lumen DPP-EX5 Service Manual

DIGITAL PHOTO PRINTER

DPP-EX5

SERVICE MANUAL

V olume 1 1st Edition

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! A VERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING

This unit has no power switch.

When installing the unit, incorporate a readily

accessible disconnect device in the fixed wiring, or

connect the power cord to a socket-outlet which must

be provided near the unit and easily accessible, so that

the user can turn off the power in case a fault should

occur.

WARNUNG

Dieses Gerät hat keinen Netzschalter.

Beim Einbau des Geräts ist daher im Festkabel ein

leicht zugänglicher Unterbrecher einzufügen, oder das

ß

Netzkabel mu

befindlichen, leicht zugänglichen Wandsteckdose

verbunden werden, damit sich bei einer

Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

mit einer in der Nähe des Geräts

DPP-EX5 V1

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 3

Related manuals......................................................................................................... 3

Trademarks ................................................................................................................ 3

1. Service Information

1-1. Main Parts Location ....................................................................................1-1

1-1-1. Main Block Location..................................................................1-1

1-1-2. Board Location ...........................................................................1-1

1-1-3. Sensor Location and Function Description ................................1-2

1-2. Removal and Installation of Cabinet........................................................... 1-4

1-2-1. Panel (L) .....................................................................................1-4

1-2-2. Panel (R).....................................................................................1-4

1-2-3. Panel (TOP) Assembly............................................................... 1-5

1-2-4. Front Door ..................................................................................1-5

1-2-5. Cabinet (L) .................................................................................1-6

1-3. Rewriting the Serial Number (when Replacing the DK-44 Board) ............1-6

2. Replacement of Main Parts

2-1. Replacement of Boards ............................................................................... 2-1

2-1-1. SW-44 Board.............................................................................. 2-1

2-1-2. DK-44 Board ..............................................................................2-1

2-1-3. UV-44 Board ..............................................................................2-2

2-1-4. MD-44 Board .............................................................................2-2

2-1-5. JD-44 Board ...............................................................................2-3

2-1-6. PE-44 Board ...............................................................................2-4

2-1-7. RM-44 Board ............................................................................. 2-5

2-2. Switching Regulator.................................................................................... 2-6

2-3. Paper Eject Guide Assembly.......................................................................2-7

2-4. E Chassis Assembly ....................................................................................2-7

2-5. Paper Feed Frame Assembly.......................................................................2-8

2-6. DC Fan ........................................................................................................ 2-8

2-7. Thermal Head.............................................................................................. 2-9

2-8. Ferrite Holder ..............................................................................................2-9

2-9. Stepping Motor..........................................................................................2-10

2-10. E Capstan Roller .......................................................................................2-10

DPP-EX5 V1

1

3. Service Mode

3-1. Density Adjustment during Thermal Head Replacement ...........................3-2

3-2. Confirmation and Adjustment of Video Output Level ...............................3-7

4. Troubleshooting

4-1. Electrical Troubleshooting ..........................................................................4-1

4-2. Error Display ...............................................................................................4-2

4-3. Upgrade .......................................................................................................4-5

4-3-1. Firmware ....................................................................................4-5

4-3-2. Upgrade ......................................................................................4-5

4-3-3. Upgrading method...................................................................... 4-6

4-4. Mechanical Troubleshooting.......................................................................4-7

2

DPP-EX5 V1

Purpose of this manual

Related manuals

Manual Structure

This manual is the service manual Vol. 1 of Digital Photo Printer DPP-EX5.

This manual describes the information on maintenance and the service information

such as service information, parts replacement, service mode and troubleshooting.

In addition to this “Service Manual Vol. 1”, this unit is provided with the manual

below.

..

. Service Manual Vol. 2 (Not supplied for products.)

..

Part No.: 9-955-370-21

This manual describes the semiconductors, spare parts, block diagrams, schematic

diagrams, and board layouts of this unit.

..

. Operating Instruction (Supplied for products.)

..

Part No.: 3-207-119-14

These manuals describe the information required for the actual management and

operation of this unit.

Trademarks

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

service manual for the corresponding unit. The service manual contains a complete list of all semiconductors and their ID Nos., and thus should be used together

with the CD-ROM.

Part number: 9-968-546-XX

Trademarks and registered trademarks used in this manual are follows.

. Memory Stick is a registered trademark of SONY Corporation.

DPP-EX5 V1

3

y

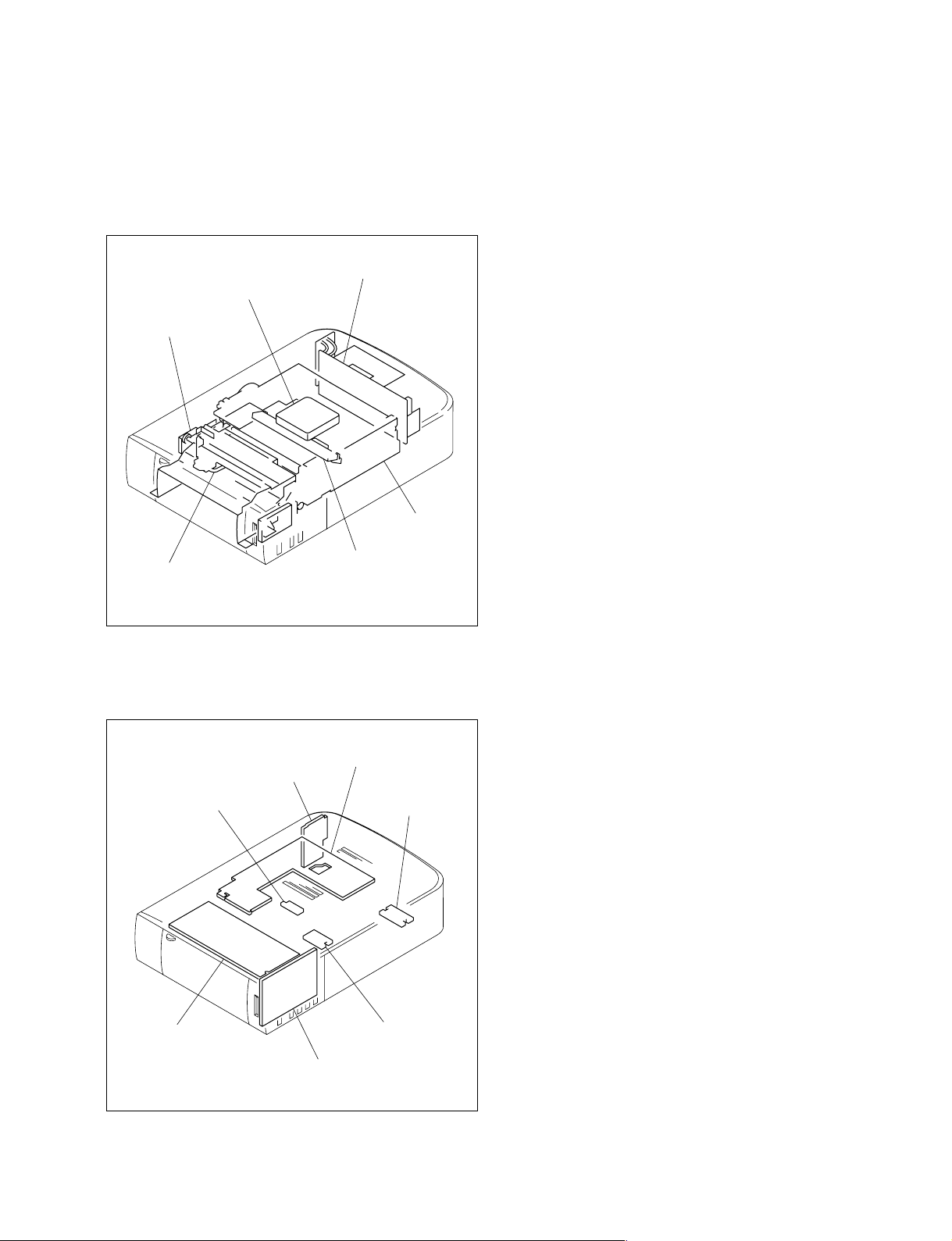

1-1. Main Parts Location

1-1-1. Main Block Location

Switching regulator

DC fan

Paper eject

guide assembly

Thermal head

Paper feed

frame assembl

Section 1

Service Information

E chassis

assembly

1-1-2. Board Location

UV-44 board

RM-44 board

DK-44 board

MD-44 board

JD-44 board

PE-44 board

SW-44 board

DPP-EX5 V1

1-1

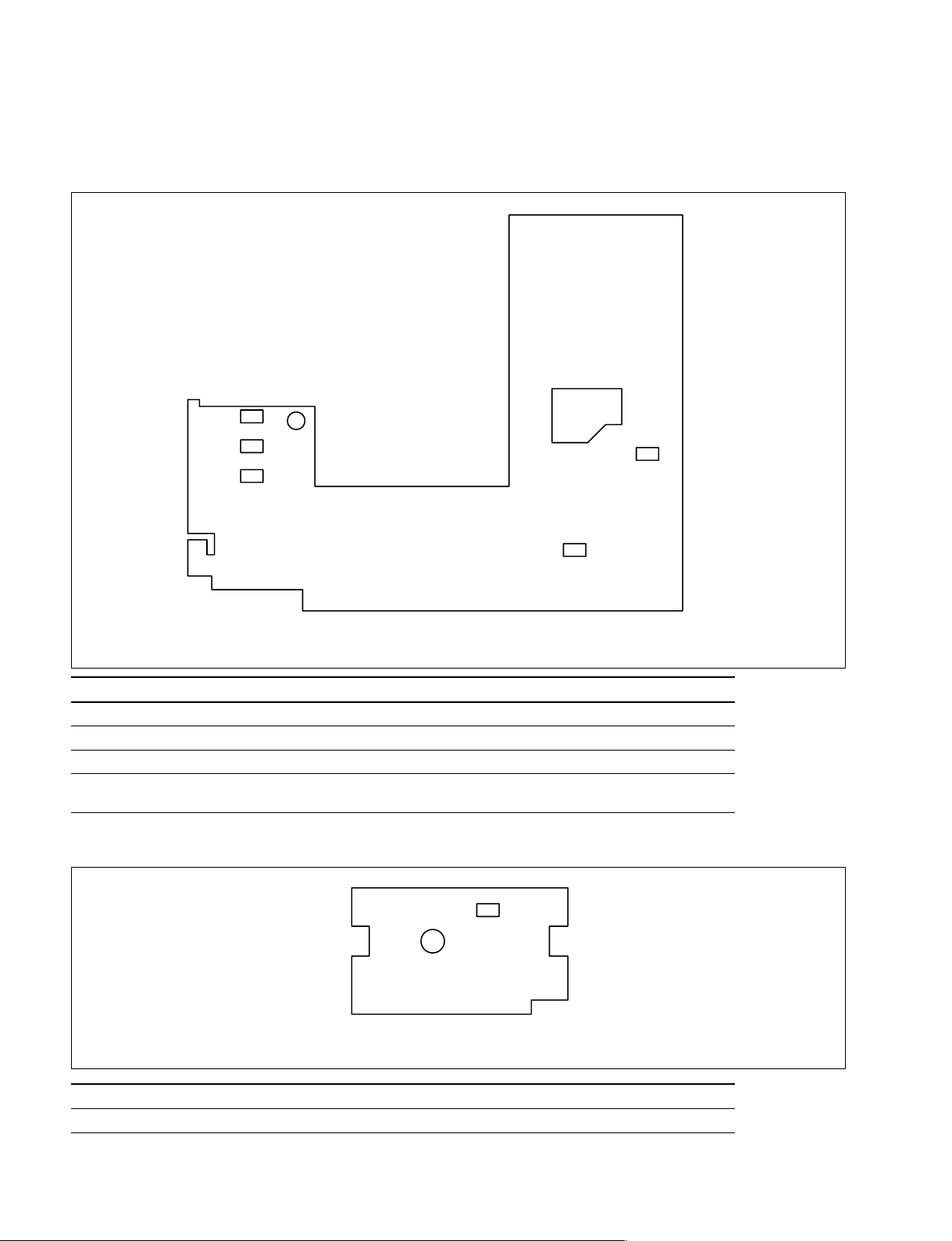

1-1-3. Sensor Location and Function Description

MD-44 board

PH901

PH902

PH905

D901

PH903

PH904

MD-44 board (Side A)

Ref. Name Type Function

PH903, 904 Mode position sensor Reflective x2 Detection of DC motor position

PH901, 902 Ribbon code sensor Reflective x2 Detection of ribbon type

D901 Ribbon mark sensor LED Detection of ribbon position

PH905 Ribbon in sensor Reflective x1 Detection of presence or absence

of ribbon cassette

JD-44 board

PH961

JD-44 board (Side A)

Ref. Name Type Function

PH961 Jamming dead sensor Reflective x1 Detection of paper position

1-2

DPP-EX5 V1

PE-44 board

PH971

PE-44 board (Side A)

Ref. Name Type Function

PH971 Paper edge sensor Reflective x1 Detection of paper position

Detection of paper type

RM-44 board

Q981

RM-44 board (Side A)

Ref. Name Type Function

Q981 Ribbon mark sensor Photo transistor Detection of ribbon position

DPP-EX5 V1

1-3

)

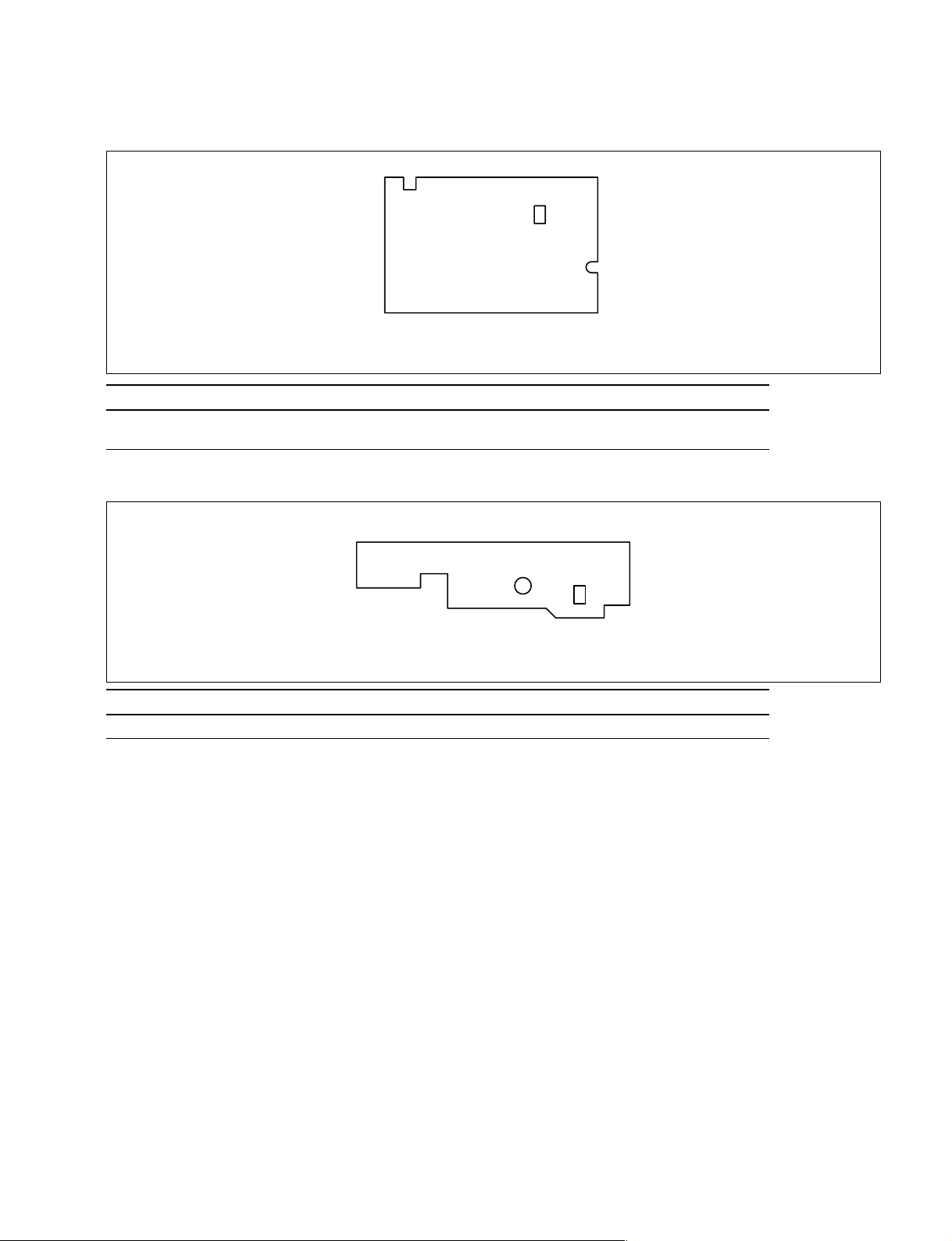

1-2. Removal and Installation of Cabinet

1-2-2. Panel (R)

1-2-1. Panel (L)

1. Open the ribbon door in the direction indicated by the

arrow A, then remove the one screw.

2. Move the panel (L) in the direction indicated by the

arrow and remove the nine hooks, then remove the

panel (L).

Ribbon door

A

BVTP

2.6x8

B

1. Open the ribbon door in the direction indicated by the

arrow A, then remove the one screw.

2. Move the panel (R) in the direction indicated by the

arrow and remove the twelve hooks, then remove the

panel (R).

Ribbon door

Hooks

BVTP

2.6x8

Hooks

Panel (R)

A

B

Hooks

Hooks

Hooks

Hooks

Panel (L

3. Attach the panel (L) in the reverse order of step 1 to 2.

3. Attach the panel (R) in the reverse order of step 1 to 2.

1-4

DPP-EX5 V1

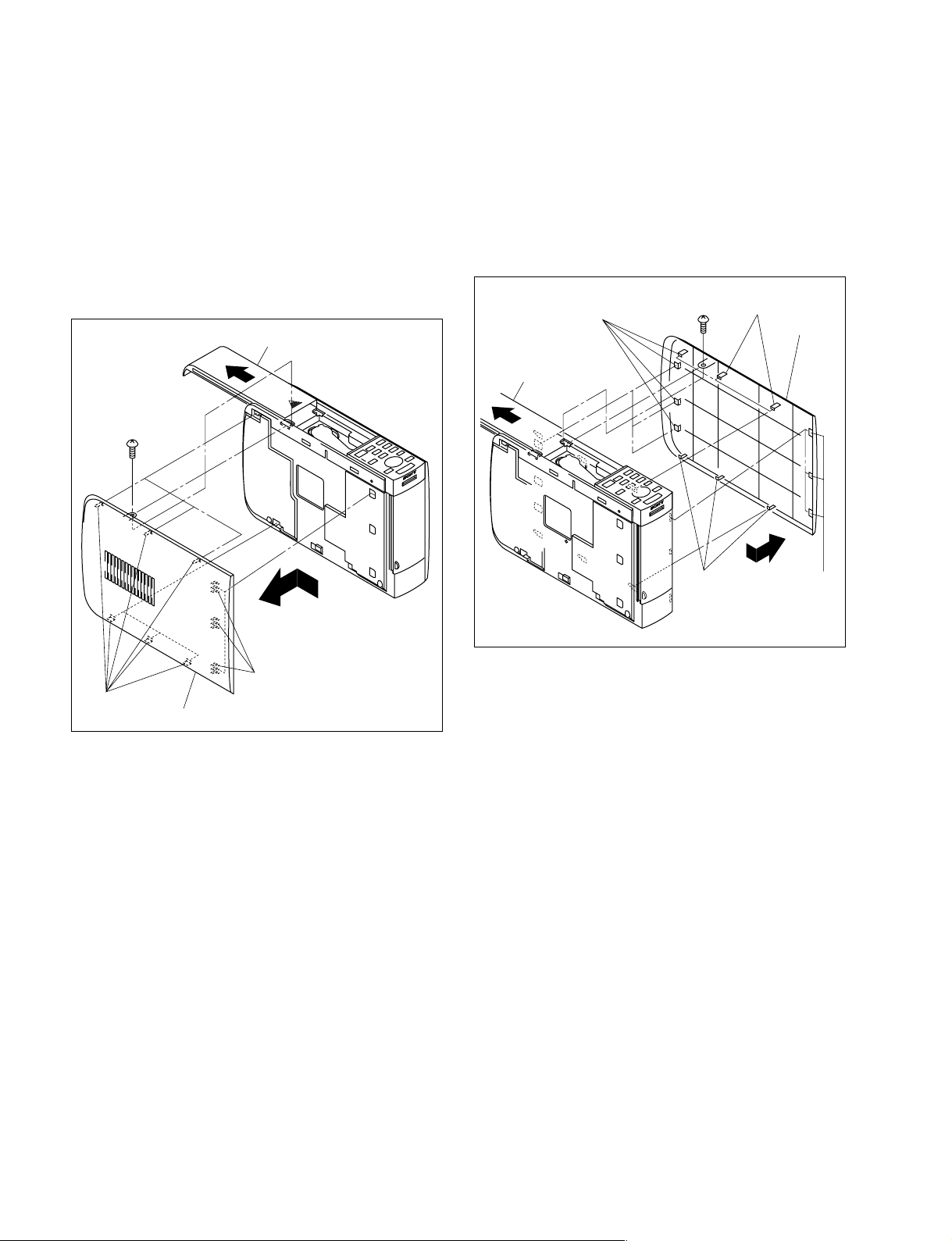

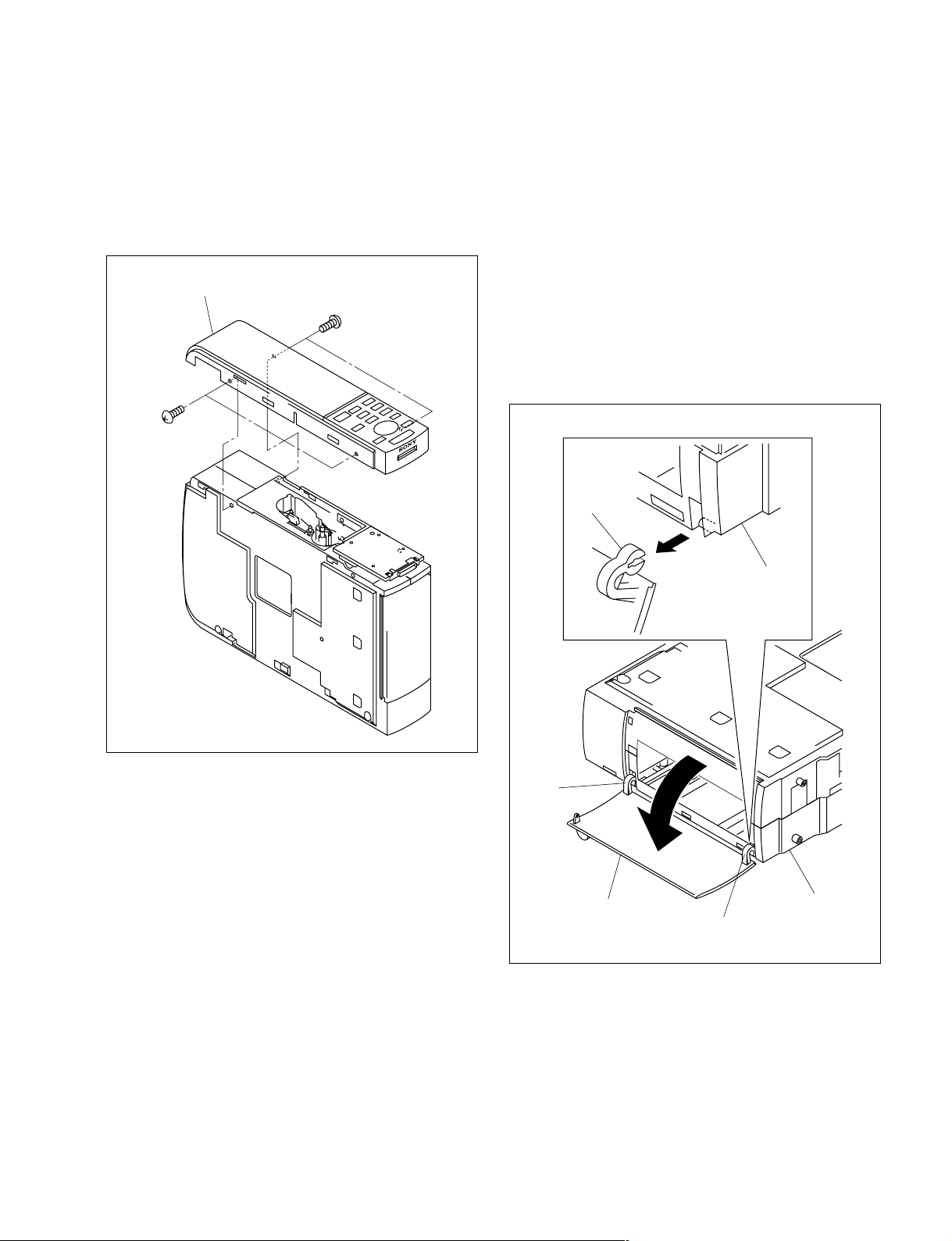

1-2-3. Panel (TOP) Assembly

1-2-4. Front Door

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the four screws, then remove the panel (TOP)

assembly.

Panel (TOP) assembly

BVTP 2.6x8

BVTP 2.6x8

n

When removing the front door, be careful not to break the

two hooks of the front door.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Open the front door in the direction indicated by the

arrow A.

4. Pull the front door in the direction indicated by the

arrow B and remove the two hooks, then remove the

front door from the cabinet R.

Hook

B

Cabinet R

4. Attach the panel (TOP) assembly in the reverse order

of steps 1 to 3.

DPP-EX5 V1

Hook

A

Front door

Hook

Cabinet R

5. Attach the front door in the reverse order of steps 1 to

4.

1-5

1-2-5. Cabinet (L)

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly. (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the two screws and expand the portion A of

the cabinet (L) in the direction indicated by the arrow

B to remove the two hooks.

7. Remove the cabinet (L) in the direction indicated by

the arrow C.

Cabinet (L)

BVTP 3x20

Hook

B

1-3. Rewriting the Serial Number (when

Replacing the DK-44 Board)

n

A serial number must be written in a new DK-44 board

when the DK-44 board is replaced.

Rewrite the serial number according to the procedure

below.

Equipment required

. Personal computer (that can copy a file to a memory

stick)

. Memory stick (to which no data is copied)

. Text file for rewriting serial number (File name:

058USBSN.txt)

n

Consult a Sony’s Sales Office for how to acquire the text

file for rewriting a serial number.

Hook

Portion A

Portion A

B

C

8. Attach the cabinet (L) in the reverse order of steps 1 to

7.

Preparation (before replacing the DK-44 board)

1. Make a note of a USB’s (eight-digit) serial number in

the test mode.

2. Create a “SONY\DPPSV” folder in the memory stick

and copy a 058USBSN.txt text file to it.

3. Open the text file copied in step 2 and enter the serial

number written in step 1 using a half-size numeric

character.

Write

1. Turn on the power of DPP-EX5.

2. Press the MENU button, ENTER button, and power

button simultaneously and start the test mode. (Refer

to Section 3.)

The test menu is then displayed.

3. Install the memory stick supplied in “Preparation” in

DPP-EX5.

4. Move the cursor to the “USB S/N” button and press

the ENTER key.

After about one second, the screen becomes dark and

the test menu is displayed again. The write operation

is then completed.

5. Confirm that the numeric characters below USB S/N

are those written in step 1 of “Preparation”.

1-6

DPP-EX5 V1

Section 2

BVTT

2.6x5

Flexible flat cable

Flexible

flat cable

CN251

DK-44 board

CN201

Replacement of Main Parts

2-1. Replacement of Boards

2-1-1. SW-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the three screws (BTP 2x6) and one precision

screw (P 2x5), then remove the SW-44 board.

5. Disconnect one flexible flat cable from the connector

(CN2002) on the SW-44 board.

6. Remove the two hooks from the holes of the SW-44

board, then remove the MS guide in the direction

indicated by the arrow.

Precision P 2x5

BTP 2x6

CN2002

Flexible flat cable

SW-44 board

Holes

Hooks

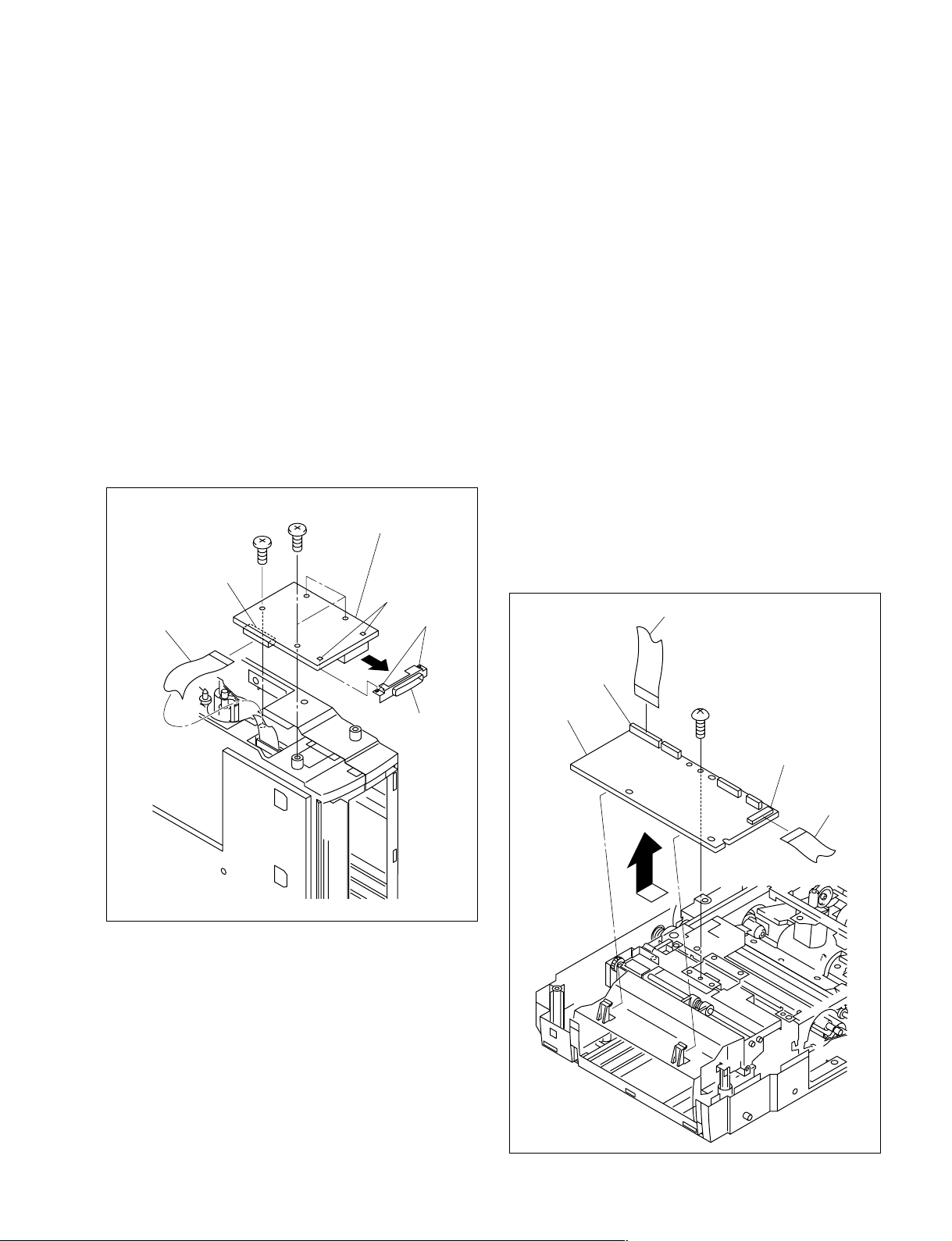

2-1-2. DK-44 Board

n

Before replacing the DK-44 board, check the serial number

in the service mode and make a note of it.

The serial number is used when writing a serial number in

a new DK-44 board.

Refer to section 1-3 for how to rewrite the serial number.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section 1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Disconnect two flexible flat cables from the

connectors (CN251 and CN201) on the DK-44 board.

9. Remove one screw, then remove the DK-44 board in

the direction indicated by the arrow.

MS guide

7. Install the SW-44 board in the reverse order of steps 1

to 6.

DPP-EX5 V1

10. Install the DK-44 board in the reverse order of steps 1 to 9.

2-1

Loading...

Loading...