Page 1

Installation Manual

Installation and Appliance Setup

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

NOTICE: DO NOT discard this manual!

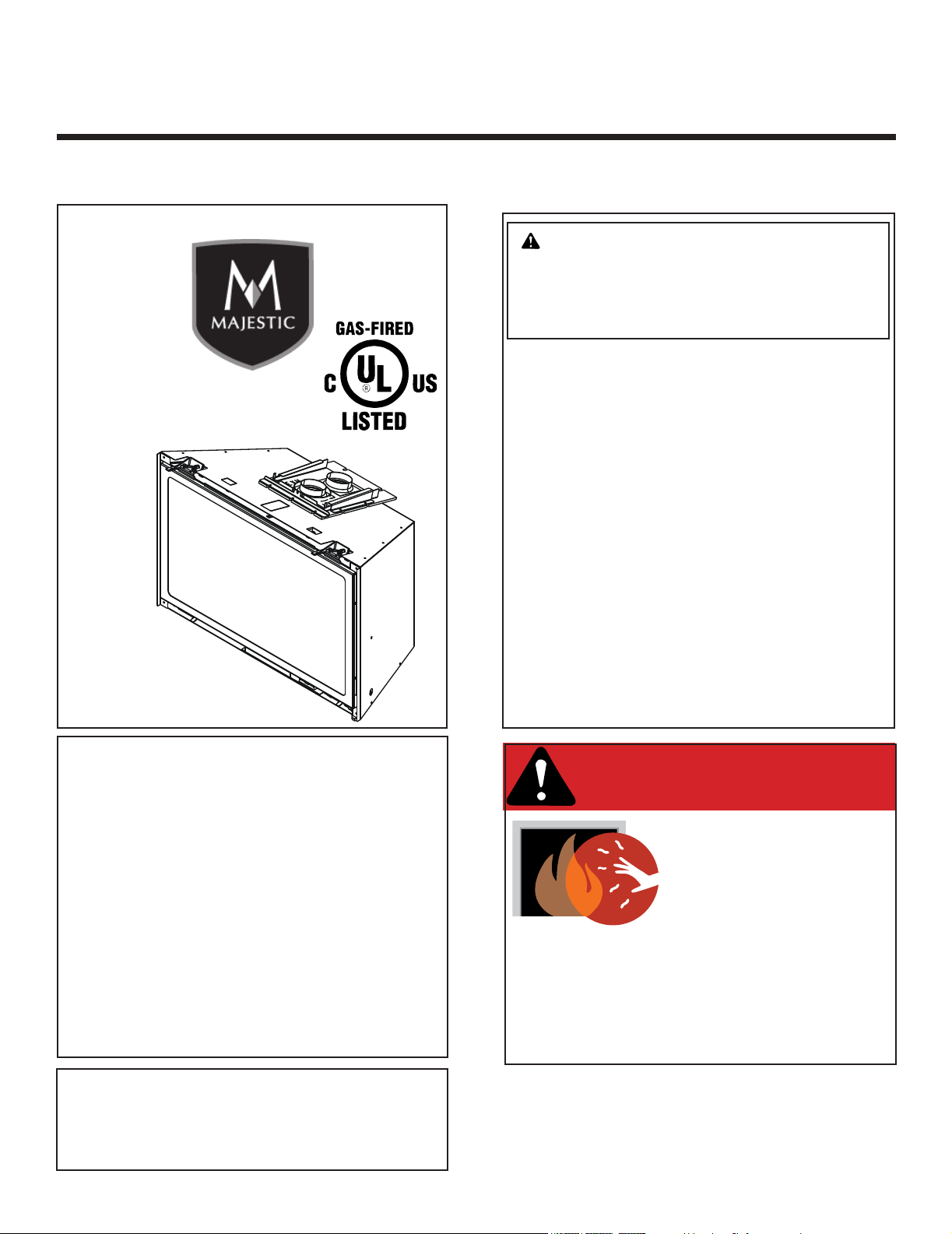

Models:

RUBY25IN

RUBY25IL

RUBY30IN

RUBY30IL

RUBY35IN

RUBY35IL

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

• DO NOT store or use gasoline or other am-

mable vapors and liquids in the vicinity of this

or any other appliance.

• What to do if you smell gas

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch. DO

NOT use any phone in your building.

- Leave the building immediately.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the re department.

• Installation and service must be performed

by a qualied installer, service agency, or the

gas supplier.

This appliance may be installed as an OEM

installation in manufactured home (USA

only) or mobile home and must be installed

in accordance with the manufacturer’s

instructions and the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 in the United States, or the

Standard for Installation in Mobile Homes,

CAN/CSA Z240 MH Series, in Canada.

This appliance is only for use with the type(s)

of gas indicated on the rating plate. This

appliance is not convertible for use with other

gases, unless a certied kit is used.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas tter.

See Table of Contents for location of additional Commonwealth

of Massachusetts requirements.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of

burns from the hot viewing glass is provided

with this appliance and shall be installed for

the protection of children and other at-risk

individuals.

1

Page 2

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Used to address practices not related to personal injury.

Table of Contents

Installation Standard Work Checklist ....................3

1 Product Specic and Important Safety Information

A. Appliance Certication ............................4

B. Glass Specications ..............................4

C. BTU Specications ............................... 4

D. High Altitude Installations ..........................4

E. Non-Combustible Materials Specication. . . . . . . . . . . . . . 4

F. Combustible Materials Specication .................4

G. Electrical Codes .................................4

H. California ...................................... 4

2 Getting Started

A. Design and Installation Considerations ............... 5

B. Good Faith Wall Surface .......................... 7

C. Tools and Supplies Needed ........................7

D. Inspect Appliance and Components ..................7

3 Appliance / Fireplace Requirements and

Clearances

A. Appliance/Decorative Front Dimension Diagrams .......8

B. Minimum Fireplace Opening ......................12

C. Wall Extension .................................14

D. Mantel, Wall Projections, & Hearth Extensions ........16

E. Hearth Extension ...............................17

4 Installation Preparation

A. Cleaning ...................................... 19

B. Flue Damper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

C. Gas Line ......................................19

D. Fireplace Conversion Notice ...................... 19

E. Electrical Outlet Box .............................19

6 Electrical Information

A. General Information .............................27

B. Wiring Requirements ............................28

C. Installation / Service for Fan ......................29

D. Installation / Service for Halogens .................. 30

7 Gas Information

A. Fuel Conversion ................................ 31

B. Gas Pressure ..................................32

C. Gas Connection ................................32

D. High Altitude Installations .........................33

E. Air Shutter Setting .............................. 33

F. Service / Replace Appliance Gas Valve ..............33

8 Finishing

A. Mantel, Wall Projections & Hearth Extensions .........34

B. Hearth Extension ...............................35

9 Appliance Setup

A. Fixed Glass Assembly ...........................37

B. Remove the Shipping Materials ....................38

C. Clean the Appliance .............................38

D. Accessories ...................................38

E. Mystic Embers Placement ........................38

F. Ember Placement ...............................38

G. Install the Log Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 39

H. Install Decorative Front and Surround ...............45

I. Appliance Break-In .............................. 46

J. Heat Management .............................. 46

10 Reference Materials

A. Vent Components ...............................47

B. Accessories ................................... 48

5 Installing Vent Pipe and Appliance

A. Vent Limits .................................... 20

B. Using Vertical Restrictor .......................... 21

C. Venting Components ............................ 22

D. Connecting to SLP ..............................23

E. Connecting Vent Pipe ............................24

F. Placing, Securing and Leveling the Appliance .........25

G. Installing Termination Cap ........................ 26

= Contains updated information.

2

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 3

Installation Standard Work Checklist

ATTENTION INSTALLER:

Follow this Standard Work Checklist

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in this

installation manual.

Customer:

Lot/Address:

Model (circle one): RUBY25IN, RUBY25IL, RUBY30IN,

RUBY30IL, RUBY35IN, RUBY35IL

WARNING! Risk of Fire or Explosion! Failure to install appliance according to these instructions could

lead to a re or explosion.

Appliance Install YES IF NO, WHY?

Verify replace is clean and remove/block open damper/modify

damper for vent pipe clearance (Section 4). ___________________________

Locate multi-purpose tool (Section 2). ___________________________

Appliance is leveled and secured (Section 5.F). ___________________________

Venting/Chimney Section 5

Exhaust and inlet ex vent pipe are properly formed and routed through

existing replace damper. ___________________________

Exhaust and inlet ex vent pipe are properly installed to the correct collars,

sealed and secured to top slide plate and to the termination cap. ___________________________

Vertical restrictors are properly set (if applicable). ___________________________

Exterior roof ashing installed and sealed. ___________________________

Termination cap installed, secured and sealed to top slide plate. ___________________________

Date Installed:

Location of Fireplace:

Installer:

Dealer/Distributor Phone #

Serial #:

Electrical Section 6

Unswitched power (110-120 VAC) provided to the appliance. ___________________________

Switch wires properly installed. ___________________________

Gas Section 7

Proper appliance for fuel type. ___________________________

Was a conversion performed? ___________________________

Leak check performed and inlet pressure veried. ___________________________

Veried proper air shutter setting for installation type. ___________________________

Finishing Section 8

Combustible materials not installed in non-combustible areas. ___________________________

Veried all clearances meet installation manual requirements. ___________________________

Mantels and wall projections comply with installation manual requirements. ___________________________

Appliance Setup Section 9

All packaging and protective materials removed (inside & outside of appliance). ___________________________

Refractories, logs, media and embers installed correctly. ___________________________

Glass assembly and glass seal plate installed and secured. ___________________________

Accessories installed properly. ___________________________

Surround and decorative front properly installed. See instructions shipped

with appliance front. ___________________________

Manual bag and all of its contents are removed from inside/under

the appliance and given to party responsible for use and operation. ___________________________

Fireplace warning plate is attached to the existing woodburning replace. ___________________________

Remote control is programmed, functions veried using remote control ___________________________

instructions.

Started appliance and veried no gas leaks exist. ___________________________

Hearth & Home Technologies recommends the following:

• Photographing the installation and copying this checklist for your le.

• That this checklist remain visible at all times on the appliance until the installation is complete.

Comments: Further description of the issues, who is responsible (Installer/ Builder/ Other Trades, etc) and corrective

action needed _____________________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

Comments Communicated to party responsible ____________________ by ______________________on ___________

= Contains updated information.

(Builder / Gen. Contractor/) (Installer) (Date)

2542-982B 5/19

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

3

Page 4

1

Product Specic and Important Safety Information

A. Appliance Certication

MODELS: RUBY25IN, RUBY25IL, RUBY30IN,

RUBY30IL, RUBY35IN, RUBY35IL

LABORATORY: Underwriters Laboratories, Inc. (UL)

TYPE: Direct Vent Heater

STANDARD: ANSI Z21.88-2017 CSA 2.33-2017

This product is listed to ANSI standards for “Vented Gas

Fireplace Heaters” and applicable sections of “Gas Burn-

ing Heating Appliances for Manufactured Homes and

Recreational Vehicles”, and “Gas Fired Appliances for

Use at High Altitudes”.

Majestic gas inserts are designed for installations into solid

fuel masonry or factory built replaces that have been installed in accordance with the National, Provincial, State

and local building codes. Fireplaces are to be constructed

of non-combustible materials and, in the absence of local

or regional codes, meet criteria of NFPA 211. No additional

outside air source is required.

NOTICE: This installation must conform with local codes.

In the absence of local codes you must comply with the

National Fuel Gas Code, ANSI Z223.1-latest edition in

the U.S.A. and the CAN/CGA B149 Installation Codes in

Canada.

NOT INTENDED FOR USE AS A PRIMARY HEAT SOURCE.

This appliance is tested and approved as either supplemen-

tal room heat or as a decorative appliance. It should not be

factored as primary heat in residential heating calculations.

B. Glass Specications

This appliance is equipped with 5 mm ceramic glass. Replace glass only with 5 mm ceramic glass. Please contact

your dealer for replacement glass.

C. BTU Specications

Models

(U.S. or Canada)

RUBY25IN (NG) (0-2000 FT) 27,000 18,900 40

RUBY25IL

(Propane)

RUBY30IN (NG) (0-2000 FT) 32,700 22,890 35

RUBY30IL

(Propane)

RUBY35IN (NG) (0-2000 FT) 35,000 24,500 33

RUBY35IL

(Propane)

(0-2000 FT) 25,000 17,500 53

(0-2000 FT) 32,000 22,400 51

(0-2000 FT) 35,000 24,500 50

Maximum

Input

BTU/h

Minimum

Input

BTU/h

Orice

Size

(DMS)

D. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced,

these rules do not apply. Check with your local gas utility

or authorities having jurisdiction.

When installing above 2000 feet elevation:

• In the USA: Reduce input rate 4% for each 1000 feet

above 2000 feet.

• In CANADA: Input ratings are certied without a eduction

of input rate for elevations up to 4500 feet (1370 m)

above sea level. Please consult provincial and/or

local authorities having jurisdiction for installations at

elevations above 4500 feet (1370 m).

Check with your local gas utility to determine proper

orice size.

E. Non-Combustible Materials Specication

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in

a Vertical Tube Furnace at 750 ºC shall be considered

non-combustible materials.

F. Combustible Materials Specication

Materials made of or surfaced with wood, compressed pa-

per, plant bers, plastics, or other material that can ignite

and burn, whether ame proofed or not, or plastered or

unplastered shall be considered combustible materials.

G. Electrical Codes

NOTICE: This appliance must be electrically wired

and grounded in accordance with local codes or, in the

absence of local codes, with National Electric Code

ANSI/NFPA 70-latest edition or the Canadian Electric

Code CSA C22.1.

• A 110-120 VAC circuit for this product must be pro-

tected with ground-fault circuit-interrupter protection,

in compliance with the applicable electrical codes,

when it is installed in locations such as in bathrooms

or near sinks.

H. California

WARNING: This product and the fuels used to

operate this product (liquid propane or natural

gas), and the products of combustion of such fuels, can

expose you to chemicals including benzene, which is

known to the State of California to cause cancer and

reproductive harm. For more information go to: www.

P65Warnings.ca.gov.

4

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 5

2

Getting Started

A. Design and Installation Considerations

Majestic gas inserts are designed for installations into

solid fuel masonry or UL127 listed factory built replaces.

No additional outside air source is required.

Installation MUST comply with local, regional, state and na-

tional codes and regulations. Consult insurance carrier, local

building inspector, re ofcials or authorities having jurisdiction over restrictions, installation inspection and permits.

Prior to installing the gas insert:

• Ensure chimney is constructed of non-combustible

materials.

• Ensure chimney is clean and in good working order.

• Ensure that all chimney cleanouts t properly to prevent

air leakage into chimney.

• Ensure combustible mantel and surround clearances

comply with insert requirements.

• Ensure all joints are properly engaged and the chimney

is properly secured.

• Determine minimum replace size. See Section 3.A and

3.B.

• Determine gas supply piping requirements.

• Determine electrical wiring requirements.

• Determine nishing details.

• Determine whether optional accessories—devices such

as a wall switch or remote control—are desired.

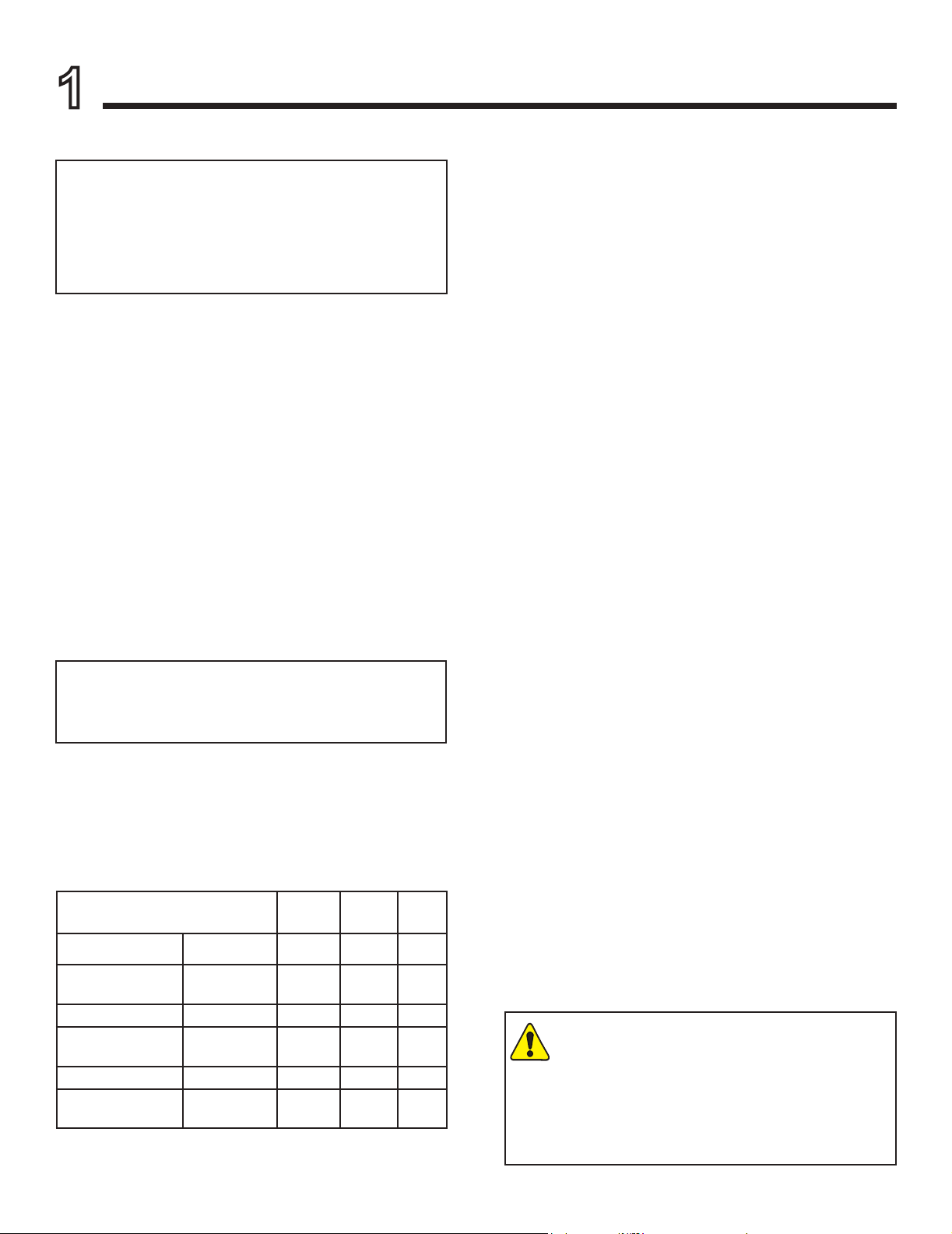

Multi-Purpose Tool

• See Figure 2.1 for multi-purpose tool functions and

features.

• See Figure 2.2 for multi-purpose tool shipping location.

• See Figure 2.3 for multi-purpose tool storage location

options.

GLASS CLIPS

DISENGAGE

SLIDE PLATE

ENGAGE

SLIDE PLATE

GAS SHUT-OFF

Figure 2.1 Multi-Purpose Tool

Installation and service of this appliance should be performed by

qualied personnel. Hearth & Home Technologies recommends

HHT Factory Trained or NFI certied professionals.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. For

assistance or additional information, consult a qualied

service technician, service agency or your dealer.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

5

Page 6

Multi-Purpose Tool - Shipping Location

MULTI-PURPOSE

TOOL SHIPPED ZIPTIED IN THIS AREA OF

THE APPLIANCE

Figure 2.2 Multi-Purpose Tool shipping Location

Multi-Purpose Tool - Storage Options

OPTION A

Multi-purpose tool can be

stored behind the appliance

front.

MULTI-PURPOSE TOOL

NOTE: This is not an option for

all Inside Fit (INFIT) fronts.

OPTION B

Multi-purpose tool can be

stored behind the surround.

• Remove multi-purpose tool by cutting and discarding

zip-tie.

• See Figure 2.3 for multi-purpose tool storage.

• See Figure 2.1 for multi-purpose tool features / functions.

OPTION C

Multi-purpose tool can be stored in appliance manual

bag.

Figure 2.3 Multi-Purpose Tool Storage Options

DO NOT store appliance manual bag in or around

the appliance.

6

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 7

B. Good Faith Wall Surface

MEASUREME NTS FROM TOP

OF THE SUR ROUND OPENING

CEILING

APPLIANCE SURROU ND

SURROUND

OPENING

18 IN.

22 IN.

16 IN.

12 IN.

24 IN.

28 IN.

34 IN.

40 IN.

46 IN.

52 IN.

151 ºF

138 ºF

135 ºF

127 ºF

125 ºF

120 ºF

115 ºF

110 ºF

108 ºF

106 ºF

Figure 2.4 Good Faith Wall Surface Temperatures Above Appliance

If installing a television (TV) above the appliance, see

Section 3 of the appliance Owner’s Manual.

NOTICE: Temperatures listed above are taken with a

temperature measuring probe as prescribed by the test

standard used for appliance certication. Temperatures

on walls or mantels taken with an infrared thermometer

may yield increased temperatures of up to 30 ºF or more

depending on the thermometer settings and material

characteristics being measured. Use appropriate nishing

materials that are able to withstand these conditions. For

additional nishing guidelines, see Section 8.

D. Inspect Appliance and Components

• Carefully remove the appliance and components from

the packaging.

• The vent system components, decorative fronts and

surrounds are shipped in separate packages.

• If packaged separately, the log set must be installed.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benet.

WARNING! Risk of Fire or Explosion! Damaged parts

could impair safe operation. DO NOT install damaged, incomplete or substitute components. Keep appliance dry.

Hearth & Home Technologies disclaims any responsibility for,

and the warranty will be voided by, the following actions:

• Installation and use of any damaged appliance or vent

system component.

• Modication of the appliance or vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a re hazard.

WARNING! Risk of Fire, Explosion or Electric Shock!

DO NOT use this appliance if any part has been under

water. Call a qualied service technician to inspect the

appliance and to replace any part of the control system

and/or gas control which has been under water.

C. Tools and Supplies Needed

Before beginning the installation be sure that the following

tools and building supplies are available.

Tape measure Pliers

Hammer Phillips screwdriver

Voltmeter Electric drill and bits (1/4 in.)

Gloves Safety glasses

Level Reciprocating saw

Manometer Flat blade screwdriver

Stove cement / Aluminum foil tape

3/16 in. Allen wrench (Rear Leveling Legs)

Elongated pressure taps (Recommended)

Noncorrosive leak check solution

Caulking material (300 ºF minimum continuous exposure

rating)

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

7

Page 8

3

Appliance / Fireplace Requirements and Clearances

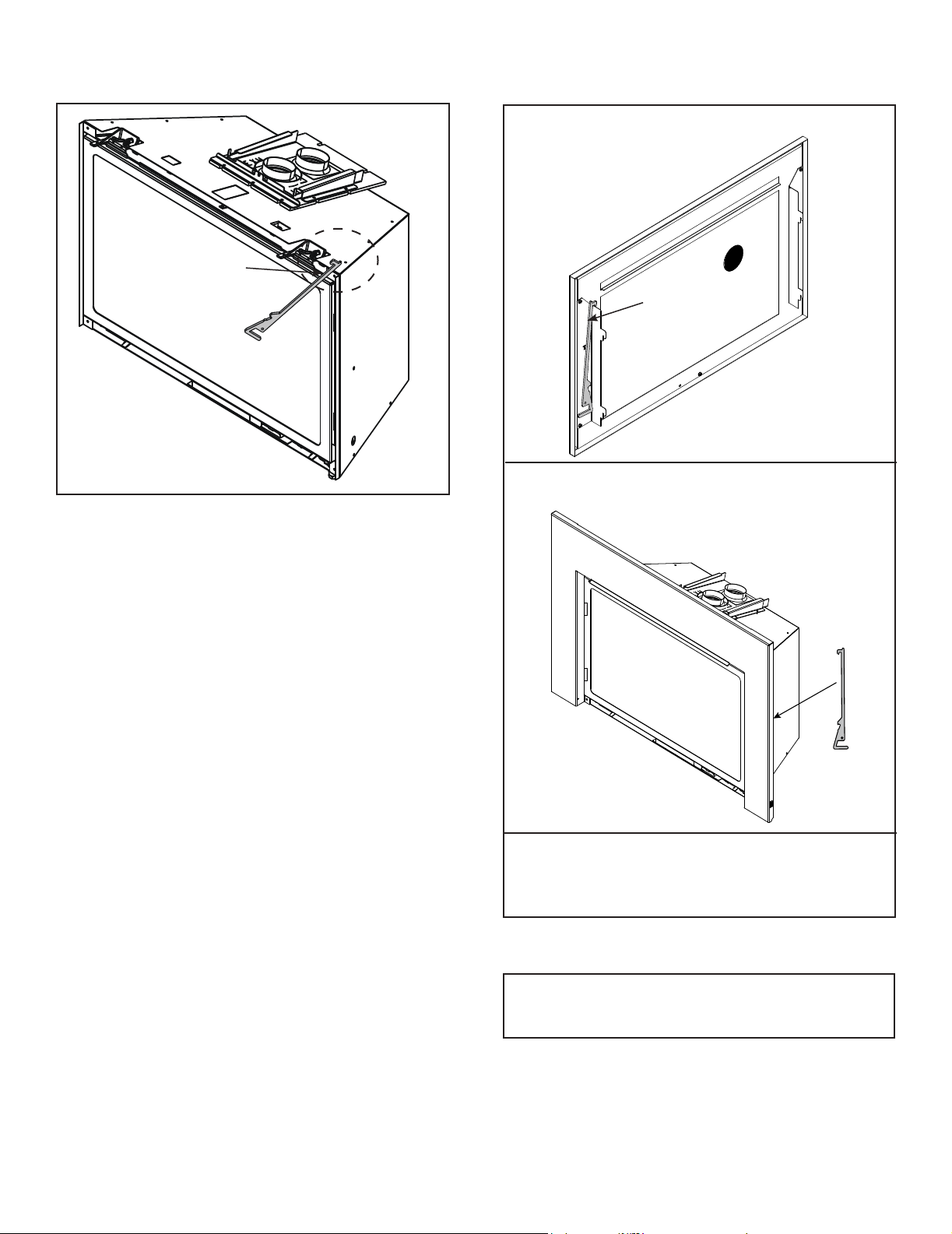

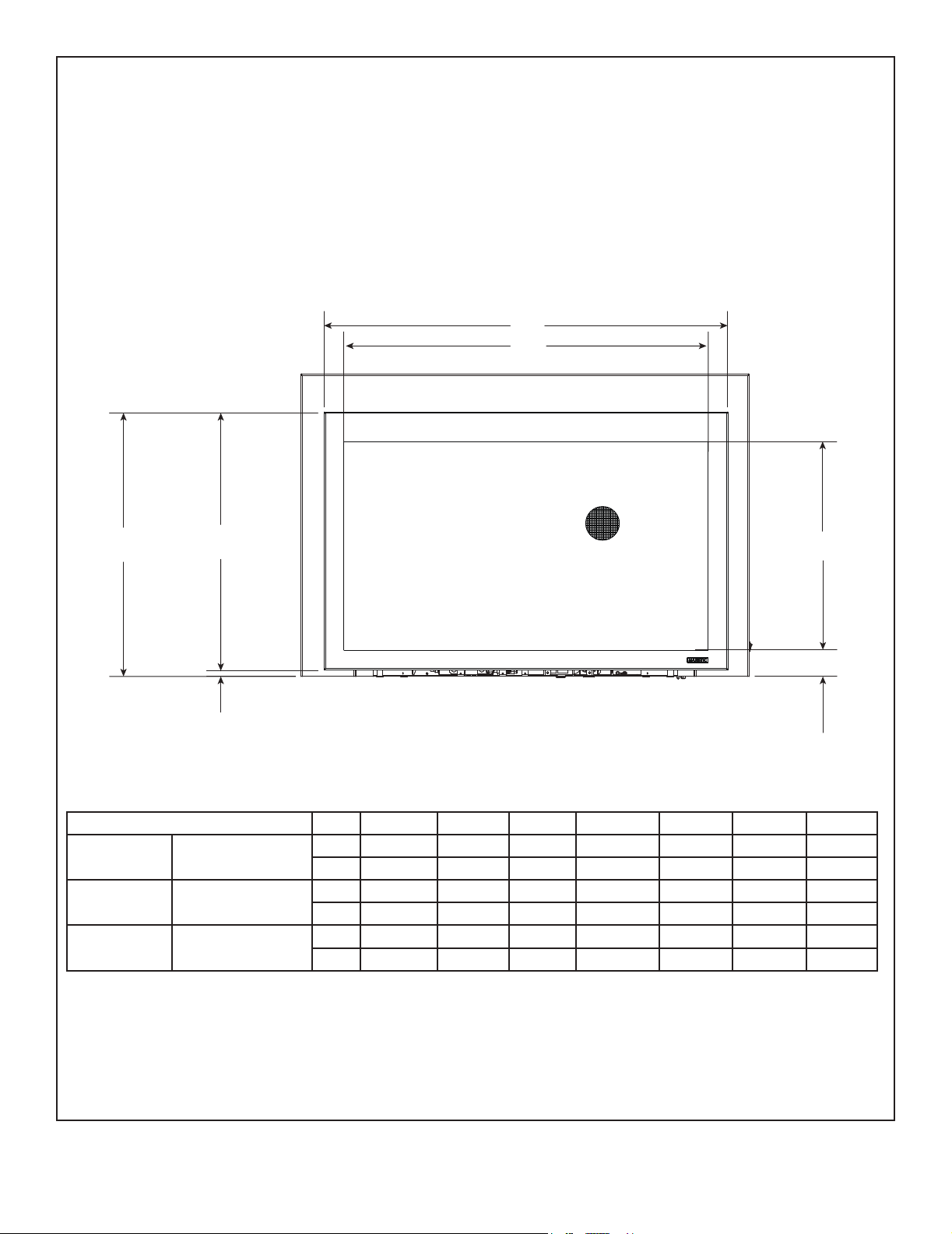

A. Appliance/Decorative Front Dimension Diagrams

Dimensions are actual appliance dimensions. Use for reference only. For addditional clearances refer to Sections 3.D and 3.E.

A

H

N

O

Q

B

TOP VIEW

C

P

G

F

ELECTRICAL

ACCESS

K

L

GAS LINE

ACCESS

M

J

E

LEFT SIDE

MODEL DIMENSIONS

Location

A 14-5/8 372 19-5/8 499 24-5/8 626

B 26-1/8 664 31-1/8 791 36-1/8 918

C 22-1/2 572 27-1/2 699 32-1/2 826

D 12-7/16 316 15-15/16 405 19-3/8 492

E 17-1/16 433 20-3/4 527 24 610

F 16-5/8 422 20-1/8 511 23-5/8 600

G* 14-1/2 368 14-1/2 369 14-1/2 368

H 7-5/16 186 9-13/16 249 12-5/16 313

I 15 381 18-15/16 481 21-7/16 545

25 in. 30 in. 35 in.

IN MM IN MM IN MM

FRONT VIEW

D

R

RIGHT SIDE

MODEL DIMENSIONS

Location

J 5-11/16 144 5-11/16 144 5-11/16 144

K 5-7/8 149 5-7/8 149 5-7/8 149

L 9 229 9 229 9 229

M 8-3/4 222 8-3/4 222 8-3/4 222

N 2-1/8 54 2-1/8 54 2-1/8 54

O 4-1/16 103 4-1/16 103 4-1/16 103

P 5-3/4 146 5-3/4 146 5-3/4 146

Q 8-3/4 222 8-3/4 222 8-3/4 222

R 2-7/16 62 2-7/16 62 2-7/16 62

25 in. 30 in. 35 in.

IN MM IN MM IN MM

I

*Note: Location G is the appliance depth measurement, for installation depth reference Location E on

Figure 3.7.

Figure 3.1 Appliance Dimensions

8

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 9

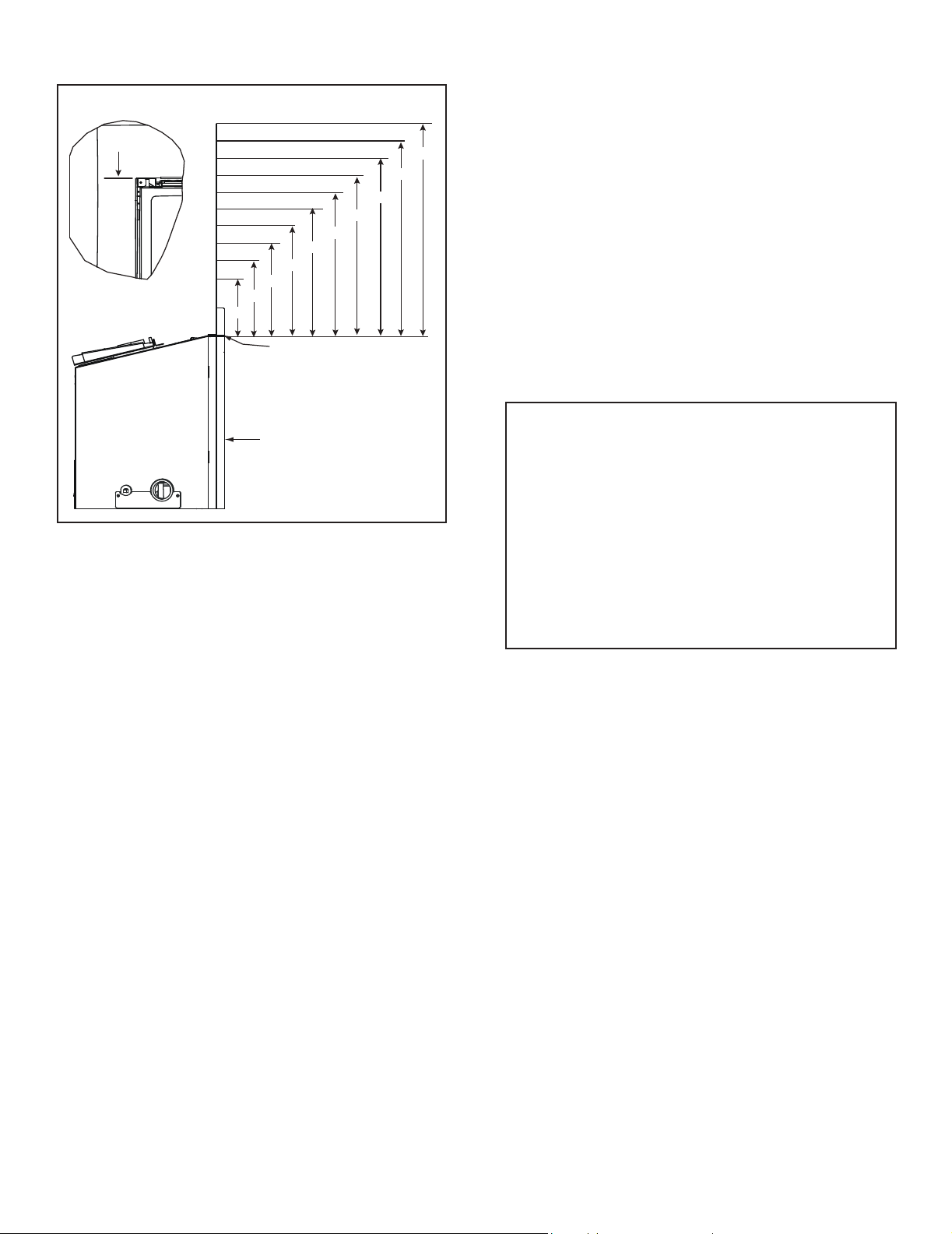

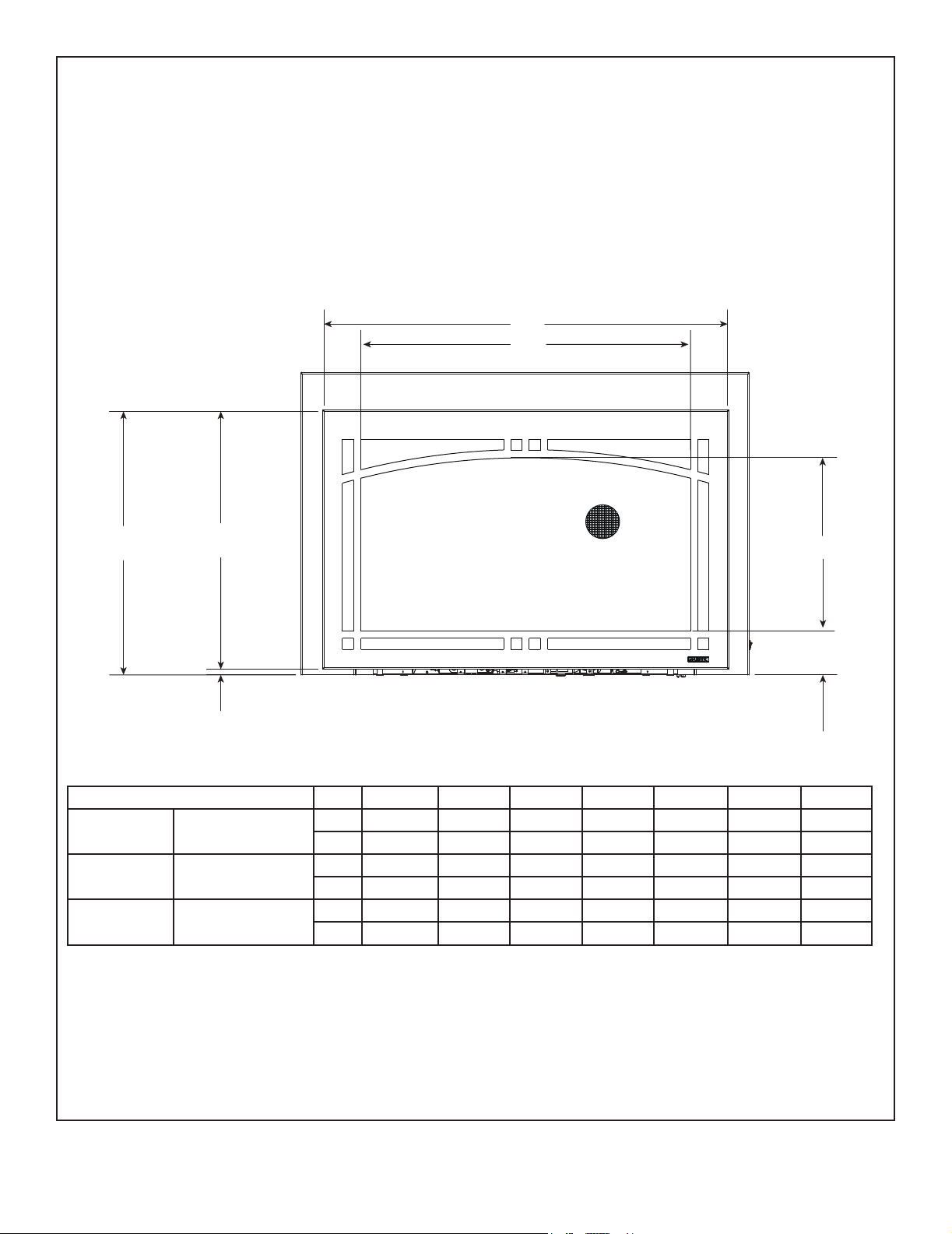

DECORATIVE FRONTS - INSIDE FIT

* NOTICE: 1/2 inch gap must be maintained

or components will overheat.

D

A

E

RUBY25 INFIT-25

RUBY30 INFIT-30

RUBY35 INFIT-35

F

*

G

B

C

A B C D E F G

in. 22-5/8 12-9/16 1-7/8 25-5/8 17 16-1/2 1/2

mm 575 319 48 651 432 420 13

in. 27-5/8 16-1/16 1-7/8 30-5/8 20-1/2 20 1/2

mm 702 408 48 778 521 508 13

in. 32-5/8 19-9/16 1-7/8 35-5/8 24 23-1/2 1/2

mm 829 497 48 905 610 597 13

Figure 3.2 Decorative Front Dimensions - Inside Fit

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

9

Page 10

DECORATIVE FRONTS - CLEAN SCREEN

* NOTICE: 1/2 inch gap must be maintained

or components will overheat.

D

A

E

RUBY25 CSFI25

RUBY30 CSFI30

RUBY35 CSFI35

F

*

G

B

C

A B C D E F G

in. 27-3/8 15-1/8 3-1/2 31 20 19-1/2 1/2

mm 695 384 89 787 508 495 13

in. 32-3/8 18-5/8 3-1/8 36 23-1/2 23 1/2

mm 822 473 79 914 597 584 13

in. 37-3/8 22-1/8 3-1/8 41 27 26-1/2 1/2

mm 949 562 79 1041 686 673 13

Figure 3.3 Decorative Front Dimensions - Clean Screen

10

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 11

DECORATIVE FRONTS - CONTEMPORARY ARCH

* NOTICE: 1/2 inch gap must be maintained

or components will overheat.

D

A

E

RUBY25 CASFI25

RUBY30 CASFI30

RUBY35 CASFI35

F

*

G

B

C

A B C D E F G

in. 24-1/16 12 3-7/8 31 20 19-1/2 1/2

mm 610 305 98 787 508 495 13

in. 29-1/16 15-3/8 3-7/8 36 23-1/2 23 1/2

mm 738 391 98 914 597 584 13

in. 34-1/16 18-7/8 3-7/8 41 27 26-1/2 1/2

mm 865 479 98 1041 686 673 13

Figure 3.4 Decorative Front Dimensions - CONTEMPORARY ARCH

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

11

Page 12

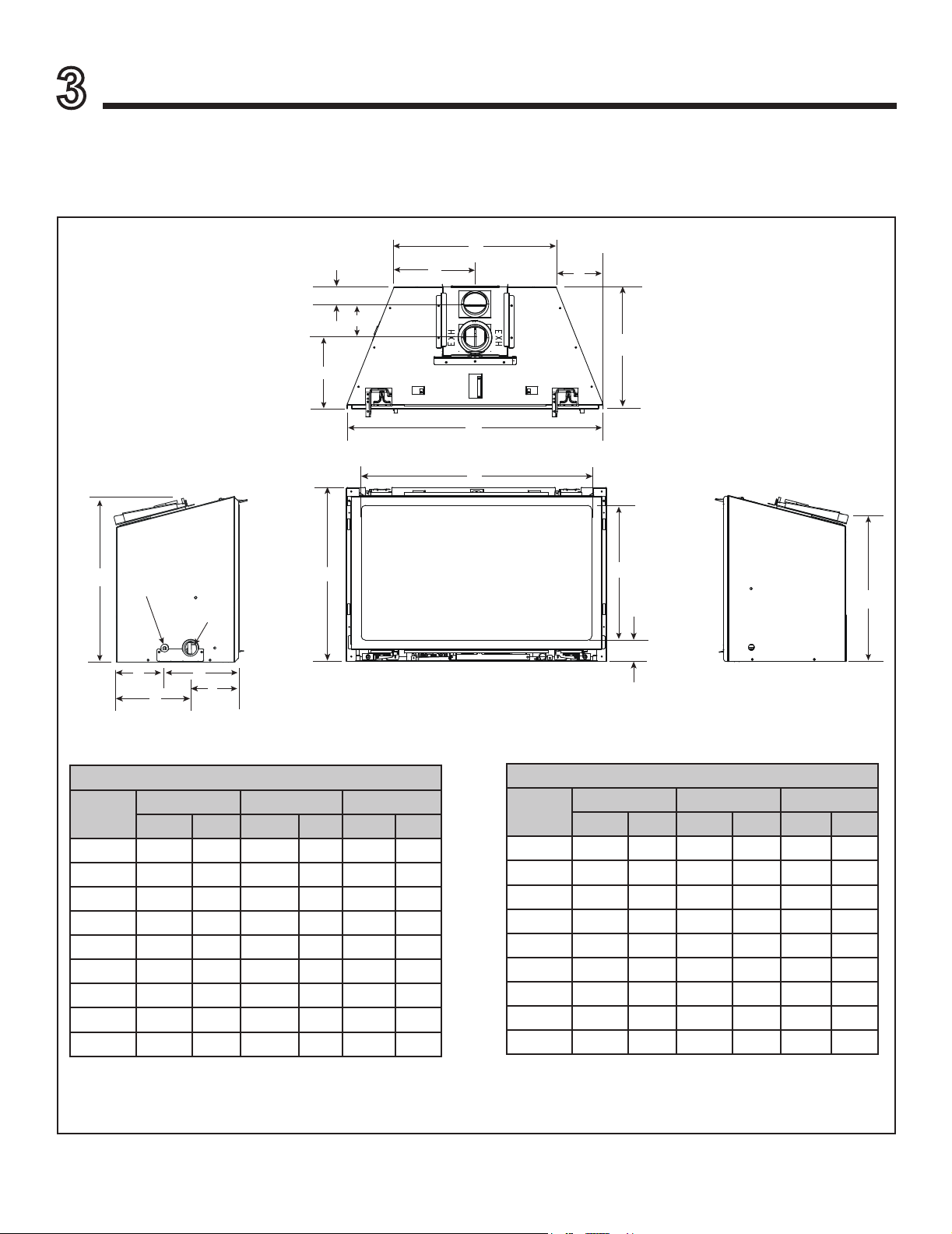

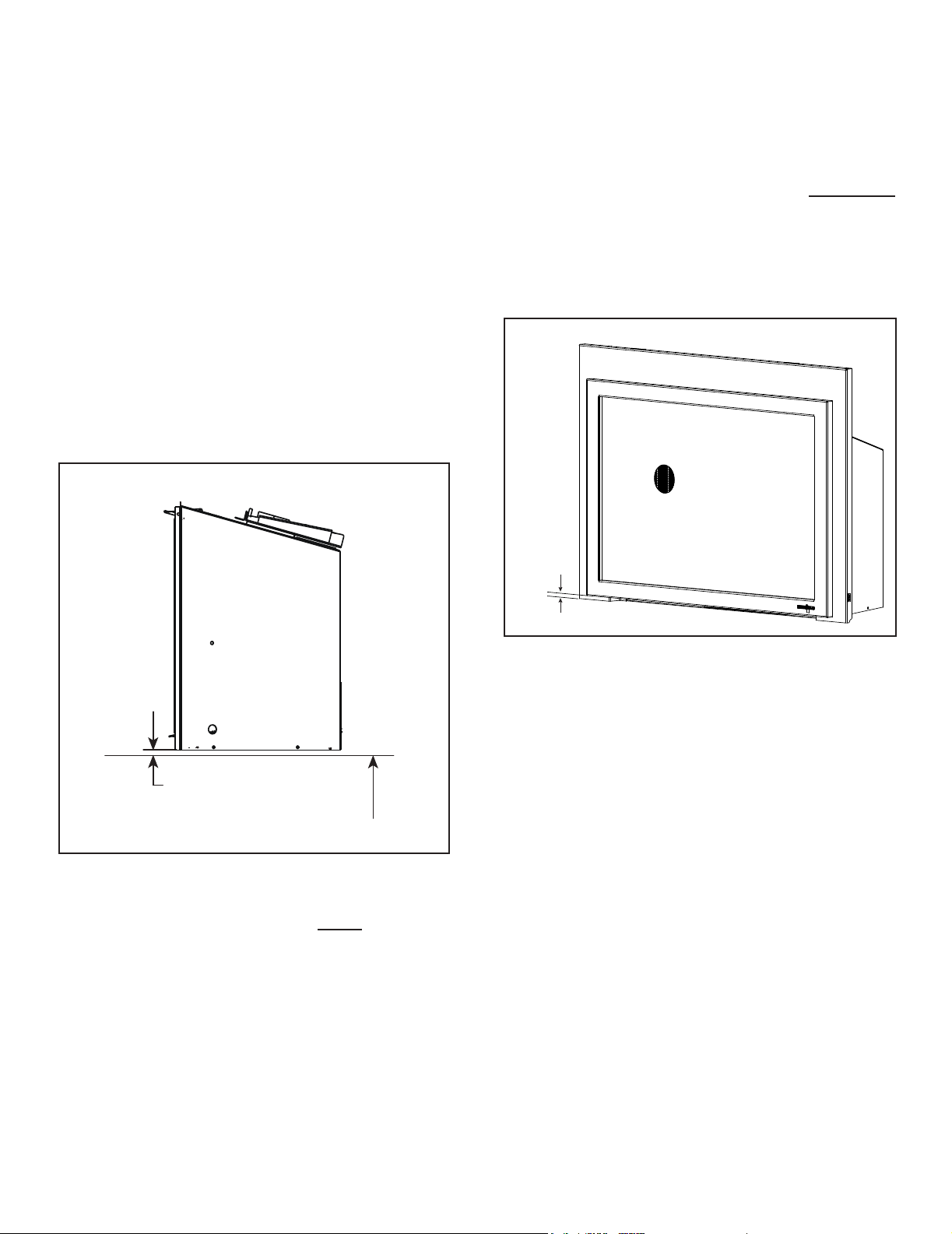

B. Minimum Fireplace Opening

SIDE VIEW

MINIMUM 1/4 IN. REQUIRED

COMBUSTIBLE FLOOR UNDERNEATH APPLIANCE

Minimum replace opening requirements for a standard 3/4

inch deep surround are shown in Figure 3.7. For smaller

openings, a custom surround is available.

WARNING! Risk of Fire or Burns! Provide adequate

clearance around air openings and for service access.

Due to high temperatures, the appliance should be located out of trafc and away from furniture and draperies.

For Installation into a Zero Clearance Wood burning replace:

• The brick (refractory), glass doors, screen rails, screen

mesh and log grates can be removed from a factory

built rebox in order to gain minimum gas insert opening

requirements.

• Any smoke shelves, shields and bafes may be removed

from the factory built rebox if attached with mechanical

fasteners.

• The metal oor of the solid fuel rebox may be removed

to facilitate the installation of the insert.

• Cutting of any sheet metal parts of the replace in which

the gas replace insert is to be installed is prohibited,

except the oor as tested for and as noted above.

• A minimum 1/4 inch gap from the bottom of the appliance

to the metal oor of the solid fuel rebox is REQUIRED.

See side view in Figure 3.5.

• Manufactured gas inserts can be installed as a zero

clearance appliance. See Section 3C for clearance

detail.

Figure 3.5 Solid Fuel Floor Clearance

• The appliance may not be placed directly on the base of

the outer wrap, a 1/4 inch airspace MUST be provided

between the insert and the oor of the outer wrap. Use

the leveling legs to raise the insert a minimum of 1/4 inch.

The original replace may never be returned to solid

fuel in this condition. The sidewalls and top structure

of the rebox may not be altered with the exception of

removable bafes and dampers.

1/2 in.

Figure 3.6 Minimum Required 1/2 in. Gap

NOTICE: 1/2 inch gap must be maintained or components

will overheat.

12

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 13

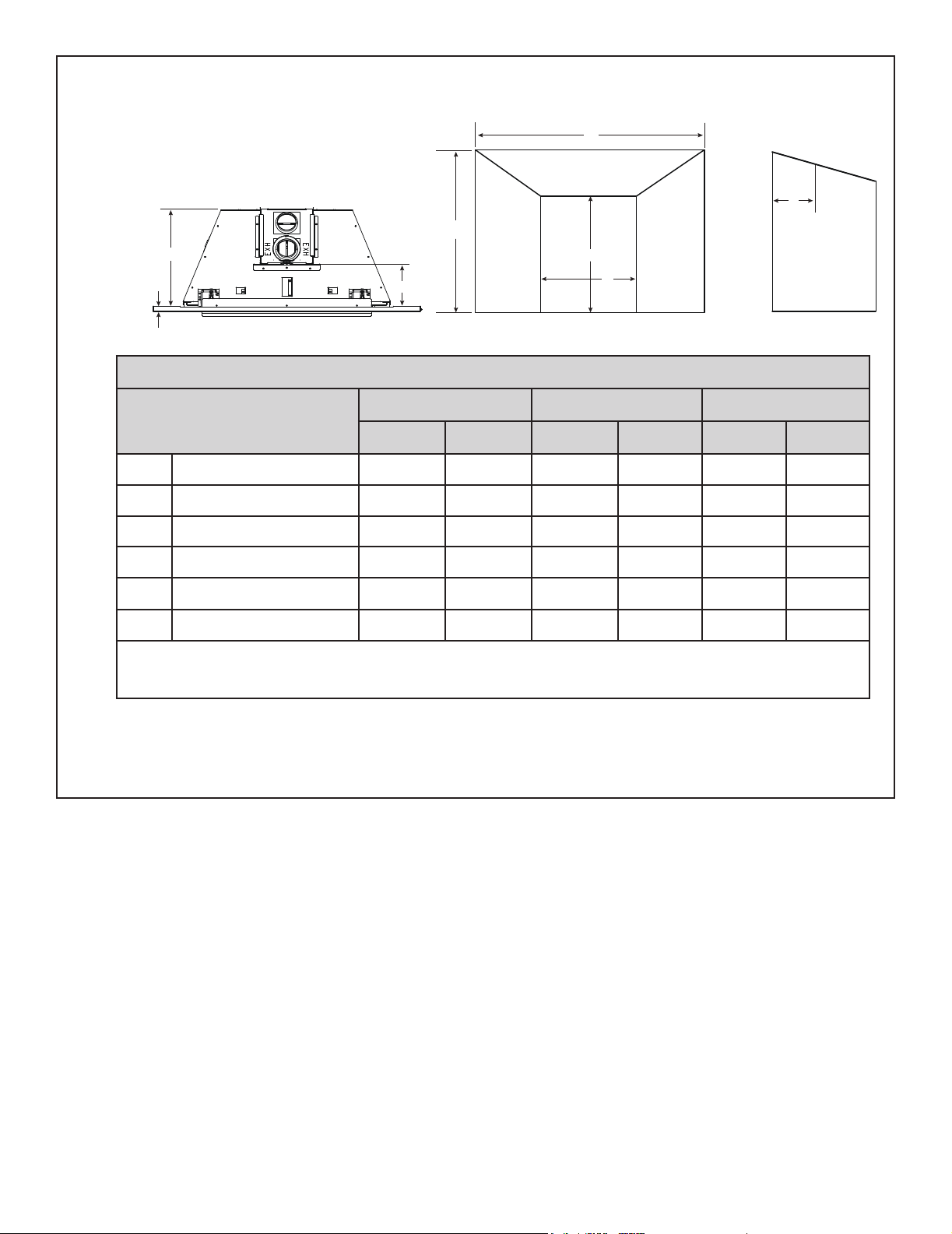

TOP VIEW

E

F

3/4 in.

FRONT VIEW SIDE VIEW

B

F

C

D

A

MINIMUM FIREBOX OPENING

25 inch 30 inch 35 inch

Location

Inches Millimeters Inches Millimeters Inches Millimeters

A Opening Width - Rear 15-1/8 384 20-1/8 5 11 25-1/8 638

B Opening Width - Front 26-5/8 676 31-5/8 803 36-5/8 930

C Opening Height - Front 17-5/16 439 21 533 24-1/4 616

D Opening Height - Rear 15-1/4 387 19-3/16 487 21-11/16 551

E* Unit Opening Depth 15 381 15 381 15 381

F Venting Depth - Front 7-5/8 194 7-5/8 194 7-5/8 194

Note: Dimensions assume 1/4 inch clearance on all sides.

Note: If exhaust collar on insert and replace damper do not line up, add 4 inches (102 mm) to minimum replace

height for bends in vent pipe.

*Unit depth is measured to the back of the surround to give the depth needed for installation.

In addition to these dimensions, also reference Section 3.D and 3.E..

Figure 3.7 Firebox Opening - Standard Surround - 3/4 in.

Custom Surrounds

Custom surrounds are available. See your dealer for information. Standard surrounds are 3/4 inches deep. Custom

surrounds are available up to 3 inches deep. A 3 inch deep surround would reduce the unit opening depth (E*) by 2-1/4

inches (3 in. - 3/4 in. = 2-1/4 in).

On Site Custom Surrounds

On site custom surrounds are available. See your dealer for information. On site custom surrounds are ush and have

no depth. A ush surround would increase the unit opening depth (E*) by 3/4 inch.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

13

Page 14

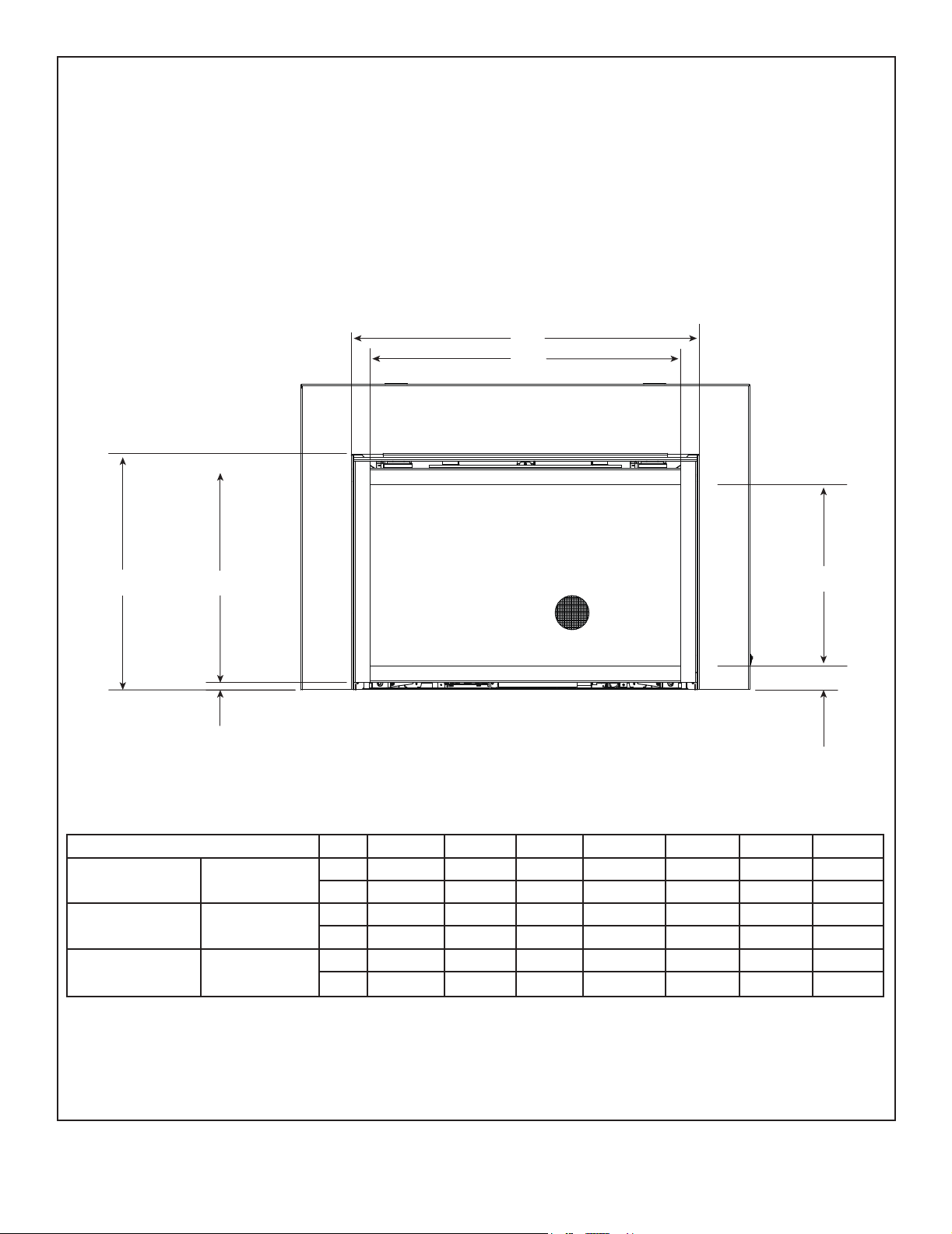

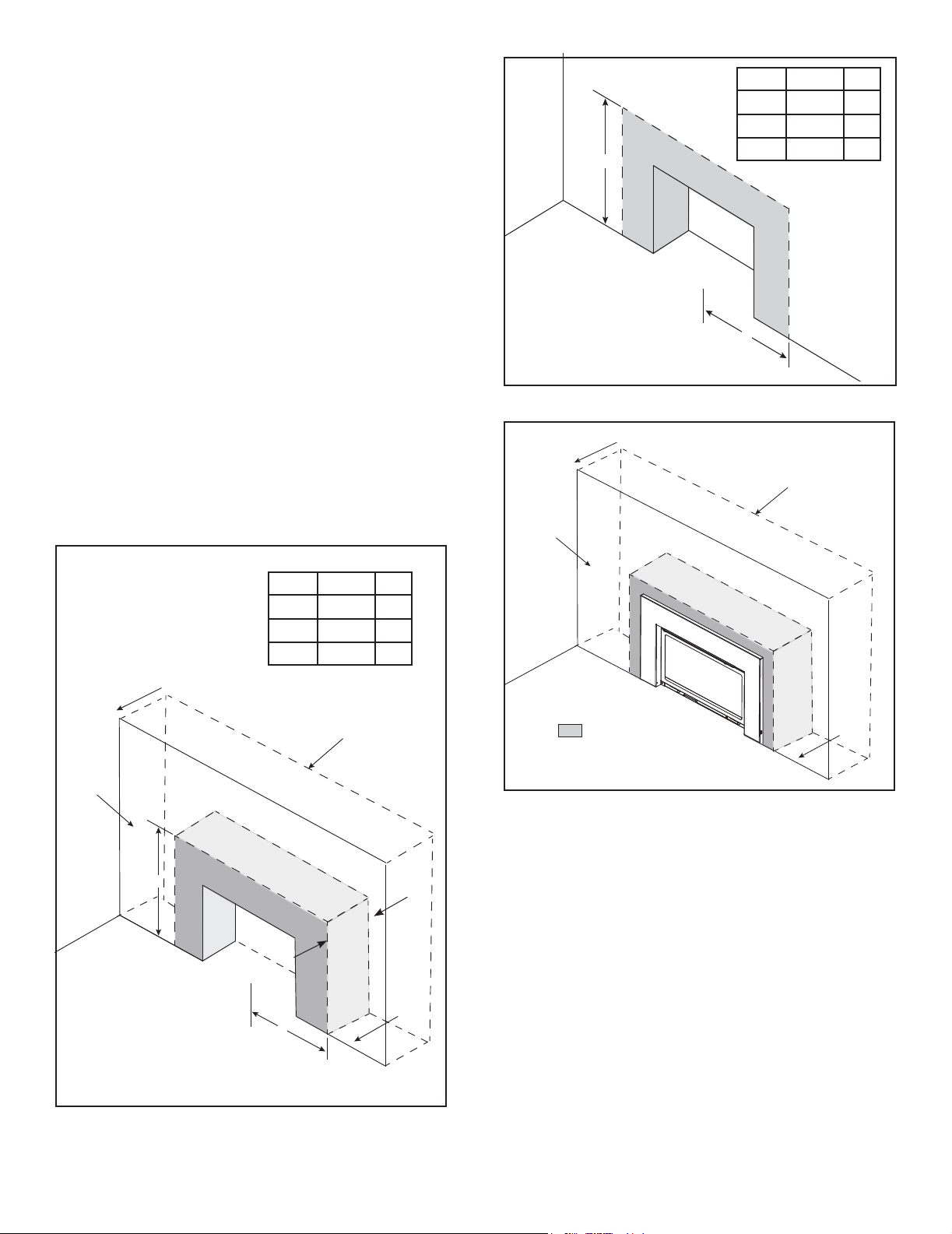

C. Wall Extension

FLOOR

x

Y

NON-COMBUSTIBLE ZONE

C

L

FLOOR

EXISTING MASONRY WALL

NEW WALL

FACE

WALL EXTENSION

NON-COMBUSTIBLE ZONE

FLOOR

x

Y

NON-COMBUSTIBLE ZONE

C

L

EXISTING MASONRY WALL

NEW WALL

FACE

WALL EXTENSION

Surrounds MUST overlap wall extension.

A non-combustible wall extension can be used to cover

an existing masonry surface. Wall extensions are typically

used to improve cosmetics.

WARNING! Risk of Fire! Comply with all minimum clear-

ances to combustibles as specied. Framing or nishing

material closer than the minimums listed must be constructed entirely of noncombustible materials (i.e., steel studs,

concrete board, etc).

Combustible facings must not extend behind the insert

surround. See Section 1.E and 1.F.

Non-Combustible Materials Specication

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750 ºC.

UNIT X Y

25 in. 31 52

30 in. 33-1/2 56

35 in. 36 60

X - Measure from center

of rebox opening.

Y - Measure from the

bottom of the appliance.

Figure 3.9 Non-Combustible Facing Requirement

X - Measure from center

of rebox opening.

Y - Measure from the

bottom of the appliance.

Figure 3.8 Non-Combustible Framing Requirement

14

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

UNIT X Y

25 in. 31 52

30 in. 33-1/2 56

35 in. 36 60

12 in. max.

DEPTH

Figure 3.10 Non-Combustible Framing / Facing Requirement

• Facing and/or nishing materials must not interfere with

air ow through decorative fronts.

• Facing and/or nishing materials must never overhang

into the glass opening.

• Observe all clearances when applying combustible

materials.

• Maximum depth of wall extension is 12 inches. This

may be limited by the ex pipe’s ability to connect to the

starting collar.

• Covering combustible materials with non-combustible

materials does not qualify material as non-combustible.

WARNING! Risk of Fire! DO NOT apply combustible

materials beyond the minimum clearances. Comply with

all minimum clearances to combustibles as specied in

this manual. Overlapping materials could ignite and will

interfere with proper operation of decorative fronts.

Page 15

FACING

STEEL STUD

END VIEW

MASONRY

WALL

STEEL STUD

SIDE VIEW

SEAL

TRANSITION

12 in.

MAXIMUM

APPLIANCE

Painting

If desired nishing includes a painted wall, a high-quality

100% acrylic latex paint with a high-quality latex primer

base coat are recommended around the appliance to limit

discoloration. Oil-based or standard acrylic paints may

be more prone to discoloration due to heat exposure.

Drywall Joint-Crack Prevention and Repair

Drywall joints around the replace will be affected by exposure to elevated temperatures, along with other environmental, structural factors due to new construction, and

methods used to install and nish the drywall. If a crack

does emerge adjacent to the replace, it can be permanently repaired by lling it with a paintable latex caulk,

followed by repainting.

Some movement of the screws used to secure the non-

combustible board to the appliance/surround framing is

expected. If a blemish begins to show over a screw head,

sand the surface to remove the blemish and repaint.

NOTE: Concealed sections of 3 in. ex pipe must

be contained inside existing masonary replace

ue vent or installed into an existing wood burn-

ing vent system.

Figure 3.11 Transition Sealing Detail for Wall Extensions (Side View)

Wall Extension

Wall extension must be sealed to existing masonry wall.

See Figure 3.11. Framing studs may not sit ush against

existing masonry wall. In order to keep heat from escaping behind the wall this transition must be sealed.

• Seal with a high temperature silicone 300 °F.

and / or

• Packing insulation into voids between the masonry wall

and steel studs is acceptable.

Note: Combustible materials may be used to seal wall

extension to existing masonry wall as long as it is outside the non-combustible zone.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

15

Page 16

D. Mantel, Wall Projections, & Hearth

INTERIOR WALL

TOP VIEW

MANTEL LEG OR WALL PROJECTIONS

SURROUND OPENING

∞

18 in.

12 in.

12 in.

1/4 in. GAP

6 in.

6 in.

INTERIOR WALL

TOP VIEW

MANTEL LEG OR

WALL PROJECTIONS

SURROUND OPENING

∞

18 in.

1/4 in. Gap

12 in.

A

6 in.

12 in.

*

C

L

*S EE TA BLE

1 or 2

1/4 in. gap

SURROUND

OPENING

6 in.

12 in.

12 in.

*B

*S EE TABL E

1 or 2

Extensions

WARNING! Risk of Fire! Comply with all minimum clear-

ances to combustibles as specied. Framing or nishing

material closer than the minimums listed must be constructed entirely of noncombustible materials (i.e., steel studs,

concrete board, etc).

Clearance to combustible material under the insert is 1/4

inch (6 mm).

• Use leveling legs to raise insert minimum 1/4 inch (6

mm) above combustible material or outer wrap of factory

built rebox.

Combustible facings must not extend behind the insert

surround. For non-combustible material specications

refer to Section 1.E and 1.F.

Mantel Legs or Wall Projections

Combustible

Mantels or Wall Projections - Non-Combustible

Note: Measurement is taken from top of the surround

opening.

Figure 3.13 Minimum Vertical and Maximum Horizontal

Dimensions- Non-Combustible

Non-Combustible

Figure 3.12 Clearances to Mantel Legs or Wall Projections

(Acceptable on both sides of surround opening)

Unit Size

Surround

Model

A B

MI25-3523 17-15/16 in. 6-1/16 in.

25 in.

MI25-3726 18-15/16 in. 9-1/16 in.

MI25-3928 19-15/16 in. 11-1/16 in.

MI30-4027 20-7/16 in. 6-9/16 in.

30 in.

MI30-4230 21-7/16 in. 9-9/16 in.

MI30-4432 22-7/16 in. 11-9/16 in.

MI35-4229 21-7/16 in. 5-1/16 in.

35 in.

MI35-4432 22-7/16 in. 8-1/16 in.

MI35-4832 24-7/16 in. 8-1/16 in.

Table 1 Mantel Leg or Wall Projection Minimum Dimension

needed when Installing a Standard Surround

Unit Size

25 in.

30 in.

35 in.

Table 2 Mantel Leg or Wall Projection Minimum Dimension

needed when Installing a Custom Surround. Front Model

Determines the Minimum Size of the Custom Surround

Front Model A B

INFIT 14-5/16 in. 1-1/4 in.

CSFI, CASFI 16-1/16 in. 2-1/2 in

INFIT 16-13/16 in. 1-1/4 in.

CSFI, CASFI 18-9/16 in. 2-1/2 in

INFIT 19-5/16 in. 1-1/4 in.

CSFI, CASFI 21-1/16 in. 2-1/2 in

Note: All numbers in Tables 1 and 2 include the 1/4 in. gap on

surround edge.

16

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 17

Mantels - Combustible

Measurement to bottom

of appliance:

= 29-1/4 in . (25")

= 32-3/4 IN. (30")

= 36-1/4 IN. (35")

Measurement

from su rround

opening.

12 in.

12 in.

Figure 3.14 Minimum Vertical and Maximum Horizontal

Dimensions - Combustible

E. Hearth Extension

1/2 in.

Figure 3.16 Minimum Required 1/2 in. Gap to Bottom of Front

• All ooring and hearth material must remian below the

bottom of the surround. See Figure 3.17.

• Combustible ooring may be located in front of the

appliance. Exception - no vinyl / adhesive ooring.

See Figure 3.17.

• 1/2 inch gap under the bottom of the front must be

maintained. See Figure 3.16.

• A minimum 1/4 inch gap from the bottom of the appliance

to the metal oor of the solid fuel rebox is REQUIRED.

See side view in Figure 3.18.

• Combustible flooring underneath the appliance is

acceptable with a 1/4 inch gap. See Figure 3.18.

YES

Flooring & Hearth Material

Flooring & hearth material must remain below the bottom of surround

Figure 3.17 Flooring & Hearth Material

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

SURROUND

SURROUND

NO

Flooring & Hearth Material

17

Page 18

Y

X

NO VINYL /

SIDE VIEW

MINIMUM 1/4 IN. REQUIRED

COMBUSTIBLE FLOOR UNDERNEATH APPLIANCE

ADHESIVE FLOORING

Figure 3.18 Hearth - Combustible Material Exception

Vinyl / Adhesive Flooring - Minimums

Appliance Size Depth (X) Width (Y)

25 in. 16 in 25-3/4 in.

30 in. 16 in 30-3/4 in.

35 in. 16 in 35-3/4 in.

Figure 3.19 Solid Fuel Floor Clearance

18

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 19

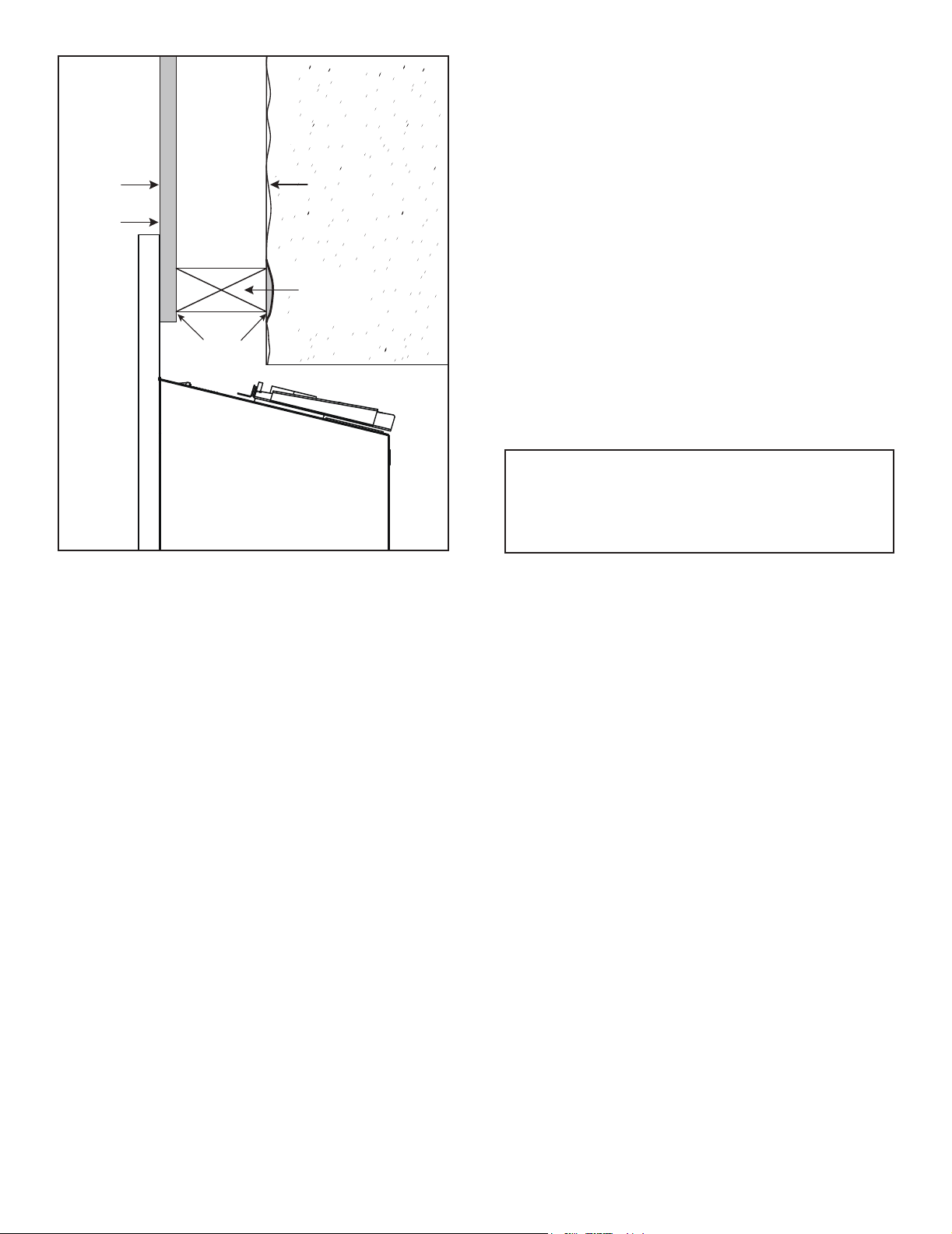

4

ELECTRICAL OUTLET LOCATIONS

MASONRY

MASONRY

APPLIANCE

RECOMMENDED

Installation Preparation

Prepare the existing solid fuel masonry or factory built

non-combustible rebox for installation.

A. Cleaning

Prior to installing the gas insert:

• Ensure that the woodburning replace cavity is clean

and free of ash, soot, and other debris.

B. Flue Damper

Fully lock the solid fuel replace’s ue damper in the open

position, OR completely remove it.

C. Gas Line

Note: If the factory built replace has no gas access hole

provided, an access hole of 1 inch (25 mm) diameter or

less may be drilled through the lower sides or bottom of the

rebox in a proper workmanship - like manner. This access

hole must be plugged with non-combustible insulation after

the gas supply line has been installed.

• Install gas line to the factory provided ex line. See

Figure 4.1.

• Check local codes and gas line sizing requirements

following NFPA54. See Section 7.

• It is recommended that extra length of gas line be

installed within the existing wood burner or masonry

replace to allow removal of the insert for future servicing

needs.

D. Fireplace Conversion Notice

The replace conversion notice is included in the appliance

manual bag. Permanently attach the label with the following warning to the inside lower back of the replace rebox

into which the insert is being installed. Silicone or mechanical fasteners may be required to properly secure the label.

WARNING! Risk of Fire! This replace has been converted for use with a gas replace insert only and cannot

be used for burning wood or solid fuels unless all original

parts have been replaced, and the replace re-approved

by the authority having jurisdiction.

E. Electrical Outlet Box

An outlet box may be installed in a bottom back corner of

the existing solid fuel masonry or factory built replace

to power the appliance. Each unit ships standard with a

cord assembly to permit blowers or other optional acces-

sories to be used. The accessories plug into the new outlet box or may be routed out onto the hearth to a nearby

outlet.

NOTICE: DO NOT wire 110-120 VAC to wall switch.

Figure 4.1

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Figure 4.2 Electrical Outlet Detail

Appliance Cord Length (approximate)

Appliance Size Left Side Right Side

25 in. 10 ft. 6 in. 8 ft.

30 in. 10 ft. 3 in. 7 ft. 6 in.

35 in. 10 ft. 7 ft.

19

Page 20

5

EXHAUST

AIR

VENT PIPE

EXHAUST STARTING COLLAR

COLLAR SLIDE PLATE ASSEMBLY

EXHAUST STARTING COLLAR

INLET AIR STARTING COLLAR

COLLAR SLIDE PLATE ASSEMBLY

INLET AIR STARTING COLLAR

INLET AIR

VENT PIPE

V = 10 FT. MINIMUM

50 FT. MAXIMUM

NOTE: TO ACHIEVE OPTIMUM PERFORMANCE OF INSERT, MINIMIZE OR AVOID

BENDS IN EXHAUST VENT PIPE.

EXHAUST

COLLAR

INLET

COLLAR

MULTI-PURPOSE TOOL

TERMINATION

CAP

(SEE FIGURE 2.1)

Installing Vent Pipe and Appliance

A. Vent Limits

The abbreviations listed in this vent table key are used in

the vent diagrams.

Description

Minimum Vertical Run Length 10 ft.

Maximum Vertical Run Length 50 ft.

WARNING! Risk of Fire/Explosion/Asphyxiation! Do

NOT connect this gas appliance to a chimney ue serving

a separate solid fuel or gas burning appliance.

• Could impair safe operation of this appliance or other

appliances connected to the ue.

• Vent this appliance directly outside.

• Use separate vent system for this appliance.

CAUTION! ALL vent specications MUST be followed.

This product is tested and listed to these specications.

Appliance performance will suffer if specications are not

followed.

BE SURE SLIDE

PLATE SCREW IS

FULLY TIGHTENED.

COLLAR SLIDE

PLATE ASSEMBLY

INSTALLED.

Figure 5.1

20

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 21

B. Using Vertical Restrictor

EXHAUST

AIR

VENT PIPE

TERMINATION

CAP

INLET AIR

VENT PIPE

V = 10 FT. MINIMUM

50 FT. MAXIMUM

NOTE: TO ACHIEVE OPTIMUM PERFORMANCE OF INSERT, MINIMIZE OR AVOID

BENDS IN EXHAUST VENT PIPE.

EXHAUST

COLLAR

INLET

COLLAR

1 2

FRONT VIEW SHOWS RESTRICTORS IN THE OPEN POSITION AND BENT AT 90º

RESTRICTOR DOORS

When 20-25+ feet of vertical venting is used, vertical

restrictors will need to be adjusted. See Figure 5.2 and

5.3.

Figure 5.2 Min. / Max. Venting Requirement

Figure 5.3 Firebox Bafe

To open restrictors, push the restrictor doors upward.

The restrictor doors should be bent at a 90°. See Figure

5.3.

Opening restrictors will help reduce cold start or sooting

issues (cycling).

Appliance - 25 in. & 30 in.

10 ft. - 25 ft. No adjustment needs to be done.

V=

26 ft. - 35 ft. Open 1 restrictor opening.

36 ft. - 50 ft. Open both restrictor openings.

Appliance - 35 in.

10 ft. - 20 ft. No adjustment needs to be done.

V=

21 ft. - 35 ft. Open 1 restrictor opening.

36 ft. - 50 ft. Open both restrictor openings.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

21

Page 22

C. Venting Components

EXHAUST

AIR

VENT PIPE

TERMINATION

CAP

LINK-DV30B

LINKSQ-DV30

Installation*

LINK-DV4-30B

LINKSQ-DV4-30

Installation**

INLET AIR

VENT PIPE

WARNING:

DO NOT BLOCK

THIS PIPE END!

INLET AIR

VENT PIPE

EXHAUST

AIR

VENT PIPE

WOODBURNING PIPE

LINK-DV4-30B

LINKSQ-DV4-30

Installation**

OPTIONAL LINK-ZC-ADPB

FOR USE WITH CLASS A

WOODBURNING PIPE

LINK-DV30B

LINKSQ-DV30

Installation*

CAUTION! Risk of Cuts/Abrasions/Flying Debris.

Wear protective gloves and safety glasses during installation. Sheet metal edges are sharp.

The vertical vent termination system installed on this model

includes:

• One length of 3-inch exible vent pipe for exhaust air

(included with vent kit).

• One length of 3-inch exible vent pipe for combustion

air (included with vent kit).

• One vertical termination cap (included with vent kit).

To prevent odors and cold air drafts, it may be necessary to

place non-combustible insulation or eld fabricated metal

plates around the vent pipe ues as they go through the

damper.

Note: The LINK-DV4-30B and LINKSQ-DV4-30 systems

REQUIRE this insulation.

Masonry

OR

Note: Untwist the

pipe while extending it, to achieve

full 30’ length.

Factory Built

Wood Burning

Remove 18 inch x 18 inch

ashing on cap by removing

3 screws. Connect both the

LINK-ZC-ADPB to Class A

Pipe and the termination cap

to the LINK-ZC-ADPB with

self tapping screws.

Note: Untwist the

pipe while extending it, to achieve

full 30’ length.

OR

Figure 5.4

22

*LINK-DV30B/LINKSQ-DV30: This installation may perform better and allow less cold air inltration in

negative pressure settings.

**LINK-DV430B/LINKSQ-DV4-30:

• This installation may be more susceptible to cold air inltration and the effects of negative pressure

on the appliance’s performance.

• Depending on the chimney cleanliness, consider using the full length intake so as to lessen

the possibility of sense rod contamination and ame rectication issues.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 23

SLP-TVHW

SLP 6-5/8 Ø

COLINEAR TO COAXIAL

ADAPTER DV-46DVA-GK

FLEXIBLE FLUE

SLP

3 in

Flex

D. Connecting to SLP

Terminating horizontally is not allowed.

Vertical terminations are measured to top of chimney.

INLET AIR

VENT PIPE

This appliance is listed for use with LINK-DV systems

and components only. It is permissible to extend venting

above existing chimney (within specied maximum vertical limits) using SLP series 6-5/8 inch gas direct-vent

pipe. Connection is made using DV-46DVA-GK.

Must adhere to pipe clearances.

Flex Min SLP

5 ft. 8 ft.

6 ft. 7 ft.

7 ft. 6 ft.

8 ft. 5 ft.

9 ft. 4 ft.

10 ft. N/A

NOTE: 3 in. sections

of flex pipe must be

enclosed to existing

masonary replace ue

vent or installed into an

existing wood burning

vent system.

EXHAUST AIR VENT PIPE

LINK-DV30B/LINKSQ-DV30: This installation

may perform better and allow less cold air in-

ltration in negative pressure settings.

LINK-DV430B/LINKSQ-DV4-30:

• This installation may be more susceptible to

cold air inltration and the effects of negative

pressure on the appliance’s performance.

• Depending on the chimney cleanliness,

consider using the full length intake so

as to lessen the possibility of sense rod

contamination and ame rectication

issues.

Four 45 degree elbows can be used in the vertical section of SLP venting to avoid structural members such as

oor joist or trusses. Maximum total vent run is 50 ft. 90 degree elbows may NOT be used.

Up to four 45 degree elbows may be used as long as the minimum venting requirements are met per the above

chart.

Figure 5.5 Optional SLP Venting Conguration - Vertical Termination

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

23

Page 24

CUT AND BEND

FLASHING AS NEEDED

TO FIT CHIMNEY

SEALANT

ADHESIVE

E. Connecting Vent Pipe

Reference instructions in the termination kit.

• Install the 3 in. exible vent pipe(s) down through the

chimney.

• Secure the exhaust exible vent pipe to the exhaust

starting collar on top of the appliance with three screws.

See Figure 5.1.

For best results in cold climate be sure 3 in. ex is ush

and tight to the collar slide plate assembly. Seal with

stove cement or aluminum foil tape. Do not use silicone.

• Use 3 screws to attach the section of inlet air vent to the

inlet air starting collar on the collar slide plate assembly.

See Figure 5.1. NOTE: The collar slide plate assembly

may be removed from appliance to aid installation and

service.

For best results in cold climate be sure 3 in. ex is ush

and tight to the collar slide plate assemby. Seal with

stove cement or aluminum foil tape. Do not use silicone.

Figure 5.6

• Trim chimney top plate to minimize excess overhang or

bend over ue tile. See Figure 5.6.

• Place 3/8 inch bead of 300 ºF minimum continuous

exposure rating silicone on ue tile top.

24

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 25

F. Placing, Securing and Leveling the

3/16 in.

ALLEN BOLT

3/16 in.

ALLEN BOLT

RAISE

2 in.

2 in.

GAS LINE

ACCESS

W

A

L

L

FLOOR

REDUCE GAP

ABOVE SURROUND

LOWER REAR

LEVEL LEGS

TO REDUCE

GAP ABOVE

SURROUND

Appliance

WARNING! Risk of Explosion/Combustion Fumes!

Connect vent sections per installation instructions.

• Connect exhaust vent pipe ONLY to exhaust starting

collar and termination cap center collar.

• Connect inlet air vent ONLY to inlet air collar on

appliance and either the termination cap inlet air collar

OR terminate within chimney.

• DO NOT allow vent to sag below connection point to

appliance.

• Install insert (without surround attached) into existing

replace while pulling collar slide plate assemby forward.

• Install gas line into hole provided on side. See Figure

5.7.

• Secure collar slide plate assemby to appliance by

securing with #8 screw. See Figure 5.1.

• Level the appliance from side to side and front to back.

Adjust leveling legs to desired vertical position so

appliance is level. Use the leveling bolts included with

the manual bag.

• Position any excess exible vent pipe back up into

chimney without sagging. Twist and push flex vent

together to shorten.

• Attach surround. Follow instructions for surround

installation included with the front.

• Push insert into the opening so that it tightly overlaps

the replace opening.

NOTE: Use Allen bolts to

adjust rear level legs.

WARNING! Risk of Fire! Only an approved Hearth &

Home Technologies surround may be used to cover integral grills on solid fuel burning replaces. No other components such as shrouds, sheetmetal plates, etc., may be

used to seal off vents.

WARNING! Risk of Explosion! Failure to position the

parts in accordance with these diagrams or failure to use

only parts specically approved with this appliance may

result in property damage or personal injury.

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Figure 5.7 Leveling Leg Detail

25

Page 26

G. Installing Termination Cap

WARNING

Fire Risk.

Maintain vent clearance to combustibles as

specied.

• DO NOT pack air space with insulation or other

materials.

Failure to keep insulation or other materials away

from vent pipe may cause overheating and re.

CAUTION! Risk of Cuts/Abrasions/Flying Debris.

Wear protective gloves and safety glasses during installation. Sheet metal edges are sharp.

For installation of termination cap see minimum vent

heights for various pitched roofs. See Figure 5.8.

HORIZONTAL

OVERHANG

2 FT.

MIN.

GAS DIRECT VENT

TERMINATION CAP

Roof Pitch H (Min.) Ft.

Flat to 6/12....................1.0*

Over 6/12 to 7/12 ........1.25*

Over 7/12 to 8/12 ..........1.5*

Over 8/12 to 9/12 ..........2.0*

Over 9/12 to 10/12 ........2.5*

Over 10/12 to 11/12 ..... 3.25

20 INCHES MIN.

LOWEST

DISCHARGE

OPENING

X

12

ROOF PITCH

IS X/ 12

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

Roof Pitch H (Min.) Ft.

Over 11/12 to 12/12 ....... 4.0

Over 12/12 to 14/12 ....... 5.0

Over 14/12 to 16/12 ....... 6.0

Over 16/12 to 18/12 ....... 7.0

Over 18/12 to 20/12 ....... 7.5

Over 20/12 to 21/12 ....... 8.0

* H minimum may vary depending on regional snowfall.

Refer to local codes.

VERTICAL

WALL

Figure 5.8 Minimum Height from Roof to Lowest Discharge

Opening

26

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 27

6

ELECTRICAL OUTLET LOCATIONS

MASONRY

MASONRY

APPLIANCE

RECOMMENDED

Electrical Information

A. General Information

WARNING! Risk of Shock or Explosion! DO NOT wire

110-120 VAC to the valve or to the appliance wall switch.

Incorrect wiring will damage controls.

NOTICE: This appliance must be electrically wired

and grounded in accordance with local codes or, in the

absence of local codes, with National Electric Code

ANSI/NFPA 70-latest edition or the Canadian Electric

Code CSA C22.1.

• This appliance comes with a 110-120 VAC cord

assembly. This is required for proper operation of the

appliance (IntelliFireTM Touch Ignition). An outlet box may

be installed in a bottom back corner of the existing solid

fuel masonry or factory built replace to plug in the cord

assembly, or the supplied power cord may be routed out

onto the hearth to a nearby outlet.

• A 110-120 VAC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in

compliance with the applicable electrical codes, when

it is installed in locations such as in bathrooms or near

sinks.

• Low voltage and 110-120 VAC voltage cannot be shared

within the same wall box.

• In some instances, the spark ignition of the replace may

cause intermittent, non-damaging, interference during

the lighting sequence with a TV plugged into the same

circuit. It is recommended that the replace and TV use

different circuits to mitigate the interference potential.

If interference is occurring on the same circuit, the use

of surge protectors may help alleviate the interference.

Appliance Cord Length (approximate)

Appliance Size Left Side Right Side

25 in. 10 ft. 6 in. 8 ft.

30 in. 10 ft. 3 in. 7 ft. 6 in.

35 in. 10 ft. 7 ft.

Electrical Service and Repair

WARNING! Risk of Shock! Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper

operation after servicing.

WARNING! Risk of Shock! Replace damaged wire with

type 105 ºC rated wire. Wire must have high temperature

insulation.

• Refer to Service Parts section of appliance Owner’s

Manual for replacement part information.

Reset Switch

• A reset switch is included with the appliance surround

and should be attached to the side of the surround. See

Installation instructions shipped with the appliance front.

• Reset switch must be installed and in the “ON” position

for appliance to operate.

NOTICE: DO NOT wire 110-120 VAC to wall switch.

Figure 6.1 Electrical Outlet Detail

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

27

Page 28

FLAME

SENSE

IGNITER

TO CORD

ASSEMBLY

110-120 VAC

FAN 110-120 VAC

RF MODULE

6V TRANSFORMER

PLUG

I

S

6 PIN

BATTERY PACK

BRN

ORANGE

(PILOT)

GREEN

(MAIN)

IFT-RC400

REMOTE

CONTROL

BLK

RED

IFT-RC150

WIRELESS

WALL SWITCH

(OPTIONAL)

APPLIANCE

ON/OFF

CONTROL

BRN

BLK

WIRE ASSEMBLY

SPLITTER

BLK

RED

BLK

(OPTIONAL)

TO CORD ASSEMBLY 110-120 VAC

(OPTIONAL)

2206-299

* MODULE RESET SWITCH

(LOCATED ON SURROUND)

* Reset switch must be installed

and in the “ON” position for

appliance to operate.

2550-013 (NG)

2550-014 (LP)

2326-131

2326-152

2326-130

2326-150

2179-300

2326-120

2166-302 (NG)

2166-303 (LP)

2326-132

GFK-160A

2326-134

2187-198

WSK-21-W

2159-310

LIGHT WIRE

ASSEMBLY

2532-017

2201-150

HALOGEN BULBS (X 2)

NOT AN OPTION WITH 25 in. MODELS

B. Wiring Requirements

IntelliFire™ Touch Ignition System Wiring

WARNING! Risk of Shock or Explosion! DO NOT wire

IPI controlled appliance power cord to a switched circuit.

Incorrect wiring will override IPI safety lockout.

• Refer to Figure 6.2, IntelliFireTM Touch (IPI) Wiring

Diagram.

• This appliance is equipped with an IntelliFire control valve

which operates on a 6 volt system.

• Ensure the 6 volt transformer is plugged into the supplied

cord assembly to supply power to the unit OR install 4 AA

cell batteries (not included) into the battery pack before

use.

• Reset switch must be installed and in the “ON” position

for appliance to operate.

Battery Pack

Battery pack is not factory installed in appliances. See

appliance manual bag for battery pack. Battery pack

should only be installed during power outages.

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

Battery polarity must be correct when installing batteries.

DO not store batteries in the battery pack when the

appliance is powered by the 6 volt transformer connected

to permanent electrical service. Store battery pack in

apppliance manual bag when not in use.

Halogen Lights (Optional)

Halogen lights are Optional.

Note: Not offered with 25 in. model.

Figure 6.2 IntelliFire™ Touch Wiring Diagram

28

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 29

INSTALL FAN

C. Installation / Service for Fan

On units already installed, removal of decorative front

and gas insert may be required.

Option 1:

• Detach exible liner from top of unit if insert is installed by

removing the collar slide plate screw. See Figure 5.1.

• Remove the ve screws on the rear cover plate. See

Figure 6.3.

• Service / replace fan. Figure 6.2 shows a wiring diagram.

• Reinstall the rear cover plate back on the unit.

• Reattach exible liner and replace collar slide plate

screw. See Figure 5.1.

Option 2:

• Remove appliance front, glass, logs, base pan assem-

bly, burner assembly and valve plate assembly. See

Figure 6.4.

• Service / install fan. Figure 6.2 shows a wiring diagram.

• Reinstall valve plate assembly, burner assembly, base

pan assembly, logs and appliance glass and front.

INSTALL FAN

REAR COVER PLATE

Figure 6.3 Cover Plate Removed (Option 1)

OPTION 1

OPTION 2

Figure 6.4 Through Valve Plate Opening (Option 2)

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

29

Page 30

D. Installation / Service for Halogens

On units already installed, removal of decorative front and

gas insert may be required.

Option 1:

• Detach exible liner from top of unit if insert is installed by

removing the collar slide plate screw. See Figure 5.1.

• Remove the ve screws on the rear cover plate. See

Figure 6.5.

• Service / replace halogens. Figure 6.2 shows a wiring

diagram.

• Reinstall the rear cover plate back on the unit.

• Reattach exible liner and replace collar slide plate

screw. See Figure 5.1.

Option 2:

• Remove appliance front, glass, logs, base pan assem-

bly, burner assembly and valve plate assembly. See

Figure 6.6.

• Service / replace halogens. Figure 6.2 shows a wiring

diagram.

• Reinstall valve plate assembly, burner assembly, base

pan assembly, logs and appliance glass and front.

INSTALL HALOGENS

REAR COVER PLATE

Figure 6.5 Cover Plate Removal (Option 1)

OPTION 1

INSTALL HALOGENS

Figure 6.6 Through Valve Plate Opening (Option 2)

OPTION 2

30

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 31

Gas Information

BASE REFRACTORY

GLASS CLIP

ASSEMBLIES

GLASS

CLIP ASSEMBY

SCREW ACCESS

OFF POSITION

(TURN KNOB CLOCKWISE)

GLASS SEAL PLATE

COMPONENT TRAY

WITH HEAT SHIELD

PRESS

TAB TO

RELEASE

UNCLIP

WIRES

COMPONENT

TRAY

COMPONENT

TRAY RECEIVER

7

A. Fuel Conversion

• Make sure the appliance is compatible with available gas

types.

• Conversions must be made by a qualified service

technician using Hearth & Home Technologies specied

and approved parts.

• Reference the following diagrams for gas shut off detail

and component access.

• Reference Section 9.A to remove xed glass assembly.

NOTE: The gas ball

valve is in the “OFF

position from

manufacturer.

NOTE: Use the Multi-Purpose

Tool to assist with gas shut-off.

MULTI-PURPOSE TOOL

GAS SHUT OFF

Figure 7.1 Gas Shut-off

• Use multi-purpose tool to assist with gas shutoff. See

Figure 7.1. The gas ball valve is in the “OFF” position

from manufacturer.

• Glass clip assemblies can be removed for additional

component accessibility.

NOTE: Bottom right glass clip on 25 inch models must

be removed to gain access to controls.

Figure 7.3 Component Tray

WARNING! Glass seal plate must be properly installed.

Risk of elevated component temps and carbon monoxide

exposure.

CAUTION: Be sure to reinstall the component heat shield

before ring the appliance. Components will overheat.

Figure 7.2 Glass Clip Assembly Removal

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

31

Page 32

B. Gas Pressure

• Optimum appliance performance requires proper input

pressures.

• Gas line sizing requirements will be determined in ANSI

Z223.1 National Fuel Gas Code in the USA and CAN/

CGA B149 in Canada.

• Pressure requirements are:

Gas Pressure Natural Gas Propane

Minimum inlet pressure 5.0 in. w.c. 11.0 in. w.c.

Maximum inlet pressure 10.0 in. w.c. 13.0 in. w.c.

Manifold pressure 3.5 in. w.c. 10.0 in. w.c.

WARNING! Risk of Fire or Explosion! High pressure

will damage valve. Low pressure may cause explosion.

• Verify inlet pressures. Verify minimum pressures when

other household gas appliances are operating.

• Install regulator upstream of valve if line pressure is

greater than 1/2 psig.

WARNING

Fire Risk.

Explosion Hazard.

High pressure will damage valve.

• Disconnect gas supply piping BEFORE

pressure testing gas line at test pressures

above 1/2 psig.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 1/2 psig.

Note: Have the gas supply line installed in accordance with

local codes, if any. If not, follow ANSI Z223.1. Installation

should be done by a qualied installer approved and/or

licensed as required by the locality. (In the Commonwealth

of Massachusetts installation must be performed by a

licensed plumber or gas tter).

Note: A listed (and Commonwealth of Massachusetts ap-

proved) 1/2 in. (13 mm) T-handle manual shut-off valve

and exible gas connector are connected to the 1/2 in. (13

mm) control valve inlet.

• If substituting for these components, please consult

local codes for compliance.

C. Gas Connection

• Refer to Reference Section 3 for location of gas line

access in appliance.

• The gap between supply piping and gas access hole

may be caulked with caulk with a minimum of 300

ºF continuous exposure rating or stuffed with non-

combustible, unfaced insulation to prevent cold air

inltration.

• Ensure that gas line does not come in contact with outer

wrap of the appliance. Follow local codes.

• Pipe incoming gas line to the factory supplied ex line.

See Figure 7.4.

• Connect incoming gas line to the 1/2 in. (13 mm)

connection on manual shutoff valve.

WARNING! Risk of Fire or Explosion! Support control

when attaching pipe to prevent bending gas line.

• A small amount of air will be in the gas supply lines.

WARNING! Risk of Fire or Explosion! Gas build-up during line purge could ignite.

• Purge should be performed by qualified service

technician.

• Ensure adequate ventilation.

• Ensure there are no ignition sources such as sparks

or open ames.

Light the appliance. It will take a short time for air to purge

from lines. When purging is complete the appliance will

light and operate normally.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Check all ttings and connections with a non-corrosive

commercially available leak-check solution. DO NOT use

open ame. Fittings and connections could have loosened during shipping and handling.

WARNING! Risk of Fire! DO NOT change valve settings.

This valve has been preset at the factory.

32

Figure 7.4

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 33

D. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced,

these rules do not apply. Check with your local gas utility

or authorities having jurisdiction.

When installing above 2000 feet elevation:

• In the USA: Reduce input rate 4% for each 1000 feet

above 2000 feet.

• In CANADA: Input ratings are certied without a reduction

of input rate for elevations up to 4500 feet (1370 m)

above sea level. Please consult provincial and/or

local authorities having jurisdiction for installations at

elevations above 4500 feet (1370 m)

Check with your local gas utility to determine proper

orice size.

E. Air Shutter Setting

Air shutter settings should be adjusted by a qualied service technician at the time of installation. The air shutter

is set at the factory for minimum vertical vent run. Adjusting air shutter may be desired for longer vent runs. See

Figure 7.5.

NOTICE: If sooting occurs, provide more air by opening

the air shutter.

F. Service / Replace Appliance Gas Valve

• See Figure 7.6.

• Remove appliance front, glass, logs, base pan assem-

bly, burner assembly and valve plate assembly. See

Figure 7.6.

• Service/Replace gas valve.

• Reinstall valve plate assembly, burner assembly, base

pan assembly, logs and appliance glass and front.

SERVICE / REPLACE

APPLIANCE GAS VALVE

Figure 7.5 Air Shutter

Air Shutter Settings

RUBY25IN 1/4 in.

RUBY30IN 1/2 in.

RUBY35IN 3/8 in.

RUBY25IL 1/2 in.

RUBY30IL Full Open

RUBY35IL Full Open

Figure 7.6 Gas Valve Detail

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

33

Page 34

8

INTERIOR WALL

TOP VIEW

MANTEL LEG OR WALL PROJECTIONS

SURROUND OPENING

∞

18 in.

12 in.

12 in.

1/4 in. GAP

6 in.

6 in.

INTERIOR WALL

TOP VIEW

MANTEL LEG OR

WALL PROJECTIONS

SURROUND OPENING

∞

18 in.

1/4 in. Gap

12 in.

A

6 in.

12 in.

*

C

L

*S EE TA BLE

1 or 2

1/4 in. gap

SURROUND

OPENING

6 in.

12 in.

12 in.

*B

*S EE TABL E

1 or 2

Finishing

A. Mantel, Wall Projections & Hearth

Extensions

WARNING! Risk of Fire! Comply with all minimum clear-

ances to combustibles as specied. Framing or nishing

material closer than the minimums listed must be constructed entirely of noncombustible materials (i.e., steel studs,

concrete board, etc).

Clearance to combustible material under the insert is 1/4

inch (6 mm).

• Use leveling legs to raise insert minimum 1/4 inch (6

mm) above combustible material or outer wrap of factory

built rebox.

Combustible facings must not extend behind the insert

surround. For non-combustible material specications

refer to Section 1.E and 1.F.

Mantel Legs or Wall Projections

Mantels or Wall Projections - Non-Combustible

Combustible

Non-Combustible

Figure 8.1 Clearances to Mantel Legs or Wall Projections

(Acceptable on both sides of surround opening)

Note: Measurement is taken from top of the surround

opening.

Figure 8.2 Minimum Vertical and Maximum Horizontal

Dimensions- Non-Combustible

Unit Size

Surround

Model

A B

MI25-3523 17-15/16 in. 6-1/16 in.

25 in.

MI25-3726 18-15/16 in. 9-1/16 in.

MI25-3928 19-15/16 in. 11-1/16 in.

MI30-4027 20-7/16 in. 6-9/16 in.

30 in.

MI30-4230 21-7/16 in. 9-9/16 in.

MI30-4432 22-7/16 in. 11-9/16 in.

MI35-4229 21-7/16 in. 5-1/16 in.

35 in.

MI35-4432 22-7/16 in. 8-1/16 in.

MI35-4832 24-7/16 in. 8-1/16 in.

Table 1 Mantel Leg or Wall Projection Minimum Dimension

needed when Installing a Standard Surround

Unit Size

25 in.

30 in.

35 in.

Table 2 Mantel Leg or Wall Projection Minimum Dimension

needed when Installing a Custom Surround. Front Model

Determines the Minimum Size of the Custom Surround

Front Model A B

INFIT 14-5/16 in. 1-1/4 in.

CSFI, CASFI 16-1/16 in. 2-1/2 in

INFIT 16-13/16 in. 1-1/4 in.

CSFI, CASFI 18-9/16 in. 2-1/2 in

INFIT 19-5/16 in. 1-1/4 in.

CSFI, CASFI 21-1/16 in. 2-1/2 in

Note: All numbers in Tables 1 and 2 include the 1/4 in. gap on

surround edge.

34

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 35

Mantels - Combustible

Measurement to bottom

of appliance:

= 29-1/4 in. (25")

= 32-3/4 IN. (30")

= 36-1/4 IN. (35")

Measurement

from surround

opening.

12 in.

12 in.

Figure 8.3 Minimum Vertical and Maximum Horizontal

Dimensions - Combustible

B. Hearth Extension

1/2 in.

Figure 8.4 Minimum Required 1/2 in. Gap

• All ooring and hearth material must remian below the

bottom of the surround. See Figure 8.5.

• Combustible ooring may be located in front of the

appliance. Exception - no vinyl / adhesive ooring. See

Figure 8.6.

• 1/2 inch gap under the bottom of the front must be

maintained. See Figure 8.4.

• A minimum 1/4 inch gap from the bottom of the appliance

to the metal oor of the solid fuel rebox is REQUIRED.

See side view in Figure 8.7.

• Combustible flooring underneath the appliance is

acceptable with a 1/4 inch gap. See Figure 8.7.

YES

Flooring & Hearth Material

Flooring & hearth material must remain below the bottom of surround

Figure 8.5 Flooring & Hearth Material

SURROUND

SURROUND

NO

Flooring & Hearth Material

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

35

Page 36

Y

X

NO VINYL /

SIDE VIEW

MINIMUM 1/4 IN. REQUIRED

COMBUSTIBLE FLOOR UNDERNEATH APPLIANCE

ADHESIVE FLOORING

Figure 8.6 Hearth - Combustible Material Exception

Vinyl / Adhesive Flooring - Minimums

Appliance Size Depth (X) Width (Y)

25 in. 16 in 25-3/4 in.

30 in. 16 in 30-3/4 in.

35 in. 16 in 35-3/4 in.

Figure 8.7 Solid Fuel Floor Clearance

36

Majestic • RUBY25IN, RUBY25IL, RUBY30IN, RUBY30IL, RUBY35IN, RUBY35IL Installation Manual • 2542-980 Rev. i • 9/19

Page 37

9

GLASS SEAL

PLATE INSTALLED

Appliance Setup

A. Fixed Glass Assembly

WARNING! Risk of Asphyxiation! Handle xed glass

assembly with care. Inspect the gasket to ensure it is

undamaged and inspect the glass for cracks, chips or

scratches.

• DO NOT strike, slam or scratch glass.

• DO NOT operate replace with glass removed, cracked,

broken or scratched.

• Replace as a complete assembly.

Removing Fixed Glass Assembly

CAUTION! Handle xed glass assembly with care.

Glass is breakable.

• Avoid striking, scratching or slamming glass

• Avoid abrasive cleaners

• DO NOT clean glass while it is hot

• The glass assembly fastens to the replace in four

places. Four of the fastening mechanisms are springloaded glass latches. An example of the glass latch is

shown in Figure 9.2.

• To release glass assembly, use the supplied multi-

purpose tool to pull the two bottom spring-loaded

latches forward and allow them to retract away from

the glass assembly. Tilt the bottom of the glass

assembly outward until the top latches disengage.

GLASS SEAL PLATE

GLASS CLIPS

Figure 9.1 Multi-PurposeTool

Replacing Fixed Glass Assembly

• Tilt the top of the glass assembly toward replace and

slide glass assembly upward to engage

top latches. Verify top latches are fully engaged and

then fasten the two bottom latches using the supplied

multi-purpose tool.

• Reinstall door or decorative front.

Figure 9.2 Glass Seal Plate