Page 1

5-Axis Vertical Machining Center

D200Z

Instruction Manual

Professional 6

29F-21E-2006 (en)

Original instructions

MAKINO GmbH

Kruichling 18, D-73230 Kirchheim unter Teck

Phone ++49 / 7021 / 503 0

Fax ++49 / 7021 / 503 400

Page 2

Page 3

Imprint I

Imprint

Editor: MAKINO GmbH

Essener Bogen 5

D-22419 Hamburg

Germany

Tel.: ++49 / 40 / 298 09 - 0

Fax: ++49 / 40 / 298 09 - 400

e-mail: documentation@makino.eu

Date issued: 2020-06

MAKINO 29F-21E-2006 (en)

Page 4

II Imprint

29F-21E-2006 (en) MAKINO

Page 5

Revisions III

Revisions

Date Chapter/Page Modification

MAKINO 29F-21E-2006 (en)

Page 6

IV Revisions

Revisions

Date Chapter/Page Modification

29F-21E-2006 (en) MAKINO

Page 7

Table of contents V

Table of contents

0 GENERAL SAFETY INSTRUCTIONS ....................................................................................................... 0-1

0.1 Indicator words and their meaning .......................................................................................................... 0-1

1 PREFACE ............................................................................................................................................................. 1-1

1.1 Operation Route Map .................................................................................................................................... 1-2

1.2 Important Information ................................................................................................................................... 1-3

1.3 Manuals and How to Use Them ................................................................................................................. 1-4

1.4 General Contents ............................................................................................................................................. 1-5

2SAFETY ................................................................................................................................................................ 2-1

2.1 Safety Precautions ........................................................................................................................................... 2-1

2.1.1 Operator Checks .............................................................................................................................................. 2-1

2.1.2 Work Environment Checks ........................................................................................................................... 2-1

2.1.3 Precautions for Potential Fire Hazards .................................................................................................... 2-2

2.1.4 Confirmation of Machine Status ................................................................................................................ 2-2

2.1.5 Pre-operation Checks .................................................................................................................................... 2-3

2.1.6 Implementing Lock-out and Tag-out ....................................................................................................... 2-4

2.1.7 During Work ...................................................................................................................................................... 2-5

2.1.8 Handling of Hazardous and Toxic Materials ......................................................................................... 2-7

2.2 Warning Labels ................................................................................................................................................. 2-7

2.2.1 Signal Word Definitions ................................................................................................................................ 2-7

2.2.2 Using Warning Labels .................................................................................................................................... 2-8

2.2.3 Information Contained in Warning Labels ............................................................................................. 2-8

2.2.3.1 Warning Labels with Warning Text ........................................................................................................... 2-8

2.2.3.2 Warning Labels with Warning Marks Only ............................................................................................ 2-9

2.2.4 Warning Label Locations .............................................................................................................................. 2-9

2.2.4.1 Area around Operator Door ...................................................................................................................... 2-10

2.2.4.2 Area around Tool Magazine ...................................................................................................................... 2-11

2.3 Safety Devices ................................................................................................................................................. 2-12

2.3.1 [Emergency Stop] Switch ............................................................................................................................ 2-12

2.3.1.1 [Emergency Stop] Switch Installation Location (Machine Body) ................................................. 2-13

2.3.1.2 [Emergency Stop] Switch Installation Location (Large Capacity Tool Magazine) ................. 2-14

2.3.2 Door Switch ..................................................................................................................................................... 2-14

2.3.2.1 Door Switch Installation Location (Machine Body) .......................................................................... 2-15

2.3.2.2 Door Switch Installation Location (Disk Type Tool Magazine 21-tool/40-tool) .................... 2-15

2.3.2.3 Door Switch Installation Location (Large Capacity Tool Magazine) ........................................... 2-16

2.4 Work Hazards .................................................................................................................................................. 2-16

2.4.1 Area Surrounding Machine ........................................................................................................................ 2-17

2.4.2 Electrical System ............................................................................................................................................. 2-17

2.4.3 Parameters ....................................................................................................................................................... 2-18

MAKINO 29F-21E-2006 (en)

Page 8

VI Table of contents

2.4.4 Inside the Machining Chamber ............................................................................................................... 2-18

2.4.5 Tool Magazine ................................................................................................................................................ 2-19

2.4.6 Cutting Fluid Supply Unit/Chip Disposal Device/Cutting Fluid Temperature Controller/Dust

Collector (Graphite Specifications) ......................................................................................................... 2-20

2.4.7 Temperature Controller ............................................................................................................................... 2-20

2.4.8 Hydraulic Unit ................................................................................................................................................. 2-21

2.4.9 Pneumatic Unit ............................................................................................................................................... 2-21

2.4.10 Splash Guard ................................................................................................................................................... 2-22

2.4.11 Other Peripheral Equipment ..................................................................................................................... 2-22

2.5 Occupational Health and Safety Management ................................................................................. 2-22

2.5.1 Safety Device Inspection ............................................................................................................................ 2-22

2.5.2 Noise .................................................................................................................................................................. 2-22

2.5.3 Personal Protective Equipment ................................................................................................................ 2-23

2.5.4 Disposal of Waste Products ...................................................................................................................... 2-24

2.5.4.1 Disposal of Waste Oil, Waste Fluids, and Waste Materials ........................................................... 2-24

2.5.4.2 Disposal of This Machine ........................................................................................................................... 2-24

3 SPECIFICATIONS ............................................................................................................................................. 3-1

3.1 Machine Basic Specifications ....................................................................................................................... 3-1

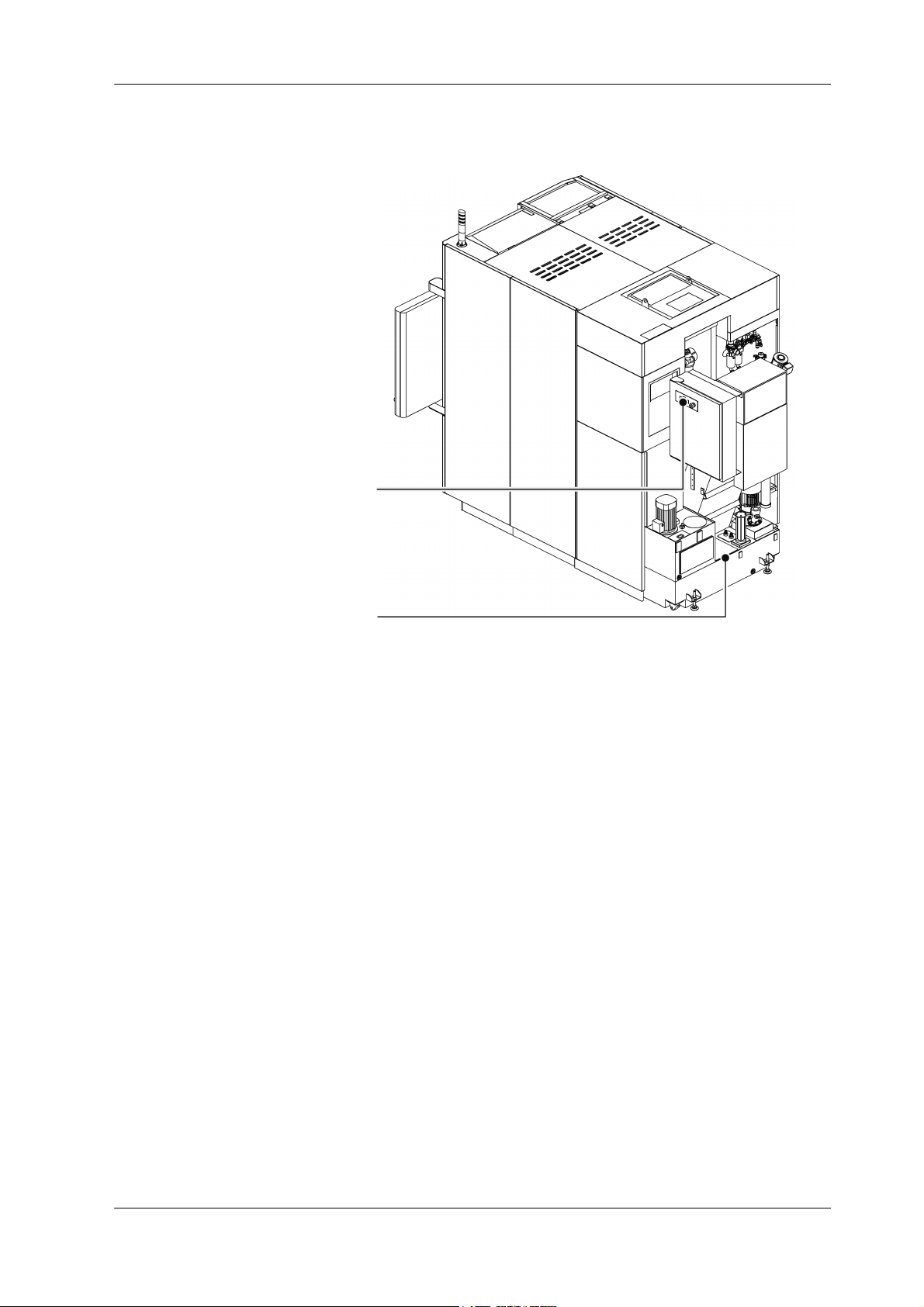

3.2 Machine Primary Components ................................................................................................................... 3-1

3.3 Axis Configuration ........................................................................................................................................... 3-4

3.4 Operation Unit and Display Unit ................................................................................................................ 3-5

4 OPERATION PANEL ....................................................................................................................................... 4-1

4.1 Main Operation Panel .................................................................................................................................... 4-1

4.1.1 Switches and Panels on Main Operation Panel .................................................................................... 4-1

4.1.1.1 One-touch Function Operation Procedure ............................................................................................ 4-7

4.1.2 MDI Panel ............................................................................................................................................................ 4-8

4.2 Manual Pulse Generator ................................................................................................................................ 4-9

4.2.1 Display Unit (Manual Pulse Generator with Position Indicator) .................................................. 4-12

4.3 Machine Control Box Door Interlock Release Key Switch ............................................................. 4-13

4.4 Tool Magazine Operation Panel .............................................................................................................. 4-14

4.5 Lift-up Chip Conveyor Operation Panel (other than Graphite Specifications) ...................... 4-15

4.6 Cumulative Operation Hour Meters ...................................................................................................... 4-17

4.6.1 Viewing the Cumulative Operation Hours Meters ........................................................................... 4-17

4.6.2 Viewing and Resetting the Meters ......................................................................................................... 4-18

5 SCREENS ............................................................................................................................................................. 5-1

5.1 Main Operation Panel Screen ...................................................................................................................... 5-1

29F-21E-2006 (en) MAKINO

Page 9

Table of contents VII

5.1.1 Screen Types ...................................................................................................................................................... 5-2

5.1.1.1 Screens Displayed from Main Menu of Main Operation Panel ..................................................... 5-2

5.1.1.2 Screens Displayed from Support Menu of Main Operation Panel ............................................... 5-3

6 BASIC OPERATION ........................................................................................................................................ 6-1

6.1 Turning Power ON/OFF ................................................................................................................................. 6-1

6.1.1 Switches to Turn Power ON/OFF ............................................................................................................... 6-1

6.1.2 Turning Power ON ........................................................................................................................................... 6-1

6.1.3 Execution of Spindle Running Program .................................................................................................. 6-2

6.1.4 Turning Power OFF ......................................................................................................................................... 6-3

6.1.4.1 Manually Turning OFF the Power .............................................................................................................. 6-3

6.1.4.2 Using the POWER OUT Function to Automatically turn OFF the power .................................... 6-3

6.2 Opening and Closing Doors ........................................................................................................................ 6-3

6.2.1 Opening and Closing the Operator Door .............................................................................................. 6-3

6.2.2 Opening and Closing the Tool Magazine Door ................................................................................... 6-4

6.2.2.1 Opening and Closing the Tool Magazine Door ................................................................................... 6-4

6.2.2.2 Opening and Closing the Large Capacity Tool Magazine Door (When the Machine Is

Equipped with a Large Capacity Tool Magazine) ................................................................................ 6-5

6.3 Tool Preparations ............................................................................................................................................. 6-7

6.3.1 Tool Storage Limitations ............................................................................................................................... 6-7

6.3.2 Tool Shank Specifications ............................................................................................................................. 6-8

6.3.3 Calling Tools ....................................................................................................................................................... 6-9

6.3.4 Removing and Mounting Tools ................................................................................................................ 6-10

6.3.4.1 Tool Handling Precautions ......................................................................................................................... 6-10

6.3.4.2 Removing and Mounting Tools (Disk Type Tool Magazine) .......................................................... 6-10

6.3.4.3 Removing and Mounting Tools (Large Capacity Tool Magazine) ............................................... 6-11

6.4 Workpiece Preparations .............................................................................................................................. 6-12

6.4.1 Loadable Workpieces (Standard Specifications) ................................................................................ 6-13

6.4.2 Loadable Workpieces (Models with Pallet Specifications) ............................................................. 6-13

6.4.3 Removing and Mounting Workpieces ................................................................................................... 6-14

6.5 Operation Modes .......................................................................................................................................... 6-15

6.5.1 Available Operations in Operation Modes .......................................................................................... 6-15

6.5.2 Mode Switching (Standard Specifications) .......................................................................................... 6-17

6.5.2.1 Performing Operation in Mode 1 ............................................................................................................ 6-17

6.5.2.2 Performing Operation in Mode 2 ............................................................................................................ 6-17

6.5.2.3 Performing Operation in Mode 3 ............................................................................................................ 6-17

6.5.3 Mode Switching (CE Specifications) ....................................................................................................... 6-18

6.5.3.1 Performing Operation in Mode 1 ............................................................................................................ 6-18

6.5.3.2 Performing Operation in Mode 2 ............................................................................................................ 6-18

6.5.3.3 Performing Operation in Mode 3 ............................................................................................................ 6-19

6.6 Manual Axis Feed .......................................................................................................................................... 6-20

6.6.1 Manual Reference Position Return .......................................................................................................... 6-20

6.6.2 Jog Feed ............................................................................................................................................................ 6-21

6.6.3 Handle Feed ..................................................................................................................................................... 6-22

6.7 Cutting Fluid Supply and Chip Disposal ............................................................................................... 6-24

6.7.1 Cutting Fluid Supply and Cleaning Air (other than Graphite Specifications) ......................... 6-24

MAKINO 29F-21E-2006 (en)

Page 10

VIII Table of contents

6.7.2 Chip Disposal and Cleaning Air (Graphite Specifications) ............................................................ 6-28

6.7.3 Operation of Workpiece Cleaning Gun ................................................................................................ 6-28

6.7.4 Through spindle coolant pressure switching function ................................................................... 6-29

6.7.4.1 Set the pressure for each tool .................................................................................................................. 6-29

6.7.4.2 Switching pressure during processing .................................................................................................. 6-30

6.8 Signal Lamp ..................................................................................................................................................... 6-30

6.9 Software Weekly Timer ............................................................................................................................... 6-32

6.9.1 Settings ............................................................................................................................................................. 6-33

6.9.1.1 Scheduler Screen ........................................................................................................................................... 6-33

6.9.1.2 Starting Periodically ...................................................................................................................................... 6-33

6.9.1.3 Starting at Specified Date and Time ...................................................................................................... 6-34

6.9.1.4 Starting on Specified Day of the Week ................................................................................................. 6-35

6.9.1.5 Selecting a Program ..................................................................................................................................... 6-37

6.9.2 Switching to Standby Mode ...................................................................................................................... 6-38

6.9.3 Canceling Standby Mode ........................................................................................................................... 6-39

7 AUTOMATIC OPERATION ........................................................................................................................... 7-1

7.1 Execution of Automatic Operation ............................................................................................................ 7-1

7.1.1 Automatic Operation Mode ......................................................................................................................... 7-1

7.1.2 Precautions when Creating a Program .................................................................................................... 7-1

7.1.3 Starting a Program .......................................................................................................................................... 7-1

7.1.4 Pausing and Restarting a Program ............................................................................................................ 7-2

7.1.4.1 Pausing and Restarting a Program by Stop Commands (Program) ............................................. 7-2

7.1.4.1.1 Stopping by Program Stop M0 ................................................................................................................... 7-2

7.1.4.1.2 Stopping by Optional Stop M1 ................................................................................................................... 7-2

7.1.4.1.3 Restarting a Program that was Already Started ................................................................................... 7-2

7.1.4.1.4 Restarting a Program from the Start (Program Rewinding) ............................................................ 7-2

7.1.4.2 Pausing and Restarting a Program by Switches ................................................................................... 7-3

7.1.4.2.1 Stopping by [FEED HOLD] Switch .............................................................................................................. 7-3

7.1.4.2.2 Stopping by [SINGLE BLOCK] Switch ........................................................................................................ 7-3

7.1.4.2.3 Restarting a Program that was Already Started ................................................................................... 7-3

7.1.4.2.4 Restarting a Program from the Start (Program Rewinding) ............................................................ 7-4

7.1.5 Ending a Program ............................................................................................................................................ 7-4

7.2 Automatic Tool Change ................................................................................................................................. 7-4

7.2.1 Tool Change Operation Start Conditions ................................................................................................ 7-5

7.2.2 Tool Change Program ..................................................................................................................................... 7-5

7.2.2.1 Tool Indexing Command (Txxxxxxxx) ........................................................................................................ 7-6

7.2.2.2 Tool Change Command (M6/M666) ......................................................................................................... 7-6

7.2.2.3 Tool Change Program ..................................................................................................................................... 7-7

8 TROUBLESHOOTING .................................................................................................................................... 8-1

8.1 Overview of Problems .................................................................................................................................... 8-1

8.2 Machine Abnormal Condition ..................................................................................................................... 8-1

8.2.1 Recovery from Emergency Stop Status .................................................................................................... 8-2

8.2.1.1 [Emergency Stop] Switch Was Pressed During Tool Change Operation .................................... 8-2

29F-21E-2006 (en) MAKINO

Page 11

Table of contents IX

8.2.1.2 [Emergency Stop] Switch Was Pressed during Machining

(No Workpiece and Tool Contact) ............................................................................................................. 8-3

8.2.1.3 [Emergency Stop] Switch Was Pressed during Machining

(Workpiece and Tool Contact) .................................................................................................................... 8-4

8.2.1.4 Power Turned ON While Door Was Open ............................................................................................. 8-6

8.2.1.5 Abnormal Condition in Machine Controller (MTC) or Servomotor .............................................. 8-6

8.2.2 Overtravel 1 (OT1) Was Detected .............................................................................................................. 8-6

8.2.2.1 Feed Axis Overtravel 1 (OT1) Was Detected ......................................................................................... 8-7

8.2.3 Axis Fails to Move ............................................................................................................................................ 8-7

8.2.4 Program Fails to Start ..................................................................................................................................... 8-7

8.2.5 Programs Are Executed in Single Block Only ....................................................................................... 8-7

8.2.6 Operator Door Fails to Open ...................................................................................................................... 8-8

8.2.7 Operator Door Lock Malfunction .............................................................................................................. 8-8

8.2.8 Alarm Occurred and Machine Operation Stopped ............................................................................ 8-8

8.2.8.1 Switch Is Either Incorrectly Adjusted or Malfunctioning, or Signal Input/Output Device (I/O

Module) Is Malfunctioning ......................................................................................................................... 8-10

8.2.8.2 Inspection of the Hydraulic/Air Cylinder or Solenoid Valve .......................................................... 8-10

8.3 Spindle Head ................................................................................................................................................... 8-10

8.3.1 Spindle Does Not Start ................................................................................................................................ 8-10

8.3.2 Spindle Does Not Stop ................................................................................................................................ 8-11

8.3.3 Abnormal Spindle Speed or Start/Stop Timing ................................................................................. 8-11

8.3.4 Orientation Malfunction ............................................................................................................................. 8-12

8.3.4.1 Alarm Occurs When Orientation Is Performed .................................................................................. 8-12

8.3.4.2 Orientation Position Is Shifted .................................................................................................................. 8-12

8.3.4.3 Overshoot Occurs or Spindle Moves ..................................................................................................... 8-12

8.3.5 Tool Clamp Malfunction .............................................................................................................................. 8-12

8.3.6 Tool Unclamp Malfunction ......................................................................................................................... 8-13

8.3.7 Abnormal Noise Is Emitted during Spindle Rotation ...................................................................... 8-13

8.4 Feed Axis ........................................................................................................................................................... 8-14

8.4.1 Feed Axis Fails to Move in Manual Mode ............................................................................................ 8-14

8.4.2 Feed Axis Runs Until Hitting Mechanical Stopper ............................................................................ 8-14

8.4.3 Positioning Accuracy Is Not Achieved ................................................................................................... 8-14

8.4.4 Abnormal Noises During Axis Operation ............................................................................................. 8-15

8.4.5 Abnormal Vibration During Axis Operation ........................................................................................ 8-15

8.5 Rotary Table ..................................................................................................................................................... 8-15

8.5.1 C-axis/B-axis Fails to Rotate in Manual Mode .................................................................................... 8-15

8.5.2 B-Axis Runs Until Hitting Mechanical Stopper ................................................................................... 8-16

8.5.3 Positioning Accuracy Is Not Achieved ................................................................................................... 8-16

8.5.4 Abnormal Noises During Axis Operation ............................................................................................. 8-16

8.5.5 Machine Operation Stopped During Program Execution .............................................................. 8-17

8.5.6 Strong Clamp and Unclamp Operation for Rotating Axis (C-axis)/Inclined Axis (B-axis) Cannot

be Performed .................................................................................................................................................. 8-17

8.6 Automatic Tool Change (ATC) ................................................................................................................... 8-17

8.6.1 Tool Change Operation Does Not Start ................................................................................................ 8-17

8.6.1.1 Machine Controller Does Not Receive M6/M666 Command ...................................................... 8-17

8.6.1.2 Machine Controller Has Received M6/M666 Command, but Operation Does Not Start . 8-17

8.6.2 Abnormal Noise Is Emitted During Tool Change Operation ........................................................ 8-18

8.6.3 Tool Is Dropped During Tool Change .................................................................................................... 8-18

8.6.4 Abnormal Opening and Closing of ATC Shutter ................................................................................ 8-19

MAKINO 29F-21E-2006 (en)

Page 12

X Table of contents

8.7 Tool Magazine ................................................................................................................................................ 8-19

8.7.1 Tool Magazine Door Lock Release Malfunction ................................................................................ 8-19

8.7.2 Large Capacity Tool Magazine Door Lock Release Malfunction (When the Machine Is

Equipped with a Large Capacity Tool Magazine) .............................................................................. 8-19

8.7.3 Tool Magazine Door Lock Malfunction ................................................................................................ 8-20

8.7.4 Large Capacity Tool Magazine Door Lock Malfunction (When the Machine Is Equipped with a

Large Capacity Tool Magazine) ................................................................................................................ 8-20

8.7.5 Unable to Turn On Manual Intervention Mode ................................................................................ 8-20

8.7.6 Unable to Turn Off Manual Intervention Mode ................................................................................ 8-21

8.7.7 Tool Magazine Does Not Rotate When Manual Intervention Mode Is On ............................. 8-21

8.7.8 Tool Magazine Does Not Stop Rotating ............................................................................................... 8-21

8.7.9 Tool Indexing (T Command) Operation Does Not Start ................................................................. 8-21

8.7.10 Wrong Tool Is Indexed to Tool Change Position ............................................................................... 8-22

8.7.11 Tool or Tool Pot Dropped during Operation ...................................................................................... 8-22

8.7.12 Manually Recovering the Tool Magazine (Disk Type Tool Magazine 21-tool) ...................... 8-22

8.7.13 Manually Recovering the Tool Magazine (Disk Type Tool Magazine 40-tool) ...................... 8-25

8.7.14 Manually Recovering the Tool Magazine (Large Capacity Tool Magazine) ............................ 8-27

8.8 Temperature Controller ............................................................................................................................... 8-29

8.8.1 Excessively High Cooling Oil Consumption Rate .............................................................................. 8-30

8.9 Oil Air Supply Device ................................................................................................................................... 8-30

8.9.1 Lubricant Is Not Discharged (Pump Is Not Running) ...................................................................... 8-30

8.9.2 Lubricant Is Not Discharged (Pump Is Running) ............................................................................... 8-30

8.9.3 Pump Pressure Does Not Rise ................................................................................................................. 8-31

8.9.4 No Signal from Float Switch ..................................................................................................................... 8-31

8.9.5 Air Bubbles in Oil Piping ............................................................................................................................ 8-31

8.10 Hydraulic Unit ................................................................................................................................................. 8-32

8.10.1 Excessively High Hydraulic Oil Consumption Rate .......................................................................... 8-32

8.10.2 Accumulator Pressure Does Not Rise ................................................................................................... 8-32

8.11 Pneumatic Unit ............................................................................................................................................... 8-32

8.11.1 Supply Air Pressure Does Not Rise ........................................................................................................ 8-32

8.11.2 Pressure Switch Malfunction ..................................................................................................................... 8-33

8.11.2.1 Pressure Switch Is Not Activated Even Though Air Pressure Is Low ......................................... 8-33

8.11.2.2 Pressure Switch Is Activated Even Though Supply Pressure Is Normal ................................... 8-34

8.12 Chip Disposal Device/Cutting Fluid Supply Unit ............................................................................... 8-34

8.12.1 Lift-up Chip Conveyor ................................................................................................................................. 8-34

8.12.1.1 Chip Sludge Accumulates in Coolant Tank ......................................................................................... 8-34

8.12.1.2 Large Amounts of Chips Accumulate in Clean Tank ........................................................................ 8-34

8.12.1.3 Filter Is Clogged ............................................................................................................................................. 8-35

8.12.1.4 Conveyor Is Running in Reverse Rotation ........................................................................................... 8-35

8.12.1.5 Geared Motor Does Not Run ................................................................................................................... 8-36

8.12.1.6 Geared Motor Generated Excessive Heat ............................................................................................ 8-36

8.12.1.7 Abnormal Noise Emitted from Geared Motor ................................................................................... 8-37

8.12.2 Cutting Fluid Supply Unit ........................................................................................................................... 8-37

8.12.2.1 Cutting Fluid Is Not Discharged (Pump Is Not Running) .............................................................. 8-37

8.12.2.2 Cutting Fluid Is Not Discharged (Pump Is Running) ....................................................................... 8-37

8.12.2.3 Cutting Fluid Is Leaking from Pump ...................................................................................................... 8-38

8.12.2.4 Line Filter, Suction Filter or Y-Strainer Is Clogged ..................................................................

8.12.2.5 Through-spindle Coolant Pump Is Not Pressurized ........................................................................ 8-38

8.12.2.6 Incorrect Coolant Unit Was Activated ................................................................................................... 8-39

.......... 8-38

29F-21E-2006 (en) MAKINO

Page 13

Table of contents XI

8.13 Dust Collector (Graphite Specifications) ............................................................................................... 8-39

8.13.1 Dust Collector Does Not Collect Dust ................................................................................................... 8-39

8.13.2 Internal Chip Conveyor Does Not Start ................................................................................................ 8-39

8.14 Other .................................................................................................................................................................. 8-39

8.14.1 Alarm Occurred Due to Low Battery ...................................................................................................... 8-39

8.14.2 Oil Leakage ...................................................................................................................................................... 8-40

8.15 Device Manager Screen .............................................................................................................................. 8-40

8.15.1 Oil Air Supply Device .................................................................................................................................... 8-41

8.15.2 Spindle ............................................................................................................................................................... 8-41

8.15.3 ATC ...................................................................................................................................................................... 8-42

8.15.4 Tool Magazine ................................................................................................................................................. 8-44

8.15.5 Tool Magazine (40 or more) ...................................................................................................................... 8-45

8.15.6 Additional Tool Stocker ............................................................................................................................... 8-47

8.15.7 Table Chuck ...................................................................................................................................................... 8-49

8.15.8 AWC .................................................................................................................................................................... 8-50

8.15.9 Work Measurement Function ................................................................................................................... 8-51

8.15.10 Non-Contact Type Tool Measurement Function (Fixed laser type) ............................................ 8-53

8.15.11 Special User Input/Output Interface ...................................................................................................... 8-55

8.15.12 Auxiliary Control Unit (ACU) ...................................................................................................................... 8-56

8.15.13 Service Condition ........................................................................................................................................... 8-57

8.15.14 Eco Monitor ..................................................................................................................................................... 8-58

8.15.15 Servo Amp Capacitor ................................................................................................................................... 8-58

9 INSTALL ATION PREPARAT ION ............................................................................................................... 9-1

9.1 Checking Installation Requirements ......................................................................................................... 9-1

9.2 Allocation of Installation Area .................................................................................................................... 9-1

9.3 Requirements for Carry-in Route .............................................................................................................. 9-8

9.4 Installation Requirements ........................................................................................................................... 9-12

9.5 Recommended Foundation Conditions ................................................................................................ 9-13

9.6 Air and Power Sources ................................................................................................................................. 9-15

9.7 Preparation of Equipment for Transfer/Installation .......................................................................... 9-18

10 INDEX ............................................................................................................................................................... 10-1

11 REVISION HISTORY ................................................................................................................................... 11-1

MAKINO 29F-21E-2006 (en)

Page 14

XII Table of contents

29F-21E-2006 (en) MAKINO

Page 15

GENERAL SAFETY INSTRUCTIONS 0-1

0 GENERAL SAFETY INSTRUCTIONS

The hazards involved in operating the machine are identified by the following means:

- In this manual, warning notices serve to indicate aspects which are relevant to safety.

- On the machine, warning signs point out aspects which are relevant to safety.

0.1 Indicator words and their meaning

The indicator words use for warning notices are divided into the categories listed below, according to the

accepted degree of risk involved.

Consciously ignoring these warning notices can result in accidents, serious injuries or death.

Furthermore, serious damage may be caused to the machine and its auxiliary units. The warning notices

below must there be followed without fail!

DANGER!

Indicator word used to denote an immediately hazardous situation which, if not avoided,

will result in serious injury or death.

WARNING!

Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in serious injury or death.

CAUTION!

Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in slight to moderate injuries.

NOTICE! Indicator word used to denote a potentially hazardous situation which, if not avoided,

could result in damage to property.

REMARK Indicator word used to point out important or useful information.

MAKINO 29F-21E-2006 (en)

Page 16

0-2 GENERAL SAFETY INSTRUCTIONS

29F-21E-2006 (en) MAKINO

Page 17

PREFACE 1-1

1PREFACE

REMARK Do not operate, maintain, or inspect this machine without carefully reading and under-

standing this manual.

Store this manual in a clearly marked location for easy reference.

All rights reserved. No part of this document may be reproduced, copied, or modified in

any form or any means without direct permission of Makino Milling Machine Co., Ltd.

This machine, including technical data and software, may be subjected to the Japanese Foreign Exchange

and Foreign Trade Law. Prior to any re-sell, re-transfer, or re-export of controlled items, please contact

Makino to obtain any required authorization or approval.

MAKINO 29F-21E-2006 (en)

Page 18

1-2 PREFACE

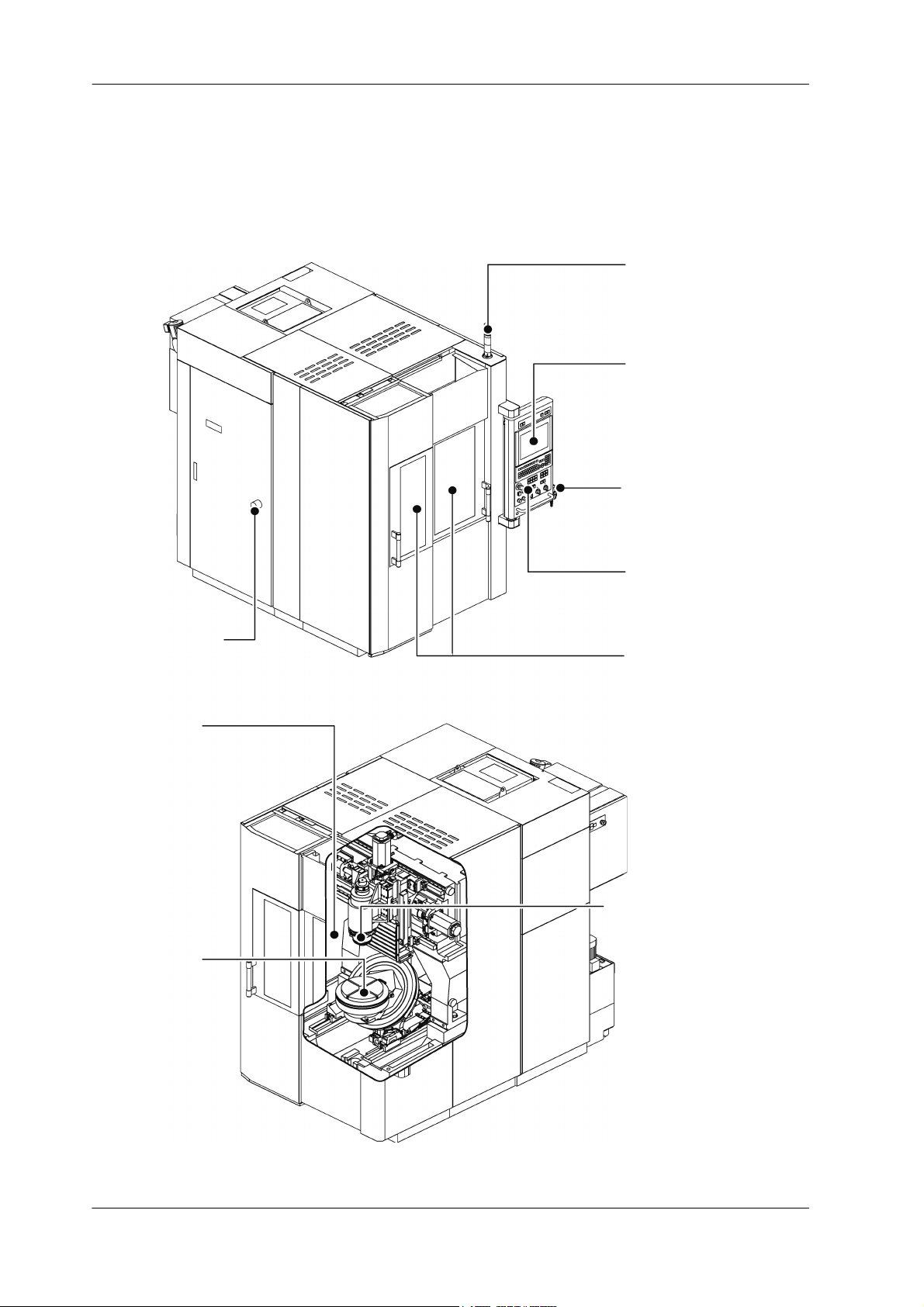

Signal lamp

Refer to chap. “6 BASIC

OPERATION”

Operation modes

Refer to chap. “6 BASIC OPERATION”

Tool magazine

operation panel

Refer to chap. “4 OPERATION

PAN EL”

Screen types

Refer to chap. “5 SCREENS”

Manual pulse generator

Refer to chap. “4 OPERATION

PAN EL”

Main operation panel

switches

Refer to chap. “4 OPERATION

PAN EL ”

Opening and

closing doors

Refer to chap. “6 BASIC

OPERATION”

Manual axis feed

Refer to chap. “7 AUTOMATIC

OPERATION”

Tur ning p ower

ON/OFF

Refer to chap. “6 BASIC

OPERATION”

Tool preparations

Refer to chap. “6 BASIC

OPERATION”

Automatic tool

change

Refer to chap. “7 AUTOMATIC OPERATION”

Workpiece preparations

Refer to chap. “6 BASIC

OPERATION”

1.1 Operation Route Map

Fig. 1-1:

29F-21E-2006 (en) MAKINO

Page 19

PREFACE 1-3

Lift-up chip conveyor operation panel

Refer to chap. “4 OPERATION PANEL”

Cutting fluid supply

Refer to chap. “6 BASIC OPERATION”

1.2 Important Information

General

- Do not attempt to modify the machine.

- Operation, maintenance, and inspection of this machine must be performed by staff who have received

technical training for the machine, training in machine hazards and their prevention, and safety training.

- Observe the laws, regulations, and other rules of the relevant national and local administrative agencies.

- This machine, including technical data and software, may be subject to the Japanese Foreign Exchange

and Foreign Trade Law.

Prior to any resale, transfer or re-export of controlled items, contact Makino to obtain any required authorization or approval.

- The specifications and design are subject to change without prior notice.

This Manual

- This manual is prepared for usage by experienced operators. For this reason, it does not include safety

precautions for operators who do not have mechanical or technical knowledge of machine operation,

programming, and maintenance.

- If the machine is operated by persons who are not native speakers of the language in this manual, the

customer must ensure that the operators receive complete safety training. Also, warning labels must be

affixed in a language that the operators can understand.

- The copyright for the entire content of this manual belongs to Makino Milling Machine Co., Ltd. The

copying, reproduction, or transfer of this manual, in whole or in part, without the express written permission of Makino Milling Machine Co., Ltd., is strictly prohibited.

MAKINO 29F-21E-2006 (en)

Fig. 1-2:

Page 20

1-4 PREFACE

- Illustrations and other details may differ from the actual machine due to the selected options, modified

specifications, or other reasons.

- Store the manuals needed for operation, maintenance, and inspection of this machine in a location

where they can be easily accessed by the operator.

- Be sure to perform periodic inspection and maintenance of the machine according to the periodic

maintenance manual or the legend plate to prevent breakdown of the machine.

Important Points for Work Safety

- Familiarize yourself with the safety precautions and functions before attempting to operate, maintain,

or inspect the machine.

- The points that the operator must observe when performing machine operation and maintenance vary

depending on the situation. All possible points cannot be covered in the content of this manual. Be sure

to fully understand the machine, and remain constantly aware of safety and the potential hazards while

doing work.

- If the safety devices or protective devices do not operate properly, stop operation of the machine and

notify the supervisor or manager. The supervisor or manager must immediately notify your authorized

Makino dealer or Makino service representative.

- When the machine is stopped due to an unknown cause, immediately contact the supervisor or manager, and wait for permission before restarting operation.

Keeping Machining Accuracy

- After installing the machine, to keep machining accuracy, conduct periodic inspection such as performing level adjustment. If the level of the machine changes, high-accuracy machining cannot be performed. In addition, normal machining cannot be performed if the machine vibrates.

- Especially, for approximately six months after installation, the level of the machine might change significantly until the foundation becomes stable.

- Depending on the condition of the foundation or the machine usage frequency, conduct inspection and

adjustment approximately every six months or every year.

1.3 Manuals and How to Use Them

Manuals Belonging to This Machine

Name Description

Instruction Manual This manual includes the basic information (overview, specifications)

needed for operation, practical operating procedures (operation),

and troubleshooting procedures.

Periodic Maintenance Manual This manual explains the intervals for periodic maintenance and

work that is required for maintaining optimum performance of this

machine.

Peripheral Device Manual This manual describes the operating procedures for the peripheral

devices connected to the machine body.

Parts Manual This manual provides the machine component part names and their

order numbers.

Professional 6 Operation Manual This manual describes the operating procedures and various func-

tions of the controller (Professional 6).

Professional 6 M Code List This manual describes the M codes of Professional 6.

Table 1-1: (1 / 2)

29F-21E-2006 (en) MAKINO

Page 21

PREFACE 1-5

Name Description

FANUC

Set of NC Manuals

Maintenance Manual (option) This manual describes the mechanisms of the machine and how to

Installation Manual (option) This manual describes the preparation, carry-in, and installation pro-

Other manuals for options These manuals describe the operating procedures for the optional

Notation Used in This Manual

See chapter “0 GENERAL SAFETY INSTRUCTIONS” for the description of used warning symbols.

These manuals describe the operating procedures for FANUC equipment.

perform the maintenance and adjustment work.

cedures for setup of the machine.

devices.

Table 1-1: (2 / 2)

1.4 General Contents

Chap. “2 SAFETY”

This chapter describes the safety devices and warning labels, work and operating precautions, and other

information for ensuring safety operation of the machine. Be sure to read this chapter before using the

machine.

Chap. “3 SPECIFICATIONS”

This chapter describes the basic configuration and specifications of the machine.

Chap. “4 OPERATION PANEL”

This chapter describes the main operation panel, manual pulse generator, and other details about the operation panels used in this machine.

Chap. “5 SCREENS”

This chapter provides an overview of the screens used in this machine.

Chap. “6 BASIC OPERATION”

This chapter describes machine power ON/OFF, door open/close, tool and workpiece preparation, manual

axis feed, and other manual operations required before machining.

Chap. “7 AUTOMATIC OPERATION”

This chapter describes the execution of automatic operation, automatic tool change operation, and similar

operations.

Chap. “8 TROUBLESHOOTING”

This chapter provides the basic troubleshooting information when the machine does not operate properly.

Chap. “9 INSTALLATION PREPARATION”

This chapter includes the dimensions required for machine carry-in and other operations.

MAKINO 29F-21E-2006 (en)

Page 22

1-6 PREFACE

29F-21E-2006 (en) MAKINO

Page 23

SAFETY 2-1

2SAFETY

2.1 Safety Precautions

- Disregarding the specific instructions or precautions included in this manual may result in serious injury

or death to the operators or surrounding workers, or damage to the machine.

- Never disable or remove any safety device. Operating the machine while the safety devices are disabled

may result in serious injury, death, or damage to the machine.

- Observe the safety precautions provided in this manual at all times and fully implement safety measures.

- Inspect and maintain the machine regularly to keep it in optimum operating condition. Do not run the

machine if it shows any signs of abnormal operation.

- The keys (release key for door switch, machine controller panel key, etc.) which are not necessary for

regular operation and maintenance must be removed from the machine and managed by supervising

personnel.

- The lubricating oil, cutting fluid, and other chemical substances used with the machine must be managed by supervising personnel.

- Workpiece materials such as magnesium and titanium may cause a fire if mishandled, so be particularly

careful when machining workpieces and handling cutting chips made from these types of materials.

2.1.1 Operator Checks

- Only qualified personnel who have adequate mechanical and technical knowledge are allowed to operate and maintain the machine.

- Only qualified electrical engineers may perform electrical work.

- Only qualified personnel may use a crane or forklift.

- Wear suitable work clothes whenever operating or maintaining the machine. Do not operate the machine while wearing loose-fitting clothes, a necktie, jewelry, or any other clothing or objects which may

become entangled with the moving parts of the machine.

- Tie up long hair, and wear a cap.

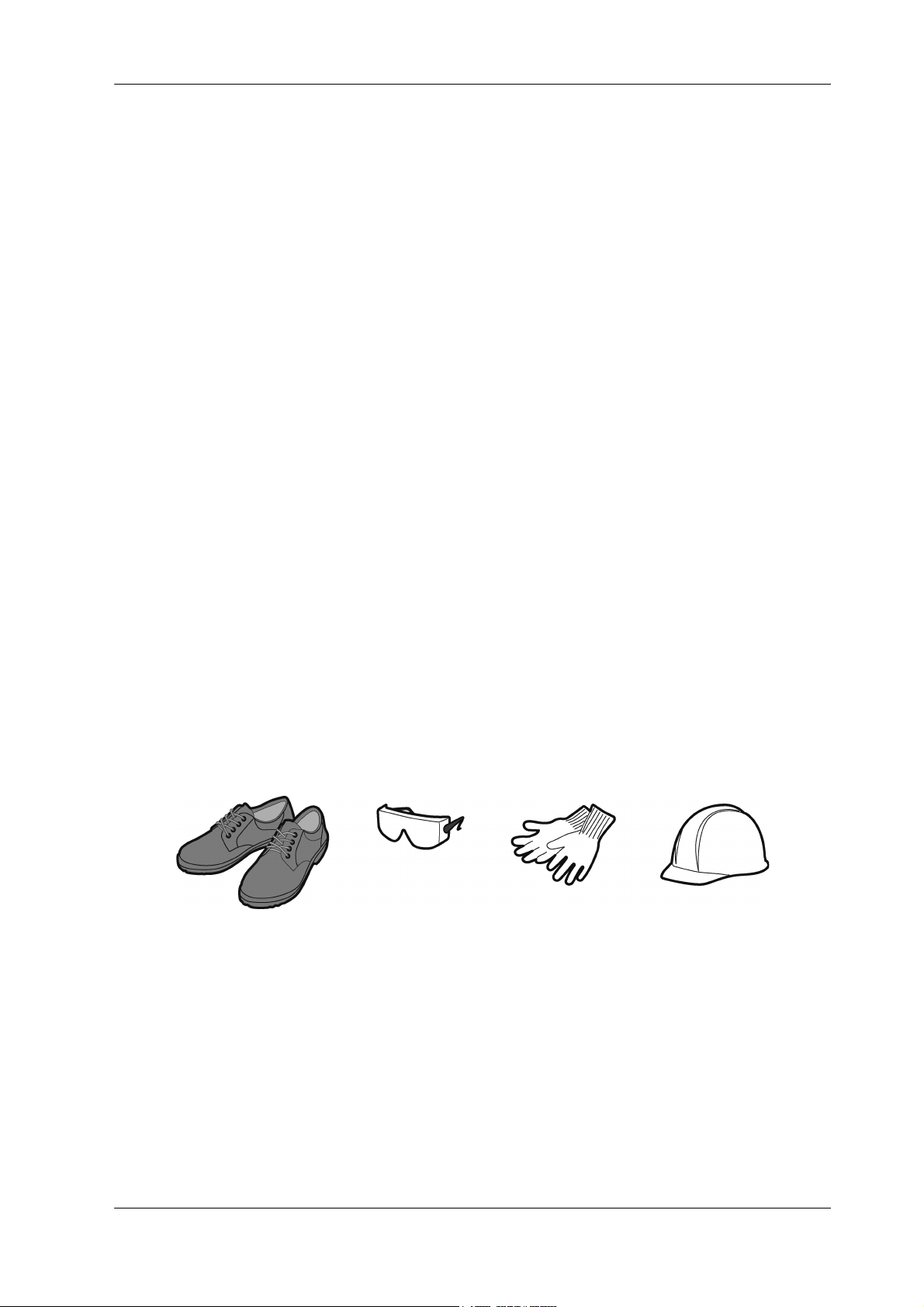

- Wear safety glasses, safety shoes, safety cap (including safety helmet), and safety gloves as needed.

Fig. 2-1:

- Protective gear should be worn to protect hearing when excessive noise may be generated during operation or maintenance.

- Never operate any machinery while under the influence of alcohol or drugs.

- The operator should be in proper physical condition. If the operator suffers from a condition that impairs judgment, it may result in serious injury or death.

2.1.2 Work Environment Checks

- Make sure the machine and surrounding area are fully lighted.

MAKINO 29F-21E-2006 (en)

Page 24

2-2 SAFETY

- Make sure the machine and surrounding area are tidy and clean at all times.

- Clean up any oil, cutting fluid, or chips scattered around the machine.

- When performing work at high locations, use a stable footstool or stepladder.

- Keep all flammable substances away from the work area.

- Maintain adequate working space.

2.1.3 Precautions for Potential Fire Hazards

Use the machine by following the precautions below to protect the machine equipment, plant, and surrounding environment from the danger of fire and to ensure the safety of operators.

When using cutting fluid, be sure to use a water-soluble cutting fluid (type A1).

There is no fire hazard when using water-soluble cutting fluids (except when using them with special materials).

Oil-based cutting fluids present a potential fire hazard.

- If an oil-based cutting fluid must be used due to unavoidable circumstances, be sure to observe the

precautions below.

- Do not run the machine in an unmanned operation mode.

- Install the proper fire-extinguishing equipment near the machine.

- Provide alarm devices to detect a fire, automatic fire-extinguishing devices, and other equipment to the

greatest extent possible.

- Do not create situations which may potentially start a fire.

• Machine under the proper cutting conditions.

• Perform proper tool management to prevent the occurrence of abnormal frictional heat and sparks.

• Do not allow chips to accumulate in the machining chamber.

• Check that a constant and full supply of cutting fluid is provided.

• Always clean up and organize the area around the machine, and do not place flammable objects in the

area.

Precautions for machining of flammable solids, resins, wood, and other flammable materials.

When machining flammable solids or other special materials, be sure to fully implement safety measures

after gaining a thorough understanding of the material properties. Be sure to also pay careful attention to

safety when machining resins, wood, and other materials.

When machining materials that generate dust and powder, be sure to provide equipment that takes into

account the danger of a dust explosion for certain material types.

Precautions for machining while blowing air.

Because air blowing has weak cooling performance, the chips that spray and fly out in the surrounding

area are extremely hot. Do not place flammable objects in the machining chamber or in the area surrounding the machine.

2.1.4 Confirmation of Machine Status

- Machine inspections and maintenance must be performed regularly to maintain optimum machining

accuracy and long-term performance, and increase machine operating efficiency.

- Confirm that all safety devices are functioning normally.

- Make sure the operator knows the location of the [Emergency Stop] switches to enable easy access in

the event of an abnormal or dangerous situation (refer to “2.3.1 [Emergency Stop] Switch”).

29F-21E-2006 (en) MAKINO

Page 25

SAFETY 2-3

- Check for any loose, damaged, or worn parts on the machine. Operating the machine in a condition in

which any of the parts has an abnormality may cause abnormal noises or damage to the machine.

- Check for any damaged piping or wiring. Operating the machine with the piping or wiring left damaged

may cause oil leakage, electrical shock, or fire.

- Use the most appropriate cutting tool, tool holder, retention knob, and workpiece, and make sure that

they are all secured firmly in place. Otherwise, the workpiece may fall or the tool may fly out, and this

may result in damage to the machine, serious injury, or death.

- Check that the tool numbers are registered correctly. Otherwise, the spindle may rotate at a speed outside the allowable range, the tool may fly out, and this may result in damage to the machine, serious injury, or death.

2.1.5 Pre-operation Checks

- Be sure that you fully understand the work procedures and precautions before operating and maintaining the machine. Never operate any machinery if you are unsure about any points.

- Check that the clothes you are wearing are suitable for operation.

- Perform periodic maintenance.

- Confirm that all safety devices are functioning properly before operating and maintaining the machine.

- Periodically back up the parameters when the machine was shipped and the program and offset data

that have been prepared by the customer. Makino is not liable for any program or offset data that is

corrupted or lost.

- Makino does not accept responsibility for any trouble caused by apparatus or programs prepared by

the customers, such as damage to workpieces or the machine.

- For details about replacement parts, contact your Makino service representative. Use of improper parts

may result in reduced machine performance or safety, damage to the machine, or operator injuries.

- Before entering inside the machine to perform work, be sure to confirm the escape procedure in the

event that you inadvertently become shut inside the machine.

- Perform the lock-out and tag-out procedures.

- Make sure the operator knows the location of the [Emergency Stop] switches for each device so that

they can be easily operated in the event of an abnormal or dangerous situation.

- Be sure to observe the information on the warning labels. Contact your Makino service representative if

a warning label comes off or becomes illegible.

- When handling a hazardous or toxic material (oils, cutting fluids, and other chemical substances), obtain

the safety data sheet (SDS), and follow the instructions. The safety data sheet (SDS) contains information about the safe handling of hazardous and toxic materials, and emergency measures.

- For the graphite specifications, do not let the dust collector collect anything other than graphite dust.

Failure to observe this precaution may result in a dust explosion. Also, it may damage the filter or cause

other malfunctions.

- For the graphite specifications, observe the following precautions to prevent health problems related to

the inhalation of graphite dust.

• After machining the workpieces, wait for the dust collector to remove airborne dust particles before

opening the operator door. If you open the operator door immediately after machining, the airborne

dust will disperse throughout the machining room.

• Wear a high-performance dust-proof mask when doing the following (particle collection efficiency of

99.9% or more is recommended).

- Opening and closing the operator door

- Performing an operation with the operator door open

- Replacing a tool in the tool magazine

- Handling dust

• Do not remove the dust car and chip bucket while the dust collector is operating. Otherwise, dust will

disperse in the surrounding area.

MAKINO 29F-21E-2006 (en)

Page 26

2-4 SAFETY

DANGER

Under Maintenance/

Inspection

Operator’s Name: xxxxx

Department: xxxxx

D

A

N

G

E

R

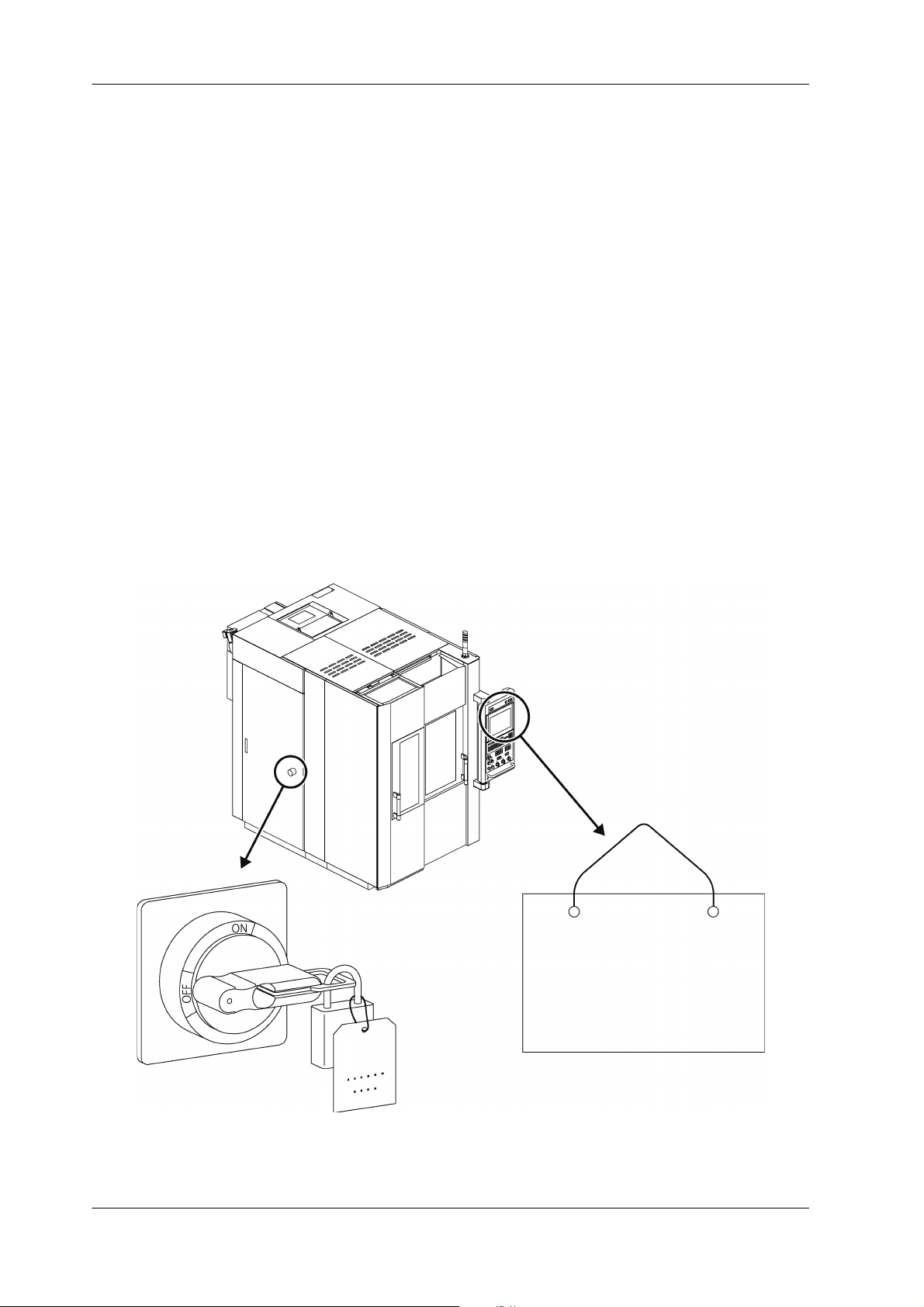

2.1.6 Implementing Lock-out and Tag-out

Lock-out consists of shutting down the power source to the machine or devices and locking it.

Example: .................... Set the main power switch to the “OFF” position and secure it using a padlock or a

lockout device such as a cover.

Tag-out consists of placing a warning tag to prevent anyone from turning ON the power.

Example: .................... Place a “Do Not Operate” or “Under Maintenance” sign with the operator’s name and

department and indicating that machine operation is prohibited on the main power

switch and main operation panel.

Lock-out/tag-out should be performed to prevent inadvertent operation and ensure operator safety.

- Performing lock-out/tag-out alone does not completely ensure operator safety. The operator must read

and thoroughly understand the work procedures and safety precautions, and always be aware of potential hazards.

Each operator should perform lock-out or tag-out by himself or herself. Perform this procedure before

starting the work, and release the lock and remove warning tag yourself after finishing work. Never release a lock and remove a sign without confirming with the operator or without the presence of the operator himself or herself.

Be sure to clearly define and implement the lock-out and tag-out procedures of your company.

Fig. 2-2: Implementing Lock-out and Tag-out

29F-21E-2006 (en) MAKINO

Page 27

SAFETY 2-5

2.1.7 During Work

- Turn OFF the power before performing maintenance of the machine. When work must be performed

with the machine power ON, confirm that all machine operations are completely stopped. Check that

any residual energy in the machine is completely discharged.

- Never go near the moving parts of the machine. If you must approach moving parts to perform maintenance, be sure to take adequate safety precautions. Inadequate attention to safety may result in death

or another serious accident.

- Always keep the doors and covers closed during operation. If you must work with the doors and covers

open, be sure to take ade quate safety precautions. Inadequate attention to safety ma y result in death or

another serious accident.

- If an operator gets trapped inside the machine, press the [Emergency Stop] switch regardless of whether the machine power is ON or OFF.

- If the machine is stopped by a power failure or power supply fault, turn OFF the machine power. If the

power is not turned OFF, the machine may start operating unexpectedly when the power is restored,

and this may result in serious injury, death, or damage to the machine.

- If the machine is stopped by a power failure or power supply fault, check that the parameter, program,

and offset data have not been corrupted. The machine may be damaged if it is operated using corrupted data.

- Be aware of the movement range of the machine and auxiliary components (each axis stroke, rotation

range, etc.), and keep all body parts clear of moving components.

- When two or more people are required for maintenance work, be sure to maintain clear communication

at all times to ensure operator safety. When performing work, be ready to press the [Emergency Stop]

switch at any time.

- Be sure to always pay attention to the safety precautions listed on the warning labels affixed to the machine (refer to “2.2 Warning Labels”).

- Do not operate the switches or change the circuits except for adjustment purposes. In particular, operating the machine with the interlock(s) or other safety devices or functions disabled is extremely dangerous and may result in death or damage to the machine.

- If a circuit or other component needs to be changed for adjustment purposes, be sure to return it to the

original setting after adjustment is completed.

- The optimum values for the NC parameters and machine parameters are set when the machine is

shipped. Do not change any parameter setting unless it is described in the manual. Also, be sure that

you fully understand the function of a parameter before attempting to change the parameter setting,

and return the parameter to its original setting after the work is completed. If you try to operate the

machine without the proper settings, the machine may operate unexpectedly, and this may result in serious injury, death, or damage to the machine.

- If the memory clear operation needs to be performed, be sure to contact your Makino service representative beforehand.

- If an alarm is triggered, eliminate the cause of the alarm using the appropriate procedure. If the remedy

procedure is unclear, contact your Makino service representative.

MAKINO 29F-21E-2006 (en)

Page 28

2-6 SAFETY

- Never climb onto the covers. This may deform the covers or result in injury.

- When using a stepladder or stool, it should be sturdy, safe, and have anti-slip surfaces.

- If any oils or cutting fluids get into your eyes, body, or on your skin surface, they may cause severe

health problems. Wear safety gloves, mask, safety glasses, and other safety equipment.

- Wear safety gloves whenever handling chips, tools, and workpieces.

- Protective gear should be worn to protect hearing when excessive noise may be generated during operation or maintenance.

- If lubricating oil, grease, cutting fluid, or other substances are spilled on the floor, it may result in slippage, causing injury. Wipe up any spilled fluids as soon as possible.

- Never touch a switch, button, or key while your hands are wet. Failure to observe this precaution may

result in electric shock.

- Some devices (motors, lighting equipment, valves, etc.) may become very hot while the machine is operating and remain hot soon after the power is turned OFF, so be careful to avoid burns.

- Do not subject the machine to sudden impact or jolts. This may cause the machine to perform an unexpected motion or result in damage to the machine.

- Do not use the machine for operation outside the specifications or exceeding the performance range.

This may cause the machine to perform an unexpected motion or result in serious injury, death, or damage to the machine.

- Use the most appropriate cutting tool, tool holder, retention knob, and workpiece, and make sure that

they are all secured firmly in place. Otherwise, the workpiece may fall or the tool may fly out, and this

may result in damage to the machine, serious injury, or death.

- Be careful that you do not leave objects such as tools or jigs inside the machine.

- Do not place the tools, workpiece, or other parts on an unstable location.

- When a lifting sling or attachment is necessary, verify that it is strong enough to support the weight of

the parts. Confirm that no one is close to the machine and the parts are well balanced, and be careful

not to hit to the machine.

- Never go under a load that is being lifted. While transferring the hoisted load, constantly pay careful attention to the hoisted load during the operation.

- Check that the tool numbers are registered correctly. Otherwise, the spindle may rotate at a speed outside the allowable range, the tool may fly out, and this may result in damage to the machine, serious injury, or death.

- Never insert hands or feet into the chip conveyor. They may be pulled in, and this may result in death or

another serious accident.

- For the graphite specifications, observe the following precautions to prevent health problems related to

the inhalation of graphite dust.

• After machining the workpieces, wait for the dust collector to remove airborne dust particles before

opening the operator door. If you open the operator door immediately after machining, the airborne

29F-21E-2006 (en) MAKINO

Page 29

SAFETY 2-7

dust will disperse throughout the machining room.

• Wear a high-performance dust-proof mask when doing the following (particle collection efficiency of

99.9% or more is recommended).

- Opening and closing the operator door

- Performing an operation with the operator door open

- Replacing a tool in the tool magazine

- Handling dust

• Do not remove the dust car and chip bucket while the dust collector is operating. Otherwise, dust will

disperse in the surrounding area.

2.1.8 Handling of Hazardous and Toxic Materials

Handlers of hazardous and toxic materials (such as oils and cutting fluid) must receive information, education, and training in accordance with the stipulations in JIS Z 7253 (revised March 2012)/ISO 11014: 2009.

Particular attention must be paid to the following points.

- Be sure that there is adequate ventilation in areas where hazardous and toxic materials are used.

- Hazardous and toxic materials must be handled and stored based on the handling procedures recommended by the manufacturer.

- Identify hazardous and toxic materials by affixing labels to their containers.

- Assign a person in charge to handle the hazardous and toxic materials, and provide education and

training in emergency response procedures and handling procedures.

- Before handling any hazardous or toxic material, be sure to check the safety data sheet (SDS). The safety

data sheet (SDS) contains detailed information on health and safety hazards, safe handling procedures,

and responses to emergency situations.

2.2 Warning Labels

Warning labels are affixed to machine parts that are potentially hazardous to warn operators about the

hazard and its level of danger and ensure the safety of operators.

The warning labels include symbols to indicate the source of the danger, signal words to indicate the level

of danger, and warning text to describe how to prevent the danger. When working at a location where a

warning label is affixed, make sure that you fully understand the warning label information and definitions

and follow the warning text that is provided. Failure to observe the information in the warning labels may

result in death or another serious accident or damage to the machine.

2.2.1 Signal Word Definitions

Signal words are divided into four classes based on the degree of expected risk.

See chapter “0 GENERAL SAFETY INSTRUCTIONS” for the description of used warning symbols.

MAKINO 29F-21E-2006 (en)

Page 30

2-8 SAFETY

2.2.2 Using Warning Labels

- Do not cover up or peel off the warning labels.

- Confirm that the operators and maintenance personnel are familiar with the language on the labels. If

labels in other languages are required, contact your Makino service representative.

- Check that all the information in the warning label is legible. If any portion of the warning text or symbol is not visible, clean by wiping with a soft cloth dipped in water or household cleanser. Do not use organic solvents or gasoline. These may damage the surface of the warning label.

- Replace the warning label if the information in the warning label is no longer visible. To obtain new

warning labels, contact your Makino service representative.

- If a part is replaced where a warning label was affixed, obtain a new warning label and affix it at the

same position as before on the new part. To obtain new warning labels, contact your Makino service

representative.

2.2.3 Information Contained in Warning Labels

The two types of warning labels are shown below.

- Labels with warning text and a warning mark

- Labels with a warning mark only

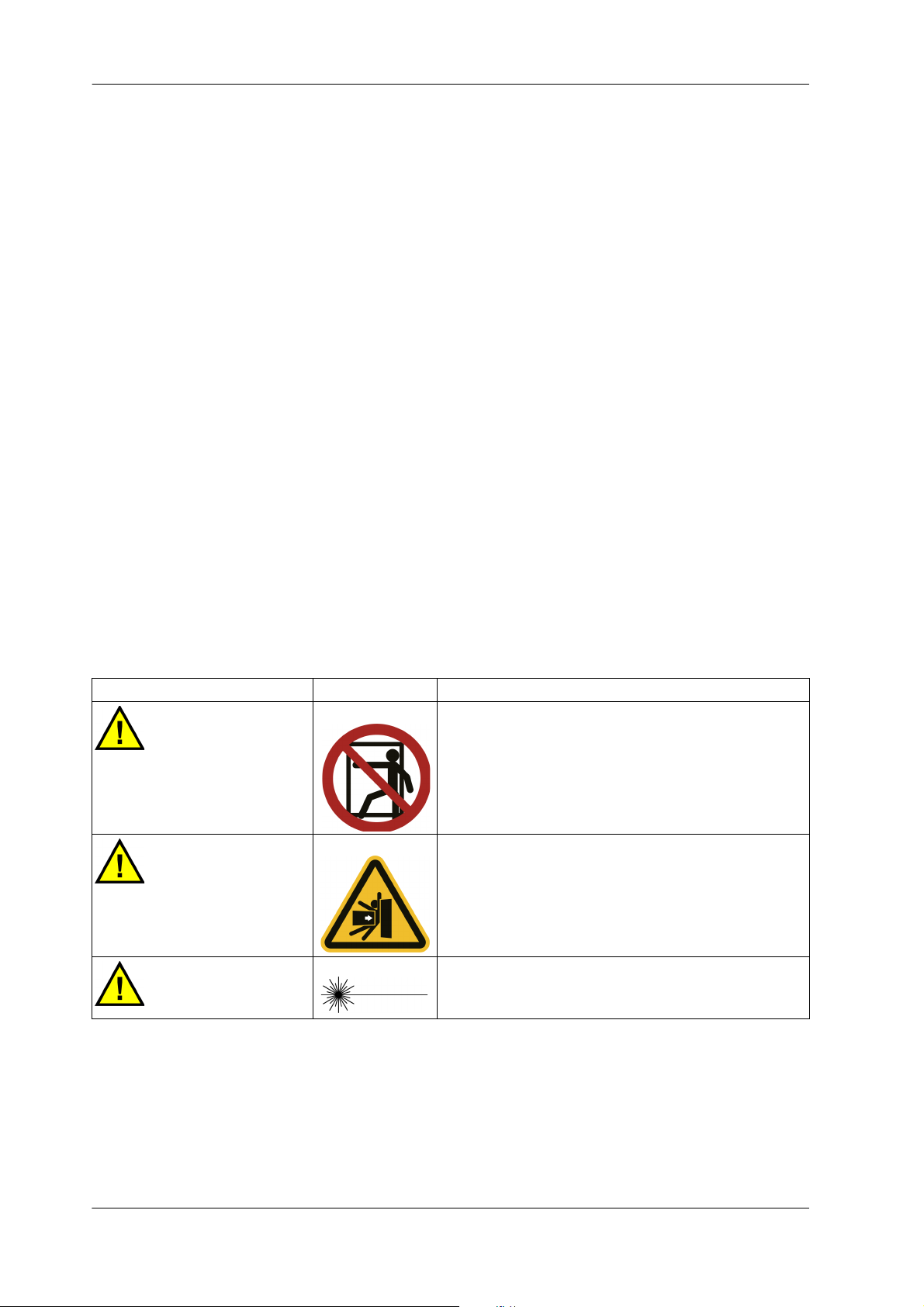

2.2.3.1 Warning Labels with Warning Text

Signal Word Symbol Description

DANGER

DANGER

CAUTION

This warning label is affixed to areas where entry is

prohibited.

This warning label is affixed to places where serious

injury, death, or another accident occurs by being

crushed, entangled, or pierced, or by falling.

Maximum output 1 mW, semiconductor laser

Class 2 laser product

Do not stare into the beam.

Table 2-1:

29F-21E-2006 (en) MAKINO

Page 31

SAFETY 2-9

2.2.3.2 Warning Labels with Warning Marks Only

Symbol Description

This warning label is affixed to parts where touching the internal high-voltage components may result in electrical shock.

Workers who are not qualified electrical engineers must not access the parts where this