makino EDGE2 Installation Guide

3UH ,QVWDOODWLRQ *XLGH ('*(

Makino EDGE2

Ram Electrical Discharge Machine

with MGF Control

Pre-Installation Guide

This guide is intended for use by Makino customers and Makino employees and assigns for the safe operation and maintenance of Makino equipment.

This guide was developed through the combined efforts of:

Makino Documentation Group - Mason USA

MBS Associates (Lynne Hays)

Makino Customer Support

1st Release Date: July 20, 2000

Copyright © 2000 Makino, Inc. All Rights Reserved

•No part of this manual may be reproduced or transmitted by any means or in any form to parties other than which it is intended, without the expressed written permission of Makino.

•All specifications and designs may change without notice.

Every attempt was made to ensure that the information in this publication was correct at the time of printing. As specifications and designs change, Makino is not responsible for information that becomes incorrect or inaccurate after publication.

20ED3A1863 (E) |

i |

('*( 3UH ,QVWDOODWLRQ *XLGH

The following icons are used in this document. Safety and precautionary statements are presented as shown below.

A DANGER icon precedes each danger statement. A DANGER icon indicates an existing hazardous condition with a high probability of death or severe injury. Precautions must be taken immediately to prevent personal injury or death.

A WARNING icon proceeds each warning statement. A WARNING icon indicates a potentially hazardous situation with some probability of death or serious injury. Precautions must be taken immediately to prevent personal injury.

A CAUTION icon proceeds each caution statement. A CAUTION icon indicates a potentially hazardous situation with some probability of personal injury or damage to the machine. Precautions must be taken immediately to prevent personal injury or machine damage.

•Precautionary statements must be followed to prevent personal injury or damage to the machine.

•In addition, all safety requirements and guidelines found in Chapter 1 -

Safety, the ANSI safety guidelines the Makino Safety Manual, shipped with the machine, and established company safety requirements and regulations must be followed. Taking personal responsibility for safety will prevent most accidents.

Notes are presented using the following icon format

A NOTE icon indicates information that expands on information given or indicates where additional infromation can be found. Notes are presented immediately following the applicable content.

A copy of the ANSI Safety Manual, ANSI document number ANSI B11.8 was shipped with the machine. If this manual was lost or misplaced, another copy can be obtained from Makino at no charge.

Write us at: |

Call or FAX us at: |

Makino |

Phone: (513) 573-7200 |

P.O. Box 8003 |

ask for Information Services |

7680 Innovation Way |

FAX: (513) 573-7360 |

Mason Ohio, 54040-8003 |

Attn: Information Services |

Attn: Information Services |

|

ii

3UH ,QVWDOODWLRQ *XLGH ('*(

To contact Makino, for service after the sale:

Makino

7680 Innovation Way

Mason, Ohio 45040 USA

Technical Support Services |

(888) Makino4 (625-4664) |

Mon.-Fri. 7:00 a.m. to 8:00 p.m. |

Fax: (513) 459-1825 |

Sat. 8:00 a.m. to 2:00 p.m. (Eastern Standard Time) |

|

|

|

Parts Express |

(888) Makino1 (625-4661) |

24 hours, 7 days a week |

Fax: (888)-881-9289 |

|

|

Training Services |

(888) Makino1 (625-4661) |

The following acronyms and abbreviations are used in this document:

Term |

Meaning |

|

|

APC |

Automatic Pallet Changerwork table (pallet) storage and exchange device |

|

|

ATC |

Automatic Tool Changer - tooling storage and exchange device |

|

|

ccw |

counterclockwise - direction of rotation |

|

|

CNC |

Computerized Numerical Control - control unit for machine tool system |

|

|

cw |

clockwise - direction of rotation |

|

|

DEC |

Deceleration - axis slow down for reference operations |

|

|

DI |

Dielectric (i.e. DI Fluid, DI unit) |

|

|

EOB |

End Of Block - program code at end of each block of data |

|

|

E-Stop |

Emergency Stop - machine condition halting all machine operation |

|

|

FPB |

Flexible Pendant Box - portable control and axis positioning device |

|

|

FSE |

Field Service Engineer - customer service technician |

|

|

LS |

Limit Switch - LS00 = limit switch 00 |

|

|

MDI |

Manual Data Input - operating mode for direct input of NC data |

|

|

MTC |

Machine Tool Cabinet - Cabinet housing main machine electrics/electronics |

|

|

NC |

Numerical Control - input data (i.e. NC program) |

|

|

PM |

Preventive Maintenance - routine maintenance items and checks |

|

|

S/G |

Splash Guard - machining area enclosure |

|

|

SOL |

Solenoid - SOL01 = Solenoid 01 |

|

|

20ED3A1863 (E) |

iii |

('*( 3UH ,QVWDOODWLRQ *XLGH

AVISO!

Las personas que no pueden leer o entender en Ingles deben mandar traducir este manual y solicitar entrenamiento antes de operar o mantener la maquina. Todos los que trabajen en esta maquina deberan saber como operarla con toda seguridad y en forma correcta para evitar un posible dano.

ATTENTION!

Les personnes ne sachant pas lire l'anglais devront se faire lire et expliquer le manuel avant d'utiliser ou de faire l'entretien de la machine. Toute personne travaillant sur la machine doit savoir comment l'utiliser sans danger et correctement afin d'eviter tout accident.

HINWEIS

Alle Personen die nur Teile des Handbuches oder kein Englisch verstenen, müssen sich dieses Handbuch erklären lassen, bevor sie die Maschine in Betrieb nehmen oder instandhalten. Alle Personen, die an der Maschine arbeiten, müssen zur Vermeidung von Verletzungen zur korrekten Handhabung angeleitet werden.

WARNING!

Persons unable to read English or do not understand any part of this guide, must have this guide read and explained to them before operating or maintaining the machine. Everyone working on the machine must know how to operate and maintain it safely and correctly to prevent possible serious injury.

iv

3UH ,QVWDOODWLRQ *XLGH ('*(

CONTENTS

Chapter 1 Safety Precautions

Chapter 2 |

Specifications |

Chapter 3 Installation Process Overview

Chapter 4 Pre-Delivery Preparations

Chapter 5 Machine Delivery

Appendix A Conversion Factors

20ED3A1863 (E) |

v |

('*( 3UH ,QVWDOODWLRQ *XLGH

vi

3UH ,QVWDOODWLRQ *XLGH ('*(

Chapter 1 Safety Precautions

For a Safe Working Environment

Makino EDGE2

Ram Electrical Discharge Machine

with MGF Control

01_20ed3a Safety.fm

('*( 3UH ,QVWDOODWLRQ *XLGH

Chapter 1

Safety Precautions

Contents

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 1.2 General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 1.2.1 Danger, Warning, Caution Statements and Symbols . . . . . . 1 - 2 1.2.2 Access to Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4 1.2.3 Point-of-operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4 1.2.4 Lockout/Tagout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5 1.3 Personal and Professional Safety . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6 1.4 Equipment and Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7 1.5 Environmental Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10 1.6 Lifting Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11 1.6.1 Slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11 1.6.2 Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11 1.6.3 Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12 1.6.4 Eye Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12 1.6.5 Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12 1.6.6 Lifting the Machine or Components . . . . . . . . . . . . . . . . . . . 1 - 13 1.6.7 Lifting Workpieces and Fixtures . . . . . . . . . . . . . . . . . . . . . . 1 - 13 1.7 Mechanical Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14 1.8 Electrical Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15 1.9 EDGE2 Ram Electrical Discharge Machine Safety . . . . . . . . . . . 1 - 16 1.9.1 Fire Hazard and Prevention . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16 1.9.1.1 EDM Fire Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18 1.9.2 Machine Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20 1.9.3 Location of Emergency (E-Stop) Button . . . . . . . . . . . . . . . 1 - 20 1.9.4 Location of Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 21 1.10 EDGE2 Equipment and Operation Safety . . . . . . . . . . . . . . . . . 1 - 23

3UH ,QVWDOODWLRQ *XLGH ('*(

1.11 Installation Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

01_20ed3aSafety.fm

('*( 3UH ,QVWDOODWLRQ *XLGH

NOTES:

SKETCHES:

3UH ,QVWDOODWLRQ *XLGH ('*(

1.1Overview

This chapter provides proven general safety guidelines that, if followed, promote a safer working environment. It also contains safety information specific to the EDGE2.

All machining centers have inherent hazards the manufacturer either designs out, guards against, or warns about. Even though the manufacturer has this responsibility, the machine user has ultimate responsibility to ensure that a safe working environment is maintained in and about the machining center. This includes, but is not limited to, allowing only properly trained and technically qualified personnel program, operate, and maintain the machining center.

It is Makino’s policy and responsibility to design, manufacture, and market machining centers that are as reasonably safe as possible for their intended use.

1.2General Safety

Safety precautions or requirements discussed in Makino guides or manuals do not supersede any safety requirements imposed by local, state, or federal governments. All government-imposed guidelines, i.e. OSHA (Occupational Safety and Health Administration), NEC (National Electric

Code), NFC (National Fire Code), ANSI (American National Standard

Institute) standards, shall take precedence.

To protect against injury or damage operate the machining center within the guidelines described in the provided documentation. Consider

Makino’s safety precautions supplemental to:

•Other Makino supplied guides or manuals related to programming, operation, and maintenance of this specific machining center.

•Your company’s safety rules and regulations.

•All local, state, and federal regulations.

Your particular application may require additional safety measures to ensure proper operator safety.

Additional copies of any guide or manual provided with your Makino machining center may be purchased from Makino.

01_20ed3a Safety.fm |

1 - 1 |

('*( 3UH ,QVWDOODWLRQ *XLGH

Prior To Installation, Operation, or Service,

Do NOT attempt to install, operate, or service this machining center until:

•You have read and understand the safety instructions contained in this guide.

•You have read and understand all Danger, Warning, and Caution safety labels attached to the machining center and its related equipment.

•You have read and understand all technical information, including the following sections of this safety chapter.

Questions Regarding Safe Operation

Before you operate this machine – contact your Makino service group for answers to any questions about safety and your Makino machine.

1.2.1Danger, Warning, Caution Statements and Symbols

It is important that all employees recognize each safety symbol on the machine and understand the meaning of Danger, Warning, and Caution.

These safety labels must never be removed, covered, or painted over, and must be replaced if they are damaged, defaced, or become unreadable.

Table 1-1 presents the meaning of each safety statement. It is important that all employees recognize and understand the meaning of the safety symbols shown in Table 1-2.

The location of safety labels for specific hazards on the EDGE2 is described in section 1.9.4.

1 - 2

3UH ,QVWDOODWLRQ *XLGH ('*(

TABLE 1-1 DEFINITION OF DANGER, WARNING, AND CAUTION STATEMENTS

Statement |

Meaning |

|

|

|

|

DANGER |

DANGER is the most severe safety statement. This statement means |

|

that either severe personal injury or death may result if the instruc- |

||

|

tion(s) is not followed. |

|

|

|

|

WARNING |

WARNING is the next level of safety statement. It indicates that if the |

|

|

instruction(s) is not followed severe personal injury could result. |

|

CAUTION |

A CAUTION is the least severe safety statement and indicates that if |

|

the instruction(s) is not followed damage to the equipment may result. |

||

|

||

|

|

TABLE 1-2 SAFETY SYMBOL SHAPES AND THEIR MEANING

Symbol |

Meaning |

|

|

A triangle or diamond shaped safety symbol indicates a hazard exists in the area or behind the enclosure where the symbol is placed.

The symbol at left indicates an electrical shock hazard exists.

A solid colored circle shaped safety symbol with an icon inside indicates the action shown by the icon is mandatory.

The symbol at left indicates that safety glasses be worn.

A square shaped safety symbol is used to convey information relative to the area where the symbol is placed.

The symbol at left indicates the area is hot.

A circle shaped safety symbol with a diagonal slash across the image indicates the action shown is prohibited in or around that area.

The symbol at left indicates that smoking is not allowed in the area.

01_20ed3a Safety.fm |

1 - 3 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.2.2Access to Information

We strongly recommend that a copy of these safety instructions and all provided guides, manuals, and technical information be kept near the machine. This information should be organized for quick access and used by operators, maintenance, and other personnel with duties related to the machining center.

Access to this information:

•May save a life.

•Will prevent or reduce injury, mis-operation, and machining center damage.

In the event that parts of this information become damaged or unusable, replace them immediately.

1.2.3Point-of-operation

“Point-of-operation” should be safeguarded to the greatest extent possible for all machining operations.

In addition to panel locks, interlocks, and guarding, certain areas of the machining center are color coded for safety. It is important that the original color and vividness of these areas be maintained.

Different operations or applications may make the general purpose safeguards unsuitable and require additional safeguards. You and your company are required to use special safeguards in these situations.

To assist in designing point-of-operation safeguards for specific machining center applications:

•OSHA has published a booklet called OSHA Publication No. 3067.

•Films regarding safety requirements for machine tools are available from ANSI and trade groups such as NMTBA (National Machine Tool Builders Association).

1 - 4

3UH ,QVWDOODWLRQ *XLGH ('*(

1.2.4Lockout/Tagout Procedure

The machining center is powered by high voltage and other energy sources that represent potential hazards. To reduce the risk of injury or death establish, define, and practice a Lockout/Tagout procedure for the equipment in your facility.

Lockout/Tagout defines a minimum safe procedure to be followed by persons who might be confronted with unexpected energizing, start-up, or release of stored energy that could cause injury or death. At a minimum, all Lockout/Tagout procedures should include:

Electrical Shock Hazards Exist - Work Safely

Failure to turn the Main Power disconnect to the Off position, lock it out, and tag it could result in severe personal injury or death.

1.Set the machine’s Main Power switch to the Off position.

2.Affix a DO NOT START tag with your name and department at, on, or near the machine’s Main Power switch, until all repairs are complete.

3.Turn the Main Power disconnect to the Off position.

4.Install an industry approved lockout device through the Main Power disconnect handle.

5.Install a tamper-proof padlock onto the lockout device. All persons performing maintenance on the machine at the same time shall install their own padlock onto the lockout device.

6.Disconnect the main power of all power sources (i.e. electrical, air, hydraulic, etc.).

Use the Lockout/Tagout policy and procedures defined by your company. If no Lockout/Tagout procedure has been communicated to you, please ask your supervisor to provide and explain one or obtain copies of standards to develop and implement Lockout/Tagout in your plant.

•ANSI has issued a standard to assist in the design and development of a Lockout/Tagout policy. It is written as a guide to follow when determining the specific procedures and training necessary and appropriate to your plant operations.

-Copies of the ANSI standard are available from ANSI at 1430 Broadway, New York, NY 10018, ask for: Standard ANSI Z244.1- 1982, or as modified, for personal protection - Lockout/Tagout Of Energy Sources - Minimum Safety Requirements.

01_20ed3a Safety.fm |

1 - 5 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.3Personal and Professional Safety

General safety precautions should be practiced everyday, but never become common place. Safety is the responsibility of every person on the job site. In this regard, consider yourself responsible for safety in your workplace. No one is better positioned to eliminate or prevent unsafe conditions than you. Each employee should practice the following, regardless of their position, title, or labor grade:

•Approach and intercede anytime you witness unsafe procedures.

•Be prepared to report any condition which seems unsafe to your company’s safety department or any supervisory or management staff. It could save lives. In particular report such things as:

-Missing or defective guards and protective devices.

-Leaks and spills of cutting fluid, lubricants, or any liquids.

-Improperly stored chemicals or flammable materials and any unusual fumes.

-Loose, worn, or broken flooring.

-Slippery, broken, or unstable platforms.

-Missing, broken, or unstable handrails.

•Avoid making sudden movements, loud noises, engaging in horseplay, or other activities that may prove distracting and result in an unsafe or dangerous work environment. Remember that around machinery, it only takes a second’s inattention to result in personal injury or death.

•Observe and obey all signs posted on the machinery and its components and signs placed by your company, like:

-NO SMOKING

-SAFETY GLASSES MUST BE WORN WHILE OPERATING THIS

MACHINE

-DANGER - HIGH VOLTAGE, etc.

•Wear appropriate safety equipment as defined by OSHA, the equipment manufacturer, your company safety policy, or MSDS (Material

Safety Data Sheet). Always wear approved eye protection and other safety equipment to meet the demands of current conditions while operating or working around the machining center.

•Clean up any oil or other liquid spills immediately.

1 - 6

3UH ,QVWDOODWLRQ *XLGH ('*(

•Obtain an MSDS for each chemical (such as cutting fluids, lubricating oils, greases, etc.) used on or around the machining center. Practice safe working habits and wear all protective equipment required. Know and understand the procedures to follow in the event:

-Your skin is exposed to the chemical.

-Your eyes are contacted by the chemical.

-You ingested or inhaled the chemical.

1.4Equipment and Operation Safety

We urge that all machining centers be operated, equipped, and cared for in strict compliance with all local, state, and federal safety regulations. The following safety requirements apply to all machinery and should be practiced in addition to machine specific safety guidelines.

•Do not neglect your responsibility to ensure that all machining centers are operated, maintained, and equipped with complete regard for operator safety.

Only qualified personnel, trained in safety and all machining center functions should be allowed to operate, maintain, or repair the machine.

To be considered qualified, all personnel whose duties are related to the operation, maintenance, or repair of the machining center should:

•Know the location and operation of the [EMERGENCY] (E-Stop) button.

•Study the related guides or manuals prior to attempting to operate, maintain, or repair the machine.

•Locate and understand all Danger, Warning, and Caution labels on the machining center and accessories.

Machining centers are designed for operation by one person at a time.

•Persons other than the designated operator should stay out of the area during operation.

•Unauthorized personnel may increase the potential for injury or damage due to inattentiveness.

01_20ed3a Safety.fm |

1 - 7 |

('*( 3UH ,QVWDOODWLRQ *XLGH

Be sure to Always:

•Take steps to protect the machine tool and control cabinets from moisture and condensation. Moisture can damage electrical components, causing unwanted machine motion, leading to injury or machine damage.

•Maintain the exact original color and vividness of any machine areas that are color coded as safety precautions.

•Ensure that all shields and guards are in place and all covers, cabinet doors, and terminal boxes are closed prior to operation.

•Avoid accidentally bumping any machine controls, as this may cause unintended machine motion causing injury or machine damage.

•Be alert for loose, damaged, or worn parts on the machine and associated equipment. Immediately correct or report any loose items, noticeable change in operating noise, or any unusual machine action.

•Be aware of the machine and auxiliary components’ moving members and range of movement which may create pinch points. Always be cautious of these areas. Avoid pinch points entirely during machine operation.

•Keep the machining center properly maintained. Perform maintenance at prescribed intervals, as described in the Mechanical Editions.

Machining center maintenance should be performed only by authorized individuals.

•Check the level of each fluid reservoir periodically. Add fluids, if needed, as described in the Mechanical Editions. Use only recommended lubricants.

•Keep the machining center clean. Keep the work area clear of chips, rags, etc. Clean up any spilled or splashed fluid on the floor immediately. Cleaning should be performed at least daily.

•Double check the set up and workpiece before power up.

•Check all clamp bolts for tightness and verify the accuracy of all set ups before restarting machining operation.

•Use caution when handling workpieces after machining. Machining can produce sharp edges and, at times, considerable heat.

1 - 8

3UH ,QVWDOODWLRQ *XLGH ('*(

You should:

•Never wear loose-fitting clothing or accessories that may be entangled in machine components. In particular, never wear any of the following items when working in a shop environment:

-Jewelry (rings, bracelets, watches, or necklaces) and accessories (necktie, scarf, or loose fitting belt)

-Long hair (tie back and contain it under a hair net or cap)

•Never operate any machinery after taking strong medication, using nonprescription drugs, or consuming alcoholic beverages.

•Do not make modifications to the machine or associated equipment that may reduce the operational safety of the device such as:

-Never paint, alter, deface, or remove any danger, warning, or caution label. (Replacement labels are available from Makino)

-Never change or by-pass the location of the stroke limit dogs, limit switches, interlock circuitry, etc.

-Never operate the machine with any safety device disabled or removed or any cover open or removed

•Do not allow yourself to become trapped or caught in pinch points:

-Always be aware of a safe exit, when in or around any type of equipment. Know the travel limits of the machining center and always keep all body parts clear of moving components.

-Never enter an area restricted by a barrier without first properly shutting down the equipment and locking out the power sources to prevent its restarting.

-Never perform any set up, check the set up, or reach into the work area or across moving parts while the machine is in automatic operation.

-Never change a workpiece or perform a manual operation on a workpiece while the machine is in automatic operation.

•Never activate or press any button or other operating control unless you are trained on the operation of that device, machine, or equipment.

•Never use compressed air to clean or blow chips or dirt off the table, workpiece, or the machining center.

01_20ed3a Safety.fm |

1 - 9 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.5Environmental Safety

Follow these specific practices when working at the machining center:

•The area around the machine should be well lighted, dry, and free from obstructions. Keep the area around the machine clean and in good order at all times.

•Equipment should not be operated during severe thunderstorms or other electrical disturbances.

•In the event of a power failure, turn the Main Power switch Off immediately. Leave the switch in the Off position until the power is fully restored and normal operations can safely be resumed.

•Never step on machine covers as they can become slippery during normal operation and are not designed to support your weight.

•Never perform grinding operations in the vicinity of the machining center. The dust created by grinding can contaminate components, cause premature wear, and cause inaccuracies or component failure.

•Never weld on parts mounted on or in the machine. Electrical currents associated with welding could cause bearing damage or explosions and result in serious injury or equipment damage.

•When a platform is placed around the machining center, it should be extremely sturdy, safe, and have anti-slip surfaces.

•Keep all flammable liquids away from the work area.

1 - 10

3UH ,QVWDOODWLRQ *XLGH ('*(

1.6Lifting Safety

These lifting safety precautions must be followed by all persons responsible for lifting. This includes, but is not limited to, lifting machinery, machine components, and workpieces:

•All lifting equipment must be properly rated for the weight being lifted.

•All lifting equipment must be inspected on a regularly scheduled basis.

•Any lifting device found to be defective must be repaired in accordance with industry standards.

•Any lifting device that cannot be repaired must be destroyed.

1.6.1Slings

Use nylon slings when lifting irregularly shaped objects and:

•Never exceed the lifting capacity of any sling.

•Protect slings with heavy padding when lifting objects with sharp edges.

1.6.2Chains

Lifting chains must be stored properly to prevent damage when not in use.

When using chains:

•Never exceed the lifting capacity of any chain.

•Do not drag chains.

•Do not allow chains to become tangled or kinked.

•Never twist chains in an attempt to shorten their length. Use proper devices to shorten a chain’s length.

•Use chains equipped with enclosed lifting hooks.

01_20ed3a Safety.fm |

1 - 11 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.6.3Hooks

When using hooks:

•Never exceed the lifting capacity of any lift hook.

•Do not repair lifting hooks.

•Destroy and discard bent lifting hooks.

1.6.4Eye Bolts

To ensure a safe load carrying capacity:

•Never exceed the lifting capacity of any eye bolt.

•An eye bolt must be engaged to at least 90 percent of its threaded portion.

•Never weld or heat an eye bolt to a temperature in excess of 480° C

(900° F). Heat exposure can change the physical properties of the stock and create an unsafe eye bolt.

•Never use an inch eye bolt in a metric thread or vice versa:

-Use inch series thread eye bolts in inch series threads.

-Use metric series thread eye bolts in metric series threads.

•Never use a painted or coated eye bolt as this may cover up defects.

•Discard and destroy any defective eye bolts.

1.6.5Rings

When possible use a lifting ring or clevis instead of an eye bolt. Secure the lifting ring with the correct inch/metric series bolt.

•Never exceed the lifting capacity on any lifting ring or clevis.

1 - 12

3UH ,QVWDOODWLRQ *XLGH ('*(

1.6.6Lifting the Machine or Components

Use only a lifting device and related equipment that is capacity rated to lift the total weight of the machining center (and shipping skid, if the skid is attached during lifting). Always follow the lifting instructions provided in the Pre-Installation Guide.

Before lifting, refer to shipping documents to obtain the weight of the machine or component being lifted. If the necessary weights cannot be determined, consult Makino. In addition:

•Only qualified riggers should perform machine lifting operations.

•Never place any portion of your body beneath a suspended object.

•Lift the machining center only at the designated lifting points.

•Never lift the machine higher than necessary.

•Always maintain the center of gravity by properly adjusting the leg lengths of the lifting device.

1.6.7Lifting Workpieces and Fixtures

Always use a lifting device and related lifting equipment that is capacity rated for the workpiece or fixture being lifted.

•Never place hands, arms, feet, or any other portion of your body beneath a suspended workpiece fixture.

•Always maintain the center of gravity by properly adjusting the leg lengths of the lifting device.

01_20ed3a Safety.fm |

1 - 13 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.7Mechanical Maintenance Safety

Mechanical maintenance procedures for Makino machining centers should be performed by properly trained and technically qualified personnel. They should adhere to these specific practices when working with the machining center:

•Always perform Lockout/Tagout before removing any safety guard, cover, barrier, or any basic component of the machining center. See section 1.2.4.

•Block vertical sliding members before disassembling any portion of their drive train.

•Be familiar with and adhere to safe lifting practices described in section 1.6 before lifting the machine or components.

•Never return the machining center to production until all safety guards, covers, barriers, or other safety devices are reinstalled and confirmed operational.

Mechanical Maintenance Equipment

Mechanical maintenance personnel should:

•Keep all hand tools in good repair.

•Use each hand tool in a manner for which it is intended.

•Never use any hand tool that is defective, broken, or worn out.

•Keep alert with regard to nearby hazards.

•Do not use extenders in an effort to gain leverage; use a bigger tool.

1 - 14

3UH ,QVWDOODWLRQ *XLGH ('*(

1.8Electrical Maintenance Safety

Electrical maintenance procedures for Makino machining centers must be performed by properly trained and technically qualified personnel. They should adhere to these specific practices when working with the machining center:

•Always perform Lockout/Tagout before working on electrical circuits. See section 1.2.4.

•Use extreme care when troubleshooting with power On.

•With the power Off, identify and discharge any power retaining devices, such as capacitors, before starting any maintenance procedure within any electrical control cabinet.

Electrical Maintenance Equipment

Use only industry standard approved electrical testing equipment.

•Volt/Ohm Meters.

•Oscilloscopes.

•Static Ground Wrist Straps.

Machine Grounding

All Makino machining centers must be properly grounded at the time of installation.

•JIS class 3 grounding (resistance of 100 Ohms or less) is recommended.

•Proper grounding requires an isolated earth ground.

•Ground the machine in accordance with local, state, and federal regulations.

Machine Electrical Devices

Always replace defective electrical components, such as fuses, shunts, overloads, etc., with components of the same capacity and rating as the original equipment. If you are unsure of the correct electrical component or part, refer to the machine’s electrical drawings or consult Makino.

01_20ed3a Safety.fm |

1 - 15 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.9EDGE2 Ram Electrical Discharge Machine Safety

In addition to safety precautions for all machining operations, Become familiar with the machine specific safety features listed below.

1.9.1Fire Hazard and Prevention

Fire Hazard

RAM type EDM uses a dielectric fluid in the machining process. This fluid is flammable and may ignite, if improperly applied.

All Makino RAM machines are provided with the following fire related safety features:

1.Dielectric Temperature Detector – to immediately stops the machining process when the temperature of the dielectric fluid rises above a set value of 53°C.

2.Dielectric Level Detector – to immediately stops the machining process when the dielectric level falls below the set level. The set level must be at least 50mm above the workpiece.

3.Abnormal Machining Detector – stops the machining process if an arc occurs for an extended duration. During an arc the head retracts to clear the problem. If the head retracts beyond a specified distance, machining stops and an “abnormal machining” alarm is generated.

4.Automatic Fire Extinguisher – If the dielectric fluid catches fire a sensor detects the temperature rise and discharges the extinguishing agent into the work area. Additionally, all machine functions stop and an audible alarm sounds. To resume machining operations, you must change filters and dielectric fluid to remove the extinguishing agent. Do

NOT remove or change the positions of the fire extinguisher sensor(s) or jet nozzle(s).

1 - 16

3UH ,QVWDOODWLRQ *XLGH ('*(

Be sure to Always:

•Keep all fire extinguishers fully maintained and operational and train all personnel in their proper use.

•Ensure the automatic fire extinguisher is fully operational. Perform a functional test at the prescribed intervals. Never operate the machine with the fire extinguisher testing knob in the "LOCK" position.

•Install additional fire extinguishers of a type for liquid applications in the work area.

•Fully ventilate the work area at all times.

•Pay attention to the mounting method of the electrode, workpiece and fixture so that electrical discharge does not occur near the surface of the dielectric.

•Monitor the machining process. Never leave the machine totally unattended for extended periods of time. Allocate workers in such a manner that necessary measures can be taken if a problem occurs or if a fire arises.

•Use only approved dielectric fluids.

You Should Never:

•Never substitute any other flammable liquids, such as kerosene for dielectric fluid.

•Never use fire or heat sources such as heaters, welding machines or open flame, near the machine.

•Never machine with fluid only being jetted onto the workpiece.

•Never machine with less than 50mm of dielectric fluid covering the workpiece.

01_20ed3a Safety.fm |

1 - 17 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.9.1.1EDM Fire Conditions

The following conditions may result in fire during machining operations (Figure 1-1).

1.Fire hazard caused by spraying dielectric fluid onto workpiece. Workpiece should be submerged in the dielectric fluid to ensure safe burning.

2.Fire hazard from machining without enough dielectric fluid covering the workpiece. Dielectric level must be 50mm above the top of the workpiece.

3.Fire hazard from machine platen contacting a clamp. Ensure moving machine members will clear clamps, workpiece, and fixturing.

4.Fire hazard due to arcing between shank and electrode. This is caused if the electrode becomes loose or is improperly mounted.

5.Fire hazard due to carbon build up is caused by a combination of too little dielectric fluid covering the part and arcing.

6.Fire hazard can be caused by concave electrode shape (not shown), as gas can collect in cavity. Ensure a vent hole is drilled at the high point of the cavity.

1 - 18

3UH ,QVWDOODWLRQ *XLGH ('*(

Legend

[1] |

Electrode |

|

|

[2] |

Jet Nozzle |

|

|

[3] |

Workpiece |

|

|

[4] |

Table |

|

|

[5] |

Dielectric |

|

|

[6] |

Clamp |

|

|

[7] |

Shank |

|

|

FIGURE 1-1 EDM FIRE CONDITIONS

01_20ed3a Safety.fm |

1 - 19 |

('*( 3UH ,QVWDOODWLRQ *XLGH

1.9.2Machine Safety Features

The EDGE2 provides the following safety features:

•[EMERGENCY] button, to immediately halt all machine functions.

•Automatic Fire Extinguisher and other fire related equipment, see section 1.9.1 (pg 1-16).

Descriptions, operational detail, and precautions related to these safety features are described in the Operation Guide.

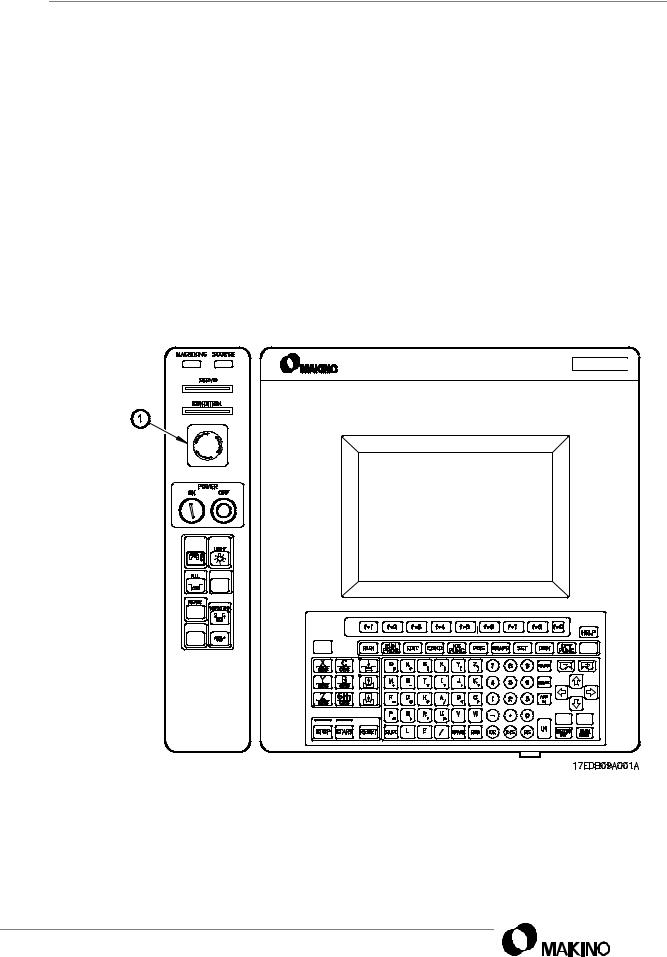

1.9.3Location of Emergency (E-Stop) Button

The [EMERGENCY] button [1] is on the Main operation panel (Figure 1-2).

MGF

FIGURE 1-2 EMERGENCY BUTTON LOCATION

1 - 20

Loading...

Loading...