Page 1

Outline

Preface

1

1.1

“Preparations

conditions

checks

In

shown

To

the

Outline

required

the

following

in

ensure

previous

Preface

for

a

flowchart.For

safety

Installation

for

installation,

after

section,

personnel

of

“Safety”

and

machine

installation.

sequence

the

details

and

carefully

and

Installation”

and

of

each

prevent

understand

peripheral

of

preparation

item,

refer

damage

it

describes

unit

for

the

to

the

to

thoroughly

the

necessary

installation

installation

respective

machine,

to

prior

preparations

procedures,

and

actual

chapter

be

installation.

sure

and

to

and

installation

section.

read

this

and

required

confirmation/

is

work

chapter

and

I

c

3

o

27M-1

105B-1-EN

1

Page 2

Outline

Installation

Flow

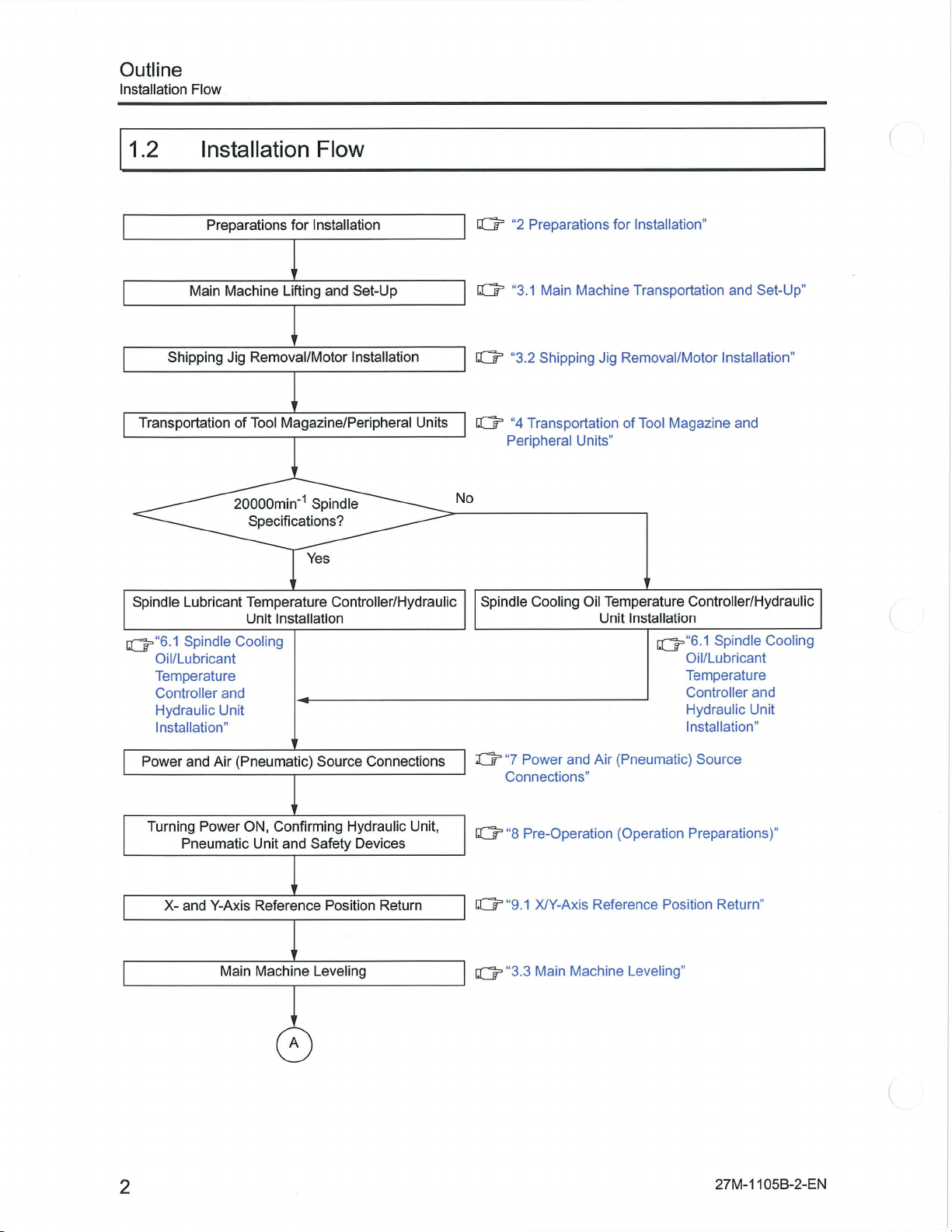

1.2

Main

Shipping

Transportation

Spindle

lQ=“6.1

Lubricant

Spindle

Oil/Lubricant

Temperature

Controller

Hydraulic

Installation”

Installation

Preparations

for

I

Machine

Jig

of

20000min‘1

Cooling

and

Unit

Lifting

Removal/Motor

Magazine/Peripheral

Tool

Specifications?

Temperature

Unit

Installation

Flow

Installation

Set-Up

and

Installation

Spindle

Yes

Controller/Hydraulic

Units

No

tjh

O’

IQ3

Q=

Spindle

Preparations

“2

Main

“3.1

“3.2

Shipping

Transportation

”4

Peripheral

Cooling

for

Machine

Jig

Removal/Motor

Units”

Temperature

Oil

Unit

Installation”

Transportation

of

Tool

Magazine

Controller/Hydraulic

Installation

IQ=“6.1

Oil/Lubricant

Temperature

Controller

Hydraulic

Installation”

Set-Up”

and

Installation”

and

Spindle

Cooling

and

Unit

2

Power

Turning

X-

(Pneumatic)

Air

and

Power

Pneumatic

and

Y-Axis

Main

ON,

Confirming

Unit

and

Reference

Machine

A

Source

Hydraulic

Safety

Position

Leveling

Connections

Unit,

Devices

Return

"7

Ch

Connections”

tQ=

“8

[ÿh“9.1

Q=“3.3

Power

and

Air

Pre-Operation

X/Y-Axis

Main

Reference

Machine

(Pneumatic)

(Operation

Position

Leveling”

Source

Preparations)”

Return”

105B-2-EN

27M-1

Page 3

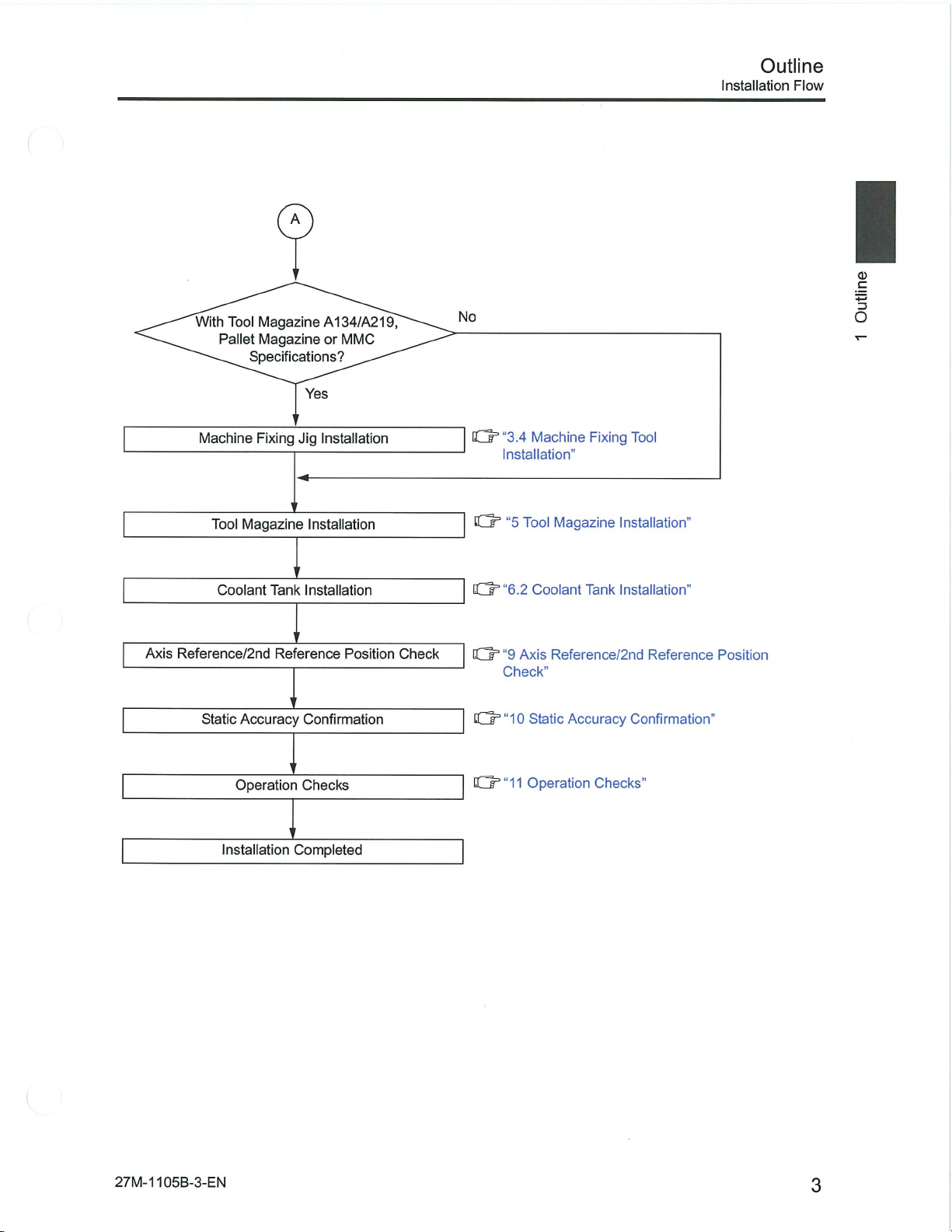

Tool

With

Pallet

Machine

A

Magazine

Magazine

Specifications?

Fixing

A134/A219,

or

Yes

Jig

Installation

MMC

No

C

dr"

“3.4

Machine

Installation”

Fixing

Tool

Outline

Installation

Flow

I

c

3

O

Axis

Reference/2nd

Static

Magazine

Tool

Coolant

Accuracy

Operation

Installation

Installation

Tank

Installation

Reference

Confirmation

Checks

Completed

Position

Check

HJT”

“5

0=“6.2

“9

0=

Check”

CQ3

“10

Cdr’“11

Tool

Magazine

Coolant

Axis

Reference/2nd

Static

Accuracy

Operation

Installation”

Tank

Installation”

Checks”

Reference

Confirmation”

Position

27M-1

105B-3-EN

3

Page 4

Preparations

Confirmation

Preparations

of

for

Installation

for

Installation

2

2.1

Perform

installation.

•

•

•

•

•

•

•

•

Preparations

Confirmation

following

the

For

Preparation

PreparationofTransport

Set-Up

Preparation

Preparation

Preparation

PreparationofTransportation

Equipment

PreparationofRequired

Installation

of

Conditions

of

of

of

preparations

details,

refer

Set-Up

Foundation

Electric

Source

Air

for

of

the

to

Area

Route

Source

Manpower

Installation

Preparations

ensure

to

respective

for

all

installation

sectioninthis

“2.2

O’

“2.3

0°

G=“2.4

Q=“2.5

0”“2.6

“2.6

KJ

G=“2.7

Equipment”

0=“2.8

Installation

for

are

conditions

chapter.

Preparation

PreparationofTransport

Set-Up

Recommended

and

Air

and

Air

Preparation

Required

of

Conditions”

Power

Power

of

Manpower

satisfied

Set-Up

Foundation”

Sources”

Sources”

Transportation/lnstallation

Area”

for

prior

Route”

Installation”

machine

to

Safety

•

Confirmation

Precautions

Check

List

and

i

for

Installation

Check

Other

Preparation

Table

Check

2.1

Preparation

Preparation

Set-Up

Preparation

Preparation

Preparation

“2.9

O’

During

O’

for

List

Set-Up

of

Transport

of

Conditions

Foundation

of

Electric

of

Air

of

Inspection

Installation”

Table

2.1

Installation

Item

Area

Route

Source

Source

Prior

Preparation

Installation

to

and

Precautions

Transportation

Preparation

Preparation

of

of

Air

Dryer

4

Equipment

27M-1

105B-4-EN

Page 5

Preparations

Preparation

for

Installation

Set-Up

of

Area

2.2

Refer

specifications

Note

•

•

•

Preparation

to

the

following:

the

When

The

maintenance

maintenance

The

specifications:

Tool

Magazine

Tool

Magazine

Magazine

Tool

Magazine

Tool

Tool

Magazine

Magazine

Tool

figures

to

confirm

lifting

this

in

space

the

machine

area

A40/A60

and

A99

A134/A219

A40/A60

and

A99

A134/A219

of

Set-Up

section

area

that

requirements

using

body

is

the

maintenance

varies

Left-Discharge

and

Left-Discharge

Left-Discharge

and

Rear-Discharge

and

Rear-Discharge

and

Rear-Discharge

Area

show

the

and

crane,

a

space

depending

Conveyor

Conveyor

general

prepare

the

total

required

on

the

Conveyor

Conveyor

Conveyor

Conveyor

view

the

lifting

and

required

height

after

type

floor

plan

set-up

required

installation.

tool

of

Q=

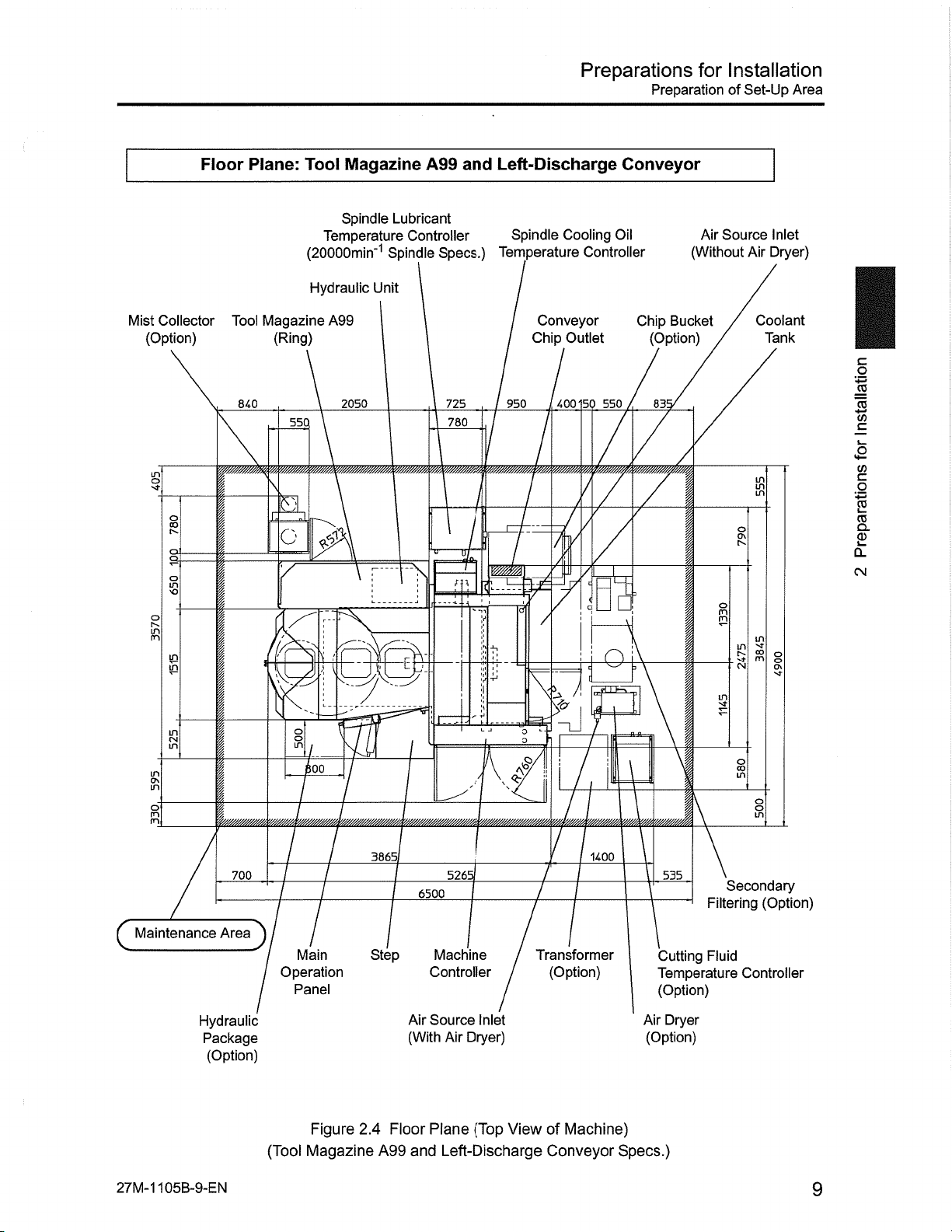

Figure

Figure

0=

Figure

0°

Figure

O’

Figure

0=

Figure

O’

respective

for

area.

is

magazine

2.1,

2.3,

2.5,

2.7,

2.9,

2.11,

3700mm.

and

Figure

Figure

Figure

Figure

Figure

Figure

machine

conveyor

2.2

2.4

2.6

2.8

2.10

2.12

B

.1

TO

3

c

a

B

ro

o.

2

Q.

CM

27M-1

105B-5-EN

5

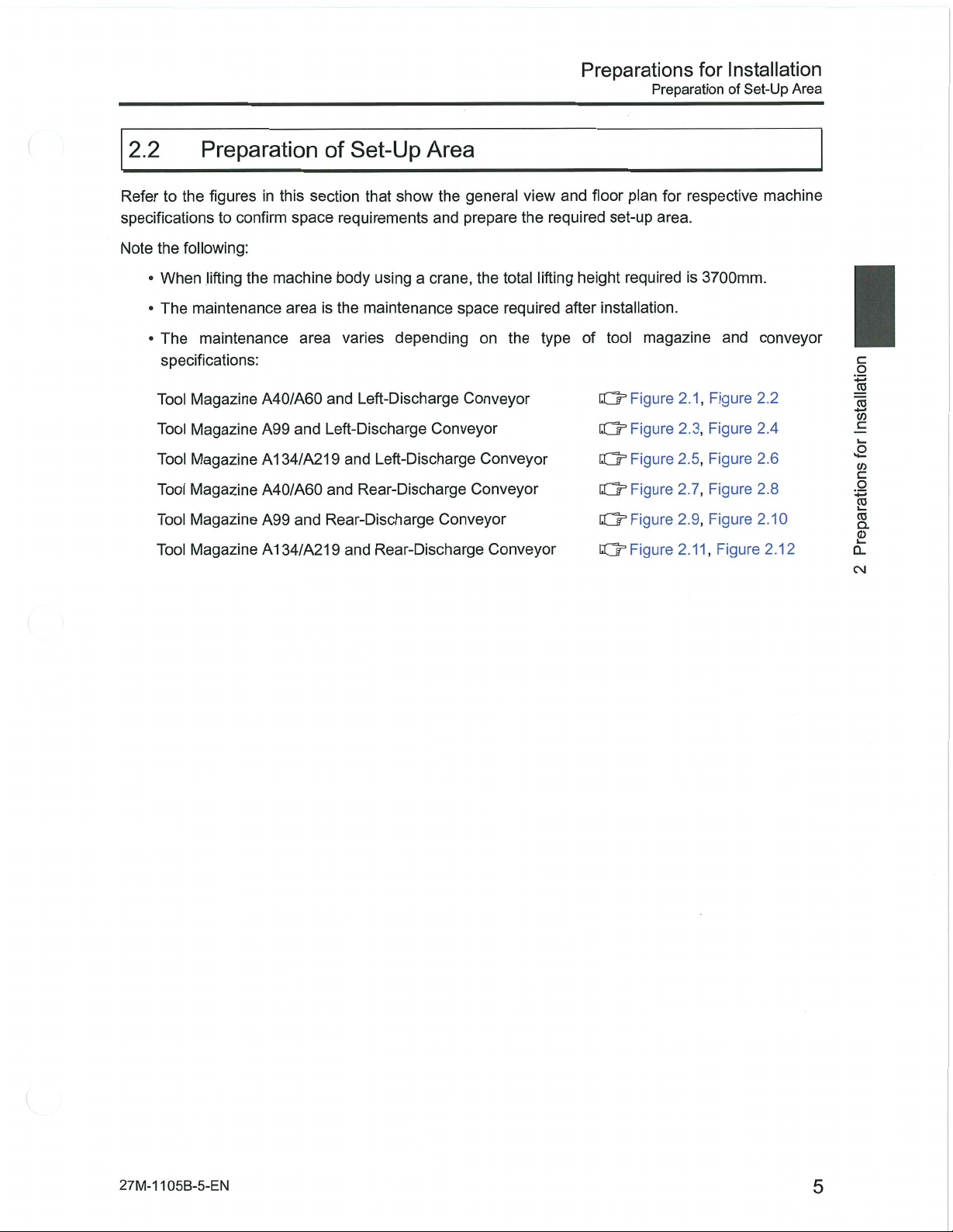

Page 6

Preparations

Preparation

Set-Up

of

installation

for

Area

General

in

8

os

CN

FI

CN

View:

I

n

Magazine

Tool

Maintenance

j,

,,

2195

5

Height

3865

A40/A60

>

5265

1610

Left-Discharge

and

Conveyor

o

in

CN

!

'O

F

(N

;

in

co

co

I

!

l!

1400

]

Ln

£

m

o\

LTI

(Tool

600

Figure

Magazine

A

¥

650

Side

2.1

A40/A60

740

1515

2690

3290

and

Front

Left-Discharge

and

775

a

View

o

.n

i

525

of

m

co

Machine

Conveyor

CN

m

CN

O

O

CN

m

CN

Specs.)

27M-1

6

105B-6-EN

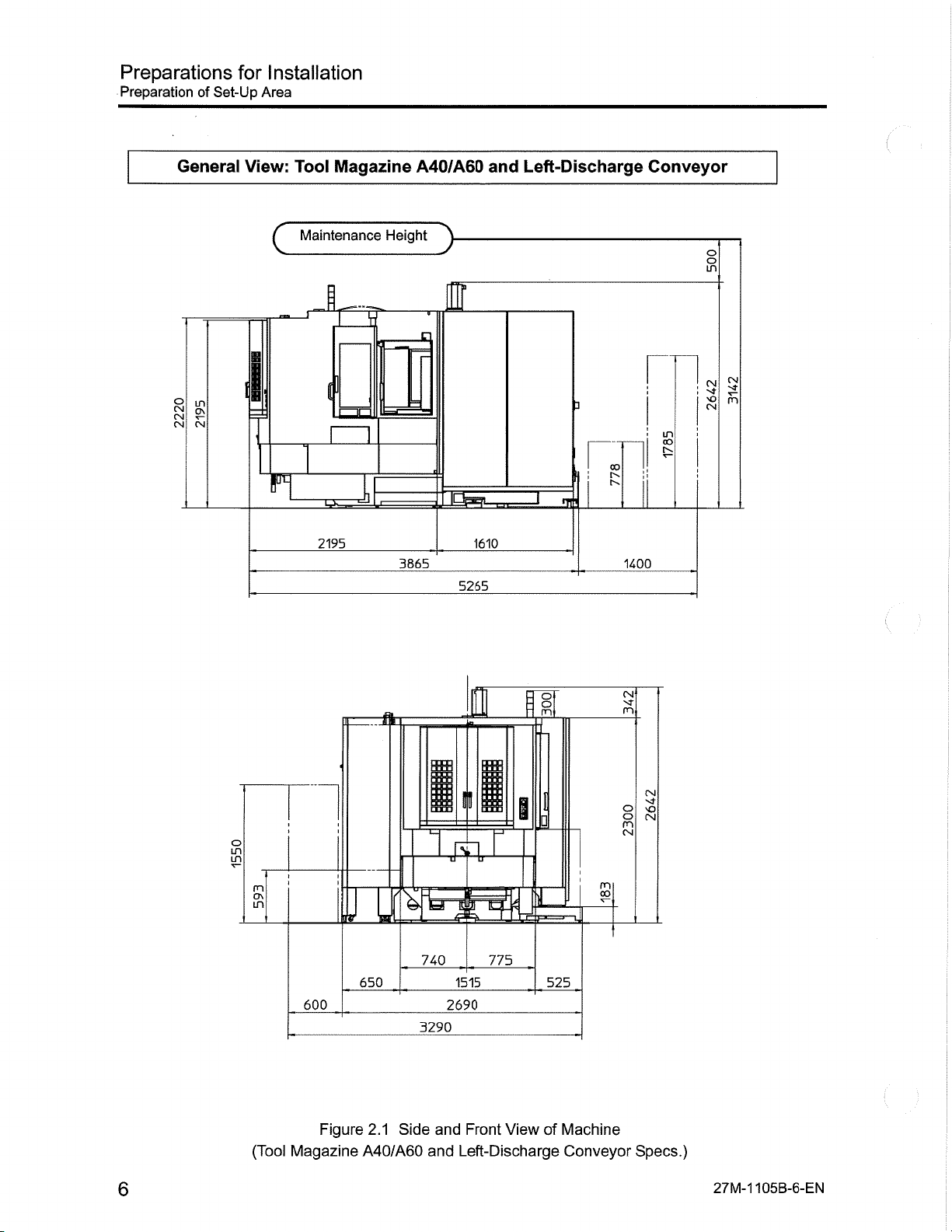

Page 7

Preparations

Preparation

Installation

for

of

Set-Up

Area

Air

Source

(With

in

co

o

s

e*

o

8

in

ON

in

rn

o

O

'O

1

in

04

in

Air

Floor

Inlet

Dryer)

Mist

/

Plane:

Collector

(Option)

11140

V//////M

r

1

y/////////?A

Tool

Tool

A40/A60

1630

o

in

Magazine

Magazine

(Ring)

O

A60

A40

\

800

Hydraulic

1750

1260

K

A40/A60

Spindle

Temperature

(20000"1

Unit

4

%

])

725

780

jr

t

and

Lubricant

Controller

Spindle

Spindle

Oil

1

WM

%

\

Left-Discharge

Specs.)

Cooling

Temperature

Controller

951

40<

150

I

L

W/zr/A.

i

7

/

3

/

w

ii

_

\

Conveyor

Conveyor

Chip

Outlet

Bucket

Chip

(Option)

/

msttfm

7

835

4-

550

0

n

1

__

_

;

Air

Source

(Without

s

P

I

\

§

tn

s

Inlet

Dryer)

Air

Coolant

Tank

in

in

in

CO

o

m

5

o

in

I

§

|

8

C

a

c

.2

s

ro

2

Q.

CM

Air

(Option)

(

27M-1

Dryer

Maintenance

105B-7-EN

700

Area

(Tool

)

Figure

Magazine

Hydraulic

Package

(Option)

2.2

A40/A60

3865

6501

Main

Operation

Panel

Floor

5265

Machine

Step

Plane

and

(Top

Left-Discharge

View

1400.

Controller

of

Machine)

Conveyor

535

Cutting

Temperature

(Option)

Transformer

(Option)

Specs.)

Filtering

Fluid

Secondary

(Option)

Controller

7

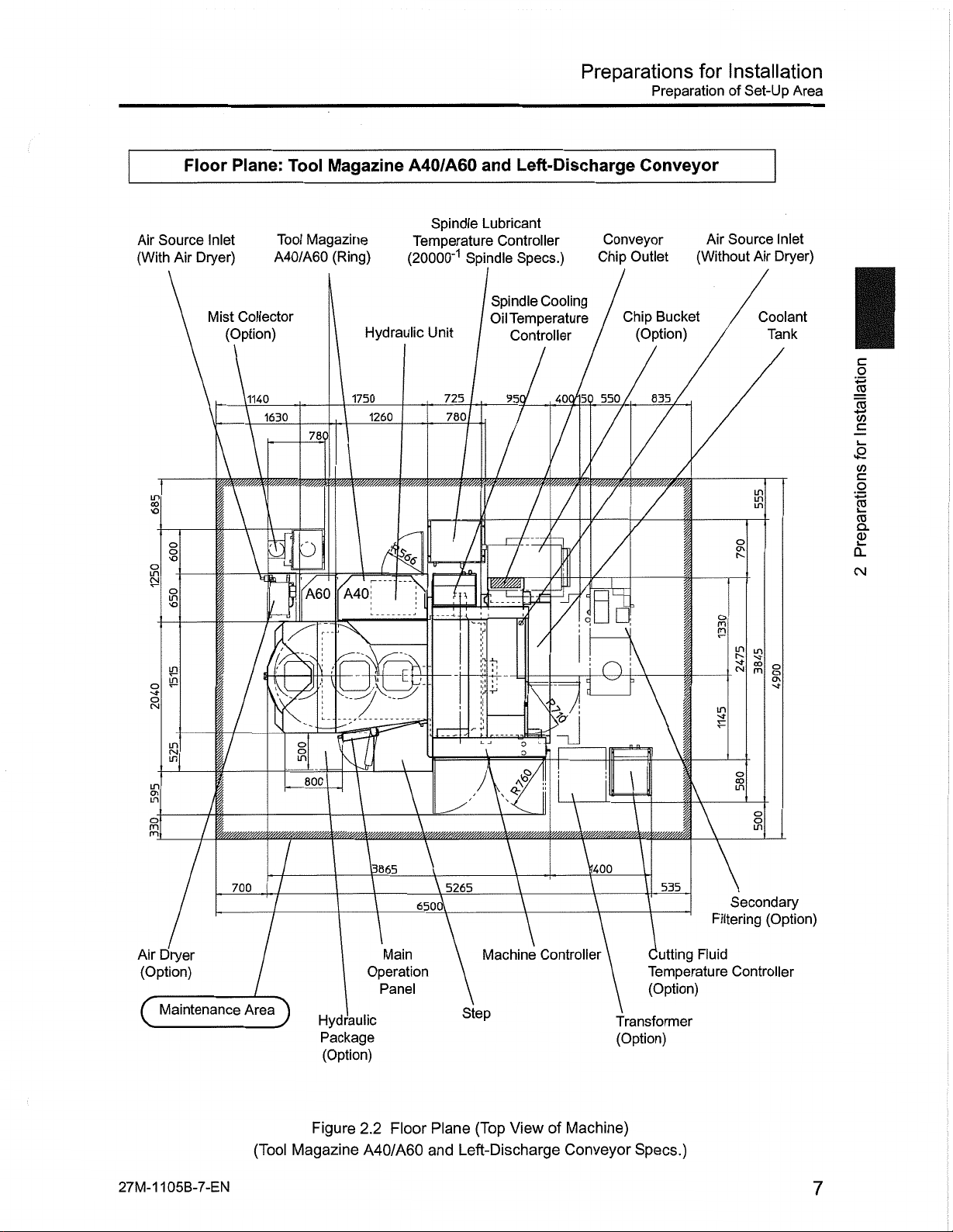

Page 8

Preparations

Preparation

Set-Up

of

for

Installation

Area

General

in

CM

os

CM

CM

View:

1

F

Tool

Maintenance

Q

2195

Magazine

Height

I

r;_

-J

3865

A99

,

Left-Discharge

and

lOgBL

1610

5265

3

mi*

JB

Conveyor

CO

:

1400

O

in

CM

in

oo

(N

sQ

CM

S

I

>

I

Ji

m

CM

SO

CM

(Tool

g

£

DU

880

Figure

Magazine

650

2.3

~E

A99

740

3570

Side

and

and

Left-Discharge

ITW

II

775

1515

2690

Front

View

I

525

Machine

of

Conveyor

CM

m

o

m

CM

m

Specs.)

CM

sO

CM

105B-8-EN

8

27M-1

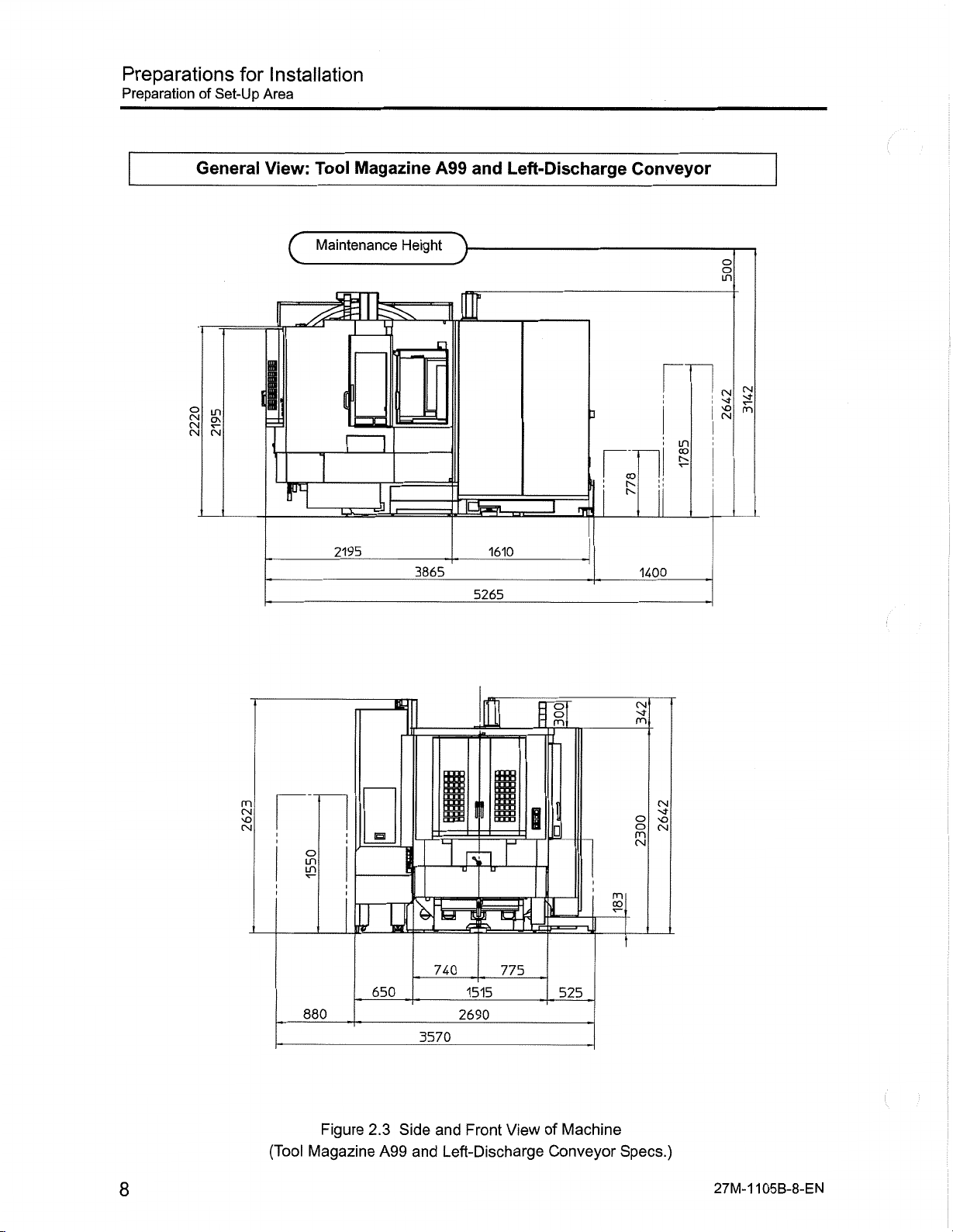

Page 9

Preparations

Preparation

for

Installation

Set-Up

of

Area

Mist

(Option)

s

o

R

in

o\

in

s

m

Floor

Collector

§

S

>o

£

in

in

CM

in

i

I

Plane:

Tool

840

700

Tool

(20000min'1

Hydraulic

Magazine

(Ring)

55Q

\

B.

1

O

21

s

o

in

\oo_

Magazine

Spindle

Temperature

Unit

A99

2050

1

V.

386;

A99

Lubricant

Controller

Spindle

"EH-

6500

and

Specs.)

725

780

m

5265

Left-Discharge

Spindle

Temperature

950

WtM

Cooling

Conveyor

Chip

Outlet

400

Ww//////m.

/

/

ti

•i

%

;

i:

*

/

Oil

Controller

550

150

/

j

/

S

n

•

/

!

_

i

1400

Conveyor

Chip

Bucket

(Option)

13!

/

~\

7

I

7

\

535

Source

Air

(Without

P

I

Secondary

Filtering

Air

Coolant

in

in

§

t".

in

CO

§

m

CM

§

in

o

Inlet

Dryer)

Tank

o

5

(Option)

§

§

a

w

a

w

%

s

£

CL

CM

Maintenance

(

Hydraulic

Package

(Option)

27M-1105B-9-EN

Area

)

(Tool

Main

Operation

Panel

Figure

Magazine

2.4

Step

A99

Air

(With

Floor

and

Machine

Controller

Source

Plane

Air

Inlet

Dryer)

(Top

Left-Discharge

Transformer

View

of

Conveyor

(Option)

Machine)

Cutting

Temperature

(Option)

Air

(Option)

Specs.)

Fluid

Controller

Dryer

9

Page 10

Preparations

Preparation

of

Set-Up

Installation

for

Area

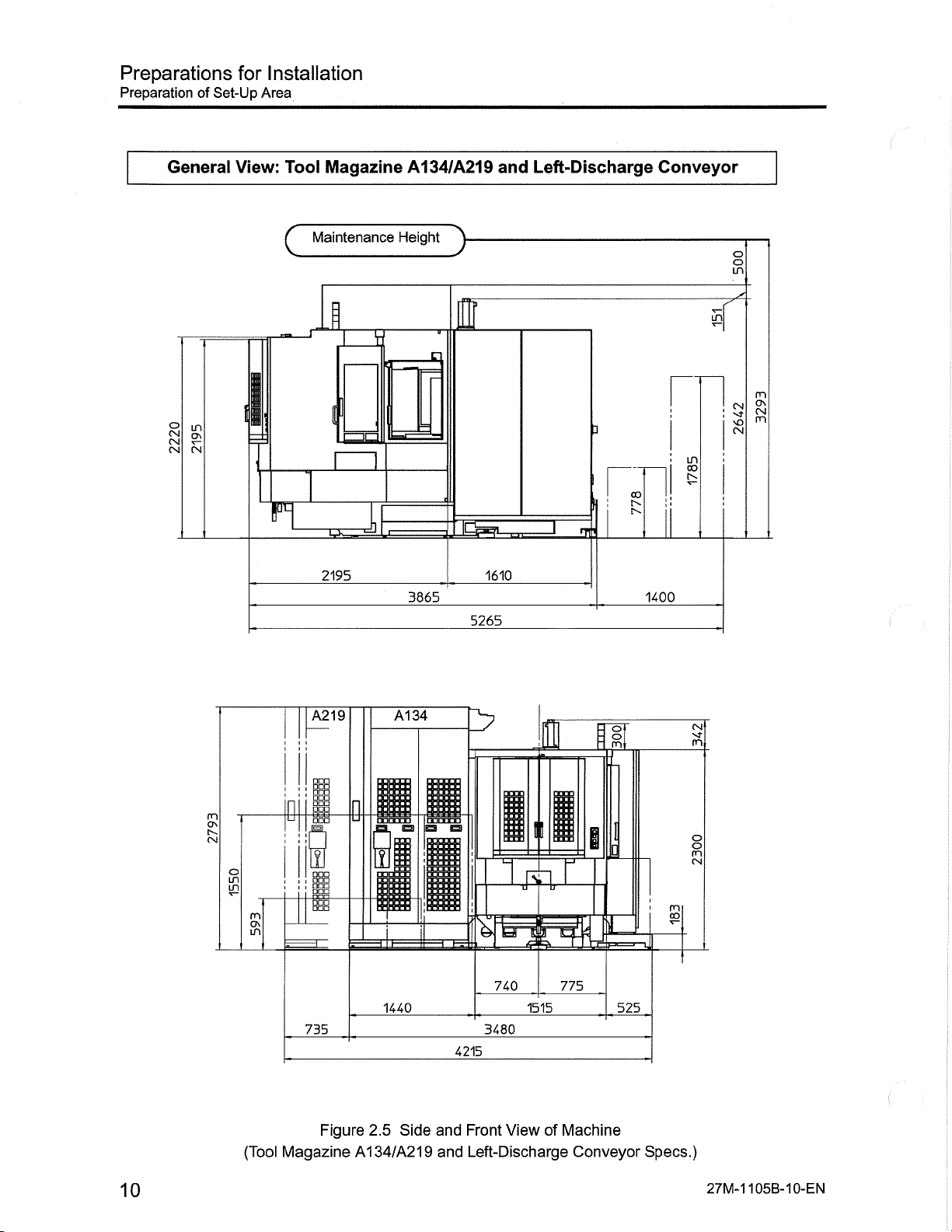

General

in

CM

ON

CM

CM

View:

Tool

F

Magazine

Maintenance

I

2195

A134/A219

Height

3865

1610

5265

Left-Discharge

and

Conveyor

O

m

w

m

ON

CM

5

!

m

co

NO

CM

3

in

I

CO

nj'

1400

m

ON

CM

LO

\P

m

ON

in

(Tool

A219

1

1

755

Figure

Magazine

A134

D

1440

2.5

Side

A134/A219

740

3480

4215

and

Front

Left-Discharge

and

I

775

1515

ViewofMachine

Conveyor

i

o

m

525

mi

co

Specs.)

CM

m

O

m

CM

10

27M-1

105B-10-EN

Page 11

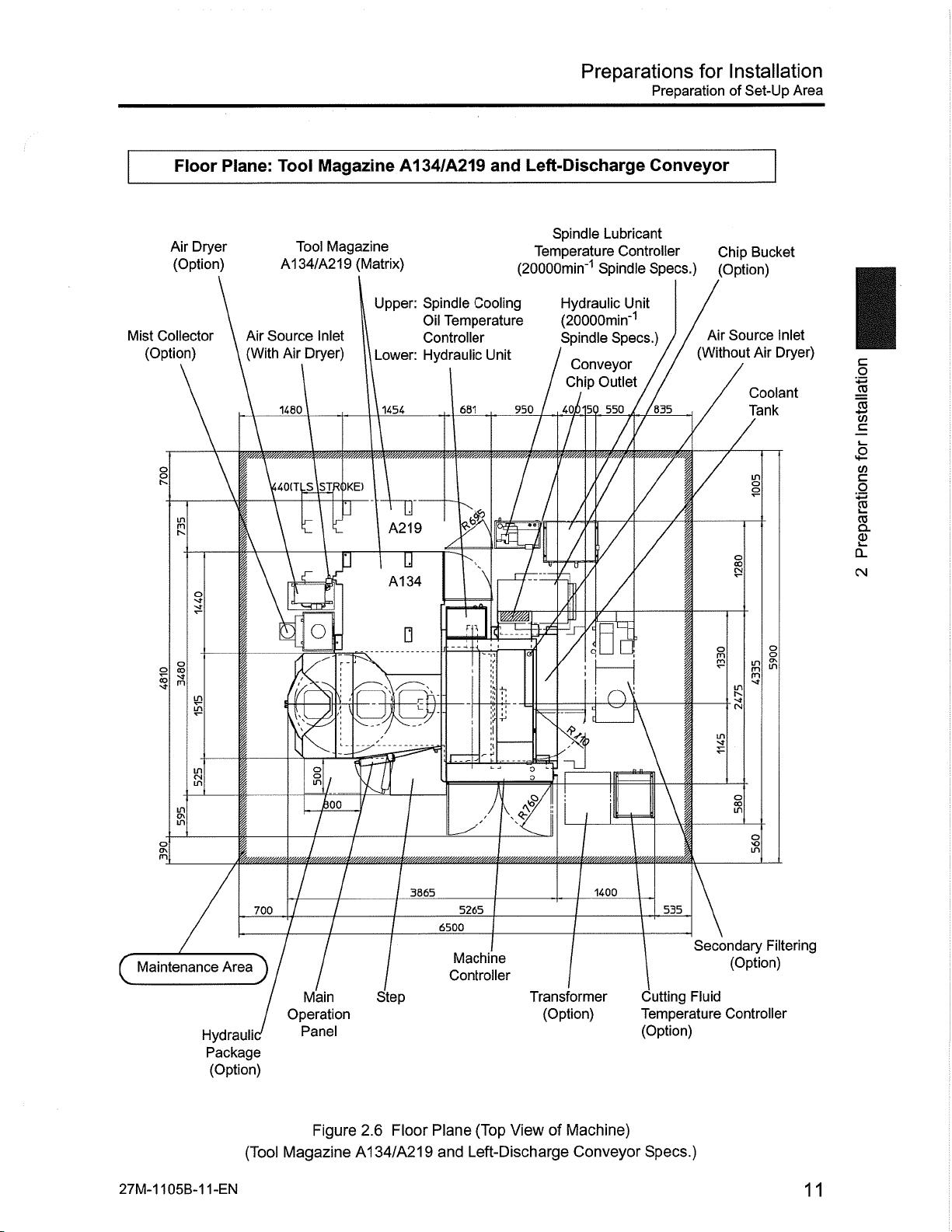

Preparations

Preparation

for

Installation

Set-Up

of

Area

Mist

(Option)

Floor

Dryer

Air

(Option)

Collector

o

s

o

2

S

rn

5

£

in

Plane:

Air

(With

Tool

Tool

A134/A219

Air

1480

140IT

Inlet

Dryer)

'STROKE)

US

Source

O

4.

Magazine

Magazine

(Matrix)

Upper:

Lower:

1454

I

7

-

1

A134/A219

Spindle

Temperature

Oil

Controller

Hydraulic

IT

A219

IT

A134

-Ei

Cooling

681

m

Left-Discharge

and

Temperature

(20000min'1

Unit

950

mwA

/

X

Spindle

Lubricant

Spindle

Hydraulic

Controller

Unit

(20000min"1

Conveyor

Chip

Outlet

550

50

Specs.)

Spindle

40/

7

/

/

/!

y

/

I

s

n\

Conveyor

Specs.)

(Without

/

/

835

/

i

Chip

(Option)

Source

Air

§

£

I

in

3

Bucket

Inlet

Dryer)

Air

Coolant

Tank

i

in

'is

1

a

a

Q.

U

§

To

c

2

2

CM

s

Maintenance

(

105B-1

27M-1

in

o\

in

Area

Hydraulii

Package

(Option)

(Tool

1-EN

700

)

iOO.

Main

Operation

Panel

Figure

Magazine

X

3865

Step

Floor

2.6

A134/A219

5265

6500

Machine

Controller

(Top

Plane

Left-Discharge

and

$

ii

Transformer

(Option)

of

View

1400

Machine)

Conveyor

I

535

Secondary

Cutting

Temperature

(Option)

Fluid

Specs.)

§

§

in

Filtering

(Option)

Controller

11

Page 12

Preparations

Preparation

of

Set-Up

Installation

for

Area

General

in

8

o\

CM

CM

CM

View:

Maintenance

n

Tool

2195

Magazine

Height

A40/A60

'y

1

4940

5440

1610

Rear-Discharge

and

3

ml

1135

Conveyor

K

CM

500

O

in

CM

m

5

>o

in

CM

co

&

8

£

(Tool

m

o\

in

Figure

Magazine

600

ft

OH

650

2.7

Side

A40/A60

JO

740

1515

2690

3290

and

Front

Rear-Discharge

and

o

m

775

525

ViewofMachine

Conveyor

mi

col

Specs.)

CM

m

O

m

CM

CM

<3

CM

12

27M-1105B-12-EN

Page 13

Preparations

Preparation

Installation

for

of

Set-Up

Area

Air

Source

(With

Dryer

Air

(Option)

vO

o

'O

8

?!

s

O

in

CM

in

in

o\

in

Floor

Air

I

|

Plane:

Inlet

Dryer)

Mist

_

'///////////z,

7

700

Tool

Tool

A40/A60

Collector

(Option)

1140

163(

v/MM

o

o

v////////ÿy//////////////#ÿÿ

Magazine

Magazine

(Ring)

Hydraulic

I

1750

1260

780

A60

[*4°[77

loo

38P5

A40/A60

Spindle

Temperature

(20000min‘1

Unit

780)

r-T,

-E

l

>440

6700

Rear-Discharge

and

Lubricant

Controller

Spindle

Spindle

Oil

Controller

Specs.)

Cooling

Temperature

2750

2395

1600

m

Prjg

=i

i:

I

0

]E2lg_

/

Conveyor

Source

Air

(Without

Coolant

Tank

400

Air

660

1415

Inlet

Dryer)

Filtering

Secondary

(Option)

o

I

B

j

7

o

in

(M

0\

a

C

a

2

S.

2

Q.

CM

1

CO

o

m

m

fit

3

o\

CM

f

/

y/M

1P5

32!

J

I

175

560

CM

3

rn

CM

•o

m

Maintenance

Area

c

Hydraulic

Package

27M-1105B-13-EN

)

(Option)

(Tool

Main

Operation

Panel

Figure

Magazine

Step

Machine

Controller

Floor

2.8

A40/A60

Transformer

(Option)

(Top

Plane

Rear-Discharge

and

Conveyor

Outlet

Chip

View

of

Cutting

Temperature

Controller

Machine)

Conveyor

Fluid

(Option)

Specs.)

Chip

(Option)

Bucket

13

Page 14

Preparations

Preparation

of

Set-Up

Installation

for

Area

8

CM

(N

General

in

ON

CN

View:

Maintenance

Tool

Magazine

Height

A99

'y

and

Rear-Discharge

Conveyor

O

in

E_F

CN

R

£

CNJ

m

'O

CN

in

00

\

]

r=

:

F

2

2195

4940

5440

1610

1135

500

m

CN

NO

CN

(Tool

8

!P

880

Figure

Magazine

2.9

A99

m

650

740

3570

Side

and

and

Rear-Discharge

m

1515

2690

Front

775

View

m.

I

525

of

Machine

Conveyor

CN

m

o

m

CN

m

oo

Specs.)

CN

NO

CN

14

27M-1

105B-14-EN

Page 15

Preparations

Preparation

Installation

for

of

Set-Up

Area

Air

Source

(With

Air

(Option)

o

s

tv.

s

-o

O

in

m

8

Air

Dryer

Floor

Inlet

Dryer)

Mist

|840

Plane:

Tool

Collector

(Option)

55Q

a

o

Tool

Magazine

(Ring)

(050

1

V.

Magazine

A99

Temperature

(20000min'1

Hydraulic

A99

Spindle

Unit

m

/

r-T,

Rear-Discharge

and

Lubricant

Controller

Spindle

/

j

I

n

Specs.)

Spindle

Oil

Cooling

Temperature

Controller

2395

1600

MMWMMMWW.

r~

i

o

Air

Source

(Without

355

£Zf

3

Conveyor

Inlet

Air

Dryer)

Secondary

(Option)

660

/00

MW.

/

I

Filtering

Coolant

(N

ON

1

m

ON

(N

CN

Tank

s

o

CO

m

rn

I

§

'ÿs

1

w

c

a

2

CD

Q_

eg

8

o\

in

CM

in

in

o\

in

n

Maintenance

(

1

///////////////,

r

700

Area

),

Hydraulic

Package

(Option)

o

in

_8(

ym/////////m//m///////ÿ

Main

Operation

Panel

Figure

(Tool

Magazine

3805

2.10

A99

Step

Floor

//////////////////////,

5440

6700

Machine

Controller

Transformer

(Option)

Plane

and

Rear-Discharge

1

(Top

A*?

my/////////,

View

:

;

/////»////////.

113!

Controller

Conveyor

Outlet

Chip

of

Machine)

Conveyor

:1

ymym.

325

175

Cutting

Temperature

Fluid

(Option)

Specs.)

w/A.

560

4

2

l

rn

>4-

Chip

(Option)

£

in

Bucket

27M-1

05B-1

1

5-EN

15

Page 16

Preparations

Preparation

Set-Up

of

Installation

for

Area

General

in

8

o\

CM

S

CM

View:

r

Magazine

Tool

Maintenance

T

2195

A134/A219

Height

4940

>

if

5440

1610

Rear-Discharge

and

2

i

1135

Conveyor

\\

500

o

in

m

ON

CM

CM

m

>o

CM

-£

£

CM

£

:

m

ON

CM

8

£

(Tool

m

ON

in

Magazine

A219

BBS

BOO

BBB

735

Figure

A134

m

1440

Side

2.11

A134/A219

3480

4215

Front

and

Rear-Discharge

and

J

I!

r=rik_

740

ViewofMachine

775

1515

Conveyor

o

m

i

525

Specs.)

CM

m

o

m

CM

m

oo

16

27M-1

105B-16-EN

Page 17

Preparations

Preparation

Installation

for

Set-Up

of

Area

Mist

O

tv

1

vf

§

Floor

Air

(Option)

Collector

(Option)

in

m

tv

1

g

8

K3

in

in

o\

in

Plane:

Dryer

\

\

|440(TL

I

_

Source

Air

(With

1480

wyyy/tWy

;

Tool

Air

Magazine

Magazine

Tool

A134/A219

(Matrix)

Inlet

Dryer)

11454

7

J

o

HREi

o

*00

yyyyyyyy,

A134/A219

(20000min‘1

Upper:

Temperature

Lower:

Spindle

Hydraulic

w,

A219

u

A134

a

_

and

Spindle

Temperature

Controller

751

Lubricant

Spindle

Cooling

Unit

l#

7

a

£

4

-4

l

$

'ft

Rear-Discharge

Controller

Specs.)

Oil

27t

/Air

1600

Source

(Without

7

Inlet

Air

Dryer)

5

RE

vyyyyyyyyyyyyyyyy'yyyy

Conveyor

Secondary

Filtering

(Option)

/

Coolant

/

Tank

/

660

;00,/

535

880

V/M.

/

/

7

'/yyyyyyyy.

Secondary

Filtering

(Option)

20000min‘1

Spindle

1

O

tv

m

o\

eg

CN

Specs.

55

§

oo

in

in

o

I

rn

oo

\Q

in

I

s

I

2

c

a

W

B

E

£

Q.

CM

Maintenance

(

27M-1105B-17-EN

Area

Hydraulic

Package

(Option)

700

)/

(Tool

Main

Operation

Panel

Figure

Magazine

3805J

Step

Floor

2.12

A134/A219

5440

6700

Machine

Controller

Transformer

(Option)

Plane

(Top

Rear-Discharge

and

View

1131

Conveyor

Outlet

Chip

of

Machine)

Conveyor

32!

175

560

Cutting

Temperature

Controller

Specs.)

Fluid

(Option)

Chip

(Option)

Bucket

17

Page 18

Preparations

Preparation

of

Transport

for

Installation

Route

2.3

Prepare

machine

For

Tool

The

tool

Machine

(Tool

Magazine

Machine

container

Machine

(Tool

Magazine

Machine

container

Preparation

the

machine

size

shipment

Magazine

magazine

Table

when

when

(Tool

when

when

(Tool

A40/A60/A99:

A40/A60/A99

2.2

Item

transported

A40)

transported

Magazine

transported

A60)

transported

Magazine

of

transport

dimensions.

Machine

A40)

A60)

by

in

by

in

Size

truck

truck

Transport

route

(adequate

O’

Table

2.2,

(ring)

is

assembled

Shipment

Height

2642mm

2300mm

2642mm

2413mm

Route

space

Figure

Dimensions

2.13

onto

Height

Lifting

Equipment

(O’

3700mm

3700mm

3700mm

3700mm

transporting

for

machine

the

(Tool

With

NOTE)

prior

Magazine

2260mm

2144mm

2260mm

2144mm

machine),

to

shipment.

referring

A40/A60/A99)

Width

to

Depth

3865mm

3865mm

3865mm

3865mm

the

Machine

(Tool

Machine

container

For

Tool

The

tool

Machine

Machine

container

Tool

Magazine

Tool

Magazine

when

Magazine

when

(Tool

Magazine

magazine

Table

when

when

transported

A99)

transported

Magazine

A134/A219

A134/A219

2.3

Machine

Item

transported

transported

34

A1

A21

9

by

in

A99)

by

in

truck

O’

is

truck

not

Size

2642mm

2642mm

Table

2.3,

installed

Shipment

Height

2642mm

2300mm

3795mm

2795mm

Figure

onto

2.13,

the

Dimensions

(O’

3700mm

3700mm

Figure

machine

(Tool

Height

With

Lifting

Equipment

NOTE)

3700mm

3700mm

3795mm

3795mm

2391mm

2144mm

2.14

priortoshipment.

Magazine

A134/A219)

Width

2260mm

2122mm

1440mm

2175mm

3865mm

3865mm

Depth

3865mm

3865mm

1454mm

1454mm

18

27M-1

105B-18-EN

Page 19

Preparations

PreparationofTransport

Installation

for

Route

Lifting

•

•

•

•

NOTE:

When

lifting

Units

of

Magazine

Tool

Spindle

4.3

Spindle

Coolant

lifting

space

Cooling

Lubricant

Tank

the

main

500mm

is

1

A134/A219

Temperature

Oil

Temperature

Figure

Ch

machine

the

plus

w

(Matrix)

4.4

using

height

w

Q=

Controller

Controller

crane,

a

the

with

Figure

2.14

(Other

than

(20000min"1

necessary

the

lifting

equipment.

The

for

The

the

2.2

20000min'1

Spindle

height

total

dimensions

the

tool

dimensions

of

type

and

Table

Spindle

Specs.)

requiredtoprovide

magazine

magazine.

tool

2.3.

0°

shown

A40

differ

Specs.)

Figure

in

depending

the

(Ring)

Refer

O’

4.3

Figure

specs.

to

Figure

adequate

are

upon

Table

I

o

1

i

.E

a

c

.2

1

8.

2

CL

CM

Ns

&

(

Required

Crane

Height

Lifting

for

m

Using

,o

ivUl

o

>

cirÿriL

s*1

O'

§

3

I

I

o

27M-1

05B-1

1

9-EN

Figure

2.13

Lifting

of

Main

Machine

When

2173

2364

Transported

19

Page 20

Preparations

Preparation

Transport

of

for

Installation

Route

Tool

Magazine

C£

A134/A219

5

(Matrix)

o

o

m

ON

LTI

ON

fn

20

Figure

2.14

735

Depth

Lifting

of

1440

2175

O’

Tool

(A134)

(A219)

2.3

Table

Magazines

(Matrix)

When

Transported

27M-1

05B-20-EN

1

(

Page 21

Preparations

Installation

for

Set-Up

Conditions

2.4

Confirm

Ambient

Relative

Temperature

Well-illuminated

Free

Dust-free

Available

Available

Adequate

Required

Set-Up

the

following

Temperature

Humidity

direct

from

space

space

space

electrical

set-up

Fluctuation

sunlight

for

storing

for

maintenance

around

power

Conditions

location

Table

Set-Up

10°C

RH

Less

raw

machine

sources

Location

to

40°C

35%to70%

than

materials,

work

open

to

environmental

and

2.4

and

(Optimum

(No

1°C/30

minutes

finished

completely

doors

conditions

Set-Up

workpiece

Conditions

Environmental

20±1°C)

Temp:

Condensation)

(Range

and

Conditions

which

does

tools

prior

machine

to

influence

not

set-up.

machining.)

I

1

%

.E

a

S

2.

2

CL

CM

§

c

A

level

foundation

Appropriate

strong

distance

from

enough

factory

support

to

air

ducting/inlets

the

weight

(Air

of

the

Flow)

machine

27M-1105B-21-EN

21

Page 22

Preparations

Recommended

Foundation

for

Installation

2.5

Construct

Symbol

a

b

c

e

f

Recommended

appropriate

an

*

Ground

Foundation

Machine

Machine

Jet

Anchor

Insulated

Vibration

Anchor

Jet

Jet

Anchor

Foundation

Recommended

Rubble

foundation,

Resistance

Thickness

Support

Tool

Fixing

for

Machine

Foundation

Tool

for

for

Tool

Reinforcing

Concrete

Foundation

referring

Table

2.5

Item

Point

Surrounding

from

Magazine

Magazine

Bar

to

Table

Recommended

(Matrix)

A134

A219

(Matrix)

2.5,

Table

Foundation

5

ton/m2

300mm

points

3

points

3

points

6

Small

points

4

points

4

Vertical

FC180

Medium

2.6,

or

above

(M16:

crushed

(M16:

(M16:

and

Horizontal:

standard

or

large

Figure

Description

Anchor)

Jet

stone

Anchor)

Jet

Anchor)

Jet

and

size

2.15

<|>22mm

above

crushed

and

(O3

Figure

(Q=

NOTE

stones

2.16.

NOTE

1)

1)

A

D

E

Indicates

NOTE:

These

1

2

When

3

Machine

magazine,

Dimensions

4

installation

recommended

5

As

this

the

professional

according

Leveling

Concrete

Magazine

(Tool

Concrete

Magazine

Concrete

Magazine

symbol

the

values

machine

(*)

are

fixing

pallet

indicated

foundation.

values.

machine

surrounding

civil

the

to

Concrete

Weight

Weight

A134

Weight

A219

used

Thickness

Foundation

of

A40/A60/A99)

Foundation

of

(Q=

NOTE

Foundation

of

(O’

NOTE

in

Figure

2.15

1)

1)

and

reference/recommended

tool

equipped

is

tools

must

magazine

operates

area,

engineer

actual

in

depending

ground

with

used

be

MMC

or

foundation

this

The

foundation

high-speeds,

at

determine

to

conditions

to

(tO“3.4

Machine

for

Tool

for

for

Tool

Figure

magazine

secure

upon

the

values.

the

Machine

drawing

drawings

vibration

the

final

and

possible

50mm

7.1tons

0.9ton

0.9ton

2.16.

(ring),

A99

machinetothe

Fixing

minimum

are

on

generated

foundation

foundation

influence

(Q*

NOTE

support

a

Tool

following

the

by

and

dimension

on

1)

is

leg

when

floor

Installation”).

requirements

pages

machine

ground

operation

conditions.

requirements

surrounding

the

required.

installing

a

for

show

as

area.

matrix

a

good

only

may

affect

Consult

they

solid

the

a

vary

22

27M-1

05B-22-EN

1

Page 23

Preparations

Recommended

for

Installation

Foundation

Foundation

A

A+D

A+D+E

Tool

o

LH

8

R

LH

£

Area

Magazine

Table

2.6

Foundation

Foundation

Foundation

A40/A60/A99

trr

b

Foundation

Machine

for

Machine

for

Machine

for

and

b

vr

a

a

iim

\

r

b

AreabyMachine

Machine

Magazine

Tool

and

Tool

Tool

Magazine

Magazine

and

and

Specs.

Specifications

A40/A60/A99

A134

A219

Left-/Rear-Discharge

A

Vrl?

in

m

oo

8

8

O

in

CM

X

CM

(Matrix)

(Matrix)

Conveyor

8

CM

(Ring)

75

%

a

.2

CL

CM

§

c

c

2

£

27M-1

(Tool

105B-23-EN

470

I50

mmmimimiimmk

Magazine

820

1595

2550

250X9=2250

250

Figure

A40/A60

775

Rubble

2.15

/A99

485

7

Foundation

Left-/Rear-Discharge

and

Drawing

8

in

CNI

Wi|

Leveling

Sj

ml

—

Reinforcing

Vertical

<(>1

and

0x250

Reinforced

o

o

Concrete

Conveyor

(Double):

Bar

Horizontal

Concrete

Specs.)

23

Page 24

Preparations

Recommended

Foundation

Installation

for

Tool

Magazine

LTI

m

in

vO

LH

in

s

GO

m

a

A134/A219

g

in

LH

in

e,

/"

b

Left/Rear-Discharge

and

f

e

f

0

m

T

a

lu

\

t

b-

A

\if

in

m

oo

Conveyor

(N

Jl_

X

CM

£

CN.

450

350

300,

100

50

E

D

24

(Tool

[50

Magazine

820

470

2550

250X9=2250

250

flllllllllllllttllllllilllllli

Figure

A134/A219

775

1595

Rubble

2.16

and

485

Foundation

Left-/Rear-Discharge

7

Drawing

in

¥

Leveling

Reinforcing

Vertical

(]>

-

and

10x250

Reinforced

a

Concrete

Conveyor

Bar

(Double):

Horizontal

Concrete

Specs.)

27M-1

05B-24-EN

1

Page 25

Preparations

Air

for

Installation

and

Power

Sources

2.6

Item

Electrical

Maximum

Consumption

Total

Requirement

Circuit

Power

Ground

Ground

Air

Source

Power

Power

Breaker

Cable

Cable

and

Power

AC200/220V

50/60Hz

48kVA

Approx.

The

48x0.6=29kVA

93x0.6

225A

60mm2

or

38mm2

cable

Ground

30mm2

0.5-0.

-

410L/min:

-

Dew

-

NOTE:

Clean

Sources

Table

10%

±

±

2%

(Standard)

93kVA

(including

power

actual

56kVA

=

more

or

or

more

SP39-10021J)

resistance

more

or

8MPa

ANR

point

temperature:

air

(free

from

and

are

options)

cables

cables

condition)

or

iron

and

Power

Description

shown

less

rust)

Air

2.7

options)

requirements

(Standard)

(including

insulated

(600V

(600V-flame-retardant

100Q

insulated

(600V

(Standard

-20°C

solvent

Sources

below:

specified

poly-flex

specified

required.

is

JIS

by

insulated

JIS

by

C3307)

cables

C3307)

made

HITACHI

by

I

1

&

a

£

o.

CM

§

w

c

E

8.

E

Air

Air

Air

Source

Dryer

Filter

Equivalent

particles

Max.

-

particles

Max.

-

particles

Max.

-

point

Dew

-

oil

Max.

-

NOTE:

The

machine

feature.

When

may

Standard

(without

With

Must

5pm

Periodic

maintenance

occurina

scale)

Scale

be

ordered

0.3pm

+

grade

the

to

number/1

number/1

number/1

pressure:

max.

at

concentration:

requires

+

the

maintenance

the

of

period

short

except

remover

water

IS02.5.2

m3:

Below

m3:

Below

m3:

Below

Below

0.1mg/m3

above

must

filters

time.

of

Required

Standard

prepared

when

specified

or

air

neglected,

is

410

460

10

(diameter:

1000

1000000

7°C

(Absolute

less

quality.

performed

be

Flow

Air

by

by

IS08573-1

0.001

(diameter:

(diameter:

The

air

to

pollution

filter

(L/min:

Using

Spindle

customer.

(equivalent

x

<

0.0005<

0.0001

Pressure:

are

filters

maintain

ANR)

Through

Frequently

Air

600

690

<

0.005mm)

<

x

<

0.8MPa)

installed

optimum

an

damage

and

JIS

to

0.001mm)

<

0.0005mm)

x

as

a

to

With

8392-1)

B

standard

supply.

air

filter

the

Blow

Air

660

750

27M-1

105B-25-EN

25

Page 26

Preparations

Air

and

Power

Sources

NOTE:

The

air

air

quality

quality

varies

values

Installation

for

according

satisfy

the

to

the

required

factory

values.

circumstances.

Use

particle

a

counter

confirm

to

that

the

The

air

Earth

Terminal

quality

Connecting

Point

Size:

specified

M8

CD

ISO

by

Electric

Connection

Terminal

Power

Size:

8573-1

Source

Point

M8

\

(equivalent

rFk

*

to

i*

JIS

8329-1)

B

recommended.

is

"

'

t

Air

RC1/2

Setting:

Inlet

Dryer)

(PT1/2)

0.5MPa

Source

Air

(Without

Size:

Pressure

Air

Figure

O

rvj

Dryer

2.17

§i

_WfeD

o

Power

Source

'Qo

D

Detailed

Source

-Air

(With

Air

RC1/2

Size:

To

Source

Air

Main

Machine

Connection

off1

D

View

Inlet

Dryer)

(PT1/2)

Inlet

Point

of

of

and

°

A

Air

A

Source

N

X

Inlet

o

8

(With

Air

Dryer)

26

27M-1

105B-26-EN

Page 27

Preparation

Preparations

Transportation/Installation

of

for

Installation

Equipment

2.7

Prepare

and

withstanding

If

the

Preparation

equipment

required

representative

Parts/Tools

Transfer

Necessary

Measurement

Machine

Machine

Machine

To

Equipment:

Tools:

(Without

(Tool

(Tool

such

the

weight

transportation

for

further

Be

Prepared

Crane,

Tools

supplied

Tools:

Precision

Tool

Magazine)

Magazine

Magazine

of

crane,

as

a

of

the

assistance.

Forklift,

standard

Level,

A40)

A60)

Transportation/Installation

fork

lift

machine

equipment

Table

2.8

Lifting

Equipment

with

Indicator

Table

Item

truck,

prior

cannot

Required

the

machine

Machine

2.9

casters/rollers,

and

to

machine

be

Equipment

transportation.

prepared,

Weigh

Equipment

capable

contact

of

supporting

your

Makino

Weight

7400kg

7600kg

7800kg

the

size

service

EJ

o

1

B

w

a

£

2

S.

2

CL

CM

Machine

Tool

Magazine

Tool

Magazine

Spindle

(Ring

Magazine

Spindle

Spindle

(Matrix

Hydraulic

Coolant

and

Cutting

Coolant

and

Cutting

Coolant

and

Cutting

Coolant

and

Cutting

Coolant

and

Cutting

(Tool

Magazine

A134

A219

Cooling

Lubricant

Cooling

Magazine

Unit

(Ring

Tank

Left

Fluid

Tank

Left

Fluid

Tank

Left

Fluid

Tank

Rear

Fluid

Tank

Rear

Fluid

A99)

Oil

Temperature

and

other

than

Temperature

Oil

Temperature

and

other

Magazine

Discharge

Temperature

Discharge

Temperature

Discharge

Temperature

Discharge

Temperature

Discharge

Temperature

Controller

20000min'1

Controller

Controller

20000min'1

than

Specs.,

(Through-Spindle

Controller:

(Through-Spindle

Controller)

(Through-Spindle

Controller)

(Through-Spindle

Controller:

(Through-Spindle

Controller)

(20000min‘1

Matrix

Standard)

Standard)

Spindle

and

Specs.)

Spindle

Hydraulic

Spindle

Specs.)

Magazine

1.5MPa/Without

3.0MPa/Without

7.0MPa/Without

1.5MPa/Without

3.0MPa/Without

Specs.)

Unit

20000min"1

and

Workpiece

Workpiece

Workpiece

Workpiece

Workpiece

Spindle

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

Specs.)

Gun

Gun

Gun

Gun

Gun

8500kg

2100kg

2700kg

95kg

280kg

160kg

60kg

370kg

420kg

437kg

610kg

660kg

Coolant

and

*

27M-1105B-27-EN

Tank

1

3kg

Fluid

to

Cutting

Add

temperature

Rear

coolant

controller.

Discharge

Temperature

weight

tank

(Through-Spindle

Controller)

listed

above

7.0MPa/Without

installing

when

Workpiece

workpiece

a

Cleaning

cleaning

Gun

gun

or

cutting

677kg

fluid

27

Page 28

Preparations

Required

Manpower

for

installation

for

Installation

2.8

The

following

installation

the

table

This

work

Machine

Tool

Magazine

Spindle

and

Spindle

Spindle

Hydraulic

Coolant

Cooling

Hydraulic

Specs.)

Lubricant

Tank

Required

table

of

the

a51

below.

schedule

Work

Installation

A134/A219

Oil

Unit

(Other

Temperature

(20000min‘1

Unit

Manpower

shows

may

Temperature

the

machine.

change

Item

than

Spindle

for

minimum

Prepare/reserve

for

different

Table

Controller

20000min"1

Controller

and

Specs.)

Installation

required

installation

2.10

manpower,

manpower

Work

Required

Manpower

1

2

1

1

1

necessary

environments

Schedule

time

and

for

and

Required

(hrs/person)

22

4

1

1

4

the

number

installation

machine

Time

of

by

referring

options.

Required

(day/person)

3

1

1

1

1

days

Day

for

to

Operation

Checks

After

Installation

1

4

1

28

27M-1

105B-28-EN

Page 29

Inspection

Prior

Installation

to

Preparations

and

Precautions

Installation

for

During

Installation

2.9

previous

The

inspection

This

section

checked

thoroughly

2.9.1

Confirm

2.9.2

A

the

Inspect

•

•

Check

Unassisted

Inspection

Installation

“Safety”

general.

in

specifically

when

performing

and

observe

Inspection

following

any

for

attachments

all

Handling

Lifting

Installation

to

safety

Read

precautions

chapter

Read

describes

installation.

the

Prior

describes

“Safety”

the

safety

PriortoInstallation

prior

to

points

machine

Heavy

of

and

installation

damage.

accessory

Components

safety

chapter

precautions

and

to

work:

units

and

precautions

thoroughly

for

understand

the

safety.

shipping

ensure

with

Precautions

machine

for

to

prior

installation

section

this

operation,

installation.

as

and

packing

and

well

During

as

“Safety”

the

check

maintenance

needs

what

precautions

list.

to

and

be

I

I

I

*

a

c

.2

2

8.

2

o.

CM

Avoid

lifting

persons

stacker,

B

The

components

damage

following

according

pallet

Lifting

breakage

to

points:

Forklifts

•

Do

not

•

machine

Safety

•

hook

All

•

personnel.

the

Use

•

specialized

Use

•

Confirm

•

center

keeping

heavy

of

trolley

a

with

rope

of

being

components

the

must

attempt

whileitis

helmets

and

crane

weight

the

gravity,

of

weight

the

machine

circumstances.

to

the

or

chain

Crane

during

lost,

and

always

to

enter

being

shoes

and

linking

within

tools

of

attach

as

components

block,

the

them

may

and

operated

be

area

the

transferred.

must

tasks

range

the

where

component

the

wires

stable

by

Use

depending

lifting

of

falling.

required

prescribed.

guaranteed

as

The

result

by

qualified

under

worn

be

its

rated

of

to

possible.

person

one

mechanical

on

the

falling

serious

in

lifted

all

at

crane

capacity.

be

lifted.

to

components

personnel

times.

carry

heavy

the

for

alone.

Lift

equipment

requirements.

can

heavy

of

injury

machine.

lifting

Then,

the

components

or

only.

Exercise

must

considering

weight

them

such

result

death.

be

of

the

with

as

a

in

may

careful

Pay

extreme

performed

the

presumed

the

component

help

crane,

the

caution

two

of

electric

balance

cause

attention

for

by

only

position

and

more

or

forklift

heavy

of

irreparable

the

to

lifted

the

qualified

the

of

slowly,

lift

27M-1

Clearly

•

105B-29-EN

indicate

off-limit

zones

and

keep

unauthorized

all

personnel

from

entering

these

areas.

29

Page 30

Preparations

Inspection

PriortoInstallation

Installation

for

and

Precautions

During

Installation

C

Forklift

using

When

or

overturning

Safety

•

Forklifts

•

Use

•

Widen

•

convenient

•

Do

of

When

•

2.9.3

When

following

workingathigh

Safety

•

Lifting

a

helmets

the

the

attempt

not

the

forklift.

lifting

Working

points:

helmets

forklift

forklift.

the

must

forklift

forks

a

a

carry

to

and

always

within

height

to

component

and

heavy

Pay

shoes

be

the

much

as

as

possible.

balanceanun-balanced

Elevated

at

locations,

shoes

components,

careful

must

operated

range

as

a

with

falling

must

there

attentiontothe

be

worn

by

its

of

possible

forklift,

all

at

qualified

capacity.

rated

to

load

stay

allow

out

Locations

can

resultinserious

worn

be

at

all

is

the

following

times.

personnel

weight

the

extra

with

the

area

of

times.

danger

points:

only.

personnel

for

injury.

of

be

to

which

the

Pay

falling

load

raisedtobe

riding

entrance

careful

on

the

is

attention

the

from

stable

opposite

prohibited.

at

to

forks

as

side

the

Use

•

other.

•

Extreme

positions

Use

•

2.9.4

When

working

catching

worn

at

2.9.5

When

working

the

machine

between

•

Confirm

warning

stable

a

safety

Working

clothing

all

times.

Working

moving

steps

shouldbetaken

care

performing

when

rope

in

or

low

protruding

on

combination,

in

may

resultindeath

parts.

the

location

starting

when

or

a

stepladder.

when

in

Confined

confined

Groups

in

careful

Pay

and

to

Do

avoid

to

using

tasks

performing

Spaces

spaces,

machine

lack

tasks

operate

parts.

communication

of

duetoaccidents

attentiontothe

being

the

stand

not

slippingonoily

both

hands

tasksonthe

care

take

Proper

following

performed

machine.

pail,

on

a

or

cans

surfaces,

freely.

splashguard.

striking

avoid

to

attire,

work

when

a

turning

suchaselectric

points:

other

by

personnel

boxes

or

etc.

your

safety

ON

shock,

and

head,

helmet

the

and

stacked

ensure

shoulders

and

power

main

falling,

or

giveaclearly

on

top

stable

or

shoes

or

being

each

of

working

arms,

or

be

must

operating

caught

audible

30

Display

•

power

clear

switch

work

and

description

the

main

warnings

operation

and

panel

signs

etc.

so

in

that

front

the

of

the

content

crane

of

operation

can

work

panel,

understood.

be

105B-30-EN

27M-1

the

main

Page 31

Inspection

Preparations

PriortoInstallation

and

Precautions

Installation

for

Installation

During

2.9.6

A

WARNING

Work

-

-

Requiring

-Some

installation

adequate

OFF

Turn

ON.

power

Perform

person.

Machine

procedures

precautions

power

the

“Lockout/Tagout”

are

supply

Operation

can

only

takenatall

except

for

prevent

to

preformed

be

times.

some

accidental

inspections

operation

by

that

moving

must

of

the

machine.

the

performed

be

machine

by

Ensure

the

with

another

u

§

i

a

«

B

CO

to

S>

Q.

CM

27M-1

105B-31-EN

31

Page 32

Main

Main

Machine

Machine

Installation

Transportation

and

Set-Up

3

3.1

Confirm

•

Inspect

Check

•

A

WARNING

Rear

(Tool

Magazine

Main

Main

the

following

for

all

Upper

Rope,

Side)

Machine

Machine

points

any

machine

attachments

the

Keep

-

no

higher

Lift

-

Prevent

-

Do

-

All

-

times,

impact

remove

not

procedures

ensure

to

Installation

Transportation

installation

to

prior

damage.

and

accessory

machine

than

with

the

are

operator

Rear

(Operator

level.

necessary.

nearby

shipping

be

to

Upper

Lifting

work:

units

with

objects.

prior

jig

performed

safety.

Rope

Door

Side)

Bar

Set-Up

and

the

shipping

installationofthe

to

pairs,

in

and

packing

and

machine.

communication

clear

check

list.

maintained

all

at

Front

Rope

Center

Socket

(S'

II

Trough

Cover

Head

Rope

Rear

Upper

Upper

Rear

(Operator

Door

Rope

Side)

Rear

(Tool

Magazine

Rope

Side)

4

il

A

w

Rear

.Shackle

Lifting

Rope

Bar

II

\

*

i

i

JO

o

\

\

Bed

Cap

Screws

Lifting

Jo

Plate

32

Figure

3.1

Lifting

of

Main

Machine

27M-1

05B-32-EN

1

Page 33

Parts/Tools

To

Be

Prepared

(Lifting/Transportation):

Name

For

Tool

Main

Magazine

Part

Main

Machine

Machine

Transportation

A40/A60/A99

No.

Installation

Set-Up

and

Q'ty

Front

Rope

Rear

Rope

Upper

Rear

Rear

Upper

Lifting

Plate

Socket

Head

Washer

Shackle

Lifting

Bar

Parts/Tools

Rope

Front

Rear

Rope

Upper

Rear

Upper

Rear

Lifting

Plate

Rope

Rope

Cap

To

Rope

Rope

(Operator

(Tool

Screw

Be

Prepared

(Operator

(Tool

Door

Side)

Magazine

Side)

(Lifting/Transportation):

Name

Side)

Door

Magazine

Side)

For

Tool

21M74B705=1

21M74A702

T13M-0734E

T13M-0272E

T27M74AA701

Z271B1114130

Z275A11

Z259B7240000

T13M-0269D

Magazine

21M74B705=1

21

T13M-0272E

T13M-0272E

T27M74AA701

01400

A134/A219

Part

No.

M74A702

QP

2

1

1

1

2

2

1

1

Q'ty

1

2

1

1

1

§

1

to

c

IE

3

c

to

co

Socket

Head

Washer

Shackle

Lifting

Bar

Parts/Tools

Leveling

Leveling

Flat

Protective

Shaft

Shaft

Coil

Washer

Adjuster

Base

Bolt

Point

(only

Holder

Spring

(only

Pad

Set

Cap

To

Screw

Metal

Tool

(only

(only

Tool

(only

Screw

Be

Prepared

Magazine

Tool

Tool

Magazine

Magazine

Tool

(Installation)

Name

A99)

Magazine

A99)

Magazine

A99)

A99)

A99)

Z271B1114130

Z275A1101400

Z259B7240000

T

1

3M-0269D

No.

Part

13M30B209

1

3M30B424

Z272A1112020

13M30B703=1

27M30C2021

Z392C1

Z392F1

Z275A1

Z392O1916130

800001

840060

102000

2

2

1

1

Q'ty

3

3

3

3

1

1

1

1

1

Plate

27M-1

(only

Tool

1

05B-33-EN

Magazine

A99)

27M30C2022

2

33

Page 34

Main

Main

Machine

Machine

Installation

Transportation

and

Set-Up

3.1.1

Main

Machine

Main

Dd

1

2)

3)

4)

5)

6)

7)

8)

9)

and

Lifting

Machine

Figure

Remove

)

Remove

Secure

cap

head

Mount

the

Lift

main

the

the

Insert

side.

Mount

plate.

lifting

Mount

Place

the

boltismountedoneach

foundation.

Set-Up

Lifting

3.1,

Figure

top

the

center

the

lifting

the

screws

ropes

the

assembled

machine.

front

the

front

rear

two

the

three

cover.

to

rope

rope

leveling

3.2,

trough

plate

and

the

lifting

ropes

Set-Up

and

Figure

cover.

to

the

washers.

lifting

equipment

from

the

onto

the

to

bases

of

3.3

main

as

bar

top

shackle

the

bedonthe

(

Q=

the

three

Procedure

machine

shown

cover

using

and

in

a

into

rear

Figure

machine

(bed)

Figure

crane,

the

secure

side

3.8)

support

the

with

.

3.1

move

and

machining

the

shackle

machine.

of

which

in

points

socket

two

it

chamber

to

leveling

a

on

near

the

the

10)

11)

This

Next,

Removal”).

the

Lift

3.2.

Confirm

30mm~35mm

completes

remove

machine

the

height

(

the

the

carefully

Id

main

lifting

using

between

Figure

machine

2.13).

equipment

a

crane

the

lifting

floor

and

(Id

and

and

set-up

place

the

procedure.

“3.1.2

as

it

main

Lifting

shown

machine

Equipment

Figure

in

is

34

27M-1

105B-34-EN

Page 35

Main

Main

Machine

Machine

Transportation

Installation

Set-Up

and

Support

in

o

n

n

Xt-

n

Point

I

470

7///////////////////////////y

4

////////////////,

+

1595

Y//S/////S//////////////////////*

+

.+

+

++

485

!

I

j

|

S\

t

Support

;

Point

Support

o

rx

O

Point

in

Ch

o

CN

n

rn

oo

§

1

B

£

•g

CD

.E

CD

CO

27M-1105B-35-EN

Figure

3.2

2550

Main

Machine

Installation

35

Page 36

Main

Main

Machine

Machine

Installation

Transportation

and

Set-Up

3.1.2

Lifting

Equipment

Removal

When

1)

perform

reverse

Lift

2)

of

•

•

Mount

3)

•

Mount

4)

completes

This

Next,

Installation”).

Removal

Procedure

the

the

order

assembled

the

main

the

Take

precautions

window

Take

precautions

the

column

of

the

Mount

prevent

the

the

remove

main

main

to

machine.

[2]

the

of

center

gasket

coolant

cover

top

lifting

the

the

shipping

0=

machine

machine

remove

lifting

to

prevent

machining

to

prevent

chamber.

trough

on

leakage.

[1].

equipment

is

placed

lifting

ropes

chamber.

the

3.1,

the

Figure

the

equipment

cover.

center

the

removal

(Q=

jigs

and

from

using

front

rear

trough

“3.2

Figure

on

the

set-up

the

a

rope

rope

procedure.

Shipping

3.3

foundation

procedure

main

machine.

crane,

from

hitting

from

cover

and

specified,

as

step

in

move

and

hitting

Jig

the

parts

the

apply

Removal/Motor

3-8

outside

it

ceiling

inside

silicon

(

in

to

Top

Cover

[1]

Ceiling

Window

[2]

36

Figure

3.3

Lifting

Equipment

Removal

27M-1

1

05B-36-EN

Loading...

Loading...