Page 1

1

PREPAR3D GUIDE

MAJESTIC SOFTWARE’S

BOMBARDIER Q400 “DASH 8”

BY CHUCK

LAST UPDATED: 06/03/2018

Page 2

TABLE OF CONTENT

• PART 1 – INTRODUCTION

• PART 2 – COCKPIT LAYOUT

• PART 3 – FLIGHT PLANNING

• PART 4 – START-UP PROCEDURE

• PART 5 – TAXI

• PART 6 – TAKEOFF, CLIMB & CRUISE

• PART 7 – AUTOPILOT

• PART 8 – ENGINES & HYDRAULICS

• PART 9 – ICE PROTECTION

• PART 10 – APPROACH & LANDING

2

MAJESTIC Q400 EDITION: PRO

PLATFORM: PREPAR3D V 4.1

Page 3

3

The Dash 8 “Q400” is a series of twin-engine, medium-range, turboprop regional airliners. The

aircraft was introduced by de Havilland Canada (DHC) in 1984. Originally named the DHC-8

(nicknamed “Dash 8”), the aircraft started as the -100 series, then the -200 series, the -300

series and finally the -400 series. They are now produced by Bombardier Aerospace. De

Havilland Canada was sold to Boeing in 1986, but then re-sold to Montreal-based Bombardier

Aerospace in 1992. This acquisition was done in the midst of Bombardier’s expansion of the late

80’s; it had acquired Canadair in 1986, Short Brothers in 1989 and then Learjet as well in 1990.

The Dash 8 was developed from the de Havilland Canada Dash 7, which featured extreme short

take-off and landing (STOL) performance. With the Dash 8, DHC focused on improving cruise

performance and lowering operational costs. The engine chosen was the Pratt & Whitney

Canada PW100. The aircraft has been delivered in four series. The Series 100 has a maximum

capacity of 39, the Series 200 has the same capacity but offers more powerful engines, the

Series 300 is a stretched, 50-seat version, and the Series 400 is further stretched to 78

passengers. Over 1,000 Dash 8s of all models have been built.

The DHC-8-400 “Q400” is a stretched and improved version of the Dash 8 that entered service

in 2000. It is equipped with an ANVS system (Active Noise and Vibration Suppression). Models

delivered after 1997 have cabin noise suppression and are designated with the prefix "Q“, as in

“Q400”. Its 360 knot (667 km/h) cruise speed is 60–90 knots (111–166 km/h) higher than its

competitors and predecessors. Powered by PW150A engines rated at 5,071 shp (3,781 kW) at

maximum power (4,850 shp or 3,620 kW maximum continuous rated). The maximum operating

altitude is 25,000 ft (7,600 m) for the standard version. Production of the Series 100 ceased in

2005, and the Q200 and Q300 in 2009.

The Q400 has been through two company acquisitions, one of which was near fatal. The

engineers who worked on this airframe are very proud of its rich history and know all too well

the challenges of stretching the airframe and stretching a shrinking budget. We have to

remember that this started as a bush flying aircraft that has been marketed to compete with

jets. The aircraft is incredibly diverse being able to serve in high end commuter markets, to

military platforms and even as a water bomber. This is an aircraft that has adapted to changing

economic times and kept a great safety rating.

This is an aircraft designed to operate in the harsh canadian winter and difficult weather

conditions that you will have to fly into without expensive automation systems: there is no

auto-throttle nor auto-land system. The approaches need to be planned very carefully and most

of your landings will be quite “firm” because of the landing gear’s configuration. Give it a

chance and I am sure that you will enjoy its superbly simulated systems. Great job, Majestic

Software!

PART 1

–

INTRODUCTION

Dash 8-100 Cutaway

Page 4

4

PART 1

–

INTRODUCTION

DHC-1 Chipmunk (1946) DHC-2 Beaver (1947) DHC-3 Otter (1951)

DHC-4 Caribou (1958)

DHC-5 Buffalo (1964)

DHC-6 Twin Otter (1965)

DHC-7 Dash 7 (1975) DHC-8 Dash 8 “Q-Series” (1983)

De Havilland Canada Aircraft

Page 5

5

Before you even step foot in your virtual cockpit, you need to know where you are, where you are going, how you will

get there, what you need to get there. This document is structured like a short tutorial flight.

The flight tutorial is structured as follows:

• Familiarize yourself with the cockpit layout

• Plan your flight

• Determine the flight route, fuel & cargo loads

• Spawn the aircraft and set it in a Cold & Dark state

• Provide aircraft with power

• Program the FMC (Flight Management Computer)

• Start–up the aircraft and make it ready for flight

• Taxi

• Takeoff

• Climb and cruise

• Explore autopilot capabilities

• Explain engine and hydraulic system functionalities

• Explain the ice protection systems

• Descend, approach and land

TUTORIAL STRUCTURE

PART 1

–

INTRODUCTION

Page 6

6

DISCLAIMER: Do not use this guide for real life flying. I mean it.

Majestic Software Downloads Section

http://majesticsoftware.com/mjc8q400/downloads.html

Smart Cockpit Dash-8-400

http://www.smartcockpit.com/plane/BOMBARDIER/DASH-8-400.html

Froogle Sims Q400 Fully Loaded Playlist (Youtube)

https://www.youtube.com/watch?v=PkOc2gIS_s8&list=PL_xDmvmUFDEjAyzamHQaoM7hXrJudErUX

Airline2Sim (Payware Course)

https://www.airline2sim.com/course/q400-cadet/

Airline2Sim SIDs and STAR (Youtube)

https://www.youtube.com/watch?v=CKhxjVHTJYc

Aircraft Icing:

https://aircrafticing.grc.nasa.gov/1_1_3_3.html

BEST RESOURCES

PART 1

–

INTRODUCTION

Page 7

7

PART 2

–

COCKPIT LAYOUT

Page 8

8

PART 2

–

COCKPIT LAYOUT

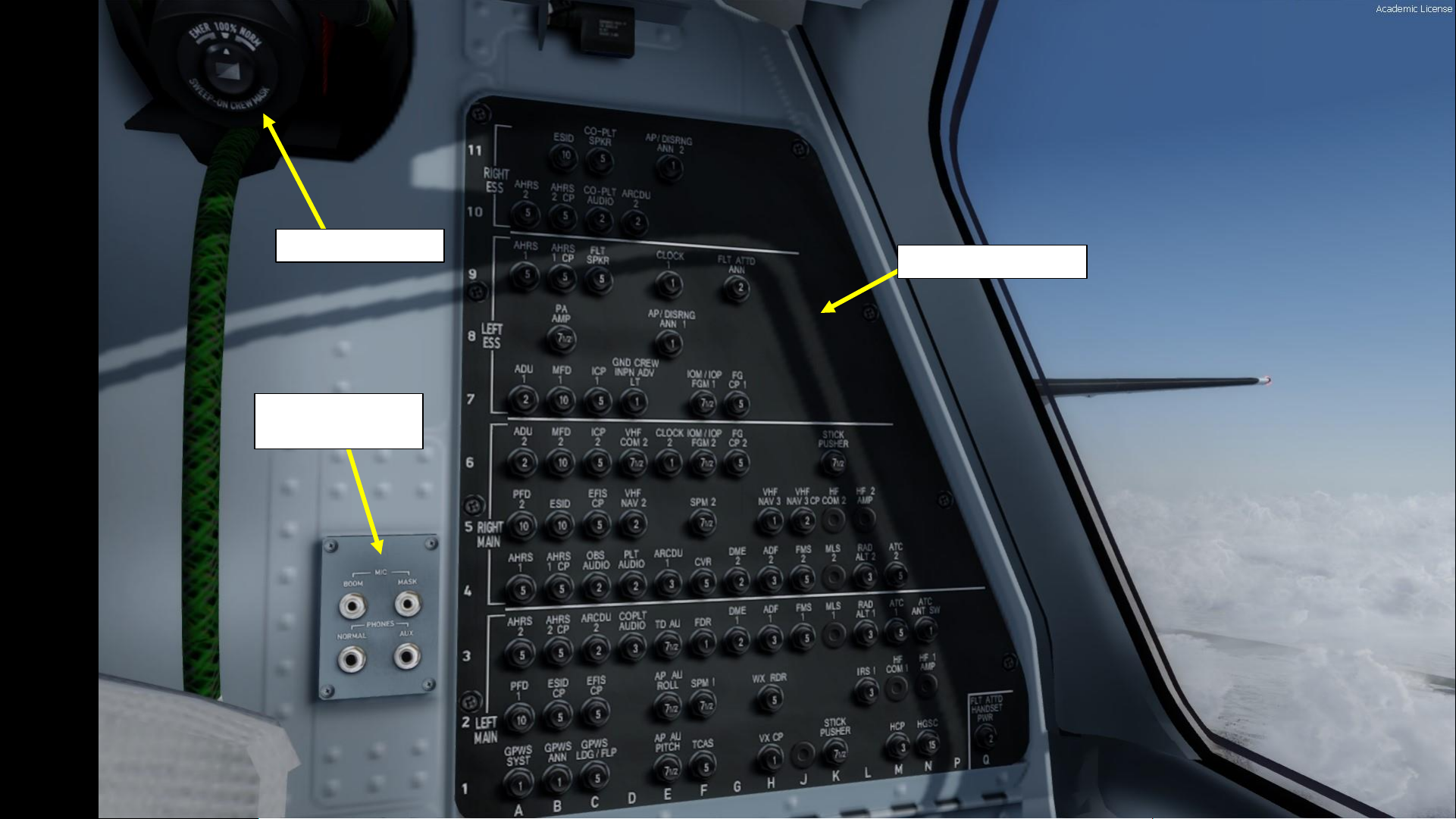

Circuit Breaker Panel

Microphone &

Headset Jacks

Oxygen Crew Mask

Page 9

9

PART 2

–

COCKPIT LAYOUT

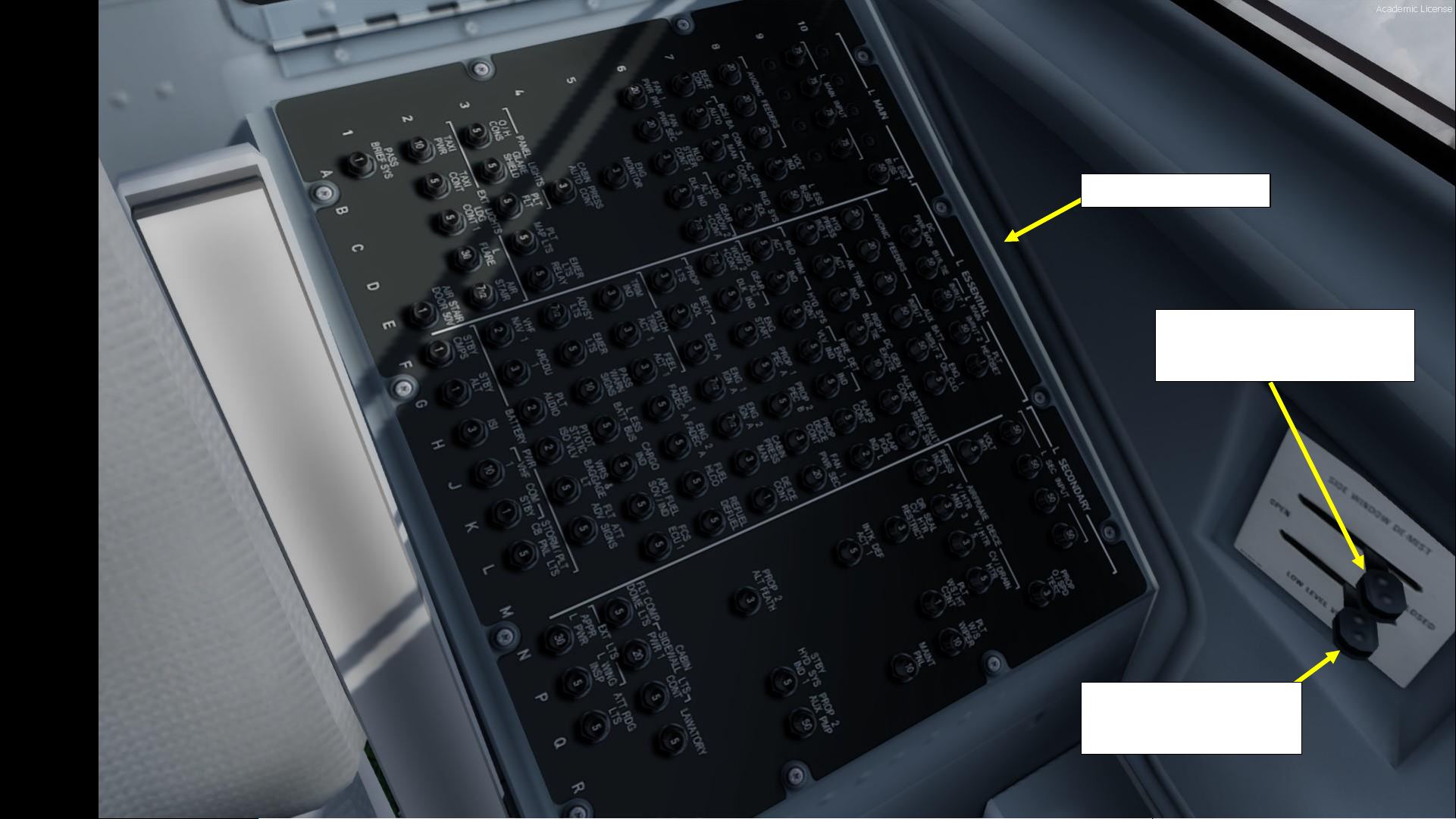

Circuit Breaker Panel

Side Window De-Mist Control

AFT = OPEN

FWD = CLOSED

Low Level Vents Control

AFT = OPEN

FWD = CLOSED

Page 10

10

PART 2

–

COCKPIT LAYOUT

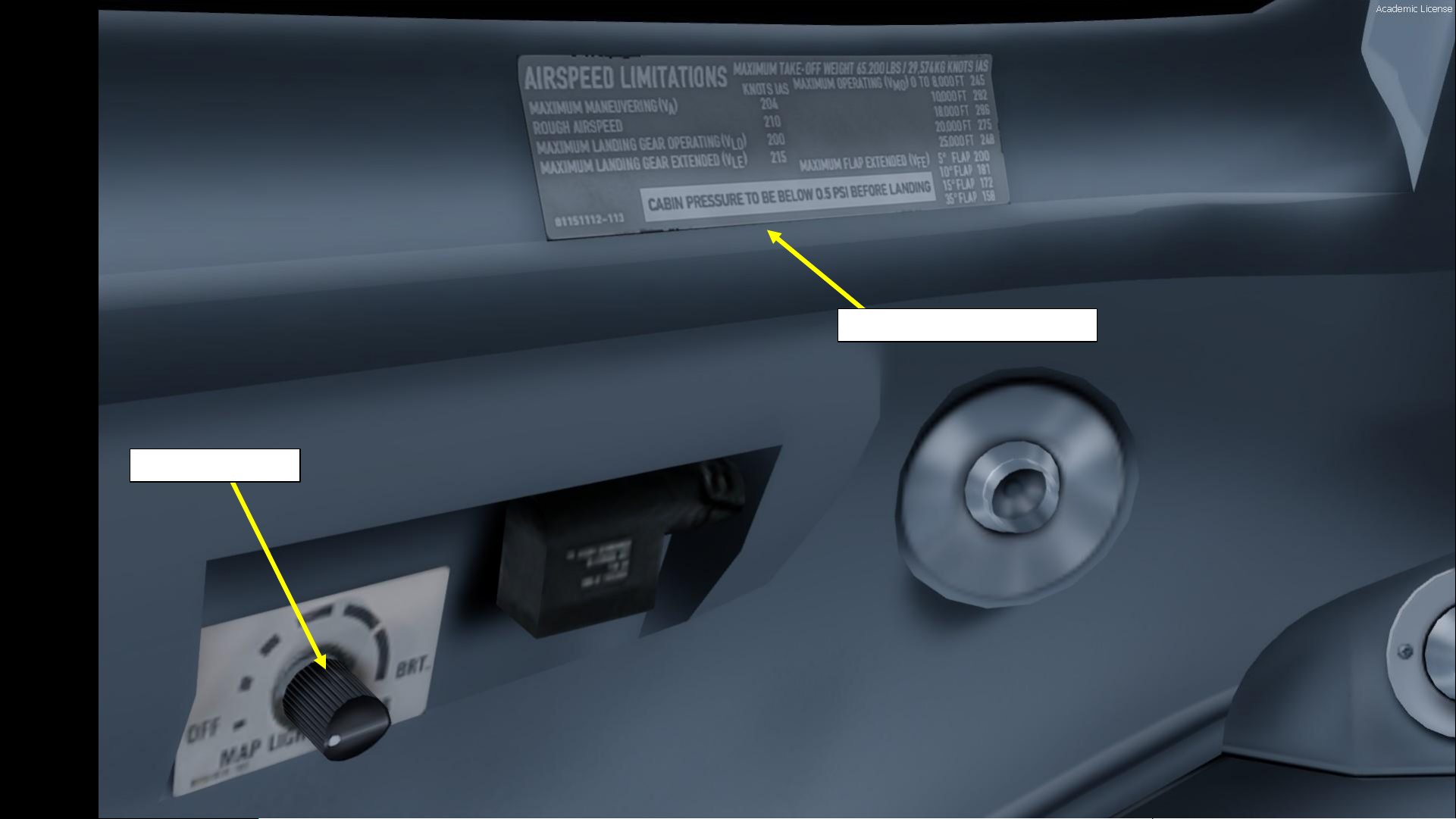

Map Light Control

Airspeed Limitations Placard

Page 11

11

PART 2

–

COCKPIT LAYOUT

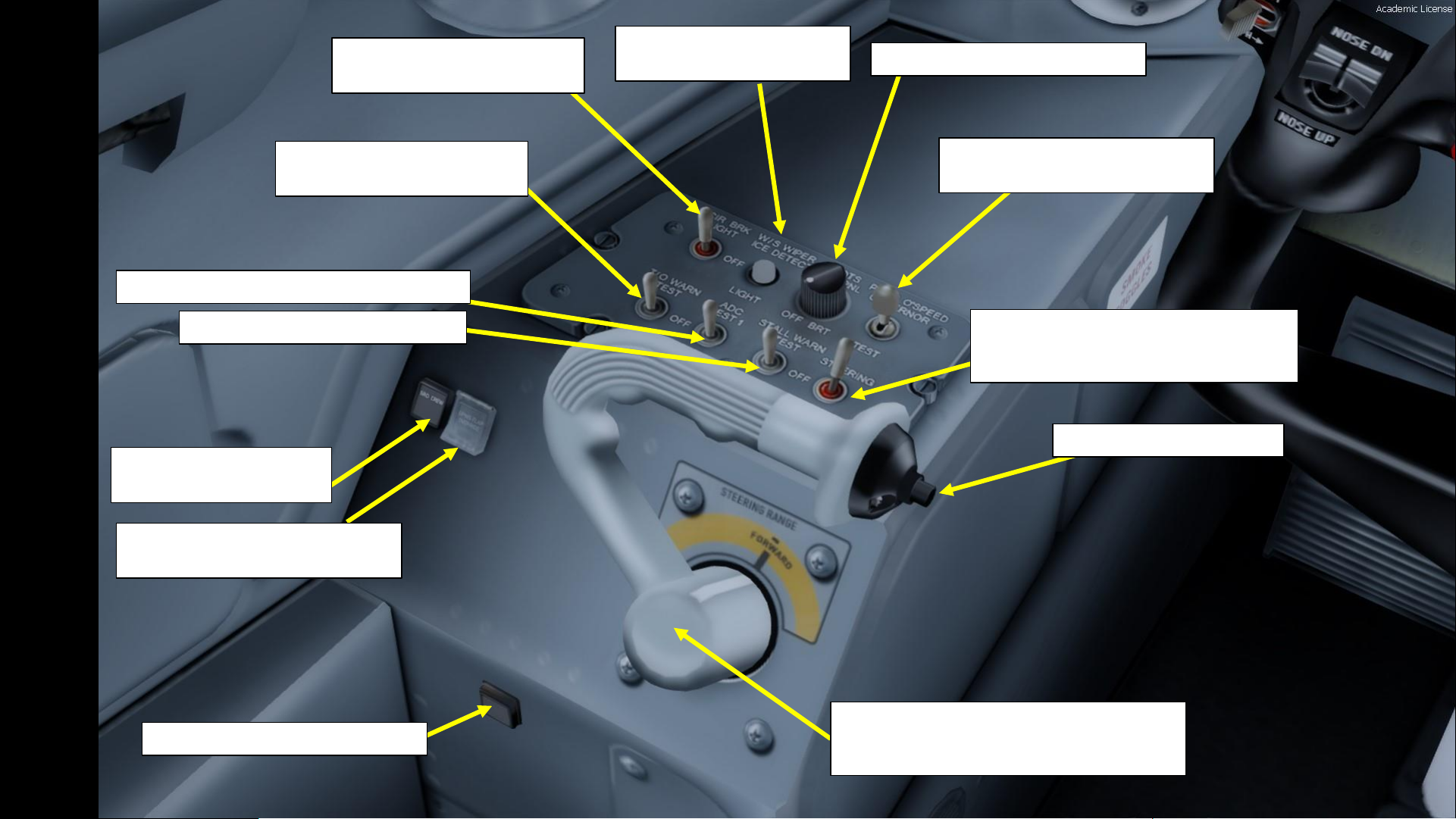

GPWS (Ground Proximity Warning

System) Flap Override Button

Ground Crew Connection

Annunciator

Steering Hand Control (Tiller)

Used to steer aircraft on ground. Left click and drag

to steer.

Push-To -Talk (PTT) Switch

Circuit Breaker Panel Lighting

Control Toggle Switch

Windshield Wiper Ice

Detection Light Pushbutton

Pilot’s Side Panel Dimmer Knob

Propeller Overspeed Governor

Test Toggle Switch

Nosewheel Steering Toggle Switch

AFT = OFF

FWD = NOSEWHEEL STEERING ON

Takeoff Warning System Test

Toggle Switch

ADC (Air Data Computer) Test Toggle Switch

Stall Warning Test Toggle Switch

Alternate Pilot Wiper Pushbutton

Page 12

12

PART 2

–

COCKPIT LAYOUT

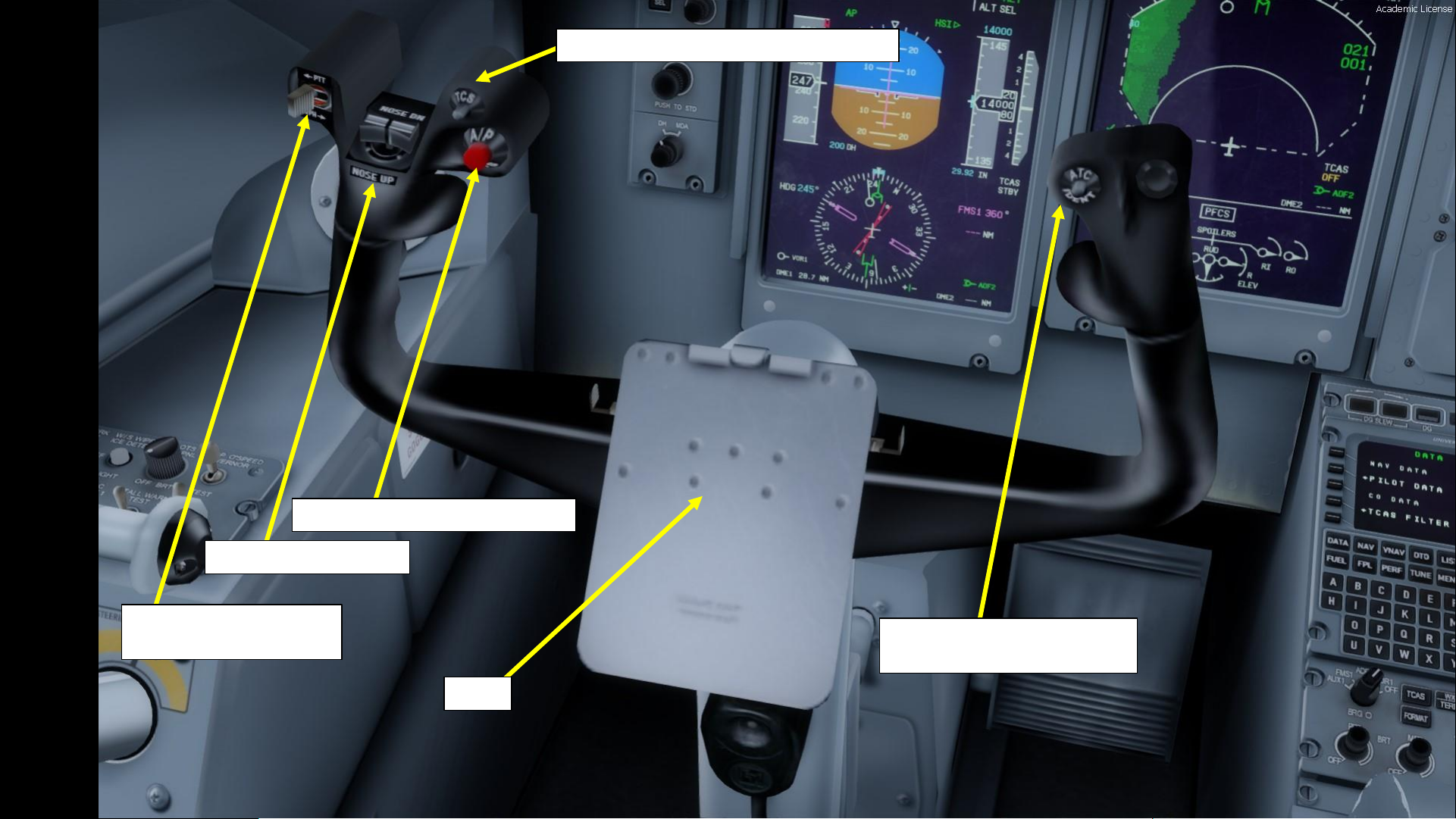

Transmit/Interphone

Push-to-Talk Switch

Elevator Trim Switches

Autopilot Disengage Pushbutton

Yoke

TCS (Tactile Control Steering) Pushbutton

ATC (Air Traffic Controller)

Identification Pushbutton

Page 13

13

PART 2

–

COCKPIT LAYOUT

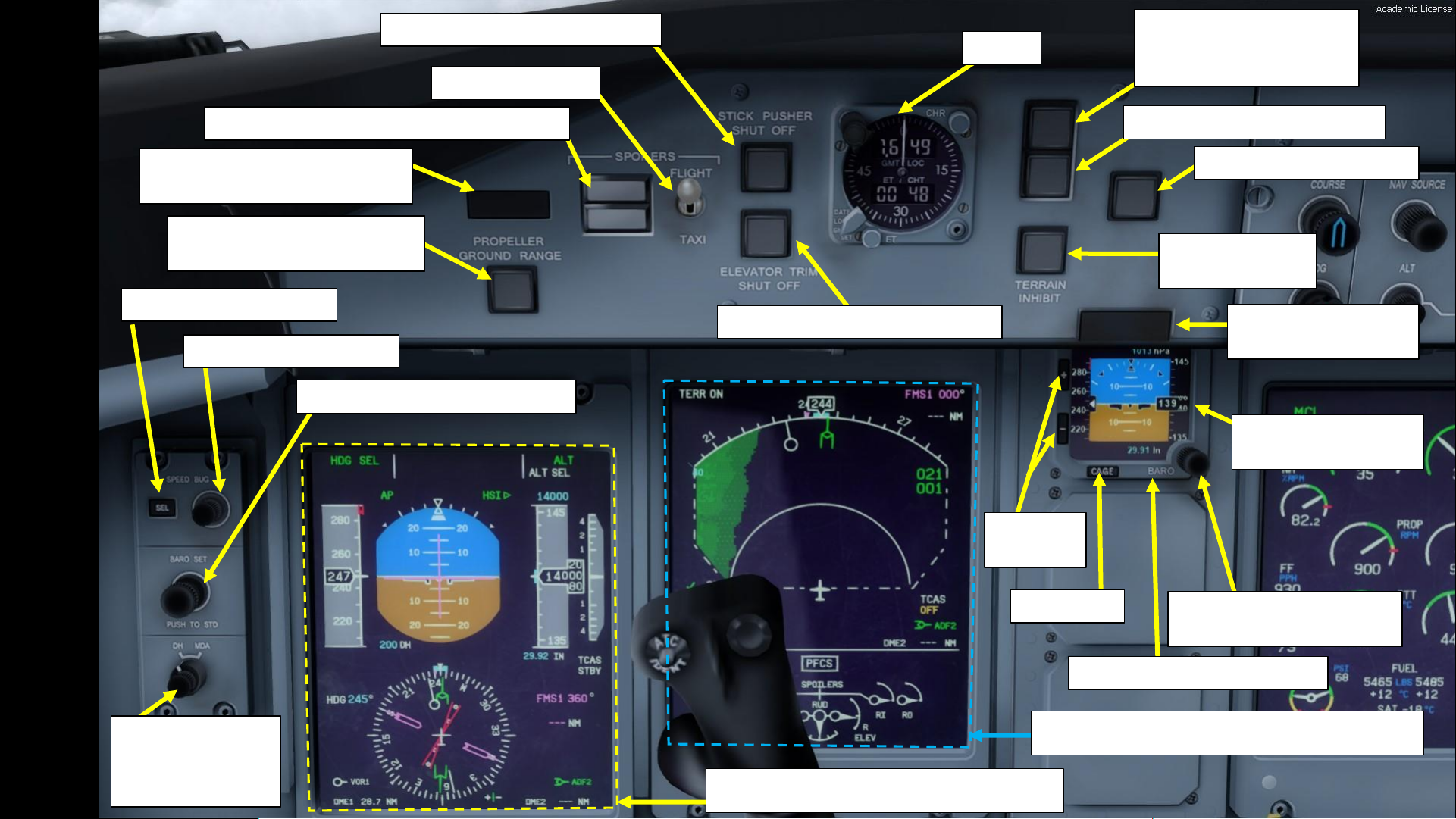

Barometric Pressure Setting

Adjustment Knob

Standby ADI (Attitude

Director Indicator)

Caution Press-toReset Switchlight

Terrain Warning

Inhibit Switch

Autopilot Disengage Light

PULL UP GPWS (Ground-

Proximity Warning

System) Test Light

BELOW G/S (Glide Slope) Light

Clock

Elevator Trim Push Switchlight

Stick Pusher Shut Off Switchlight

Flight/Taxi Switch

Roll Outboard & Roll Inboard Spoilers Lights

Roll Outboard & Roll Engine Fire

Press-to-Reset Switchlight

Propeller Ground (Beta) Range

Lights (1/2)

Speed Bug Select Button

Speed Bug Setting Knob

Barometric Pressure Setting Knob

DH/MDA Switch

Selects Designated

Height or Minimum

Descent Altitude

PFD 1 (Primary Flight Display)

MFD 1 (Multifunction Display)

Barometric Pressure Setting

Cage Reset

Brightness

Control

Page 14

14

PART 2

–

COCKPIT LAYOUT

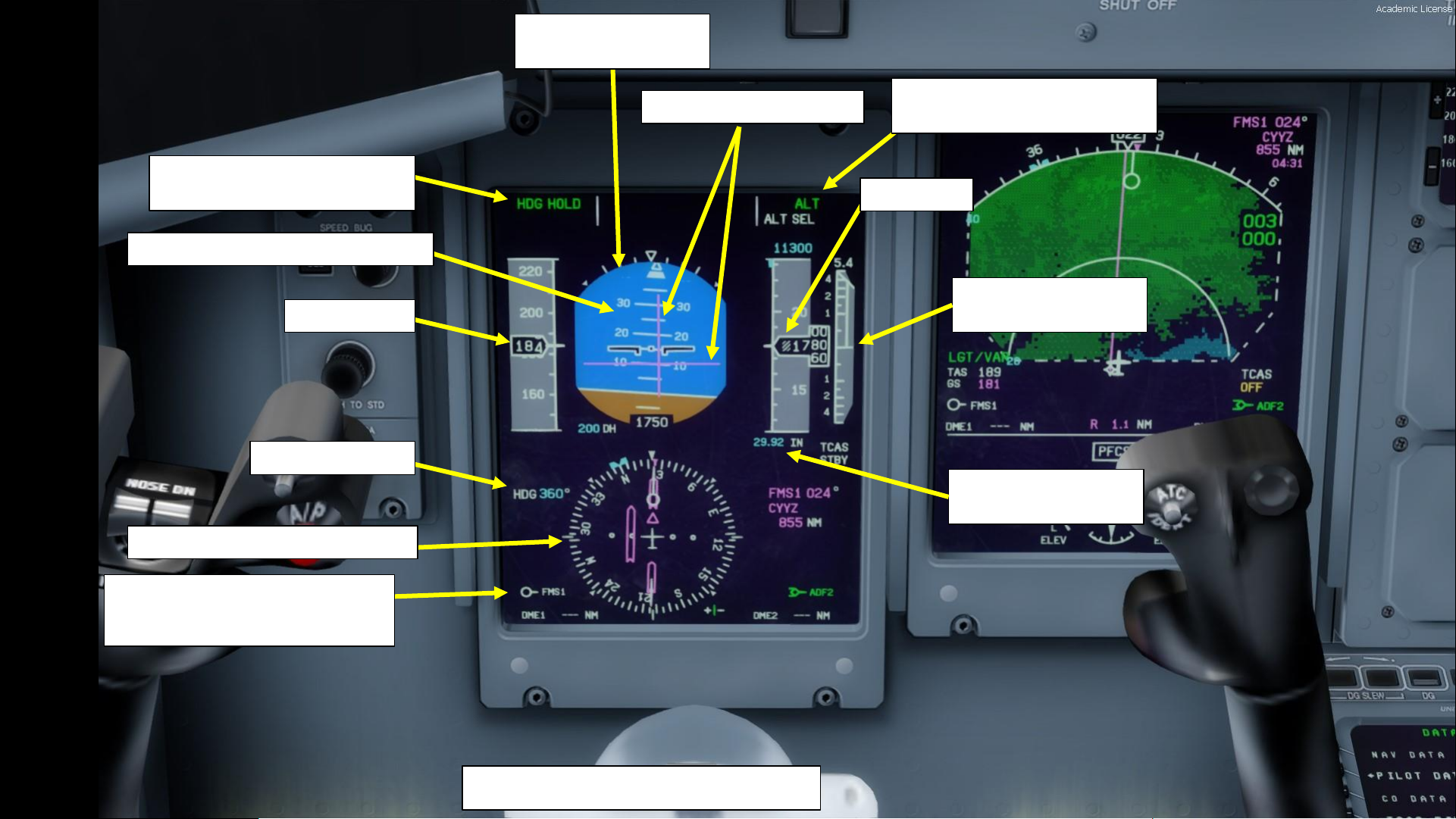

PFD 1 (Primary Flight Display)

Airspeed (kts)

Selected Heading

AFCS (Automatic Flight Control

System) Lateral Mode

Flight Director Indications

Primary ADI (Attitude

Director Indicator)

Aircraft Pitch Ladder (Angle in deg)

HSI (Horizontal Situation Indicator)

Selected Navigation Source Data

FMS: Flight Management System

VOR: VHF Omnidirectional Range Beacon

Vertical Speed

(x1000 ft per minute)

Barometric Pressure

Setting (in Hg or hPa)

Altitude (ft)

AFCS (Automatic Flight Control

System) Vertical Mode

Page 15

15

PART 2

–

COCKPIT LAYOUT

MFD 1 (Multifunction Display)

Terrain Radar Information

GREEN = LAND

BLUE = WATER

Navigation Page Display

(Top Down View)

Navigation Source Data

FMS: Flight Management System

024: Heading to next waypoint

CYYZ: Next Waypoint (Toronto)

856 NM: Distance to next waypoint

Heading

Magenta Line

Leads to next waypoint

PFCS (Primary Flight Control System)

LO: Left Outer Aileron Indication

LI: Left Inner Aileron Indication

RO: Right Outer Aileron Indication

RI: Right Inner Aileron Indication

RUD: Rudder Indication

L ELEV: Left Elevator Indication

R ELEV: Right Elevator Indication

True Airspeed (kts)

Ground Speed (kts)

Page 16

16

PART 2

–

COCKPIT LAYOUT

Pitot Static Isolation

Valve Switch

Page 17

17

PART 2

–

COCKPIT LAYOUT

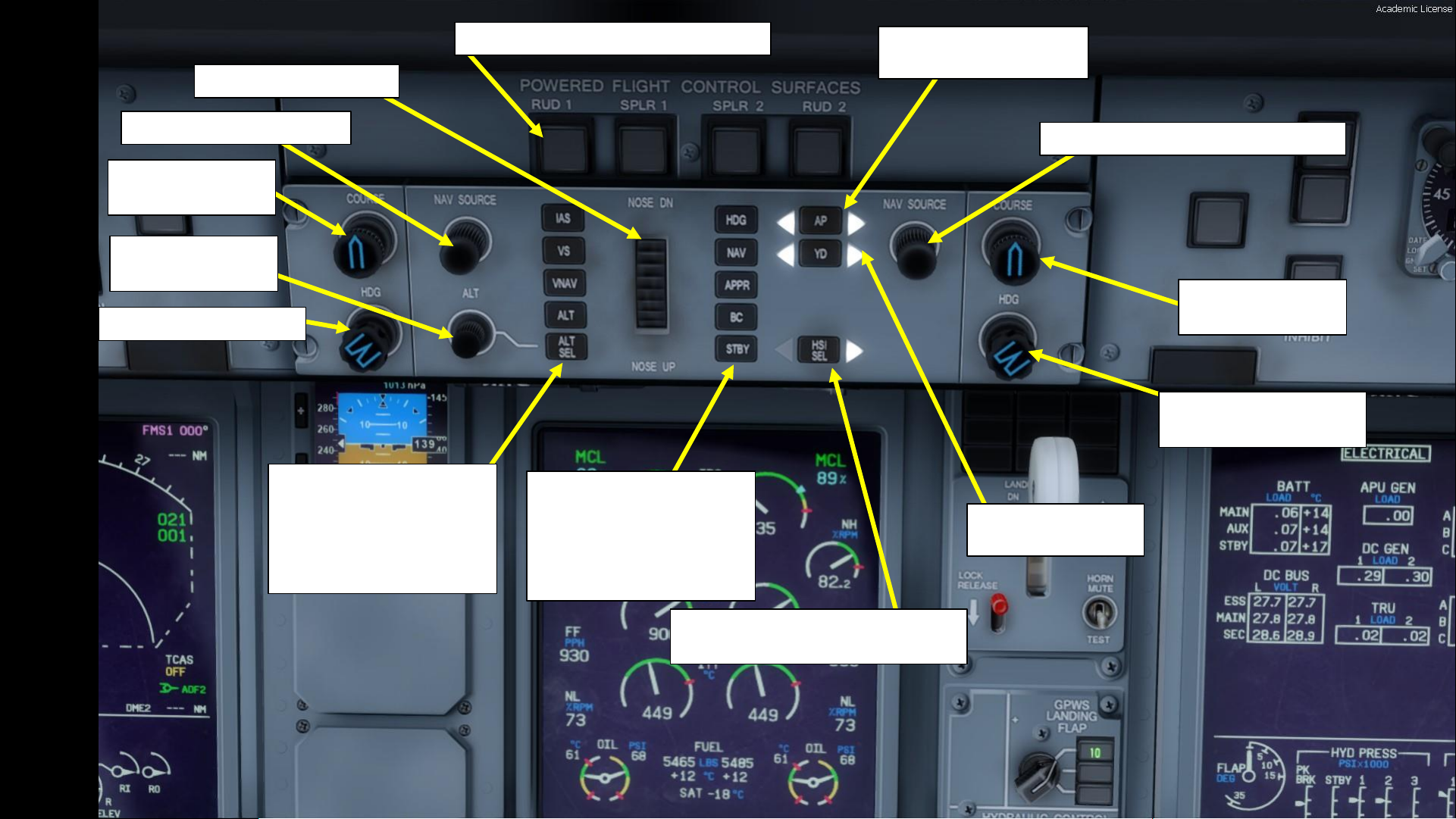

Rudder & Spoilers PUSH OFF switches

Autopilot Pitch Wheel

Navigation Source Selector

Course Selection

Knob

Altitude Selection

Knob

Heading Selection Knob

Autopilot Mode Selectors

IAS: Indicated Airspeed

VS: Vertical Speed

VNAV: Vertical Navigation

ALT: Altitude Hold

ALT SEL: Selected Altitude

Autopilot Mode Selectors

HDG: Heading

NAV: Navigation

APPR: Approach

BC: Back Course

STBY: Standby

HSI (Horizontal Situation Indicator)

Source Selector for Autopilot

Yaw Damper Button

Illuminated = Engaged

Autopilot Master Switch

Illuminated = Engaged

Navigation Source Selector (Copilot)

Course Selection

Knob (Copilot)

Heading Selection Knob

(Copilot)

Page 18

18

PART 2

–

COCKPIT LAYOUT

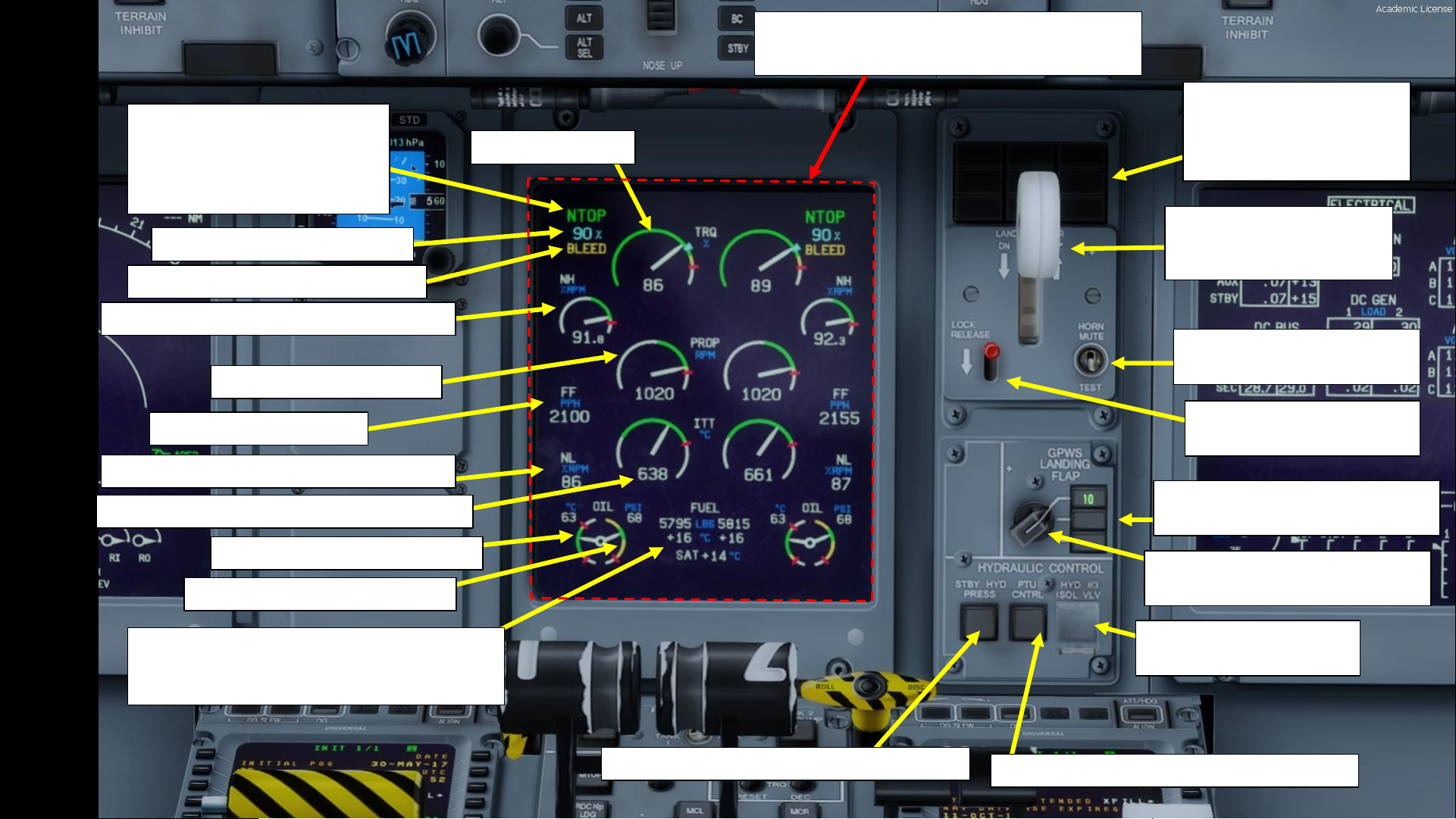

ED: Engine Display

Displays EFIS (Electronic Flight Instrument System) data

Engine Rating Mode

NTOP: Normal Takeoff

MCL: Maximum Climb

MCR: Maximum Cruise

MTOP: Maximum Takeoff Power

Engine Rating Target Torque (%)

Engine Torque (%)

NH (High-Pressure Turbine Speed) (% RPM)

NP (Propeller Speed) (RPM)

Fuel Flow (lbs per hour)

NL (Low-Pressure Turbine Speed) (% RPM)

Engine Oil Temperature (deg C)

Fuel Quantity – Left & Right Tank (lbs)

Fuel Temperature – Left & Right Tank (deg C)

SAT: Static Air Temperature (deg C)

ITT (Interstage Turbine Temperature) (deg C)

Engine Bleed Status Annunciation

Engine Oil Pressure (psi)

Landing Gear Lever

DOWN = GEAR DEPLOYED

UP = GEAR RETRACTED

Landing Gear Indications

Yellow: Gear Doors Open

Green: Gear Down

Red: Gear Unsafe

Landing Configuration

Warning Mute & Test Switch

Gear Handle Lock Release

Switch

GPWS (Ground Proximity Warning

System) Landing Flap Indication

GPWS (Ground Proximity Warning

System) Landing Flap Control

Standby Hydraulic Pressure Pump switch

PTU (Power Transfer Unit) Control switch

No. 3 Hydraulic System

Isolation Valve switch

Page 19

19

PART 2

–

COCKPIT LAYOUT

HGS (Head-Up Guidance System) Advisory Panel

Anti-Skid Switch

DOWN = OFF

MIDDLE = ON

UP = TEST

Page 20

20

PART 2

–

COCKPIT LAYOUT

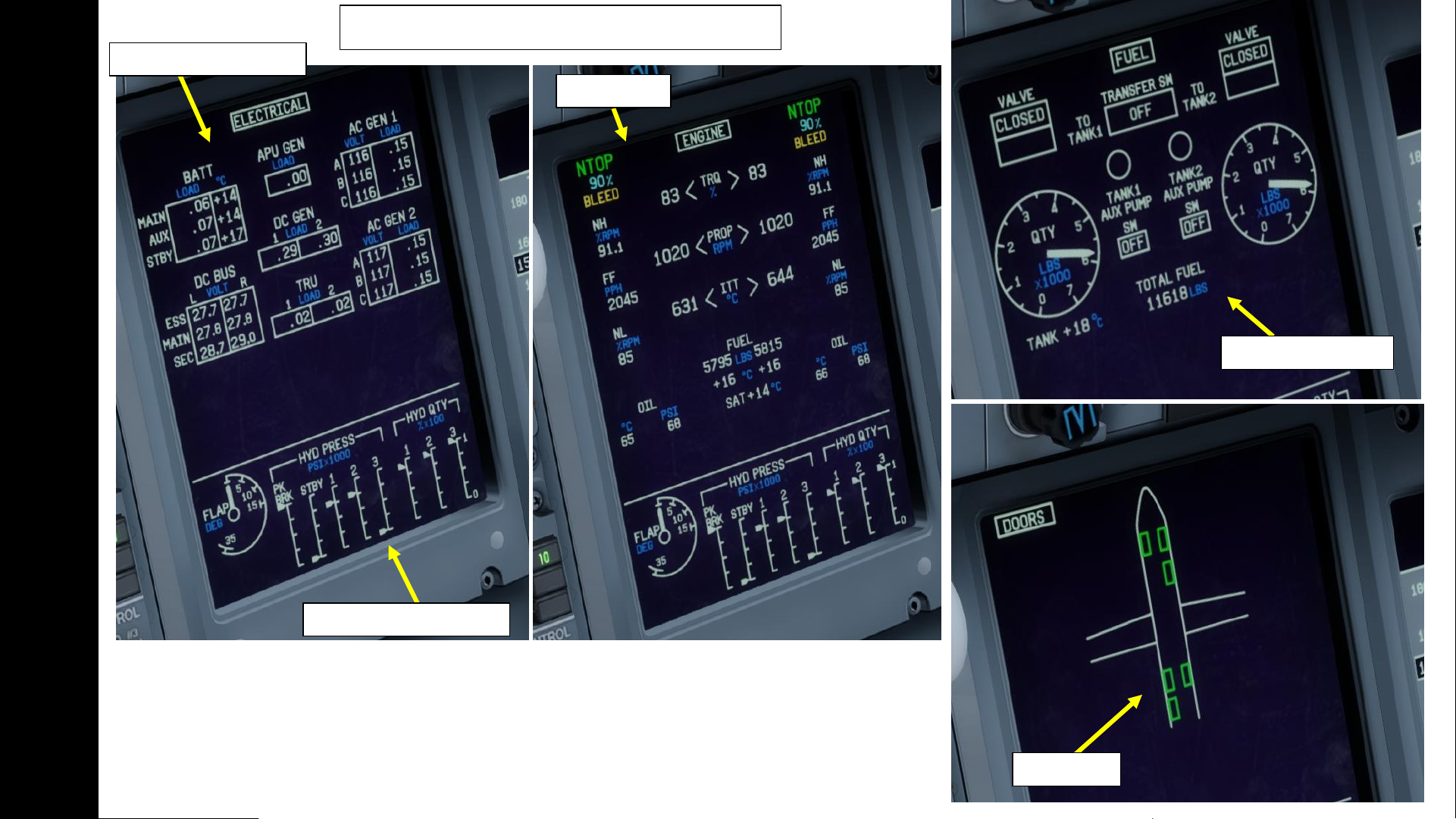

MFD 2 (Multifunction Display)

Page 21

21

PART 2

–

COCKPIT LAYOUT

MFD 2 (Multifunction Display) Pages

Electrical Systems Page

Hydraulic Systems Page

Engine Page

Fuel Systems Page

Doors Page

Page 22

22

PART 2

–

COCKPIT LAYOUT

Forward Outflow Valve Guard

Circuit Breaker Panel Lighting

Control Toggle Switch

Copilot’s Side Panel Dimmer Knob

Windshield Wiper Ice

Detection Light Pushbutton

Microphone Interphone/Transmit

Toggle Switch

Forward Outflow Valve Control

Oxygen Supply Pressure (psi)

De-Ice Pneumatic Pressure (left

and right systems)

Page 23

23

PART 2

–

COCKPIT LAYOUT

AHRS (Attitude & Heading Reference System) Alignment Switch

FMS (Flight Management System) CDU (Multifunction Control Display Unit)

• An FMS is a specialized computer system that automates a wide variety of in-flight

tasks, reducing the workload on the flight crew to the point that modern civilian aircraft

no longer carry flight engineers or navigators. A primary function is in-flight

management of the flight plan.

• The FMS is controlled through the MCDU physical interface.

• The FMS sends the flight plan for display to the Electronic Flight Instrument

System (EFIS), NavigationDisplay (ND),or Multifunction Display (MFD).

AHRS Pitch Basic

Mode Switch

AHRS Directional Gyro

Slew Buttons

AHRS Directional Gyro

Slaved Mode Switch

AHRS Directional Gyro

Mode Switch

Pitch Disconnect Handle

Roll Disconnect Handle

Fuel Tank 1 Auxiliary Pump Pushbutton

Fuel Tank 2 Auxiliary Pump Pushbutton

Fuel Transfer Switch

LEFT / TO TANK 1: Transfers fuel to left fuel tank

MIDDLE: OFF

RIGHT / TO TANK 2: Transfers fuel to right fuel tank

Page 24

24

PART 2

–

COCKPIT LAYOUT

MTOP (Maximum Takeoff Power) Engine

Rating Selector

RDC NP LDG (Reduced Propeller Speed

Landing) Engine Rating Selector

Event Marker Pushbutton

Stores a data snapshot in the Engine Management System

leading up to the recorded event (i.e. engine malfunction)

RDC TOP (Reduced Takeoff Power) Engine Mode Reset Button

RDC TOP (Reduced Takeoff Power) Engine Mode Selector

MCR (Maximum Cruise) Engine Rating Selector

MCL (Maximum Climb) Engine Rating Selector

No. 2 Propeller Alternate Feathering Button

No. 1 Propeller Alternate Feathering Button

Autofeather Pushbutton

COM 1 Radio Frequency Display

COM 1 Radio Frequency Tuner

COM 1 Power Selector

OFF / ON / TEST

COM 1 Activate Frequency

Button

Cockpit Voice Recorder

Microphone Monitor Panel

EFCP (Electronic Flight Instrumentation System

Control Panel)

Page 25

25

PART 2

–

COCKPIT LAYOUT

Left Navigation Source Selector 1

AUX1: Auxiliary Equipment (i.e. MLS)

FMS1: Flight Management System 1

ADF1: Automatic Direction Finder 1

VOR1: VHF Omnidirectional Range 1

OFF

TCAS (Traffic & Collision

Avoidance System) Button

WX/TERR (Weather /Terrain Radar) Button

FMS Data Selection Button

• Push 1 shows 10 nearest navigation aids on MFD NAV page

• Push 2 shows the 10 nearest airports on MFD NAV page

• Push 3 shows navigation aids + airports on MFD NAV page

• Push 4 removes all options

• Push & HOLD removes all nav aids + airports

Left Navigation Source Selector 2

AUX2: Auxiliary Equipment (i.e. MLS)

FMS2: Flight Management System 2

ADF2: Automatic Direction Finder 2

VOR2: VHF Omnidirectional Range 2

OFF

WX/TERR (Weather /Terrain Radar)

Brightness Control

Navigation Display Range Selector (nm)

MFD Navigation Display Format Switch

PFD (Primary Flight Display) Brightness Control

MFD (Multifunction Display) Brightness Control

Page 26

26

PART 2

–

COCKPIT LAYOUT

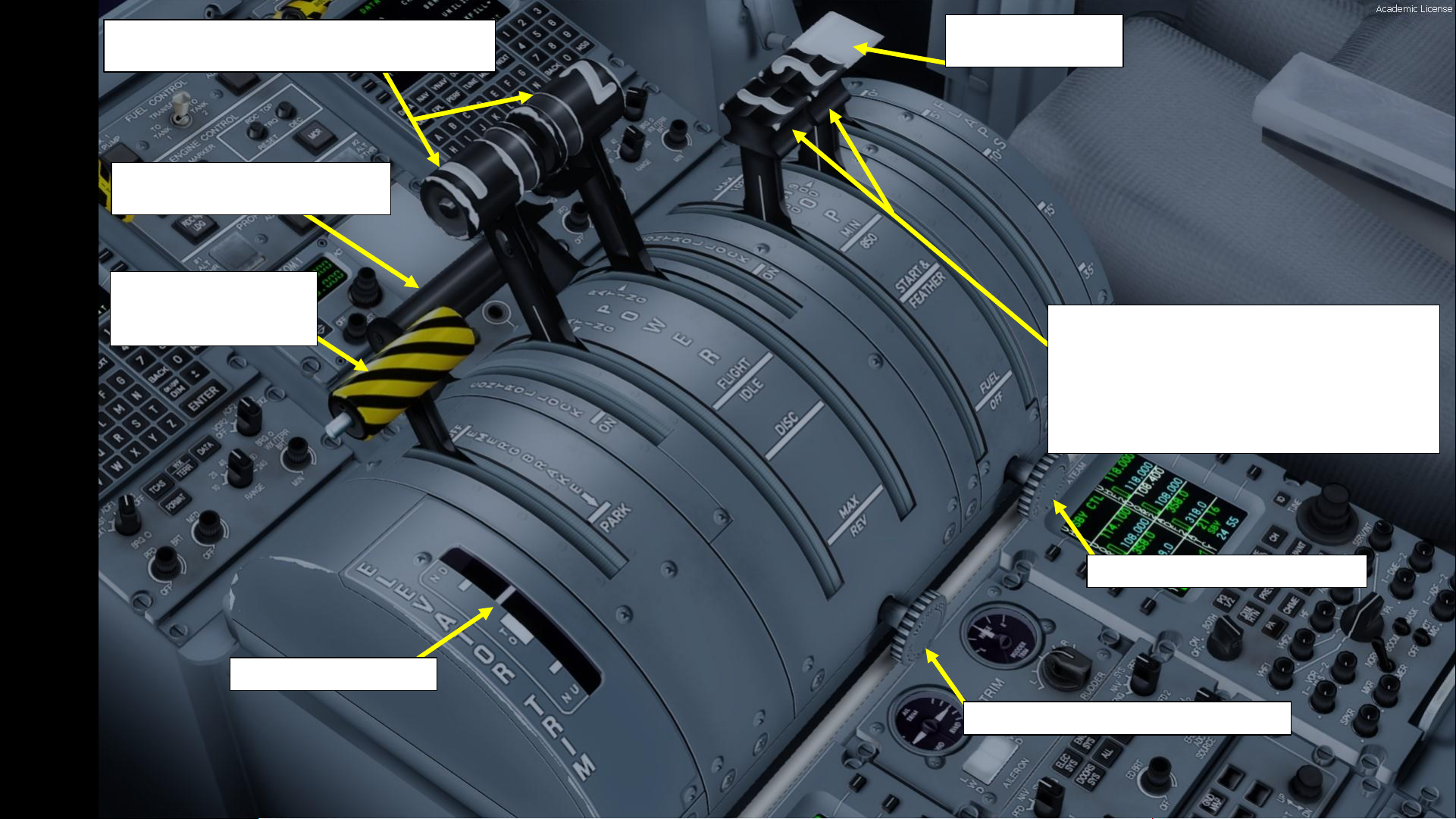

Throttle Power Levers

Positions: MAX / FLIGHT IDLE / DISC / MAX REV

Condition Levers

• MAX: 1020 RPM (Normal Takeoff Rating)

• MCL: 900 RPM (Maximum Climb Rating)

• MIN: 850 RPM (Maximum Cruise Rating)

• START & FEATHER: Propeller Blade Angle is Feathered

during engine start

• FUEL OFF: Fuel shutoff

Condition Lever Friction Control

Throttle Power Lever Friction Control

Elevator Trim Indicator

Parking Brake

FWD: OFF (DISENGAGED)

AFT: ON (ENGAGED)

Control Lock Lever

Physically blocks throttle power levers

Flaps Control Lever

0 / 5 / 10 / 15 / 35 deg

Page 27

27

PART 2

–

COCKPIT LAYOUT

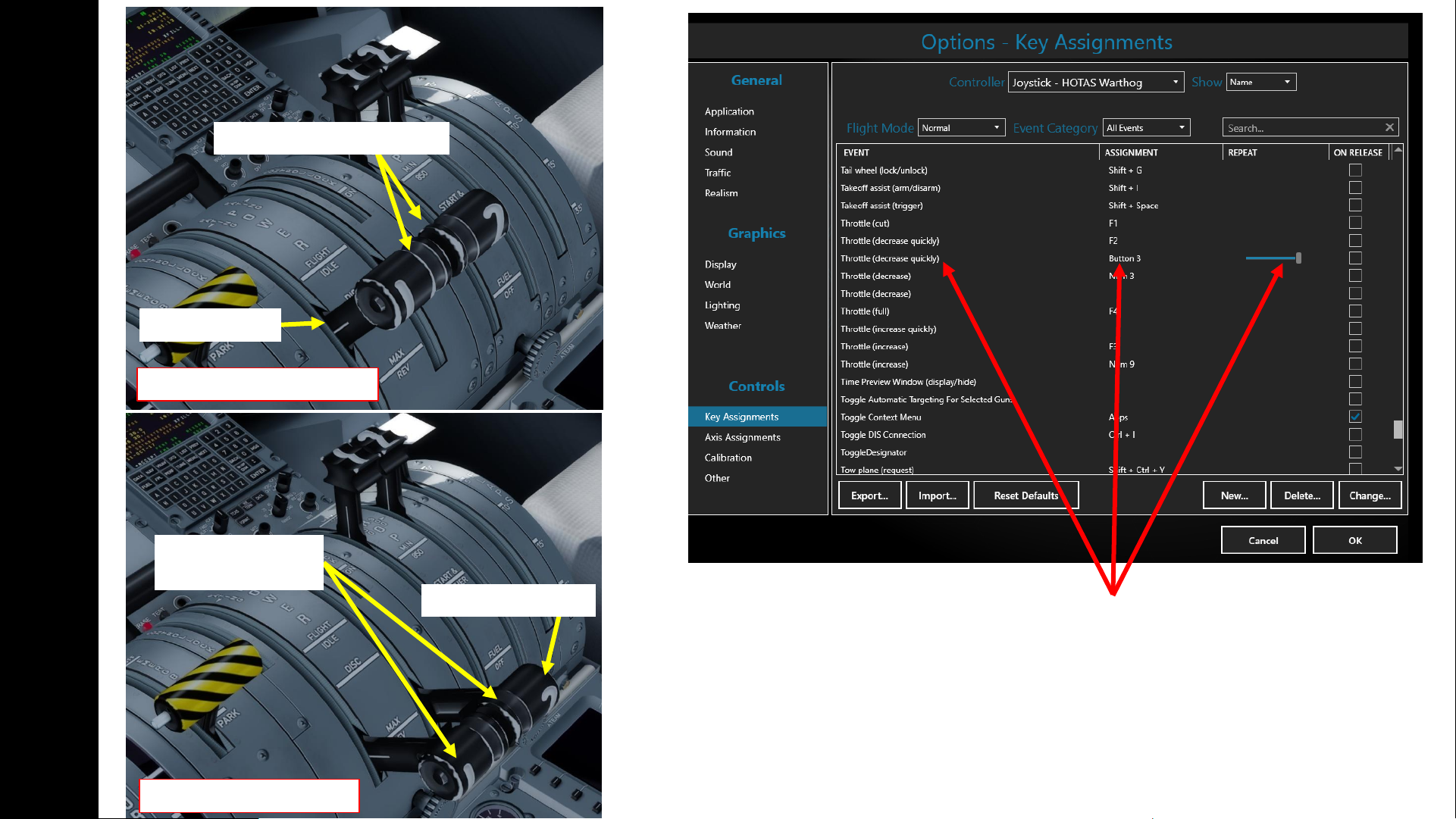

The Thrust Reverser lever can be moved by pressing and holding the “Throttle (decrease

quickly)” control mapped to your joystick. Make sure that the “Repeat” slider is set fully

to the right. The default key binding is “F2”.

Take note that the Reverse Thrust lever can only be engaged if your throttle is at IDLE.

The reason for that is a mechanical stopper that prevents you from engaging thrust

reversers at high throttle settings.

No Reverse Thrust Generated

Reverse Thrust Generated

Throttle at IDLE

Thrust Reversers Disarmed

Throttle at MAX REV

Thrust Reversers

Armed

Page 28

28

PART 2

–

COCKPIT LAYOUT

ARCDU 1 (Audio & Radio

Control Display Unit)

Frequencies: UHF1 / UHF2 / VOR1 /

VOR2/ ADF1 / ADF2 / INT / ATC1

IRS (Inertial Reference System) 1

Mode Switch

OFF: OFF

NAV: Navigation Mode

ATT: Attitude Information Only

Page 29

29

PART 2

–

COCKPIT LAYOUT

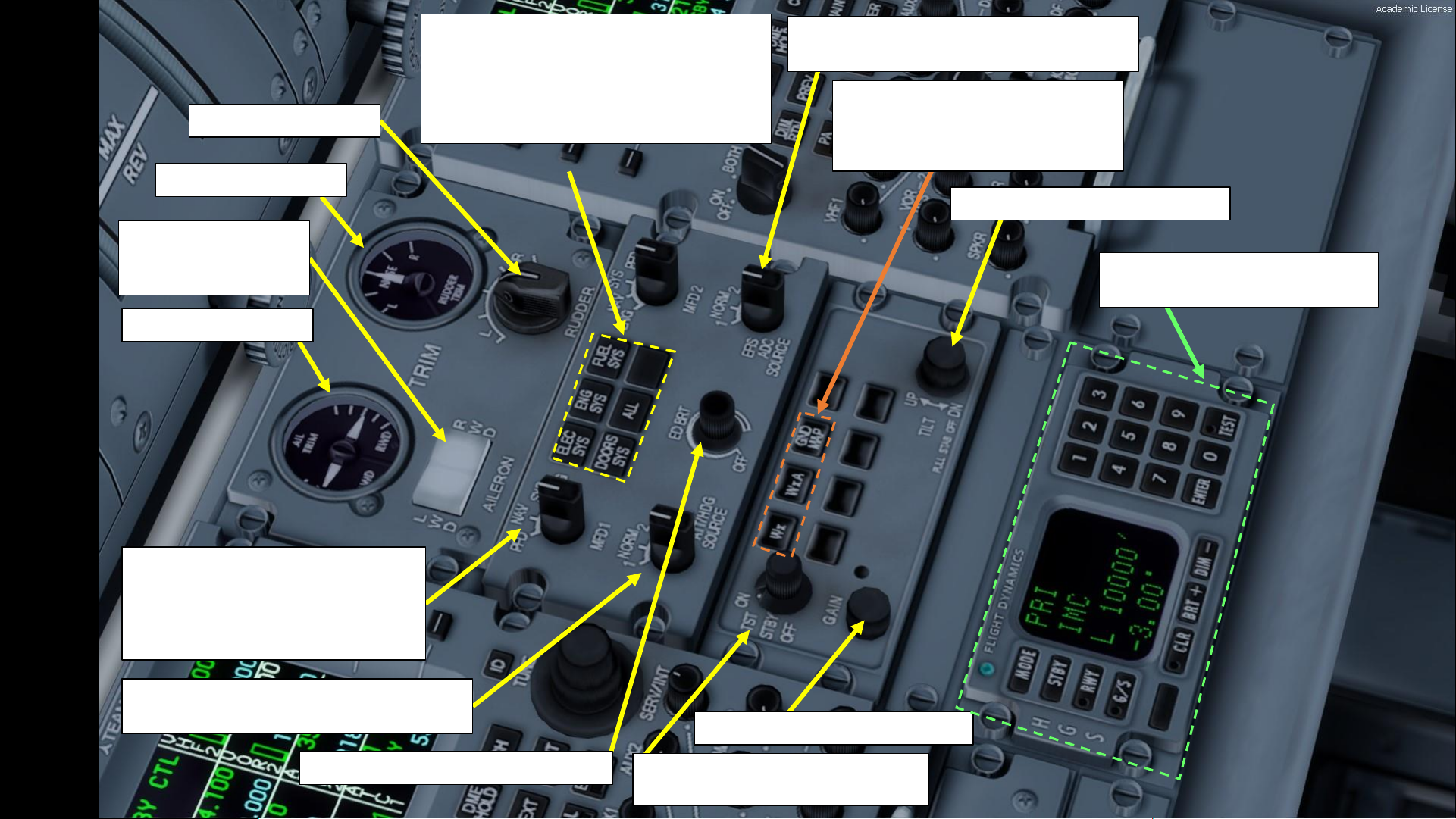

Rudder Trim Indicator

Aileron Trim Indicator

Rudder Trim Control

Aileron Trim Control

LWD: Left Wing Down

RWD: Right Wing Down

MFD (Multifunction Display) 1 Mode

PFD: Primary Flight Display

NAV: Navigation Page

SYS: System Page

ENG: Engine Page

EFIS (Electronic Flight Instrument System)

Attitude/Heading Source Selector

MFD (Multifunction Display) Page Selector

Electrical Systems Page

Engine Systems Page

Fuel Systems Page

Doors Systems Page

Test Button (not simulated)

EFIS (Electronic Flight Instrument System)

ADC (Air Data Computer) Source Selector

ED (Engine Display) Brightness Control

WX (Weather Radar) Power Switch

OFF / STANDBY / TEST / ON

WX (Weather Radar) Gain Control

WX (Weather Radar) Mode Buttons

WX: Weather Radar Mode

WXA: Weather Radar Alert Mode

GND MAP: Ground Map Mode

WX (Weather Radar) Tilt Control

HGS (Head-Up Guidance System)

Control Panel

Page 30

30

PART 2

–

COCKPIT LAYOUT

ARCDU 2 (Audio & Radio

Control Display Unit)

Frequencies: UHF1 / UHF2 / VOR1 /

VOR2/ ADF1 / ADF2 / INT / ATC1

Page 31

31

PART 2

–

COCKPIT LAYOUT

Landing Gear Locking Pins

(stowed in bag)

Nose Landing Gear

Emergency Release Lever

Page 32

32

PART 2

–

COCKPIT LAYOUT

Caution & Warning Panel

Magnetic Compass

Page 33

33

PART 2

–

COCKPIT LAYOUT

Page 34

34

PART 2

–

COCKPIT LAYOUT

HGS (Head-Up

Guidance System)

HGS Brightness Control

HGS Stow/Deploy Handle

Page 35

35

PART 2

–

COCKPIT LAYOUT

Pressure Differential between

Cabin and Surrounding

Environment (psi)

Current Pressure Altitude

Inside Cabin (x1000 ft)

Pressure Altitude Change Rate

(x1000 ft per minute)

Taxi Lights Switch

Landing Flare

Lights Switch

Landing Approach

Lights Switch

Pilot Side Window Heat Switch

Wiper Control Switch

Windshield De-Icing

Mode Selector

Pitot Static Heat Probe 2 Switch

Pitot Static Heat Probe 1 Switch

Pitot Static Standby Probe Switch

Boot Air (Airframe

Deice Air Isolation

Valve) Switch

Page 36

36

PART 2

–

COCKPIT LAYOUT

Flight Data Recorder Switch

ELT (Emergency Locator

Transmitter) Switch

PFD (Primary Flight Display) Altimeter Units Switch

(ft / ft+m)

Propeller De-Icing

Status Indicator

Increase Reference Speeds Switch

Engine Intake De-Ice Indicators

Propeller De-Ice Mode Switch

De-Ice Wing Boots

Status Indicators

Airframe De-Ice

Mode Switch

De-Ice Tail Boots

Status Indicators

Airframe Manual

De-Ice Switch

Page 37

37

PART 2

–

COCKPIT LAYOUT

Generator 1 Switch

Generator 2 Switch

Main Bus Tie Switch

Bus Fault Reset Switch

External Power Switch

Standby Battery Switch

Auxiliary Battery Switch

Main Battery Switch

Battery Master

Switch

Page 38

38

PART 2

–

COCKPIT LAYOUT

Engine 1 Fuel Valve Indicator

Engine 1 Extinguisher Aft/Forward Bottle Selector Switch

APU Extinguisher

Bottle Arming Light

APU (Auxiliary Power Unit) Fuel Valve Indicator

APU Fire Extinguish Button

APU Fire Detected Light

APU Extinguisher Bottle Low / Fault light

APU Fire Test Switch

Engine 1 Fire Detection Fault Lights

(Systems A & B)

Engine 1 Fire Extinguish Handle

(Illuminates when fire is detected)

Engine 1/2 Fire Detection Test

Selector Switch

Engine 2 Fire Extinguish Handle

(Illuminates when fire is detected)

Aft Baggage Compartment

Fire Detection Panel

Page 39

39

PART 2

–

COCKPIT LAYOUT

Emergency Exit Hatch Handle

Landing Gear Alternate Release Handle

Page 40

40

PART 2

–

COCKPIT LAYOUT

Overhead Console Panel Lighting Brightness Control

Glare Shield Panel Lighting Brightness Control

Forward Center Console Panel Lighting Brightness Control

Aft Center Console Panel Lighting Brightness Control

Storm Lights Switch

Dome Lights Switch

AC External Power Switch

AC Generator 2 Switch

AC Generator 1 Switch

Air Conditioning Duct

Temperature (deg C)

Recirculation Fan Switch

Engine 1 Bleed Switch

Engine 2 Bleed Switch

Bleed Flow Mode Selector

MIN/NORM/MAX

Temperature Indicator Switch

Cabin Duct

Cabin

Flight Compartment Duct

PACKS (Pressurization & Air

Conditioning Kit) 1 & 2 Switches

OFF / MANUAL / AUTOMATIC

Flight Compartment

Temperature Regulator

Cabin Compartment

Temperature Regulator

Page 41

41

PART 2

–

COCKPIT LAYOUT

Selected Landing Altitude

Indicator (x1000 ft)

Landing Altitude Selector

Manual Pressure Control

Pressurization Mode Selector

Pressurization Fault Light

Manual Forward Outflow Valve Control

Engine 2 Ignition Selector

Engine 1 Ignition Selector

APU (Auxiliary Power Unit) Power Switch

APU (Auxiliary Power Unit) Start Switch

APU (Auxiliary Power Unit) Generator Switch

APU (Auxiliary Power Unit) Bleed Air Switch

Note: APU Bleed Air only works if engine bleed air

switches are OFF

Engine Start Button

Engine Start Selector Button (1/2)

Page 42

42

PART 2

–

COCKPIT LAYOUT

Emergency Lights Switch

Fasten Seatbelts Light Switch

No Smoking Light Switch

Caution/Advisory Panel Lights Test Switch

Caution/Advisory Lights Dimming / Brightness switch

Wing Inspection Light Switch

White/Red Anti-collision

Lights Switch

Position Lights Switch

Logo Light Switch

Page 43

43

PART 2

–

COCKPIT LAYOUT

Circuit Breaker Panel

Side Window De-Mist Control

AFT = OPEN

FWD = CLOSED

Low Level Vents Control

AFT = OPEN

FWD = CLOSED

Page 44

44

PART 2

–

COCKPIT LAYOUT

Circuit Breaker Panel

Microphone &

Headset Jacks

Oxygen Crew Mask

Page 45

45

In real life, you cannot just fly an Q400 wherever and whenever you please.

Just like on land, the sky is littered with an intricate network of waypoints and

aerial highways. Therefore, it is necessary to plan your flight route and to

determine how much fuel you will need to carry in order to reach your

destination.

In order to do this, we will use a tool called “Online Flight Planner” available

here: http://onlineflightplanner.org/

There are a number of fuel planners available online. These estimates may or

may not be very accurate. There are specific charts created by Bombardier to

come up with accurate fuel estimates which are unfortunately not available to

the public. Therefore, for the sake of simplicity we will just use a rule of thumb

that’s good enough for the purpose of this tutorial.

PLANNING THE FLIGHT

PART 3

–

FLIGHT PLANNING

Page 46

46

Today’s flight will start from TORONTO / LESTER B. PEARSON INTERNATIONAL AIRPORT

(CYYZ) and our destination will be MONTREAL / PIERRE-ELLIOTT TRUDEAU

INTERNATIONAL AIRPORT (CYUL).

Using the “Online Flight Planner” available here: http://onlineflightplanner.org/ we will

enter the Departure airport (CYYZ), the Destination airport (CYUL) and the AIRAC Cycle

desired (we will use the AIRAC cycle 1710 as explained on the next page).

Click on CREATE PLAN to generate a flight plan.

Bombardier Dash 8 Q400

Click CREATE PLAN

Choose your fuel units: LBS in our case

PART 3

–

FLIGHT PLANNING

PLANNING THE FLIGHT

Page 47

47

In aviation, an Aeronautical Information Publication (or AIP) is defined by the International Civil Aviation Organization as a publication issued by or with the authority of a state and

containing aeronautical information of a lasting character essential to air navigation. It is designed to be a manual containing thorough details of regulations, procedures and other information pertinent to flying

aircraft in the particular country to which it relates. It is usually issued by or on behalf of the respective civil aviation administration. AIPs are kept up-to-date by regular revision on a fixed cycle. For operationally

significant changes in information, the cycle known as the AIRAC (Aeronautical Information Regulation And Control) cycle is used: revisions are produced every 56 days (double AIRAC cycle) or every 28 days

(single AIRAC cycle). These changes are received well in advance so that users of the aeronautical data can update their flight management systems (FMS). (Source:

https://en.wikipedia.org/wiki/Aeronautical_Information_Publication )

In other words, some Youtube tutorials might show you flight routes with certain waypoints that got changed with more recent AIRAC updates. Some waypoints or even airports may not exist anymore.

Therefore, you have two options:

1. Plan your flight using the default AIRAC cycle programmed in the FMC when it was first released by Majestic Software during early October, 2017 (period 10) 2017 (AIRAC cycle 1710), which is what we will

do for this tutorial. This option is free and simple if you fly alone. However, if you fly with online ATCs in multiplayer that use the latest AIRAC database, you should go for the second option.

2. Plan your flight using the latest AIRAC cycle. You will need to update your AIRAC, SID and STAR database by using a paid subscription service called “Navigraph”, which is available here

https://www.navigraph.com/FmsDataManualInstall.aspx .

PART 3

–

FLIGHT PLANNING

PLANNING THE FLIGHT

Note:

• For the FSX version of the Q400, use

AIRAC cycle 1304 since this version

was released in late april 2013

• For the Prepar3d Version 4.1 of the

Q400, use AIRAC cycle 1710.

Page 48

48

FUEL

For a flight of approx. 290 nm, fuel planning can be estimated with the following graph from

MJCJavelin (http://majesticsoftware.com/forums/discussion/344/fuel-planning/p1), which he

obtained by programing a regression and an interpolationbased on fuel consumption tables:

Imperial Units

Fuel for flight = Fuel Quantity for required distance (300 nm approx.) on graph below

= 1.3 tons = 2600 lbs (or 1.3 tons x 2000 lbs/ton)

Reserve Fuel = 2500 lbs (approximative figure)

Total (Block) Fuel = Fuel for Flight + Reserve Fuel = 5100 lbs

Note: An alternate way to calculate the fuel for flight is to use a fuel consumption of 1300 lbs

of fuel per engine per hour of flight. For an hour-long flight from Montreal to Toronto, the fuel

quantity would be: Fuel for Flight = 1300 lbs/hour x 2 engines x 1 hour = 2600 lbs approx.

PART 3

–

FLIGHT PLANNING

PLANNING THE FLIGHT

Page 49

49

FLIGHT ROUTE (POTENTIAL)

The flight route we could take from onlineflightplanner.com is:

CYYZ SID MIGLO STAR CYYZ

But what does it all mean? Here is a breakdown of this route:

• Depart from Toronto Lester B. Pearson Airport (CYYZ)

• Follow the SID (Standard Instrument Departure) route from CYYZ to MIGLO

• Navigate to MIGLO VOR

• Follow the STAR (Standard Terminal Arrival Route) from MIGLO to CYUL

• Land at Montreal Pierre-Elliott Trudeau Airport (CYUL)

Not our flight plan

(thank god)

PART 3

–

FLIGHT PLANNING

PLANNING THE FLIGHT

WOAH, STOP RIGHT THERE!

Did you really think the flight plan would be that easy? No Sir/Madam!

We will spice things up a bit and slightly modify the flight plan. Why?

Because that simple flight plan will not force you to know how to plug in

airways and use the FMS (Flight Management System) to do cool things

like giving you lists of waypoints already stored in the database.

Relax, we won’t do a complicated flight plan like Boeing’s custom “787shaped” flight plan. We will just modify a little bit the existing flight plan

using Sky Vector, a great tool available for free online. See next page.

Page 50

50

FLIGHT ROUTE (ACTUAL) <- This is what we’ll use

The actual flight route we will take is:

CYYZ SID DEDKI Q913 IGSEB DCT MIGLO STAR CYUL

Write this route down. This is the one we will plug in the Flight Management System (FMS).

But what does it all mean? Here is a breakdown of this route:

• Depart from Toronto Lester B. Pearson Airport (CYYZ)

• Follow the SID (Standard Instrument Departure) route from CYYZ to DEDKI

• Follow Q913 airway

• Navigate to IGSEB VOR

• Navigate directly from IGSEB to MIGLO VOR (“DCT” means “Direct to”)

• Follow the STAR (Standard Terminal Arrival Route) from MIGLO to CYUL

• Land at Montreal Pierre-Elliott Trudeau Airport (CYUL)

PART 3

–

FLIGHT PLANNING

PLANNING THE FLIGHT

CYYZ DEDKI

IGSEB

MIGLO

CYUL

Airway

Q913

SKY VECTOR

https://skyvector.com/

Page 51

51

WHAT IS A SID AND A STAR?

A SID (Standard Instrument Departure) is a small initial route

which leads an aircraft from the runway they've just taken off

from to the first point in his/her intended route. An airport usually

has a lot of aircraft departing from it's runways. To save confusion

(and for safety), a busy airport will publish standard routes from

it's runways to the various routes away from that airport. This way

a controller can be sure that even if a steady stream of aircraft is

leaving the airport they will all be following in a nice neat line, one

behind the other (that's the idea anyhow!).

Standard routes are the preferred method to fly from airport to

airport. This is why we use a flight plan generator. Arriving at an

airport is just the same. The STARs (STandard Arrival Routes) are

also published in chart form and allow you to fly into an airport

using standard procedures. This way, less communication is again

needed with the controllers as (once you have declared your

intention or been given a route to fly by name) the controller and

you both know exactly how you are going to approach the airport.

The end of the STAR route will normally leave your aircraft at a

position where controllers can give you final instructions to set

you up for a landing.

SIDs and STARs are quite similar to highways; they have speed

limits and altitude restrictions at certain waypoints to make sure

the air traffic is flying safely and on the same trajectory. The FMC

(Flight Management Computer) will automatically try to respect

these restrictions.

In other words, you can see SIDs and STARs like road junctions in

the sky that lead to other waypoints and airways from or to your

desired airport. One airport has many SIDs and STARs.

Typically, SIDs and STARs are provided by the ATC (Air Traffic

Controller). Since we’re doing a tutorial, I will just give you the SID

and STAR to plug in the FMC.

PART 3

–

FLIGHT PLANNING

Page 52

52

PLANNING THE DEPARTURE - SID

1: Gate B22

These charts are for the SID (Standard Instrument Departure)

from Toronto Pearson (CYYZ) to DEDKI. We intend to:

1. Spawn at Gate B22 (personal preference)

2. Taxi towards runway 05 (orientation: 057) using taxiways

3, Alpha-Juliet (AJ), Alpha (A), November (N), Echo (E),

Golf (G), Hotel (H) and holding point H6.

3. Depart from CYYZ using the SID from CYYZ to DEDKI

(DEDKI4) to a target altitude of 3000 ft (FL030).

NOTE: the chart shows DEDKI3 (valid for November 2014) since

I could not find the chart for DEDKI4 (valid for January 2018).

Therefore, we will assume DEDKI3 and DEDKI4 are roughly the

same for the purpose of this tutorial.

4. Climb to a cruising altitude of 24,000 ft

2: Runway 05

(holding point H6)

PART 3

–

FLIGHT PLANNING

3: SID towards DEDKI

Page 53

PLANNING THE

APPROACH - STAR

These charts are for the STAR (Standard Terminal Arrival

Route) from MIGLO to Montreal Pierre-Elliott Trudeau

(CYUL). We intend to:

1. Come from MIGLO waypoint

2. Fly from MIGLO towards the HABBS3 arrival route.

3. Follow the STAR (MIGLO -> REEDO -> IGVUD -> KAVSU ->

ARVIE -> HABBS -> XULTA)

4. Follow the approach towards the runway, guided by the

CYUL airport’s ILS (InstrumentedLanding System).

5. Land at Montreal (CYUL) on runway 06L (orientation:

060 Left)

PART 3

–

FLIGHT PLANNING

Fun fact: The HABBS STAR name

actually comes from the Montreal

Canadiens hockey team, nicknamed

the “Habs”.

53

Page 54

54

So there it is! This is more or less all the information you need to plan your flight!

PLANNING THE FLIGHT - SUMMARY

Flight Plan Input to FMC

PART 3

–

FLIGHT PLANNING

CYYZ SID DEDKI Q913 IGSEB DCT MIGLO STAR CYUL

Page 55

55

MCDU/FMC IN A NUTSHELL

Most of the aircraft setup and flight planning will be done with the help of the

MCDU, which encompasses various systems such as the FMC system.

MCDU: Multifunction Control Display Unit

FMC: Flight Management Computer

Fundamental component of a modern airliner's avionics. The FMC is a

component of the FMS (Flight Management System), which is a specialized

computer system that automates a wide variety of in-flight tasks, reducing

the workload on the flight crew to the point that modern civilian aircraft no

longer carry flight engineers or navigators. A primary function is in-flight

management of the flight plan. All FMS contain a navigation database. The

navigation database contains the elements from which the flight plan is

constructed. The FMS sends the flight plan for display to the Electronic Flight

Instrument System (EFIS), Navigation Display (ND), or Multifunction Display

(MFD).

MCDU DATA PAGE

PART 3

–

FLIGHT PLANNING

Fun fact: FMS installed on the Q400 is the UNS-1E by Universal Avionics

Systems Corporation. It differs significantly from the usual Thales or Rockwell

Collins FMCs you might have already seen on Boeing or Airbus aircraft.

Page 56

56

FMC -> Flight Management Computer

• DATA : Obtains information and status about the FMS, Navigation database and

attached sensors. It also has the “SERVICES” page which is used to simulate ground

crew behavior such as setting a GPU (Ground Power Unit), or removing/installing

landing gear locking pins.

• NAV : Displays navigation data pages.

• VNAV : Vertical Navigation page allows a pilot to define a desired vertical flight

profile along the flight plan route. It also computes deviation from that profile.

• DTO : The “Direct To” key allows the pilot to alter his flight plan.

• FUEL : displays fuel and weight pages.

• FPL : The “Flight Plan” pages access waypoints, stored arrivals, departures, SIDs,

and STARs.

• PERF : The “Flight Performance” page displays in flight performance information

(read-only).

• TUNE : Selects and stores preselected frequencies for each radio.

• LIST : Displays a list of options during data entry

• MENU : Displays a list of alternate formats or options for the FUEL, FPL, NAV,

VNAV or TUNE pages when selected. When the MENU key is active, the letter “M”

will appear in a box on the title line of the selected page.

• PREV/NEXT: Cycles through previous and next page of selected FMC page

• BACK: Backspace (deletes text)

• MSG: Displays messages

• ON/OFF DIM: Turns ON or OFF Flight Management Computer

• ENTER: Enters data

LSK: Line Select Keys

PART 3

–

FLIGHT PLANNING

MCDU/FMC IN A NUTSHELL

Sounds complicated? Don’t worry, it’s much simpler than it looks. We’ll see

how it works in the tutorial section.

Page 57

57

The Q400 is steered on the ground by using a tiller.

However, in Prepar3d or FSX you cannot map a joystick axis to your nosewheel steering tiller:

it’s a limitation of the sim itself. In order to steer the aircraft, Majestic programmed different

options available in their own custom Control Panel; you can either use the mouse to click and

drag on the tiller lever, or you can have the tiller axis mapped to your stick aileron control. I

suggest you use the latter option.

1. The Control Panel will not work properly if it is not run in “Administrator Mode”. Make sure

you have the Control Panel executable “mjc84cspan.exe” property “Run the program as an

administrator” ticked (right-click file & click “Properties” tab). This executable is available in:

C:\Program Files\Lockheed Martin\Prepar3D v4\SimObjects\Airplanes\mjc8q400\cpan

2. Open the MJC8 Q400 control panel (mjc74cpsan.exefile) before starting Prepar3d

a) Open “mjc84cspan.exe” and go in “Flight Controls” tab

b) Click “Ailerons+Mouse” option

c) Click “Apply”

d) You can now start Prepar3d with the desired steering control mode set.

SET UP CONTROLS

PART 3

–

FLIGHT PLANNING

1a

1b

1c

1d

1e

2a

2a

2b

2c

Page 58

58

In Prepar3d or FSX, you will generally spawn with your engines

running. A “cold & dark” start-up means that your aircraft is in an

unpowered state with engines and every other system off. Here is the

procedure to spawn in such a state:

1. Spawn like you normally would at Gate B22 in CYYZ (departure

airport) in the MJC8Q400

2. Set cockpit in cold & dark state

a) Engage Parking Brake lever (AFT = ENGAGED)

b) Set GEN1, GEN2, BUS FAULT RESET, and EXT PWR

switches to OFF

c) Set STBY BATT, AUX BATT, MAIN BATT and BATTERY

MASTER switches to OFF (in that order)

d) Set MAIN BUS TIE to TIE

SPAWN COLD & DARK

PART 3

–

FLIGHT PLANNING

1: Gate B22

2b

2c

2d

2b

2a

Page 59

59

We will dynamically set our fuel, cargo and passenger

loads using the MajesticControl Panel.

3. Open the MJC8 Q400 control panel

(mjc74cpsan.exe file)

a) Open “mjc84cspan.exe”

b) Go in “Weight & Balance” tab

4. Set fuel loads (we will use 8000 lbs takeoff fuel and

5100 trip fuel, leaving us 1900 lbs extra fuel)

5. Set baggage weight (2000 lbs for this flight)

6. Set number of passengers (58 in our case) through

the PAX sections and make sure that the TOM, LM

and ZFM are within the Trim Envelope

7. Click “Calculate”

8. Verify that the Takeoff Mass, Landing Mass and

Zero Fuel Mass are all under their respective MAX

limits as shown on the graph.

9. Once Weight and Balance configuration is deemed

correct, click on “Send Data to Flightsim” to set the

loads on the aircraft.

LOAD FUEL, CARGO & PASSENGERS

PART 3

–

FLIGHT PLANNING

DOI: Dry Operating Index (position

of CG @ Dry Operating Mass)

TOM: Takeoff Mass

LM: Landing Mass

ZFM: Zero Fuel Mass

Trim Envelope Index

Calculates T/O & Trip Fuel

Sends Fuel/Weight

Configuration To Simulation

Trip Fuel: Required fuel for

duration of flight

Takeoff Fuel: Fuel at

moment of takeoff

Baggage weight

Number of

Passengers

Weight and Balance Page

3a

This executable is available in:

C:\Program Files\Lockheed Martin\Prepar3D v4\SimObjects\Airplanes\mjc8q400\cpan

3b

4

5

6

7

8

6

9

Page 60

Note: In real life, when using external power, the pilot switches the battery switches OFF after switching to the external battery source. This

helps protect batteries from depleting while the ground power unit is in use, or from GPU surges, or in the case of a weak GPU which will

make the batteries “discharge” into the GPU. For simplicity’s sake, we will simply leave the batteries ON.

60

10. On Overhead panel, turn on battery power

a) Set BATTERY MASTER, MAIN BATT, AUX BATT and STBY BATT

switches to ON (in that order)

b) Set Main Bus Tie to TIE

c) Press Master Warning and Master Caution lights to reset them

Note: the aircraft will begin a series of Automatic BITs (built-in

tests).

11. OPTIONAL: Go on MCDU main menu to connect ground power unit

(GPU) to the aircraft

a) Power up FMC by pressing and holding the “DIM ON/OFF”

button on the MCDU.

b) Wait for FMC BIT to complete

c) Click on the “ACCEPT” LSK (Line Select Key) once the INIT page

is displayed

d) Press the MCDU “DATA” button

e) Click on the “SERVICES” LSK to enter ground crew services

page.

f) Click on the “GPU REQUEST” LSK to set ground power. The

MCDU will then display “CANCEL” when GPU is set.

12. OPTIONAL: On overhead panel, click on the “EXT PWR” switch to power

connect aircraft to GPU

13. OPTIONAL: On Electrical Systems page, confirm that the “DC EXT PWR

ON” indication is illuminated

NOTE: Steps 11 to through 13 are optional.

POWER UP AIRCRAFT

6b

PART 3

–

FLIGHT PLANNING

11a

10a

10b

10c

11b

11c

11e

11f

11d

11f

11f

12

13

Page 61

61

Fun fact: the engines of the Q400 can be started either with the APU (Auxiliary Power Unit) or with an external electrical power source like a GPU (Ground Power Unit). The aircraft startup procedures vary from company to company. There is a debate as to whether you shoulduse the GPU or not.

The APU of the Dash 8 Q400 are considered by some to be fragile and unreliable. It supplies electrical power and bleed air, while the GPU provides electrical power only. Why would we

need to use a GPU then? Well, a reason for using the GPU when the APU is running is to lessen on the load on the APU. Certain Canadian airlines will use the APU for air conditioning and

the GPU for electrical power during the engine start. The Q400 uses electrical starter generators instead of a pneumatic starter, meaning the engines can start with electric motors

cranking the engines insteadof a starter powered by APU bleed air like standard airliners like the Airbus A320 or the Boeing 737.

Therefore, for simplicity’s sake, we will use both the GPU and the APU in our tutorial, even if real life procedures are a bit different. Keep in mind that this tutorial is done within the

scope of a simulationand should not be used for real life operation of the aircraft.

POWER UP AIRCRAFT

PART 3

–

FLIGHT PLANNING

Ground Power Unit (GPU)

Auxiliary Power Unit (APU)

Auxiliary Power Unit (APU)

Page 62

62

14. Go on MCDU “DATA -> SERVICES -> EXITS” menu to open doors to

communicate with ground crew personnel

a) In DATA -> SERVICES page, click “EXITS” LSK

b) Click on the LSKs next to FWD PAX, AFT PAX, AFT BAG, and

SERVICE doors to open them (or use the “LSHIFT + E” key

binding)

c) Doors will now be open

15. Click on “RETURN” to go back to the “SERVICES” page

16. Make sure the landing gear pins are removed

a) If the GEAR PINS option shows “GND OPS ONLY”, this means

that either the parking brake is not set or that doors are not open

b) If the GEAR PINS option shows “INSTALL”, this means that the

landing gear pins are removed and are stored in the bag with red

flags behind the copilot’s seat. Your landing gears will now deploy

or retract normally. In that case, you can proceed to the next

page

c) If the GEAR PINS option shows “STOW”, this means that the

landing gear pins are still installed (notice the empty bag behind

the copilot’s seat). Your landing gears will remain locked in their

current position no matter what you do with the landing gear

lever. In that case, you should click on the LSK next to “STOW” to

stow the landing gear pins.

CHECK LANDING GEAR PINS

PART 3

–

FLIGHT PLANNING

14a

14b

14c

15

16a

16b

16c

14c

Landing Gear Pins

Stowed

Landing Gear Pins

Installed

Page 63

63

17. The AHRS (Attitude & Heading Reference System,

which drives the flight instruments) alignment

starts immediately when the battery switches are

ON. The alignment phase is on-going when the

ATT/HDG ALIGN light illuminates and lasts between

45 sec and 2 minutes.

18. The positional information of the navigation

systems are provided by GPS and/or VOR-based

RNAV, which do not require any alignment. The IRS,

on the other hand, acts as a short time supplement

to the GPS in this aircraft. If you see the “GPS

INTEG” caution on the PFD (Primary Flight Display),

this means that the FMC is not turned on.

19. Make sure the IRS (Inertial Reference System)

switch is set to NAV. If it’s not, set it to OFF for 5-10

sec, then set it back to NAV to restart IRS

alignment. You can monitor the alignment process

in the second DATA page of the FMC by pressing

the DATA button two times.

AHRS & IRS ALIGNMENT

PART 3

–

FLIGHT PLANNING

17a

17b 17c

17a

Appears if

FMC is OFF

17d

Alignment

complete

AHRS Alignment

is in process

AHRS Alignment

is in process

19

IRS1 D -> OFF

19

IRS1 ALIGN -> Alignment Phase

IRS1 NAV -> Alignment Complete

AHRS Alignment

is in process

Page 64

64

PART 3

–

FLIGHT PLANNING

17. Initialize the FMC (Flight Management Computer) if

you have not done it already

a) Power up FMC by pressing and holding the

“DIM ON/OFF” button on the MCDU.

b) Wait for FMC BIT (Built-In Test) to complete

c) Click on the “ACCEPT” LSK (Line Select Key)

once the INIT page is displayed

18. Go on FMC (Flight Management Computer) and

initialize your flight plan

a) Press the FPL page button

b) Type “CYYZ” (Pearson Airport) on the

MCDU keypad and press “ENTER”.

c) Click LSK next to “ACCEPT” on the

confirmation screen to validate entry.

d) Type “CYUL” (Trudeau Airport) on the

MCDU keypad and press “ENTER”.

e) Click LSK next to “ACCEPT” on the

confirmation screen to validate entry.

FMC SETUP – FLIGHT PLAN

PART 3

–

FLIGHT PLANNING

17a

17b

17c

18a

18b

18d

18c

18b

18d

18e

18f

Page 65

65

PART 3

–

FLIGHT PLANNING

19. Go on FMC (Flight Management Computer) and set up your

departure parameters

a) Press the FPL page button

b) Press the MENU page button

c) Select LSK next to “DEPART” to enter Departure sub-

menu

d) Type desired runway selection number (runway 05 in

our case, so we type “1” since it is selection item

number 1) on the MCDU keypad and press “ENTER”

FMC SETUP – FLIGHT PLAN

(DEPARTURE)

PART 3

–

FLIGHT PLANNING

Runway 05

(holding point H6)

Gate B22

19a

19b

19b

19d

19d

19c

Page 66

66

PART 3

–

FLIGHT PLANNING

20. Go on FMC (Flight Management Computer) and set up your

departure parameters for the SID (Standard Instrument

Departure)

a) Type desired SID selection number (DEDKI4 in our case,

so we type “6” since it is selection item number 6) on

the MCDU keypad and press “ENTER”

b) Type desired SID transition selection number (Runway

05 in our case, so we type “1” since it is selection item

number 1) on the MCDU keypad and press “ENTER”

c) All departure data is now entered in the FMC.

d) You can click on the FPL page button to verify new

entries.

FMC SETUP – FLIGHT PLAN

(DEPARTURE)

PART 3

–

FLIGHT PLANNING

SID towards DEDKI

20a

20a

20b

20b

20d

20c

Page 67

67

PART 3

–

FLIGHT PLANNING

21. Go on FMC (Flight Management Computer) and set

up your arrival parameters

a) Press the FPL page button

b) Press the MENU page button

c) Select LSK next to “ARRIVE” to enter

Arrival sub-menu

d) Type desired runway selection number

(runway 06 Left in our case, so we type “1”

since it is selection item number 1) on the

MCDU keypad and press “ENTER”

FMC SETUP – FLIGHT PLAN

(ARRIVAL)

PART 3

–

FLIGHT PLANNING

21a

21b

21b

21c

21d

21d

Page 68

68

PART 3

–

FLIGHT PLANNING

PART 3

–

FLIGHT PLANNING

22. Go on FMC (Flight Management Computer) and set up your

departure parameters for the SID (Standard Instrument

Departure)

a) Type desired STAR selection number (HABBS3 in our

case, so we type “2” since it is selection item number

2) on the MCDU keypad and press “ENTER”

b) Type desired STAR transition selection number

(MIGLO VOR waypoint in our case, so we type “3”

since it is selection item number 3) on the MCDU

keypad and press “ENTER”. In other words, we will

enter the STAR from the MIGLO transition point.

c) Type desired approach selection number (I06L ILS in

our case, so we type “1” since it is selection item

number 1) on the MCDU keypad and press “ENTER”.

d) All arrival data is now entered in the FMC.

e) You can click on the FPL page button to verify new

entries.

FMC SETUP – FLIGHT PLAN

(ARRIVAL)

22a

22a

22b

22c

22d

Page 69

69

PART 3

–

FLIGHT PLANNING

23. Go on FMC (Flight Management Computer) and set up your

remaining waypoints and airways

a) Press the FPL page button and click NEXT button to show

page 2

b) Click on LSK next to the next waypoint after DEDKI to

select it (it should be a discontinuity reading “NO LINK”

in flashing amber).

c) Press the LIST button

d) Click on LSK next to the AIRWAYS sub-menu

e) Type desired airway selection number from DEDKI

waypoint (airway Q913 in our case, so we type “1” since

it is selection item number 1) on the MCDU keypad and

press “ENTER”

f) Type desired next waypoint selection number after

DEDKI (IGSEB VOR waypoint in our case, so we type “1”

since it is selection item number 1) on the MCDU

keypad and press “ENTER”.

g) IGSEB waypoint has now been added after DEDKI and

will be accessible through airway Q913

h) We will now have to check for discontinuities

FMC SETUP – FLIGHT PLAN

(COMPLETE ROUTE)

CYYZ SID DEDKI Q913 IGSEB DCT MIGLO STAR CYUL

23b

23a

23c

23d

23e

23e

23f

23f

23g

Page 70

70

PART 3

–

FLIGHT PLANNING

24. Go on FMC (Flight Management Computer) and remove remaining

discontinuities from the flight plan

a) Click on LSK next to the next “NO LINK” waypoint (in our case

after IGSEB).

b) Click on LSK next to “DELETE” two times to delete

discontinuity between IGSEB and MIGLO.

c) Click on NEXT button until you reach page 4 of the FPL menu.

d) Click on LSK next to the next “NO LINK” waypoint (in our case

after XULTA).

e) Click on LSK next to “DELETE” two times to delete

discontinuity between XULTA and the I06L approach fix.

f) Most discontinuities should now be removed. You can cycle

through waypoints by pressing the “FORMAT” button while

being in the FPL page and pressing “NEXT” or “PREV” to cycle

through waypoints on the MFD. Press the “FORMAT” button

again to return to the normal navigation display.

FMC SETUP – FLIGHT PLAN

(CLEAN UP DISCONTINUITIES)

24a

24b

24c

24b

“NO LINK”

DELETED!

24d

24e

24f

“NO LINK”

DELETED!

24f

MFD in FORMAT mode

MFD in NAV mode

Page 71

71

PART 3

–

FLIGHT PLANNING

FMC SETUP – FUEL & WEIGHT

25. Check the MJC8 Q400 control panel and find your resulting Zero

Fuel Mass (ZFM)

a) Open “mjc84cspan.exe”

b) Go in “Weight & Balance” tab

c) Zero Fuel Weight/Mass is 53502 lbs

d) Our total fuel is 8000 lbs

26. Enter Fuel & Weight information in FMC (Flight Management

Computer)

a) Press the FUEL page button. You will see a BASIC WT entry

that is erroneous. Let’s fix this.

b) Press LSK next to ZFW, type “53502” ZFW value we

obtained from the control panel and press ENTER.

c) Press LSK next to FUEL ONBOARD, type “8000” total fuel

value we obtained from the control panel and press ENTER.

d) The Gross Weight will automatically be calculated based on

the two values we entered previously. We’re good to go!

Zero Fuel Mass (lbs)

This executable is available in:

C:\Program Files\Lockheed Martin\Prepar3D v4\SimObjects\Airplanes\mjc8q400\cpan

Total Fuel Mass (lbs)

26a

25d

25d

26b

26c

26d

Page 72

72

PART 3

–

FLIGHT PLANNING

FMC SETUP – CROSS-FILL

24a

27. Initialize the second FMC (Flight Management

Computer) on the First Officer’s side

a) Power up FMC by pressing and holding the

“DIM ON/OFF” button on the MCDU.

b) Wait for FMC BIT (Built-In Test) to complete

c) Click on the “ACCEPT” LSK (Line Select Key)

once the INIT page is displayed

d) Press the DATA button to open up the Data

page

e) Press the LSK next to the XFILL sub-menu

f) Press the LSK next to the XFILL FLIGHT

PLAN sub-menu to start transfer the flight

information from the captain’s FMC to the

first officer’s FMC

g) Wait for the CROSSFILL RECEIVE IN

PROGRESS to complete

h) Press the LSK next to the XFILL FUEL sub-

menu to start transfer the fuel information

from the captain’s FMC to the first officer’s

FMC

i) Wait for the CROSSFILL RECEIVE IN

PROGRESS to complete

27d

27e

27f

27h

27g 27i

Page 73

73

PART 3

–

FLIGHT PLANNING

ARCDU – UHF RADIO

28. Set ARCDU (Audio & Radio Control Display Unit) radio frequencies to CYYZ (Toronto) and

CYUL (Montreal) airport ATIS (Automatic Terminal Information Service) in order to gather

meteo conditions and atmospheric pressure

a) Power up ARCDU by setting radio power switch to ON.

b) Press the LSK next to UHF1 to select frequency 1. Frequency 1 will be highlighted in

white.

c) Scroll mousewheel over TUNE knob to tune UHF1 radio frequency 1 to the Toronto

ATIS (120.825 MHz).

d) Press LSK next to UHF1 to validate frequency 1.

e) Repeat steps b) to d) to set UHF1 frequency 2 to the Montreal ATIS (133.700).

f) Press LSK next to UHF1 to cycle active frequency (in green) to CYYZ ATIS (120.825).

g) Write down the altimeter setting broadcast by Toronto ATIS. In our case, altimeter

setting is 29.52 in Hg (inches of mercury).

h) Set COM1 radio switch to ON

28g

28a

28b 28c

28d

28f

28h

Page 74

74

PART 3

–

FLIGHT PLANNING

ARCDU – RADIO NAV

29. Set ARCDU (Audio & Radio Control Display Unit) ILS frequency to CYUL (Montreal) airport ILS frequency

a) Press the « FPL » button to enter the Flight Plan page

b) Press the « MENU » button to enter the FPL MENU

c) Click the LSK next to « APPR PLAN ».

d) ILS frequency for Montreal runway 06L is 109.30 MHz.

e) Link ARCDU to FMS (Flight Management System) by setting radio power switch to FMS.

f) Press the LSK next to VOR1 to select frequency 1. Frequency 1 will be highlighted in white.

g) Scroll mousewheel over TUNE knob to tune VOR1 radio frequency 1 to the Montreal ILS (109.30 MHz).

h) Press LSK next to VOR1 to validate frequency 1. Frequency will now read “ILS1” instead of “VOR1”.

i) Repeat steps f) to h) to set VOR2 frequency 1 to the Montreal ILS (109.30 MHz) to make sure both

FMCs track the same ILS frequency.

29a

29b

29c

29d

29f

29e

29g

29h

29h

Page 75

75

PART 3

–

FLIGHT PLANNING

CABIN PRESSURE &

ALTIMETER SETTING

30. Set altimeter barometric setting on the PFD

(Primary Flight Display) to 29.52 in Hg, as stated by

the Toronto ATIS.

31. Set standby ADI (Attitude Director Indication)

barometric setting to 29.52 in Hg, as stated by the

Toronto ATIS.

32. Set landing cabin pressure altitude setting to

approx. 100 ft (CYUL airport elevation is 118 ft).

Take note that the gauge is in thousands of feet.

30

30

31

32

32

Page 76

76

PART 3

–

FLIGHT PLANNING

WEATHER RADAR TEST

33. Power up and test Weather radar

a) Press the WX/TERR button to togglebetween TERRAIN MAP

(EGPWS, or Enhanced Ground Proximity Warning System) and

WEATHER RADAR display

b) Set weather radar mode to WX

c) Set weather radar switch to TEST

d) Check that WX TEST occurscorrectly

e) Set weather radar switch to ON

f) Confirm that WEATHER RADAR display shows WX ON

g) Press WX/TERR button back to TERRAIN MAP

33a

33c

33b

33b

33d

33e

33f

33g

33g

Page 77

77

PART 3

–

FLIGHT PLANNING

TCAS TEST

34. Power up and test TCAS (Traffic & Collision Avoidance System)

a) Click the LSK next to ATC1 on the ARCDU to select TCAS menu

b) ATC1 transponder frequency will be highlighted in white when selected

c) Click on the EXP button to expand TCAS menu

d) Press the LSK next to the TEST option to start TCAS BIT (Built-In Test)

e) Wait for the BIT to complete

f) Confirm that TEST OK appears on navigation display

g) Click and hold LSK next to ATC1 to set TCAS mode to TA ONLY (Traffic Advisory Only)

h) Confirm that TA ONLY is in AUTO mode. If not, press the TCAS power button.

i) To return ARCDU to main page, click on PG 1/2 button.

34a

34b

34c

34d

34e

34e

34f 34h

34h

34g

34i

Page 78

78

PART 3

–

FLIGHT PLANNING

V-SPEEDS SETTING

35. Find V-Speeds

a) Press FUEL button on the MCDU to find our

Gross Weight: 61502 lbs

b) The airport altitude at CYYZ (Toronto) is 173 m,

or 567 ft

c) Find VR, V2, VFRI & VCLIMB for a Flaps 5

takeoff for 62000 lbs and 2000 ft to be

conservative. V1 is assumed equal to VR.

d) V1: 131 kts

e) VR: 131 kts

f) V2: 132 kts

V1 is the Decision Speed (minimum airspeed in the takeoff, following

a failure of the critical engine at VEF, at which the pilot can continue

the takeoff with only the remaining engines), VR is the rotation speed

(airspeed at which the pilot initiates rotation to obtain the scheduled

takeoff performance), and V2 is Takeoff Safety Speed (minimum safe

airspeed in the second segment of a climb following an engine failure

at 35 ft AGL).

g) V

FRI

: 162 kts (142 + 20 kts)

Flaps Retraction Initiation Speed. Table gives us 142 kts, but since

we have possible snow and icing conditions above 1000 ft, we will

increase that value by 20 kts since Bombardier requires to have

the INCR REF SPEEDS switch to ON, which increases the stall

warning speed by 20 kts and provides us a safe margin.

h) V

CLIMB

: 174 kts (154 + 20 kts)

Final Takeoff Speed. Table gives us 154 kts, but we will increase

that value by 20 kts for the same reason as mentioned above.

i) To set V-Speeds, press the SEL button to select V1 (highlighted)

and scroll mousewheel on SPEED BUG knob to set its value.

j) Repeat previous step for VR, V2, VFRI (full triangle) and VCLIMB

(empty triangle).

k) V-Speed selector will automatically be unselected.

36. Set DH/MDA switch (Decision Height / Mean Descent Altitude) to MDA

and scroll mousewheel on knob to set accelerationaltitude to the airport

elevation + 1000 ft (567 ft + 1000 ft = 1567 ft) rounded up to 1570 ft.

35a

35c

35c

35i

35j

V1

VR

V2

VCLMB

VFRI

36

MDA

1570 ft

36

36

Page 79

79

PART 3

–

FLIGHT PLANNING

V-SPEEDS REFERENCE TABLES

These speed tables are available on the Majestic Software website:

http://majesticsoftware.com/mjc8q400/downloads.html

Page 80

80

PART 3

–

FLIGHT PLANNING

TRIM SETTING & AUTOPILOT SETUP

37. Set elevator trim in the middle of the TO (Takeoff)

white line as shown.

38. Press the YD (Yaw Damper) button to set it to ON

39. Make sure the HSI (Horizontal Situation Indicator)

SELECT button has the arrow pointing to the pilot’s

seat (left).

40. Rotate the NAV SOURCE knob to make sure the

navigation systems source is the FMS1 (pilot’s Flight

Management System)

41. Click on the TAKEOFF/GO AROUND button on the

throttles to arm the Go Around (GA) autopilot

mode

42. Rotate the ALT knob and set the autopilot altitude

target to 3000 ft

Note: Canadian law restricts our speed below 3000

ft to 200kts

43. Press the ALT SEL button to arm the altitude select

autopilot mode

44. Press the HDG (Heading) button to arm the heading

autopilot mode

45. Rotate the HDG knob and set the autopilot heading

target to 057 (CYYZ runway 05 heading is 057

according to Jeppesen chart)

37

38

39

40

40

40

41

41

42

43

42

43

44

44

45

45

45

Page 81

81

PART 3

–

FLIGHT PLANNING

DOORS

46. Verify that all doors are closed

a) Press the DOORS SYS page

b) Look for any door that is open (red)

47. Close any door that is still open by going on MCDU

“DATA -> SERVICES -> EXITS” menu

a) In DATA -> SERVICES page, click “EXITS” LSK

b) Click on the LSKs next to FWD PAX, AFT

PAX, AFT BAG, or SERVICE doors to close

them if required (or use the “LSHIFT + E”

key binding)

c) All doors should be in green (closed)

46a

46b

47c

47c

ALL DOORS CLOSED

47a

47a

47a

47b

47c

46b

PAX DOOR OPEN

Page 82

82

ENGINE START

APU

AUXILIARY

POWER UNIT

FUEL

IGNITION

ELECTRICAL POWER

(ELECTRICAL STARTER)

GROUND

POWER CART

ENGINE

(RUNNING)

ENGINE START SELECTOR

&

ENGINE START BUTTON

&

THROTTLE POSITION

ENGINE

IGNITION

SWITCH

APU GENERATOR

APU BLEED AIR

(USED FOR PNEUMATIC SYSTEMS)

EXTERNAL POWER

ENGINE GENERATOR

(ENGINE CROSS-START)

ENGINE BLEED AIR

(USED FOR PNEUMATIC SYSTEMS)

ENGINE START SELECTOR AT 1 OR 2, ENGINE

START BUTTON PUSHED & THROTTLE AT DISC

FUEL STARTER VALVE CONTROLS FUEL FLOW

CONTROLLED BY FADEC

IGNITION SELECTION SWITCH – NORM

IGNITION CONTROLLED BY FADEC

PART 4

–

START

-UP PROCEDURE

NOTE: For those who are used to fly Boeing and Airbus aircraft, you will notice

that the Q400 PW150A engine does not require bleed air to start since it has an

electrical starter instead of a pneumatic one. This is pretty common among

smaller regional aircraft.

ENGINE START-UP

Page 83

83

ENGINE START

APU

AUXILIARY

POWER UNIT

APU GENERATOR

BATTERY SWITCHES ON

EXTERNAL POWER

ENGINE START SELECTOR AT 1 OR 2

ENGINE START BUTTON PRESSED

THROTTLE AT DISC

ENGINE IGNITION SELECTOR - NORM

FUEL STARTER VALVE

IGNITER

APU POWER SWITCH & APU START SWITCH ON

NOTE: It is usually common practice to start your engines during pushback.

We will start our engines before that for simplicity.

PART 4

–

START

-UP PROCEDURE

ENGINE START-UP

Page 84

1. On Overhead Panel, press on the APU PWR switch. Wait

5-6 seconds for the BIT (Built-In Test) to complete after

the switchlights have flashed.

2. Press the APU START switch. The “START” indication will

illuminate while the start sequence is active and

extinguish once it is complete. The APU PWR switch will

then display “RUN”.

3. Once APU start cycle is finished, press the GEN switch

to turn the APU generator ON. The “WARN” indication

appears since we are running on the Ground Power

Unit. Don’t worry, it’s normal. In case the GPU fails, the

power will be provided by the APU automatically.

4. Press the APU BL AIR (Bleed Air) pushbutton

5. Look on the Electrical Systems page and make sure that

the APU/External Power is producting sufficient voltage

(at least 24.5 volts)

84

APU (AUXILIARY POWER UNIT) START

1

PART 4

–

START

-UP PROCEDURE

2a

3

2b

4

5

5

Page 85

6. Press the AUTOFEATHER button to select

autofeather test.

7. The AUTOFEATHER BIT (Built-In Test) will be

complete once the “A/F TEST PASSED” caution

appears on the engine page.

8. Once test is complete, press the

AUTOFEATHER button to set it to OFF. We will

use autofeather only when the engines are

running.

85

AUTOFEATHER TEST

6a

PART 4

–

START

-UP PROCEDURE

7

8

6b

6c 6d

6e

Page 86

9. Set Control Lock lever aft after FLIGHT IDLE.

10. Set both throttles to DISC

11. Set GEN 1 and GEN 2 switches ON on both the

DC CONTROL and the AC CONTROL panel.

12. Set both Ignition switches to NORM

13. Set Engine Start SELECT switch to 2 (right

engine)

14. Press the ENGINE START button

15. Once NH starts increasing, set Condition Lever

#2 to START/FEATHER

16. Once NH is greater than 50 %, the starter will

automatically disengage (you should hear a

“click” of the Engine Start SELECT switch going

back to the middle position).

86

ENGINE START-UP

9

PART 4

–

START

-UP PROCEDURE

10

11

11

13

12

14

15

15

16

16

Page 87

17. Repeat steps 13 through 16 to start left engine

(#1).

18. You can monitor engine parameters on the

Engine page too.

19. Set Condition Levers 1 and 2 to MAX/1020.

20. Once engines have stabilized, press the

AUTOFEATHER button to arm the autofeathering system. You should see the A/F

SELECT indication on the engine page.

87

ENGINE START-UP

18

PART 4

–

START

-UP PROCEDURE

18

17

20

19

20

NOTE: The autofeather system on the Dash 8 is only designed to be used on takeoff. If it is armed for

the approach it would not work as designed if you had an engine failure due to the other parameters

such as the torque settings/requirements and angle of the power levers which would unlikely be met in

order for the system to function. Autofeathering is triggered from the armed state when the torque of

the failed engine, as detected by dual torque sensors, falls below 25% for at least three seconds. The

ATPCS system sends dual uptrim signals to the FADEC of the working engine to increase its power by

approximately 10%. The effect of this is to replace the NTOP (Normal Takeoff Power) rating with an

MTOP (Maximum Takeoff Power) rating.

Page 88

88

ENGINE START-UP

NL

NH

NH

NL

High-pressure compressor and

high-pressure turbine are driven

by the same shaft. This is NH

speed in percentage of

maximum RPM.

Low-pressure compressor and low-pressure turbine are driven by the same shaft. This is

NL speed in percentage of maximum RPM.

N2

PART 4

–

START

-UP PROCEDURE

NH

NL

NPROP

NPROP

Propeller Speed in RPM

Page 89

21. Set TANK 1 and TANK 2 AUX PUMP switches ON

22. Set STANDBY HYDRAULIC PRESSURE pump

switch ON

23. Set PTU (Power Transfer Unit) CONTROL switch

ON

24. Set MAIN BUS TIE switch OFF

25. Set EXT PWR switch to OFF to remove ground

power

26. Remove Ground Power Unit

27. APU GEN indication should illuminate normally

now

89

ENGINE START-UP

21

PART 4

–

START

-UP PROCEDURE

22 23

24

25

27

26a

26b

26c

26d

Page 90

28. Set De-Misters and Side Vent levers to OPEN

(AFT) for both pilot and copilot’s sides

29. Set RECIRC switch – ON

30. Set engine BLEED switches 1 & 2 – ON

Note: Wait a few seconds before you set

switch 2 to avoid a pressure bump

31. Set BLEED FLOW Controller switch – MIN

Note: you can keep it at NORM until you start your

takeoff roll to make sure the passengers are

comfortable during the taxi phase. The bleed flow is

set to MIN on takeoff simply to maximize engine

power available during takeoff.

32. Set PACK (Pneumatic Air Conditioning Kit)

switches – AUTO

33. Set APU BLEED switch – OFF

34. Set APU GEN switch – OFF

35. Press APU PWR button to shut APU down.

Make sure you let the APU cool off at least 1

minute after you set the BLEED and GEN

switches to OFF before you shutdown the APU.

90

COMPLETE PRE-FLIGHT

PART 4

–

START

-UP PROCEDURE

28

28

32

29

30

31

33

34

35

Page 91

36. Set Position Lights – ON

37. Set Emergency Lights – ARM

38. Set Anti-collision lights – ON (WHT/ON

STROBES)

39. Set Wing lights – ON

40. Set Landing lights – ON

41. Set TAXI lights – ON

42. Set FASTEN SEAT BELTS switch – ON

43. Set NO SMOKING switch – ON

44. Set Icing Protection systems based on icing

level (see more in the ICE PROTECTION

section). Since we are at LEVEL 2 (icing

conditions exist), we will:

a) Set PITOT HEAT switches – ON

b) Set WINDSHIELD & WINDOW HEAT

switch – ON / NORM

c) Set PROP HEAT switch – ON

d) Set Engine Intake Doors – OPEN

e) Make sure the REF SPEEDS INCR switch

is OFF

91

COMPLETE PRE-FLIGHT

PART 4

–

START

-UP PROCEDURE

ICING LEVEL 1: used in all conditions

ICING LEVEL 2: used on ground when icing conditions exist,

temperature + 10 deg C or below, in-flight + 5 deg C or below

ICING LEVEL 3: used in flight during visual accretion or ICE

DETECTED is displayed on Engine Display

36

37

36

39

40

40

41 38

42

43

44b

44a

44b

44c

44d

44e

Page 92

45. Select Engine Rating – NTOP (you could use

RTOP for Reduce-Takeoff Power too but we

will assume this is the first flight of the day)

46. Set FLIGHT/TAXI spoilers switch – TAXI

47. Set Flaps Lever to 5 deg for takeoff

48. Release Parking Brake

49. Press T/O Warning Test switch and make sure

you hear no alarm sound. You will hear an

alarm sound if:

• Parking brake is set

• Flaps still at 0 deg

• Spoilers up with power levers more

than Flight Idle + 12 deg angle

• Trim not in white arc

• Condition levers not at MAX

92

COMPLETE PRE-FLIGHT

45

PART 4

–

START

-UP PROCEDURE

45

46

47

48

49

Page 93

1. Set Nosewheel Steering switch – OFF

2. Set Anti-Skid switch – ON

3. Make sure parking brake is released

4. On FMC, press the DATA button, then click the

LSK next to the SERVICES sub-menu.

5. Click the LSK next to “PUSHBACK – STRAIGHT”

to start pushback

6. Click the LSK next to “PUSHBACK – END” to

stop pushback about 100 m from your initial

parking spot.

7. Set Nosewheel Steering switch – ON

8. Push Control Lock Lever FORWARD

93

PUSHBACK

1

PART 5

–

TAXI

7

2

3

8

5

4b

4a

6

Page 94

94

PUSHBACK

PART 5

–

TAXI

Page 95

The Q400 is steered on the ground by using a tiller.

However, in FSX or Prepar3d you cannot map a

joystick axis to your nosewheel steering tiller: it’s a

limitation of the sim itself. In order to steer the

aircraft, Majestic Software gives you options in the

Control Panel (see section 4) as to how you want to

use the tiller: you can either use your mouse to click

and drag the tiller lever, or you can use your aileron

controls while on the ground to act as an axis for

tiller control. Both options are equally valid, so pick

whichever suits you best.

Using rudder pedals to taxi will give you a range of