and Tool Radius(Check) data with 3DC is set.

0: Do not use

1: Use

Setting Standard setting: 0

Power Off Not Required

No. 02077 Enable Tool Length & Diameter Transfer Function for T0 Pot

Description Use or not Tool Length and Diameter Transfer Function for T0 pot is set.

0: Do not use

1: Use

Setting Standard setting: 0

Power Off Required

No. 02081 Existence of tool length / diameter transfer function for 3D Crash Avoidance function

Description 0: Not Effective

1: Effective

Setting (Standard setting: 0)

Power Off Required

0847C-1610 (en) MAKINO

Page 43

MACHINE PARAMETERS 9-3

No. 02085 Tool length value for Collision Check

Description Define the tool length value which is used if the calculated total length of the spindle

tool is 0 for below functions (Set other than 0.)

- Tool Shape Data Transfer Function in Spindle-Table Crash Avoidance Function

- Simplified Tool Setting in Collision Safeguard

Setting For example 100 mm: 100.0

Power Off Required

No. 02086 Tool diameter value for Collision Check

Description Define the tool diameter value which is used if the calculated total diameter of the

spindle tool is 0 for below functions (Set other than 0.)

- Tool Shape Data Transfer Function in Spindle-Table Crash Avoidance Function

- Simplified Tool Setting in Collision Safeguard

Setting For example 100 mm: 100.0

Power Off Required

No. 02088 Tool diameter value for CNC built-in 3-dimensional Crash Avoidance function (Sub spindle)

Description Tool diameter value for CNC built-in 3-dimensional Crash Avoidance function

(Set value other than 0. Regardless of machine’s inch / metric specification, set this

value in mm)

Setting For example 100 mm: 100.0

Power Off Required

No. 02089 Tool length value for CNC built-in 3-dimensional Crash Avoidance function (Sub spindle)

Description Tool length value for CNC built-in 3-dimensional Crash Avoidance function

(Set value other than 0. Regardless of machine’s inch / metric specification, set this

value in mm)

Setting For example 100 mm: 100.0

Power Off Required

No. 02093 Distance Between the Table and the Work in Y Axis Direction

Description Defines the distance between the table and the work in the 3DC Y position setting

function for table collision avoidance.

Set a positive value that contains 0.

Setting Standard setting: 0

Power Off Required

MAKINO 0847C-1610 (en)

Page 44

9-4 MACHINE PARAMETERS

No. 02168 Base Function of Z Axis Collision Avoidance

Description Set in which function Z Axis Collision Avoidance is used.

0: 3D Crash Avoidance

1: Collision Safeguard

Setting Standard setting: 0

Power Off Required

0847C-1610 (en) MAKINO

Page 45

MACHINE ALARMS 10-1

10 MACHINE ALARMS

The machine alarms related to this function are described in this section.

Alarm Number 311000

Alarm Message 3D Crash Avoidance Data Setting Abnormal (Mode)

Alarm Cause 3D Crash Avoidance mode is disabled.

Recovery Procedure Check 3D Crash Avoidance mode.

Alarm Number 311001

Alarm Message 3D Crash Avoidance Data Setting Abnormal (S-Code)

Alarm Cause 3D Crash Avoidance commanded data is abnormal.

Recovery Procedure Check commanded data.

Alarm Number 311002

Alarm Message 3D Crash Avoidance Data Setting Abnormal

Alarm Cause 3D Crash Avoidance data were not set correctly.

Error Codes:

3:Data Number Error. Check data number and correct it.

5:Data Error. Check data and correct it.

6:The option of this function does not exist.

13:Proccess was rejected by CNC.

Recovery Procedure Check data number.

Alarm Number 311003

Alarm Message 3D Crash Avoidance Function Related Settings Change Abnormal

Alarm Cause 3D Crash Avoidance related settings change was not completed in specified

time.

Recovery Procedure Contact the Service Center.

Alarm Number 311007

Alarm Message CNC address setting failure for spindle tool diameter / length transfer

Alarm Cause Setting of the machine parameter No.2066 is incorrect or Focas function for

spindle tool diameter / length transfer address setting has failed. Spindle

tool diameter / length transfer is impossible.

Recovery Procedure Check machine and NC parameter and other settings related to CNC built-in

3-dimensional Crash Avoidance function.

MAKINO 0847C-1610 (en)

Page 46

10-2 MACHINE ALARMS

Alarm Number 311008

Alarm Message Spindle tool diameter / length / wear data for CNC built-in 3-dimensional

Crash Avoidance function reading failure

Alarm Cause Failed to read some of the spindle tool diameter / length / wear data for CNC

built-in 3-dimensional Crash Avoidance function. Due to this failure spindle

tool diameter / length / wear data will not be transferred to the CNC and the

correct execution of the 3-dimensional Crash Avoidance function is not ensured.

Recovery Procedure Verify correctness of diameter / length / wear data of the spindle tool, then

check correct transfer of these data when spindle tool is changed.

Alarm Number 311009

Alarm Message Diameter / length data of CNC built-in 3-dimensional Crash Avoidance func-

tion read-back failure

Alarm Cause Failed to read back immediately after writing some of the diameter / length

data of CNC built-in 3-dimensional Crash Avoidance function. Due to this

failure the correct execution of the 3-dimensional Crash Avoidance function

is not ensured.

Recovery Procedure Verify correctness of diameter / length / wear data of the spindle tool, then

check correct transfer of these data when spindle tool is changed.

Alarm Number 311011

Alarm Message Z Axis Collision Avoidance Setting Failure

Alarm Cause Could not perform settings because the machine was moving.

Recovery Procedure Command again after having confirmed that the machine is stopped.

Alarm Number 311012

Alarm Message Data Reading Failure with the Z Axis Collision Avoidance Function

Alarm Cause Failed to read from CNC some of the data for Z Axis Collision Avoidance

function. Due to this failure the correct execution of the Z Axis Collision

Avoidance function is not ensured.

Recovery Procedure Contact the service center.

Alarm Number 311013

Alarm Message Data Writing Failure with the Z Axis Collision Avoidance Function

Alarm Cause Failed to write from CNC some of the data for Z Axis Collision Avoidance

function. Due to this failure the correct execution of the Z Axis Collision

Avoidance function is not ensured.

Recovery Procedure Contact the service center.

0847C-1610 (en) MAKINO

Page 47

MACHINE ALARMS 10-3

Alarm Number 311015

Alarm Message Data Writing Failure with the 3DC Y Position Setting Function

Alarm Cause Failed to write to CNC some of the data for 3DC Y Position Setting function.

Due to this failure the correct execution of the 3DC Y Position Setting function is not ensured.

Recovery Procedure Contact the service center.

Alarm Number 311027

Alarm Message Z Axis Collision Avoidance Setting Failure

Alarm Cause Could not perform settings because the machine was moving.

Recovery Procedure Command again after having confirmed that the machine is stopped.

Alarm Number 410011

Alarm Message Inch/Metric Status Alarm

Alarm Cause Machine parameter No. 73 is different from the Inch/Metric status (G20/

G21).

Recovery Procedure Check the program.

MAKINO 0847C-1610 (en)

Page 48

10-4 MACHINE ALARMS

0847C-1610 (en) MAKINO

Loading...

Loading...