Page 1

Preparations

for

Installation

and

Installation

fe

|S>

Pi

Page 2

Preparations

Installation

for

and

Installation

1

Outline

1.1

1.2

Preparations

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

Preface

Installation

Confirmation

Preparation

2.2.1

2.2.2

Flow

Installation

for

Preparations

of

of

Set-Up

Preparation

Preparation

for

for

Area

Set-Up

Set-Up

PreparationofTransport

Set-Up

Recommended

Air

Preparation

Required

Conditions

and

Power

Foundation

Sources

of

Transportation/lnstallation

Manpower

for

Installation

for

Area:

Area:

Route

Installation

a81

a82

Equipment

1

1

2

4

4

5

6

14

22

25

26

34

36

37

3

2.9

Main

3.1

3.2

Inspection

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

2.9.6

Inspection

HandlingofHeavy

Working

Working

Working

Work

Machine

Main

Machine

3.1.1

3.1.2

Shipping

3.2.1

3.2.2

3.2.3

Main

Lifting

Axis

Y-Axis

Machine

PriortoInstallation

Installation

to

Prior

Components

Elevated

at

Confined

in

Group

in

Requiring

Machine

Installation

Lifting

Machine

Equipment

Jig

Removal/Motor

Shipping

Ball

Screw

Rear

and

Lifting

Removal

Jig

Removal

Shipping

Shipping

and

Locations

Spaces

Operation

Set-Up

/Set-Up

Installation

Jig

Precaution

Removal

Jig

Removal

During

and

Installation

Y-Axis

Motor

Installation

38

38

38

39

39

39

39

40

40

42

44

46

46

48

50

3.2.4

APC

Safety

Guard

Shipping

Jig

Removal

51

Page 3

3.2.5

Operator

Door

Shipping

Jig

Removal

52

4

5

3.2.6

3.2.7

3.2.8

3.2.9

3.3

3.4

Main

Machine

Placing

Tool

5.1

5.2

5.3

Magazine

Outline

Tool

5.2.1

5.2.2

5.2.3

Tool

Main

ATC

BTS

Y-Axis

Machine

Fixing

Tool

of

Magazine

Tool

Tool

Tool

Magazine

Operation

Shutter

(Optional)

Shipping

Support

Shipping

Panel

Jig

Shipping

Stylus

Removal

Jig

Removal

Jig

Leveling

Installation

Tool

Magazine/Peripheral

Installation

A60)

and

Installation

Magazine

Magazine

Magazine

A97/A137

(A40

Installation

Installation

Reference

(Matrix)

(A40)

(A60)

Position

Installation

Removal

Removal

Devices

Return

53

54

55

56

58

60

62

66

66

67

67

72

78

81

5.4

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

ool

T

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.4.8

Outline:

Magazine

Tool

Magazine

Tool

Magazine

Tool

Magazine

Tool

Magazine

Tool

Fixing

Magazine

Outline:

Sub-Arm

Sub-Arm

Sub-Arm

Sub-Arm

Magazine

Tool

Magazine

Tool

Magazine

Tool

Tool

Magazine

Tool

86

A1

Tool

Installation

Piping

Position

Pan/Bracket

Oil

Magazine

Set-Up

Piping

Reference

Reference

Inclination/Position

or

Magazine

and

Set-Up

Piping

Reference

Installation

Wiring

and

Position

Position

Position

Above

Adjustment

(Matrix)

Installation

Wiring

Installation

Wiring

and

Position

Flow

Return

Adjustment

Adjustment

Installation

Flow

Return

81

82

88

92

96

100

108

111

111

112

115

118

122

126

130

132

5.4.9

5.4.10

Magazine

Tool

Retaining

Position

Bracket

Adjustment

Installation

134

146

Page 4

5.4.11

Cover/Oil

Installation

Pan

149

6

Peripheral

6.1

6.2

6.3

Unit

.1

.2

Cooling

Spindle

Spindle

Oil

Spindle

Spindle

Tank

Coolant

Coolant

Coolant

Coolant

Coolant

Cutting

Spindle

6.1

6.1

Spindle

(20000min-1

6.2.1

6.2.2

Coolant

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.3.6

Installation

Temperature

Oil

Cooling

Cooling

Temperature

Spindle

Oil

Oil

Installation

Tank

Tank

Tank

Tank

Tank

Fluid

Oil

Oil

Spec.)

Temperature

Temperature

Set-Up

Left

Rear

1200L

Double

Temperature

Controller/Hydraulic

Temperature

Temperature

Controller/Hydraulic

Controller/Hydraulic

Controller/Hydraulic

Controller/Hydraulic

Controller/Hydraulic

Coolant

to

(Common

Discharge

Discharge

Piping

Lift-Up

Controller

and

All

Spec.

870L

870L

Spec.

Wiring

Conveyor

(Option)

!

Unit

Unit

Unit

Piping

Piping

(a81/a82)

Spec.

Unit

Unit

Unit

Installation

Set-Up

Piping

Tanks)

Wiring

and

Wiring

and

Piping

and

Piping

Installation

Set-Up

Piping

and

Wiring

Wiring

(a81)

(a81)

and

....

(a81/a82)

..

..

Wiring

153

154

154

158

160

160

162

166

166

170

172

174

176

...

178

6.4

6.4A

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

Power

7

7.1

7.2

8

Pre-Operation

8.1

8.2

Power

Air

Initial

Lighting

8.2.1

Supply

and

to

Peripheral

Recommended

Spindle

Spindle

Spindle

Hydraulic

Oil

Air

Coolant

(Pneumatic)

Air

Source

(Pneumatic)

(Operation

Cleaning

Device

Machining

Lubricant/Cooling

Cooling

Spec.)

Oil

Unit

Supply

Tank

Oil

Temperature

Oil

Unit

Cutting

Connection

Supply

Wiring

Chamber

Units

Temperature

Controller

Supply

Oil

Supply

Fluid

(Other

Supply

Source

Source

Connection

Preparations)

Checks

Lighting

Device

Oil/Hydraulic

Controller

Oil

than

Oil

Supply

(20000min"1

20000min'1

Connection

Wiring

Check

Oil

Supply

(Control

..

Spindle

(Other

Spindle

Panel)

than

Spec.)

179

179

20000min'1

180

181

Spec.)

..

182

183

184

186

186

186

188

188

189

189

Page 5

8.2.2

Tool

Magazine

A186

or

Above

Lighting

Device

Wiring

Check

(Lighting

Device)

190

C;

8.3

8.4

Axis

9

9.1

9.2

9.3

9.4

10

Static

Operation

1

1

Turning

8.3.1

8.3.2

8.3.3

Safety

Power

Turning

Checks

Hydraulic

Device

ON/Checks

Power

When

Piping

Function/Operation

Reference/2nd

Y-Axis

Axis

X/Y-Axis

Z-Axis

Reference

Reference

2nd

Accuracy

2nd

Reference

Position

Position

Reference

Confirmation

Checks

When

ON

Turned

Removal

Air

Is

Power

Reference

Return

Checks

(ATC)

(APC)

Position

Position

Power

Checks

Is

ON

Position

Check

Check

Turned

Check

...

ON

191

191

192

194

196

198

198

200

202

204

205

207

(

27

28M-1

(

105A-27-EN

Page 6

Outline

Preface

1

1.1

“Preparations

conditions

checks

In

shown

To

the

Outline

required

following

the

in

ensure

previous

Preface

for

a

flowchart.

safety

Installation

for

installation,

after

section,

personnel

of

“Safety”

and

machine

main

installation.

sequence

the

details

For

and

chapter

carefully

Installation”

of

each

of

prevent

and

describes

peripheral

and

preparation

refer

item,

damage

understand

to

to

the

the

the

unit

installation

installation

for

respective

machine,

thoroughly

it

necessary

procedures,

and

chapter

be

prior

preparations

actual

and

sure

read

to

installation.

to

and

and

confirmation/

installation

section.

this

chapter

required

work

is

and

I

o

1

O

29M-1

105B-1-EN

1

Page 7

Outline

installation

Flow

1.2

Transportation

lQ=“6.2

Installation

Preparations

Main

Machine

Shipping

Spindle

Spindle

Temperature

Controller/Hydraulic

Unit

Installation

(200Q0min-1

Spindle

Spec.)”

Flow

for

Installation

Transportation/Installation

Jig

Removal/Motor

Magazine/Peripheral

Tool

of

Yes

Unit

Installation

Spindle

20000min'1

Specifications?

Temperature

Oil

Hydraulic

Oil

Installation

Controller/

Units

No

|Q=

0=

Gr’

G”

Preparations

“2

Main

“3.1

Shipping

“3.2

Placing

“4

Spindle

Machine

Jig

Tool

of

Cooling

Hydraulic

Installation”

for

Set-Up”

and

Lifting

Removal/Motor

Magazine/Peripheral

Temperature

Oil

Unit

Installation

CQ=“6.1

Installation”

Controller/

Spindle

Oil

Temperature

Controller/Hydraulic

Unit

Installation”

Devices”

Cooling

2

Power

Turning

(Pneumatic)

Air

and

Power

Pneumatic

Y-Axis

Reference

Main

I

ON,

Confirming

Unit

Machine

and

Position

A

Source

Hydraulic

Safety

Leveling

Connections

Unit,

Devices

Return

[jj5=‘'7

Connection”

“8

G”

HZjh“9.1

“3.3

Q=

and

Power

Pre-Operation

Y-Axis

Main

Air

Reference

Machine

(Pneumatic)

(Operation

Position

Leveling”

Source

Preparations)"

Return”

29M-1

105B-2-EN

(

Page 8

Outline

Installation

A

Flow

I

a?

Axis

Reference/2nd

With

Tools,

More

-~ÿk/lMC

Machine

Tool

Coolant

Static

Tool

Magazine

Pallet

Specifications?ÿ-

Fixing

Jig

Magazine

Installation

Tank

Reference

nr

Accuracy

97

for

Magazine

Yes

Installation

Installation

Position

Checks

or"

or

Confirmation

No

IQ=“3.4

Q=

CQ”

O’9

O’

Machine

Installation”

Magazine

Tool

“5

"6.3

Coolant

Reference/2nd

Check

“10

Static

Fixing

Tank

Accuracy

Tool

Installation”

Installation”

Reference

Confirmation"

3

O

Position

29M-1

105B-3-EN

Operation

Installation

Checks

Completed

O’

Operation

“11

Checks”

3

Page 9

Preparations

Preparations

Confirmation

2

2.1

Perform

installation.

of

Preparations

Confirmation

following

the

For

for

Installation

preparations

details,

for

refer

Installation

Installation

for

Preparations

of

ensure

to

respective

the

to

all

installation

section

Installation

for

conditions

this

chapter.

in

are

satisfied

prior

machine

to

•

Preparation

PreparationofTransport

•

Confirmation

•

Preparation

•

•

Preparation

•

Preparation

•

Preparation

•

Preparation

Safety

•

of

Set-Up

of

Set-Up

Foundation

of

Electric

of

of

Air

Transportation

of

Required

of

Precautions

Check

List

Source

for

Area

Route

Conditions

Source

Manpower

and

Other

I

Installation

Equipment

Installation

for

Confirmation

Preparation

“2.2

0=

Q=“2.3

IQ3

“2.4

“2.5

Q=

“2.6

Q=

“2.6

cCt3

[Q=“2.7

Installation

[Q=“2.8

Installation”

y-“2.9

I,r

and

Table

er

Preparation

Preparation

Set-Up

Recommended

and

Air

and

Air

Preparation

Required

Inspection

Precaution

2.1

of

of

Conditions”

Power

Power

Equipment”

Prior

During

Set-Up

Transport

Area"

Foundation”

Sources”

Sources”

Transportation/

of

Manpower

Installation

to

Installation”

Route”

for

Installation

for

List

Set-Up

of

Transport

of

Conditions

Foundation

of

Electric

of

Air

of

Transportation

of

of

Air

Area

Route

Source

Source

Dryer

Check

Table

Check

2.1

Preparation

Preparation

Set-Up

Preparation

Preparation

Preparation

Preparation

Preparation

4

Preparation

Items

Equipment

29M-1

05B-4-EN

1

Page 10

Preparations

Preparation

Installation

for

Set-Up

of

Area

2.2

Refer

specifications

Note

•

•

•

Preparation

the

to

following:

the

When

The

maintenance

maintenance

The

specifications:

Tool

a81

Tool

a81

Tool

a81

Tool

a81

Spec.

Tool

a82

Tool

a82

Tool

a82

figures

to

confirm

lifting

the

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

Set-Up

of

section

this

in

requirements

space

machine

area

body

the

is

varies

area

A40/Left-Discharge

A60/Left-Discharge

A97/A1

A40/Left-Discharge

A60/Left-Discharge

A97/A1

37/Left-Discharge

A186

37/Left-Discharge

Area

show

that

using

a

maintenance

depending

Above/Rear-Discharge

or

general

the

prepare

and

crane,

space

Conveyor

Conveyor

Conveyor

Conveyor

Conveyor

Conveyor

the

on

view

the

lifting

total

required

type

the

Spec.

Spec.

Spec.

Conveyor

Spec.

Spec.

Spec.

floor

and

required

height

after

of

for

plan

set-up

installation.

tool

area.

required

magazine

Figure

G3

Figure

0=

Figure

0=

Figure

0=

Figure

Q=

Figure

0=

Figure

Q=

respective

is

4627mm.

and

and

2.1

2.3

and

and

2.5

and

2.7

and

2.9

2.11

2.13

machine

conveyor

2.2

2.4

2.6

2.8

2.1

and

2.12

2.14

and

I

§

1

ro

w

a

c

.2

2

CO

0

a.

CM

2

Tool

a82

Spec.

NOTE:

general

A

specifications

view

Magazine

and

not

are

A186

floor

plan

showninthis

Above/Rear-Discharge

or

20000min'1

the

for

section.

spindle

Conveyor

specifications

EQ=

and

Figure

double

2.15

lift-up

2.16

and

conveyor

29M-1

05B-5-EN

1

5

Page 11

Preparations

Set-Up

Preparation

of

Installation

for

Area

2.2.1

a81

Preparation

General

tn

ON

CM

m

View:

109

Tool

I

Set-Up

for

Magazine

Heightÿ-

'<3#$

3443

i

l£J

Area:

Left-Discharge

A40,

n

In

IZJ

tZJ

5475

a81

6652

Conveyor

1550

482

Jd

n

(1068)

in

CM

ON

CM

o

m

CM

m

m

r\j

CO

m

£

M-

m

CM

vO

CM

o

P

o

973

1080

2220

3693

g/

1140

mjy-1

500

in

CM

r".

(495)

o

m

in

CM

ON

CM

m

m

CM

4188

View

of

Lift-Up

(Tool

Figure

Magazine

2.1

A40

Front

and

and

Left

Side

Discharge

Machine:

6

a81

Conveyor

Spec.)

29M-1105B-6-EN

Page 12

Preparations

Preparation

Installation

for

Set-Up

of

Area

a81

APC

o\

trt

Floor

Collector

Mist

(Option)

Operation

Panel

o

m

o\

m

S

CO

S

o

Plan:

Tool

Tool

\

Magazine

Magazine

(Ring)

A40

2142

IF

A40,

Hydraulic

/

%-HO

Left-Discharge

Spindle

Temperature

Unit

5932

1857

m

Conveyor

Cooling

Controller

1933

Iff

B

Oil

Lift-Up

9

Conveyor

Chip

Outlet

o_

2120

Air

(Option)

/

"c

|S

C

o

Dryer

o

N

tn

CM

NO

m

in

o

K

I

|

§

S

w

a

w

a

E

0

CL

CM

o

NO

o

(Maintenance

Areaÿ)

Operationÿ

Main

(Tool

109

809

2300

Panel

Figure

Magazine

2.2

7

Machine

Floor

A40

and

R,

W/

Or,

3443

Controller

Plan

Left

\

Step

5475

8052

Additional

Torque

View

(Top

Discharge

A

&

1550

5752

Transformer

Controller

Spindle

Machine):

of

Lift-Up

Conveyor

71

482

(Option)

Head

a81

600

(1068)1

High-

for

(Option)

Spec.)

5

3

700

Cutting

Temperature

in

m

in

/

NO

inf

ON

ON

Fluid

Controller

(Option)

29M-1

05B-7-EN

1

7

Page 13

Preparations

Preparation

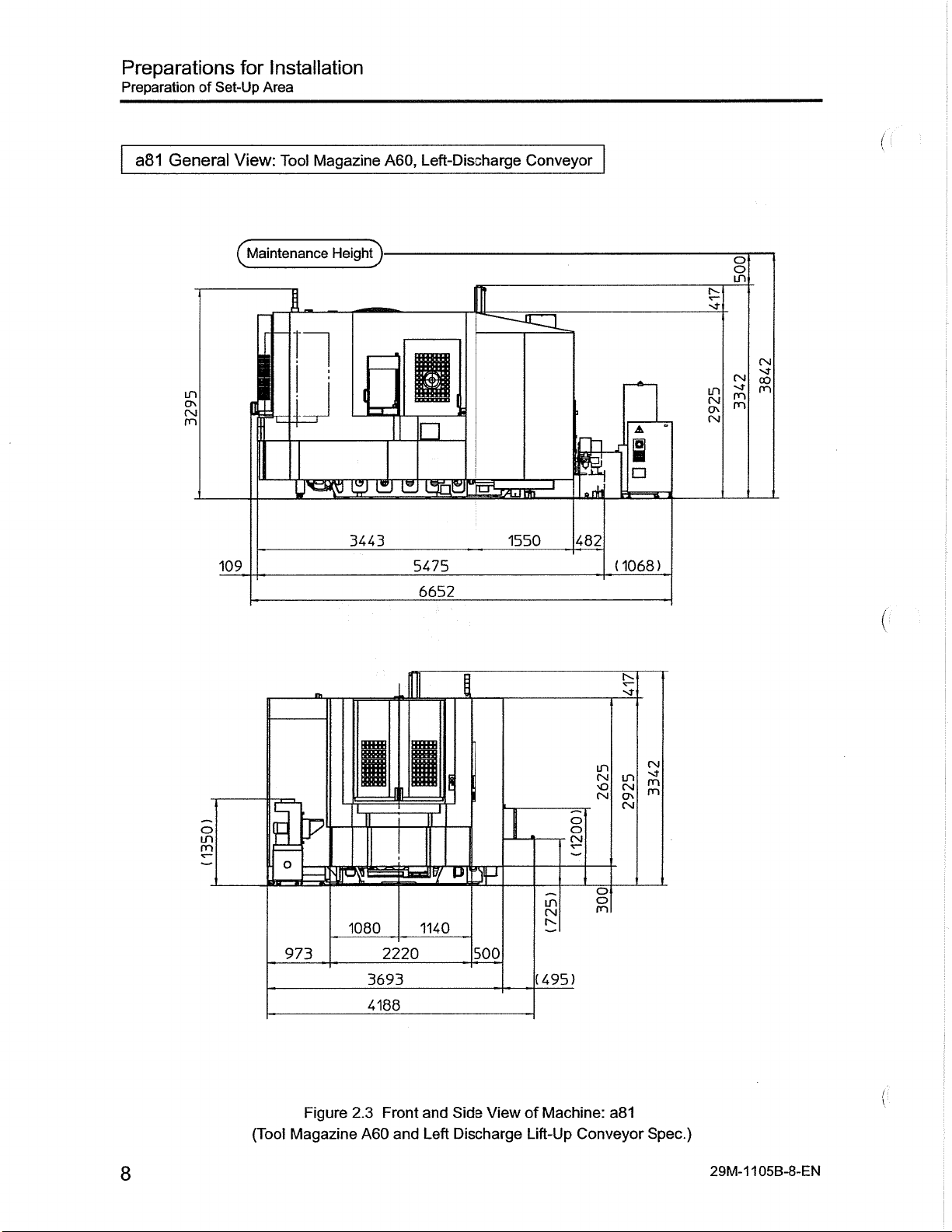

General

a81

of

Set-Up

for

Installation

Area

View:

Tool

Magazine

Left-Discharge

A60,

Conveyor

in

c?\

Osl

m

109

1

n

Heightÿ-

gj

0

3443

I

gj

In

I3i

5475

6652

is!

J«!

W

1550

ath

482

A

1

(1068)

M-

in

CM

CK

CM

o

in

CM

m

m

m

CM

00

in

CM

o\

CM

a81

CM

m

m

Spec.)

29M-1105B-8-EN

in

CM

NO

CM

m

CN

(495)

of

Machine:

Lift-Up

o

CM

o

m

Conveyor

s

in

H-P

o

973

(Tool

IT

mssssmamu

Figure

Magazine

1080

3693

4188

2.3

A60

2220

Front

and

1140

and

Left

500

View

Side

Discharge

8

Page 14

Preparations

Preparation

Installation

for

Set-Up

of

Area

APC

m

o\

in

a81

Floor

Collector

Mist

(Option)

Operation

Panel

o

s

00

§

m

o\

£

m

o

Plan:

Tool

\

Magazine

Tool

Magazine

1379

\

A60

/

*

A60,

Spindle

(Ring)

2620

Hydraulic

5

3

Left-Discharge

Temperature

Cooling

5932

Oil

Controller

Unit

\

i

s

Conveyor

1933

Lift-Up

Conveyor

Chip

Outlet

O

2120

Dryer

Air

(Option)

(2

I

§

is

3

a

B

0.

<N

eg

w

2

CO

£

>o

m

in

o

o

c

03

O

m

04

o\

m

o

in

o

in

in

o

%

&

1550

5752,

Controller

Spindle

&

(Option)

Head

482

600

(1068

for

High-

(Option)

700

Controller

Area

109

809

J

Main

2300

Operation

Panel

m

Or

Step

3443

5475

8052

Machine

Additional

Torque

Controller

Transformer

m

in

/

„/

'O

in

O'

ON

vt

Cutting

Temperature

Fluid

(Option)

29M-1

105B-9-EN

(Tool

Figure

Magazine

2.4

A60

Floor

and

Plan

Left

View

(Top

Discharge

Machine):

of

Lift-Up

a81

Conveyor

Spec.)

9

Page 15

Preparations

Set-Up

Preparation

of

Installation

for

Area

a81

General

View:

in

o\

(SI

m

109

Tool

Magazine

Heightÿ-

n

A97/A137,

izjgj

ci

3443

Left-Discharge

Q

5475

6652

1550

Conveyor

i

482

(1068?

I

o

in

£

Csl

CvJ

oo

in

(NJ

c?\

A

m

m

m

10

o

JR

(Tool

s

IP

Magazine

m

IB

1542

Figure

2.5

A97A/A137

Front

and

1080

4262

4732

and

2220

Side

Left

I

u

1140

View

Discharge

2E

500

Machine

of

Lift-Up

O

£

in

CN

r-.

(470)

Conveyor

in

[SI

o

CM

o

m

(Nj

m

m

CN

m

o

CNI

Spec.)

29M-1105B-1

('

0-EN

Page 16

Preparations

Preparation

Installation

for

Set-Up

of

Area

a81

Mist

APC

CM

vO

m

in

Plan:

Floor

Tool

Magazine

Collector

(Option)

Operation

Panel

o

o\

CO

CM

NO

§

£

o

o

T—

Tool

A97/A137

\

Magazine

1983

A97/A137,

(Matrix)

5034

O

:Ef

Left-Discharge

Spindle

Upper:

Hydraulic

Lower:

2351

5

;

V/

IB

Cooling

700

ZZ3I

Q

Conveyor

Oil

Unit

Lift-Up

Chip

r

Temperature

3018

Conveyor

Outlet

Air

(Option)

_-4

-"1

Controller

Dryer

|2

m

oo

T~

in

CM

oo

NO

co

in

in

I

§

2

&

a

a

5

to

£

CL

CM

o

o

rÿ

3

Maintenance

109

809

Area)

(Tool

2300

Operation

Main

Panel

Figure

Magazine

to,

Q:

7

Floor

2.6

A97/A137

3443

Machine

Plan

and

Step

5475

8052

Left

Controller

Transformer

Additional

Torque

(Top

View

Discharge

A

1550

5752

Controller

Spindle

Machine):

of

&

(Option)

Head

Lift-up

482

600

(1068)1

High-

for

(Option)

a81

Conveyor

700

Controller

Spec.)

in

m

in

/

in

vo

o\

05

Cutting

Temperature

Fluid

(Option)

29M-1

105B-1

1-EN

11

Page 17

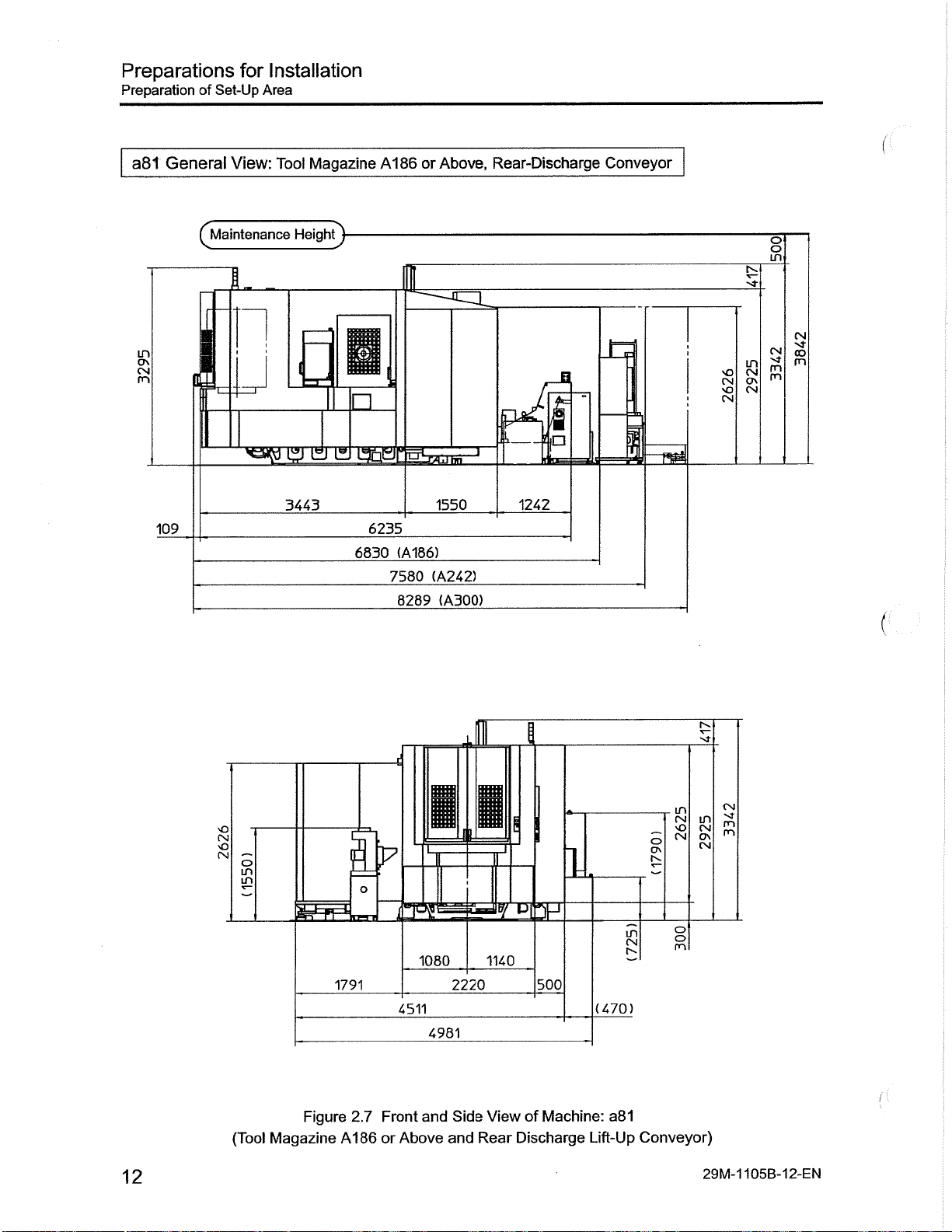

Preparations

Preparation

of

Set-Up

for

Installation

Area

a8t

in

o\

CN

m

General

109

View:

1

Magazine

Tool

Heightÿ

gfe

igj

3443

6235

6830

A186

(A186)

7580

8289

Above,

or

1550

(A242)

(A300)

Rear-Discharge

)ÿ

1242

Conveyor

CM

o

CN

o

in

CM

CM

CO

in

CN

vO

Ov

CN

m

m

m

(

12

o

CN

vO

CM

LH

in

(Tool

Figure

Magazine

B»

o

1791

Front

2.7

A186

or

II

I

1080

4511

and

Above

4981

and

2220

Side

1140

View

Rear

i

1

500

Machine:

of

Discharge

(470)

a81

Lift-Up

in

CM

Conveyor)

in

CM

CN

o

m

CN

in

vO

CN

o\

CN

29M-1105B-1

m

m

2-EN

Page 18

Preparations

Preparation

Installation

for

Set-Up

of

Area

Tool

Mist

APC

00

'O

o

es

o

'O

m

5

a81

r*-.

Floor

Magazine

Collector

(Option'

Operation

Panel

o

5

5

Nj-

§

o

5=

O

Cÿ.

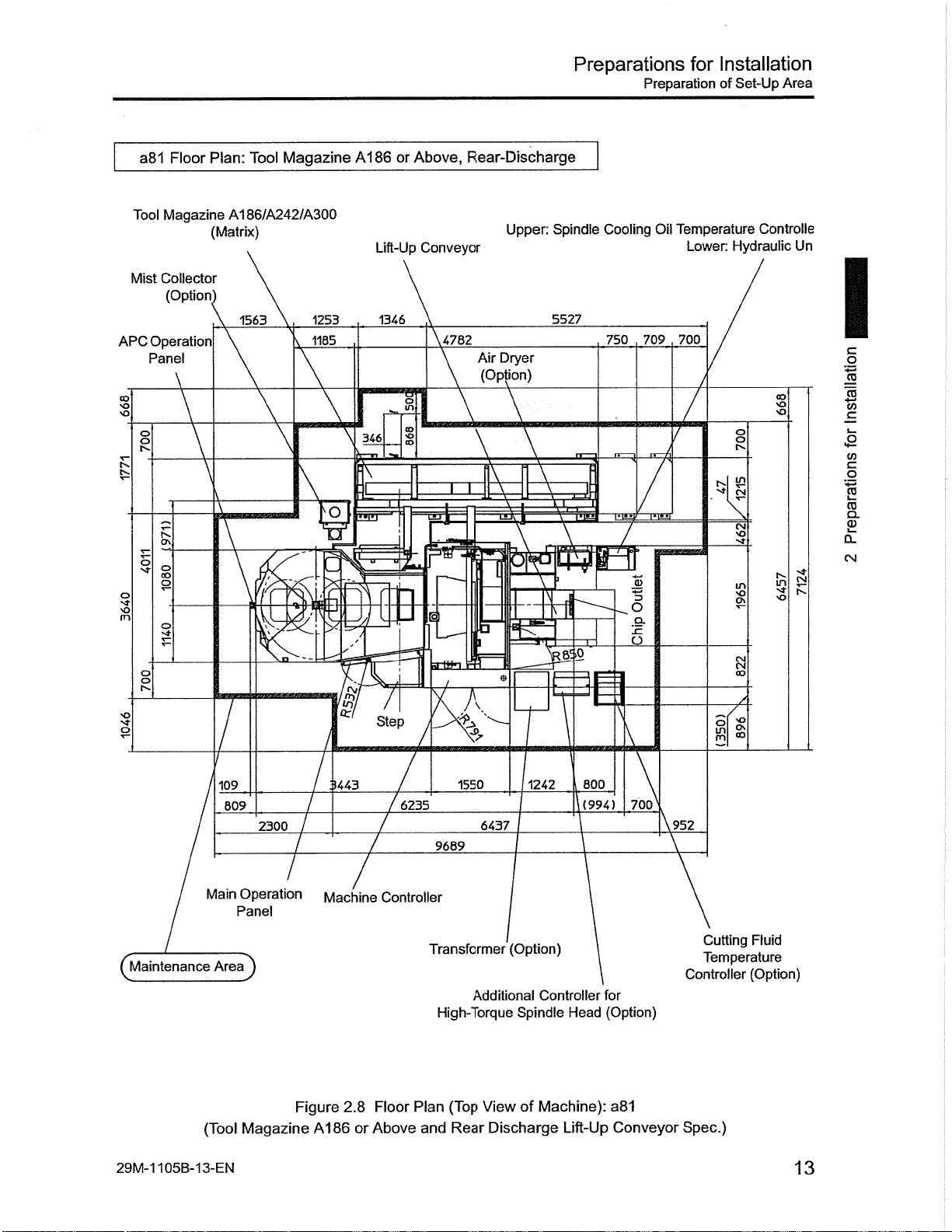

Plan:

Tool

A1

86/A242/A300

(Matrix)

1563

x

Magazine

1253

1165

\

w

3

(£/

A186

Lift-Up

1346

346

m

/I

Step

Above,

or

Conveyor

CO

CO

/

Rear-Discharge

\4782

Air

(Option)

~

T

T

B5

{£

I

A

S’

Upper:

Dryer

$

Spindle

5527

\

Cooling

750

a>

o

f

O

\

\

Temperature

Oil

709

700

7

Lower:

/

-IS

fi

Controlle

Hydraulic

o

fv.

CN

>0

in

o

£

CN

CN

CO

/

/

§

0O

>o

>o

Eri

3

Un

(N

tZ

I

1

§

B

£

C

2

2

a.

CNJ

29M-1

109

Main

AreaJ)

(Tool

105B-13-EN

809

2300

Operation

Panel

Magazine

Machine

Figure

A186

3443

2.8

7

or

7

Floor

Above

6235

/

Controller

Transformer

Plan

and

1550

6437

9689

Additional

High-Torque

(Top

View

Discharge

Rear

1242

(Option)

Controller

Spindle

Machine):

of

800

(994)

Head

Lift-Up

700

for

(Option)

a81

Conveyor

952

Cutting

Temperature

Controller

Spec.)

Fluid

(Option)

13

Page 19

Preparations

Set-Up

Preparation

2.2.2

of

Preparation

Installation

for

Area

.

for

Set-Up

Area:

a82

a82

S

co

m

m

General

View:

Tool

3130

Magazine

HeightJ-

6405

A40,

Left-Discharge

~ar\

7230

i

o

eSiP

2183

Conveyor

_

Li

1092

lidri

(825)

o

in

rn

NT

oo

GO

OS

GO

m

GO

m

i

14

in

CM

01

CM

(Tool

§

SB

Figure

Magazine

F

973

3HE=

Front

2.9

A40

1180

3891

and

2360

4344

and

Left

!msi

1180

View

Side

Discharge

558

Machine:

of

Lift-Up

in

CM

CM

453

Conveyor

o

CM

*-

a82

3

CM

in

CM

3

CM

o

m

Spec.)

29M-1

05B-1

1

4-EN

Page 20

Preparations

Preparation

Installation

for

Set-Up

of

Area

a82

Floor

Mist

Collector

(Option)

o

fn

D\

§

m

CNJ

1

GO

in

m

APC

Operation

Panel

Plan:

Tool

Tool

Magazine

A40

550

24Q

///W/>

77/

'/////A

\

®

O

I

u

s

J0(,0

lili

I

r

/

700

j

///////y/////////////)//////////j

Magazine

(Ring)

863

////////////

a

a

635

635

2480

Left-Discharge

A40,

Operation

185;

v&A£ÿ////r//////////////,

-VV'c

1220

STROKE)

Z

Tool

--

-Sies

6405

Magazine

Panel

Hydraulic

454.6

'///A/y

200

/

GAUGE

2833

6605

Conveyor

750

/

////////A

si

W

Wllf

1

1

Unit

'///////////As

o

co

Nj

_[

iStf

Controller

Coolant

o

o

o

o

Oil

Tank

Air

(Option)

2

I

Dryer

CN|

m

P

g

•-a-

I

Outlet

15(

Cooling

,390,

:

Spindle

Temperature

Conveyor

Lift-Up

W777777Z77777777777A7777777777rf

Chip

m

ml

A

m

a

H

!n

I

s

t>.

§

>50

/

1092

m

:

||

IPO

ooi

800

1

650

-

„

in

NO

B

1500

cr\

m

-

I

y,

m

s

|

\

2

1

vx

A

700

I

§

’is

=3

to

_c

£

w

~

CO

to

CD

a.

CM

Maintenance

(

29M-1

105B-15-EN

Collector

Mist

(Option):

or

MMC

Area)

(Tool

with

PM

Main

Figure

Magazine

Operation

Panel

2.10

A40

Floor

and

Machine

Plan

Left

Controller

Transformer

View

(Top

Discharge

High-Torque

Machine):

of

Lift-Up

(Option)

Additional

Conveyor

Spindle

a82

Controller

Head

Spec.)

Cutting

Temperature

Controller

for

(Option)

Fluid

(Option)

15

Page 21

Preparations

Preparation

General

a82

Set-Up

of

Installation

for

Area

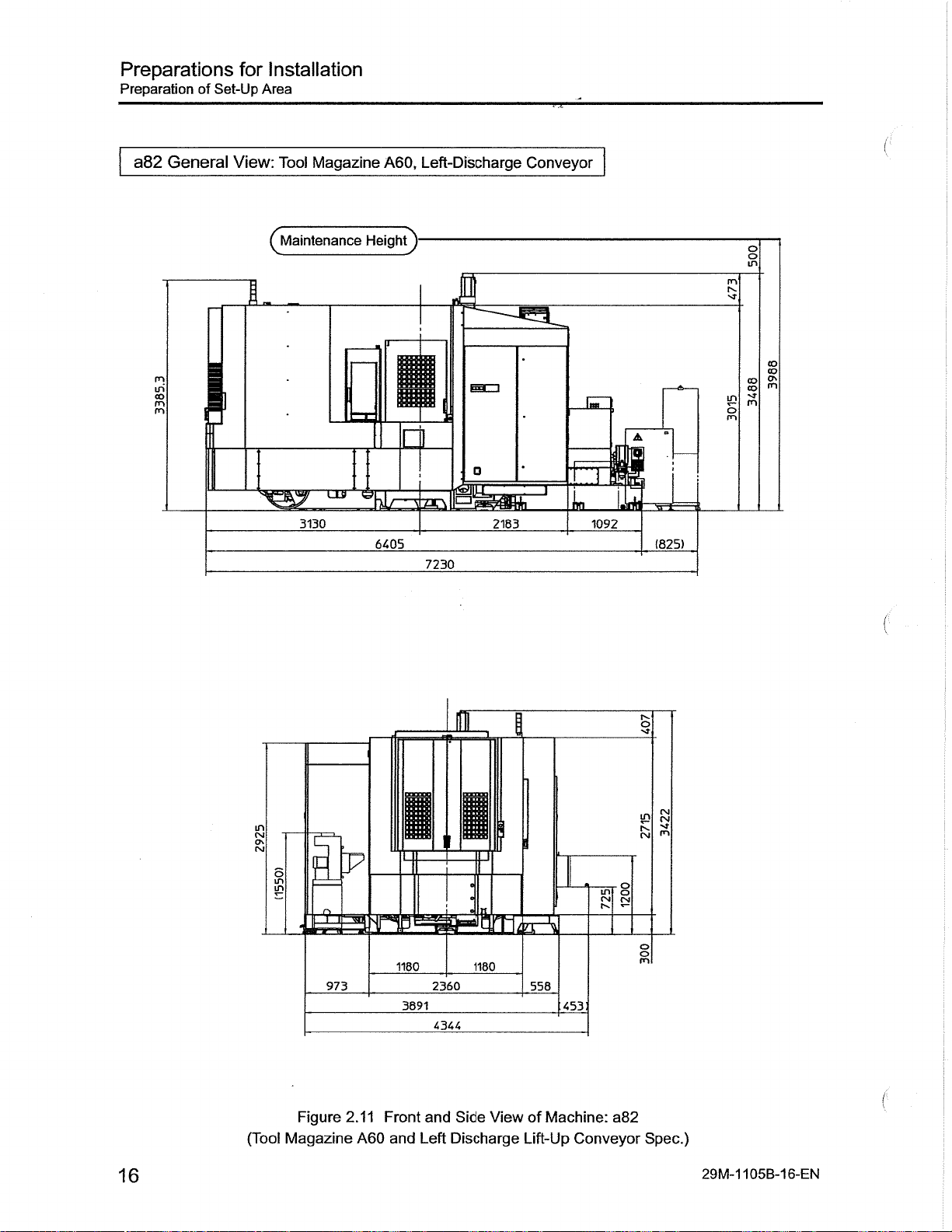

View:

Tool

Magazine

Left-Discharge

A60,

Conveyor

5

m

m

CO

(ÿMaintenance

3130

Heightÿ-

1

19

33

6405

7230

1

2183

L

1092

A

LLI

1825)

o

in

rn

sj-

co

CO

ON

co

m

co

rn

§

16

in

(SI

ON

(SI

(Tool

ELF

a

£

Figure

Magazine

973

2.11

A60

I

Front

1180

3891

and

2360

4344

and

Left

KH

1180

Side

View

Discharge

558

of

Machine:

Lift-Up

O

in

o

(SJ

CM

a82

Conveyor

3

CM

LT)

CM

rn

(SI

o

m

Spec.)

29M-1

105B-16-EN

Page 22

Preparations

Preparation

Installation

for

of

Set-Up

Area

a82

Mist

Collector

(Option)

o

fs.

m

s

s

m

CM

I

co

in

in

APC

Operation

Panel

Floor

r

I

f

H

I

\

Z

v////////

Plan:

Z///X,

ill

'00

24Q

s'

Tool

Tool

A60

550

///

'///////

vO

u

\

v//////////////r//////////y

Magazine

Magazine

(Ring)

1(

ZV777X777777777Zÿ7777777777777777y77

\

Left-Discharge

A60,

Hydraulic

2620

\

Spindle

Temperature

Unit

,454.6

V///A

\

13

530

635

IP

a

635

2480

1220

///////

5TR|

l

6405

_

200

GAUGE

8605

Conveyor

Cooling

Controller

\750

Y777A77777.

W

TOIE"

2833

Oil

,3Ll

/

Lift-Up

V777777777}

I'M

100

V/A/S/S/////,

Coolant

Conveyor

V7777777777777777T777777777/7?t

Chip

Outlet/

1507,390,

1

Tank

Air

(Option)

I

2

Dryer

CM

m

P

I

?0Q

1

I

650

.1

\

s

|

I

3

sj

in

I

Ovi

in

I

CM

£

rs

1

1

o

1092

700

'//////////

800

700

1500

I

1

8

’is

v>

c

£

W

S

2

TO

a>

Q.

CM

29M-1

Areaÿ

Mist

105B-17-EN

Collector

MMC

with

(Tool

Main

Operation

Panel

(Option):

or

PM

Figure

Magazine

2.12

A60

Step

Floor

and

Plan

Left

Machine

Transformer

(Top

View

Discharge

Controller

(Option)

High-Torque

Machine):

of

Lift-Up

Additional

Spindle

a82

Conveyor

Controller

Head

Spec.)

Cutting

Temperature

Controller

for

(Option)

Fluid

(Option)

17

Page 23

Preparations

Preparation

Set-Up

of

Installation

for

Area

a82

General

m

in

co

m

m

View:

Tool

Magazine

(ÿMaintenance

LJJ)

3130

A97/A1

37,

Heightÿ-

d

<S(

6405

7230

Left-Discharge

II

Lf

2183

Conveyor

L

1092

o

in

m

oo

co

ON

CO

m

co

in

rn

m

A

(825)

18

(Tool

g

8

e

Figure

Magazine

1540

2.13

Front

A97/A137

1180 1180

2360

4458

4911

and

Side

Discharge

Left

and

558

453:

ViewofMachine:

Lift-Up

Conveyor

II

a82

I

Sg

fvj

1

Spec.)

29M-1

05B-1

1

8-EN

Page 24

Preparations

Preparation

Installation

for

Set-Up

of

Area

a82

Floor

Mist

I

c\i

&

I

5

Plan:

Magazine

Tool

Operation

Collector

(Option)

§

§

Tool

Tool

Panel

m

i

K

i

Magazine

Loading

Station

844

5

§

in

2

S

19

p

in

550

\

\

Tf

5

635

A97/A137,

\100

O

a

U

635

Left-Discharge

2351

\

3!

1020

KE)

STH

a

Conveyor

Tool

Upper:

Lower:

480

Magazine

Spindle

Hydraulic

Lift-Up

1915

A97/A137

Cooling

Unit

Conveyor

(Matrix)

Temperature

Oil

Chip

Outlet

Coolant

/

/

Controller

Tank

Dryer

Air

(Option)

I

§

1

2

I

3

K

1170

rm

540

g

S

L

|

1

1

I

I

s

IL

2

\

TZ

i*

m

S3

§

I

t

y

y

200

0AU0I

w

SL

/

ioo

650

100,

1

W

a

w

a

E

0

CL

CM

Operation

29M-1

/

APC

Areaÿ)

(Tool

105B-19-EN

/

Mist

700

Collector

MMC

with

Machine

Magazine

1133,

Main

(Option

or

Figure

550

2480

Operation

Panel

):

PM

Controller

Floor

2.14

A91/A137

797

Step

Plan

and

'1100

2833

6405

Machine

Controller

(Top

Discharge

Left

1733

/8605

Transformer

Machine):

of

View

Lift-Up

1092

(Option)

Additional

Torque

Spindle

Conveyor

800

Controller

Head

a82

1500

Controller

for

(Option)

Spec.)

Cutting

Temperature

High-

Fluid

(Option)

19

Page 25

Preparations

Set-Up

Preparation

of

Installation

for

Area

a82

s

s

General

View:

Tool

3130

Magazine

3763

i

Above,

or

A186

Heightÿ

&

2183

8545

Rear-Discharge

i

1550

]ÿ,

1736

Conveyor

:

3232

nn

:

: :

A

(1496)

1

5

I

20

(Tool

S

£

Magazine

1790

Figure

A1

IIP

o

2.15

or

86

4708

Front

Above

1180

and

and

2360

Side

Rear

I

1180

Machine:

of

View

Discharge

558

Lift-Up

§

s

§

£

a82

Conveyor

CM

CM

Spec.)

29M-1

105B-20-EN

Page 26

Preparations

Preparation

Installation

for

Set-Up

of

Area

a82

Mist

o

£

I

s

I

§

S

APC

Operation

Panel

Floor

Collector

(Option)

li

7

/

700

Plan:

1609

w

Ss

/

640

Tool

700

s

5

635/

>480

Magazine

Magazine

Tool

1533

550

100/

o

m

A

CF

1020

635

A186

(Matrix)

1391

500,391,500

F

m

200

913B

Above,

or

A186/A242/A300

Rear-Discharge

6291

I

5532

4782

\

s

T

GAUGE

&

LINE

2B33

9900

$

Upper:

6241

oT

>o

'650

100

Spindle

Coolant

5367

Irr,

~

5B5

Cooling

i

660/242

N

Ml

T

>9(

7001

Tank

80u

-lx

Temperature

Oil

Dryer

Air

(Option)

74B,

;

\\

\

\

'00

Lower:

700

655

V

\

\

762

Controller

Hydraulic

I

gv

s

I

jy?

§

I

s

3l§

Wi

6

Outlet

Chip

Unit

S

I

I

I

11

8

is

a

c

-2

E

CL

CM

Q.

£

29M-1

Areaÿ)

MistCollector(Option):

(Tool

105B-21-EN

/

Main

or

MMC

with

Figure

MagazineA186

Step

Operation

PM

2.1

or

Panel

Machine

Floor

6

Above

Controller

(Top

Plan

Left

and

Transformer

Additional

High-Torque

View

of

Discharge

(Option)

Controller

Spindle

(Option)

Machine):

Lift-Up

for

Head

a82

Conveyor

Cutting

Temperature

Controller

Lift-Up

Conveyor

Spec.)

Fluid

(Option)

21

Page 27

Preparations

Preparation

Transport

of

for

Installation

Route

'*

*

2.3

Prepare

Magazine

Tool

The

tool

a81

Main

Magazine

(Tool

a81

Main

(Tool

Magazine

a82

Main

Magazine

Magazine

Tool

The

tool

Table

a81

Main

a82

Main

Tool

Magazine

Magazine

Tool

Tool

Magazine

Magazine

Tool

Tool

Magazine

PreparationofTransport

machine

the

magazine

Table

2.2

Item

Machine

Machine

Machine

A40/A60)

magazine

2.3

Item

Machine

Machine

A40/A60

is

Machine

A40)

A60)

(Tool

A97

is

Machine

A97

A137

A186

A242

A300

transport

assembled

and

not

Size

Above

installed

Size

Shipment

route,

onto

Shipment

3342mm

(10=

3342mm

(Gh

3422mm

(Gh

onto

3342mm

(GhNOTEI)

3422mm

(Oh

3090mm

3090mm

2626mm

2626mm

2626mm

referring

main

the

Dimensions

Height

NOTE

1)

NOTE

1)

NOTE

1)

the

main

Dimensions

Height

NOTE

1)

Route

the

machine

to

machine

Height

Lifting

(Ch

(Q=NOTE

(O’

machine

(a81/a82

Height

Lifting

(GhNOTE

(GhNOTEI)

shipment

size

priortoshipment.

With

With

with

1)

1)

1)

shipment.

to

Tool

with

1)

(a81/a82

Equipment

4727mm

NOTE

4727mm

4807mm

NOTE

prior

Equipment

4727mm

4807mm

4080mm

4080mm

5310mm

5310mm

5310mm

Magazine

Tool

Width

3032mm

3007mm

3255mm

Magazine

Width

3020mm

3255mm

1835mm

1835mm

1096mm

1096mm

1096mm

dimensions.

A40/A60)

or

A97

Depth

4993mm

4993mm

5356mm

Above)

Depth

4993mm

5356mm

2462mm

2462mm

4782mm

5532mm

6241mm

(

(

Lifting

•

Tool

•

Spindle

0=

Spindle

•

•

Coolant

NOTES:

For

1

above

When

2

adequate

22

of

Units

Figure

the

Magazine

Cooling

4.3

Oil

Temperature

Tank

high-torque

lifting

lifting

plus

the

height

A97

Gh

66mm.

main

space

and

Above

Oil

Temperature

Controller

Figure

spindle

machine

is

500mm

4.4

(Matrix)

Controller

(For

20000min*1

and

using

the

plus

Figure

Ch

20000min"1

spindle

crane,

a

height

the

with

2.18

other

(For

spindle

specifications,

necessary

lifting

the

20000min"1

than

spec.)

total

Gh

the

height

equipment.

Figure

machine

required

spindle

4.3

height

29M-1

spec.)

is

the

provide

to

105B-22-EN

Page 28

Preparations

Preparation

Installation

for

Transport

of

Route

|

a81/a82

|

a81

A

a

rÿu

i

i

1

a

;

I

j

1

«

£.

&

c

a

2

TO

£

CL

C\J

1ÿ1

TBj

°ÿ3Z>

Q

n

Width

Height

II

jl

jj

A

°

n

Q=

Using

ox

—

qpHPP

o

BB

Q

Table

Crane

JTQ

2.2,

a

§

n

Table

for

Lifting)-

2.3

Height

Using

Crane

for

O

in

§

!M

CM

m

m

(Required

n

II

II

jj

u

I

*

TBj

4

o

n

Width

o

n

10=

o>

—

qmpo

Q

a

Table

JTo

R

2.2,

R

n

Table

Lifting)-

2.3

o

in

CO

CM

CM

rn

in

C7\

CM

8

Figure

29M-1

2.17

05B-23-EN

1

Main

Machine

Size

When

Being

Transported

(With

4-Point

Lifting

Equipment:

a81/a82)

23

Page 29

Preparations

Transport

Preparation

of

Installation

for

Route

l

o

3534

Tool

Sfi

Magazine

1835

A97/A1

O

3

as

37

I

g

8

(Matrix)

(

te1

24

Tool

-=S=r

Depth

Magazine

<r

|

*

2.3

Table

O’

A186/A242/A300

Figure

2.18

LI

j

Lifting

a

D

(Matrix)

Tool

of

s

SQ

Magazines

Sub-Arm

(Matrix)

A1

86

(Tool

or

Above)

Magazine

105B-24-EN

29M-1

(

Page 30

Preparations

Installation

for

Set-Up

Conditions

2.4

-

Confirm

Ambient

Relative

Temperature

Well-illuminated

Free

Dust-free

Available

Available

Adequate

Required

Set-Up

following

the

Temperature

Humidity

from

direct

space

space

space

electrical

set-up

Fluctuation

sunlight

storing

for

maintenance

for

around

power

Conditionsÿ

-

to

than

work

to

Table

Location

70%

1°C/30

open

and

(Optimum

(No

finished

doors

location

Set-Up

10°Cto40°C

35%

Less

materials,

raw

machine

sources

.

environmental

Set-Up

2.4

Environmental

and

Temp:

Condensation)

minutes

(Range

workpiece

completely

conditions

Conditions

Conditions

20°C

which

and

±

1

tools

°C)

does

prior

not

machine

to

influence

set-up.

machining.)

I

1

§

c

£

w

a

S

to

£

Q.

eg

level

A

foundation

Appropriate

strong

distance

from

enough

factory

to

support

air

ducting/inlets

the

weight

(Air

of

the

Flow)

machine

29M-1

105B-25-EN

25

Page 31

Preparations

Recommended

Foundation

for

Installation

2.5

Construct

Symbol*

a

b

c

d

Indicates

*

Recommended

appropriate

an

Ground

Foundation

Main

Machine

Jet

Resistance

Machine

Fixing

Anchor

Insulated

Jet

Anchor

Foundation

Recommended

Recommended

Leveling

Concrete

(Weight

-Figure

Concrete

(Weight

-Figure

symbols

Concrete

based

2.21

based

2.24

used

foundation,

Thickness

Support

Tool

for

Main

Foundation

for

Iron

Weight

Magazine

Tool

Bar

Concrete

Rubble

Thickness

for

on

the

0=NOTE

Weight

on

G1

in

for

the

NOTE1)

Figure

machine

from

Tool

dimensions

Tool

Foundation

referring

by

2.5

Table

Item

Point

Surrounding

A97

Magazine

1)

Magazine

dimensions

Figure

2.19

-

to

Table

Recommended

Vibration

and

Above

(a81)

Figure

(a82)

Figure

2.24.

2.19

2.22

in

in

and

2.5

Foundation

ton/m2

8

500mm

points

3

points

3

points

crushed

points

NOTE

(CCS3

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

Magazine

(M16:

(M16:

<|>19mm,

standard

or

6

Small

4

Vertical:

(G=

FC180

Medium

50mm

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Figure

above

or

Jet

stone

Jet

)

1

Large

NOTE

A97/A1

A186/A242:

A40/A60:

A97/A1

A186:

A242:

A300:

2.19

Description

Anchor)

Anchor)

Horizontal:

and

above

Size

Crushed

1)

A40/A60:

37:

A300:

22.7ton

37:

21.4ton

22.1

22.8ton

Figure

~

(Q=

16,3ton

18ton

21ton

18.5ton

18.5ton

ton

2.24.

<|>22mm

NOTE1

Stones

)

NOTES:

These

1

is

It

2

when

Tool

3

Dimensions

installation

values.

As

4

the

professional

according

26

values

necessary

installing

Installation”

foundation.

machine

this

surrounding

to

reference/recommended

are

to

use

the

machine

options

the

indicatedinthis

operates

area

engineer

civil

the

actual

(matrix

foundation

foundation

The

high-speeds,

at

depending

determine

to

ground

fixing

magazine,

upon

conditions

values.

tools

pallet

drawing

drawings

vibration

the

the

final

and

possible

to

order

in

magazine

minimum

are

following

on

generated

foundation

foundation

influence

secure

or

the

MMC).

requirements

pages

by

machine

ground

and

dimension

the

on

machine

main

“3.4

Q=

Machine

given

only

show

operations

conditions.

requirements

surrounding

29M-1105B-26-EN

the

floor

to

Fixing

solid

good

for

recommended

may

affect

Consult

they

as

a

vary

area.

/

Page 32

Preparations

Recommended

Installation

for

Foundation

a81:

Magazine

Tool

g

tL

Is

§

o

CM

§

Leveling

X

I

A40/A60

A

Concrete

ZHZ

\

/

Z

/

a

424

100

Main

150

Left-Discharge

and

5

I

s

\

1520

Machine

u

mrr°

/

Rubble

200

200X15-3000

3300

Main

b

E

4-r

2480

3300

3500

Foundation

b

l/\

B

Conveyor

Machine

b

V

b

960

b

I

TfTTT

C

-eÿ|

Foundation

c

396

100

Reinforced

I

\

C

150

a;

Main

b:

Jet

Isolated

c:

u

w

\o

&

:

in

co

T~

Machine

Anchor

Concrete

§

s

m

m

o

CM

O

c$

>o

£

s

-o

S

rn

rn

in

o

o

V

Support

Machine

for

Foundation

Point

I

1

.2

to

to

k.

£

.2

CL

CM

c:

w

c

ro

TO

Q.

(D

Angle

Detailed

Figure

29M-1

Steel

65

15

50.

in

o

in

tv.

\0

View

of

A

/

a81

2.19

105B-27-EN

Plate

sr

Detailed

of

Foundation

Hex

C7v

in

rv*

CM

O*

o-

Section

Bolt

026

View

B

Drawing

/

485

O

022

(Tool

o

mi

'P

DRILL

Magazine

Anchor

Bolt

o

S

A40/A60

°

9

tri

'

and

Hex

in

cK

rsi

Detailed

of

Section

Left

Bolt

A

030

View

C

Discharge

485

022

/

Anchor

-o

DRILL

Conveyor

Bolt

Spec.)

27

Page 33

Preparations

Recommended

Foundation

Installation

for

Tool

Main

Tool

a81:

Magazine

Machine

Magazine

FoundationN

Foundation

C

o

$<

O

(N

LA

lf§

VO

5?

o

CM

s

a

A97/A137

439

100

i

424

100

and

>

-

\

XQEffi

1520

Left-Discharge

2500

2300

n

n

B

b

-

960

2460

3300

3500

V

b

561

100

b

396

Conveyor

/I

D

3

a

100

§r

o

vO

£

ov

5

in

CO

-O

Main

a:

b:

Jet

Isolated

c:

d:

Jet

o

S

in

in

m

m

o

Machine

Anchor

Anchor

30Q

250

m

£

o

o

o

"S

O

£

.£

<D

cc

Support

Machine

for

Foundation

for

Tool

150

50

Leveling

Concrete

Rubble

m

WB

|—

Point

Magazine

(

Angle

Detailed

Figure

Leveling

Steel

65

-

877777/

View

D

of

2.20

Main

D

Concrete

Plate

/

Foundation

a81

Machine

150

Hex

Ov

K

CM

o

sr

Detailed

Section

of

Foundation

TJTJ

Rubble

200

Bolt

i

n

Ov

026

View

Drawing

1

£

200X15-3000

3300

O

022

E

/

(Tool

b

r

IH

485

o

m

£

s

o

DRILL

Magazine

j-,

Anchor

Reinforced

\

c

150

Bolt

III

o

R;

s

A97/A137

8

8

ui

m

O

tn

IM

Hex

Detailed

and

Concrete

Bolt

o\

030

of

Section

Left

485

[

022

View

F

/

Discharge

:ns[

'

1

51

DRILL

Conveyor

Anchor

«3:

>Ol

Bolt

Spec.)

28

29M-1

105B-28-EN

Page 34

Preparations

Recommended

Installation

for

Foundation

a81

Tool

Main

a:

b:

c:

d:

Magazine

:

Tool

Magazine

Machine

II

ft

I

in

m

>o

m

I

i

I

Main

Machine

Jet

Anchor

Isolated

Jet

Anchor

Foundation

Foundation

c

|

\h

I

1

§

Support

Machine

for

Foundation

for

Tool

G

iN

Ilf

or

A186

1033

\

a

424

100

Point

Magazine

Main

II

Above

100

\

7

1520

Machine

and

Rear

d

960

2480

3300

3500

Foundation

b

b

Discharge

T1

.a

V

k

396

100

Reinforced

Conveyor

d

n

T2

Tool

A186

A242

A300

Concrete

100

8

I

I

1

1

3

Magazine

1

2

0)

o

I

5/

O

2

.£

©

in

as

in

s

rn

Foundation

T1

5060

5810

6520

250

500

300

200

50

(unit:

2593

3333

3943

Leveling

Concrete

Rubble

mm)

T2

I

B

§

'is

16

to

_C

£

5

<j)

0.

CM

Angle

Detailed

29M-1

Steel

ini

in)

Mb}

View

of

Concrete'

Rubble

65

15

bo.

r

G

/

Leveling

of

r->{

105B-29-EN

Plate

(Tool

150

sT

Detailed

Magazine

\\\w

/

m/

HH

-f

3000

—

3300

Hex

Bolt

CN

in

|

oCJ

O’

View

of

Section

Figure

A1

86/A242/A300

w\w

_

I

iHu

026

H

2.21

022

/

a81

150

Anchor

’p

DRILL

Foundation

and

Rear

Bolt

§

Drawing

Discharge

c

Hex

el

Lri

Ii

Conveyor

SI

Bolt

-O.

0

30

Spec.)

485

022

\

Anchor

|

PRILL

Detailed

of

Section

Bolt

o

>o

View

J

29

Page 35

Preparations

Recommended

Installation

for

Foundation

a:

Main

b:

Jet

Isolated

c:

a82:

Machine

Anchor

Magazine

Tool

o

|

J'.

s

1

§

1

s

CM

m

i

Ji

©

Support

for

Machine

Foundation

c\

\

100

Point

A40/A60

FH7

/

7

<75

Left-Discharge

and

N,

T

T

'

2

7

txm

1760

27<0

3500

3700

Main

i

Machine

3S553S5S

\/

b

960

Conveyor

Foundation

b

2

i

iE:

5

285

I

a

6=

b

100

NOTES:

50mm=Thickeness

1

200mm=Height

2

\

S

§

H

o

j

•

Eg

m

in

m

£S

s

Concrete

of

Rubble

Leveling

of

§

-I

3

SI

f'4'

rJ

fn

Detailed

of

Section

200

131

View

Hex

35

L

/

Main

Machine

e

6

s

150

Leveling

Bolt

J

10

>9

4B5

555

Foundation

m\iu>

KH

Rubble

Concrete

/

022

t

/

3200

Anchor

/

Slgl«

'mm-

V////A

I

Ohlrÿ

I-200X16)

3500

fM

CO

CM

Bolt

_

b

b

K

t

iZ

mr

150

1

yf

I

86

JWIi

&

p.

§

s

a

o

o

2

8

§

Detailed

Hex

Bolt

,165

V/

35

Reinforced

IV

in

in

of

View

465

555

Concrete

Angle

65

K

/

Anchor

m

022

35

Detailed

of

\

Steel

100

230

SI

Section

Plate

HI

65

Bolt

g|

o

View

M

Figure

30

2.22

Foundation

a82

Drawing

(Tool

Magazine

A40/A60

and

Left

Discharge

Conveyor

105B-30-EN

29M-1

Spec.)

Page 36

Preparations

Recommended

Installation

for

Foundation

Tool

a82:

Magazine

Tool

Main

Machine

i

NOTES:

50mm=Thickeness

1

200mm=Height

2

Magazine

Foundation

c

a

I

i

§i

1

I

I

a

of

Rubble

of

A97/A1

Foundation

62S

/

;

/

475

sa.

Leveling

Concrete

x

\

«0\

37

Left-Discharge

and

2700

2500

\

>d

[3

\

\

1780

2740

3500

3700

Conveyor

Reinforced

100

375

d

b

a

Concrete!-ÿ

II

1

250,

150

50

leveling

Concrete

Rubble

i,

m

fit

s

1

2

I

c

.2

To

TO

E:

BE

lif¬

b

JOO

\

3

a:

b:

c:

d:

960

285'ÿb

1

8

Main

Machine

Jet

Anchor

Isolated

Anchor

Jet

:=

Support

Machine

for

Foundation

Tool

for

Point

Magazine

a

w

.2

ts

co

Q.

£

Q_

CNJ

Hex

s

S

S|-°|

Detailed

Section

of

Main

$

E

E

S

Leveling

Bolt

\200

!!ÿÿÿÿ

S

View

O

/

Machine

150

Concrete

.10

485

555

Foundation

UJJ

TTTTT

200

'3200

Rubble

022

t

I

u

[ÿ200X16)

3500

Anchor

/

4siir

b

b

I

Bolt

•

\

i

N

/

c

Detailed

I

in

Si

Reinforced

j/l

8

1

sr

tU

E

O

O

s

s

53ÿ

SI

«i

w

r5i

ITHVK,

«™

View

Hex

86

a

3!

Concrete

Angle

in

o

of

N

/

Bolt

<05

555

vs/ys/ys

Steel

\

65

\

100

230

Anchor

»22

Detailed

of

Section

Plate

65

Bolt

s

View

P

Figure

29M-1

2.23

a82

105B-31-EN

Foundation

Drawing

(Tool

Magazine

A97/A137

and

Left

Discharge

Conveyor

Spec.)

31

Page 37

Preparations

Recommended

Foundation

Installation

for

a82:

Main

a:

Jet

b:

Isolated

c:

Jet

d:

Leveling

Tool

Tool

Machine

Main

Foundation

a

1

i

I

I

I

I

i

i

J

§

Machine

Anchor

Anchor

Main

£

£

»

Magazine

Magazine

c

y

a

100

Support

Machine

for

Foundation

Tool

for

Machine

r

150

Concrete

A186

Foundation

1350

*ÿ

£

z

475

Magazine

Foundation

1760

Point

TmT

200

Rubble

or

*5

\,

Above

\

3=

1

7740

3500

3700

1-200X16)

3200

3500

and

Left

d

JL

m

IE

h:

b

960

NOTES:

50mm=Thickeness

1

Leveling

200mm=Height

2

Tuu

Anchor

Bolt

Discharge

T1

b

265

100

Concrete

of

Q

go

Reinforced

!

of

Rubble

C

Conveyor

w

T2

_

i

raym,

i

s

I

S'

a

o

o

5.

£

s

I

Concrete

d

a

Tool

A186

A242

A300

sd

Tuff

100

I

Magazine

I

Detailed

II

1

S

I

§

S

Foundation

5060

5810

6445

Angle

View

Q

of

a

£

£

CC

T1

/

450

SO

250.

50

a>

£

o

o

S

o

Leveling

Concrete

Rubble

(

mm)

(unit:

T2

2690

3440

4075

Steel

65

230

WO

Plate

65

32

Hex

Bolt

485

555

Spec.)

Anchor

a

22

Detailed

of

\\

29M-1

Bolt

W/////,

View

Section

S

105B-32-EN

131

200

3|

iy

___

69

(Tool

JO

/Hex

555

Magazine

485

Bolt

mm

a

22

Figure

A1

2.24

86/A242/A300

COt

CM

Detailed

of

Section

Foundation

a82

and

View

R

Left

§

ajjli

si

Drawing

Discharge

86ÿ65,

J5

Conveyor

I

I

5'

S|

Page 38

M

<D

£

O

cn

co

w

co

m

z

i

00

00

Preparations

2

for

Installation

O

g

O

Page 39

Preparations

and

Power

Air

2.6

Sources

Air

Installation

for

and

Power

Sources

Table

2.6

Required

Air

and

Power

Sources

Item

Electrical

Maximum

Consumption

Total

Power

Requirement

Breaker

Circuit

Cable

Power

Ground

Air

Cable

Source

Ground

Source

Power

AC200/220V

50/60HZ

78kVA

Approx.

options)

The

actual

0.6=46.8kVA

78

x

x

100

options)

225A

60mm2

38mm2

cable

Ground

30mm2

0.5MPato0.8MPa

•

•

OL/min:

41

Dew

•

NOTE:

±

2%

±

(a81

standard)

100kVA(a81:

power

0.6=60kVA

more

or

or

more

SP39-10021J)

resistance

or

more

ANR

point

temperature:

10%

including

requirements

standard)

(a81

including

(a81:

insulated

(600V

are

cables

shown

(600V-flame-retardant

Q

100

section

cross

(Standard

(600V

Condition)

or

-20°C

less

Description

80kVA

Approx.

below:

x

80

100x0.6

specified

poly-flex

insulated

(a82

100kVA

48kVA

0.6

=

=

by

insulated

cables

standard)

(a82:

(a82

60kVA

C3307)

JIS

cables

specified

including

standard)

(a82:

or

made

by

including

by

JIS

C3307)

options)

options)

HITACHI

Air

Air

Dryer

Filter

air

Clean

Equivalent

Max.

•

Max.

•

Max.

•

Dew

•

Max.

•

NOTE:

The

feature.

damage

performed

Standard

(without

With

Mustbeordered

5pm

(free

to

particles

particles

particles

point

concentration:

oil

machine

However,

the

to

to

Spec.

scale)

Scale

+

0.3pm

the

at

requires

maintain

+

from

grade

solvent

and

IS02.5.2

number/1m3:

number/1m3:

number/1

max.

when

filter

except