Page 1

F F

Vertical Machining Center

Page 2

02

Page 3

“Defining the art of

precision mold making”

In the evolution of consumer goods, there is a

demand for continuous improvement in aesthetics,

styling, cost and performance. It is a tremendous

challenge for manufacturers to provide an efficient

and competitive mold making solution to automotive,

aerospace, 3C & medical industries. Each industry

has its own demanding requirements on surface

finish, contouring accuracy, and tool life, with the

ultimate goal being a lower cost per part with

improved quality.

Makino is well-established in bringing this value to

these markets through the reliability of our product

line, the innovation of the technologies employed

in them, and the expertise of our engineering and

applications personnel. Makino's F-series vertical

machining centers is another example of Makino's

ability to bring the finest machining solutions to the

marketplace. Three elements make this possible:

• Rigid Machine Construction

• Advance Spindle Technology

• Motion Technology

The F-series combines these advantages with an

ergonomic design and an efficient chip evacuation

system. This line was designed with the customer and

operator in mind. Parts are easily loaded, programs

easily run, and high-quality machining finishes are

achieved all at a lower cost per part.

03

Page 4

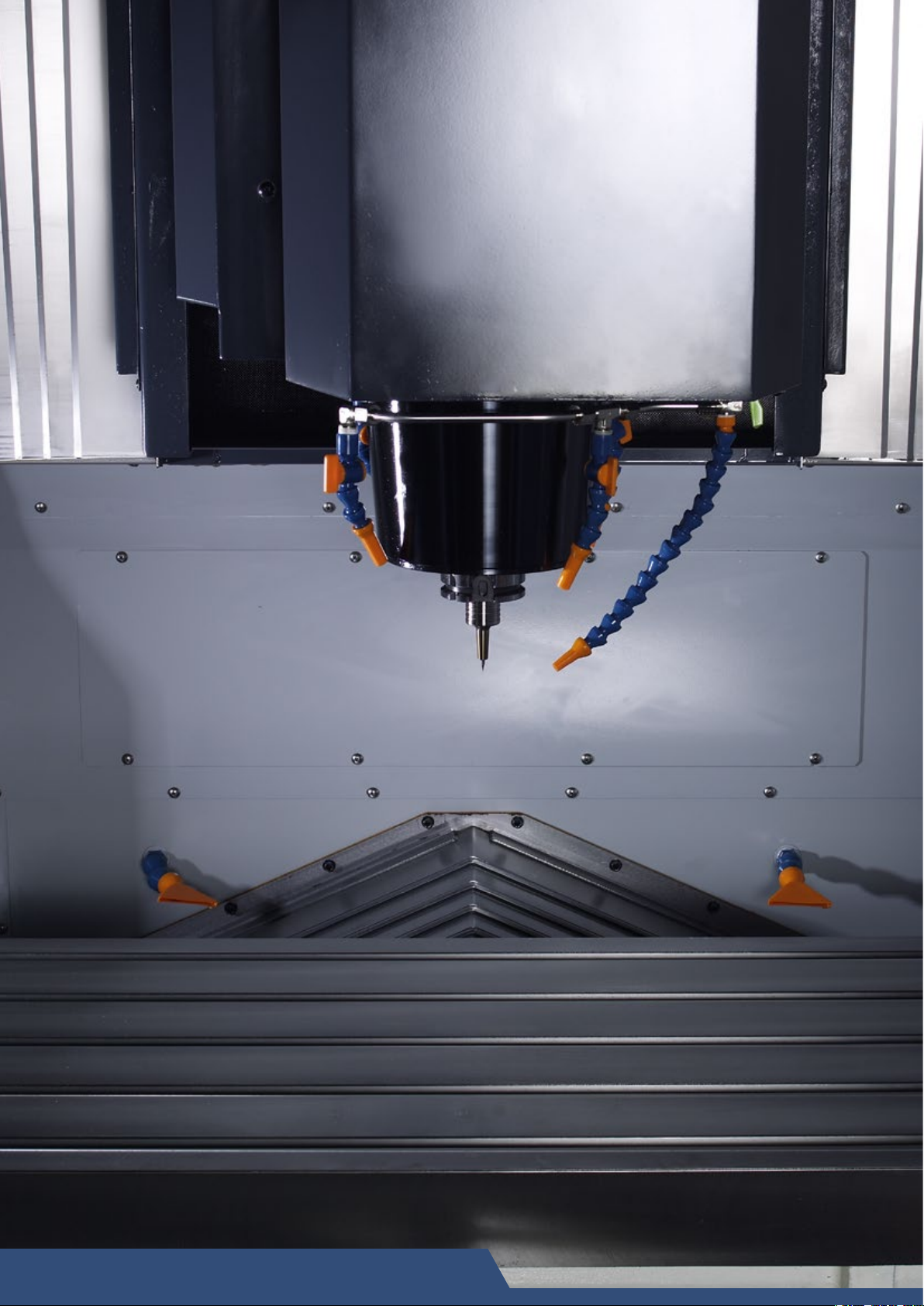

Competitive Solutions for Die & Mold

Makino F-series Vertical Machining Centers

The F-series machine delivers positioning accuracies

and repeatability in the microns. The spindle assures

the capability to address a wide variety of tooling and

machining applications, and SGI.4 provides unsurpassed

accuracy and speed in tough, challenging, and complex

geometries. This platform is an ideal choice for shops

looking to get “top-shelf” machining performance and

superior machining results at a reasonable investment a true value proposition.

From...

• Plastic, die cast to blow molds

• Stamping to forging

• Prototype to production

• Medical, electronics, aerospace,

optical consumer products, to packaging

04

Page 5

Superior Surface Finish

Die cast Die

Plastic mold

High Efficiency Machining

Stamping die

Forging die

Machining hard materials from rough to finish,

increasing productivity and efficiency

Surface Finish: Ra 1µm

General

Process

MAKINO

Process

Setup

Setup

Roughing

All in One Machine

Machine 1Machine 2

Roughing

Finishing

Setup

Finishing

30-50%

05

Page 6

Rigid Structure

Heavy cast iron construction and a unique axis configuration

provides outstanding stiffness, rigidity, thermal stability, accuracy

and unequaled axis support throughout the full travel of each axis:

• X and Z on the column

- Constant spindle support distance

- Fully supported throughout travel

• Y under table

- No “stack-up” of X and Y

- No off-center table load condition

- Fully supported throughout travel

Finite Element Analysis (FEA) of the basic components

insure optimized structural rigidity and tortional stiffness for

ultimate performance characteristics and consistent results.

This structural rigidity is the foundation for superior cutting

performance, provides damping against vibration, and

sustained accuracy for the life of the machine.

Most competitive machines feature some variation

of a traditional "C-frame" design. Therefore, in most

die and mold applications, by virtue of the machine

configuration and associated geometry, the machine

tool elements significantly overhang their support

structure:

•The Z axis is cantilevered from the X axis (Figure 1)

•The X axis is “stacked up” on the Y axis (Figure 2)

•The X axis is overhung from the Y axis (Figure 3)

Overhung

Z-axis

T

N

T

N

E

M

O

M

Z

Y

“Stack up”

X on Y - axis

E

M

O

M

Z

Y

As a result, cutting forces - combined with these long,

unsupported, cantilevered distances create stiffness,

rigidity and dynamic distortion issues that produce

vibration and chatter. Such instabilities, inertial factors

and bending moments during cutting dramatically

impact surface finish, final part accuracy, cutting

speeds and feeds, achievable depth of cut, cycle time,

tool life, and productivity. By virtue of the unique

F-series construction, the machine provides a stiffer,

more rigid, highly accurate, chatter-free platform for

even the most difficult of cuts.

Z

X

Overhung

X-axis

M

O

M

E

N

T

“Stack up”

X on Y - axis

06

Figure 1 Figure 2 Figure 3

Page 7

Thermal Stability

High performance linear guideways (utilizing

“caged ball” technology) provide extremely precise,

anti-friction motion. In addition, pre-tensioned, dual

supported, large diameter ballscrews and powerful,

direct-coupled, digital servo motors - tuned for peak

performance - provide the stiffness and rigidity for the

most challenging applications.

Fine ballscrew motion provides greater precision

for blends, matches and complex geometry

applications. Temperature controlled lubrication

maintains and controls the thermal stability of the

ballscrew bearing mounting area, ensuring stable,

long cycle time cutting accuracy.

OUT

IN

Lubrication of support bearing of X & Y Axis

• Thermally stabilizes support bearing as

it is bathed with oil flow

• Extends life span of the support bearing

• Smoothens axis movement especially

during small step machining

OUT

IN

Achieving High Precision Accuracy Through Mechanical Means

Parts are accurately manufactured, meticulously adjusted and

assembled with exacting precision.

Scrapping is incorporated in the machine assembly in order

to achieve better profile accuracy and surface matching which

results to mechanical accuracy in order to further enhance and

increase the machine performance and increase the machine

life at the same time.

Machining accuracy

Squareness 0.005 mm / Full Stroke

Straightness 0.005 mm / Full Stroke

(*Guaranteed values: tolerance at Makino's assembly

plant - daily temperature change of ±10C)

(*In accordance to JIS B6338 - 1985)

07

Page 8

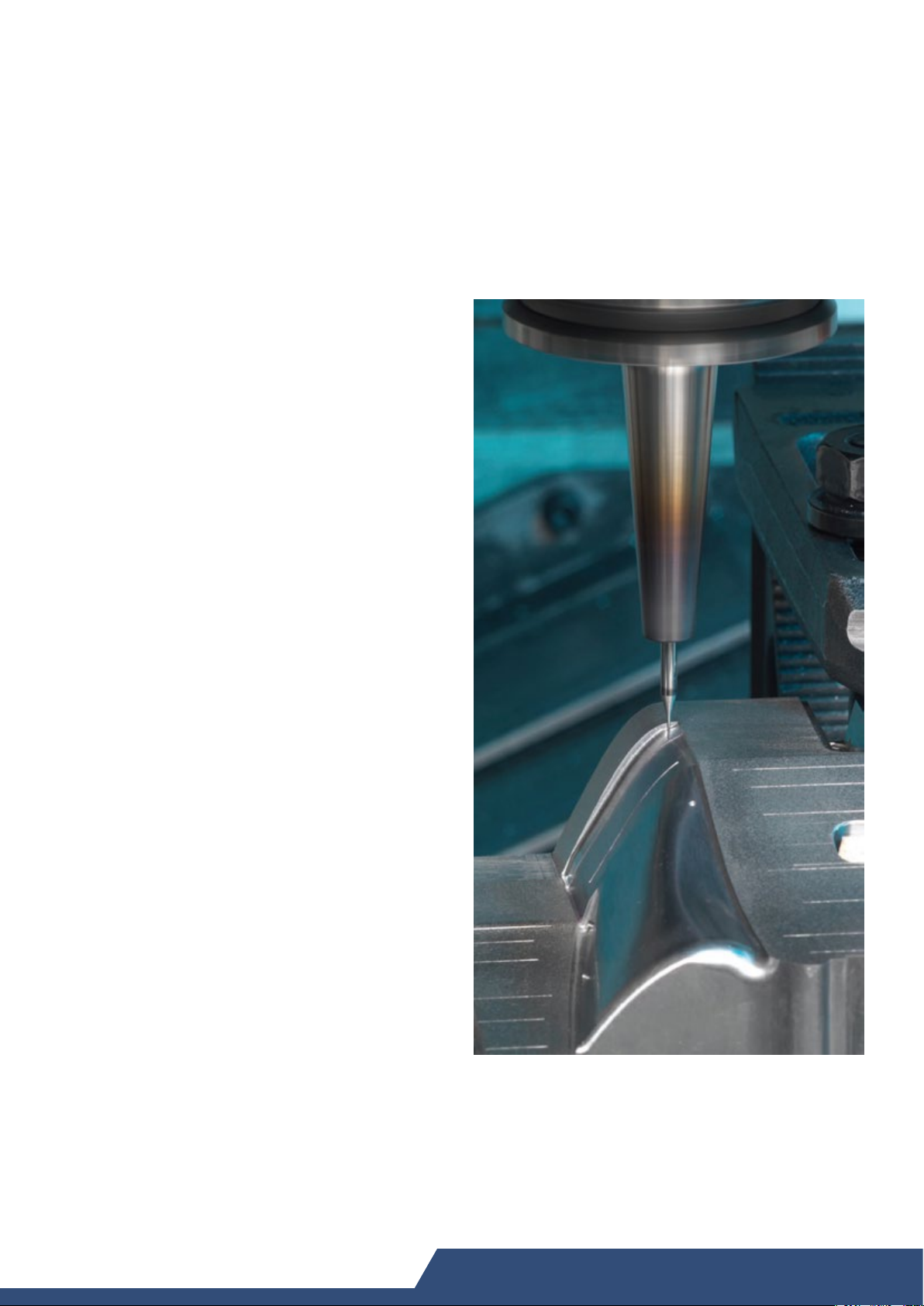

Advanced Spindle Technology

Makino’s leadership in spindle technology is renowned throughout the world. Spindle rigidity,

higher rpm, constant pre-load, multi-plane balancing, minimizing vibration, and controlling thermal growth

are all issues that Makino has solved through years of experience and application of spindle design,

manufacture, and assembly.

The optional 20,000 rpm, HSK-A63 spindle

incorporates Makino’s patented spindle technology:

Spindle core cooling

Under-race bearing lubrication

Closed loop oilmatic temperature control

The spindle provides characteristics required in any

number of high-speed machining applications

typical of the die and mold industry. The two-range,

unique integral design provides wide-range capability

with stiffness and rigidity at lower ranges (roughing

operations) to vibration & chatter-free production of

small details and fine features when using small tools

at a high rpm.

Spindle Temperature Controller

The F-series machine is the only machine of

its class to combine a large capacity, heat

dissipating spindle chiller, and the Makino technologies

mentioned above. This maintains tight control over the

spindle, bearings, and motor area, thus minimizing any

spindle thermal growth effects upon spindle pre-load

that impacts spindle stiffness and rigidity, tool life,

surface finish, and ultimately final part accuracy.

Cooling oil

support port

Cooling oil exit

Spindle BT40 HSK-A63 HSK-F63

12,000 rpm

20,000 rpm

30,000 rpm

Legend

- standard - option x - N/A

x x

x x

x

HSK spindle (Option)

The HSK shank system with two restrained faces

simultaneously couples the taper portion of the shank

and the flange end face.

HSK-A63 holder

*Available for

20,000 rpm spindle

HSK-F63 holder

*Available for

30,000 rpm spindle

1. Improved Heavy-Duty Cutting Performance

The difference in cutting performance is especially

noticeable when machining with longer shank tools.

2. Improved Accuracy

Excellent attachment accuracy is faithfully reproduced

for greater machining accuracy. This system firmly

secures the tool holder both on face and the shank and

provides very high rigidity and improved accuracy.

Strongly recommended for high-speed applications.

08

Page 9

120 ~ 12,000 rpm Spindle

This high-torque spindle provides superior

heavy-duty cutting performance for handling a

wide range of machining.

12,000 rpm Spindle

Performance Characteristics of Standard Spindle

Spindle power (kW)

1,500 rpm

2,500 rpm

3,500 rpm

5,000 rpm

4,000 6,000 8,000 10,000 12,000

2,000

Spindle speed (rpm)

Torque (Nm)

10,000 rpm

200 ~ 20,000 rpm Spindle

This high-speed spindle is ideal for high-speed

machining. Versatile for handling a wide range

of medium to small diameter tools.

300 ~ 30,000 rpm Spindle

This high-speed spindle is ideal for high-speed

machining with small diameter tools, such as

hair-line machining.

20,000 rpm Spindle

Performance Characteristics of High-speed Spindle

3,300 rpm

3,800 rpm

Spindle power (kW)

2,000 4,000 6,000 8,000 10,0 00 12,000

(Optional specification)

3,300 rpm

7,500 rpm

5,500 rpm

12,000 rpm

20,000

Spindle speed (rpm)

30,000 rpm Spindle (Optional specification)

Performance Characteristics of High-speed Spindle

240

220

200

180

160

140

120

100

80

60

40

20

Torque (Nm)

Spindle power (kW)

Spindle speed (rpm)

Torque (Nm)

30,00025,00020,00015,00010,0005,000

09

Page 10

Motion Technology

Super Geometric Intelligence (SGI.4) software - developed specifically

for high feedrate, tight tolerance machining of complex, 3D-contoured

shapes involving continuous tiny blocks of NC data. It ensures production

rates faster than standard CNC systems while maintaining high accuracy.

SGI.4 helps provide the lowest cycle time and cost.

• Fine Motion Control Even At High Feedrate

• F series Provides advanced acceleration and deceleration

control technology

• High-Speed & High-Accuracy machining made possible

• Enhanced cutting point accuracy

• Cutting mode selection

• CMD optimized machine

• Look ahead

• HPCC (High Precision Contour Control)

G.I. & S.G.I.

8

6

4

2

Direction (X-Y) CW CCW

Diameter, mm 20 20 20 20

Feedrate, mm/min 200 8,000 200 8,000

Roundness, µm 1.1 4.8 1.4 4.8

(*Guaranteed values: tolerance at Makino's assembly plant - daily temperature change of ±10C)

(*In accordance to JIS B6338 - 1985)

Technology by others

F series Technology

Direction (Y-Z) CW CCW

Diameter, mm 20 20 20 20

Feedrate, mm/min 200 8,000 200 8,000

Roundness, µm 1.9 5.7 1.6 5.4

Dynamic Calibration of 3 Axes

YZ Plane

XY Plane

The machining mode that optimally matches the machining job can be selected with M code commands.

High

Performance

Mode

M251

High

Accuracy

Mode

M250

Ultra High

Accuracy

Mode

M252

10

High Speed High accuracy

With Super GI.4 controlWithout GI control

Page 11

Pro 5 Controller

F series utilizes the Makino Professional 5 Control which affords the

perfect blend of a Windows CE graphical user interface (GUI), touch-screen

selection that provides instant access to information literally at your

fingertip, user-friendly, efficient PC-like capability for data management

and editing, and the networking and storage capability of a Makino

proprietary data center.

Key Features

Controller

• Data Center

• Tool Data Screen

• Machine uptime

management

• Alarm Display

Tool Data

– Single screen to check, edit and manually read/

write NC data

– Spindle load, tool life and tool data management

– The operating time for each machining process is

recorded as a machining result

– Easy to understand alarm display screen for

quick machine recovery

Spindle Load

& Tool Life

ATC

Recovery

Preventive

Maintenance

Machine Uptime

Management

11

Page 12

Efficient Chip Removal

5 nozzles supply device (standard specification)

• 4 coolant nozzles and 1 air blower nozzle are effectively positioned around the spindle.

Through-spindle air (optional specification)

• Air is supplied from the tool tip and holder.

Through-spindle coolant (1.5 MPa and 3.0 MPa) (optional specification)

• Coolant is supplied from the inside of the holder through the tool tip.

Unmanned machining application and highly efficient machining processes generate high volume of

chips. Therefore, a quick, good and reliable machine chip evacuation system is required. In F series,

optional two spiral type chip conveyors is used in transporting chips from the machining zone to the

rear of the machine. This efficient system will enable operator to focus on the machining tasks and

hence improve his work efficiency.

Spiral Conveyor

Chip Tray is located at the front of the

machine and can be emptied even during

machining

An optional Rear Tank is equipped with 2 x spiral

conveyors to evacuate chips to the rear side of the

machine

12

An optional lift up chip conveyor can be installed

along with the rear tank to further improve the chip

management of the machine.

Page 13

The chip and splashguard doors, as well as

the machine ceiling, open together to facilitate

easy handling of large, heavy workpieces that

require an overhead crane. Combined with the

movement of the table, and the convenient

table loading height, the F-series machines

significantly reduces part exchange load times

and operator fatigue.

The machine control is on a pivot that provides

90° of swing. This assures the operator will

always have easy access to the control during

set-up, program prove-out, operation, and

even manual tool loading through the front of

the machine.

Ease of Operation

An integral ATC shutter separates the machine

workzone from the tool magazine, assuring the

chips and coolant from the machining area do

not migrate into the tool magazine.

The tool changer door provides ready access

for easy loading and unloading of tooling to

the machine magazine. An ATC control panel

is located adjacent to the tool changer door

to assist the operator in manual operation of

the tool magazine and double gripper for tool

replenishment and maintenance.

13

Page 14

Measurement Systems

Automatic tool length measuring device (contact)*

This device measures the length of small

diameter tools with diameter more than 0.5 mm.

An air blower is attached to remove chips and coolant

before the measurement so as to ensure that the tool

length is measured accurately.

Automatic workpiece measuring device*

This device can be programmed to measure

workpieces automatically before, during and after

machining.

Non-contact tool measuring device (laser type)*

This device measures the length & diameter of small tools.

14

*Optional Equipment

Page 15

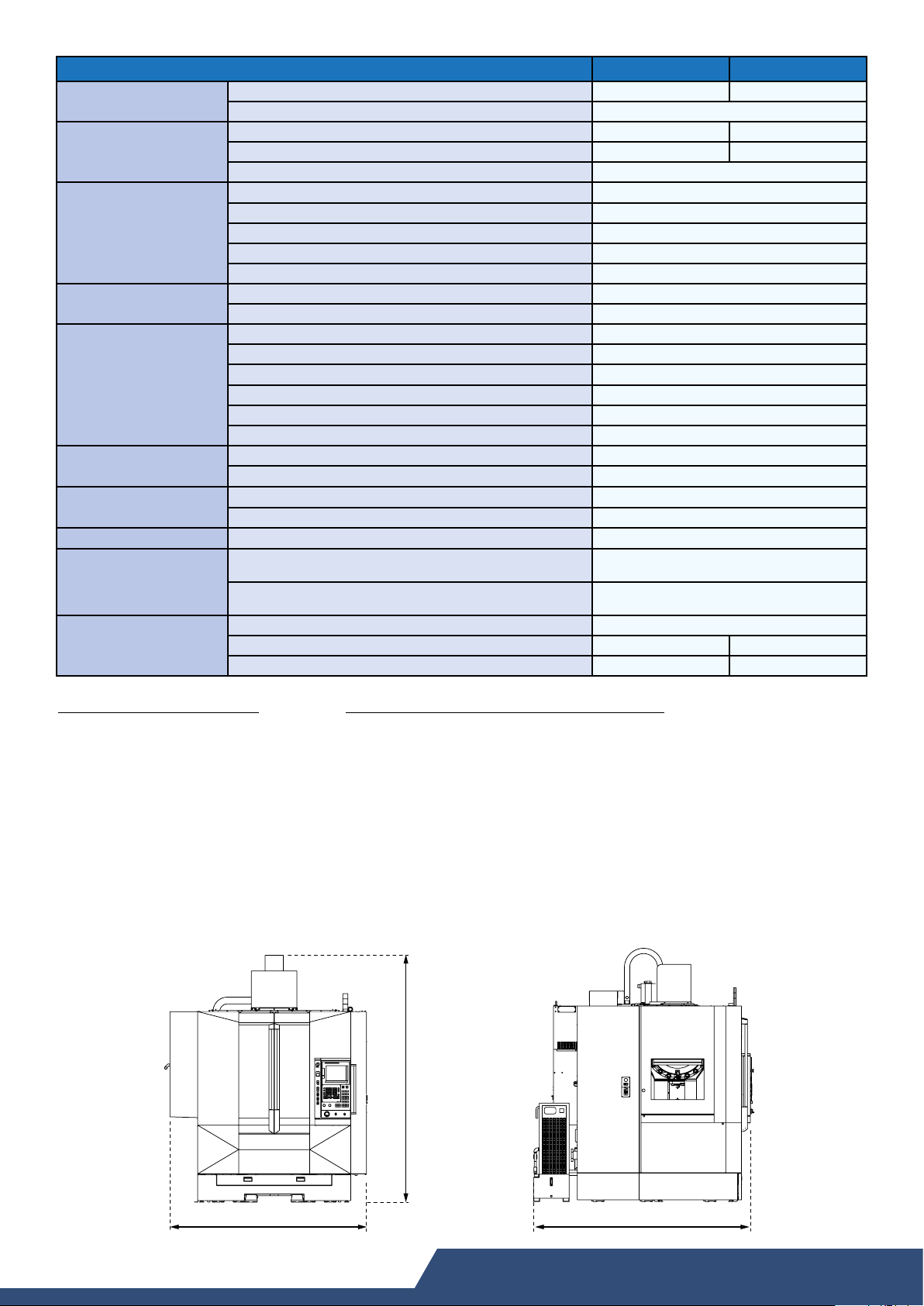

Machine Specifications

Travels

Table

Spindle

Feedrates

Automatic tool changer

Coolant tank

Air supply

Power supply (Standard)

Machine accuracy

(Tolerance measure at

Makino's assembly plant)

Machine size (Standard)

F3 F5

X x Y x Z axes

Distance from table surface to spindle gauge line plane

Table working area (WxD)

Maximum table load (Evenly distributed)

Table surface configuration 5 x T-slots, size 18H8 mm, pitch 100 mm

Spindle speed range

Spindle taper hole 7/24 taper No. 40

Spindle drive motor power (15 min. / cont.)

Spindle drive motor torque (15 min. / cont.)

Spindle bearing diameter (inner/outer)

Rapid traverse

Cutting feed

Tool shank type MAS 403 BT40 (JIS B6339 40T)

Tool storage capacity 20 tools

Maximum tool diameter (with adjacent pots occupied)

Maximum tool diameter (with adjacent pots empty)

Maximum tool length

Maximum tool weight

Tank capacity

Flowrate

Pressure

Consumption

Main electrical power capacity

Positioning (Full stroke without / with scale feedback)

Repeatability (Full stroke without / with scale feedback)

Height (H)

Floor space (W x D)

Weight

mm

mm

mm

rpm

kW

Nm

mm

mm/min

mm/min

mm

mm

mm

L/min

MPa

L/min

kVA

mm

mm

mm

mm

650 x 500 x 450 900 x 500 x 450

150 ~ 600

850 x 500 1,000 x 500

kg

800 1,000

120 ~ 12,000

22 / 18

117 / 95

Ø70 / Ø100

20,000

1 - 20,000

Ø 114

Ø 120

300

kg

L

8

160

80

Min 0.5 ~ 0.8

400

40 (AC 200V, 3P)

JIS Standards: ±0.0025 / ±0.0015

ISO 230.2 (1997) :≤0.010 / ≤0.006

JIS Standards: ±0.0014 / ±0.0010

ISO 230.2 (1997) :<0.006 / <0.004

3,065

2,440 x 2,625 2,565 x 2,625

kg

7,300 7,500

Standard Specifications

• 12,000 rpm spindle

• 20-tool ATC

• Automatic Air Blower

• Complete set of manuals

• Data Center A - 160MB

• Fixed Manual Pulse Generator (MPG)

• Fluorescent lighting within splash guard

• Helical Interpolation

• Makino Professional 5 controller

• Manual centralized lubrication system

• Nozzle coolant (4 nozzles)

• Number of registerable programs: 120

• Part program storage memory: 160 m

• Rigid tapping

• Splash guard door lock

• Super GI.4 control

Optional Specifications (•) & Equipment (

• 30-tool ATC

• HSK-A63 Spindle (for 20,000 rpm spindle)

• HSK-F63 Spindle (for 30,000 rpm spindle)

• Through spindle air

• Through spindle coolant (1.5/3.0 MPa)

▲ 4th axis NC rotary table interface

▲ Air dryer

▲ ATLM (Automatic Tool Length Measuring Device)

▲ Auto power out

▲ AWM (Automatic Workpiece Measuring Device)

▲ Lift-up Chip Conveyor

▲ Chip bucket for lift-up chip conveyor

F3 | F5: 3,065

▲ Mist collector

▲ MTC cabinet door interlock

▲ Portable manual pulse generator

▲ Power failure monitoring (3 axes)

▲ Rear coolant tank

▲ Scale feedback (X, Y, Z axes)

▲ Work wash gun

▲)

F3: 2,440 | F5: 2,565

F3 | F5: 2,625

15

Page 16

http://www.makino.com.sg

*The specifications in this catalog may be changed without prior notice to incorporate improvements resulting from ongoing R&D programs.

*The machines displayed in this catalog are fitted with optional equipment.

*The accuracy and output of machine may vary according to conditions of working environment.

*This product, including technical data and software, may be subjected to the Singapore Foreign Exchange and Foreign Trade Law.

* Prior to any re-sale or re-export of controlled items, please contact Makino to obtain any required authorization or approval.

Printed in Singapore AH010Ea 1511/2 (C/D)

Loading...

Loading...