Page 1

3UH,QVWDOODWLRQ*XLGH

('*(

Makino EDGE2

Ram Electrical Discharge Machine

with MGF Control

Pre-Installation Guide

This guide is intended for use by Makino customers and Makino employees and assigns for the safe operation and maintenance of Makino equipment.

This guide was developed through the combined efforts of:

Makino Documentation Gro up - Mason USA

MBS Associates (Lynne Hays)

Makino Customer Support

st

Release Date: July 20, 2000

1

Copyright © 2000 Makino, Inc. All Rights Reserved

• No part of this manual may be reproduced or transmitted by any means or in any

form to parties other than which it is intended, without the expressed written

permission of Makino.

• All specifications and designs may change without notice.

Every attempt was made to ensure that the information in this publication was correct at

the time of printing. As specifications and designs change, Makino is not responsible for

information that becomes incorrect or inaccurate after publication.

20ED3A1863

(E)

i

Page 2

('*(

g

g

g

g

3UH,QVWDOODWLRQ*XLGH

The following ic ons are used in this document. Safety and precau tionary

statements are presented as shown below.

DANGER

A

existin

tions must be taken immediately to prevent personal injury or death.

WARNING

A

potentially hazardous situation with some probability of death or serious injury. Precautions must be taken immediately to prevent personal injury.

CAUTION

A

potentially hazardous situation with some probability of personal injury or dama

the machine. Precautions must be taken immediately to prevent personal injury or

machine dama

icon precedes each danger statement. A

hazardous condition with a high probability of death or severe injury. Precau-

icon proceeds each warning statement. A

icon proceeds each caution statement. A

e.

DANGER

WARNING

CAUTION

icon indicates an

icon indicates a

icon indicates a

e to

• Precautionary statements must be followed to prevent personal injury

or damage to the machine.

• In addition, all safety requirements and guidelines found in Chapter 1 Safety, the ANSI safety guidelines the Makino Safety Manual, shipped

with the machine, and established company safety requirements and

regulations must be followed. Taking personal responsibility for safety

will prevent most accidents.

Notes are presented using the following icon format

A NOTE icon indicates information that expands on information given or indicates

where additional infromation can be found. Notes are presented immediately followin

the applicable content.

A copy of the ANSI Safety Manual, ANSI document number ANSI B11.8

was shipped with the machine. If this manual was lost or misplaced,

another copy can be obtained from Maki no at no charg e.

Write us at: Call or FAX us at:

Makino

P.O. Box 8003

7680 Innovation Way

Mason Ohio, 54040-8003

Attn: Information Services

Phone: (513) 573-7200

ask for Information Services

FAX: (513) 573-7360

Attn: Information Services

ii

Page 3

3UH,QVWDOODWLRQ*XLGH

To contact Makino, for service after the sale:

Makino

7680 Innovation Way

Mason, Ohio 45040 USA

('*(

Technical Support Services

Mon.-Fri. 7:00 a.m. to 8:00 p.m.

Sat. 8:00 a.m. to 2:00 p.m.

(Eastern Standard Time)

Parts Express

24 hours, 7 days a week

Tr aining Services

(888) Makino4 (625-4664)

Fax: (513) 459-1825

(888) Makino1 (625-4661)

Fax: (888)-881-9289

(888) Makino1 (625-4661)

The following acronyms and abbreviations are used in this document:

Term Meaning

APC Automatic Pallet Changer- work table (pallet) storage and exchange device

ATC Automatic Tool Changer - tooling storage and exchange device

ccw counterclockwise - direction of rotation

CNC Computerized Numerical Control - control unit for machine tool system

cw clockwise - direction of rotation

DEC Deceleration - axis slow down for reference operations

DI Dielectric (i.e. DI Fluid, DI unit)

EOB End Of Block - program code at end of each block of data

E-Stop Emergency Stop - machine condition halting all machine operation

FPB Flexible Pendant Box - portable control and axis positioning device

FSE Field Service Engineer - customer service technician

LS Limit Switch - LS00 = limit switch 00

MDI Manual Data Input - operating mode for direct input of NC data

MTC Machine Tool Cabinet - Cabinet housing main machine electrics/electronics

NC Numerical Control - input data (i.e. NC program)

PM Preventive Maintenance - routine maintenance items and checks

S/G Splash Guard - machining area enclosure

SOL Solenoid - SOL01 = Solenoid 01

20ED3A1863

(E)

iii

Page 4

('*(

3UH,QVWDOODWLRQ*XLGH

AVISO!

Las personas que no pueden leer o entender en Ingles deben mandar traducir este

manual y solicitar entrenamiento antes de operar o mantener la maquina. Todos los

que trabajen en esta maquina deberan saber como operarla con toda seguridad y en

forma correcta para evitar un posible dano.

ATTENTION!

Les personnes ne sachant pas lire l'anglais devront se faire lire et expliquer le manuel

avant d'utiliser ou de faire l'entretien de la machine. Toute personne travaillant sur la

machine doit savoir comment l'utiliser sans danger et correctement afin d'eviter tout

accident.

HINWEIS

Alle Personen die nur Teile des Handbuches oder kein Englisch verstenen, müssen

sich dieses Handbuch erklären lassen, bevor sie die Maschine in Betrieb nehmen

oder instandhalten. Alle Personen, die an der Maschine arbeiten, müssen zur Vermeidung von Verletzungen zur korrekten Handhabung angeleitet werden.

WARNING!

Persons unable to read English or do not understand any part of this guide, must have

this guide read and explained to them before operating or maintaining the machine.

Everyone working on the machine must know how to operate and maintain it safely

and correctly to prevent possible serious injury.

iv

Page 5

3UH,QVWDOODWLRQ*XLGH ('*(

CONTENTS

Chapter 1 Safety Precautions

Chapter 2 Specifications

Chapter 3 Installation Process Overview

Chapter 4 Pre-Delivery Preparations

Chapter 5 Machine Delivery

Appendix A Conversion Factors

20ED3A1863

(E)

v

Page 6

('*( 3UH,QVWDOODWLRQ*XLGH

vi

Page 7

3UH,QVWDOODWLRQ*XLGH

Chapter 1 Safety Precautions

For a Safe Working Environment

Makino EDGE2

('*(

Ram Electrical Discharge Machine

with MGF Control

01_20ed3a Safety.fm

Page 8

('*(

g

g

g

g

g

g

g

g

g

3UH,QVWDOODWLRQ*XLGH

Chapter 1

Safety Precautions

Contents

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2 General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2.1 Dan

1.2.2 Access to Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

1.2.3 Point-of-operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

1.2.4 Lockout/Ta

1.3 Personal and Professional Safety. . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

1.4 Equipment and Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

1.5 Environmental Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

1.6 Liftin

1.6.1 Slin

1.6.2 Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 11

1.6.3 Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12

1.6.4 Eye Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12

1.6.5 Rin

1.6.6 Liftin

1.6.7 Liftin

1.7 Mechanical Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

er, Warning, Caution Statements and Symbols . . . . . . 1 - 2

out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 11

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12

the Machine or Components . . . . . . . . . . . . . . . . . . . 1 - 13

Workpieces and Fixtures . . . . . . . . . . . . . . . . . . . . . .1 - 13

1.8 Electrical Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

1.9 EDGE2 Ram Electrical Dischar

1.9.1 Fire Hazard and Prevention . . . . . . . . . . . . . . . . . . . . . . . . .1 - 16

1.9.1.1 EDM Fire Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 18

1.9.2 Machine Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 20

1.9.3 Location of Emer

1.9.4 Location of Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 21

1.10 EDGE2 Equipment and Operation Safety. . . . . . . . . . . . . . . . . 1 - 23

ency (E-Stop) Button . . . . . . . . . . . . . . . 1 - 20

e Machine Safety. . . . . . . . . . .1 - 16

Page 9

3UH,QVWDOODWLRQ*XLGH

1.11 Installation Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

('*(

01_20ed3a Safety.fm

Page 10

('*(

OTES

N

3UH,QVWDOODWLRQ*XLGH

:

KETCHES

S

:

Page 11

1.1 Overview

This chapter provid es proven general safety guidelines t hat, if followed,

promote a safer working environment. It also contains safety information

specific to the EDGE2.

All machining centers have inherent haz ards the manufacturer either

designs out, guards against, or warns about. Even though the manufacturer has this responsibility, the machine user has ultimate responsibility

to ensure that a safe working environment is maintained in and about the

machining center. This includes, but is not limited to, allowing only properly trained and technically qualified personnel program, operate, and

maintain the machin in g cent er.

It is Makino’s po licy and respo nsibility to d esign, manu facture, and m arket

machining centers that are as reasonably safe as possible for their

intended use.

3UH,QVWDOODWLRQ*XLGH

('*(

1.2 General Safety

Safety precautions or requirements discus sed in Makino gu ides or manuals do not supersede any safety requirements imposed by local, state, or

federal governments. All government-imposed guidelines, i.e. OSHA

(Occupational Safety and Health Administration), NEC (National Electric

Code), NFC (National Fire Code), ANSI (American National Standard

Institute) standards, shall take precedence.

To protect against injury or damage operate the machining center within

the guidelines described in the provided documentation. Consider

Makino’s safety precautions supplemental to:

• Other Makino supplied guides or manuals related to programming,

operation, and maintenance of this specific machining center.

• Your company’s safety rules and regulations.

• All local, state, and federal regulations.

Your particular application may require additional safety measures to

ensure proper operator safety.

Additional copies of any guide or manual provided with your Makino

machining center may be purchased from Makino.

01_20ed3a Safety.fm 1 - 1

Page 12

('*(

3UH,QVWDOODWLRQ*XLGH

Prior To Installation, Operation, or Service,

Do NOT attempt to install, operate, or service this machining center until:

• You have read and under stand th e safety i nstru ctions containe d in th is

guide.

• You have read and understand all Danger, Warning, and Caution

safety labels attached to the machining center and its related equipment.

• You have read and understand all technical information, including the

following sections of this safety chapter.

Questions Regard ing Safe Operation

Before you operate this machine – contact your Makino service group for

answers to any questions about safety and your Makino machine.

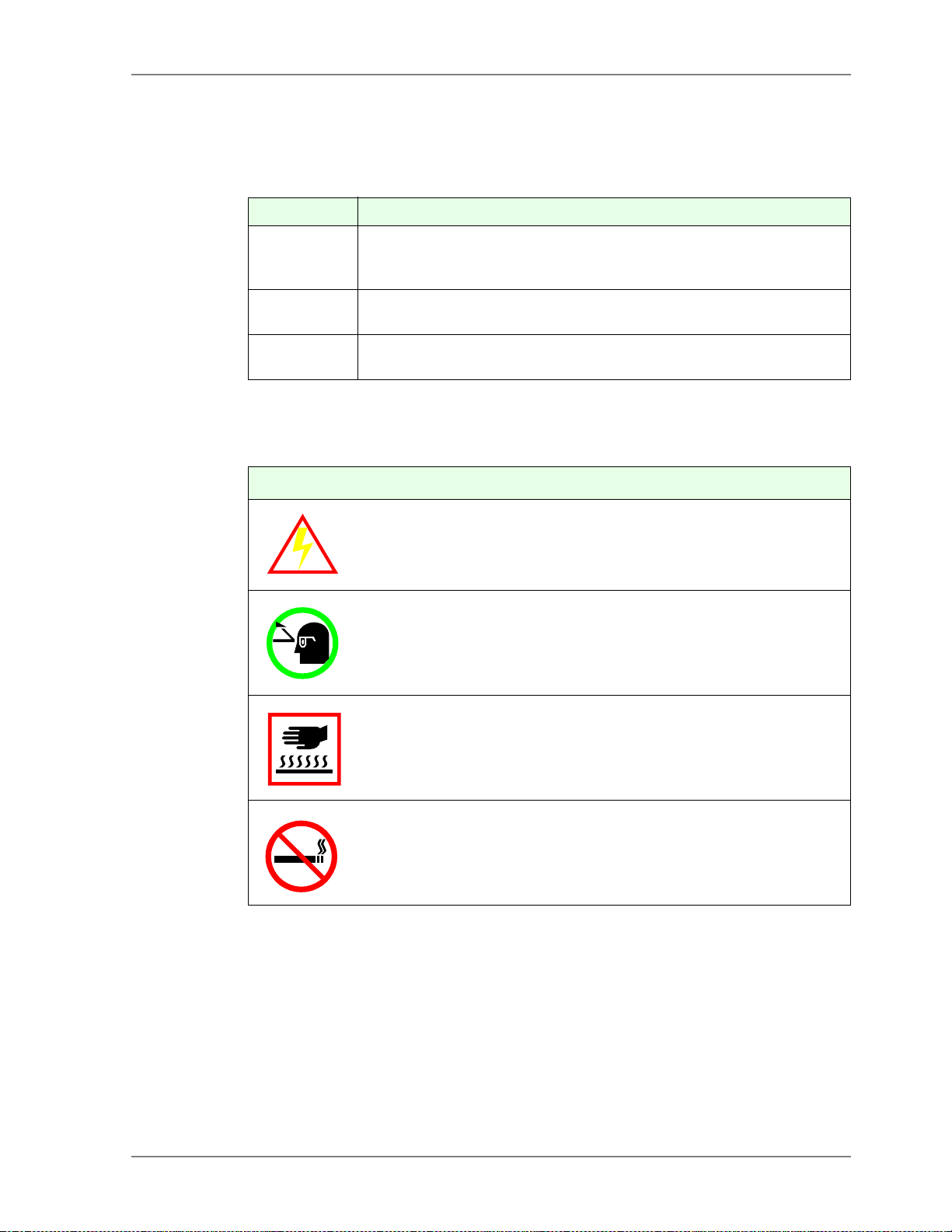

1.2.1 Danger, Warning, Caution Statements and Symbols

It is important that all employees recognize each safety symbol on the

machine and understand the meaning of Danger, Warning, and Caution.

These safety labels must never be removed, covered, or painted over,

and must be replaced if they are damaged, defaced, or become unreadable.

Table 1-1

that all employees recognize and understand the meaning of the safety

symbols shown in

The location of safety labels for specific hazards on the EDGE2 is

described in

presents the meaning of each safety statement. It is important

Table 1-2

section 1.9.4

.

.

1 - 2

Page 13

3UH,QVWDOODWLRQ*XLGH

('*(

ABLE

T

1-1

DEFINITION OF DANGER, WARNING, AND CAUTION STATEMENTS

Statement Meaning

DANGER is the most severe safety statement. This statement means

DANGER

WARNING

CAUTION

ABLE

T

1-2

that either severe personal injury or death may result if the instruction(s) is not followed.

WARNING is the next level of safety statement. It indicates that if the

instruction(s) is not followed severe personal injury could result.

A CAUTION is the least severe safety statement and indicates that if

the instruction(s) is not followed damage to the equipment may result.

SAFETY SYMBOL SHAPES AND THEIR MEANING

Symbol Meaning

A triangle or diamond shaped safety symbol indicates a hazard

exists in the area or behind the enclosure where the symbol is

placed.

The symbol at left indicates an electrical shock hazard exists.

A solid colored circle shaped safety symbol with an icon inside indicates the action shown by the icon is mandatory.

The symbol at left indicates that safety glasses be worn.

A square shaped safety symbol is used to convey information relative to the area where the symbol is placed.

The symbol at left indicates the area is hot.

A circle shaped safety symbol with a diagonal slash across the

image indicates the action shown is prohibited in or around that

area.

The symbol at left indicates that smoking is not allowed in the area.

01_20ed3a Safety.fm 1 - 3

Page 14

('*(

3UH,QVWDOODWLRQ*XLGH

1.2.2 Access to Information

We strongly recommend that a copy of these safety instructions and all

provided guides , manuals, and technical information be kept near the

machine. This infor matio n shou ld be o rgan ized for quick acce ss and u sed

by operators, maintenance, and other personnel with duti es related to the

machining center.

Access to this information:

• May save a life.

• W i l l prevent or reduce injury, mis-operation, and machining center

damage.

In the event tha t parts of this information become damaged or unus able,

replace them immediately.

1.2.3 Point-of-operation

“Point-of-operat ion” should be safeguarde d to the greate st extent po ssible

for all machining operations.

In addition to panel locks, interlocks, and guarding, certain areas of the

machining center ar e colo r coded f or safet y. It is important that the origina l

color and vividness of these areas be maintained.

Different operations or applications may make the general purpose safeguards unsuitable and require additional safeguards. You and your company are required to use special safeguards in these situations.

To assist in designing point-of-o peration safeguards for specific machining center applications:

• OSHA has published a booklet called OSHA Publi cation No. 3067.

• Films regarding safety requirements for machine tools are available

from ANSI and trade groups such as NMTBA (National Machine Tool

Builders Association).

1 - 4

Page 15

3UH,QVWDOODWLRQ*XLGH

1.2.4 Lockout/Tagout Procedure

The machining center is powered by high voltage and other energy

sources that represent potential hazards. To reduce the risk of injury or

death establish, define, and practice a Lockout/Tagout procedure for the

equipment in your facility.

Lockout/Tagout defines a minimum safe procedure to be followed by persons who might be confronted with unexpected energizing, start-up, or

release of stored energy that could cause injury or death. At a minimum,

all Lockout/Tagout procedures should include:

Electrical Shock Hazards Exist - Work Safely

Failure to turn the Main Power disconnect to the Off position, lock it out, and tag it could

result in severe personal injury or death.

1. Set the machine’s Main Power switch to the Off position.

('*(

2. Affix a

near the machine’s Main Power switch, until all repairs are complete.

3. Turn the Main Power disconnect to the Off position.

4. Install an industry approved lockout device through the Main Power

disconnect handle.

5. Install a t amper-proof padlock onto the loc kout device. Al l persons

performing maintenance on the machine at the same time shall install

their own padlock onto the lockout device.

6. Disconnect the main power of all power sources (i.e. electrical, air,

hydraulic, etc.).

Use the Lockout/Tagout policy and procedures defined by your company.

If no Lockout/Tagout procedure has been communicated to you, please

ask your supervisor to provide and explain one or obtain copies of standards to develop and implement Lockout/Tagout in your plant.

• A NSI has issued a standar d to a ssist in th e desig n and developme nt of

a Lockout/Tagout policy. It is written as a guide to follow when determining the spec ific p roced ures and trai ning n ecessar y and appr opria te

to your plant operations.

DO NOT START

tag with your na m e and department at, on, or

- Copies of the ANSI standard are available from ANSI at 1430

Broadway, New York, NY 10018, ask for: Standard ANSI Z244.11982, or as modified, for personal protection - Lockout/Tagout Of

Energy Sou rces - Minimum Safety Requirements.

01_20ed3a Safety.fm 1 - 5

Page 16

('*(

3UH,QVWDOODWLRQ*XLGH

1.3 Personal and Pr ofessional Safety

General safety precautions should be practiced everyday, but never

become common place. Safety is the responsibility of every person on the

job site. In this regard, consider yourself responsible for safety in your

workplace. No on e is better positioned to eliminat e or prevent unsafe conditions than you. Each employee should practice the following, regardless

of their position, title, or labor grade:

• Approach and intercede anytime you witness unsafe procedures.

• Be prepared to report any condition which seems unsafe to your company’s safety department or any supervisory or management staff. It

could save lives. In particular report such things as:

- Missing or defective guards and protective devices.

- Leaks and spills of cutting fluid, lubricants, or any liquids.

- Improperly stored chemicals or flammable materials and any

unusual fumes.

- Loose, worn, or broken flooring.

- Slippery, broken, or unstable platforms.

- Missing, broken, or unstable handrails.

• A v oid making sudd en movemen ts, loud noise s, engagi ng in horsep lay,

or other activities that may prove distracting and result in an unsafe or

dangerous work environment. Remember that around machinery, it

only takes a second’s inattention to result in personal injury or death.

• Observe and obey all signs posted on the machinery and its components and sign s placed by your company, like:

- NO SMOKING

- SAFETY GLASSES MUST BE WORN WHILE OPERATING THIS

MACHINE

- DANGER - HIGH VOLTAGE, etc.

• Wear appropriate safety equipment as defined by OSHA, the equipment manufacturer, your company safety policy, or MSDS (Material

Safety Data Sheet). Always wear approved eye protection and other

safety equipment to meet the demands of current conditions while

operating or working around the machining center.

1 - 6

• Clean up any oil or other liquid spills immediately.

Page 17

3UH,QVWDOODWLRQ*XLGH

• Obtain an MSDS for each chemical (such as cutti ng fluids, lubricating

oils, greases, etc.) used on or around the machining center. Practice

safe working ha bits and wear all protective equipment required. Know

and understand the procedures to follow in the event:

- Your skin is exposed to the chemical.

- Your eyes are contacted by the chemical.

- You ingested or inhaled the chemical.

1.4 Equipment an d Op e ration Safety

We urge that all machining centers be operated, equipped, and cared for

in strict compliance with all local, state, and federal safety regulations. The

following safety requirements apply to all machinery and should be practiced in addition to machine specific safety guidelines.

• Do not neglect your responsibility to ensure that all machining centers

are operated, mai ntain ed, and eq uipp ed with compl ete r egar d for o perator safety.

('*(

Only qualified personnel, trained in safety and all machining center functions should be allowed to operate, maintain, or repair the machine.

To be considered qualified, all personnel whose duties are related to the

operation, maintenance, or repair of the machining center should:

• Know the location and operation of t he [

ton.

• Study the related guides or manuals prior to attempting to operate,

maintain, or repair the machine.

• Locate and understand all

machining center and accessories.

Machining centers are designed for operation by one person at a time.

• P ersons other than the designa ted operato r should stay ou t of the area

during operatio n.

• Unauthorized personnel may increase the potential for injury or damage due to inattentiveness.

Danger, Warning,

EMERGENCY

and

Caution

] (E-Stop) but-

labels on the

01_20ed3a Safety.fm 1 - 7

Page 18

('*(

3UH,QVWDOODWLRQ*XLGH

Be sure to Always:

• Take steps to protect the machine tool and control cabinets from moisture and condensation. Moisture can damage electrical components,

causing unwanted machine motion, leading to injury or machin e damage.

• Maintain the exact original color and vividness of any machine areas

that are color coded as safety precautions.

• Ensure that all shields and gu ards are in place and all covers, cabinet

doors, and terminal boxes are closed prior to operation.

• Avoid accidentally bumping any machine controls, as this may cause

unintended machine motion causing injury or machine damage.

• Be alert for loose, damaged, or worn parts on the machine and associated equipment. Immediately correct or report any loose items, noticeable change in operating noise, or any unusual machine action.

• Be aware of the machine and auxiliary components’ moving members

and range of movement which may create pinch points. Always be

cautious of these areas. Avoid pinch points entirely during machine

operation.

• Keep the machining center properly maintained. Perform maintenance

at prescribed int ervals, as describe d in the Mechanical Editions.

Machining center maintenance should be performed only by authorized individuals.

• Check the level of each fluid reservoir periodically. Add fluids, if

needed, as described in the Mechanical Editions. Use only recommended lubricants.

• Keep the machining center clean. Keep the work area clear of chips,

rags, etc. Clean up any spilled or splashed fluid on the floor immediately. Cleaning should be performed at least daily.

• Double check the set up and workpiece before power up.

• Check all clamp bolts for tightness and verify the accuracy of all set

ups before restarting machining operation.

• U se caution when handli ng workpieces after machini ng. Machining can

produce sharp edges and, at times, considerable heat.

1 - 8

Page 19

3UH,QVWDOODWLRQ*XLGH

('*(

You should:

• N ever wear loose -fitt ing cl othing or acc essories tha t may be entan gled

in machine components. In particular, never wear any of the following

items when working in a shop environment:

- Jewelry (rings, bracelets, watches, or necklaces) and accessories

(necktie, scarf, or loose fitting belt)

- Long hair (tie back and contain it under a hair net or cap)

• Never operate any machinery after taking strong medication, using

nonprescription drugs, or co nsuming alcoholic beverages.

• Do not make modifications to the machine or associated equipment

that may reduce the operational safety of the device such as:

- Never paint, alter, deface, or remove any danger, warning, or cau-

tion label. (Rep lacement labels are available from Makino)

- Never change or by-pass the location of the stroke limit dogs, limit

switches, interlock circuitry, etc.

- Never operate the machine with any safety device disabled or

removed or any cover open or removed

• Do not allow yourself to become trapped or caught in pinch points:

- Always be aware of a safe exit, when in or around any type of

equipment. Know the travel limits of the machining center and

always keep all body parts clear of moving components.

- Never enter an area restricted by a barrier without first properly

shutting down the equipment and locking out the power sources to

prevent its restarting.

- Never perform any set up, check the set up, or reach into the work

area or across moving par ts while th e mach ine is in autom atic ope ration.

- Never change a workpiece or perform a manual operation on a

workpiece while the machine is in automatic operation.

• Never activate or press any button or other operating control unless

you are trained on t he ope ration of that d evice, ma chine , or e quipm ent.

• Never use compressed air to clean or blow chips or dirt off the table,

workpiece, or the machining center.

01_20ed3a Safety.fm 1 - 9

Page 20

('*(

3UH,QVWDOODWLRQ*XLGH

1.5 Environmental Safety

Follow these specif ic practices when work ing at the machining center:

• T he area arou nd the machine shou ld be well lig hted, dry, and free from

obstructions. Keep the area around the machine clean and in go od

order at all times.

• Equipment should not be operated during severe thunderstorms or

other electrical disturbances.

• In the event of a power failure, turn the Main Power switch Off immediately. Leave the switch in the Off position until the power is fully

restored and no rmal operations can safely be resumed.

• Never step on machine covers as they can become slippery during

normal operation and are not designed to support your weight.

• Never perform grinding operations in the vicinity of the machining center. The dust created by grinding can contaminate components, cause

premature wear, and cause inaccuracies or component failure .

• Never weld on parts mounted on or in the machine. Electrical cu rrents

associated with welding could cause bearing damage or explosions

and result in serious injury or equipment damage.

• When a platform is placed around the machining center, it should be

extremely sturdy, safe, and have anti-slip surfaces.

• Keep all flammable liquids away from the work area.

1 - 10

Page 21

1.6 Lifting Safety

These lifting safety precautions must be followed by all persons responsible for lifting. This includes, but is not limited to , lifting machinery, machine

components, and workpieces:

• All lifting equipment must be properly rated for the weight being lifted.

• All lifting equipment must be inspected on a regularly scheduled basis.

• A ny lifting device fo und to be defe ctive must be repa ired in accord ance

with industry standards.

• Any lifting device that cannot be repaired mus t be destroyed.

1.6.1 Slings

Use nylon slings when lifting irregularly shaped objects and:

• Never exceed the lifting capacity of any sling.

3UH,QVWDOODWLRQ*XLGH

('*(

• Protect slings with heavy padding when lifting objects with sharp

edges.

1.6.2 Chains

Lifting chains must be stored prop erly to prevent da mage when not in use.

When using chains:

• Never exceed the lifting capacity of any chain.

• Do not drag chains.

• Do not allow chains to become tangled or kinked.

• Never twist chains in an attempt to shorten their length. Use proper

devices to shorten a chain’s length.

• Use chains equipped with enclosed lifting hooks.

01_20ed3a Safety.fm 1 - 11

Page 22

('*(

1.6.3 Hooks

When using hooks:

• Never exceed the lifting capacity of any lift hook.

• Do not repair lifting hooks.

• Destroy and discard bent lifting hooks.

1.6.4 Eye Bolts

To ensure a safe load carrying capacity:

• Never exceed the lifting capacity of any eye bolt.

• An eye bolt must be en gaged to at least 90 per c en t of its threaded portion.

• Never weld or heat an eye bolt to a temperature in excess of 480° C

(900° F). Heat exposure can change the physical properties of the

stock and create an unsafe eye bolt.

3UH,QVWDOODWLRQ*XLGH

• Never use an inch eye bolt in a metric thread or vice versa:

- Use inch series thread eye bolts in inch series threads.

- Use metric series thread eye bolts in metric series threads.

• Never use a painted or coated eye bolt as this may cover up defects.

• Discard and destroy any defective eye bolts.

1.6.5 Rings

When possible use a lifting ring or clevis instead of an eye bolt. Secure the

lifting ring with the correct inch/metric series bolt.

• Never exceed the lifting capacity on any lifting ring or clevis.

1 - 12

Page 23

3UH,QVWDOODWLRQ*XLGH

1.6.6 Lifting the Machine or Components

Use only a lifting dev ice and relate d equi pment t hat is capa city ra ted to li ft

the total weight of the machining center (and shipping skid, if the skid is

attached during lifting). Always follow the lifting instructions provided in the

Pre-Installation Guid e.

Before lifting, refer to shipping documents to obtain the weight of the

machine or component being lifted. If the necessary weights cannot be

determined, consult Makino. In addition:

• Only qualified riggers should perform machine lifting operations.

• Never place any portion of your body beneath a suspended object.

• Lift the machining center only at the designated lifting points.

• Never lift the machine higher than necessary.

• Always maintain the center of gravity by properly adjusting the leg

lengths of the lifting device.

('*(

1.6.7 Lifting Workpieces and Fixtures

Always use a lifting device and related lifting equipment that is capacity

rated for the workpiece or fixture being lifted.

• Never place hands, arms, feet, or any other portion of your body

beneath a suspended workpiece fixture.

• Always maintain the center of gravity by properly adjusting the leg

lengths of the lifting device.

01_20ed3a Safety.fm 1 - 13

Page 24

('*(

3UH,QVWDOODWLRQ*XLGH

1.7 Mechanical Maintenance Safety

Mechanical maintenance procedures for Makino machining centers

should be performed by properly trained and technically qualified personnel. They should ad here to the se specif ic pra ctices wh en wo rkin g wi th th e

machining center:

• Always perform Lockout/Tagout before removing any safety guard,

cover, barrier, or any basic component of the machining center. See

section 1.2.4

• Block vertical sliding members before disassembling any portion of

their drive train.

.

• B e familiar with and adhere to safe lifting practices described in

before lifting the machine or components.

1.6

• Never return the machining center to production until all safety guards,

covers, barriers, or other safety devices are reinstalled and confirmed

operational.

section

Mechanical Maintenance Equipment

Mechanical maintenance personnel should:

• Keep all hand tools in good repair.

• Use each hand tool in a manner for which it is intended.

• Never use any hand tool that is defective, broken, or worn out.

• Keep alert with regard to nearby hazards.

• Do not use extenders in an effort to gain leverage; use a bigger tool.

1 - 14

Page 25

3UH,QVWDOODWLRQ*XLGH

1.8 Electrical Maintenance Safety

Electrical maintenance procedures for Makino machining centers must be

performed by properly trained and technically qualified personnel. They

should adhere to these specific practices when working with the machining center:

• Always perform Lockout/Tagout before working on electrical circuits.

See

section 1.2.4

• Use extreme care when troubleshooting with power On.

• With the power Off, identify and discharge any power retaining

devices, such as capacitors, before starting any maintenance procedure within any electrical control cabinet.

.

Electrical Maintenance Equipment

Use only industry standard approved electrical testing equipment.

('*(

• Volt/Ohm Meters.

• Oscilloscopes.

• Static Ground Wrist Straps.

Machine Grounding

All Makino machin ing centers must be properly grounded at the time of

installation.

• JIS class 3 grounding (resistance of 100 Ohms or less) is recommended.

• Proper grounding requires an isolated earth ground.

• Ground the machine in accordance with local, state, and federal regulations.

Machine Electrical Devices

Always replace defective electrical components, such as fuses, shunts,

overloads, etc., with components of the same capacity and rating as the

original equipment. If you are unsure of the correct electrical component

or part, refer to the machine’s electrical drawings or consult Makino.

01_20ed3a Safety.fm 1 - 15

Page 26

('*(

g

3UH,QVWDOODWLRQ*XLGH

1.9 EDGE2 Ram Electrical Discharge Machine Safety

In addition to safety precautions for all machining operations, Become

familiar with the machine specific safety features listed below.

1.9.1 Fire Hazard and Prevention

Fire Hazard

RAM type EDM uses a dielectric fluid in the machining process. This fluid is flammable

and may i

All Makino RAM machines are provide d with the following fire related

safety features:

1. Dielectric Temperature Detector – to immediately stops the machining

process when the temperature of the dielectric fluid rises above a set

value of 53°C.

nite, if improperly applied.

2. Dielectric Level Detector – to immediately stops the machining process when the dielectric level falls below the set level. The set level

must be at least 50mm above the workpiece.

3. Abnormal Machining Detector – stops the machining process if an arc

occurs for an extended duration. During an arc the head retracts to

clear the problem. If the head retracts beyond a specified distance,

machining stops and an “abnormal machining” alarm is generated.

4. Automatic Fire Extinguisher – If the dielectric fluid catches fire a sensor detects the temperature rise and discharges the extinguishing

agent into the work area. Additionally, all machine functions stop and

an audible alarm sounds. To resume machining operations, you must

change filters and di electric fluid t o remove the exti nguishing age nt. Do

NOT remove or chang e th e p ositi on s of the fire extinguishe r senso r (s)

or jet nozzle(s).

1 - 16

Page 27

3UH,QVWDOODWLRQ*XLGH

('*(

Be sure to Always:

• Keep all fire extinguishers fully maintained and operational and train all

personnel in their proper use.

• Ensure the automatic fire extinguisher is f ully operational. Perform a

functional test at the prescribed intervals. Never operate the machine

with the fire extinguisher testing knob in the "LOCK" position.

• In stall addition al fire extinguisher s of a type for liquid app lications in the

work area.

• Fully ventilate the work area at all times.

• Pay attention to the mounting method of the electrode, workpiece and

fixture so that electrical discharge does not occur near the surface of

the dielectric.

• Monitor the machining process. Never leave the machine totally unattended for extended periods of time. Allocate workers in such a manner that necessary measures can be taken if a problem occurs or if a

fire arises.

• Use only approved dielectric fluids.

You Should Never:

• Never substitute any oth er flammable liquids, such as kerosene for

dielectric fluid.

• Never use fire or heat sources such as heaters, welding machines or

open flame, near the mach ine.

• Never machine with fluid only being jetted onto the workpiece.

• Never machine with less than 50mm of dielectric fluid covering the

workpiece.

01_20ed3a Safety.fm 1 - 17

Page 28

('*(

3UH,QVWDOODWLRQ*XLGH

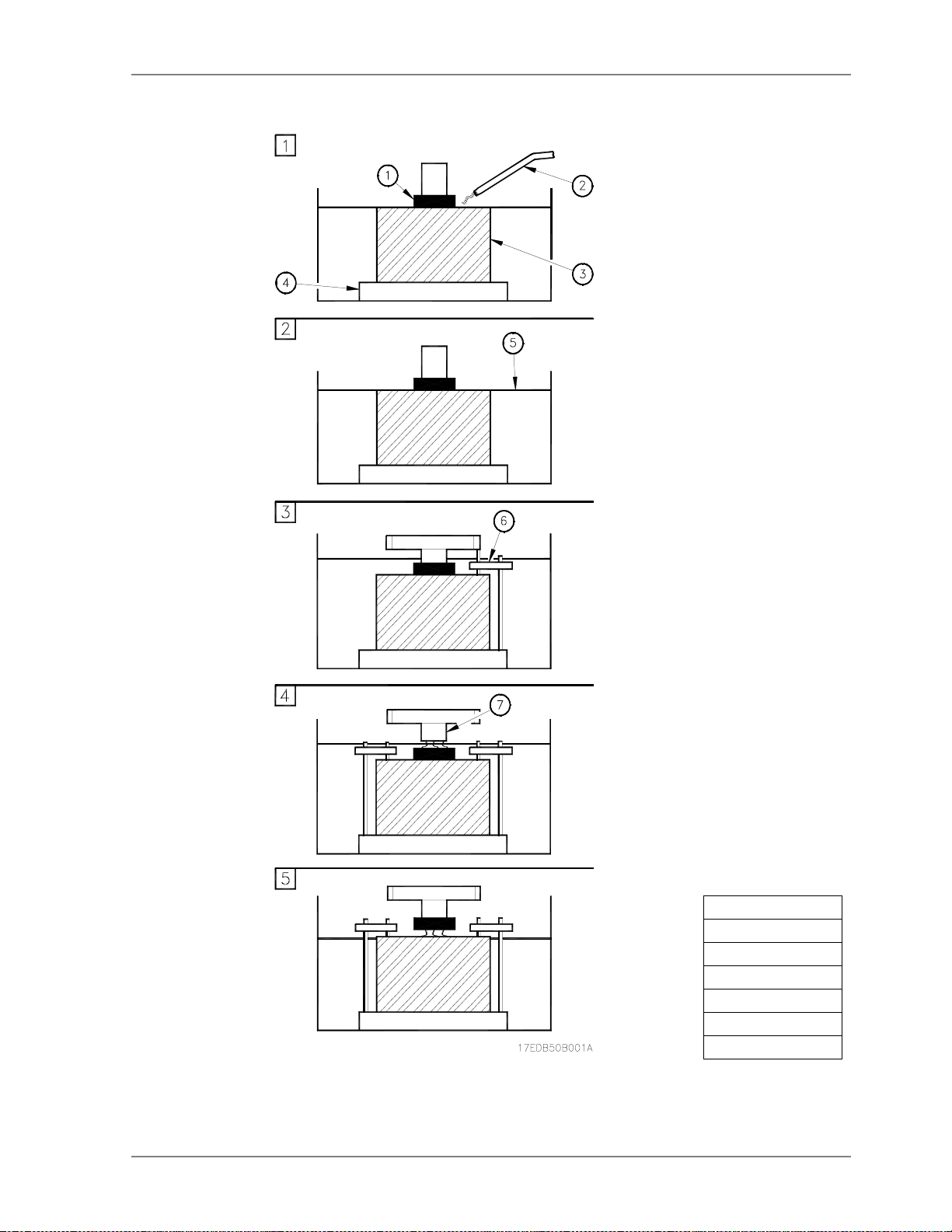

1.9.1.1 EDM Fire Conditions

The following conditions may result in fire during machining operations

(

Figure 1-1

1. Fire hazard caused by spray ing dielectr ic fluid onto workpiece. Workpiece shou ld be submerge d in the dielect r ic fluid to ensure safe bu rning.

2. Fire hazard from mach ining without e nough dielectri c fluid covering th e

workpiece. Dielectric level must be 50mm above the top of the workpiece.

3. Fire hazard from machine platen contacting a clamp. Ensure mo ving

machine members will clear clamps, work piece, and fixturing.

4. Fire hazard due to arcing between shank and electrode. This is

caused if the electrode becomes loose or is im properly mounted.

).

5. Fire hazard due to carbon build up is caused by a combination of too

little dielectric fluid covering the part and arcing.

6. Fire hazard can be caused by concave electrode shape (not shown),

as gas can collect in cavity. Ensure a vent hole is drilled at the high

point of the cavity.

1 - 18

Page 29

3UH,QVWDOODWLRQ*XLGH

('*(

Legend

[1] Electrode

[2] Jet Nozzle

[3] Workpiece

[4] Table

[5] Dielectric

[6] Clamp

[7] Shank

IGURE

F

01_20ed3a Safety.fm 1 - 19

EDM FIRE CONDITIONS

1-1

Page 30

('*(

3UH,QVWDOODWLRQ*XLGH

1.9.2 Machine Safety Fe atures

The EDGE2 provides the following safety features:

EMERGENCY

•[

] button, to immediately halt all machine functions.

• Automatic Fire Extinguisher and other fire related equipment, see

tion 1.9.1

Descriptions, operational detail, and precautions related to these safety

features are described in the Operation Guide.

(pg 1-16)

.

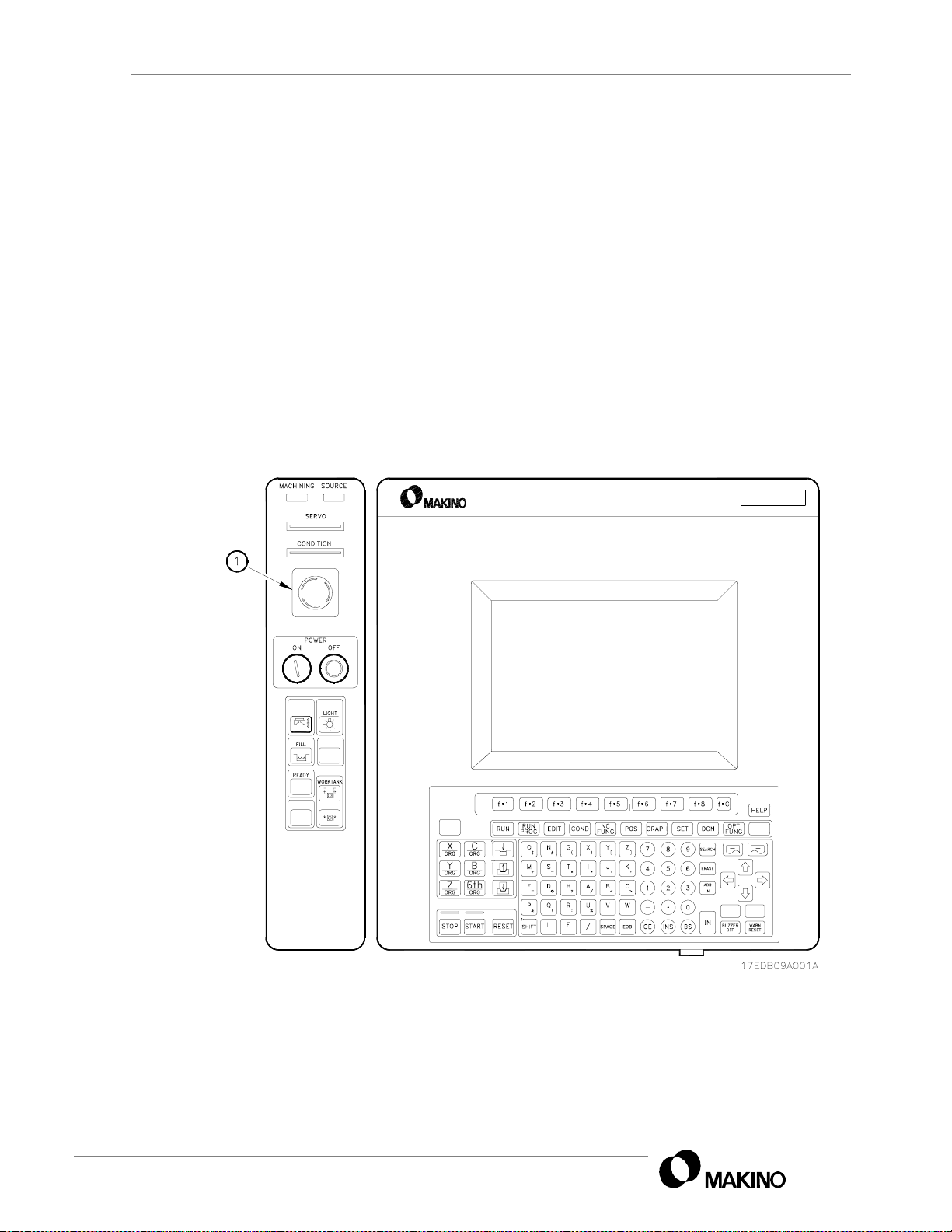

1.9.3 Location of Emergency (E-Stop) Button

EMERGENCY

The [

] button [1] is on the Main operation panel (

sec-

Figure 1-2

MGF

).

1 - 20

IGURE

F

EMERGENCY BUTTON LOCATION

1-2

Page 31

3UH,QVWDOODWLRQ*XLGH

1.9.4 Location of Safety Labels

Labels attached to the machine at specific areas, ident ify safety risks and

provide important instructions that must be read and followed.

('*(

• Machine safety labels (

• Oilmatic safety labels (

Figure 1-3

Figure 1-4

)

(pg. 1-22)

)

IGURE

F

01_20ed3a Safety.fm 1 - 21

MACHINE SAFETY LABELS

1-3

RIGHT VIEW

-

Page 32

('*(

3UH,QVWDOODWLRQ*XLGH

IGURE

F

OILMATIC SAFETY LABELS

1-4

1 - 22

Page 33

3UH,QVWDOODWLRQ*XLGH

1.10 EDGE2 Equipment and Operation Safety

('*(

In addition to the general safety precautions in

specific practices when working with the EDGE2.

section 1.2

, adhere to these

Be sure to Always:

• Inspect all tool holders for nicks or other damage to ensure the accuracy of machining operations and prevent damage to the equipment.

• Check with the manufacturer to ensure proper and safe operat ion in a

RAM EDM environment, of any accessory NOT specifically built,

designed, or s upplied by Makino .

• Use extreme caution when changing electrodes. Make sure that all

electrodes are properly loaded and secured and that they will not come

into undesirable contact with items in the work ar ea during oper ation.

• Load or unload workpieces only when the machine is completely

stopped and the control is in the STOP or RESET status.

• DRY RUN machining programs to verify that there is no chance of any

interference be twee n an y mach ine pa rts, f ixtur ing, and wor kpie ce pr ior

to unattended operation of the machine.

• Before moving the X, Y, or Z axes, make sure that there are no

obstructions within the range of movement.

• Check the tightness of all clamping devices, fixture mounting, electrodes and tool holders prior to any machining operations. Be sure to

verify the acc uracy of the set up prior to automatic operations.

You should Never:

• Never use any device NOT specifically designed for use in an EDM

environment. The dielectric fluid and electrical energies will cause

damage to improperly designed devices.

• N ever lay too ls on t he machi ne wher e they may i nter fere wi th machi ne

movement or can become entangled with the work.

• Never exceed the machines specified maximum workpiece weight

(500kg) or electrode weight (50kg).

• Never perform any set up work while the machine is in operation.

01_20ed3a Safety.fm 1 - 23

Page 34

('*(

3UH,QVWDOODWLRQ*XLGH

Working Inside the Machine

When working inside the machine be aware that axes and work tank operation are hazards that could result in serious injury or death. Therefore:

• Enter the machining area only when all machine motion is completely

stopped and the control is in the STOP or RESET state.

• Remember injury can occur if any body parts are caught between top

of the work tank and the workpiece or fixture or between work tank bottom and a platform or steps set near the machine.

• Ensure the Flexible Pendant Box cable does not interfere with the

workpiece or fixture.

• Always place the Flexible Pendant Box to prevent accidental key activation resulting in unexpected machine movement.

Prior to Machining

• Check with the manufacturer of any accessory not designed, built, or

supplied by Makino to ensure the device will opera te properly and

safely under the proposed operating conditions.

• P rio r to unatte nd ed op eratio n, p rove ou t p art p rogram s t o ensu re cl earance between machine parts, fixturing, and the workpiece.

• Before moving the axes, make sure there are no obstructions within

the range of movement.

• Verify the accuracy of the set up prior to automatic operation. Check

the tightness of all clamping devices, fixture mounting, etc.

Workpiece Handling Safety

These specific l if ti ng safe ty p r ecau ti on s must be followed by a ll personnel

responsible for lifting workpieces. In addition to the general lifting precautions in

• The EDGE2 has a maximum allowable table capacity of 500kg. Never

• U se liftin g equi pmen t for heavy w orkpiec es an d other ma terial s. Never

section 1.6

exceed this weight limit.

attempt to lift anything beyond a reasonable weight without proper

devices.

, adhere to these specific practices with the ED GE2:

1 - 24

• Use care not to place fingers or hands where they may be pinched by

the table or lower head while loading/unloading workpieces.

Page 35

3UH,QVWDOODWLRQ*XLGH

1.11 Installation Safety Instructions

The following information is related to installation of the machining center.

Adhere strictly to the installation instructions provided in the Pre-Installation Guide:

('*(

• Review the general lifting safety rules in

procedures in the Pre-Installation Guide, prior to moving the machine.

• Review the general electrical safety rules in

procedures in the Pre-Installation Guide, prior to connecting power to

the machining center.

section 1.6

section 1.8

and the specific

and the specific

01_20ed3a Safety.fm 1 - 25

Page 36

('*(

OTES

N

3UH,QVWDOODWLRQ*XLGH

:

KETCHES

S

:

1 - 26

Page 37

3UH,QVWDOODWLRQ*XLGH

Chapter 2 Specifications

Machine Unit and Control Specifications

Makino EDGE2

('*(

Ram Electrical Discharge Machine

with MGF Control

02_20ed3a Specifications.fm

Page 38

('*(

g

g

g

g

3UH,QVWDOODWLRQ*XLGH

Chapter 2

Specifications

Contents

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.2 Installation Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.2.1 Layout Drawin

2.2.2 Foundations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

2.3 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

2.3.1 Machine Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

2.3.2 Machine Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

2.3.3 Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

2.3.4 Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 8

2.4 Unit Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

2.4.1 Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9

2.4.1.1 C Axis (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 10

2.4.2 Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 11

2.4.3 Axis Components (Spindle, Ram, Saddle) . . . . . . . . . . . . .2 - 12

2.4.4 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 12

2.4.5 ATC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 14

2.4.5.1 Maximum Electrode Size. . . . . . . . . . . . . . . . . . . . . . . .2 - 14

2.4.6 Dielectric Fluid Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 15

2.4.6.1 Dielectric Fluid.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 16

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.4.7 Machinin

2.5 Makino MGF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

2.5.1 Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 18

2.5.2 Machine Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

2.5.3 Operational Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 19

2.5.4 Maintenance and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

2.5.5 Controlled Axes and Coordinate System . . . . . . . . . . . . . . .2 - 20

2.5.6 Auxiliary Functions and Machinin

2.5.7 Interpolation and Feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

2.5.8 Pro

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 17

Conditions . . . . . . . . . . 2 - 21

ramming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 22

Page 39

3UH,QVWDOODWLRQ*XLGH

g

2.1 Overview

Makino’s EDGE2 prov ides fully automated function al machine capabilities. Machine and MGF control specifications follow.

Information Subject to Change

Every effort was made to ensure the accuracy of the data presented in this chapter at

the time of publication. Machine and control specifications are subject to chan

prior notification.

2.2 Installation Specif ica tions

Dimensional and general arrangement drawings are included in this section to ensure proper machine site selection.

The machine tool sh ould be placed with sufficient clearance to:

• Access the rear of the machine and all auxiliary components.

('*(

e without

• Completely open all cabinet doors and panels.

• Prevent interference and pot ential pinch points of moving components

with structural features (pillars, walls, etc.), other machines, their range

of movement, or components.

02_20ed3a Specifications.fm 2 - 1

Page 40

('*(

3UH,QVWDOODWLRQ*XLGH

2.2.1 Layou t Drawings

2 - 2

IGURE

F

2-1 EDGE2

Legend

[1] Work Table [5] NC Unit

[2] ATC [6] Flexible Pendent Panel

[3] Ram [7] Work Tank

[4] Main Operation Panel

FRONT VIEW

Page 41

3UH,QVWDOODWLRQ*XLGH

g

('*(

Legend

[1] Dielectric Unit [5] Air Filter Regulator

[2] Oilmatic [6] Automatic Fire Extin

[3] Ram [7] Work Ta nk

[4] NC Unit [8] Work Table

IGURE

F

02_20ed3a Specifications.fm 2 - 3

2-2 EDGE2

LEFT AND RIGHT VIEWS

uisher

Page 42

('*(

3UH,QVWDOODWLRQ*XLGH

2 - 4

IGURE

F

2-3 EDGE2

Legend

[1] Dielectric Unit [3] NC Unit

[2] Oilmatic [4] Main Operation Panel

GENERAL ARRANGEMENT DRAWING

Page 43

2.2.2 Foundations

The machine should be placed on a continuous concrete pad. The

required floor space (including standard accessories) is 2225

for a standard m achine. The required floor space increases with ATC or

booster options.

• The recommended concrete thickness is 300m m.

3UH,QVWDOODWLRQ*XLGH

('*(

2370mm

×

02_20ed3a Specifications.fm 2 - 5

Page 44

('*(

g

g

3UH,QVWDOODWLRQ*XLGH

2.3 General Information

This section contains general information on EDGE2 environment,

machine size, power, and air requirements.

2.3.1 Machine Environment

The EDGE2 performan ce is dire ctly af fected by t he env ironmen t.

lists key environmental specifications.

ABLE

T

2-1 EDGE2

Item Specification

Ambient Temperature Range 10 – 35°C

Optimum Temperature 20±1°C

Maximum Relative Humidity 75% (no condensation)

Maximum Vibration 0.7m/s

EDGE2 Heat Release Rate 30A 5.3kW

EDGE2 Heat Release Rate 60A 7.1kW

In addition, protect the EDGE2 from:

• Dust, like that from grinding or polishing machines.

• Direct sun light , excess air from ventilation systems, or any source that

may affect the machine temperature.

2.3.2 Machine Size

ENVIRONMENTAL SPECIFICATIONS

2

Table 2-1

Machine dimensions are listed in

plans are presented in

ABLE

T

2-2

Height 2290mm

Width 1625mm

Depth 1770mm

Wei

ht (including NC unit and generator) 3000k

Required Floor Space 2225×2370mm

2 - 6

MACHINE DIMENSIONS

Item Specification

section 2.2.1

Table 2-2

.

. External dimensions and floor

Page 45

2.3.3 Electrical Power

g

g

g

A 3-phase power source, with stable voltage regulation (±10%) and a JIS

class 3 ground, of 10 ohms or less, must be provided.

The EDGE2 operates on 200/ 220VAC ±10%, 50/60Hz ±1% connec ted to

a terminal in the machine tool cabinet.

• A standard machine operates on 9kVa.

The customer must:

• Provide a properly sized service box for the machine. Use local code

and

Table 2-3

machine kVa rating when calculating machine electrical consumption.

• Ensure the electrical service voltages meet all requirements.

• Install an additional automatic voltage regulator i f t he required voltage

cannot be maintained within ±10%.

to assist in sizing the machine electrical service. Use the

3UH,QVWDOODWLRQ*XLGH

('*(

• Connect incoming electrical service at the Main Power switch.

• Provide a JIS class 3 ground of 100 ohms or less.

To convert kVa to amperage for service amperage:

kVa

1000/1.73

×

Voltage

×

=

amps

then take:

amps

ABLE

T

2-3

Machine kVa Rating Standard 30amp 9kVa

Machine kVa Ratin

Source Volta

Operatin

Cycle (±1%) 50/60Hz

MACHINE POWER REQUIREMENTS

Power Requirements

60amp 12kVa

e (±10%) 200-480VAC

Voltage (±10%) 200-220VAC

125% = Service

×

02_20ed3a Specifications.fm 2 - 7

Page 46

('*(

2.3.4 Air

Dry and clean compressed air at 0.6MPa must be available. The air supply line should be permanentl y piped.

• A pressure switch detects if air pressure drops below 0.3MPa and

3UH,QVWDOODWLRQ*XLGH

stops machine operation .

ABLE

T

2-4

Standard machines Pressure 0.6MPa

With MA Head Pressure 0.6MPa

With ATC Pressure 0.6MPa

AIR SPECIFICATIONS

Item Specification

Consumption 100 liter/min.

Consumption 200 liter/min.

Consumption 200 liter/min.

2 - 8

Page 47

2.4 Unit Specifications

g

g

Specifications for each machine component follow. These specifications

are presented to serve as a quick reference.

2.4.1 Head

The head can be purchased in

several configurations. On

standard head s the electrode

is bolted directly to the platen.

Figure 2-4

bolt pattern.

Machines may also be pur-

chased with a C axis (option)

which comes with a chuck

adapter.

shows the platen

3UH,QVWDOODWLRQ*XLGH

('*(

• The C axis may be purchased with a 3R m acro or

Erowa rapid action chuck

system

IGURE

F

ABLE

T

2-5

Max Electrode Weight 3 Axis Orbiting 50k

Max Weight Capacity of Chuck 40k

HEAD SPECIFICATIONS

Item Specification

2-4

Legend

[1] M10 × 1.50 TAP (4 Places)

[2] M8 × 1.25 TAP (12 Places)

STANDARD PLATEN BOLT PATTERN

02_20ed3a Specifications.fm 2 - 9

Page 48

('*(

g

g

g

g

g

g

3UH,QVWDOODWLRQ*XLGH

2.4.1.1 C Axis (option)

The C axis is available in a MA or MR configuration (

Table 2-6

). The C axis

allows progra m ma ble indexing of th e h ea d for positioning the electrode to

a specific angle. The MA and MR heads also provide a rotary function for

rotating the electrode.

• Refer to your sales order to confirm the head provided on your

machine.

ABLE

T

2-6

Speed (Rotary Function Selected) 10~1000rpm 0~10rpm

In Rotation (C-axis and Rotary Function) 30 amps 30 amps

Fixed (C-axis and Rotary Function) 30 amps 60 amps

Max. Electrode Wei

Max. Electrode Weight Using C-axis Positioning10k

Minimum Input Increment 0.001° 0.001°

Toolin

Provisions Available Erowa ITS or 3R Macro

SPECIFICATIONS FOR MA AND MR HEADS

Specification

ht in a Fixed Position 5k

Head Type

MA MR

10k

15k

2 - 10

Page 49

2.4.2 Table

3UH,QVWDOODWLRQ*XLGH

('*(

Figure 2-5

IGURE

ABLE

T

F

2-5

2-7

shows table detail and

TABLE AND T-SLOT DETAILS

TABLE SPECIFICATIONS

Item Specification

Table 2-7

lists table specifications.

Table Size 500x350mm

Number of T-Slots / Size 10mm x 4 rows

Maximum Workpiece Weight 500kg

Table Surface Height 840mm

02_20ed3a Specifications.fm 2 - 11

Page 50

('*(

3UH,QVWDOODWLRQ*XLGH

2.4.3 Axis Components (Spindle, Ram, Saddle)

Table 2-8

lists work zone and machine travel specifications.

shows axis configuration and work cube.

ABLE

T

2-8

X,Y Axis Travel 300×250mm

Z Axis Travel 250mm

Worktank Dimensions (WxDxH) 650×450×300mm

Platen to Table Distance Bottom Point 250mm

Chuck Face to Table Bottom Point 180mm

Table Size 500×350mm

AXIS COMPONENT SPECIFICATIONS

2.4.4 Accuracy

Table 2-9

cies are checked at the factory and requir e proper instal lation, foun dation ,

environment, operation, and maintenance to be maintained or guaranteed.

lists standard machine accuracy specifications. These accura-

Item Specification

Figure 2-6

ABLE

T

2-9

Static Load Positioning ± 5 microns [0.005mm]

Repeatability ± 2 microns [0.002mm]

Dynamic Machining ± 5 microns [0.005mm]

* Above accuracies can be guaranteed, when machine is installed, operated, and main-

tained under proper conditions.

ACCURACY SPECIFICATIONS

Item Specification

2 - 12

Page 51

3UH,QVWDOODWLRQ*XLGH

('*(

Legend

[1] Machine Reference

[2] Table

IGURE

F

02_20ed3a Specifications.fm 2 - 13

AXIS CONFIGURATION AND WORK CUBE

2-6

Page 52

('*(

g

g

g

2.4.5 ATC

An ATC (Automatic Tool Changer) provides several advantages in extending no or low-attendant machining, au tomatic multiple operations, and

assigning spare tools for long job runs. The standard ATC is an A4 rack

type with an A8, A16, or A24 carousel types available.

specifications.

3UH,QVWDOODWLRQ*XLGH

Table 2-10

lists A TC

ABLE

T

2-10

ATC SPECIFICATIONS

Item Specification

Tool Selection Random or Sequential

Tool Chan

Max Electrode Wei

e Time Approximately 45 Seconds

ht by ATC 5k

2.4.5.1 Maximum Electrode Size

Maximum electrode length and

diameter (

Figure 2-7

by ATC size, chuck type, and

work tank positio n.

Maximum electrode diameter

varies by ATC size. Maximum

electrode length varies with

chuck type and work tank position. See

Table 2-11

• M ax imu m lengt h is based on

work tank in full up position.

) are limited

.

IGURE

F

Legend

[A] 230mm [C] 60mm

[B] 250mm [D] 80mm

ELECTRODE SIZE LIMITATIONS

2-7

ABLE

T

2-11

ATC Size

A16 230mm 250mm 60mm

A24 230mm 250mm 60mm

1

Maximum length with work tank in full up position.

2 - 14

ELECTRODE LIMITATIONS BY

Maximum Length

3R Macro EROWA

A4 230mm 250mm 80mm

A8 230mm 250mm 80mm

SIZE AND CHUCK TYPE

ATC

1

Maximum

Diameter

Page 53

3UH,QVWDOODWLRQ*XLGH

('*(

The maximum e lectrod e l ength, show n in

full up position and is also affected by chuck type.

Figure 2-7

, is for the work tank in

02_20ed3a Specifications.fm 2 - 15

Page 54

('*(

g

g

3UH,QVWDOODWLRQ*XLGH

2.4.6 Dielectric Fluid Supply

The dielectric supply unit (DI

unit) consists of an integrally

designed tank, filters [1], and

cooler unit.

This system filters machining

sediments from the fluid and

supplies clean fluid to the work

tank for optimum machining. For

increased accuracy, the cooler

maintains fluid temperature

within a set range of the

machine temperature.

ABLE

T

2-12

Fire Extinguisher Automatic

Worktank Vertical Slide System

Number of Pumps 1

Filtration 8 Micron × 2 Filters

Dielectric Refri

Max Worktank Level 250mm

Dielectric Reservoir Capacity 200 liter

Flushin

DIELECTRIC SUPPLY

Item Specification

eration Standard and Adjustable to ± 20°C

- Pressure/ vacuum 2 Ports – 1.05kg/cm

IGURE

F

2-8 DI

UNIT

2

2 - 16

Page 55

2.4.6.1 Dielectric Fluid

g

g

g

g

g

g

1. Always use a highly refined oil with a minimum of PAH’s. Use an oil similar to EDM244 or EDM-250 to minimize any health risks.

2. Never use a dielectric fluid with a flash point under 70°C.

Dielectric fluid is used in the machining process and is required at time of

installation and start up.

• The dielectric tank holds 200 liters.

There are three basic types of dielectric fluid, choose the type best suited

to your work

1. Mineral Fluid – provides a concentrated electrical discharge and a

removal rate 10 to 20% faster than synthetic fluids.

2. Synthetic Fluid – is recommended for machining with graphite and

when using hi gh current setti ngs. Synthe tics h ave le ss odo r an d be tter

surface roughness than mineral fluids and promote longer filter life.

3UH,QVWDOODWLRQ*XLGH

Dielectric Fluids

('*(

3. Intermediate Fluid – Provides performance characteristics between

those of mineral and synthetic fluids.

2.4.7 Machining Power Source

Table 2-13

ABLE

T

Circuit Type Transistor Pulse

Maximum Machinin

Current Settin

Volta

OFF Intervals 256 Steps

Power Stabilizin

LL Generator Circuit Standard

Power Unit Coolin

Machinin

lists the machining power source specifications.

2-13

MACHINING POWER SOURCE SPECIFICATIONS

Item Specification

Current 30A (60A optional)

s 90 Steps

e Settings8 Steps

Circuit Standard

Power Source 9kVa

Forced Air

02_20ed3a Specifications.fm 2 - 17

Page 56

('*(

3UH,QVWDOODWLRQ*XLGH

2.5 Makino MGF Control

Standard MGF control configuration is listed below.

2.5.1 Operation Panel

Feature Detail

Display

Panel

Routine

Functions

10.4 inch Color display

MDI (Manual Data Input) Function

Operation Record Display

Run Hour

Dynamic Graphic Display

Automatic Reference Return

Measurement

Return To Workpiece Zero Position

Stored Stroke Limit

2.5.2 Machine Communications

Feature Detail

I/O Communication Ports

3.5 type Floppy Disk Drive

NC Tape

EIA/ISO Recognition

RS-232C

RS-227

2DD/2HD: 720kB/1.25MB, 1.44MB

1 inch, 8 bit EIA

Automatic

2 - 18

Page 57

3UH,QVWDOODWLRQ*XLGH

2.5.3 Operational Support

Feature Detail

Operational

Support

Functions

Automatic

Operation

Support

('*(

Label Skip

Single Bloc k

Program Stop – M0

Optional Stop – M1

End of Program

Block Skip - /

Dry Run

Machine Lock

Auxiliary Function Lock

XY Axes Exchange

Manual Absolute

Automatic Return

Workpiece Edge Positioning

Hole Centering

Corner Edge Positioning

Groove Width Centering

Plate Width Centering

Cylinder Center Measurement

Work Parallelism Measurement

Automatic Measuring and Machining

Machining Time Estimation

User Creation Screen

Help Window

Key Input Pl ayback

Manual Interrupt

Process Skip and Additional Machining Function

Approach Function

Noncontact Point Search Functio n

Automatic Power Cut Off Function

02_20ed3a Specifications.fm 2 - 19

Page 58

('*(

3UH,QVWDOODWLRQ*XLGH

2.5.4 Maintenance and Safety

Feature Detail

Emergency Stop

Axis Overtravel Protection - 2 systems - Hard and

Stored Stroke Limit

Work Limit

Diagnostic Function

Maintenance

and

Safety

Regular Check Function

Maintenance Function

Parameter Output by Machine Number (G150)

Machining Condition Output (G151)

Machining Time Output (G152)

Machining Status Record Output (G153)

Data Backup (G154)

2.5.5 Controlled Axes and Coordina te System

Feature Detail

Controlled Axes

Coordinate

Systems

5

Simultaneous Control – 4

Absolute or Incremental - G90, G91

Reference Point Return - Manual, G28

Return From Reference Point - G29

Return To 2nd – 4th Reference Point - G30

Coordinate System Setting - G92

Machine Co ordinate System Setting - G53

Work Coordinate System Group – G500 – G509

Work Coordinate System Selection - G54-G61

Work Coordinate System Preset – G92

Relative Coordinate System Preset

2 - 20

Page 59

3UH,QVWDOODWLRQ*XLGH

2.5.6 Auxiliary Functions and Machining Conditions

Feature Detail

Auxiliary

Functions

Machining

Conditions

Machining (M17/M18)

Work Tank Up/Down (M28/M29)

Selection: E4 digit (E0001 – E9999)

Registered area: 600

2.5.7 Interpolation an d Feeds

Feature Detail

Rapid Positioning – Manual G0

Linear Interpolation – Manual G1

Circular Interpolation – G2 (CW), G3 (CCW)

Taper Interpolation – G51 (left), G52 (right), G50(can-

Interpolation

Feeds

Axis Motion

Overrides

cel)

Taper Corner Tangential Interpolation – G24

Spiral Interpolation – G2 5

Taper Top/Bottom Same Radius – G49

Vertical Irregular Shape Interpolation – G41/G42 P0,

P1, P2

Servo Feed by Machining Condition Setting

F4 Digit Traverse

Rapid Feed

Jog Feed (High, Middle Low)

Step Feed (Least Input Increment ×1, ×10

Incremental Feed

Dwell – G4

Automatic Accele ra tio n/De cel erati on

Override Cancel

F4 Digit Feed Override 0 – 200%

('*(

02_20ed3a Specifications.fm 2 - 21

Page 60

('*(

3UH,QVWDOODWLRQ*XLGH

2.5.8 Programmin g

Feature Detail

Storage

Methods

Editing

Programming

Support

Functions

Memory – 369,000 characters (1000m of tape)

Number of registrable programs – 9999

Standard CNC Language

Minimum Input Increment – 0.001mm (0.0001mm)

Standard or High Resolution (Parameter Selectable)

Control Unit – 0.00005mm

Maximum Programmable Increment - ±99999.999mm

Sub-Programming – Nesting level: 9

Programmable data input – G10

Custom Macro: 33 Local and 200 Common Variables

Decimal Point Programming

Diameter Compensation 10× precision (inch)

Part Program editing

Background editing

Program Number Search

Program Number Copy

Program Number Division

Program Number Collation

Sequence Number Search

Address and Word Search

Error Search

Execution Program Protection

Inch/metric selection –G20-G21

Circular Interpolation – by radius programming

Parameter Call

Modal Call

Pseudo Command Call

Scaling

Rotation

Rotation Copy

Model Plan

Sub Model

Programless Cut Off

Program Master Conversion

Built In Automatic Programming

Z axis Position Management

2 - 22

Page 61

OTES

N

3UH,QVWDOODWLRQ*XLGH

:

('*(

KETCHES

S

:

02_20ed3a Specifications.fm 2 - 23

Page 62

('*(

3UH,QVWDOODWLRQ*XLGH

2 - 24

Page 63

3UH,QVWDOODWLRQ*XLGH

Chapter 3 Installation Process

Overview

Makino EDGE2

('*(

Ram Electrical Discharge Machine

with MGF Control

03_20ed3a Install Process.fm

Page 64

('*(

g

3UH,QVWDOODWLRQ*XLGH

Chapter 3

Installation Process Overview

Contents

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.2 The Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.2.1 Customer Installation Duties . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.2.2 FSE Installation and Set-up Duties . . . . . . . . . . . . . . . . . . . .3 - 3

3.2.2.1 Machine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

3.2.2.2 On-site Trainin

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Page 65

3.1 Overview

This chapter describes Makino’s installation process and contains guidelines to prepare you for the delivery and installation of the EDGE2. It

establishes clear expectations a nd responsibilities for all of us.

The success and ef ficienc y of you r inst allation rest s, in large p art, on you r

participation and involvement in the installation process.

Sixty days before the delivery of your Makino machine take time to:

• Review the information and requirements related to pre-installation

• Establish a time-line for completion of these items

Makino’s installation process includes pre-installation duties to be performed by you.

These duties are listed in

3UH,QVWDOODWLRQ*XLGH

Installation Process

chapter 4

and

chapter 5

.

('*(

03_20ed3a Install Process.fm 3 - 1

Page 66

('*(

3UH,QVWDOODWLRQ*XLGH

3.2 The Installation Process

Makino developed a thorough process to ensure a consistent and professional installation. This process is designed to provide the maximum benefit from our FSE ( F ie l d Ser vi ce Engineer) for set-up and al i gnment of the

machine and proper training of your operator(s). Your participation and

assistance are critical to an effective installation.

3.2.1 Customer Installation Duties

Makino asks that you be an active participant in the installation process.

Your duties are listed below.

Makino recommends that you:

• Always use your unique RID (Request IDentification) number when

contacting us, to encourage clear, efficient communication (with your

sales order, Makino assigns a RID to track your machine installation).

• Read the pre-installation information in this Guide.

• Follow the instructions in

provided in

machining center.

• Complete each task in the Pre-Installatio n Checklist (

expedite the installation and ensure adequate time for training. Proper

training during the installation provides the greatest return on your

investment.

- Fax or mail your completed Pre-Installation Checklist to Makino.

This checklist is your request for installation services. The FSE

reviews the checklist to confirm completion of customer tasks, prior

to visiting your facility.

• C o nsider ha ving:

- Maintenance personnel available to the FSE during installation; this

opportunity for exposure to the machine before the covers are on

should not be missed.

- Operators and Maintenance personnel (ideally two, maximum of

four people) attend the Operation training.

chapter 4

chapter 4

to prepare for delivery and inst allation of the

and

chapter 5

. Use the worksheets

chapter 4

), to

3 - 2

Page 67

3UH,QVWDOODWLRQ*XLGH

3.2.2 FSE Installation and Set-up Duties

The Makino FSE is respo nsible for installi ng the machine a nd training your

personnel. The FSE in stalla tion p rocess shou ld be comple ted in five wo rking days.

These duties have a log ical or der an d a bui lt-i n flexib ility al lowi ng the FS E

to work around unexpected delays or problems and still complete the

installation on time. The following steps may be completed in a different

order.

• Some tasks duplicate items you already performed. This confirmation

reduces the chance of error or accident.

3.2.2.1 Machine Installation

1. Initial Checks

('*(

- Check the founda tion and placement.

- Check the machine for damage or other unacceptable conditions.

- Confirm cleanliness of machine components (i.e. anti-corrosive

grease is removed). After start up the FSE assists in final cleaning.

- Verify receipt of all accessories.

2. Remove Shipping Locks

- Remove all a xes and other compo nent shipping locks and supports.

You keep all locking and support devices in case the machine

needs to be moved.

- Check all motor connections.

3. Power, Air, and Lubrication

- Verify source voltage, transformer connections, and tap settings.

- Confirm air is supplied at the proper pressure and volume.

- Supervise filling of reservoirs with the proper fluids.

4. Machine Set-up

- Verify machine level and correct, if needed.

- Connect peripheral devices (i.e. Oilmatic).

- Install unit anchors, if needed.

03_20ed3a Install Process.fm 3 - 3

Page 68

('*(

3UH,QVWDOODWLRQ*XLGH

5. Power On

- Ensure the machine is ready for power, BEFORE applying power.

- After applying power, verify phase and confirm voltages are within

the allowable range.

6. Checks and Adjustments

- Install any required custom programs.

- Check and confirm proper operation of all machine systems and

functions (i.e. overtravel switches, spindle unclamp, etc.).

- Verify operation of CNC (Computer Numeri cal Control) and

machine parameters.

7. Finish Installation – Install any remaining covers and accessories.

8. On-site Training – Perform operation training, see

section 3.2.2.2

.

3 - 4

Page 69

3.2.2.2 On-site Training

g

g

g

g

g

Traini ng is a major compon ent in th e prop er insta llation of any equ ipm ent.

Our experience shows that incomplete training can cause:

• Increased down time and avoidable machine damage.

• Increased frustration during the learning curve.

• Reduced utility and return on investment.

Makino partnered with local educational groups to develop an on-site

training pac kage to make your operator(s) comfortable, confident, and

familiar with machine features and operation. This training is a “hands on,

practical application, competency based,” educational model.

Training during set-up is broken into three categories (each training area

is discussed below):

•Operator

3UH,QVWDOODWLRQ*XLGH

('*(

• Operator Maintenance

• Options

Makino requests the following be considered, regarding on-site training:

• We strongly recommend that both the operator(s) and maintenance

personnel are available for this training.

- The job of maintenance is to “fix the machine,” e ven if the problem

is not the “machine” itself. A working knowledge of machine operation and programming are powerful maintenance tools.

• To ensure consistency, have personnel from different shifts available

so the material is covered once.

- If scheduling does not allow this, notify the FSE, so the training tim-

ing can be adjusted to accommodate your needs.

Additional Training

Makino strongly recommends:

1. Operators/Pro

trainin

2. Maintenance personnel new to CNC or Makino machines and controls attend the

appropriate trainin

3. Companies interested in increasin

Makino’s formal learnin

classes at Makino.

rammers not familiar with this control model attend the appropriate

classes at Makino.

their capabilities and production should review

opportunities.

03_20ed3a Install Process.fm 3 - 5

Page 70

('*(

g

g

g

g

3UH,QVWDOODWLRQ*XLGH

Operator Training