Page 1

{

o

VERTICAL

MAKINO

MACHINING

INSTALLATION

CENTER

MANUAL

V1431I-I1E-XB

WARNING

/h

Do

1.

and

2.

Store

maintaining,

This

machine,

the

Japanese

retransfer

sell,

obtain

i

any

maintain,

not

understanding

this

manual

including

Foreign

or

required

inspect

this

a

in

inspecting

technical

Exchange

re-export

authorization

repair

or

manual.

clearly

or

repairing

and

of

controlled

this

marked

data

Foreign

or

approval.

machine

location

this

and

items,

for

machine.

software,

Trade

please

before

easy

may

Law.

contact

carefully

reference

subject

be

Prior

to

Makino

reading

when

to

any

re¬

to

Page 2

Installation

Manual

Fi/FI>

MACHINE

MODEL

CONTROLLER

COMPANY

manual

This

necessary

is

pre-installation

NAME

developed

TYPE

of

use

the

for

arrangements

Makino

for

F-Series

F3/F5

Professional

help

customers

machine.

to

5

and

guideinmaking

all

Release

1st

Revision(s)

Copyright

No

•

•

•

part

parties

to

Makino.

All

specifications

Every

at

for

attempt

the

time

information

Date:

©

of

Date:

this

other

of

August

26

-

manual

than

and

made

was

printing.

that

becomes

2009

All

Rights

may

be

whichitis

designs

ensure

to

specifications

As

incorrectorinaccurate

Reserved

reproduced

intended,

change

may

that

or

without

without

the

designs

and

transmitted

the

expressed

notice.

information

change,

after

by

any

means

written

publication

this

in

Makino

publication.

in

or

permission

was

is

not

responsible

any

correct

form

from

V1

431

1-11

E-XB

2

Page 3

)

)

Page 4

Installation

Contents

Manual

Fl/FS

1.

Introduction

1.1

Machine

Components

1

.2

Safety

2.

Introduction

2.1

Danger,

2.2

2.3

Installation

Specifications

3.

3.1

Introduction

3.2

Mechanical

3.3

Makino

3.4

General

Tooling

3.5

Pre

4.

Installation

Introduction

4.1

Characteristics

Precautions

Warning,

Safety

and

Professional

View

Specification

Process

Machine

and

Caution

Electrical

Dimensional

and

Function

Statements

Specification

and

5

Control

and

Specifications

Drawings

Symbols

5

5

5

6

6

6

9

12

12

13

16

19

30

31

31

Selecting

4.2

4.3

Foundation

4.4

Floor

Plan

Power

4.5

4.6

Transformer

Earthing/Grounding

4.7

4.8

Air

4.9

Machine

4.10

Service

Toolings

4.1

1

Coolant

4.12

4.13

Oil

4.14

Machine

4.15

Cables

Installation

4.16

Supply

Supply

Facilities

Requirements

Grease

and

for

Machine

the

Marking

and

and

(Option)

Handling

and

Fixtures

Requirements

and

Data

direct

Tooling

Location

Cables

Preparations

Facilities

server

communication

connection

Requirements

to

a

computer

FSE)

(By

without

a

network

HUB

31

33

34

34

36

37

37

38

38

38

55

55

56

57

58

4.17

Pre-Installation

V1431I-I1E-XB

Checklist

60

3

Page 5

Installation

Manual

F3/FIS

5.

Machine

5.1

5.2

5.3

5.4

5.5

5.6

Installation

6.

6.1

Delivery

Introduction

Container

Inspect

Unloading

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

Initial

Machine

Layout

the

Lifting

Lifting

Lifting

Lifting

Lifting

Lifting

Machine

Cleaning

Packing

Process

Introduction

Machine

and

the

Machine

the

Front

Chip

the

the

Rear

the

Transformer

Rolling

list

Moving

Coolant

Conveyor

tank

tank

64

65

65

66

66

66

69

70

71

72

73

75

.

75

76

76

6.2

6.3

6.4

6.5

6.6

6.7

General

Instructions

Installation

6.3.1

Installation

6.3.2

Installation

6.3.3

Installation

Installation

6.3.4

6.3.5

Installation

6.3.6

Installation

Procedure

Installation

Installation

Installation

conveyor

Process

ATC

of

Spindle

of

of

Transformer

Z

of

Z

of

Air

of

Machine

for

Procedure

Procedure

Procedure

covers

Oil

Cooler

axis

motor

Cable

axis

Dryer

forSSeries

for

for

(Option)

Leveling

Rear

Rear

chain

Coolant

coolant

coolant

tank

tank

tank

with

with

chip

hinge

bucket

(option)

belt/scrapper

.

Lift

up

76

76

76

78

84

85

86

87

93

95

97

chip

99

V1

431

1-11

E-XB

4

Page 6

Installation

1.

Introduction

Manual

Fi/FS

1.1

F-Series

rigidity

machining

The

achieved

axes

with

faster

operations

1.2

F-Series

which

servomotors:

•

•

•

•

•

•

•

Machine

machines

built

efficiency

main

characteristic

by

acceleration,

high

speed

ATC

Components

machines

machine

X-Axis,

The

moves

The

The

mounted

The

20000

Viewed

magazine

The

The

left

Y-Axis

Z-Axis,

spindle

rpm)

from

chip

electrical

accessible

neatly

routed

Characteristics

are

the

versatile

on

high

and

proven

speed,

and

special

design

especially

features

GI.3

sustainable

high

power

and

3-axis

are

are

comprised

an

which

and

carries

whichishousedonX-axis

the

to

is

with

the

on

disposal

locations

is

right.

the

Z-axis.

high

of

power

machine

left

the

istothe

cabinet,

the

into

table

speed

of

side

oilmatic,

the

at

column.

concepts

for

of

and

inter-plane

Makino

Machine

Vertical

bed,

of

integrated

and

with

22kW.

front,

the

and

chip

rear

Vertical

the

Die

machine,

the

SGI

machining

Professional5Control

Machining

achieve

to

Mold

and

Control,

geometrical

and

industry.

which

high

also

Function

Machining

column,

unit,

isonthe

moves

maximum

a

is

the

NC

operator

bucketatthe

hydraulic

and

side

Centers

and

the

comprises

moves

bed,

up

spindle

control

door

and

of

panel

is

front

pneumatic

machine.

the

of

and

at

tank,

Centers

productivity

high

contributes

rapid

axes

accuracy,

reducing

functions

of

fixed

Z

Y,

X,

the

the

Z-axis

back

down.

speed

on

center.

into

systems

The

axes

and

of

the

the

with

to

traverse

reducing

non

the

column

are

and

forth.

spindle

The

12000

right

130t

are

cable

high

and

high

productivity

cutting

for

type,

driven

the

rpm

side

and

front

located

and

hoses

reliability

high-speed

high

and

rates

cutting

simultaneous

the

by

spindle,

housing

(optionally

ATC

coolant

time

at

time

units

is

tank.

easily

are

and

are

with

of

V1

431

1-11

E-XB

5

Page 7

Page 8

Installation

Manual

Fi/FS

2.1

Introduction

chapter

This

environment.

Safety

thoroughly

personal

order

installing

Designate

personnel

strongly

everyone

2.2

precautions

understood

injury

to

install

this

specific

involvedinthe

recommended

and

Danger,

provides

and

and

the

machine

machine.

operators

kept

also

Warning,

Safety

2.

general

special

the

by

machine

operation,

that

near

safety

considerations

operator.

damage.

safely.

this

of

copy

a

the

of

machine

Caution

Precautions

guidelines

Careless

Read

Study

machine

maintenance

this

at

that,

if

all

for

use

pre-installation

this

safety

all

provide

and

and

Pre-Installation

all

times.

Statements

followed,

machining

of

precautions

thorough

inspection

Manual

the

and

promote

machine

Symbols

a

operations

may

Manual

and

functions

safety

this

of

easily

is

working

safer

must

result

thoroughly

before

training

machine.

accessible

for

in

It

be

a

in

all

is

to

important

is

It

understand

These

replaced

meaning

understand

hazards

safety

if

of

on

that

meaning

the

labels

they

are

each

meaning

the

F-Series

employees

all

of

must

damaged,

safety

of

is

shown

Danger,

never

statement.

the

be

defaced,

safety

Figure

in

recognize

Warning,

removed,

or

important

is

It

symbols.

2.1.

each

Caution.

and

covered

become

The

that

symbol

painted

or

all

of

safety

unreadable.

location

the

on

over,

Table

employees

safety

symbols

machine

and

presents

2.1

recognize

for

must

and

specific

and

be

the

V1

431

1-11

E-XB

6

Page 9

Installation

Manual

(!

Fi/F

*<c

-ÿO

<1

\

7ÿ

3

1

<

v

!

<ÿ

\

<£>

((

\

1

&

2

IP

Hr

s

\

;

#|

/ÿ

K

v

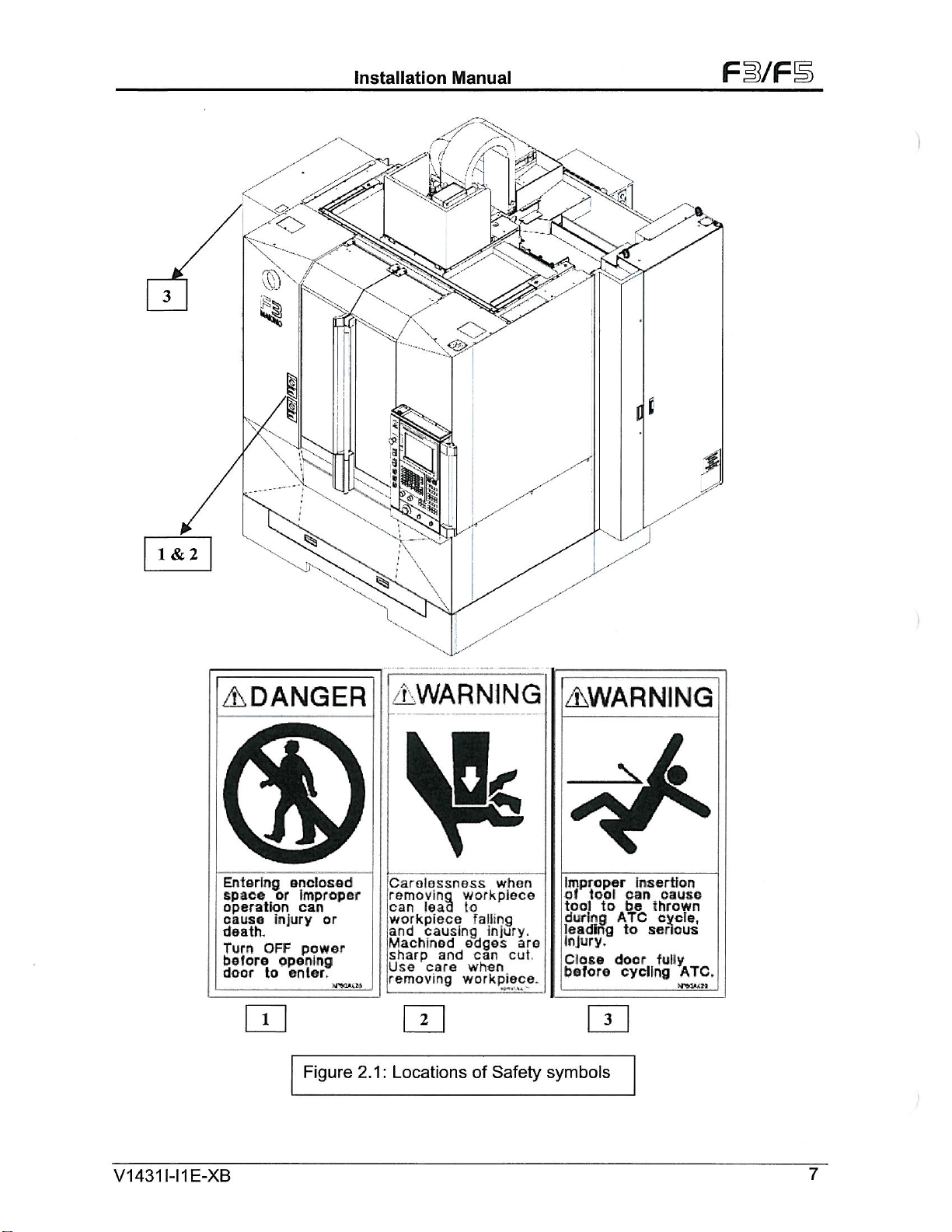

zKWARNING

zhWARNING

V1

431

1-11

®

Enterlng

E-XB

space

operation

oauso

death.

Turn

before

door

OFF

to

m

or

injury

opening

enclosed

improper

can

or

power

enter,

Figure

N>s

aro

Improper

tool

of

tool

during

leading

Injury.

Close

before

_

m

symbols

to

door

Carelessness

removing

can

workpiece

and

Machined

sharp

Use

removing

Locations

2.1:

lead

causing

care

ra

workpiece

and

workpiece.

to

falling

injury.

odges

can

when

of

whon

cut.

Safety

Insertion

can

be

ATC

to

cycling

cause

thrown

cycle,

serious

fully

>rwwa

ATC.

7

Page 10

Installation

Manual

F3/F!

Table

Statement

DANGER

WARNING

CAUTION

2.3

The

•

•

2.1:

Installation

following

Adhere

Make

.

installation

and

the

arrival

Definitions

Meaning

DANGER

means

instruction(s)

WARNING

the

result.

CAUTION

the

result.

information

strictly

thorough

a

the

of

Danger,

of

is

the

that

either

is

is

the

instruction(s)

_

the

is

instruction(s)

_

Safety

relatedtoinstallationofthe

is

installation

the

to

make

of

sure

check

to

machine.

Warning

most

severe

followed.

not

next

is

not

least

not

is

instructions

mechanical

the

that

&

severe

personal

level

followed

severe

followed

they

Caution

safety

_

safety

of

safety

and

working

are

statements

statement.

injury

statement.

severe

statement

damage

machining

provided

electrical

in

death

or

personal

to

the

in

units

good

statement

This

may

result

indicates

It

injury

indicates

and

the

equipment

center:

Pre-Installation

used

for

safe

conditions,

and

the

if

if

that

could

that

if

may

Guide.

machine

moving

before

Lifting

All

persons

but

is

not

All

•

All

•

Any

•

standards.

Slings

When

Never

•

Protect

•

Chains

Lifting

chains:

Never

•

Do

•

Do

•

Never

•

Use

•

Use

•

Safety

limited

lifting

lifting

lifting

using

exceed

slings

chains

exceed

drag

not

allow

not

twist

proper

chains

lifting

found

lifting

heavy

be

lifting

in

for

machinery,

must

must

stored

to

an

responsible

to

equipment

equipment

device

slings:

the

with

must

the

chains.

chains

chains

devicestoshorten

equipped

with

lifting

properly

be

inspected

be

to

be

capacity

padding

properly

capacity

become

attempt

enclosed

follow

must

machine

defective

any

of

when

any

of

tangled

shorten

to

chain's

a

rated

on

prevent

to

or

lifting

these

must

sling.

lifting

lifting

components,

the

for

a

regularly

be

objects

damage

chain.

kinked.

length.

their

length.

hooks.

safety

and

weight

scheduled

repaired

with

when

precautions.

work

being

lifted.

basis.

in

accordance

sharp

edges.

not

pieces:

use.

in

This

with

When

includes,

industry

using

Hooks

When

Never

•

Do

•

Destroy

•

431

V1

using

exceed

not

1-11

E-XB

hooks:

repair

and

lifting

the

lifting

discard

capacity

hooks.

bent

lifting

any

of

hooks.

lifting

hook.

8

Page 11

Eye

To

ensure

Never

An

•

Never

•

exposure

eyebolt.

Never

•

Use

•

Use

•

Never

•

Discard

•

Rings

When

When

•

Secure

•

Never

•

Bolts

exceed

eyebolt

inch

metric

using

a

safe

the

must

weld

or

can

use

an

series

series

use

a

painted

and

destroy

rings:

possible

the

lifting

exceed

load

lifting

be

heat

change

inch

thread

thread

use

ring

the

lifting

carrying

capacity

engaged

eyebolt

an

the

eye

bolt

eyebolts

eyebolts

or

coated

any

defective

a

lifting

with

capacity

Installation

capacity:

of

any

least

to

at

to

physical

metric

a

in

inch

in

in

eyebolt

eyebolts.

clevis

or

ring

the

correct

on

Manual

eyebolt.

90

percent

a

temperature

properties

thread

series

metric

any

series

as

this

instead

inch/metric

lifting

of

of

or

vice

threads.

threads.

may

cover

of

an

series

ring

or

its

excess

in

the

versa.

eyebolt.

bolt.

clevis.

threaded

of

stock

up

and

defects.

portion.

480°C

create

Fl/FS

(900°F).

an

Heat

unsafe

Machine

Whenaelectrical

Use

•

Always

•

components

If

•

electrical

Machine

All

Makino

Proper

•

Ground

•

Lifting

Use

machining

the

lifting

the

Only

•

Never

•

Lift

•

Never

•

Always

•

Electrical

only

you

Grounding

the

only

a

instructions

qualified

the

industry

replace

are

unsure

drawings

machining

grounding

the

machineinaccordance

Machine

lifting

center

place

machining

the

lift

maintain

Devices

devicesisused:

standard

defective

of

the

same

of

or

centers

requires

or

device

(and

provided

riggers

any

portion

center

machine

the

electrical

capacity

the

consult

Components

and

related

shipping

should

of

only

higher

center

approved

correct

Makino.

must

isolated

an

this

in

perform

your

at

than

gravity,byproperly

of

electrical

components,

rating

and

electrical

properly

be

earth

local,

with

equipment

skid,

if

the

pre-installation

machine-lifting

body

beneath

designated

the

necessary.

testing

as

the

componentorpart,

grounded

ground.

state,

with

skidisattached

suspended

a

lifting

equipments.

fuses,

like

original

at

and

capacity,

rated

guide.

operations.

points.

adjusting

shunts,

equipment.

the

time

federal

during

In

addition:

object.

the

overloads,

refer

to

of

installation.

regulations.

the

to

lift

lifting).

lengths

of

the

machine's

total

Always

lifting

etc.,

with

weight

follow

device.

of

B

V1

431

Before

machine

determined,

E-XB

1-11

lifting,

or

refer

component

consult

Makino.

to

shipping

being

documents

lifted.

If

the

to

obtain

necessary

the

weight

weights

of

cannot

the

be

9

Page 12

Installation

Manual

F3/F5

Lifting

Always

work

piece

Never

•

work

Always

•

device.

Work-pieces

use

lifting

a

or

fixture

place

piece

fixture.

maintain

Always

certified

hands,

display

first

and

device

being

arms,

the

center

Aid

Fixtures

and

lifted.

feet,

emergency

the

available

Kit

related

or

gravity

of

lifting

any

equipment

other

properly

by

contact

the

near

portion

adjusting

numbers

machine

that

of

your

isofrated

body

beneath

lengths

the

the

near

and

easily

capacity,

suspended

a

the

of

machines.

accessible.

for

the

lifting

Keep

a

V1

431

1-11

E-XB

10

Page 13

)

)

Page 14

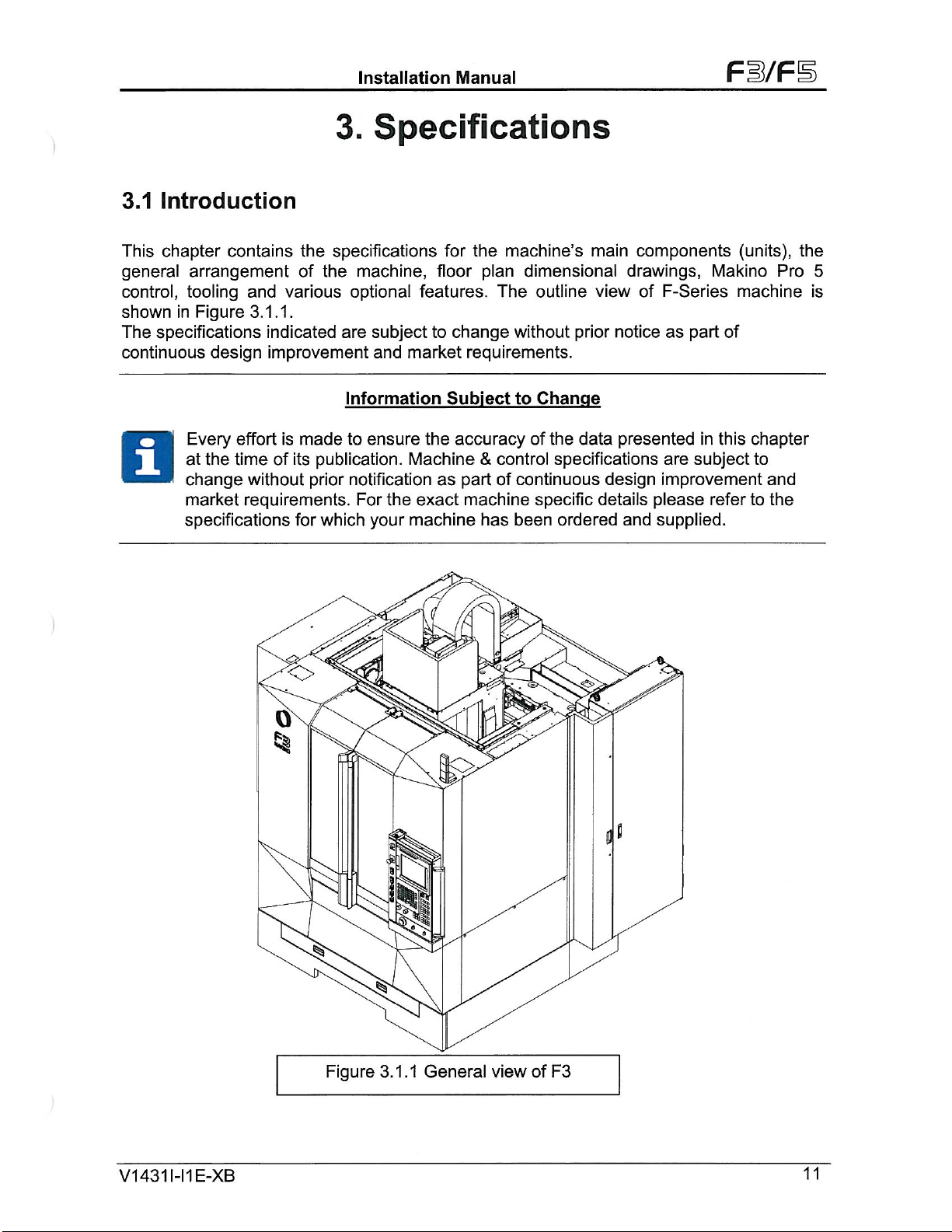

3.1

Introduction

Installation

Specifications

3.

Manual

Fi/FS

chapter

This

general

control,

shown

The

continuous

arrangement

tooling

Figure

in

specifications

Every

at

change

market

specifications

contains

and

3.1.1.

design

effort

the

timeofits

without

requirements.

specifications

the

machine,

the

of

various

indicated

improvement

is

made

for

optional

are

Information

to

publication.

prior

notification

For

which

<>

subject

market

and

ensure

Machine

the

machine

your

for

floor

features.

change

to

requirements.

Subject

accuracy

the

as

part

machine

exact

the

machine’s

plan

The

&

control

of

has

main

dimensional

outline

without

to

continuous

been

prior

Change

the

of

data

specifications

specific

ordered

•ÿ5

components

drawings,

view

of

notice

presented

design

details

and

Makino

F-Series

part

as

are

improvement

please

supplied.

machine

of

this

in

subject

refer

(units),

Pro

chapter

to

and

to

the

the

5

is

O

Jr

Figure

J'

3.1.1

General

view

of

J

F3

1431

V

1-11

E-XB

11

Page 15

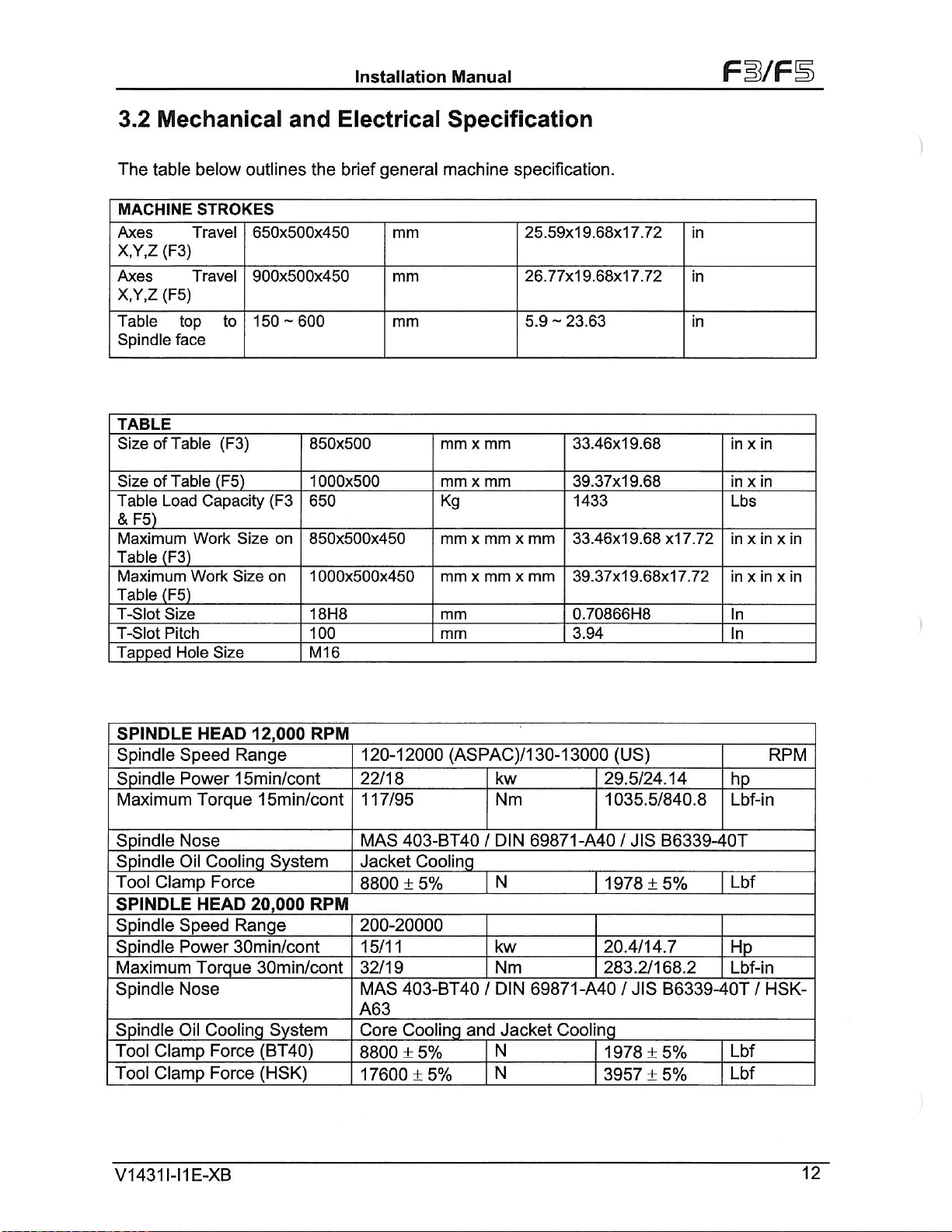

3.2

Mechanical

and

Installation

Electrical

Manual

Specification

Fl/F

The

table

MACHINE

Axes

X,Y,Z

(F3)

Axes

X,Y,Z

(F5)

Table

of

Table

of

Load

_

(F3)

(F5)

Size

Pitch

top

face

Hole

Table

Spindle

TABLE

Size

Size

Table

&F5)

Maximum

Table

Maximum

Table

T-Slot

T-Slot

Tapped

below

STROKES

Travel

Travel

Work

_

Work

outlines

to

(F3)

(F5)

Capacity

Size

Size

_

Size

the

brief

650x500x450

900x500x450

150-600

850x500

1000x500

650

(F3

on

850x500x450

on

1000x500x450

18H8

100

M16

general

mm

mm

mm

machine

mmxmm

mmxmm

Kg

mmxmmxmm

mmxmm

mm

mm

specification.

25.59x19.68x17.72

26.77x19.68x17.72

5.9

mm

x

23.63

-

33.46x19.68

39.37x19.68

1433

33.46x19.68

39.37x19.68x17.72

0.70866H8

3.94

in

in

in

x17.72

x

in

in

inxin

Lbs

inxinxin

in

xinx

in

In

In

SPINDLE

Spindle

Spindle

Maximum

Spindle

Spindle

Clamp

Tool

SPINDLE

Spindle

Spindle

Maximum

Spindle

Spindle

Tool

Clamp

Tool

Clamp

V1

431

1-11

HEAD

Speed

Power

Torque

Nose

Cooling

Oil

Force

HEAD

Speed

Power

Torque

Nose

Cooling

Oil

Force

Force

E-XB

12,000

Range

15min/cont

15min/cont

System

20,000

Range

30min/cont

30min/cont

System

(BT40)

(HSK)

RPM

RPM

120-12000

22/18

117/95

MAS

403-BT40

Jacket

8800

Cooling

5%

+

200-20000

15/11

32/19

403-BT40

MAS

A63

Cooling

Core

±

8800

17600

5%

+

5%

(ASPAC)/1

kw

Nm

DIN

/

N

kw

Nm

DIN

/

and

Jacket

N

N

30-1

69871

69871

Cooling

3000

(US)

29.5/24.14

1035.5/840.8

-A40

/

JIS

1978

20.4/14.7

283.2/168.2

-A40

/

JIS

1978

3957

B6339-40T

+

5%

B6339-40T

±5%

5%

+

hp

Lbf-in

Lbf

l

HR

Lbf-in

Lbf

Lbf

RPM

/

HSK-

12

Page 16

Installation

Manual

Fi/F

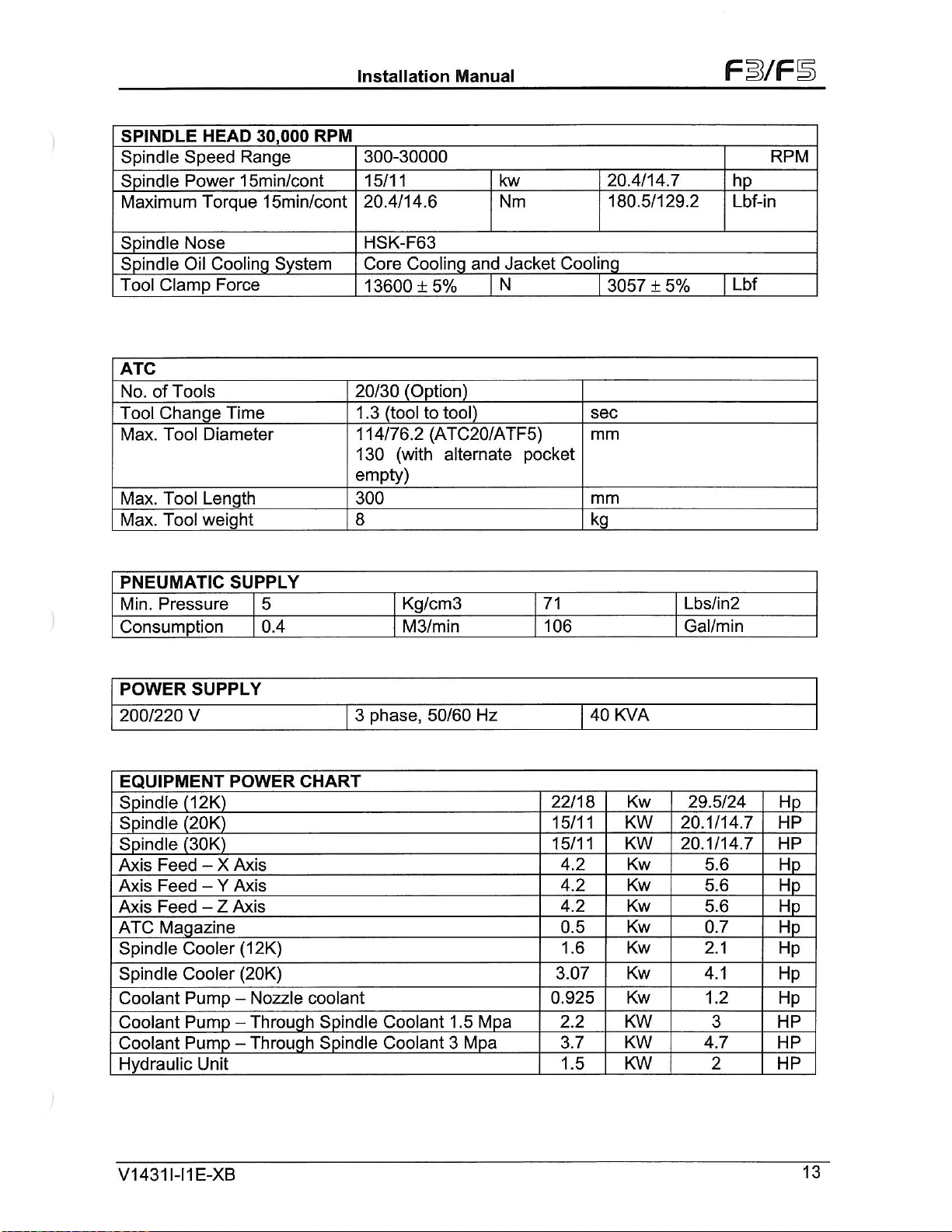

SPINDLE

Spindle

Spindle

Maximum

Spindle

Spindle

Tool

ATC

HEAD

Speed

Power

Torque

Nose

Oil

Clamp

No.ofTools

Change

Tool

Tool

Max.

Max.

Max.

PNEUMATIC

Min.

Consumption

Diameter

Length

Tool

weight

Tool

Pressure

30,000

Range

15min/cont

Cooling

Force

Time

SUPPLY

RPM

15min/cont

System

5

0.4

300-30000

15/11

20.4/14.6

MSK-F63

Cooling

Core

13600

20/30

1

.3

114/76.2

130

empty)

300

8

±5%

(Option)

(tooltotool)

(with

_

Kg/cm3

M3/min

kw

Nm

Jacket

and

IN

(ATC20/ATF5)

alternate

pocket

Cooling

71

106

20.4/14.7

180.5/129.2

3057

l

+

sec

mm

mm

k£L

5%

Lbs/in2

Gal/min

hp

Lbf-in

Lbf

l

RPM

POWER

200/220

EQUIPMENT

Spindle

Spindle

Spindle

Axis

Axis

Axis

ATC

Spindle

Spindle

Coolant

Coolant

Coolant

Hydraulic

SUPPLY

V

(12K)

(20K)

(30K)

Feed

-

-

Feed

-

Feed

Magazine

Cooler

Cooler

Pump

Pump

Pump

Unit

POWER

Axis

X

Axis

Y

Z

Axis

(12K)

(20K)

-

Nozzle

Through

-

Through

-

|

CHART

coolant

Spindle

Spindle

3

phase,

50/60

Coolant

Coolant

1

3

.5

Mpa

Hz

Mpa

22/18

15/11

15/11

4.2

4.2

4.2

0.5

1.6

3.07

0.925

2.2

3.7

1.5

40

KVA

Kw

KW

KW

Kw

Kw

Kw

Kw

Kw

Kw

Kw

KW

KW

KW

29.5/24

20.1/14.7

20.1/14.7

5.6

5.6

5.6

0.7

2.1

4.1

1.2

3

4.7

2

Hp

HP

HP

HR

HP

HR

HR

Hp

Hp

Hp

HP

HP

HP

V1431I-I1E-XB

13

Page 17

Installation

Manual

Fi/F

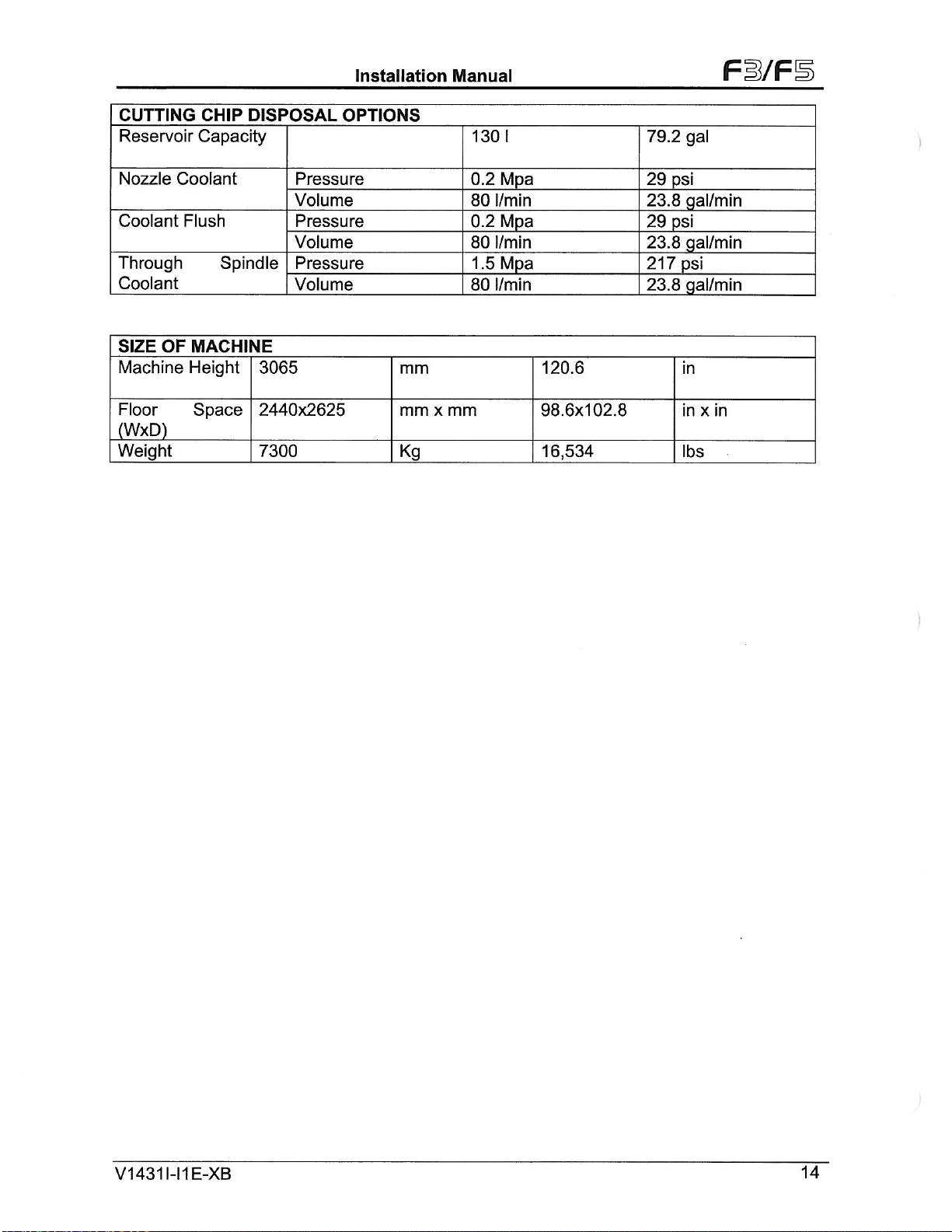

CUTTING

Reservoir

Nozzle

Coolant

Coolant

Flush

Through

Coolant

OF

SIZE

Machine

Floor

(WxD)

Weight

CHIP

DISPOSAL

Capacity

Spindle

MACHINE

Height

Space

Pressure

Volume

Pressure

Volume

Pressure

Volume

3065

2440x2625

7300

OPTIONS

mm

mm

Kg

x

mm

130

0.2

80

0.2

80

1.5

80

I

Mpa

l/min

Mpa

l/min

Mpa

l/min

120.6

98.6x102.8

16,534

79.2

29

23.8

29

23.8

217

23.8

gal

psi

gal/min

psi

gal/min

psi

gal/min

in

inxin

lbs

V1

431

1-11

E-XB

14

Page 18

Installation

Manual

Fi/FE

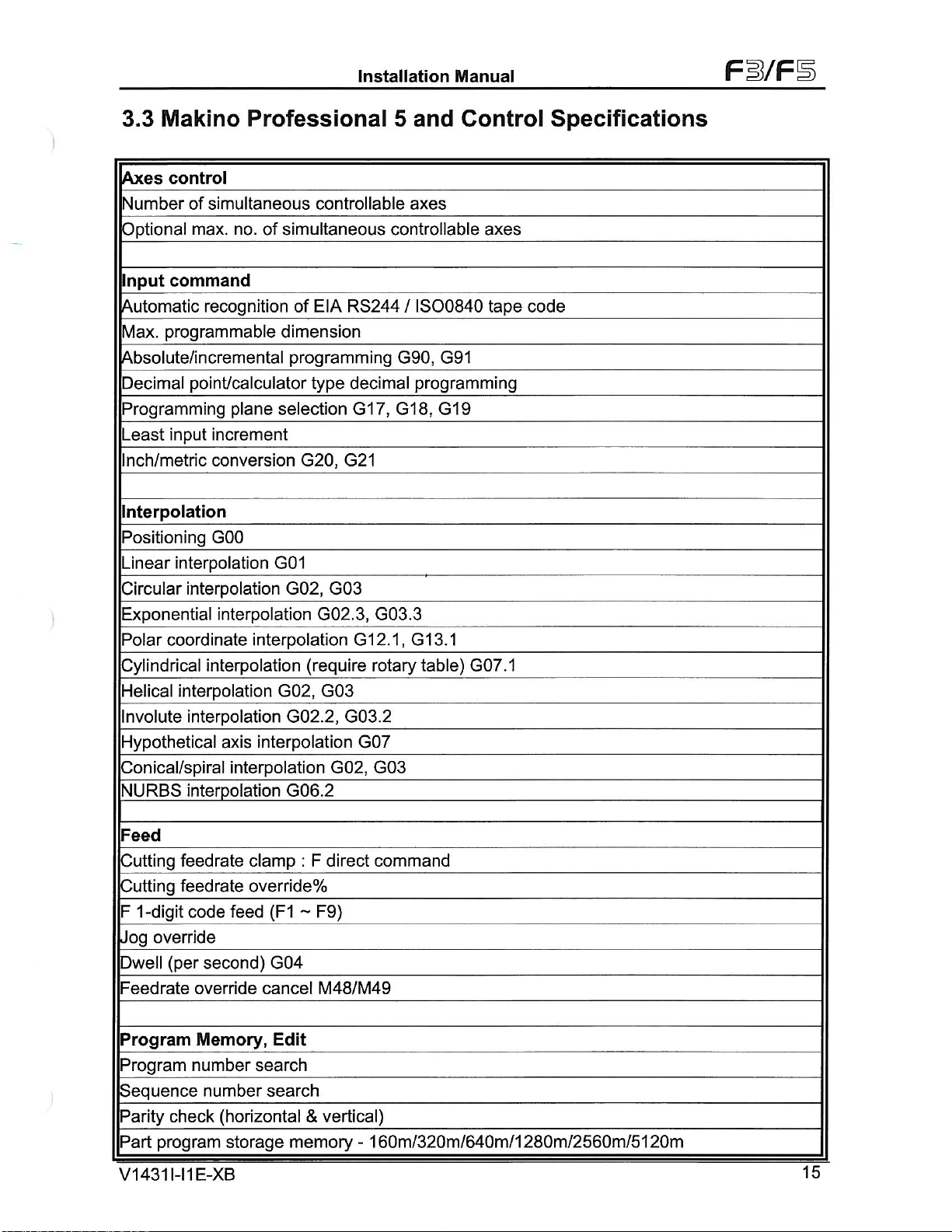

3.3

Makino

control

Axes

Number

Optional

Input

Automatic

Max.

Absolute/incremental

Decimal

Programming

Least

Inch/metric

Interpolation

Positioning

Linear

Circular

Exponential

Polar

Cylindrical

Helical

Involute

Hypothetical

Conical/spiral

NURBS

of

max,

command

programmable

point/calculator

input

interpolation

interpolation

coordinate

interpolation

interpolation

interpolation

Professional

simultaneous

no.

of

recognition

plane

increment

conversion

GOO

interpolation

interpolation

interpolation

interpolation

axis

interpolation

controllable

simultaneous

EIA

of

dimension

programming

selection

G01

G02,

G02,

G02.2,

G06.2

RS244/IS00840

type

decimal

G17,

G20,

G21

G03

G02.3,

G12.1,

(require

G03

G03.2

G07

G02,

5

and

axes

controllable

G90,

programming

G18,

G03.3

G13.1

rotary

G03

table)

Control

G91

G19

G07.1

axes

tape

Specifications

code

Feed

1

-digit

override

(per

check

program

431

1-11

feedrate

feedrate

Cutting

Cutting

F

Jog

Dwell

Feedrate

Program

Program

Sequence

Parity

Part

V1

clamp

override%

code

feed

second)

override

Memory,

number

cancel

search

number

(horizontal&vertical)

storage

:

(F1

~

G04

Edit

search

memory

F

E-XB

direct

command

F9)

M48/M49

160m/320m/640m/1280m/2560m/5120m

-

15

Page 19

Number

Part

Background

Extended

of

program

part

registerable

editing

editing

program

Installation

program

editing

Manual

120/250/500/1000/2000/4000

-

FB/FB

Operation,

Automatic

Machining

Clock,

Run-hour

Dynamic

operation

PNC

MDI

unit

12.4"

color

Manual

I/O

Functions

Input/Output

Data

S,M,T

Display

operation

time

calendar

and

graphic

standard

LCD

pulse

Function

Miscellaneous

Spindle

Tool

speed

function,

(memory)

stamp

function

count

part

display

key

full

generator

interface

(auxiliary)

direct

4

S-code,

digits

display

Operator

on

Channel

-

function

5

M

digits

panel

(RS-232C)

1

x-digit

Tool

Compensation

Tool

length

Tool

offset

offset

Tool

offset

Tool

Tool

offset

Tool

offset

Cutter

compensation

Coordinates

Reference

Reference

2nd

reference

3rd/4th

Floating

Machine

V1

431

reference

reference

coordinate

E-XB

1-11

compensation

-

pairs

memory

memory

memory

position

position

64/99/200/400/499/999/

(Geometry

A

(Geometry/wear)

B

(Geometry/wear,

C

C

return

return

position

return

position

position

system

G43,

G41

G28

check

return

return

G44/G49

Wear)

,

G42/G40

G27

G30

G30

G30.1

selection

cutter/tool

G53

length)

16

Page 20

Installation

Manual

Fi/FE

Workpiece

Workpiece

Automatic

Coordinates

Local

Work

Machine

Manual

Operation

Label

Manual

Help

Machine

Mirror

Block

Optional

Program

Z-axis

Follow

Sequence

Program

Dry

Single

Manual

Skip

Tool

run

G31

coordinates

coordinate

coordinate

reference

skip

absolute

length

function

lock

image

skip

stop

stop

feed

up

restart

block

handle

High-speed

coordinate

coordinate

return

from

setting

system

selection

position

support

and

ON

measurement

X-axis

for

M01

MOO

neglect

number

comparison

interruption

skip

system

system

selection

preset

reference

G52

setting

return

OFF

Y-axis

and

position

G92

M21

and

stop

G54-G59

G92.1

G29

,

M22/M23

Programming

Normal

Chamfering

direction

/

corner

Programmable

macro

custom

of

type

cycles

peck

E-XB

call

Sub

program

Custom

Addition

Interruption

Canned

Small-hole

431

V1

1-11

support

control

R

input

data

folds

(4

macro

custom

for

drilling

drilling

G41.1,

(offset,

nested)

common

macro

cycle

G42.1/G40.1

parameter)

variables

G10

600

numbers

17

Page 21

Installation

Manual

Fi/Fl

Circular

Scaling

Coordinate

interpolation

G51/G50

system

Programmable

Rigid

tapping

Programming

G84.2,

Playback

Tapping

Cutting

Exact

Exact

Automatic

Machine

Backlash

Stored

Single

mode

mode

mode

stop

G09

stop

corner

Accuracy

compensation

pitch

error

direction

by

rotation

mirror

support

image

G84.3,

G63

G64

G61

override

Compensation

compensation

positioning

R

programming

G68,

G69

G51.1/G50.1

M135

G60

Safety

and

Maintenance

Interlock

Self-diagnosis

Alarm

Emergency

Stored

history

stop

stroke

Professional

GI.3

control

Data

server

Super

NANO

Data

Data

Data

GI.4

control

smoothing

center

center

center

A

B

(special

The

part

exact

your

function

display

check

5

1

function

160MB

-

request

specifications

of

continuous

machine

machine

specific

has

DM

for

high

indicated

design

been

application

capacity)

are

improvement

details,

ordered

only

800MB

-

subject

please

supplied.

and

-

to

and

refer

change

market

the

to

without

requirements.

prior

specifications

notice

For

which

for

as

the

V1431I-I1E-XB

18

Page 22

Installation

Manual

Fl/F

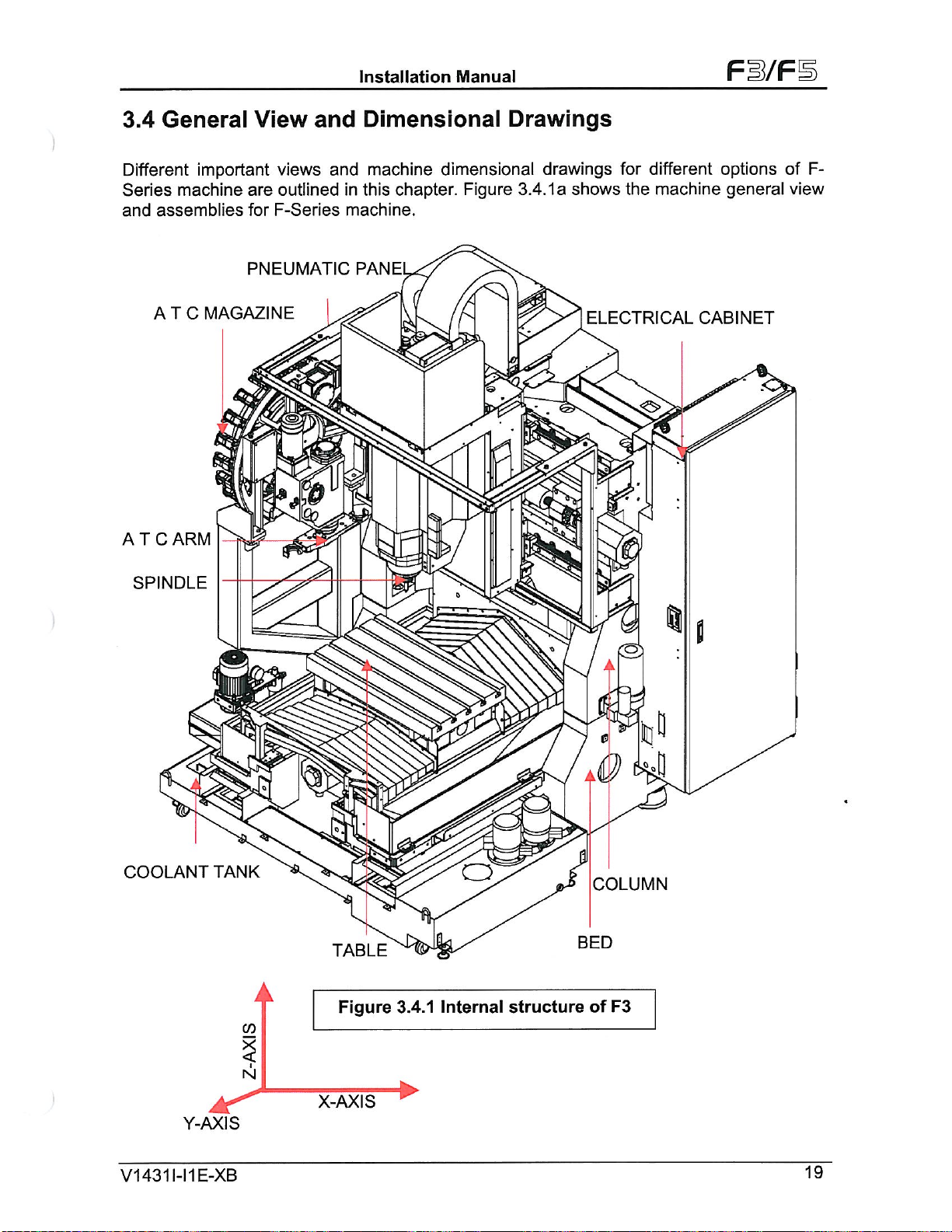

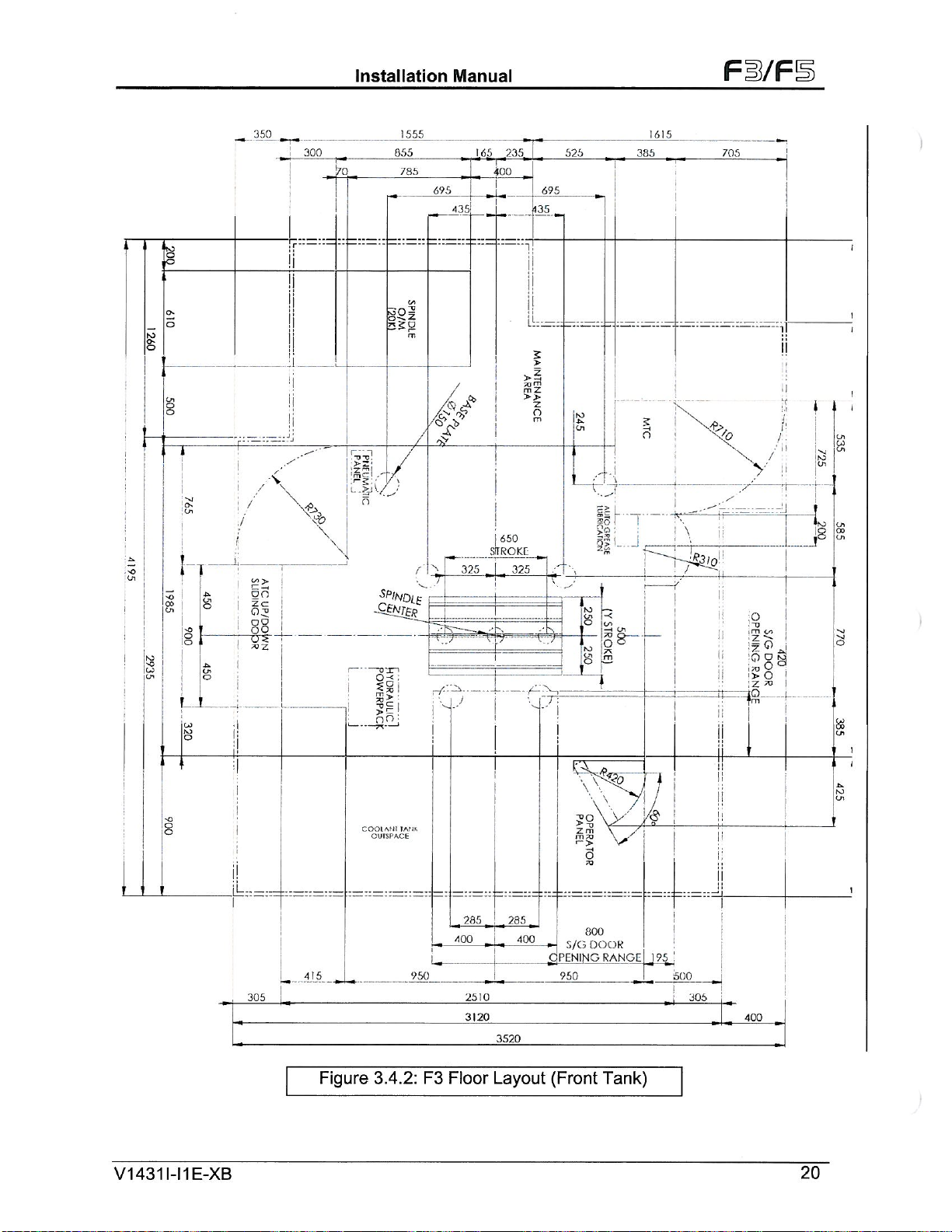

3.4

General

Different

Series

and

AT

machine

assemblies

A

T

ARM

C

important

are

for

PNEUMATIC

MAGAZINE

C

View

views

outlined

F-Series

%

and

and

in

machine.

Dimensional

machine

this

PAN

El

dimensional

chapter.

Figure

Drawings

drawings

3.4.1a

o

shows

ELECTRICAL

for

the

different

machine

CABINET

options

general

of

view

F-

SPINDLE

COOLANT

TANK

co

TABLE

Figure

3.4.1

o

Internal

structure

A

COLUMN

BED

F3

of

&S

V1

431

Y-AXIS

1-11

E-XB

4ÿ

3

N

X-AXIS

19

Page 23

Installation

Manual

Fi/F

—350...

300

j

.

£

•\

/

£5

as

Y

II

i|

I

L-|V/

ib

\

\

I

!

o

o

<>ÿ

s

1

|

g

is?

8:

1

i

I

00

Cn

Is

I

,/

!

4

g

_

Lgsi

rsf

'

I

rj

!

s

i!

1555

855

785

111

o

SP'NDLF

JI!

525

400

m

695

&

/

.

695

I

...135

Lkzÿ

m2

>>

I

I

iro

S

&

..'T\

t

O

650

\

STROKE

'N

:1S\.

.7

325

|

325

i

*‘N_

I

[8

fro

lo

to

2

t

1615

385

I

.

o

T

I

%

705

i

i

I

/,i

>ÿ

:rU

IS

«gsi

.1

?

!!

!

l

\

I

ii

I

*

/:

g

s

*IO

g

.8

3

is

'C=3S-

8

:

Cn

i

V1431

o

1-l

1

E-XB

a

RANGE

Tank)

£

J95

3-

500

i:

!

305

400

20

COOLANT

TANK

OUTSPACE

|L

285 285

305

L.

4I'>

Figure

600

950 950

2510

3120

3.4.2:

F3

Floor

400

|

,

3520

Layout

Zm

3

800

5/GDOOR

—

C]PENING

(Front

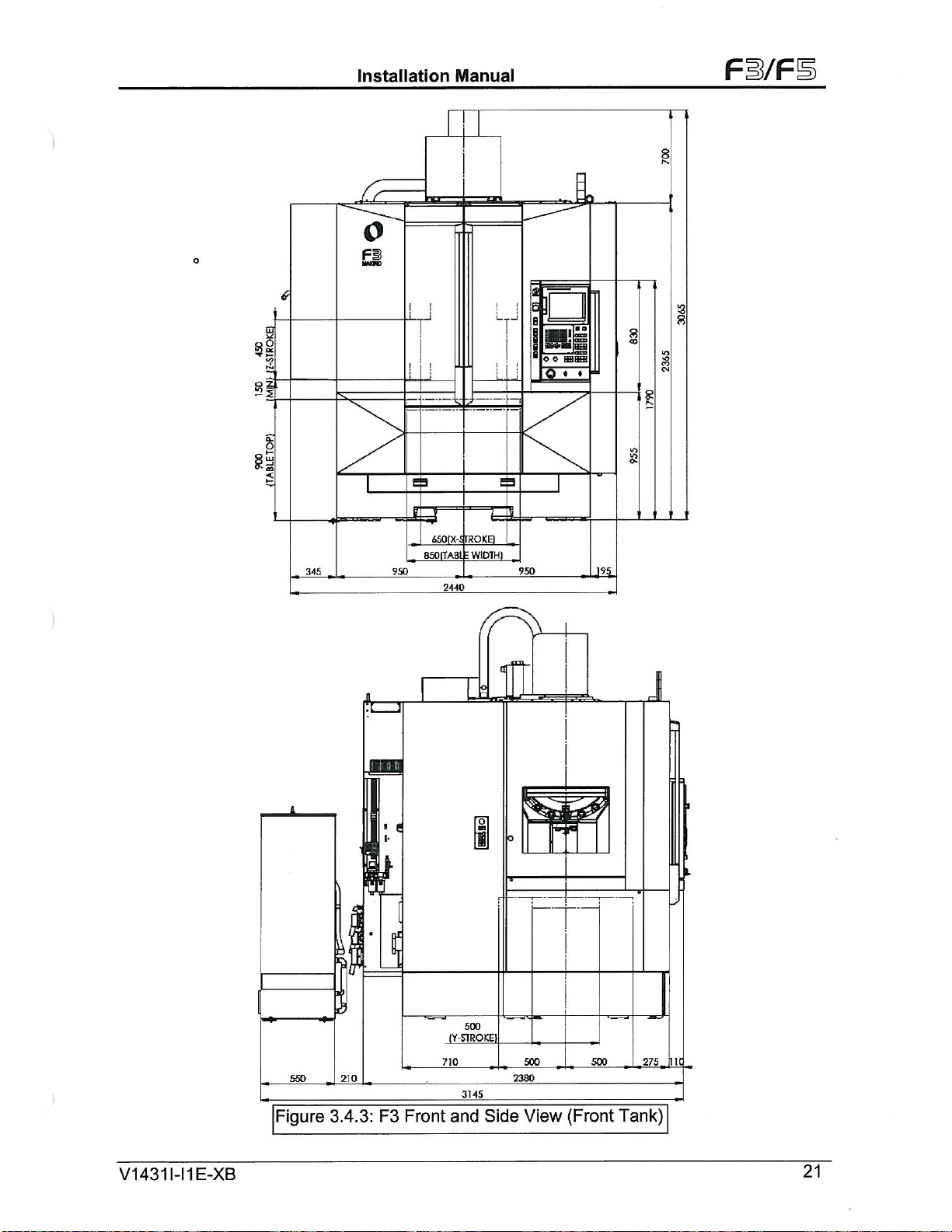

Page 24

Installation

Manual

§

Fi/F

1

o

O

Fi

u

§8

a

«i;

§

§1

§

*

u

?ÿ

§

O

a

8

I

g

a

E3

65QfX-SfROKE]

2440

WIDTH)

950

195

345

850fTABl:

950

1

14311-11

V

E-XB

550

Figure

210

3.4.3:

8

C-

F3

I

Front

500

(Y-STROKE)

710

3145

and

0

Side

500

2380

View

500

(Front

275,

Tank)

I

nc

21

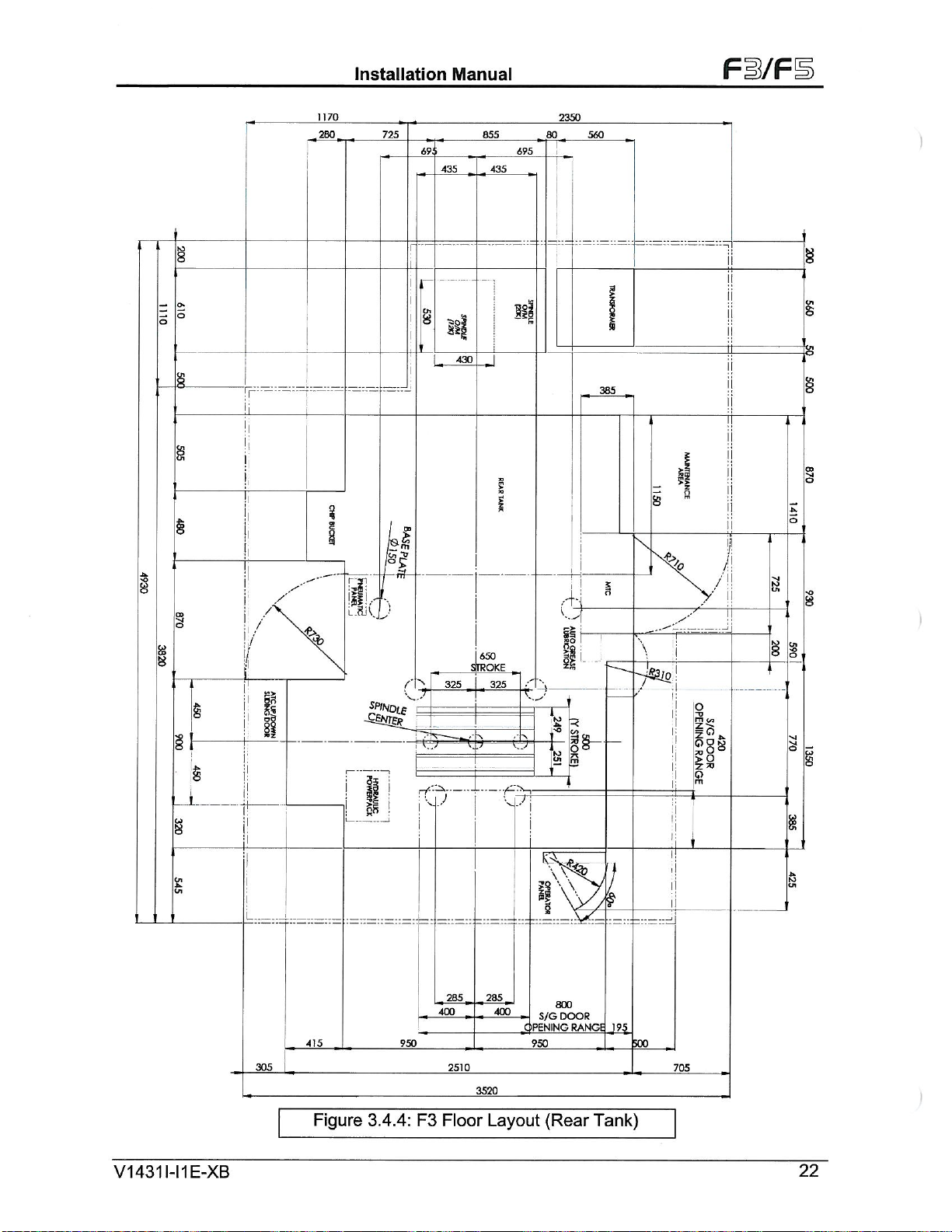

Page 25

Installation

Manual

Fi/F

695

s|

80

K

f*

2350

I

II

5

560

§

i

i

I

i

S

:a

385

I

8

5

5

§

I

TT

I

I

I

I

l

/

T

o

Is

Is

§

I

1

£

o

8

§

3

8

I

1

i

i

g

1170

280

§

CK

s

725

855

69'

435

r

i

435

g

ill

"L_*°

§.

g

i

§

I

I

I

§

8

8

§

8

§

1.

g

/

/

/

8

i

s

ijlj

m

i

I

si

n)

•s

c

SPINDLF

SiNjBR

ii

P

Y=*

l

i

i

'••Jv

325

J

I

I

650

STROKE

325

v7

V

1431

£

Ol

1-11

E-XB

i

L.

285

400 400

3.4.4:

950

F3

2510

Floor

415.

305

Figure

'T

285

3520

Layout

*

.QPENING

l~Y:

800

S/GDOOR

950

(Rear

YA

RANGE

Tank)

J3.

Ij

500.

705

K

22

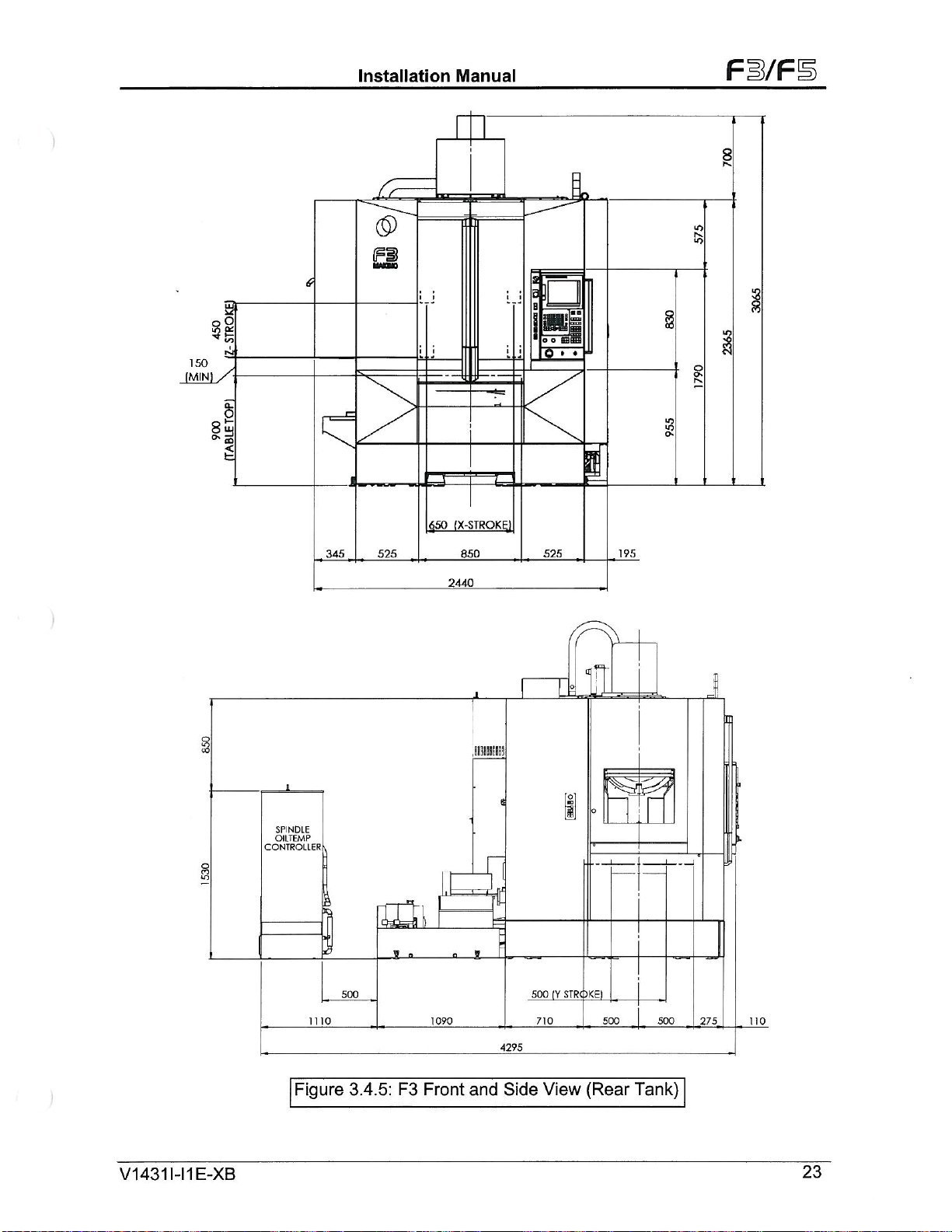

Page 26

Installation

&

Manual

Fl/F

8

K

150

IMM/i

§i

<S>

ft

F3

ij

Li

;ÿ

§

o

o

M

Li

ii

Et

>

o

%

5

£

J

650

(X-STROKE;)

345

525

850

2440

525

195

lO

•o

a*

s?

00

8

SPINDLE

OILTEMP

CONTROLLER

1110

Figure

\

500

3.4.5:

F3

1090

Front

X

and

4295

Side

500

710

View

I

STROKE)

|V

m

•O

500

(Rear

500

Tank)

275

l

110

V1431I-I1E-XB

23

Page 27

Installation

Manual

Fi/F

350

300

70

Tr;:=-~

:§

<>

to

380

855

1680

695

435

290

1

2351

435ÿ

695

525

385

1615

705

s

i

900

STROKE)

!

5

a

I&

X<?

S

\

i

>-S3J0

i

f

:§

g

cn

&

cn

g

/

/

I

!i

0

O

o

v

cPlN°l£

I

#

gs§

I

s

5

§

S

:

\v

/

/

&

H

!*!

L«J

IL

Cn

5

g

§

fO

a

u

8

.

-ii

§

!!

ii

i

r®"i

!

C'

2

S?

rrl

*io

.8

g

__

(

rf

(X

J

V1431

S

1-11

E-XB

I

ii

COOLANT

TANK

305

415

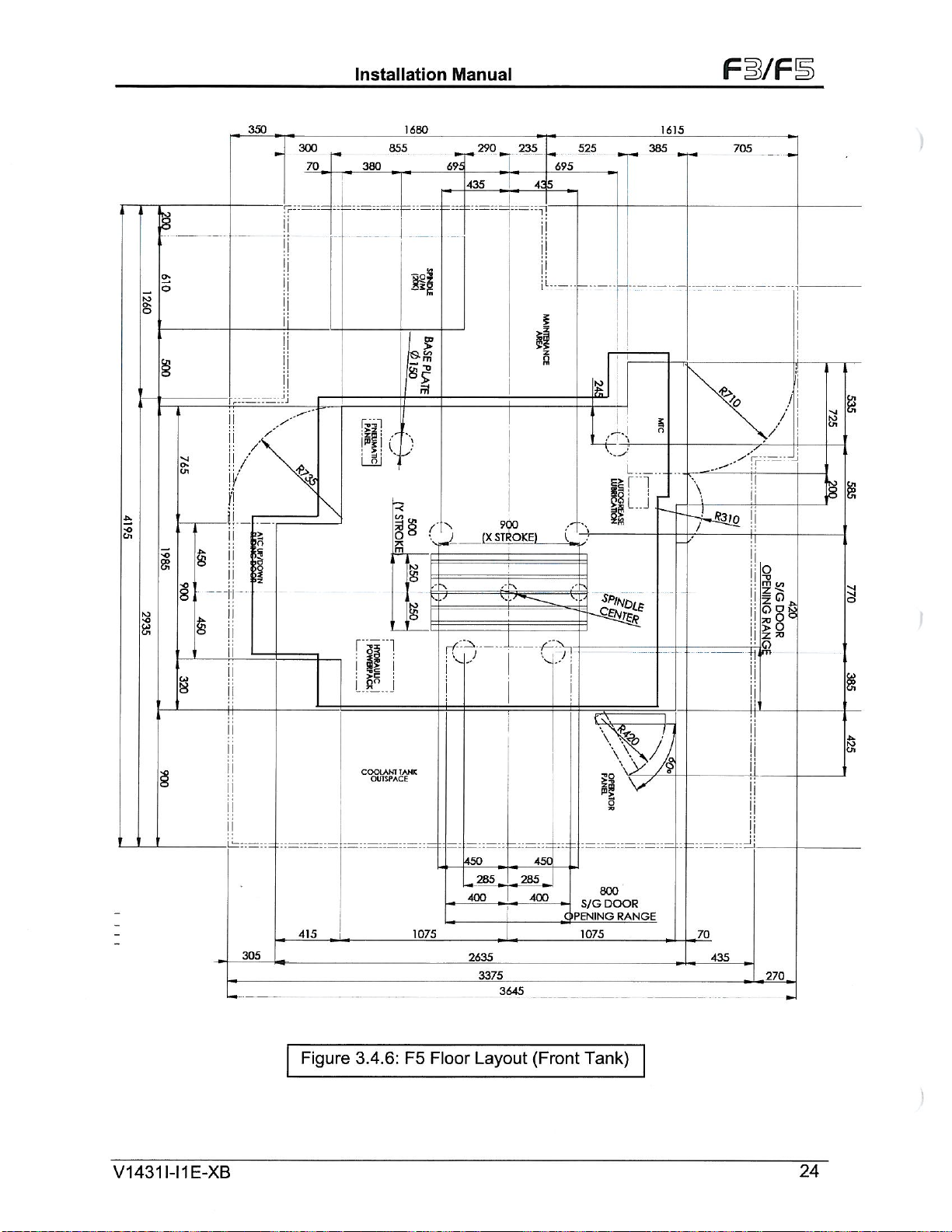

Figure

OUISPACE

3.4.6:

1075

F5

Floor

450

285

400

2635

3375

Layout

3645

450

285

400

-

OPENING

(Front

1075

1

3

800

DOOR

S/G

Tank)

V7

RANGE

i

I

I

-Z0

435

270

24

a

Page 28

Installation

Manual

Fi/F

3§

Si.

CL

2

fH

I

]

si

2

o

FS

wnc

LJ

LJ

£

Q

ini

.1075

a

o o

Q

EErTTT’

»

<

3

i

s

S

O'

_

j

L

6

!

1075

a

£

1000

900

(XJTROKE)

(TAB-EWIDTH)

2565

I

345_ÿ

/fÿV

JB

-

I

1

T

it

1

sm

X

e

&

____

_

__

_550

.270.1.

1_210

[s]

0

I

______

500

STROKE)

[Y

.710

3145

“0

L

2380

500

J_275

JOS

V1431

1-11

E-XB

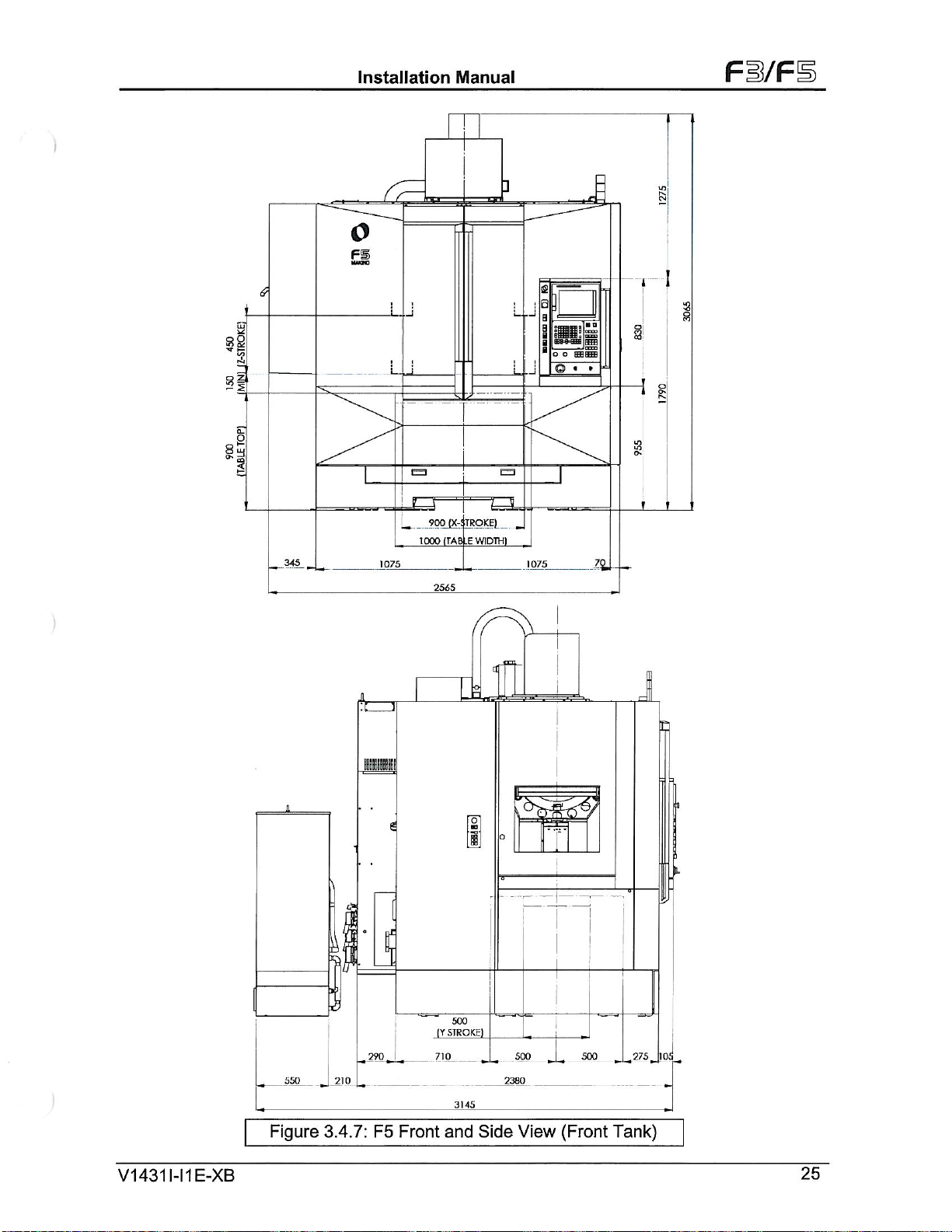

Figure

3.4.7:

F5

Front

and

Side

View

(Front

Tank)

25

Page 29

Installation

Manual

Fi/F

695

3

m

-r

l

te

1

I

2400

80

-H

irT"

560

I

8SL..J

is

I

70

>

co

o

m

385

I

I

I

4

I

I

§

c

n

8

§

I

00

>>

S

1

ir—

/

o

II

P>

!

/

s

SO

a

§

§

S

g

\p

-"'rr:

\

!

7-53/0

1245

170

725

855

6?5

435

T

§

Os

:i:.j

8

Sl

l

430

o

r

8

!i

n

?

n

CO

Sj

nt

435

-2520

?s

£

a

CD

8

/

%

sat

3

o

1

|

7-

§8

g£

2

s

!!

of

s

§1

7DZ

§

nisi

CD

a

II

6s

C

2-

g

10

.8

[f*

900

STROKE)

(X

cn

ft

1

305

V1431I-I1E-XB

£5

5

sss

5

o

„2B5_

3645

450

400

Layout

S/G

OPENING

1075

(Rear

450

285

400

415

,

JL,

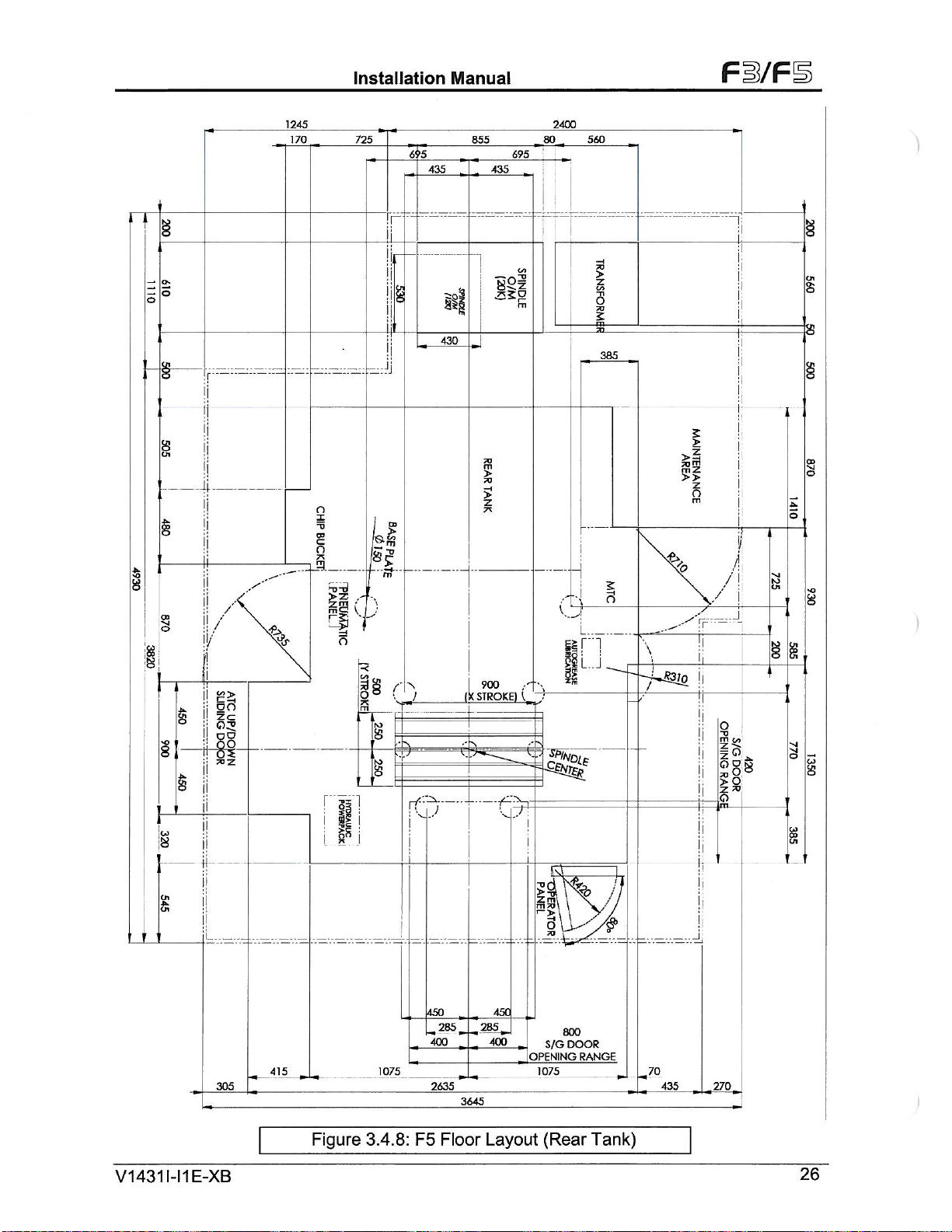

Figure

1075

3.4.8:

F5

2635

Floor

800

DOOR

£

RANGE

Tank)

-70

435

.270ÿ

26

Page 30

Installation

Manual

Fi/F

§

150

(MINI

lUr-

si.

<

(5)

FS

6

.L.

J

L.J

\M

o

•

g

3

a

s

in

'O

ro

CN

8

3

.Jr-

(X-STROKEI

900

345

575

2555

1000

575

70

2

20

500

710

1

STROKE)

(Y

View

500

(Rear

500

Tank)

.275.

110

SPINOLfc

OILTEMP

CONTROLL6

8

»o

i

J2

.rfefU

-0

1110

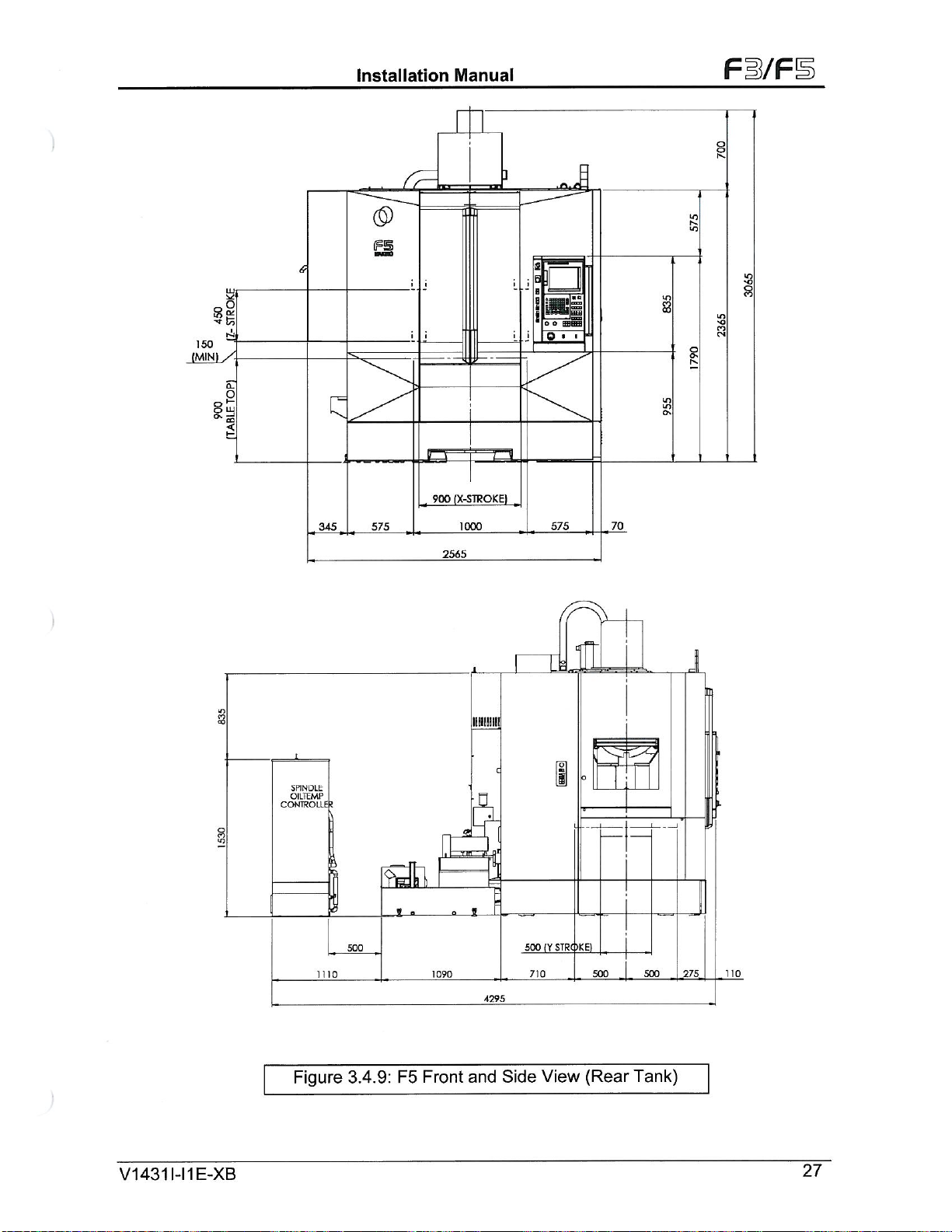

Figure

500

3.4.9:

X

F5

Front

1090

—

5

4295

and

Side

V1

431

E-XB

1-11

27

Page 31

s

I

\

i

j

1

;

i

/

Fi/F

143

120

MAX

560

TOOL

239

DIA

TOOL

CHANGE

3

§

s

EA

Al

Installation

115

C

AT

ARM

e

l

j

••

45

TOOL

CHANGE

18

5

102

r

5

300

410

D

STROKE

LEVEL

Manual

1247

348

4

I

;

f

i

n

/

iso.

517

wm

Si

s

a

g

150

450

(Z-Slroke)

g

<!o

g

I

OJ

£

i

.h

4

dN

i

i

»

\

S

/

•o

View

A

3

K>

8

8

L.

(‘

209

C=

G

G

FRONT

450

600

IPINDLE

CENTER

79

75

500

500

168

§

8

8

t

A

8

b.

fir

ho

S

In

g

8

'O

&

V1431I-I1E-XB

209

BACK

270

370

390

424

20

61

£

Figure

3.4.10:

F3

Work

Area

28

Page 32

Installation

Manual

Fi/F

1247

115

STROKE

ATC

ARM

45

TOOL

CHANGE

LEVEL

NO

©

108

140

V</0

NO

CD

NO

I

/

300

410

\

I

I

t

t

!

I

150j450

(Z-Stroke)

T

f

CD

8

CO

&

o

X

dr

O

7<r

CD

Cn

O

348

NO

NO

o

CO

O

O

i

8

o

250

517

%

m

S

(

V

\

.SPINDLE

LI.

1

CENIER

43

120

MAX

560

TOOL

239

TOOL

CHANGE

DIA

AREA

o

o

©

o

Cn

C

n

o

CO

Cn

o

(X

o

N

CO

i

i

View

A

\

sP

-o

NO

Cn

O

Cn

o

o

NO

Cn

O

s

\

L.

NO

CO

o

n

A

J

v

£

i

'i

209

d

C=

L

*

79

500

75

t

A

FRONI

600

o

,o

450

i

'

pi

7

NO

I

CA3

•On

i

370

-

424

'2Q

.

'T,

NO

I

ivj

<=>

-Vrri

NO

00

00

c*

*—

t

/

-

;

N

\

\

I

V

500

]68

J

t

Cn

O

Cn

s

209

J>\

BACK

270

390

CN

«

0

Figure

3.4.1

F5

Work

1

:

Area

V1431

1-11

E-XB

29

Page 33

Installation

Manual

F3/F1

Tooling

3.5

Preparation

Specification

tooling

of

shouldbeaddressed

fixtures

for

detailed

tooling

machine.

Fixtures

Consider

the

design

machine

for

and

a

underutilizationofthe

Tooling

The

three

cutting

and

highspeed

machining

maximize

When

•

selecting

Tool

holders

exceed

holders

Tool

•

ability,

Never

•

the

Use

•

Select

•

provide

tools

machine

use

important

most

tools

for

spindles

applications

utility,

tooling:

should

the

manufacturer’s

should

balance,

and

Weldon

shortest

the

shortest

better

and

fixtures

before

manufacturing

smooth

the

drawing

transition

machine.

factors

high-speed

have

limitations.

are

within

production,

parts

be

designed

design

designed

be

concentricity.

or

possible

tool

tool

side

life

lock

tool.

holder

and

typically

delivery

specifications

time,

of

and

into

understand

to

machining

Know

spindle’s

the

and

the

for

ratings

high-speed

for

holders

and

surface

at

cutting

finish

require

the

machine.

different

for

co-ordinate

production

and

consider

balance,

are

the

spindle

allowable

machine

highest

for

high

the

tool.

machining.

rpm.

allowed

tool

while

rpm

lead

long

Refer

completion

schedule

concentricity,

design

radial

component

available

reducing

times.

section

options

when

and

load

Look

by

the

radial

These

4.11

available

with

avoid

to

selecting

and

limitations.

and

side

spindle

and

the

on

good

for

part

geometry.

load

on

two

issues

tooling

on

Sseries

the

delivery

unnecessary

tool

holders

rigidity.

Ensuring

thrust,

life.

spindle.

the

tool

Never

holding

spindle.

and

of

All

will

Short

V1

431

E-XB

1-11

30

Page 34

Installation

Manual

Fi/FS

4.1

This

for

clear

installation

installation

The

installation.

machine

tasks:

•

•

•

•

•

Introduction

chapter

delivery

the

expectations

Review

Establishatime-line

Pre-Installation

Selecting

Dimensional

and

Electrical,

Unloading,

Preparing

describes

and

rests,

process.

information

the

The

installation.

machine

clearances.

Service,

moving.

tooling

Pre

4.

installation

installationofthe

responsibilities

and

large

in

Fifteen

items

drawings

and

part

days

and

and

checklist

checkedinthe

the

Use

location

are

requirements

Air

work

Installation

process

F-series

the

on

before

requirements

detailed

schedule

outlines

resources

(access,

provided

holding

“required”

and

High-speed

all

for

participation

delivery

the

related

for

tasks

key

this

in

environment,

in

section

and

connection

devices.

Process

contains

concerned.The

of

to

completion

to

column

guide

3.4

guidelines

Machining

involvement

and

Makino

your

pre-installation.

of

prepare

be

must

accomplish

to

foundation),

and

determine

to

details

to

Center.

success

of

machine

these

for

items.

machine

completed

the

refer

required

prepare

and

customer

customer

It

establishes

efficiency

time

take

delivery

for

an

efficient

pre-installation

section

4.2

floor

of

in

the

to:

and

space

4.2

Key

Total

The

tooling,

considered.

Room

The

considered.

Easy

The

and

path

clearance

crane,

in

easy

machine

Selecting

factors

Required

Required

accessibility

Easy

Manufacturing

Environment

Floor

machine

workpiece

Space

total

floor

Accessibility

machine

all

for

from

forklifts

unnecessary

accessibility

external

selecting

in

floor

total

Room

Space

For

cabinet

the

accommodate

to

Space

Process

machine

for

foot

print

storing

machine

the

space

placement

doors

trucktothe

over-head

and

delays

for

dimensions

the

the

Space

area

and

in

safe

the

must

Machine

machine

working

the

plus

movement,

and

footprint

total

safe

have

panels

and

machine

the

machine

crane.

machine

discharge

and

installation

floor

Location

location

working

total

to

refer

height

sufficient

swing

to

site

that

rigging

Failure

chips

of

plans,

include:

utilities

machine

the

of

room

completely

provides

and

ensure

to

and

and

various

for

required

area

and

also

plan.

floor

in

room

for

which

safe

open.

sufficient

moving

sufficient

additional

used

coolant.

machine

around

for

future

the

access

Remember

width,

equipment

moving

There

cost.

Refer

options.

the

maintenance

machine

around

height,

like

room

should

section

machine

is

located

the

machine

ensure

to

and

the

mobile

could

also

3.4

for

is

a

swing

result

be

for

V1

431

1-11

E-XB

31

Page 35

Installation

Manual

Fi/FS

Manufacturing

Ideally

reduces

Environment

Proper

than

can

machine:

The

•

•

•

•

•

•

•

•

•

•

the

machine

handling

environment

any

others,

cause

•

•

•

•

•

machine

Dust-free,

Ambient

Temperature

Relative

Dust

Freely

Available

inspection

Enough

fully

to

Adequate

dry

A

foundation

appreciable

control,

direct

In

Near

a

In

place

a

Near

a

Near

a

machine

foundation

Temperature

Humidity

Free:

flowing

room

open

supply,

air

Process

should

and

costs

for

Machine

and

ensure

machine,

sunlight.

source

subjecttolarge

source

Working

foundation

machine

heat.

of

of

extreme

sourceofsevere

be

must

with

location

lighted,

well

Fluctuation

0.3mg/m3

air.

floor

and

equipment.

for

cabinet

and

proper

etc.

flat

deflection.

located

expansion

an

should

and

or

less

bench

maintenance

doors.

sized

strong

and

be

placed

improves

accuracy

and

temperature

metallic

vibration,

such

in

meet

the

free

of

1

:

:

1

:

35

space

work.

utilities

enough

closest

communication

are

of

component

dust,

this

an

strip

following

temperature

0

40°

to

C/30

°

to

70%

for

storing

are

to

the

utmost

and

dependability.

variation.

such

may

environment,

to

absorb

C,

optimum

minutesorless

(no

raw

Adequate

available:

support

to

the

process

between

importance.

failures

affect

conditions:

condensation)

of

grinding

as

accuracy

we

the

vibration.

changes.

24±2°

finished

and

space

electrical

the

around

weight

it

supports.

process

These

A

sub-standard

types.

all

machines,

and

recommend

C

work

machine

powers

of

the

This

steps.

two

factors,

environment

Do

NOT

etc.,

alignments.

a

separate

pieces,

supply,

tooling,

and

machine

placement

more

locate

clearance

clean

the

If

the

and

and

without

V1

431

1-11

E-XB

32

Page 36

Installation

Manual

FWFB

4.3

B

A

deflection.

be

appreciable

of

•

•

•

•

•

•

•

•

•

•

Foundation

To

with

void

guaranteed

specifications

reinforced,

continuous,

thumb,

Minimum

soil

(The

Minimum

Foundation

Minimum

recommended

the

foundation

Floor

Level

If

the

maintain

contact

steel

The

Type

of

When

ensure

all

installation

accuracy

the

isolated,

Refer

the

floor

locating

o

o

o

Figure

flat,

deflection.

foundation

ground

below

thickness

should

anti

vibration

that

to

should

does

machine

Makino.

reinforcement

Concrete

the

Consult

Consult

Locate

vibration

machine

alignment.

machine

on

a

for

concrete

4.3.1

and

strong

NOT

Do

must

resistance

concrete

the

of

foundation

extend

Isolation

a

1

9-mm

absorb

be

within

not

meet

level

of

should

machine

structural

a

Makino

the

machine

environment.

provide

to

accuracy

and

portion

reinforced

the

machine.

floor

details

for

enough

place

the

meet

5

of

ton

medium

minimum

a

around

(3/4-inch)

vibration

some

3.2mm/m.

these

alignment.

and

the

steel

grade

be

of

on

an

engineer

for

acceptance

over

enough

and

foundation

of

the

warranty.

concrete

is

the

foundation

on

to

support

machine

following

/

m2

large

or

300mm.

is

300

of

the

expansion

specifications,

If

inside

upper

FC1

for

the

80

floor

load

or

pillar

a

necessary,

If

or

support

performance,

requirements.

Consistent

foundation

foundation

best

drawings.

the

separate

on

specifications:

sized

crushed

beyond

mm

Foundation

strip

special

a

you

concrete

or

of

stipulations

supporting

install

to

considering

are

more.

building,

a

bearing

one

keep

weight

sections

the

is

of

be

should

be

capacity.

on

this

beams

or

the

machine

customers

Failure

accuracy

that

meets

minimize

to

The

concrete

the

of

of

stones

can

machine

mm

100

placed

foundation

more

at

special

a

be

of

sure

to:

arrangement.

provide

to

pillars

level

must

to

comply

can

the

vibration

machine

concrete.

be

used)

boundary.

thick

anditis

the

perimeter

is

0@230

D1

a

under

and

comply

may

only

be

minimum

and

pad

should

without

As

a

rule

also

of

needed

foundation,

minimum

the

maintain

to

V1431I-I1E-XB

33

Page 37

Installation

Manual

Fi/F

\

\

\\

\

V\

150

\.

'V.

\

\

\

//

1300

£05

£/

£60

'/

s:

V

•

,

'

vT

'V

V/y

5

TEEL

*10

PITCH

£70

y/

£fefi

££5>

£05

V

r

r

150

%

/V

%.ss

g

<r

OJ

ij'i

a

\

\

5

s

»

o

LJ

g

£

f.vl

SJ

o

g

I

£

u

6

//

cz>

2

i

Note:

REINFORCING

\

BOTH

/

LE

This

foundation

These

For

The

data

the

concrete

Symbol

Machine

HORIZONTAL

ING

VELL

are

rubbles,

shows

‘a’

weight,

615

STEEL

1

CONCRE

is

given,

medium

more

standard

/

:

/

Figure

an

than

the

010

VERTICAL''

AND

/

TE

4.3.1:

example

assuming

or

large

180

FC

Machine

7500

570

l

/

REINFORCING

FoundationF3and

of

reinforced

that

allowable

sized

should

Support

kg.

concrete

crushed

be

used.

points.

i

615

/

RUBBLES

bearing

stones

CONCRETE

l

F5

thickness

capacity

should

\\\\

/

LEVELLING

1L

?Rr

/

300mm.

soil

of

be

used.

is

POINT

|!

5ft/sq

m.

V1431I-I1E-XB

34

Page 38

Installation

Manual

FB/FB

4.4

Floor

machine

on

applicable

Markings

intended

Clear

problems

space

Clean

Floor

plan

the

marking

around

the

floor,

units

requirements

considered

4.5

A

less

Power

3-phase

and

a

•

and

Table

•

•

cannot

Stabilizer

Plan

F3

for

to

for

in

floor

before

and

and

locationofthe

the

machine

gangway,

the

the

of

locating

the

machine.

area

marking.

Supply

power

125A

Provide

Ensure

Install

be

source,

breaker

a

4.6.1

the

an

maintained

in

case

and

F5

machine

its

accessories.

ordered,

near

layout

plan

other

completely

Use

and

with

must

properly

assist

to

electrical

additional

within

used

based

Marking

given

is

After

basic

machine,

and

locations

the

machine

helps

intended

before

a

bright

Cables

provided.

electrical

service

±10%.

on

the

voltage

the

stable

be

sized

sizing

in

automatic

in

Section

completion

the

per

placing

are

machine

in

paint

regulation

the

alsotobe

or

as

for

necessary

marking,

The

service

machine

voltages

voltage

(Customer

type

and

3.4

describes

of

transformer,

layout

the

foundation

the

given.

work

done

and

piece,

before

installation

units

around

make

and

marker

customer

(±10%),

box

to

must:

for

electrical

requirements.

all

meet

regulator/Stabilizer

should

plan

dimensions

the

sure

that

mark

a

the

machine.

service.

for

of

the

the

the

location

work,

other

optional

toolings,

locating

and

avoids

machine

factors

all

location.

ground

of

Use

if

required

the

the

locationofthe

unit).

various

of

clearly

the

unnecessary

and

are

25

ohms

local

mark

units

and

other

machine.

moving

or

Code

voltage

as

Table

machine.

Length

machine

the

4.5.1

S/N

Main

gives

Main

(Customer

Wire

Wire

Connecting

the

of

layout

circuit

the

total

power

Description

Breaker/lsolator

Plant

Cable

Type

Size

Size

and

Terminal

cable

istobe

Contact

breaker

Makino

and

Side)

Type

decided

Customer

cables

supply,

125A

100A

XLPE

by

for

the

the

cable

for

for

AWG300MCM

size

230/346

415/440/460