Page 1

Original instructions

29F24D-2006EN

Page 2

Page 3

English

This manual should only be used by skilled maintenance

personnel.

Japanese

Albanian

Bosnian

Brazilian

Portuguese

Bulgarian

Chinese

Croatian

Czech

Danish

このマニュアルは訓練された保守要員がご使用ください。

Ky manual duhet të përdoret vetëm nga personeli I trajnuar

i mirëmbajtjes.

Ovo uputstvo bi trebalo koristiti samo osoblje obučeno za

održavanje.

Este manual apenas deve ser utilizado por técnicos de

manutenção qualificados.

За използване само от специално обучен персонал за

поддръжка.

本手册仅供已经培训的维护人员使用。

Ovaj priručnik namijenjen je samo obučenom osoblju za

održavanje.

Tato příručka může sloužit k použití pouze pro školený

personál údržby.

Denne manual må kun anvendes af specielt uddannet

servicepersonale.

Estonian

German

Hungarian

Indonesian

Dutch

Finnish

French

Greek

Italian

Dit handboek mag enkel door speciaal opgeleid

onderhoudspersoneel gebruikt worden.

Manuaal on mõeldud kasutamiseks ainult vastavate

oskustega hoolduspersonalile.

Vain koulutetut huoltohenkilöt saavat käyttää tätä

ohjekirjaa.

Ce manuel ne doit être utilisé que par du personnel de

maintenance compétent.

Dieses Handbuch darf nur duch speziell ausgebildetes

Wartungspersonal verwendet werden.

Το παρόν εγχειρίδιο πρέπει να χρησιμοποιείται από ειδικά

εκπαιδευμένο προσωπικό συντήρησης.

Ezt a kézikönyvet csak szakképzett karbantartó

személyzet használhatja.

Manual ini harus digunakan hanya oleh petugas

pemeliharaan yang berketerampilan.

Il presente manuale deve essere utilizzato solo da parte

del personale di manutenzione appositamente addestrato.

Korean

이 작업지도서는 기술이 능수한 정비인원이 사용해

주십시요

Page 4

Latv

ian

Šo rokasgrāmatu drīkst izmantot tikai kvalificēts tehniskās

apkopes personāls.

thuanian

Li

acedonian

M

alaysian

M

orwegian

N

P

olish

P

ortuguese

R

omanian

ssian

Ru

bian (cyr)

Ser

Šį vadovą turėtų naudoti tik kompetentingi techninės

priežiūros darbuotojai.

Овој прирачник треба да го користи само квалификуван

персонал за одржување.

Manual ini hendaklah digunakan oleh kakitangan

penyenggaraan yang mahir sahaja.

Denne håndboken skal kun brukes av autoriserte

reparatører.

Ten podręcznik jest przeznaczony do użytku wyłącznie

przez odpowiednio przeszkolony personel konserwacyjny.

Este manual apenas pode ser utilizado por técnicos de

manutenção qualificados.

Acest manual trebuie utilizat numai de personal de

întreţinere calificat.

Это руководство предназначено только для

квалифицированного обслуживающего персонала.

Ово упутство би требало да користи само особље

обучено за одржавање.

erbian (lat)

S

Sl

ovak

lovenian

S

S

panish

Sw

edish

hai

T

Tu

rkish

inian

Ukra

etnamese

Vi

Ovo uputstvo bi trebalo da koristi samo osoblje obučeno za

održavanje.

Príručku môže používať len špeciálne vyškolený personál

údržby.

Ta p ri ro čnik naj bi uporabljalo le osebje, usposobljeno za

vzdrževalna dela.

Este manual sólo puede utilizarlo personal de

mantenimiento especialmente cualificado.

Denna handbok får endast användas av speciellt utbildad

underhållspersonal.

Bu kullanım kılavuzu sadece özel eğitim almış uzman

bakım personeli tarafından kullanılmalıdır.

Ця настанова призначена лише для кваліфікованого

обслуговуючого персоналу.

Tài liệu hướng dẫn này chỉ nên sử dụng bởi nhân viên bảo

trì lành nghề.

Page 5

Important Information

General

• Do not attempt to modify the machine.

• Operation, maintenance, and inspection of this machine must be performed by staff who have

received technical training for the machine, training in machine hazards and their prevention,

and safety training.

• Observe the laws, regulations, and other rules of the relevant national and local administrative

agencies.

• This machine, including technical data and software, may be subject to the Japanese Foreign

Exchange and Foreign Trade Law.

Prior to any resale, transfer or re-export of controlled items, contact Makino to obtain any

required authorization or approval.

• The specifications and design are subject to change without prior notice.

This Manual

• This manual is prepared for usage by experienced operators. For this reason, it does not include

safety precautions for operators who do not have mechanical or technical knowledge of machine

operation, programming, and maintenance.

• If the machine is operated by persons who are not native speakers of the language in this

manual, the customer must ensure that the operators receive complete safety training. Also,

warning labels must be affixed in a language that the operators can understand.

• The copyright for the entire content of this manual belongs to Makino Milling Machine Co., Ltd.

The copying, reproduction, or transfer of this manual, in whole or in part, without the express

written permission of Makino Milling Machine Co., Ltd., is strictly prohibited.

• Illustrations and other details may differ from the actual machine due to the selected options,

modified specifications, or other reasons.

• Store the manuals needed for operation, maintenance, and inspection of this machine in a

location where they can be easily accessed by the operator.

• Be sure to perform periodic inspection and maintenance of the machine according to the

periodic maintenance manual or the legend plate to prevent breakdown of the machine.

29F24D-2006EN

Page 6

Important Points for Work Safety

• Familiarize yourself with the safety precautions and functions before attempting to operate,

maintain, or inspect the machine.

• The points that the operator must observe when performing machine operation and

maintenance vary depending on the situation. All possible points cannot be covered in the

content of this manual. Be sure to fully understand the machine, and remain constantly aware of

safety and the potential hazards while doing work.

• If the safety devices or protective devices do not operate properly, stop operation of the machine

and notify the supervisor or manager. The supervisor or manager must immediately notify your

authorized Makino dealer or Makino service representative.

• When the machine is stopped due to an unknown cause, immediately contact the supervisor or

manager, and wait for permission before restarting operation.

Keeping Machining Accuracy

After installing the machine, to keep machining accuracy, conduct periodic inspection such as

performing level adjustment. If the level of the machine changes, high-accuracy machining cannot be

performed. In addition, normal machining cannot be performed if the machine vibrates.

Especially, for approximately six months after installation, the level of the machine might change

significantly until the foundation becomes stable.

Depending on the condition of the foundation or the machine usage frequency, conduct inspection and

adjustment approximately every six months or every year.

29F24D-2006EN

Page 7

Manuals and How to Use Them

DANGER

WARNING

CAUTION

NOTENOTE

Manuals Belonging to This Machine

Name Description

Instruction Manual This manual includes the basic information (overview,

specifications) needed for operation, practical operating

procedures (operation), and troubleshooting procedures.

Periodic Maintenance Manual This manual explains the intervals for periodic maintenance and

work that is required for maintaining optimum performance of this

machine.

Peripheral Device Manual This manual describes the operating procedures for the peripheral

devices connected to the machine body.

Parts Manual This manual provides the machine component part names and

their order numbers.

Professional 6 Operation

Manual

Professional 6 M Code List This manual describes the M codes of Professional 6.

FANUC

Set of NC Manuals

Maintenance Manual (option) This manual describes the mechanisms of the machine and how to

Installation Manual (option) This manual describes the preparation, carry-in, and installation

Other manuals for options These manuals describe the operating procedures for the optional

This manual describes the operating procedures and various

functions of the controller (Professional 6).

These manuals describe the operating procedures for FANUC

equipment.

perform the maintenance and adjustment work.

procedures for setup of the machine.

devices.

Notation Used in This Manual

Indicates an imminent hazard which, if not avoided, will result in

death or serious injury.

Indicates a potential hazard which, if not avoided, will result in

death or serious injury.

NOTICE

29F24D-2006EN

Indicates a possible hazard which, if not avoided, may result in

minor or moderate injury.

Indicates a potential situation which, if not avoided, may result in

physical damage to the machine or adversely affect the work

environment.

Indicates supplemental information for appropriate and efficient

work or better understanding of the operation.

Page 8

29F24D-2006EN

Page 9

Contents

Chap. 1 Safety

1 Safety Precautions .................................................................................. 1-1

1.1 Operator Checks .......................................................................................................... 1-2

1.2 Work Environment Checks ........................................................................................... 1-2

1.3 Precautions for Potential Fire Hazards ......................................................................... 1-3

1.4 Confirmation of Machine Status ................................................................................... 1-4

1.5 Pre-operation Checks ................................................................................................... 1-5

1.6 Implementing Lock-out and Tag-out ............................................................................. 1-7

1.7 During Work ................................................................................................................. 1-8

1.8 Handling of Hazardous and Toxic Materials ............................................................... 1-11

2 Warning Labels ..................................................................................... 1-12

2.1 Signal Word Definitions .............................................................................................. 1-12

2.2 Using Warning Labels ................................................................................................ 1-13

2.3 Information Contained in Warning Labels .................................................................. 1-14

2.3.1 Warning Labels with Warning Text ................................................................ 1-14

2.3.2 Warning Labels with Warning Marks Only .................................................... 1-14

2.4 Warning Label Locations ............................................................................................ 1-15

2.4.1 Area around Operator Door ........................................................................... 1-15

2.4.2 Area around Tool Magazine .......................................................................... 1-16

3 Safety Devices ...................................................................................... 1-17

3.1 "Emergency Stop" Switch ........................................................................................... 1-17

3.1.1 "Emergency Stop" Switch Installation Location (Machine Body) ................... 1-18

3.1.2 "Emergency Stop" Switch Installation Location

(Large Capacity Tool Magazine) ................................................................... 1-19

3.2 Door Switch ................................................................................................................ 1-20

3.2.1 Door Switch Installation Location (Machine Body) ........................................ 1-20

3.2.2 Door Switch Installation Location

(Disk Type Tool Magazine 21-tool/40-tool) ................................................... 1-21

3.2.3 Door Switch Installation Location (Large Capacity Tool Magazine) .............. 1-22

4 Work Hazards ....................................................................................... 1-23

4.1 Area Surrounding Machine ......................................................................................... 1-23

4.2 Electrical System ........................................................................................................ 1-24

4.3 Parameters ................................................................................................................. 1-24

4.4 Inside the Machining Chamber ................................................................................... 1-24

Page 10

Contents

4.5 Tool Magazine ............................................................................................................ 1-26

4.6 Cutting Fluid Supply Unit/Chip Disposal Device/

Cutting Fluid Temperature Controller/Dust Collector (Graphite Specifications) ......... 1-27

4.7 Temperature Controller .............................................................................................. 1-27

4.8 Hydraulic Unit ............................................................................................................. 1-28

4.9 Pneumatic Unit ........................................................................................................... 1-28

4.10 Splash Guard ............................................................................................................. 1-28

4.11 Other Peripheral Equipment ....................................................................................... 1-29

5 Occupational Health and Safety Management ..................................... 1-30

5.1 Safety Device Inspection ............................................................................................ 1-30

5.2 Noise .......................................................................................................................... 1-30

5.3 Personal Protective Equipment .................................................................................. 1-31

5.4 Disposal of Waste Products ....................................................................................... 1-32

5.4.1 Disposal of Waste Oil, Waste Fluids, and Waste Materials .......................... 1-32

5.4.2 Disposal of This Machine .............................................................................. 1-32

Chap. 2 Installation Preparation

1 Checking Installation Requirements ....................................................... 2-1

2 Allocation of Installation Area ................................................................. 2-2

3 Requirements for Carry-in Route ............................................................ 2-8

4 Installation Requirements ..................................................................... 2-15

5 Recommended Foundation Conditions ................................................ 2-16

6 Air and Power Sources ......................................................................... 2-19

7 Preparation of Equipment for Transfer/Installation ............................... 2-23

Chap. 3 Installation

1 Installation Work Flow ............................................................................. 3-1

2 Preparing Securing Fixtures for Shipment and Hoisting Attachment ...... 3-3

3 Hoisting the Machine Body ..................................................................... 3-5

3.1 Fixing Main Operation Panel ........................................................................................ 3-6

3.1.1 Fixing Main Operation Panel (When Transported on a Truck) ........................ 3-6

3.1.2 Fixing Main Operation Panel (When Transported in a Container) .................. 3-8

Page 11

Contents

3.2 Attaching Left Cover Securing Fixtures for Shipment ................................................ 3-10

3.3 Attaching Operator Door Securing Fixtures for Shipment .......................................... 3-12

3.4 Attaching Tool Magazine Door Securing Fixtures for Shipment ................................. 3-14

3.5 Hoisting ...................................................................................................................... 3-16

4 Hoisting the Peripheral Equipment ....................................................... 3-19

4.1 Hoisting the Cutting Fluid Supply Unit (Other than Graphite Specifications) ............. 3-20

4.2 Hoisting the Temperature Controller (Other than Graphite Specifications) ................ 3-21

4.3 Hoisting the Dust Collector (Graphite Specifications) ................................................ 3-22

5 Machine Setup ...................................................................................... 3-25

5.1 Setup of Machine Body .............................................................................................. 3-26

5.1.1 When Using Crane ........................................................................................ 3-26

5.1.2 When Using Forklift ....................................................................................... 3-28

5.2 Removing Hoisting Attachment .................................................................................. 3-30

5.3 Releasing Fixed Main Operation Panel ...................................................................... 3-32

5.3.1 Releasing Fixed Main Operation Panel (When Transported on a Truck) ...... 3-32

5.3.2 Releasing Fixed Main Operation Panel

(When Transported in a Container) ............................................................... 3-34

5.4 Removing Tool Magazine Door Securing Fixtures for Shipment ............................... 3-36

5.5 Removing Operator Door Securing Fixtures for Shipment ......................................... 3-37

5.6 Removing Left Cover Securing Fixture for Shipment ................................................. 3-38

5.7 Removing Machine Controller Securing Fixture for Shipment ................................... 3-39

5.8 Removing X-axis, Y-axis and Z-axis Securing Fixtures for Shipment ........................ 3-40

5.9 Releasing the Fixed Securing Bracket ....................................................................... 3-44

5.10 Adjusting the Height of the Tool Magazine ................................................................. 3-46

6 Setting Up the Peripheral Equipment and

Connecting the Piping and Wiring ........................................................ 3-47

6.1 Setting Up the Cutting Fluid Supply Unit and

Connecting the Piping and Wiring (Other than Graphite Specifications) .................... 3-48

6.2 Setting Up the Dust Collector and Connecting the Piping and Wiring (Graphite

Specifications) ............................................................................................................ 3-50

Page 12

Contents

7 Refilling Oil ............................................................................................ 3-51

7.1 Recommended Cooling Oil, Hydraulic Oil, and Lubricant .......................................... 3-51

7.2 Refilling Oil for the Temperature Controller ................................................................ 3-52

7.3 Refilling Oil for the Oil Air Supply Device ................................................................... 3-53

7.4 Refilling Oil for the Hydraulic Unit ............................................................................... 3-54

7.5 Refilling Oil for the Cutting Fluid Supply Unit

(Other than Graphite Specifications) .......................................................................... 3-56

8 Connecting the Power Supply and Air Source to the Machine ............. 3-59

8.1 Connecting the Power Supply to the Machine ........................................................... 3-59

8.2 Connecting the Air Source to the Machine ................................................................. 3-62

9 Work after Power Connection ............................................................... 3-63

9.1 Removing the Sleeper ................................................................................................ 3-63

9.2 Checking the Levelness of Installed Machine ............................................................ 3-64

9.3 Fixing the Leveling Block ............................................................................................ 3-65

9.4 Mounting Covers ........................................................................................................ 3-66

10 Operation Check ................................................................................... 3-67

Page 13

Chap. 1 Safety

1 Safety Precautions................................................................................... 1-1

1.1 Operator Checks ........................................................................................................... 1-2

1.2 Work Environment Checks............................................................................................ 1-2

1.3 Precautions for Potential Fire Hazards.......................................................................... 1-3

1.4 Confirmation of Machine Status ................................................................................... 1-4

1.5 Pre-operation Checks.................................................................................................... 1-5

1.6 Implementing Lock-out and Tag-out.............................................................................. 1-7

1.7 During Work .................................................................................................................. 1-8

1.8 Handling of Hazardous and Toxic Materials ............................................................... 1-11

2 Warning Labels...................................................................................... 1-12

2.1 Signal Word Definitions............................................................................................... 1-12

2.2 Using Warning Labels ................................................................................................. 1-13

2.3 Information Contained in Warning Labels ................................................................... 1-14

2.3.1 Warning Labels with Warning Text................................................................. 1-14

2.3.2 Warning Labels with Warning Marks Only ..................................................... 1-14

1

Safety

2.4 Warning Label Locations............................................................................................. 1-15

2.4.1 Area around Operator Door............................................................................ 1-15

2.4.2 Area around Tool Magazine .......................................................................... 1-16

3 Safety Devices ...................................................................................... 1-17

3.1 "Emergency Stop" Switch............................................................................................ 1-17

3.1.1 "Emergency Stop" Switch Installation Location (Machine Body).................... 1-18

3.1.2 "Emergency Stop" Switch Installation Location

(Large Capacity Tool Magazine) .................................................................... 1-19

3.2 Door Switch ................................................................................................................ 1-20

3.2.1 Door Switch Installation Location (Machine Body)......................................... 1-20

3.2.2 Door Switch Installation Location

(Disk Type Tool Magazine 21-tool/40-tool) .................................................... 1-21

3.2.3 Door Switch Installation Location (Large Capacity Tool Magazine) .............. 1-22

4 Work Hazards ....................................................................................... 1-23

4.1 Area Surrounding Machine.......................................................................................... 1-23

4.2 Electrical System......................................................................................................... 1-24

4.3 Parameters ................................................................................................................. 1-24

Page 14

4.4 Inside the Machining Chamber ................................................................................... 1-24

4.5 Tool Magazine............................................................................................................. 1-26

4.6 Cutting Fluid Supply Unit/Chip Disposal Device/

Cutting Fluid Temperature Controller/Dust Collector (Graphite Specifications) ......... 1-27

4.7 Temperature Controller ............................................................................................... 1-27

4.8 Hydraulic Unit .............................................................................................................. 1-28

4.9 Pneumatic Unit............................................................................................................ 1-28

4.10 Splash Guard .............................................................................................................. 1-28

4.11 Other Peripheral Equipment........................................................................................ 1-29

5 Occupational Health and Safety Management ...................................... 1-30

5.1 Safety Device Inspection ............................................................................................ 1-30

5.2 Noise ........................................................................................................................... 1-30

5.3 Personal Protective Equipment................................................................................... 1-31

5.4 Disposal of Waste Products ........................................................................................ 1-32

5.4.1 Disposal of Waste Oil, Waste Fluids, and Waste Materials ........................... 1-32

5.4.2 Disposal of This Machine ............................................................................... 1-32

Page 15

1 Safety Precautions

1 Safety Precautions

• Disregarding the specific instructions or precautions included in this manual may result in

serious injury or death to the operators or surrounding workers, or damage to the machine.

• Never disable or remove any safety device. Operating the machine while the safety devices are

disabled may result in serious injury, death, or damage to the machine.

• Observe the safety precautions provided in this manual at all times and fully implement safety

measures.

• Inspect and maintain the machine regularly to keep it in optimum operating condition. Do not run

the machine if it shows any signs of abnormal operation.

• The keys (release key for door switch, machine controller panel key, etc.) which are not

necessary for regular operation and maintenance must be removed from the machine and

managed by supervising personnel.

• The lubricating oil, cutting fluid, and other chemical substances used with the machine must be

managed by supervising personnel.

1

Safety

• Workpiece materials such as magnesium and titanium may cause a fire if mishandled, so be

particularly careful when machining workpieces and handling cutting chips made from these

types of materials.

29F24D-2006EN

1-1

Page 16

1 Safety Precautions

1.1 Operator Checks

1.1 Operator Checks

• Only qualified personnel who have adequate mechanical and technical knowledge are allowed

to operate and maintain the machine.

• Only qualified electrical engineers may perform electrical work.

• Only qualified personnel may use a crane or forklift.

• Wear suitable work clothes whenever operating or maintaining the machine. Do not operate the

machine while wearing loose-fitting clothes, a necktie, jewelry, or any other clothing or objects

which may become entangled with the moving parts of the machine.

• Tie up long hair, and wear a cap.

• Wear safety glasses, safety shoes, safety cap (including safety helmet), and safety gloves as

needed.

• Protective gear should be worn to protect hearing when excessive noise may be generated

during operation or maintenance.

• Never operate any machinery while under the influence of alcohol or drugs.

• The operator should be in proper physical condition. If the operator suffers from a condition that

impairs judgment, it may result in serious injury or death.

1.2 Work Environment Checks

• Make sure the machine and surrounding area are fully lighted.

• Make sure the machine and surrounding area are tidy and clean at all times.

• Clean up any oil, cutting fluid, or chips scattered around the machine.

• When performing work at high locations, use a stable footstool or stepladder.

• Keep all flammable substances away from the work area.

• Maintain adequate working space.

1-2

29F24D-2006EN

Page 17

1 Safety Precautions

1.3 Precautions for Potential Fire Hazards

1.3 Precautions for Potential Fire Hazards

Use the machine by following the precautions below to protect the machine equipment, plant, and

surrounding environment from the danger of fire and to ensure the safety of operators.

1 When using cutting fluid, be sure to use a water-soluble cutting fluid (type A1).

There is no fire hazard when using water-soluble cutting fluids (except when using them with

special materials).

1

2 Oil-based cutting fluids present a potential fire hazard.

If an oil-based cutting fluid must be used due to unavoidable circumstances, be sure to

observe the precautions below.

• Do not run the machine in an unmanned operation mode.

• Install the proper fire-extinguishing equipment near the machine.

• Provide alarm devices to detect a fire, automatic fire-extinguishing devices, and other

equipment to the greatest extent possible.

• Do not create situations which may potentially start a fire.

• Machine under the proper cutting conditions.

• Perform proper tool management to prevent the occurrence of abnormal frictional heat

and sparks.

• Do not allow chips to accumulate in the machining chamber.

• Check that a constant and full supply of cutting fluid is provided.

• Always clean up and organize the area around the machine, and do not place

flammable objects in the area.

Safety

3 Precautions for machining of flammable solids, resins, wood, and other flammable materials.

When machining flammable solids or other special materials, be sure to fully implement safety

measures after gaining a thorough understanding of the material properties. Be sure to also

pay careful attention to safety when machining resins, wood, and other materials.

When machining materials that generate dust and powder, be sure to provide equipment that

takes into account the danger of a dust explosion for certain material types.

4 Precautions for machining while blowing air.

Because air blowing has weak cooling performance, the chips that spray and fly out in the

surrounding area are extremely hot. Do not place flammable objects in the machining

chamber or in the area surrounding the machine.

29F24D-2006EN

1-3

Page 18

1 Safety Precautions

1.4 Confirmation of Machine Status

1.4 Confirmation of Machine Status

• Machine inspections and maintenance must be performed regularly to maintain optimum

machining accuracy and long-term performance, and increase machine operating efficiency.

• Confirm that all safety devices are functioning normally.

• Make sure the operator knows the location of the "Emergency Stop" switches to enable easy

access in the event of an abnormal or dangerous situation (Refer to 3.1 "Emergency Stop"

Switch).

• Check for any loose, damaged, or worn parts on the machine. Operating the machine in a

condition in which any of the parts has an abnormality may cause abnormal noises or damage to

the machine.

• Check for any damaged piping or wiring. Operating the machine with the piping or wiring left

damaged may cause oil leakage, electrical shock, or fire.

• Use the most appropriate cutting tool, tool holder, retention knob, and workpiece, and make sure

that they are all secured firmly in place. Otherwise, the workpiece may fall or the tool may fly out,

and this may result in damage to the machine, serious injury, or death.

• Check that the tool numbers are registered correctly. Otherwise, the spindle may rotate at a

speed outside the allowable range, the tool may fly out, and this may result in damage to the

machine, serious injury, or death.

1-4

29F24D-2006EN

Page 19

1 Safety Precautions

1.5 Pre-operation Checks

1.5 Pre-operation Checks

• Be sure that you fully understand the work procedures and precautions before operating and

maintaining the machine. Never operate any machinery if you are unsure about any points.

• Check that the clothes you are wearing are suitable for operation.

• Perform periodic maintenance.

• Confirm that all safety devices are functioning properly before operating and maintaining the

machine.

• Periodically back up the parameters when the machine was shipped and the program and offset

data that have been prepared by the customer. Makino is not liable for any program or offset

data that is corrupted or lost.

• Makino does not accept responsibility for any trouble caused by apparatus or programs

prepared by the customers, such as damage to workpieces or the machine.

• For details about replacement parts, contact your Makino service representative. Use of

improper parts may result in reduced machine performance or safety, damage to the machine, or

operator injuries.

1

Safety

• Before entering inside the machine to perform work, be sure to confirm the escape procedure in

the event that you inadvertently become shut inside the machine.

• Perform the lock-out and tag-out procedures.

• Make sure the operator knows the location of the "Emergency Stop" switches for each device so

that they can be easily operated in the event of an abnormal or dangerous situation.

• Be sure to observe the information on the warning labels. Contact your Makino service

representative if a warning label comes off or becomes illegible.

• When handling a hazardous or toxic material (oils, cutting fluids, and other chemical

substances), obtain the safety data sheet (SDS), and follow the instructions. The safety data

sheet (SDS) contains information about the safe handling of hazardous and toxic materials, and

emergency measures.

29F24D-2006EN

1-5

Page 20

1 Safety Precautions

1.5 Pre-operation Checks

• For the graphite specifications, do not let the dust collector collect anything other than graphite

dust. Failure to observe this precaution may result in a dust explosion. Also, it may damage the

filter or cause other malfunctions.

• For the graphite specifications, observe the following precautions to prevent health problems

related to the inhalation of graphite dust.

• After machining the workpieces, wait for the dust collector to remove airborne dust particles

before opening the operator door. If you open the operator door immediately after

machining, the airborne dust will disperse throughout the machining room.

• Wear a high-performance dust-proof mask when doing the following (particle collection

efficiency of 99.9% or more is recommended).

• Opening and closing the operator door

• Performing an operation with the operator door open

• Replacing a tool in the tool magazine

• Handling dust

• Do not remove the dust car and chip bucket while the dust collector is operating. Otherwise,

dust will disperse in the surrounding area.

1-6

29F24D-2006EN

Page 21

1 Safety Precautions

1.6 Implementing Lock-out and Tag-out

1.6 Implementing Lock-out and Tag-out

Lock-out consists of shutting down the power source to the machine or devices and locking it.

Example: Set the main power switch to the "OFF" position and secure it using a padlock or a

lockout device such as a cover.

Tag-out consists of placing a warning tag to prevent anyone from turning ON the power.

Example: Place a "Do Not Operate" or "Under Maintenance" sign with the operator's name and

department and indicating that machine operation is prohibited on the main power switch and

main operation panel.

Lock-out/tag-out should be performed to prevent inadvertent operation and ensure operator safety.

• Performing lock-out/tag-out alone does not completely ensure operator safety. The operator

must read and thoroughly understand the work procedures and safety precautions, and always

be aware of potential hazards.

Each operator should perform lock-out or tag-out by himself or herself. Perform this procedure before

starting the work, and release the lock and remove warning tag yourself after finishing work. Never

release a lock and remove a sign without confirming with the operator or without the presence of the

operator himself or herself.

Be sure to clearly define and implement the lock-out and tag-out procedures of your company.

1

Safety

29F24D-2006EN

OFF

OFF

ON

ON

Figure 1-1 Implementing Lock-out and Tag-out

DANGER

DANGER

Under Maintenance/

Under Maintenance/

Inspection

Inspection

Operator's Name: xxxxx

Operator's Name: xxxxx

Department: xxxxx

Department: xxxxx

1-7

Page 22

1 Safety Precautions

1.7 During Work

1.7 During Work

• Turn OFF the power before performing maintenance of the machine. When work must be

performed with the machine power ON, confirm that all machine operations are completely

stopped. Check that any residual energy in the machine is completely discharged.

• Never go near the moving parts of the machine. If you must approach moving parts to perform

maintenance, be sure to take adequate safety precautions. Inadequate attention to safety may

result in death or another serious accident.

• Always keep the doors and covers closed during operation. If you must work with the doors and

covers open, be sure to take adequate safety precautions. Inadequate attention to safety may

result in death or another serious accident.

• If an operator gets trapped inside the machine, press the "Emergency Stop" switch regardless of

whether the machine power is ON or OFF.

• If the machine is stopped by a power failure or power supply fault, turn OFF the machine power.

If the power is not turned OFF, the machine may start operating unexpectedly when the power is

restored, and this may result in serious injury, death, or damage to the machine.

• If the machine is stopped by a power failure or power supply fault, check that the parameter,

program, and offset data have not been corrupted. The machine may be damaged if it is

operated using corrupted data.

• Be aware of the movement range of the machine and auxiliary components (each axis stroke,

rotation range, etc.), and keep all body parts clear of moving components.

• When two or more people are required for maintenance work, be sure to maintain clear

communication at all times to ensure operator safety. When performing work, be ready to press

the "Emergency Stop" switch at any time.

• Be sure to always pay attention to the safety precautions listed on the warning labels affixed to

the machine (Refer to 2 Warning Labels2 Warning Labels).

• Do not operate the switches or change the circuits except for adjustment purposes. In particular,

operating the machine with the interlock(s) or other safety devices or functions disabled is

extremely dangerous and may result in death or damage to the machine.

• If a circuit or other component needs to be changed for adjustment purposes, be sure to return it

to the original setting after adjustment is completed.

• The optimum values for the NC parameters and machine parameters are set when the machine

is shipped. Do not change any parameter setting unless it is described in the manual. Also, be

sure that you fully understand the function of a parameter before attempting to change the

parameter setting, and return the parameter to its original setting after the work is completed. If

you try to operate the machine without the proper settings, the machine may operate

unexpectedly, and this may result in serious injury, death, or damage to the machine.

• If the memory clear operation needs to be performed, be sure to contact your Makino service

representative beforehand.

• If an alarm is triggered, eliminate the cause of the alarm using the appropriate procedure. If the

remedy procedure is unclear, contact your Makino service representative.

• Never climb onto the covers. This may deform the covers or result in injury.

1-8

29F24D-2006EN

Page 23

1 Safety Precautions

1.7 During Work

• When using a stepladder or stool, it should be sturdy, safe, and have anti-slip surfaces.

• If any oils or cutting fluids get into your eyes, body, or on your skin surface, they may cause

severe health problems. Wear safety gloves, mask, safety glasses, and other safety equipment.

• Wear safety gloves whenever handling chips, tools, and workpieces.

• Protective gear should be worn to protect hearing when excessive noise may be generated

during operation or maintenance.

• If lubricating oil, grease, cutting fluid, or other substances are spilled on the floor, it may result in

slippage, causing injury. Wipe up any spilled fluids as soon as possible.

• Never touch a switch, button, or key while your hands are wet. Failure to observe this precaution

may result in electric shock.

• Some devices (motors, lighting equipment, valves, etc.) may become very hot while the machine

is operating and remain hot soon after the power is turned OFF, so be careful to avoid burns.

• Do not subject the machine to sudden impact or jolts. This may cause the machine to perform an

unexpected motion or result in damage to the machine.

• Do not use the machine for operation outside the specifications or exceeding the performance

range. This may cause the machine to perform an unexpected motion or result in serious injury,

death, or damage to the machine.

• Use the most appropriate cutting tool, tool holder, retention knob, and workpiece, and make sure

that they are all secured firmly in place. Otherwise, the workpiece may fall or the tool may fly out,

and this may result in damage to the machine, serious injury, or death.

1

Safety

• Be careful that you do not leave objects such as tools or jigs inside the machine.

• Do not place the tools, workpiece, or other parts on an unstable location.

• When a lifting sling or attachment is necessary, verify that it is strong enough to support the

weight of the parts. Confirm that no one is close to the machine and the parts are well balanced,

and be careful not to hit to the machine.

• Never go under a load that is being lifted. While transferring the hoisted load, constantly pay

careful attention to the hoisted load during the operation.

• Check that the tool numbers are registered correctly. Otherwise, the spindle may rotate at a

speed outside the allowable range, the tool may fly out, and this may result in damage to the

machine, serious injury, or death.

• Never insert hands or feet into the chip conveyor. They may be pulled in, and this may result in

death or another serious accident.

29F24D-2006EN

1-9

Page 24

1 Safety Precautions

1.7 During Work

• For the graphite specifications, observe the following precautions to prevent health problems

related to the inhalation of graphite dust.

• After machining the workpieces, wait for the dust collector to remove airborne dust particles

before opening the operator door. If you open the operator door immediately after

machining, the airborne dust will disperse throughout the machining room.

• Wear a high-performance dust-proof mask when doing the following (particle collection

efficiency of 99.9% or more is recommended).

• Opening and closing the operator door

• Performing an operation with the operator door open

• Replacing a tool in the tool magazine

• Handling dust

• Do not remove the dust car and chip bucket while the dust collector is operating. Otherwise,

dust will disperse in the surrounding area.

1-10

29F24D-2006EN

Page 25

1 Safety Precautions

1.8 Handling of Hazardous and Toxic Materials

1.8 Handling of Hazardous and Toxic Materials

Handlers of hazardous and toxic materials (such as oils and cutting fluid) must receive information,

education, and training in accordance with the stipulations in JIS Z 7253 (revised March 2012)/

ISO 11014: 2009.

Particular attention must be paid to the following points.

• Be sure that there is adequate ventilation in areas where hazardous and toxic materials are

used.

• Hazardous and toxic materials must be handled and stored based on the handling procedures

recommended by the manufacturer.

• Identify hazardous and toxic materials by affixing labels to their containers.

• Assign a person in charge to handle the hazardous and toxic materials, and provide education

and training in emergency response procedures and handling procedures.

• Before handling any hazardous or toxic material, be sure to check the safety data sheet (SDS).

The safety data sheet (SDS) contains detailed information on health and safety hazards, safe

handling procedures, and responses to emergency situations.

1

Safety

29F24D-2006EN

1-11

Page 26

2 Warning Labels

DANGER

WARNING

CAUTION

2.1 Signal Word Definitions

2 Warning Labels

Warning labels are affixed to machine parts that are potentially hazardous to warn operators about the

hazard and its level of danger and ensure the safety of operators.

The warning labels include symbols to indicate the source of the danger, signal words to indicate the

level of danger, and warning text to describe how to prevent the danger. When working at a location

where a warning label is affixed, make sure that you fully understand the warning label information and

definitions and follow the warning text that is provided. Failure to observe the information in the

warning labels may result in death or another serious accident or damage to the machine.

2.1 Signal Word Definitions

Signal words are divided into four classes based on the degree of expected risk.

Signal Word Description

NOTICE

Indicates an imminent hazard which, if not avoided, will result in death or

serious injury.

Indicates a potential hazard which, if not avoided, will result in death or

serious injury.

Indicates a possible hazard which, if not avoided, may result in minor or

moderate injury.

Indicates a potential situation which, if not avoided, may result in physical

damage to the machine or adversely affect the work environment.

1-12

29F24D-2006EN

Page 27

2.2 Using Warning Labels

• Do not cover up or peel off the warning labels.

2 Warning Labels

2.2 Using Warning Labels

• Confirm that the operators and maintenance personnel are familiar with the language on the

labels. If labels in other languages are required, contact your Makino service representative.

• Check that all the information in the warning label is legible. If any portion of the warning text or

symbol is not visible, clean by wiping with a soft cloth dipped in water or household cleanser. Do

not use organic solvents or gasoline. These may damage the surface of the warning label.

• Replace the warning label if the information in the warning label is no longer visible. To obtain

new warning labels, contact your Makino service representative.

• If a part is replaced where a warning label was affixed, obtain a new warning label and affix it at

the same position as before on the new part. To obtain new warning labels, contact your Makino

service representative.

1

Safety

29F24D-2006EN

1-13

Page 28

2 Warning Labels

DANGER

DANGER

DANGER

CAUTION

CAUTION

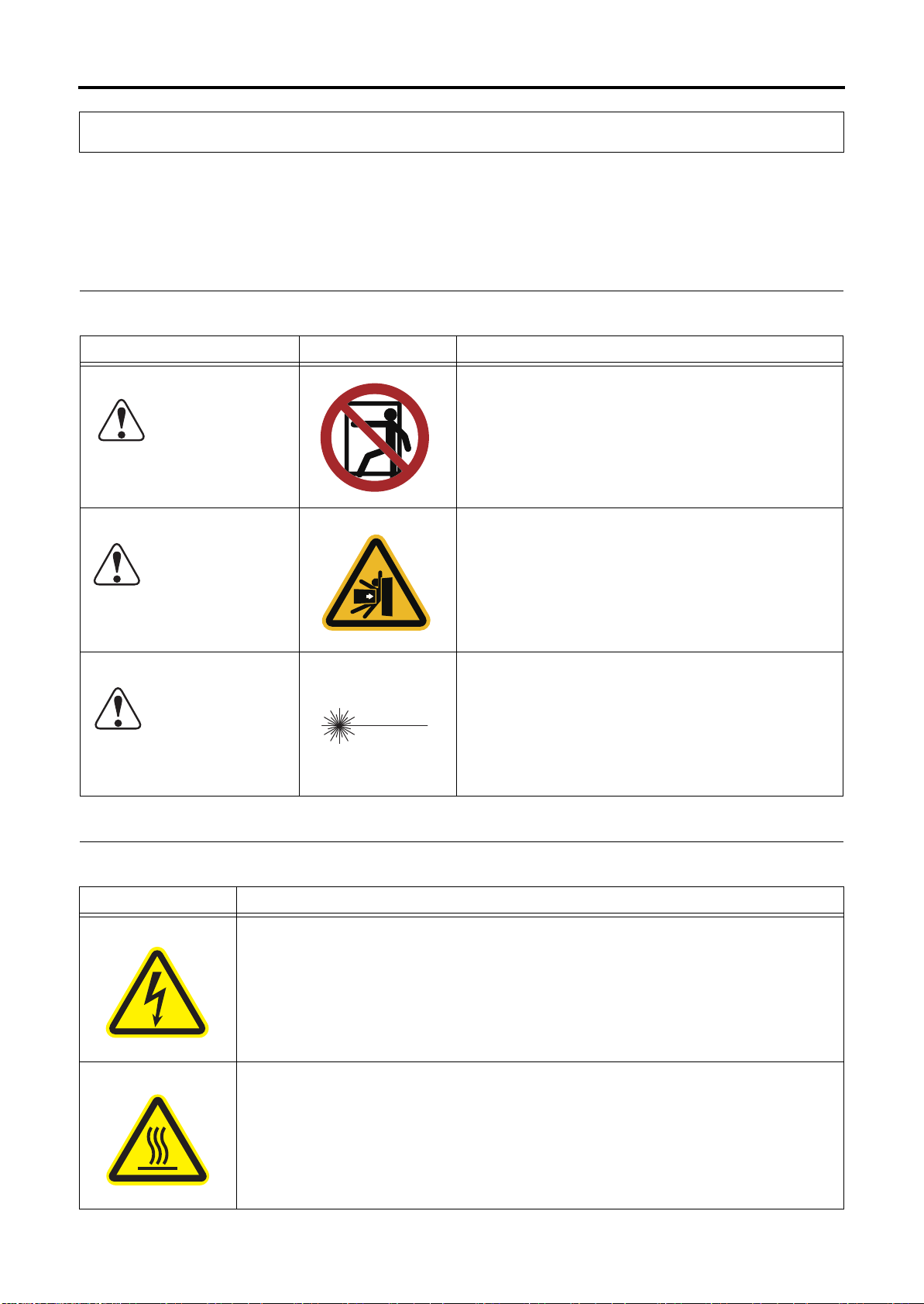

2.3 Information Contained in Warning Labels

2.3 Information Contained in Warning Labels

The two types of warning labels are shown below.

• Labels with warning text and a warning mark

• Labels with a warning mark only

2.3.1 Warning Labels with Warning Text

Signal Word Symbol Description

This warning label is affixed to areas where entry is

prohibited.

This warning label is affixed to areas where there is a

risk of getting pressed, being sucked in, stabbed, or

falling down, resulting in a serious injury, accident, or

death.

Maximum output 1mW, semiconductor laser

Class 2 laser product

Do not stare into the beam.

2.3.2 Warning Labels with Warning Marks Only

Symbol Description

This warning label is affixed to parts where touching the internal high-voltage

components may result in electrical shock.

Workers who are not qualified electrical engineers must not access the parts where

this warning label is affixed.

1-14

This warning label is affixed to parts that may become extremely hot.

Do not touch parts where this warning label is affixed. Be particularly careful

immediately after operation because these parts are extremely hot at this time.

29F24D-2006EN

Page 29

2 Warning Labels

2.4 Warning Label Locations

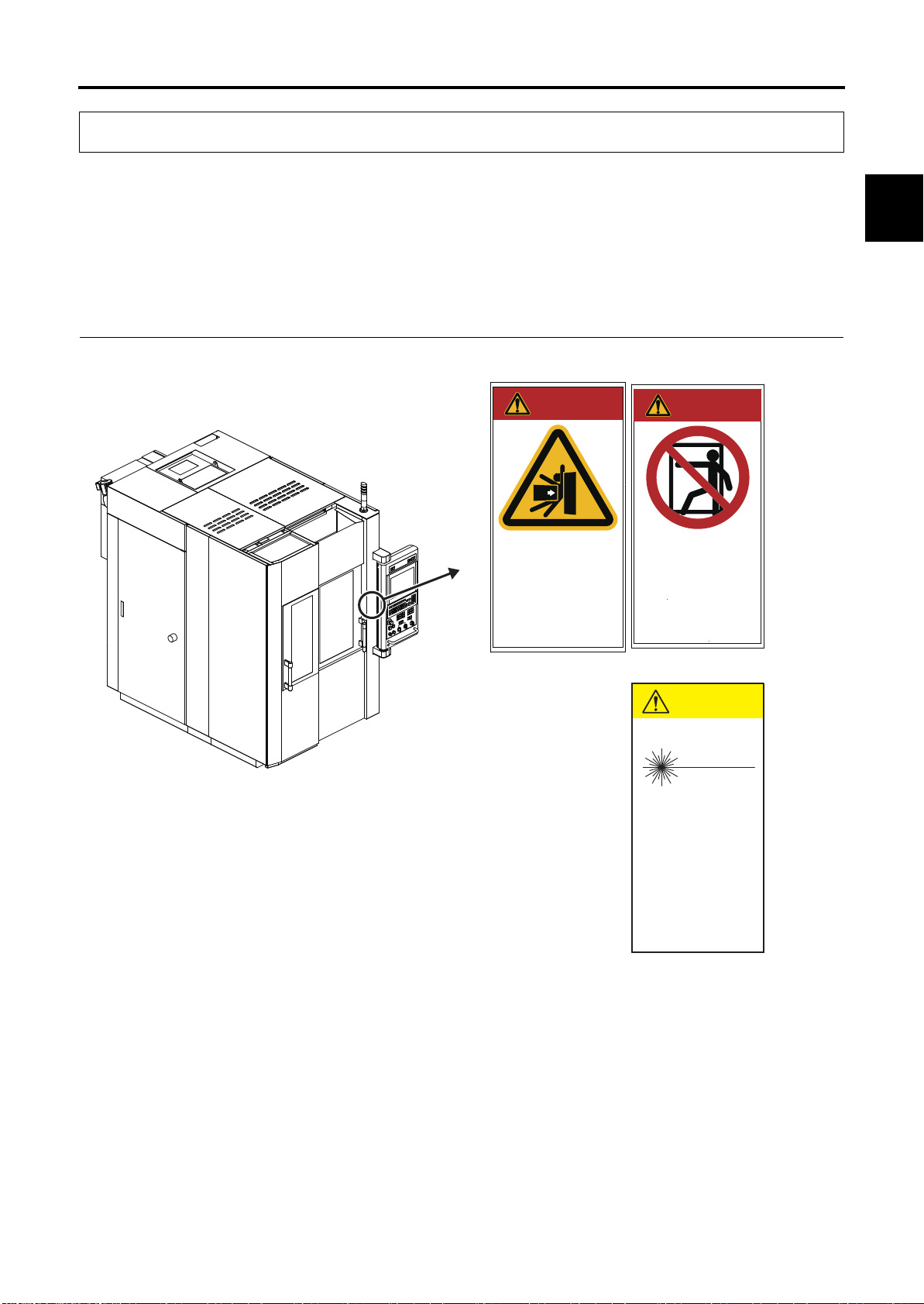

2.4 Warning Label Locations

The type of warning label and the location where the label is affixed to vary depending upon the

machine model.

Warning labels with warning marks only are affixed to various locations on the machine, and all affixing

locations are not shown in the figure.

1

2.4.1 Area around Operator Door

DANGER

危 険

Serious Injury / Death

死傷に至る

Crush, Pinch, Stab,

Slip and Fall Hazard

押しつぶし、巻込み、

突刺し、転倒、転落

Safety

DANGER

危 険

DO NOT ENTER

機械内部立入禁止

Authorized Personnel Only

許可された者以外

CAUTION

注意

29F24D-2006EN

DONOT Stare into Beam

レーザー光を覗き込むな

Power 1mW

Semiconductor laser

Class2 laser product

最大出力1mW

半導体レーザ

クラス2 レーザ製品

(When an automatic non-contact

type tool measurement device is

included)

Figure 2-1 Area around Operator Door

1-15

Page 30

2 Warning Labels

DANGER

危 険

許可された者以外

機械内部立入禁止

DO NOT ENTER

Authorized Personnel Only

Serious Injury / Death

死傷に至る

押しつぶし、巻込み、

突刺し、転倒、転落

Crush, Pinch, Stab,

Slip and Fall Hazard

DANGER

危 険

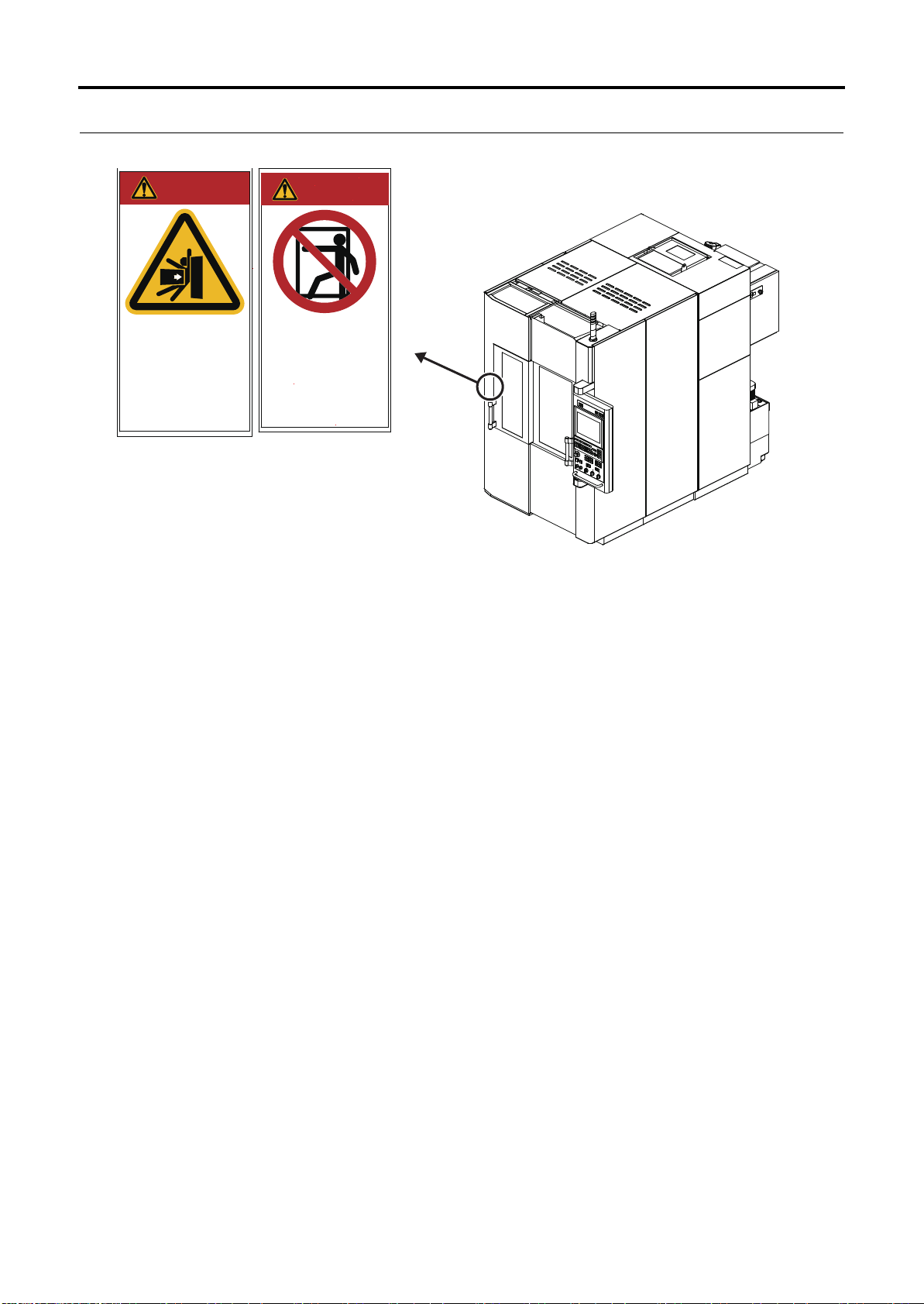

2.4 Warning Label Locations

2.4.2 Area around Tool Magazine

Figure 2-2 Area around Tool Magazine

1-16

29F24D-2006EN

Page 31

3 Safety Devices

DANGER

WARNING

3.1 "Emergency Stop" Switch

3 Safety Devices

• Never disable or remove any safety device.

Safety devices are installed on the machine to protect operators and maintenance personnel. The

safety devices also include ones that function on the condition that the operator observes the safety

procedures.

3.1 "Emergency Stop" Switch

• Make sure operators know the locations of all the "Emergency Stop"

switches prior to performing machine operation or maintenance to enable

use in an abnormal or dangerous situation.

1

Safety

The machine goes to the following status when the "Emergency Stop" switch is pressed:

• Feeding of the axes is stopped immediately.

• Spindle rotation stops if it is rotating.

• The spindle is clamped if it has been unclamped.

• When orientation of the spindle has been performed, orientation is reset.

• When a tool is being changed or the tool magazine is operating, operation stops immediately

(even during motion).

• The chip conveyor in operation comes to an immediate stop.

• The hydraulic unit is stopped.

• The cutting fluid supply is stopped.

• Supply of the air blow inside the machining chamber is stopped (graphite specifications).

• The dust collector stops collecting dust (graphite specifications).

• Energizing of all solenoid valves is reset.

• The NC is reset.

Once the "Emergency Stop" switch is pressed, it is locked in the pressed position. The lock can be

released by turning the switch in the direction indicated by the arrow or pulling out the switch.

Then, pressing the [CONTROL POWER ON] switch cancels the emergency stop state.

For details about recovery procedures following machine operation stopped by the "Emergency Stop"

switch activation (Refer to Instruction Manual Chap. 7 Troubleshooting 2.1 Recovery from Emergency

Stop Status).

29F24D-2006EN

1-17

Page 32

3 Safety Devices

3.1 "Emergency Stop" Switch

3.1.1 "Emergency Stop" Switch Installation Location (Machine Body)

崒嵒崐嵛

ૃ କ

౺જ ౪౺ো

崱崊嵕崫崗

崊嵛崗嵑嵛崿

崝崌崗嵓

崽崋嵤崱

崡崧嵤崰

嵃嵤嵓崱

1

崮嵤崟嵏嵛

(FR

ౣૐ

嵉嵊嵒

৸ກ୮ష

્ઐఌ ജ岶峁

ু

0',

සྩ

崾嵕崫崗崡崕崫崿

઼୮ష

崶崢嵓

崒崿崟嵏崲嵓

崐崊崾嵕嵤

崗嵤嵑嵛崰

崡崰崫崿

崗嵤嵑嵛崰೬ૃ

崟嵛崘嵓崾嵕崫崗

1

Figure 3-1 "Emergency Stop" Switch Installation Location (Machine Body)

No. Name

1 "Emergency Stop" switch

Z

X10 X100

4

5

Y

X1

X1000

6

X

AUX

OFF

ABS

MAC

REL

ORG

1

1-18

29F24D-2006EN

Page 33

3 Safety Devices

3.1 "Emergency Stop" Switch

3.1.2 "Emergency Stop" Switch Installation Location (Large Capacity Tool Magazine)

1

Safety

1

1

Figure 3-2 "Emergency Stop" Switch Installation Location (Large Capacity Tool Magazine)

No. Name

1 "Emergency Stop" switch

29F24D-2006EN

1-19

Page 34

3 Safety Devices

3.2 Door Switch

3.2 Door Switch

The door switch is a device for detecting and controlling the status of doors.

3.2.1 Door Switch Installation Location (Machine Body)

1

Figure 3-3 Door Switch Installation Location (Machine Body)

No. Name

1 Door switch

1-20

29F24D-2006EN

Page 35

3 Safety Devices

3.2 Door Switch

3.2.2 Door Switch Installation Location (Disk Type Tool Magazine 21-tool/40-

tool)

1

1

Safety

Figure 3-4 Door Switch Installation Location (Disk Type Tool Magazine 21-tool/40-tool)

No. Name

1 Door switch

29F24D-2006EN

1-21

Page 36

3 Safety Devices

1

1

3.2 Door Switch

3.2.3 Door Switch Installation Location (Large Capacity Tool Magazine)

Figure 3-5 Door Switch Installation Location (Large Capacity Tool Magazine)

No. Name

1-22

1 Door switch

29F24D-2006EN

Page 37

4 Work Hazards

4.1 Area Surrounding Machine

4 Work Hazards

The following tables list examples of hazardous actions and situations during machine operation and

maintenance and examples of the resulting accidents and incidents that may occur.

The points that the operator must observe when performing machine operation and maintenance vary

depending on the situation. All possible points cannot be covered in the content of this manual.

Therefore, be sure to fully understand the machine, and remain constantly aware of safety and the

potential hazards while doing work.

Improper operation may result in death or damage to the machine.

4.1 Area Surrounding Machine

Action/Situation Result

1

Safety

Tripping on piping/wiring Falling

Operator working on oily floor Fall, bone fracture, injury

Bringing an open flame into the area Fire, burn

Improper handling of chemical substances Skin lesions, eye injury, or respiratory

problems

29F24D-2006EN

1-23

Page 38

4 Work Hazards

NOTESNOTES

4.2 Electrical System

4.2 Electrical System

Action/Situation Result

Performing inspection or maintenance operation without turning

OFF the power (Refer to NOTE)

Touching a device with residual voltage (Refer to NOTE) Electrical shock

Miswiring Breakdown of the machine, abnormal

Loose screw in terminal block or other location Breakdown of the machine, abnormal

Machine controller door or junction box cover is left open Electric leakage, breakdown of the

Touching switches with wet hands Electrical shock

Damage to wiring on floor Electric leakage, breakdown of the

Operation or maintenance by non-qualified personnel Breakdown of the machine

1 Prior to performing maintenance of the servo amplifiers, spindle amplifiers, and inverters, turn OFF the main power and

confirm that the LED which indicates charging (red) for each amplifier and inverter is off.

2 High voltage current flows through components inside the junction box.

3 High voltage current continues to flow on the primary side of the main power switch even after the main power is turned

OFF.

4 Electrical current continues to flow to lamps and outlets in the machine controller even after the main power is turned

OFF.

Electric shock, breakdown of the machine,

abnormal operation, fire

operation, fire

operation, fire

machine, abnormal operation, fire

machine, abnormal operation, fire

4.3 Parameters

Action/Situation Result

Changing NC/machine parameters not listed in manual Injury or death, workpiece damage,

breakdown of the machine

Forgetting to return the parameter to its original value after

adjustment

Injury or death, workpiece damage,

breakdown of the machine

4.4 Inside the Machining Chamber

Action/Situation Result

Working without performing lock-out and tag-out Injury or death, damage to the

machine

Operator entering machining chamber without turning OFF the

power

Injury or death

1-24

29F24D-2006EN

Page 39

4 Work Hazards

4.4 Inside the Machining Chamber

Action/Situation Result

Operator entering machining chamber with safety devices or

functions disabled

Getting near the operating range of an axis when the power is turned

ON or during axis feeding

Replacing the gravity axis motor without using the fixing jig Injury or death, damage to the

Rotating spindle prior to cleaning of tapered section while operator

door is open

Rotating unbalanced tool at high speed while operator door is open Injury or death, damage to the

Hand or other body part becomes wedged in operator door when it is

opened or closed

Operator touching rotating spindle Hands or fingers cut off, body part

Touching a feed axis motor Burns

Workpiece has not been clamped Injury, bone fracture, bruises

Entering machining chamber when table is inclined Injury, bruises

Touching an operating ATC shutter Injury

Injury or death

Injury, bone fracture, bruises

machine

Injury or death, damage to the

machine

machine

Injury, bone fracture, bruises

becomes entangled, or other serious

injury or death

1

Safety

Operator becomes entangled in chip conveyor Body part pulled in, resulting in injury

or death

Climbing on top of covers Fall, bone fracture, injury

Climbing on top of the movable covers, inserting your hand into the

gaps

Operator working on oily floor Fall, bone fracture, injury

Touching the wipers Cuts to hands

Operator touching bladed tools Cuts, injuries to hands

Holding a heavy tool Strained back, hands become

Operator being struck by chips, cutting fluid, or dust scattered during

machining

Operator being splashed by cutting fluid dripping from ceiling in

machining chamber

Operating machine while there is abnormal vibration or abnormal

noise

Operating machine with a tool incorrectly clamped Injury or death, damage to the

Opening the operator door and entering the machining chamber

while mist is not being collected

Injury, bruises

wedged between tool and object

Damage to eyes, cuts or burns to skin

Damage to eyes, skin irritation

Damage to the machine

machine

Respiratory problems

Cleaning without wearing protective gloves Cuts to hands

Opening the operator door or entering the machining chamber while

dust is not being collected

Entering the machining chamber without wearing a dust-proof mask Respiratory problems

29F24D-2006EN

Respiratory problems

1-25

Page 40

4 Work Hazards

4.5 Tool Magazine

Action/Situation Result

Fastening tools or implementing other work during spindle

orientation

Inhaling dust Respiratory problems

Injury, bone fracture, bruises

4.5 Tool Magazine

Action/Situation Result

Working without performing lock-out and tag-out Injury or death, damage to the

machine

Operator entering the tool magazine without turning OFF the power Injury or death

Operator entering the tool magazine with the safety devices and

functions disabled

Manually changing tools by entering inside the tool magazine Injury or death

Performing T command or tool change while tool blade or tool is

mounted incorrectly

Tool number is registered incorrectly Damage to the machine

Operator inserting hands into tool magazine during tool magazine

operation

Injury or death

Injury or death, damage to the

machine

Cuts, bone fracture of hands

Touching the tool magazine motor Burns

Operator working on oily floor Fall, bone fracture, injury

Operator touching bladed tools Cuts, injuries to hands

Holding a heavy tool Strained back, hands become wedged

between tool and object

Hand or other body part becomes wedged in tool magazine door

when it is opened or closed.

Leaving a safety guard or maintenance cover opened or removed Injury

Holding or carrying a removed cover Injury or machine damage due to

Performing cleaning or maintenance while a tool is stored in the tool

magazine

Cleaning without wearing protective gloves Cutting or stabbing of hand

Injury, bruises

dropping of cover

Cutting or stabbing of hand or body

1-26

29F24D-2006EN

Page 41

4 Work Hazards

4.6 Cutting Fluid Supply Unit/Chip Disposal Device/Cutting Fluid Temperature Controller/Dust Collector

4.6 Cutting Fluid Supply Unit/Chip Disposal Device/Cutting Fluid

Temperature Controller/Dust Collector (Graphite Specifications)

Action/Situation Result

Working without performing lock-out and tag-out Injury or death, damage to the

machine

1

Inserting hands or feet into conveyor or tank without turning OFF the

power

Touching part or component immediately after operation Burns

Operator touching moving parts when chip discharge outlet cover is

removed

Stepping on a tank that is not fixed Fall, bone fracture, injury

Operating with low levels of cutting fluid Fire, damage to the machine

Touching cutting fluid or chemical additives Skin irritation

Touching chips Cuts, injuries, burns to hands

Replacing the filter without prior cleaning Cuts, injuries to hands

Inhaling large quantities of cutting fluid mist Respiratory organ damage

Mixing different brands of oils Breakdown of the machine

Failing to properly clean or collect flammable cutting chips or sludge Fire

Mixing cutting chips made from different materials Fire

Performing operation without wearing protective gloves Cuts, injuries to hands

Inhaling dust Respiratory problems

Serious injury due to body part

becoming entangled, or cuts to hands

and feet

Serious injury due to body part

becoming entangled

Safety

4.7 Temperature Controller

Action/Situation Result

Touching part or component immediately after operation Burns

Oil temperature exceeds flash point.

Flash point of Makino Spindle Lubricant: 95C

Changing filters without reducing the internal pressure Injury or death, damage to the

Performing operations without safety gloves, mask, and other

protective gear

Mixing different brands of oils Breakdown of the machine

Fire

machine

Damage to eyes, skin irritation,

accidental ingestion, or respiratory

organ damage

29F24D-2006EN

1-27

Page 42

4 Work Hazards

4.8 Hydraulic Unit

4.8 Hydraulic Unit

Action/Situation Result

Working without performing lock-out and tag-out Injury or death, damage to the

machine

Operator working on oily floor Fall, bone fracture, injury

Hand or other body part becomes wedged in tool magazine door

when it is opened or closed.

Leaving a safety guard or maintenance cover opened or removed Injury

Touching part or component immediately after operation Burns

Oil temperature exceeds flash point.

Flash point of standard hydraulic oil: Approximately 200C

Changing filters without reducing the internal pressure Injury or death, damage to the

Performing operations without safety gloves, mask, and other

protective gear

Mixing different brands of oils Breakdown of the machine

Injury, bruises

Fire

machine

Damage to eyes, skin irritation,

accidental ingestion, or respiratory

organ damage

4.9 Pneumatic Unit

Action/Situation Result

Removing the pneumatic unit source piping on the machine side or

disassembling the primary-side line filter without shutting of the air

supply from the factory facilities

Injury due to flying off of parts or

impact

Removing the pneumatic unit source piping on the machine side or

disassembling the primary-side line filter without releasing the

residual pressure in the air piping (inside the air circuit)

Injury due to flying off of parts or

impact

4.10 Splash Guard

Action/Situation Result

Working without performing lock-out and tag-out Injury or death, damage to the machine

Operator entering splash guard with the safety devices and

functions disabled

Operating the machine with the covers removed Injury or death

Holding or carrying a removed cover Injury or machine damage due to

Operator working on oily floor Fall, bone fracture, injury

Operator working at elevated locations Fall, bone fracture

1-28

Injury or death

dropping of cover

29F24D-2006EN

Page 43

4.11 Other Peripheral Equipment

4 Work Hazards

4.11 Other Peripheral Equipment

Action/Situation Result

Performing operation without turning OFF the power Injury or death, electric shock

1

Safety

29F24D-2006EN

1-29

Page 44

5 Occupational Health and Safety Management

NOTE

CAUTION

5.1 Safety Device Inspection

5 Occupational Health and Safety Management

5.1 Safety Device Inspection

Perform periodic maintenance and inspection of the safety devices used on this machine in order to

ensure that they continue to function normally. Make sure that all maintenance staff fully understand

the types of safety devices, functions, and locations described in 3 Safety Devices before performing

any maintenance work.

Before starting operation or maintenance work, inspect the safety devices, and if any are not

functioning properly, abort machine operation.

5.2 Noise

The noise level of the machine is shown below.

• Noise level: 80 dB maximum (A-weighted sound level)

These values are measured values at full operation (maximum rotation of the spindle without

machining a workpiece) with the safety guards and covers correctly mounted and all doors closed.

• When a workpiece is machined, noise at 80 dB or higher may occur under

certain customer cutting conditions. When performing work near the

machine during machining, be sure to wear ear protection and other

equipment to ensure that your health is not harmed.

Performing work without wearing ear protection may lead to hearing loss.

NOTE

The above noise level is measured at a location that is a distance of 0.5 m from the machine and a height of 1.2 m above

the floor.

1-30

29F24D-2006EN

Page 45

5 Occupational Health and Safety Management

WARNING

5.3 Personal Protective Equipment

5.3 Personal Protective Equipment

When conducting installation, operation, and maintenance work on the machine, be sure to protect

your body from the following potential hazards.

• Mechanical hazards

• Hazardous and toxic materials

•Heat

1

•Noise

Be sure to always use protective equipment to protect your body from these hazards. Some examples

of protective equipment are shown below.

Protected

Body Part

Head Bruises and cuts,

Eyes, nose,

mouth, face

Eyes Laser beam Laser safety goggles • Work performed with the eyes

Ears Noise Earplugs • Work where the environment

Hands Cuts, burns, and

Feet Bruises Safety shoes • Handling and transporting of

Torso Falling from high

Hazard Type Protective Equipment Work Requiring Protective

Equipment

Work cap, Helmet • Work where parts or other

falling from high

locations

Flying out of dust,

chips, chippings, and

other substances

Splashing of mist,

lubricants, grease, and

other oils

adhesion of chemical

substances

locations

Protective goggles,

dustproof mask

Protective gloves,

heat-resistant gloves,

chemical-resistant gloves

Safety belt

objects may fall on the head

• Work where the head may get

hit

• Work at locations 2 m or higher

• Work where objects may spray

or fly out

at around the same height as

the laser beam

constantly generates noise

above the stipulated level

• Work where the hands must be

protected

heavy objects

• Work at locations 2 m or higher

Safety

29F24D-2006EN

• Even when wearing laser safety goggles, do not look directly into the laser

beam or indirectly by reflecting the beam on a mirror surface.

Use laser safety goggles to protect the eyes from the dangers of accidentally

looking into the laser beam and scattered laser beams.

1-31

Page 46

5 Occupational Health and Safety Management

5.4 Disposal of Waste Products

5.4 Disposal of Waste Products

5.4.1 Disposal of Waste Oil, Waste Fluids, and Waste Materials

Dispose of any chips, graphite dust or liquids such as cutting fluid, grease, hydraulic oil and lubricant

that are discharged during operation of this machine in accordance with the laws, regulations, and

ordinances established in your country.

Also, separate and dispose of recyclable materials properly.

5.4.2 Disposal of This Machine

When disposing of this machine or its parts, disassemble and dispose of them in accordance with the

laws, regulations, and ordinances established in your country.

Also, separate and dispose of recyclable materials properly.

1-32

29F24D-2006EN

Page 47

Chap. 2 Installation Preparation

1 Checking Installation Requirements ......................................................... 2-1

2 Allocation of Installation Area ................................................................... 2-2

3 Requirements for Carry-in Route.............................................................. 2-8

4 Installation Requirements ....................................................................... 2-15

5 Recommended Foundation Conditions .................................................. 2-16

6 Air and Power Sources ........................................................................... 2-19

7 Preparation of Equipment for Transfer/Installation ................................. 2-23

2

Installation Preparation

Page 48

Page 49

1 Checking Installation Requirements

1 Checking Installation Requirements

Confirm that the requirements below are all satisfied before installing the machine.

• Allocation of installation area (Refer to 2 Allocation of Installation Area)

• Requirements for carry-in route (Refer to 3 Requirements for Carry-in Route)

• Installation requirements (Refer to 4 Installation Requirements)

• Preparation of foundation (Refer to 5 Recommended Foundation Conditions)

• Requirements for power supply (Refer to 6 Air and Power Sources)

• Requirements for air source (Refer to 6 Air and Power Sources)

• Preparation of equipment for transfer (Refer to 7 Preparation of Equipment for Transfer/

Installation)

2

Installation Preparation

29F24D-2006EN

2-1

Page 50

2 Allocation of Installation Area

NOTE

2 Allocation of Installation Area

Be sure to provide an area for machine inspection and repair in addition to an area necessary to install

the machine.

NOTE

The installation area varies depending on the machine model. For details, contact your Makino service representative.

2-2

29F24D-2006EN

Page 51

2 Allocation of Installation Area

2

Installation Preparation

29F24D-2006EN

Figure 2-1 Allocation of Installation Area (General View)

2-3

Page 52

2 Allocation of Installation Area

65

50

505

500

370 350

150

10701140(ATC100)

1150 900

TLSDOORCELING

OPENINGDEPTH

10(ATC100)

HYDRAULICOILSUUPY

(H=535)

COOLANTTEMP.CONTROLLER

(OPTION)

TRANSFORMERBOX

(OPTION)

MAINTENANCEAREA

(PNEUMATIC)

AIRDRYER

(OPTION)

AIRSUPPLYPORT(Rc1/2)

H=350(WITHAIRDRYER)

AIRSUPPLYPORT(Rc1/2)

H=1750(STANDARD)

POWERSUPPLYPORT(Ø60)

(H=500)

415

ATC100(OPTION)

441

HYDRAULICUNIT

R645.5

R645.5

128

517

660

MTC

R880

120

865

772

900(ATC100)

10

520

50

215

510

TLSDOOR

OPENINGWIDTH

900

1800(WITHROBOTSHUTTER)

2710

3295

1250250

910150

90

400

400

355

205 395

600

OP.DOOR

OPENINGWIDTH

510

600

190

Ø120

R440

368

3001500(STD.)

MAINTENANCEAREA

(COOLANTTANK)