BELT DRIVE ANALOG PLAYER

PD-171A

Owner`s Manual

Contents

Precautions ············································································································· 1

Features of This Unit ································································································ 2

Before Use ·············································································································· 4

Names and Functions ······························································································ 6

How to Assemble ·································································································· 10

Connections ·········································································································· 14

Operations ············································································································· 16

How to Replace Tone Arm ····················································································· 17

Block Diagram ······································································································· 19

Specifications ········································································································ 20

Before Asking for Repair ························································································ 21

BELT DRIVE ANALOG PLAYER PD-171A

Precautions

Installation place

• Install this unit in a horizontal and stable place where the

unit is less subject to external vibration.

• Do not install this unit near a television or color monitor.

Keep this unit away from such devices as cassette decks

that are subject to magnetism.

Do not move this unit during playback.

Moving this unit during playback may cause the needle jump,

and damage the needle and the record thereby.

When moving this unit

To move this unit, be sure to turn off the power after stopping

the turntable and removing the record. Next, unplug the pow-

er and phono cables, remove the turntable and the turntable

sheet, and move this unit.

Avoid the following locations for installation.

• Locations exposed to direct sunlight

• Places subject to humidity and with less ventilation

• Places where are extremely hot or cold

• Places subject to vibration

• Places subject to dust

• Places subject to oil, steam, and heat (such as kitchens)

Lubrication

Do not lubricate this unit yourself because special oil is used

for the spindle.

Cleaning

• Usually, wipe the unit with a dry soft cloth.

When the dirt is hard to remove, dip soft cloth in detergent

diluted 5 or 6 times with water, wring it well, and remove

contaminants. Then, remove the moisture with dry cloth.

• Be aware that acrylic portions such as dust cover may be

damaged if the portions are rubbed hard.

• Be aware that printed or painted portions may be damaged

if the portions come into contact with alcohol, thinner, ben-

zine, insecticide, or the like. In addition, do not let this unit

contact a rubber or plastic form for a long time. That may

damage the cabinet surface of the unit.

• When using a chemical cloth for cleaning, read the caution

provided with the chemical cloth product.

• Be sure to unplug the power cable from the outlet before

cleaning.

Repair and adjustment

When repairs and adjustments are needed, please ask the

dealer where you bought the unit.

Do not put articles.

Do not put any articles on this unit.

To avoid heat emission

Do not place this unit on such device as an amplifier that may

emit heat. If the unit is installed on a rack, install the unit as

distantly as possible from where the amplifier is installed so

as to avoid heat emission from the amplifier and other audio

devices.

Dew condensation

Be aware that condensation may occur when this unit is

moved from a cold place to a warm place especially in win-

ter or when the temperature of the room where this unit is

installed is quickly raised with a heater or the like. It depends

on the condensation state, however, this unit can be used

after water droplets disappear by turning on the power and

leaving the unit as it is for 1 to 2 hours to keep the unit at room

temperature.

Even in summer, dew condensation can occur if this unit is

directly exposed to cool air from an air conditioner. In such

a case, it is recommended to change the installation place.

1

Features of This Unit

Belt drive

A new drive system is introduced, in which motor-derived

noise is attenuated via a belt and smooth rotation is achieved.

Circuit configuration

AC synchronous motor is driven by sine waves coming from

32-bit microprocessor, which are DA converted and amplified

by a high-power audio amplifier.

Stroboscope

This unit is equipped with a reflective view type LED strobo-

scope to adjust the rotation speed precisely.

Arm base

This unit is finished with chromeplated and spin-stabilized

brass with 20 mm in thickness.

By replacing with the optional arm base, various types of tone

arms can be mounted, which allows users to enjoy sound

changes.

Tone arm

A universal static balance tone arm is included as a standard

equipment for the simple cartridge replacement.

Heavyweight platter

The platter weighs 5.0 kg, which is machined from aluminum

metal to improve rotational accuracy.

Approximately 0.7 t·cm2 of moment of inertia has been

achieved.

High rigidity main chassis

This unit uses an underslung vibration-damping structure ca-

pable of hanging internal main parts using machined alumi-

num plate with 15 mm in thickness as a base.

Large-sized spindle

This large-diameter spindle is equipped with polyether ether

ketone (PEEK) bearing of ball bearing specification that pro-

vides stable rotation.

2

BELT DRIVE ANALOG PLAYER PD-171A

Floating mount

The power transformer and the motor are “floating-mounted”

with rubber cushions to isolate vibration to the main chassis.

Hybrid vibration damping

The bottom face of the cabinet has a hybrid vibration-damp-

ing structure made of wood and metal for resonance disper-

sion.

Large-sized insulator

This unit adopts a damper as an insulator that is a combina-

tion of rubber and spring, made from different materials to

isolate unnecessary vibration coming from an audio rack or

others.

Unnecessary vibration from the main chassis itself is also

suppressed.

Magnesium alloy headshell

Magnesium alloy headshell with LUXMAN logo is supplied.

LED stylus light

The detachable high-intensity LED stylus light is supplied for

operation in the dark.

AC inlet

Power-cable-detachable AC inlet.

3

Before Use

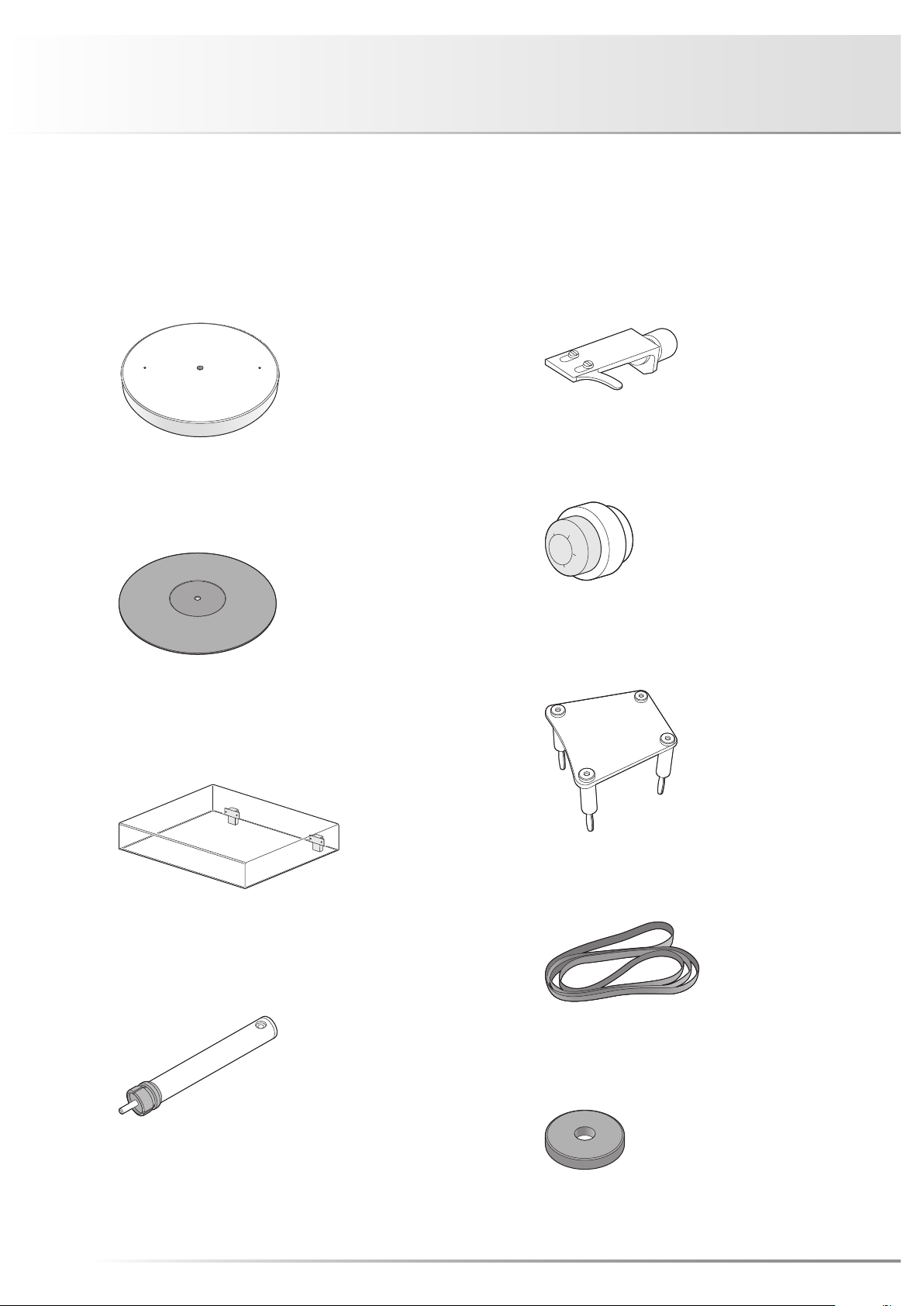

Check the accessories.

Make sure that all accessories shown below are in the package.

* No cartridge is included.

• Platter

• Rubber mat

• Headshell

• Counterweight

0

2.5

0.5

1

• Pulley cover

• Dust cover

• Stylus light

• Rubber belt

• EP adaptor

4

BELT DRIVE ANALOG PLAYER PD-171A

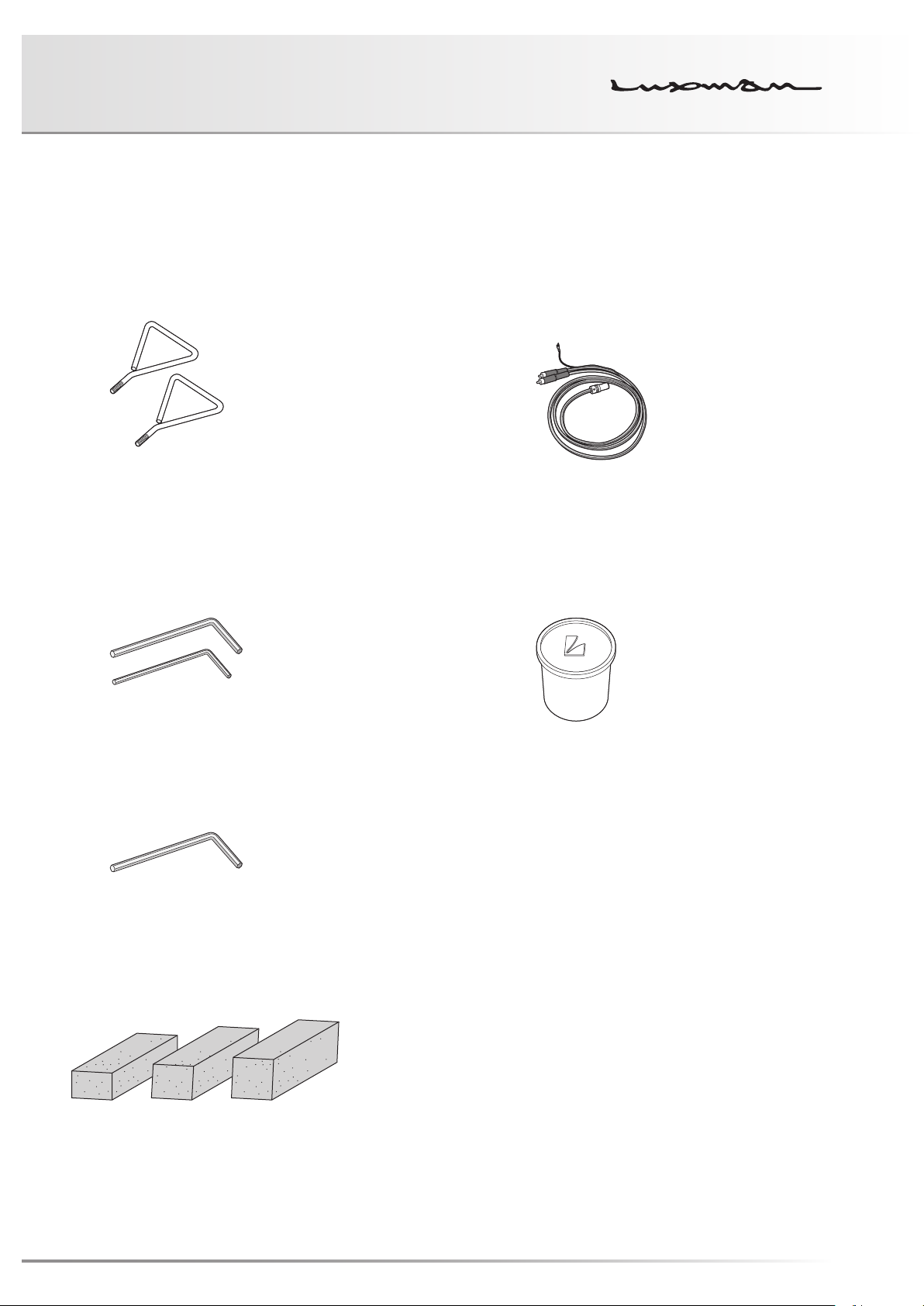

• Platter mount handle (2 pieces)

t8 t10 t12

• Phono cable (ground cable equipped)

* This cable is connected to the main unit at first.

• Tone arm adjustment wrench (2.5 mm)/

arm lifter adjustment wrench (1.5 mm)

• Arm base cover removal wrench (3.0 mm)

• Phono cable securing cushion

• Dustproof cap for stylus light connector

* This cap is mounted on the main unit at first.

• Printed matters

Safety cautions

Owner’s Manual (this document)

• Power cable

5

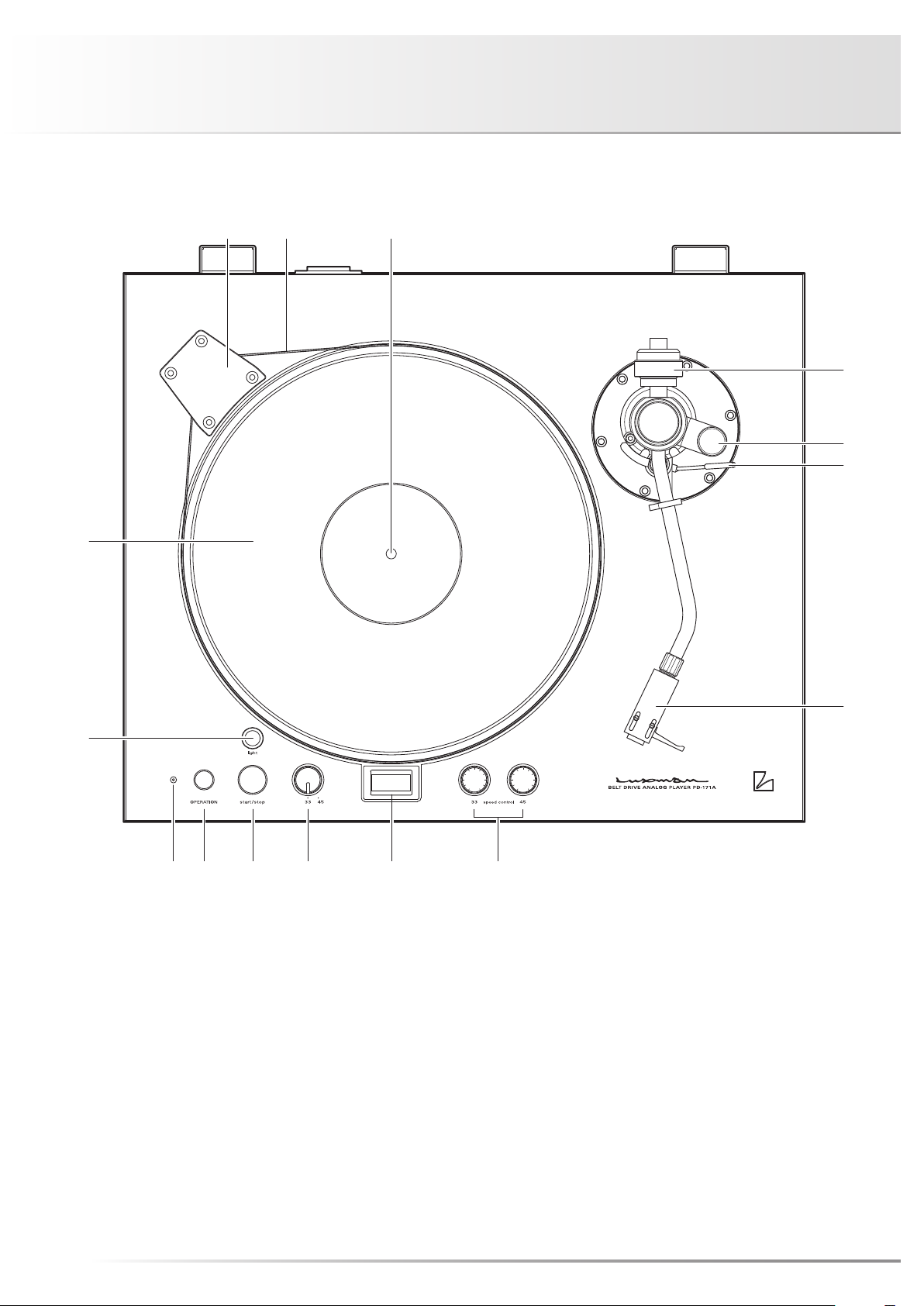

Names and Functions

61 3 4 52

8 10 9

11

13

14

15

12

Top view

7

1. Power switch (OPERATION)

This switch turns on and off the power.

2. Operation indicator

This indicator lights up when the power is turned on.

3. Start/stop switch (start/stop)

This switch starts rotating the platter at the selected rotation

speed.

This switch also stops platter rotation while the platter is

rotating because this switch serves as both start and stop

switches.

6

BELT DRIVE ANALOG PLAYER PD-171A

4. Rotation speed selection switch (33/45)

This switch toggles the rotation speed of the platter be-

tween 33 rpm and 45 rpm.

Select a rotation speed in accordance with a record to listen

to.

5. Strobo Scope

This window shows the number 33 or 45 depending on the

number selected by the rotation speed selection switch. If

the number is motionless, the rotation speed is fine-tuned.

9. Center spindle

This spindle is a guide for mounting a record.

For playing an EP record, mount the EP adaptor here.

10. Belt

This belt transfers motor rotation to the platter.

11. Rubber mat

This rubber mat suppresses platter squeaks and brings a

record into intimate contact with the platter.

6. Rotation speed fine control

(33/45 speed control)

33 rpm Fine-tunes the rotation speed. Please look into the

stroboscope and fine-tune until the number 33

completely stops moving, when the rotation speed

switch is set to 33.

45 rpm Fine-tunes the rotation speed. Please look into the

stroboscope and fine-tune until the number 45

completely stops moving, when the rotation speed

switch is set to 45.

7. Stylus light connector (light)

This light can illuminate stylus area in a dark room.

Remove the dustproof cap and mount the supplied stylus

light.

8. Pulley cover

This cover protects the rotating pulley.

Be sure to mount the cover when the platter is rotated.

12. Headshell

Headshell couples a cartridge with the tone arm.

13. Arm lifter

This lifter is used to move the tone arm vertically.

14. Anti-skating adjustment knob

This device cancels the inward force applied to the tone arm

during record playback.

Select a number in accordance with the cartridge to be

used.

15. Counterweight

This weight is used for adjusting tone arm balance and sty-

lus pressure.

7

Names and Functions

1618

16

17

Bottom view

16. Insulator

These support the entire player and absorb howling and

vibration from outside.

These insulators are set at the lowest point at first and can

be raised by up to 10 mm.

Please use these insulators for making this unit horizontal.

17. Tone arm connector

This connector connects the phono cable to the DIN5P

connector of the tone arm.

(The phono cable is connected to the main unit at first.)

18. Cable holder

This holder secures the phono cable.

8

BELT DRIVE ANALOG PLAYER PD-171A

Rear view

20 19

19. AC inlet (AC IN)

Please connect the accessory power cable to supply the

power from the AC outlet on the wall.

BELT DRIVE ANALOG PLAYER

A

20. Hinge receiver

This receiver is used for mounting the dust cover.

Insert the hinge attached to the dust cover into the hinge

receiver at the rear side of the main unit.

9

How to Assemble

Insulator

Player unit

Platter mount handle

Rubber belt

Motor pulley

Do not turn on the power until assembly is completed.

1. Installation of main body

Install the main body on a rack that is in a position as hori-

zontal as possible.

If the mounting position is inclined, rotate the insulators on

four corners of the bottom side to adjust the whole horizon-

tal balance.

Counterclockwise for up, and clockwise for down.

Please be extra careful to handle the platter because the

platter is heavy.

3. Belt wrapping

Firstly, wrap the belt around the turntable. Secondly, wrap

the belt that is wrapped around the turntable around the

pulley.

Rotate the turntable with your hand a few times, and check

to see that the belt is wrapped around the correct position

of the pulley.

2. Platter mounting

Engage the supplied platter mount handles in the platter,

align the center of the platter with the center spindle while

holding the handles, and engage them.

Be sure to use both hands to hold the platter and mount it

with extreme care not to apply any unreasonable force to

the center spindle.

Platter

10

BELT DRIVE ANALOG PLAYER PD-171A

Stylus pressure graduation

Platter

Record board ArmrestArm pipe

of tone arm

Height adjustment

screw of arm lifter

( )

Plug-in nut Height adjustment screw

Arm lifter

4. How to mount counterweight

Face the stylus pressure gauge forward and insert the coun-

terweight into the back side of the tone arm until it clicks.

0

2.5

0.5

1

0

3

1

2

5. How to mount cartridge on headshell

No cartridge is included in this unit. Please mount your car-

tridge on the headshell. Connect the lead wires (see the

table below) to your cartridge and firmly secure the cartridge

to the headshell of this unit with the screws and nuts sup-

plied with the cartridge. If the cartridge is loosely secured,

hum noise may be generated. Refer to the operating in-

structions for your cartridge regarding terminals to be con-

nected.

White Lch+

Blue Lch–

Red Rch+

Green Rch–

The distance from the connection face between the head-

shell and tone arm to the tip of the stylus should be 52 mm.

Secure the cartridge by moving the cartridge straight along

the side face of the headshell and making the cartridge par-

allel to the headshell.

52mm

The overhang distance of the tone arm mounted on this unit

is 15 mm.

11

How to Assemble

of tone arm

6. How to adjust horizontal balance

Detach the tone arm from the arm rest to make the tone

arm disengaged. Rotate the counterweight to minutely ad-

just the horizontal balance of the tone arm.

Be aware that the stylus tip of a cartridge is remarkably del-

icate. Therefore, be extra careful not to apply unreasonable

force to the stylus tip.

7. How to adjust stylus pressure

Firstly, set the stylus pressure gauge to 0 while paying at-

tention not to move the counterweigth with the tone arm

horizontally balanced.

Secondly, set the stylus pressure to a required value by ro-

tating the stylus pressure gauge in the arrow direction shown

in the drawing below. Refer to the operating instructions

for your cartridge regarding the optimal value. A cartridge

weighing 4 to 12 g is suitable for this unit. For a heavyweight

cartridge, use an optional heavy counterweight.

8. How to adjust tone arm height

Change in the height of the tone arm allows for appropri-

ately adjusting the gap between the record surface and the

bottom face of the cartridge. Loosen the screw placed at

the arm base with the tone arm adjustment wrench, move

the tone arm vertically, and tighten the screw when the tone

arm becomes parallel to the record surface.

Armrest

Height adjustment screw

0

2.5

0.5

1

0

3

1

2

The stylus pressure gauge is free from the counterweight and

rotatable freely.

The tone arm is secured only with the screw placed at the

arm base. When the screw is loosened, be sure to put the

tone arm in the arm rest and use your hand to support the

entire tone arm to prevent it from dropping.

9. How to adjust anti-skating

Rotate the anti-skating adjustment knob to set it to a value

that is appropriate to the stylus pressure of your cartridge.

0

2.5

0.5

1

0

3

1

2

12

Anti-skating is also called as inside force canceler.

BELT DRIVE ANALOG PLAYER PD-171A

10. How to mount pulley cover

Insert four corners slowly and evenly as shown below.

11. How to mount rubber mat

The face with a hollow in the center is the upper side.

Put the rubber mat on the platter by aligning it with the cen-

ter spindle.

12. How to mount dust cover

The dust cover has a plug-in type hinge.

Insert the hinge attached to the dust cover into the hinge

receiver attached to the rear side of the main unit all the way

in a straight manner.

If the acrylic portion of the dust cover is pushed firmly, it may

be cracked. Therefore, insert rather than push the hinge por-

tions at the right and left sides at the same time.

13

Connections

PHONO AMPLIFIER

BELT DRIVE ANALOG PLAYER

A

14

INTEGRATED AMPLIFIER

BELT DRIVE ANALOG PLAYER PD-171A

Before Connecting

Before connecting other devices, connect the jack side of the

accessory power cable to the AC inlet of this unit.

When connecting, turn off the power switch of this unit and the

power supplies of auxiliary devices to prevent unexpected ac-

cidents that may be caused by noises.

How to connect power supply

Use the accessory power cable and insert the AC plug in an

outlet on the wall in the room where the unit will be installed.

How to connect to phono equalizer,

integrated amplifier, or others

Connect the pin plug of the phono cable to the phono termi-

nal of a phono equalizer, an integrated amplifier, or others.

How to connect of grounding conductor

Connect the grounding conductor to the signal ground ter-

minal of a phono equalizer, an integrated amplifier or others

to be used.

Failure to observe this may induce hum noises on music sig-

nals.

15

Operations

Start/stop switch

Stylus light

connector

Rotation speed

selection switch

How to play

1. Connect the stylus light to the stylus light connector to

turn on the light for record playback in the dark.

2. Put a record on the platter while aligning the center

hole of the record with the center spindle.

For an EP record, use the EP adaptor.

3. Select a rotation speed (33 or 45) with the rotation

speed selection switch in accordance with a record

and press the start/stop switch.

4. Raise the arm lifter, disengage the tone arm from the

arm rest, and move the tone arm to a position where

you like to play.

Rotation speed fine tuning volume

(speed control)

5. Lowering the arm lifter allows the tone arm to be

lowered and playback to start.

16

6. After playback ends, raise the arm lifter, put the tone

arm back on the arm rest, and press the start/stop

switch to stop the platter.

To prevent the stylus tip and records from being damaged,

use the arm lifter for vertical movement of the tone arm if

possible.

BELT DRIVE ANALOG PLAYER PD-171A

How to Replace Tone Arm

the arm base cover from this product (PD-171A)

Align the golden label at mounting on the main unit.

Golden label sticking position on the arm base (example)

By removing the arm base placed on this product (PD-171A) and re-

placing it with the optional arm base, your tone arm can be mounted.

The optional arm bases and applicable tone arms are shown in

the table below.

Product name Applicable tone arm Contents

OPPD-AB1 SME 3009R / 3010R / Series M2-9R /

Series M2-9, M2-10 / Series Ⅳ,

OPPD-AB2 FR64 / 64S / 64FX, IKEDA IT-345

OPPD-AB3 SAEC WE-308

OPPD-AB4 SAEC WE-407 / 23

OPPD-AB5 ORTOFON: AS-212S / RS-212D

OPPD-AB6 Universal (no arm mounting hole)

*1: The attached arm mounting screws (4 pieces) are used for mounting Series M2-9, M2-10, and Series IV and V. Do not use the

screws supplied with the tone arm, but use the screws supplied with the optional arm base.

Follow the procedure below to replace the tone arm, and be

careful to prevent this product (PD-171A) and arm base from be-

ing damaged. Unplug the power cable of this product (PD-171A)

before mounting the tone arm.

Follow the operating instructions of your tone arm for adjust-

ments after mounting the arm.

Ⅴ

3. How to mount arm base on this product

1. How to remove arm and arm base from

this product (PD-171A)

Remove the turntable sheet, turntable, and belt from the

main unit, and turn the main unit upside down with the dust

cover attached. (Spread a soft cloth or the like on a table,

and put the dust cover on it.)

Unplug the phono cable of the tone arm from the tone arm.

Loosen the screw of the cable holder that secures the pho-

no cable, and remove the phono cable from the main unit.

After removing the phone cable, put the main unit back to

the normal position.

Use the arm base removal wrench (3.0 mm) supplied with

the main unit to remove the arm base mounting screws (6

pieces). (Keep the removed screws until they are used to

mount the optional arm base.)

Arm base, mounting wrench, arm mounting screw

(4 pieces)*1, Owner's Manual

Arm base, mounting wrench, Owner's Manual

(PD-171A)

Place the arm base so that the golden label on the this prod-

uct (PD-171A) from which the arm base cover is removed is

aligned with the golden label on the arm base to adjust the

screw hole position of this product (PD-171A) to the one of

the arm base. Use the screws that have been removed from

the original arm base to securely tighten them.

Note: If the screws are insufficiently tightened, the sound

quality may be adversely affected. Thus, the screws

should be securely tightened.

Golden label

Illustration showing the state of removing

Golden label

2. How to mount tone arm on arm base

Follow the operating instructions of the optional arm base to

mount your tone arm to the arm base.

17

How to Replace Tone Arm

Phono cable

securing cushion

Cable holder

Phono cable

After completion of mounting the arm base and tone arm,

put the turntable, turntable sheet and belt back to the main

unit.

4. How to connect and secure phono

cable

Connect the supplied phono cable to the tone arm securely.

Secure the phono cable using the supplied phono cable

securing cushion.

Select a cushion whose thickness is best suited for place-

ment.

5. How to adjust tone arm height

Follow the operating instructions of your tone arm for ad-

justments.

The following are adjustment examples:

• Adjustment of tone arm height

• Adjustment of Overhang

• Adjustment of lateral balance

• Adjustment of Anti-skating

(also called as adjustment of inside force canceler)

• Adjustment of stylus pressure, etc.

18

BELT DRIVE ANALOG PLAYER PD-171A

Block Diagram

Start / Stop

LED Driver

XTAL

33rpm

Speed Control

Speed Selector

System Control CPU

DAC

45rpm

Speed Control

Power TransPower Regulator

Stylus Light

AC

Motor

Synchronous

19

Specifications

Phono motor section

Drive system Belt drive system

Motor Reaction and AC synchronous motor

Platter 30 cm machined alminum plate (weight 5.0 kg)

Revolution 33 1/3 rpm, 45 rpm (2 speeds selectable)

Revolution adjustment range ±5% (each rotation speed adjustable independently)

Wow and flutter 0.04% or less (W.R.M.S)

Tone arm section

Format Static balance, S-type

Length overall 229mm

Tracking error angle +1.9° to –1.1°

Overhang 15mm

Applicable cartridge weight 4 g - 12 g * 22 g - 32 g when a heavy counterweight (option) is used

Adjustable height range 38 to 60mm

Anti-skating 0 to 3g

Attached equipment and others

[Top panel section]

• Power switch • Start/stop switch

• Rotation speed selection switch • Stroboscope

• Rotation speed fine tuning volume (speed control) (33 1/3 rpm, 45 rpm)

Attached equipment

Accessories

Power source 230 V ~ (50 Hz)

Power consumption 38 W

Weight 25.4 kg

Dimensions

Ambient operating temperature /

Ambient operating humidity

• Stylus light connector • Arm (arm base mounted)

[Rear panel section]

• AC inlet

[Bottom section]

• Insulator • Tone arm connector (DIN5P type)

• Platter • Power cable

• Dust cover • Stylus light • Headshell

• Pulley cover • Rubber belt • EP adaptor

• Rubber mat • Phono cable (connected to main unit)

• Counterweight • Platter mount handle (2 pieces)

• Tone arm adjustment wrench (2.5 mm)

• Arm lifter adjustment wrench (1.5 mm)

• Arm base cover removal wrench (3.0 mm)

• Phono cable securing cushions (3 types)

• Dustproof cap for stylus light connector (connected to main unit)

492 (W) × 140 (up to top face of platter), 195 (with dust cover mounted) (H)

× 407 (10 mm of fittings on rear face included) (D) mm

–5 °C to +35 °C / 5% to 85% (non condensing)

* Design and specifications are subject to change without notice.

20

BELT DRIVE ANALOG PLAYER PD-171A

Before Asking for Repair

While the unit is used, an unusual phenomenon may be confused as a malfunction for a certain reason. Prior to asking us for our official

sole distributor of your country, please check the table below and read the instruction manual. If the cause of the malfunction cannot

be identified, please contact your dealer. When we have once accepted your request for repair services, inspection fees and traveling

expenses may be claimed even though the unit is found to be normal.

Problem Cause Solution Ref. page

No power is supplied even

though the power switch is

pressed ON.

The platter does not rotate. · The belt is not wrapped correctly. · Wrap the belt correctly. 10

The number in the stroboscope

moves.

No sound is generated. · Connection between lead wires

· The power plug is disconnected

from the AC inlet or wall outlet, or it

is not inserted firmly.

· The power switch is not turned on. · Turn on the power switch.

· The rotation speed is not adjusted. · Adjust the rotation speed using the

and the cartridge or between the

headshell and tone arm is incomplete.

· Connection of the phono cable is

not correct.

· Settings or connections of the phono equalizer, integrated amplifier,

or others are not correct.

· Insert the power plug in the AC inlet and wall outlet firmly.

rotation speed fine tuning volume

(speed control).

· Make connections of lead wires

firmly.

Tighten the plug-in nut to secure

the connection between the headshell and tone arm.

Mount the tone arm securely.

· Connect the phono cable correctly. 8, 14 - 15

· Check connections among devices, power supplies of the phono

equalizer, integrated amplifier, and

others, the volume position, selector positions, etc.

15

11

7

The sound volume is too low or

too high.

Sound images are shaky, or

sound balance between right

and left is not favorable.

· The cartridge setting at the phono

equalizer, integrated amplifier, and

others are not correct.

· The player body is inclined. · Install this unit in a horizontal and

· Anti-skating adjustment is inappropriate.

· The cartridge is not mounted horizontally.

· Perform cartridge setting at the

phono equalizer, integrated amplifier, and others in accordance with

your cartridge (MC/MM).

stable place. Use insulators to

make this unit horizontal.

· Perform anti-skating adjustment

appropriately.

· Adjust the horizontal balance. 12

8, 10

12

21

Before Asking for Repair

Problem Cause Solution Ref. page

Playing speed is inappropriate. · The rotation speed is not adjusted

appropriately.

Hum noises (humm sound) are

generated.

Sound skip occurs, or noises

(cracking sound) are induced.

· The grounding conductor is not

connected.

· Connection of the phono cable is

not correct.

· The cartridge is not mounted securely on the headshell.

· The stylus pressure is not adjusted

appropriately.

· A scratch, a warp, or a stain is

present on the record.

The record is electrostatically

charged.

· A stain is present on the stylus tip. · Remove the stain from the stylus

· Select a rotation speed in accordance with a record on the platter, and adjust the speed with the

rotation speed fine tuning volume

(speed control).

· Connect the grounding conductor

to a GND terminal.

· Connect the phono cable correctly. 8, 14 - 15

· Mount the cartridge on the headshell with screws and nuts securely.

· Adjust the stylus pressure gauge

in accordance with your cartridge.

· Do not play a record with a scratch

or a warp on this unit.

Clean the record with a commer-

cially available cleaner.

tip.

7

14 - 15

11

12

· This unit is installed in a vibrating

place.

The stylus light does not light. · The stylus light is not inserted firmly. · Remove the dustproof cap and in-

This unit may not work normally when the unit is subject to external influence such as static electricity.

In such a case, the unit can work normally by unplugging the power cable once and plugging it again.

If this unit does not work normally even after that, please contact your dealer.

· Install this unit in a horizontal and

stable place to avoid sound skip

caused by external vibration.

sert the stylus light into the stylus

light connector firmly.

7, 16

22

BELT DRIVE ANALOG PLAYER PD-171A

MEMO

23

MEMO

24

LUXMAN CORPORATION, JAPAN

AG00987E31A

Printed in China

Loading...

Loading...