Page 1

xPONENT for MAGPIX 4.2

Software User Manual

Page 2

©

Luminex Corporation, 2011. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, or translated into any language or computer language,

in any form or by any means without prior express, written consent of Luminex Corporation.

LUMINEX CORPORATION

12212 Technology Boulevard

Austin, Texas 78727-6115

U.S.A.

Voice: (512) 219-8020

Fax: (512) 219-5195

xPONENT 4.2 for MAGPIX Software User Manual

89-00002-00-239 rev. E

November 2011

Luminex Corporation (Luminex) reserves the right to modify its products and services at any

time. This guide is subject to change without notice. Although prepared to ensure accuracy,

Luminex assumes no liability for errors or omissions, or for any damages resulting from the

application or use of this information.

The following are trademarks of Luminex Corporation: Luminex®, xMAP®, xTAG®,

xPONENT®, Luminex® 100™, Luminex® 100 IS®, Luminex® 200™, Luminex® SD™, Luminex

®

XYP™, MagPix®, MagPlex® Microspheres, MicroPlex®.

All other trademarks, including ProClin®, Cheminert®, Windows® Pentium® and Dell® are

trademarks of their respective companies.

i

Page 3

End-User License Agreement (EULA) for Luminex

xPONENT® Software

This Luminex End-User License Agreement (“EULA”) is a legal agreement between you

(either an individual or a single entity, also referred herein as “you”) the end-user and

Luminex Corporation (“Luminex”) regarding the use of the xPONENT software product

provided to you above, which includes computer SOFTWARE and online or electronic

documentation and may include associated media and printed materials (if any)

(“SOFTWARE”). The terms also apply to any updates, supplements, web content or internetbased services, such as remote access.

BY USING THE SOFTWARE, YOU ACCEPT THESE TERMS. IF YOU DO NOT ACCEPT

THEM, DO NOT USE THE SOFTWARE. INSTEAD, RETURN IT TO LUMINEX OR THE

LUMINEX AUTHORIZED THIRD PARTY FROM WHICH YOU PURCHASED THE

SOFTWARE FOR A REFUND OR CREDIT. IF YOU COMPLY WITH THESE LICENSE

TERMS, YOU HAVE THE RIGHTS TO USE THE SOFTWARE AS SPECIFICALLY SET

FORTH BELOW.

1. OVERVIEW. The SOFTWARE is protected by copyright laws and international copyright

treaties, as well as other intellectual property laws and treaties. The SOFTWARE is

licensed, not sold.

2. ADDITIONAL LICENSING REQUIREMENTS AND/OR USE RIGHTS.

a. Trial and Conversion. Some or all of the SOFTWARE may be licensed on a trial basis.

Your rights to use trial SOFTWARE are limited to the trial period. The trial SOFTWARE

and length of the trial period are set forth during the activation process. The

SOFTWARE may be used for evaluation purposes only during the trial period and not

for any commercial use, including without limitation to any diagnostic use. You may

have the option to convert your trial rights to perpetual rights. Conversion options will

be presented to you at the expiration of your trial period.

b. Activation. You can activate the SOFTWARE by obtaining a license key provided by

Luminex Technical Support at support@luminexcorp.com or 1-877-785-2323 or

1-512-381-4397.

c. Branding. You may only add additional branding or other graphics to SOFTWARE with

Luminex's express written consent.

d. Upgrades. You may only obtain updates or upgrades for the SOFTWARE from

Luminex Technical Support at orders@luminexcorp.com or authorized resellers. For

more information on obtaining updates from authorized resellers, see http://

www.luminexcorp.com.

®

xPONENT for MAGPIX 4.2 Software User Manual

ii

Page 4

3. GRANT OF LICENSE. Subject to the terms and conditions of this EULA, Luminex hereby

grants to you a nonexclusive, nontransferable, nonassignable license (without right to

sublicense) under Luminex's copyrights and trade secrets to use the SOFTWARE on a

single computer running with a single unit of a specific model of Luminex instrument, as

such model is identified on the packaging included with the SOFTWARE. You may make

one (1) copy of the SOFTWARE for backup or archival purposes only. You may also

install the SOFTWARE on up to two (2) additional computers for purposes of performing

ancillary tasks (i.e. preparing templates/protocols, performing further analysis or rerunning previous data), provided such computers are at a single location and are NOT

connected with a Luminex instrument. In addition, You may purchase the right to use the

SOFTWARE on additional computers, as agreed to in writing with Luminex or its

authorized reseller, for purposes of performing ancillary tasks (i.e. preparing templates/

protocols, performing further analysis or re-running previous data), provided such

computers are at a single location and are NOT connected with a Luminex instrument.

Although no rights or licenses under any of Luminex's patents are granted by or shall be

implied from the license of the SOFTWARE or the sale of Luminex instrumentation to

you, the purchaser, you may obtain a license under Luminex's patents, if any, to use this

unit of Luminex instrumentation with fluorescently labeled microsphere beads authorized

by Luminex by purchasing such beads from Luminex or an authorized Luminex reseller.

4. RESTRICTIONS

• SOFTWARE must only be installed and operated on a single computer running with a

Luminex instrument, as set forth above.

• You may not use this SOFTWARE for any commercial purpose, including in the

performance of testing services, unless expressly agreed to in writing by Luminex or as

authorized in writing by Luminex through an authorized reseller of the SOFTWARE.

• You may only use the SOFTWARE with microspheres manufactured by Luminex or

with kits developed, manufactured and distributed by licensees authorized in writing by

Luminex.

• You must maintain all proprietary notices on all copies of the SOFTWARE.

• You may not distribute copies of the SOFTWARE to third parties.

• You may not reverse-engineer, decompile, disassemble, or otherwise attempt to derive

source code from the SOFTWARE.

• You may not copy (other than one backup or archival copy), distribute, sublicense,

rent, lease, transfer or grant any rights in or to all or any portion of the SOFTWARE.

• You must comply with all applicable laws regarding the use of the SOFTWARE.

• You may not modify or prepare derivative works of the SOFTWARE, including

modifying any branding or graphics.

• You may not use the SOFTWARE in a computer-based service business or publicly

display visual output of the SOFTWARE.

• You may not transmit the SOFTWARE over a network, by telephone, or electronically

by any means.

iii

Page 5

5. TERM AND TERMINATION. Your rights under this EULA are effective until termination.

You may terminate this EULA at any time by destroying the SOFTWARE, including all

computer programs and documentation, and erasing any copies residing on your

computer equipment. Luminex may terminate this EULA upon thirty (30) days written

notice to you. Your rights under this EULA automatically terminate without further action

on the part of Luminex if you do not comply with any of the terms or conditions of this

EULA. Upon any termination of this EULA, you agree to destroy the SOFTWARE and

erase any copies residing on your computer equipment.

6. RIGHTS IN SOFTWARE. All rights and title in and to the SOFTWARE and any copies

thereof are owned by Luminex or its suppliers. This EULA is not a sale and does not

transfer to you any title or ownership interest in or to the SOFTWARE or any patent,

copyright, trade secret, trade name, trademark or other intellectual property right therein.

You shall not remove, alter, or obscure any proprietary notices contained on or within the

SOFTWARE and shall reproduce such notices on any back-up copy of the SOFTWARE.

All title and intellectual property rights in and to the content which may be accessed

through use of the SOFTWARE is the property of the respective content owner and may

be protected by applicable copyright or other intellectual property laws and treaties. This

EULA grants you no rights to use such content.

7. EXPORT RESTRICTIONS. You agree that you will not export or re-export the

SOFTWARE to any country, person, entity, or end-user subject to U.S.A. export

restrictions. You hereby warrant no state or federal agency has suspended, revoked, or

denied your export privileges.

8. NO WARRANTY. THE SOFTWARE IS LICENSED "AS IS." ANY USE OF THE

SOFTWARE IS AT YOUR OWN RISK. THE SOFTWARE IS PROVIDED FOR USE

ONLY WITH LUMINEX PRODUCTS. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, LUMINEX AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

AND NONINFRINGEMENT.

9. LIMITATION OF LIABILITY. IN NO EVENT SHALL LUMINEX OR ITS SUPPLIERS BE

LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS

INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF

OR INABILITY TO USE THE SOFTWARE, EVEN IF LUMINEX HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES.

10. MISCELLANEOUS. This EULA is governed by the laws of the State of Texas, U.S.A.,

without reference to conflicts of laws principles. You shall not assign or sublicense or

otherwise transfer the rights or license granted hereunder, by agreement or by operation

of law, without the prior written consent of Luminex, and all assignments in violation of

this prohibition shall be null and void. This EULA is the complete and exclusive

agreement of Luminex and you and supersedes all other communications, oral or written,

relating to the subject matter hereof. No change to this EULA shall be valid unless in

writing and signed by the party against whom enforcement is sought. The waiver or

failure of Luminex or you to exercise in any respect any right or rights provided for herein

shall not be deemed a waiver of any further right hereunder. If any provision of this EULA

is held unenforceable, the remainder of this EULA will continue in full force and effect.

89-30000-00-254 Rev. B

xPONENT for MAGPIX 4.2 Software User Manual

iv

Page 6

Standard Terms and Conditions for Use of Instrument

Product

By opening the packaging containing this product ("Product") or by using such Product in any

manner, you are consenting and agreeing to be bound by the following terms and conditions.

You are also agreeing that the following terms and conditions constitute a legally valid and

binding contract that is enforceable against you. If you do not agree to all of the terms and

conditions set forth below, you must promptly return the Product for a full refund prior to using

them in any manner.

1. Acceptance

ALL SALES ARE SUBJECT TO AND EXPRESSLY CONDITIONED UPON THE TERMS

AND CONDITIONS CONTAINED HEREIN, AND UPON BUYER'S ASSENT THERETO. NO

VARIATION OF THESE TERMS AND CONDITIONS SHALL BE BINDING UPON LUMINEX

CORPORATION ("LUMINEX") UNLESS AGREED TO IN WRITING AND SIGNED BY AN

AUTHORIZED REPRESENTATIVE OF LUMINEX. For purposes of this agreement, "Seller"

shall mean either Luminex, if the Product is purchased directly from Luminex, or a Luminex

authorized reseller. Buyer, by accepting the Product shall be deemed to have assented to the

terms and conditions set forth herein, notwithstanding any terms contained in any prior or

later communications from Buyer and whether or not Seller shall specifically or expressly

object to any such terms.

2. Warranties

THIS WARRANTY IS APPLICABLE FOR PARTS AND SERVICE FOR LUMINEX

INSTRUMENTS PURCHASED DIRECTLY FROM LUMINEX TO BUYER AND ONLY TO

THE EXTENT SUCH INSTRUMENTS ARE LOCATED IN NORTH AMERICA AND THE

COUNTRIES THAT COMPRISE THE EUROPEAN UNION. LUMINEX MAKES NO

WARRANTY, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO PRODUCTS SOLD,

DISTRIBUTED, LOCATED OR USED OUTSIDE OF NORTH AMERICA OR THE

COUNTRIES COMPRISING THE EUROPEAN UNION. PRODUCTS SOLD OUTSIDE OF

NORTH AMERICA OR THE COUNTRIES COMPRISING THE EUROPEAN UNION ARE

SOLD ONLY ON AN "AS IS, WHERE IS" BASIS. NOTWITHSTANDING THE FOREGOING,

LUMINEX SHALL PROVIDE BUYER A WARRANTY ON FIELD SERVICE PARTS

PROCURED FROM LUMINEX FOR MAINTENANCE OF LUMINEX INSTRUMENTS IN ALL

COUNTRIES IN THE WORLD AND PER THE TERMS AND CONDITIONS HEREIN. TO

THE EXTENT THAT THE FOREGOING DISCLAIMERS ARE INVALID OR

UNENFORCEABLE UNDER THE LAWS OF ANY JURISDICTION, THE WARRANTY,

DISCLAIMER, LIMITATION OF LIABILITY AND OTHER PROVISIONS SET FORTH BELOW

SHALL THEREUPON BE EFFECTIVE TO THE FULLEST EXTENT PERMITTED BY

APPLICABLE LAW.

Notwithstanding Buyer's acceptance thereof, if Product is purchased directly from Luminex,

Luminex warrants that for a period of twelve (12) months from date of delivery that the

Product shall conform in all material respects with the Product Specifications provided by

Luminex with the Product. The warranty provided herein specifically excludes any software or

v

Page 7

hardware not provided by Luminex. If Product is purchased from a Luminex authorized

reseller, any warranty obligations shall be provided in writing directly by such Luminex

authorized reseller to Buyer. THIS WARRANTY IS EXCLUSIVE AND LUMINEX MAKES NO

OTHER WARRANTY, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Seller's warranties made in connection with this sale shall not be effective if

Seller has determined, in its sole discretion, that Buyer has misused the Product in any

manner, has failed to use the Product in accordance with industry standards or practices or

has failed to use the Product in accordance with instructions, if any, furnished by Seller.

BUYER'S EXCLUSIVE REMEDY WITH RESPECT TO PRODUCT PROVED TO SELLER'S

SATISFACTION TO BE DEFECTIVE OR NONCONFORMING SHALL BE REPAIR OR

REPLACEMENT OF SUCH PRODUCTS WITHOUT CHARGE OR REFUND OF THE

PURCHASE PRICE, IN SELLER'S SOLE DISCRETION, UPON THE RETURN OF SUCH

PRODUCTS IN ACCORDANCE WITH SELLER'S INSTRUCTIONS BELOW. NEITHER

SELLER NOR LUMINEX SHALL IN ANY EVENT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY KIND RESULTING FROM ANY USE

OR FAILURE OF THE PRODUCT, EVEN IF SELLER OR LUMINEX HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGE INCLUDING, WITHOUT LIMITATION,

LIABILITY FOR LOSS OF WORK IN PROGRESS, DOWN TIME, LOSS OF REVENUE OR

PROFITS, FAILURE TO REALIZE SAVINGS, LOSS OF PRODUCTS OF BUYER OR

OTHER USE OR ANY LIABILITY OF BUYER TO A THIRD PARTY ON ACCOUNT OF

SUCH LOSS, OR FOR ANY LABOR OR ANY OTHER EXPENSE, DAMAGE OR LOSS

OCCASIONED BY SUCH PRODUCT INCLUDING PERSONAL INJURY OR PROPERTY

DAMAGE UNLESS SUCH PERSONAL INJURY OR PROPERTY DAMAGE IS CAUSED BY

SELLER'S GROSS NEGLIGENCE.

In the event that Product is located outside of North America or the European Union and fails

to conform to the warranty set forth herein, during the warranty period: (i) Buyer shall notify

Luminex in a timely manner in writing that such Product failed to conform and shall furnish a

detailed explanation of any alleged nonconformity; (ii) Buyer at it's expense will contract

either Luminex or a Luminex trained service engineer to assess the issue and identify the

defective FS-PART; and (ii) at Luminex's option and election, Buyer shall either return such

nonconforming Product to Luminex's manufacturing facility or destroy such Product and

provide Luminex with written certification of destruction. In the event that a FS-PART is

returned to Luminex's manufacturing facility, Luminex may analyze such FS-PART for

defects. In the event that Luminex determines that such FS-PART is not defective, the FSPART shall be shipped to Buyer then Buyer shall be responsible for the payment for such FSPART and related shipping charges. Furthermore, in the event that Luminex determines that

such FS-PART is defective then Luminex shall be responsible for the payment for such FSPART and related shipping charges. Except as expressly provided herein, Buyer shall not

have the right to return a Product to Luminex without Luminex's prior written consent.

3. Buyer's Use of Product

Buyer shall not use this Product for any commercial purpose, including without limitation

performance of testing services, unless expressly agreed to in writing by Luminex or as

specifically authorized by Luminex through a Luminex distributor. Buyer agrees that no rights

or licenses under Luminex's patents shall be implied from the sale of the Product, except as

expressly provided herein or as specifically agreed to in writing by Luminex, and Buyer does

not receive any right under Luminex's patent rights hereunder. Buyer acknowledges and

agrees that the Product are sold and licensed only for use with Luminex's laser based

fluorescent analytical test instrumentation. Buyer further acknowledges that, unless otherwise

xPONENT for MAGPIX 4.2 Software User Manual

vi

Page 8

indicated on the Product label, the Product has not received approval from the United States

Food and Drug Administration or other federal, state or local regulatory agencies and have

not been tested by Seller or Luminex for safety or efficacy in food, drug, medical device,

cosmetic, commercial or any other use, unless otherwise stated in Seller's technical

specifications or material data sheets furnished to Buyer. Buyer expressly represents and

warrants to Seller that Buyer will use the Product in accordance with the Product label, if

applicable, and will properly test and use any Product in accordance with the practices of a

reasonable person who is an expert in the field and in strict compliance with the United

States Food and Drug Administration and all applicable domestic and international laws and

regulations, now and hereinafter enacted.

BUYER HEREBY GRANTS TO LUMINEX A NONEXCLUSIVE, WORLDWIDE,

UNRESTRICTED, ROYALTY-FREE, FULLY PAID-UP LICENSE, WITH THE RIGHT TO

GRANT AND AUTHORIZE SUBLICENSES, UNDER ANY AND ALL PATENT RIGHTS IN

INVENTIONS COMPRISING MODIFICATIONS, EXTENSIONS, OR ENHANCEMENTS

MADE BY BUYER TO THE PRODUCT OR TO THE MANUFACTURE OR USE OF THE

PRODUCT ("IMPROVEMENT PATENTS"), TO MAKE, HAVE MADE, USE, IMPORT,

OFFER FOR SALE OR SELL ANY AND ALL PRODUCT; EXPLOIT ANY AND ALL

METHODS OR PROCESSES; AND OTHERWISE EXPLOIT IMPROVEMENT PATENTS

FOR ALL PURPOSES. NOTWITHSTANDING THE FOREGOING, "IMPROVEMENT

PATENTS" SPECIFICALLY EXCLUDES PATENT CLAIMS CONCEIVED AND REDUCED

TO PRACTICE BY BUYER CONSISTING OF METHODS OF SAMPLE PREPARATION,

METHODS OF CONJUGATING PRODUCT TO ANALYTES, THE COMPOSITION OF

MATTER OF THE SPECIFIC CHEMISTRIES OF THE ASSAYS DEVELOPED BY BUYER

AND METHODS OF PERFORMING THE ASSAYS (I.E., THE PROTOCOL FOR THE

ASSAY).

Buyer has the responsibility and hereby expressly assumes the risk to verify the hazards and

to conduct any further research necessary to learn the hazards involved in using the Product.

Buyer also has the duty to warn Buyer's customers, employees, agents, assigns, officers,

successors and any auxiliary or third party personnel (such as freight handlers, etc.) of any

and all risks involved in using or handling the Product. Buyer agrees to comply with

instructions, if any, furnished by Seller or Luminex relating to the use of the Product and not

misuse the Product in any manner. Buyer shall not reverse engineer, decompile, disassemble

or modify the Product. Buyer acknowledges that Luminex retains ownership of all patents,

trademarks, trade secrets and other proprietary rights relating to or residing in the Product

and Buyer receives no rights to such intellectual property rights by virtue of its purchase of

Product other than as expressly set forth herein. Buyer shall have no right to use any

trademarks owned or licensed to Luminex without the express written permission of Luminex.

4. Buyer's Representations, Release and Indemnity

Buyer represents and warrants that it shall use the Product in accordance with Paragraph 2,

"Buyer's Use of Product," and that any such use of Product will not violate any law,

regulation, judicial order or injunction. Buyer agrees to release, discharge, disclaim and

renounce any and all claims, demands, actions, causes of action and/or suits in law or equity,

now existing or hereafter arising, whether known or unknown, against Seller and Luminex,

and their respective officers, directors, employees, agents, successors and assigns

(collectively the "Released Parties"), with respect to the use of the Product. Buyer agrees to

indemnify and hold harmless the Released Parties from and against any suits, losses, claims,

demands, liabilities, costs and expenses (including attorney, accounting, expert witness, and

consulting fees) that any of the Released Parties may sustain or incur as a result of any claim

against such Released Party based upon negligence, breach of warranty, strict liability in tort,

vii

Page 9

contract or any other theory of law or equity arising out of, directly or indirectly, the use of the

Product or by reason of Buyer's failure to perform its obligations contained herein. Buyer shall

fully cooperate with the Released Parties in the investigation and determination of the cause

of any accident involving the Product which results in personal injury or property damage and

shall make available to the Released Parties all statements, reports, recordings and tests

made by Buyer or made available to Buyer by others.

5. Patent Disclaimer

Neither Seller nor Luminex warrants that the use or sale of the Product will not infringe the

claims of any United States or other patents covering the product itself or the use thereof in

combination with other products or in the operation of any process.

xPONENT for MAGPIX 4.2 Software User Manual

viii

Page 10

Table of Contents

Chapter 1 Introduction ........................................................................................................1

Safety Precautions .......................................................................................................................................1

Elements of the Software .............................................................................................................................1

Home Page ...........................................................................................................................................1

Screen Elements ...................................................................................................................................3

System Monitor .....................................................................................................................................4

Help .......................................................................................................................................................5

Quick Start .............................................................................................................................................6

System Info Tab ....................................................................................................................................6

Basic Procedures .........................................................................................................................................7

Starting xPONENT ................................................................................................................................7

Adding a New License Key ...................................................................................................................8

Logging On to xPONENT ......................................................................................................................8

Initial Startup .........................................................................................................................................9

Daily Activities .....................................................................................................................................13

Shutting Down the Analyzer ................................................................................................................13

Logging Off and Exiting .......................................................................................................................14

Using Online Help ...............................................................................................................................14

Luminex Support ........................................................................................................................................15

Luminex Website .................................................................................................................................15

Contacting Technical Support .............................................................................................................15

Software Packages ....................................................................................................................................15

MAGPIX Technology .................................................................................................................................16

Running Assays with MAGPIX ..................................................................................................................17

General Guidelines ..............................................................................................................................17

Biological Samples ..............................................................................................................................18

Bead (Microsphere) Handling ..............................................................................................................18

Repetitive MagPlex Bead Measurements ...........................................................................................18

Classification and Reporter Fluorochromes ........................................................................................19

Fluidics 1 and Fluidics 2 ......................................................................................................................19

Sample Volume ...................................................................................................................................19

Plates ..................................................................................................................................................20

Chapter 2 Samples Page ..................................................................................................23

Samples Page Functionality ......................................................................................................................23

Edit Samples and Create Sample Subtab .................................................................................................24

Creating a New Sample List ................................................................................................................25

Editing a Sample List ...........................................................................................................................27

Chapter 3 Batches Page ...................................................................................................29

Batches Page Functionality .......................................................................................................................29

Setting Up Batches ....................................................................................................................................30

Using the Batches Page ............................................................................................................................30

Create a New Batch from an existing Protocol ....................................................................................31

ix

Page 11

Create a New Batch from a New Protocol ...........................................................................................37

Create a New Multi-Batch ................................................................................................................... 50

Batch Procedures ......................................................................................................................................52

Running a Pending Batch ....................................................................................................................52

Importing a Batch ................................................................................................................................52

Exporting a Batch ................................................................................................................................53

Editing a Batch ....................................................................................................................................53

Deleting a Batch ..................................................................................................................................54

Chapter 4 Results Page ....................................................................................................55

Results Page Functionality ........................................................................................................................55

Performing Analysis ...................................................................................................................................56

Current Batch Tab ..................................................................................................................................... 57

Saved Batches Tab ................................................................................................................................... 61

Replaying a Batch ...............................................................................................................................65

Results Subtab ....................................................................................................................................66

Settings Subtab ..................................................................................................................................70

Log Subtab ..........................................................................................................................................71

Sample Details Subtab ........................................................................................................................72

LIS Results Tab .........................................................................................................................................73

Reports Tab ...............................................................................................................................................75

Generating a Report ............................................................................................................................76

Chapter 5 Protocols Page .................................................................................................77

Protocols Page Functionality .....................................................................................................................77

Protocol Procedures ..................................................................................................................................78

Creating an Allele Call Protocol ...........................................................................................................78

Creating a Quantitative Assay Protocol ...............................................................................................79

Creating a Qualitative Assay Protocol .................................................................................................82

Deleting a Protocol ..............................................................................................................................83

Editing a Protocol ................................................................................................................................83

Exporting a Protocol ............................................................................................................................84

Importing a Protocol ............................................................................................................................84

Adding a New Lot for Protocol .............................................................................................................84

Lots and Kits Procedures ...........................................................................................................................84

Creating a Lot ......................................................................................................................................84

Editing a Lot ........................................................................................................................................ 85

Deleting a Lot ......................................................................................................................................85

Exporting a Lot ....................................................................................................................................85

Importing a Lot .................................................................................................................................... 85

Creating a Kit .......................................................................................................................................85

Protocols Tab .............................................................................................................................................86

Settings Subtab ...................................................................................................................................87

Plate Layout Subtab ............................................................................................................................90

Standards and Controls (Stds/Ctrls) Details Subtab ..........................................................................93

Analytes Subtab ..................................................................................................................................94

Standards and Controls (Stds & Ctrls) Tab ............................................................................................... 99

Standards and Controls (Stds/Ctrls) Details Subtab ........................................................................100

Chapter 6 Maintenance Page .........................................................................................103

xPONENT for MAGPIX 4.2 Software User Manual

x

Page 12

Auto Maintenance (Auto Maint) Tab ........................................................................................................103

System Initialization ...........................................................................................................................105

Running the Performance Verification Routine .................................................................................105

Running Calibration and Verification .................................................................................................106

Lot Management Tab ...............................................................................................................................106

Importing CAL or VER Kits ................................................................................................................107

Deleting CAL and VER Kit Information ..............................................................................................108

Commands and Routines (Cmds & Routines) Tab ..................................................................................108

Creating a New Routine ....................................................................................................................111

Editing a Routine ...............................................................................................................................112

Deleting a Routine .............................................................................................................................112

Running a Routine .............................................................................................................................112

Importing a Routine ...........................................................................................................................113

Exporting a Routine ...........................................................................................................................113

Probe and Heater Tab .............................................................................................................................113

Adjusting the Sample Probe Height ..................................................................................................115

System Info Tab .......................................................................................................................................117

System Status Tab ..................................................................................................................................118

Schedule Tab ...........................................................................................................................................119

Support Utility Tab ...................................................................................................................................120

Sending a Support.zip File ................................................................................................................121

Chapter 7 Admin Page ....................................................................................................123

System Setup Tab ...................................................................................................................................123

Adding an External Analysis Program ...............................................................................................125

Editing an Analysis Program .............................................................................................................126

Removing an Analysis Program ........................................................................................................126

Arranging Main Navigation Buttons ...................................................................................................126

Maintenance Options ........................................................................................................................126

Group Setup Tab .....................................................................................................................................128

Setting Up Group Permissions ..........................................................................................................131

User Setup Tab ........................................................................................................................................131

Create User Account Window ...........................................................................................................132

Edit User Account Window ................................................................................................................133

Define Global User Settings ..............................................................................................................135

Batch Options Tab ...................................................................................................................................135

Alert Options Tab .....................................................................................................................................138

Alert Options Tasks ...........................................................................................................................140

CSV Options Tab .....................................................................................................................................140

Archive Options Tab ................................................................................................................................142

Archive Utility .....................................................................................................................................142

Licensing Tab ..........................................................................................................................................146

Adding a New License Key ...............................................................................................................147

Schedule Tab ...........................................................................................................................................147

Editing Maintenance Schedule Settings ............................................................................................148

Report Options Tab .................................................................................................................................149

Table of Contents

xi

Page 13

xPONENT for MAGPIX 4.2 Software User Manual

xii

Page 14

Chapter 1: Introduction

Safety Precautions

DANGER: Samples and waste fluid can contain biohazardous infectious

agents. Handle them at Biosafety level 2, as recommended for

any potentially infectious human serum or blood specimen in the

DCE/NIH manual, Biosafety in Microbiological and Biomedical

Laboratories, 1984.

CAUTION: Although beads do not contain hazardous or carcinogenic

components at toxic levels, they can be toxic if swallowed. In

addition, contact with acids liberates toxic gases. If beads come

into contact with skin, wash immediately with copious amounts of

water. In case of an accident, seek medical advice immediately

and show the product label or container to your medical provider.

A material safety data sheet (MSDS) is available upon request.

CAUTION: Luminex reagents can contain ProClin® as a preservative. This

can cause an allergic reaction in some people. Use personal

protective equipment (PPE), including gloves and safety glasses.

Check the assay package insert for assay component

information.

NOTE: Do not use strong organic solvents with this instrument. Contact

Luminex Technical Support when in doubt about compatibility of

cleaning and decontamination agents or materials.

Elements of the Software

Home Page

Home > Home

1

Page 15

The Home page displays a welcome message, batch creation buttons, Daily Activities

shortcuts, and the Installed Protocols list.

Return to the Home page at any time by clicking Home in the Navigation toolbar. This page

contains the following:

• Click to Create a new Batch from a New Protocol - Creates a new batch from a new

protocol. This allows you to create a new protocol while you are creating the batch. Choose

this function if you want to quickly create a batch and run it and you do not already have a

protocol that is appropriate for use. This is useful for one time batches you do not expect to

rerun frequently. However, you always have the option of saving a protocol once a batch is

created.

• Click to Create a new Batch using the highlighted Protocol below - Creates a new

batch using a selected protocol from the Installed Protocols list.

• Installed Protocols - Displays a list of protocols. The list contains the following information

about each protocol:

• Name

• Version

• Manufacturer

• Date

Use the up and down arrows on the right to move through the list of protocols.

xPONENT for MAGPIX 4.2 Software User Manual

2

Page 16

• View - Opens the Settings tab of the Protocols page to view the selected protocol. This

tab enables viewing the settings, analytes, and plate layout for the selected protocol.

• Daily Activities - Contains shortcut buttons to common commands in the xPONENT

software:

• System Initialization - Opens the System Initialization command in the Auto Maint

tab on the Maintenance page.

• Shutdown - Opens the System Shutdown command in the Auto Maint tab on the

Maintenance page.

• Probe and Heater - Opens the Probe and Heater tab on the Maintenance page.

• Sys Info - Opens the System Info tab of the Maintenance page.

• Reports - Opens the Reports tab of the Results page.

Screen Elements

This section shows screen elements and the terms used in this help or book to describe

them.

Introduction

3

Page 17

Navigation Elements

1. Page - Across the window, above the content pane, are pages. Click a page to go to that

part of xPONENT.

2. Tab - On the left side of the window, along the left side of the content pane, are tabs.

Click a tab to go to that subsection of the software.

3. Subtab - A tab can have one or more subtabs. These are located below the tab, are

smaller, and are identified by the circle on the left end of the subtab. The circle is red

when the subtab is open. For some workflows, you must move through the subtabs of a

tab sequentially, completing the work on one subtab and clicking Next to move to the

next subtab.

Right-Click Menu

Certain sections of the software such as tables, lists, and text boxes have right-click option

menus. Menus are different depending upon the item you right-clicked.

• Print All - Prints all sections or cells of the item.

• Print Selection - Prints only the selected section or cell.

• Import - Imports a file.

• Export - Opens a File Dialog dialog box. Use the Browse button to select a location, file

name, and file type (either a text or CSV file) for the export. This exports all data from the

right-clicked item.

• Cut - Cuts the selected data.

• Copy All - Copies all data.

• Copy - Copies only the selected data.

• Paste - Pastes previously copied text or data into the box.

• Delete - Erases text or data from the selection.

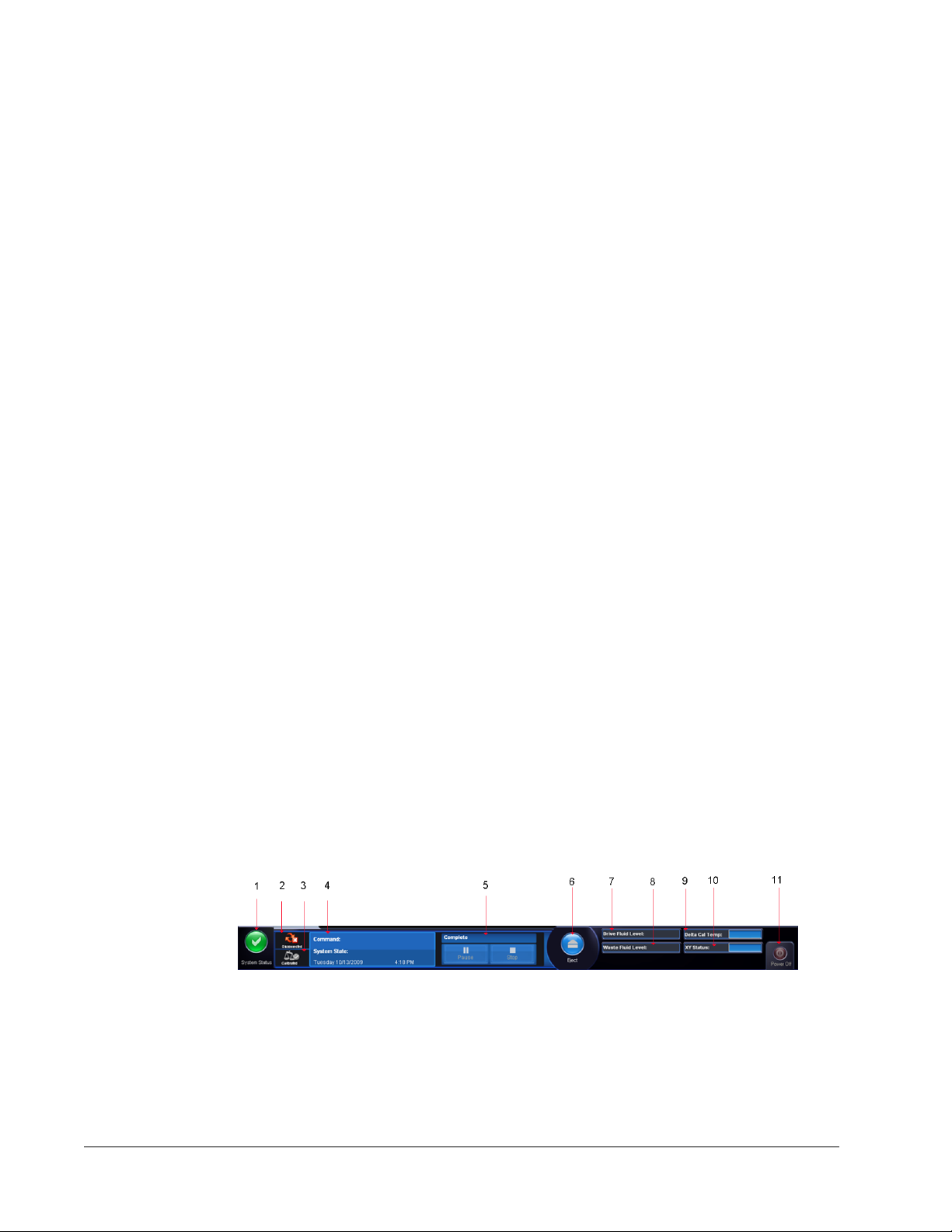

System Monitor

The System Monitor is displayed at the bottom of all xPONENT windows. It displays the

physical state of the Luminex system. Values are reported directly from the Luminex system.

1. System Status Button 2. Connection Status

3. Check Cal/Ver Status 4.Command Display

5. Progress bar, Stop button, Pause button 6. Eject Button for plate carrier

7. Drive Fluid Level 8. Waste Fluid Level

xPONENT for MAGPIX 4.2 Software User Manual

4

Page 18

9. Delta Cal Temperature 10. XY Status

11. Power Off button

System Status Button - This button has two functions: When clicked, it opens the system

log. It also displays the current status of the system. If there are no warnings or errors, the

System Status button is green with a check mark. If there is a warning, out of calibration

condition, or other important user notification, the button is yellow with an exclamation point.

Connection Status - Displays the status of the analyzer’s connection to the PC (Connected

or Disconnected). To ensure the analyzer connects to the PC, turn on the analyzer before

you start xPONENT.

Check Cal/Ver - If this displays a white X, there is a failed calibration or verification. Click the

scales to open the System Information tab to see details about the last calibration and other

important instrument information.

Command Display - Displays the following:

• The command currently running.

• The system state (i.e. running, idle, etc.).

• Date and time.

Progress - Displays a bar graph showing the progress of the current command or routine; if

the command or routine is finished, it displays a full progress bar and the command status as

Complete.

Pause - Pauses the system after the current command completes. Pause does not stop the

system in the middle of running a command. You cannot run another command while the

system is paused. Pause the system before stopping it so that it will finish the current

command and store the pending batch and then resume exactly where it left off.

Stop - Stops the system, regardless of command status. Use this only if it does not matter

whether the data from the current well is lost.

Help

Eject - Ejects the plate. Once the plate is ejected, the Eject button changes to Retract.

Retract retracts the plate, and the Retract button changes back to Eject.

Temp - Displays the difference in temperature between the current reading and the reading

when the system was calibrated, in degrees Celsius. If the temperature is out of tolerance,

this shows a high or low arrow. When clicked, it opens the Auto Maint tab.

XY Status - Displays the current location of the command, and the temperature of the plate

heating block in degrees Celsius. When clicked, it opens the Probe & Heater tab.

Drive Fluid Level - The Drive Fluid liquid level sensor warns you when the Drive Fluid is low.

There can be enough Drive Fluid left in the container to finish a plate. The system does NOT

stop until a air bubble is detected in the line coming from the Drive Fluid container.

Waste Fluid Level - The waste fluid container liquid level sensor stops the current plate if the

waste container is full.

To display online help for the tab in which you are currently working, click the blue “i” icon at

the upper right of the xPONENT window. This opens a help window with information specific

to that tab.

To display system-level help, click the blue question mark at the top of the xPONENT

window, then click Contents and Index. The online help opens and you can navigate to any

available topic.

Introduction

5

Page 19

To display quick start information, click the blue question mark at the top of the xPONENT

window, then click Quick Start. This displays information about the seven basic steps to start

the system.

Quick Start

The five steps to starting and using xPONENT are the following:

To Go to Expanded Help

Adjust the sample probe height Home > Probe and Heater Adjusting the Sample Probe

Initialize the system Home > System Initialization Running the System Initialization

Routine

Run an assay Home > Create a new Batch

Analyze Results > Saved Batches Performing Analysis

Print reports Results > Reports Reports Tab

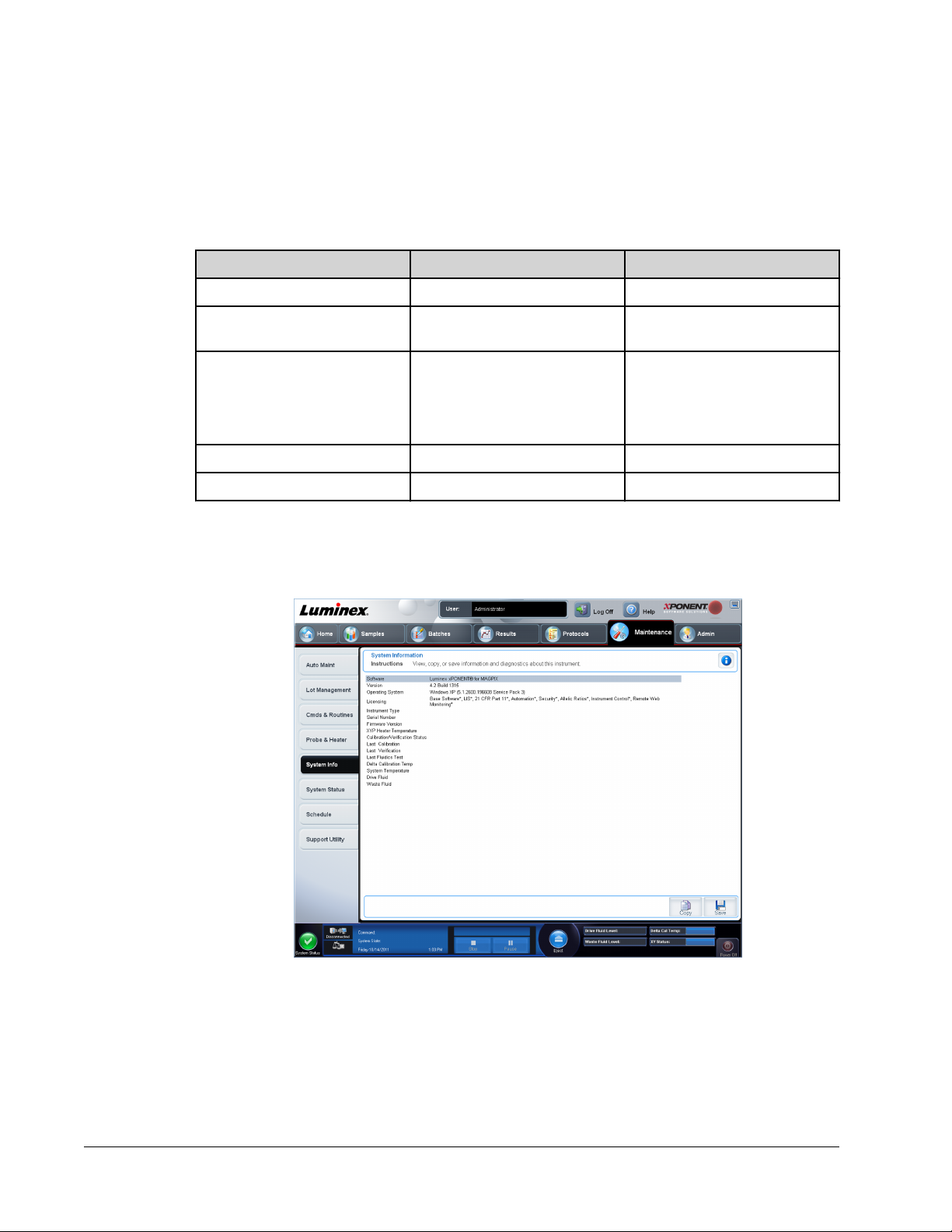

System Info Tab

Maintenance > System Info

from a new protocol, or Home

> Create a new Batch using

the highlighted protocol below

Create a New Batch from a New

Protocol

Create a New Batch from an

Existing Protocol

Use this tab to view information and diagnostics about the Luminex instrument.

This tab contains the following information:

• Software

• Version

• Operating System

• Licensing

xPONENT for MAGPIX 4.2 Software User Manual

6

Page 20

• Instrument Type

• Serial Number

• Firmware Version

• XYP Heater Temp

• Calibration/Verification Status

• Delta Calibration Temp

• System Temperature

• Last CAL Calibration

• Last VER Verification

• Last Fluidics Test

• Drive Fluid

• Waste Fluid

Items in this list relating to calibration and verification have one of the following states:

• Passed - Indicates that the process completed successfully.

• Failed - Indicates that the process was not completed successfully. Failed items appear in

red.

• Not Current - Indicates that verifiers are not current. Verifiers are not current if you have

not calibrated the system since the last time you ran the verifiers.

• Not Yet Run - Indicates that this process has not yet been run on the machine.

Copy - Copies the system information to the Windows clipboard. You can then paste it into a

text editor such as Notepad.

Save - Opens the Save As dialog box to specify a file name and location to save the system

information file.

Basic Procedures

Starting xPONENT

Perform the following steps to launch xPONENT:

• On the PC desktop, click the Luminex xPONENT icon, or click Start > All Programs >

Luminex > xPONENT > Luminex xPONENT.

• If you have a trial license, contact Luminex Technical Support to obtain a full license, or

click OK in the dialog box to continue.

• If this is the first time you have started the software, the User License Agreement may

display. Read the license agreement. Select I accept the terms of this license

agreement, then click OK.

NOTE: For safety and legal information, refer to the MAGPIX Installation and

Hardware User Manual that you received with your instrument.

Introduction

7

Page 21

Adding a New License Key

Contact Luminex Technical Support if you have any difficulty saving or adding a new license

key.

1. Access the Admin page, then the Licensing tab.

2. Click License (bottom right corner of window).

3. Copy and paste the new key into the License Code field. The License File field remains

blank.

4. Click OK. This closes xPONENT, applies the license, and restarts xPONENT.

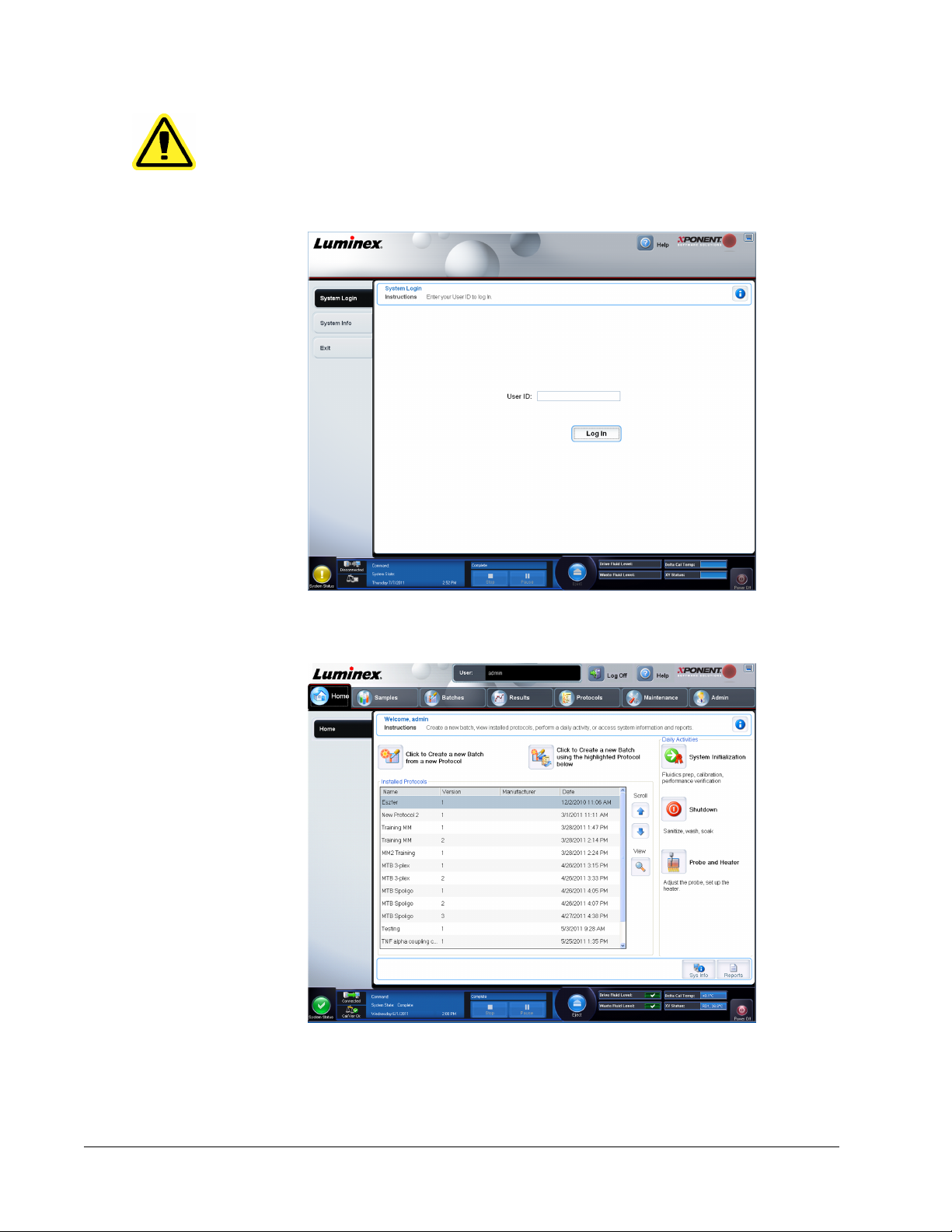

Logging On to xPONENT

If your version of xPONENT is licensed for 21 CFR Part 11, Security, or both, an application

administrator must set up user IDs (and passwords, if required). If you are not using a version

with 21 CFR Part 11, the security module, or both, users can log in with any username or with

no username.

NOTE: Contact Luminex Technical Support if you have problems logging on.

If you want to purchase a license for 21 CFR Part 11 or the security

module, contact Luminex to place an order.

xPONENT for MAGPIX 4.2 Software User Manual

8

Page 22

CAUTION: Use of this software by untrained personnel can result in

inaccurate data and test results. Users of xPONENT must read

the documentation thoroughly before operating the software.

1. On the System Login tab, type your user ID.

2. If you are using a secure version of the software, type your password. The Home page

opens.

Initial Startup

When you turn on the system for the first time, perform the following procedures:

Introduction

9

Page 23

1. Adjusting the Sample Probe Height

2. Revive After Storage (Luminex) Routine

3. Calibration/Verification

Adjusting the Sample Probe Height

Adjust the sample probe height to ensure that the probe drops far enough into the well to

acquire sample.

NOTE: Ensure that there is no liquid in the wells or reservoirs before

adjusting the sample probe height.

1. On the Home page, click Probe and Heater under Daily Activities. The Probe &

Heater tab opens.

2. Use well D6 (this is the center of a standard 96-well plate).

3. Ensure that the well location is selected on the plate image. A green pin marks the

selected well.

4. Based on the type of plate you are using, place alignment disks or an alignment sphere in

the well.

• For a standard 96-well plate - none

• For a Filter-bottom plate - two 5.08 mm disks

• For a Mylar-bottom plate - two 5.08 mm disks

• For a conical (v-shaped) plate - one sphere

5. Click Eject to eject the plate carrier.

6. Place the off plate reagent block on the plate carrier. Make sure it is well seated so that it

clips into place.

7. Place a strip well (provided with the Calibration and the Performance Verification kit) in

the off-plate reagent block.

8. In the Strip Wells section, click SD1.

9. Verify that the reservoir is empty.

10. In the Reservoir section, click well RB1.

11. Verify that the plate is not warped. Warped plates can lead to incorrect probe height

adjustment.

12. Place the plate on the plate carrier with well A1 positioned as indicated on the plate

carrier.

13. Click Retract to retract the plate carrier.

14. Type a name for the plate in the Plate Name box.

15. Click Auto Adjust Height. The probe automatically adjusts itself to the locations you

selected.

NOTE: The probe height is automatically set to 0.98 mm. The probe

automatically adjusts this distance from the bottom of the plate, or

calibration disks or spheres.

16. Click Eject to eject the plate holder. If you used alignment disks or spheres, remove them

from the plate.

xPONENT for MAGPIX 4.2 Software User Manual

10

Page 24

NOTE: When you adjust and save the probe height settings for all three

areas under a plate name, all areas retain the adjustment.

WARNING: Correct sample probe height is critical to successful sample

acquisition and calibration. Problems with the sample probe can

lead to fluid leaks and inhibit sample acquisition.

CAUTION: Ensure that the probe height is set correctly before calibrating

the system.

FIGURE 1.

Sample Probe Height Adjustment

Revive After Storage Routine

NOTE: The Revive After Storage routine is necessary when the system

runs for the first time and is recommended when the system has

been idle for more than a week.

After you have adjusted the sample probe height, run the Revive After Storage (Luminex)

routine.

1. Open the Maintenance page, then the Cmds & Routines tab.

2. Select Revive After Storage (Luminex) from the drop-down list. The Revive After

Storage routine performs the following commands:

• Prime

• Rinse

• Alcohol Flush

• Rinse

Introduction

11

Page 25

3. Add 70% isopropanol or ethanol to reservoir RB1 on the off-plate reagent block as

indicated on the Cmds & Routines tab.

NOTE: The rinse reservoir (RD1) should be empty.

4. Click Retract.

5. Click Run.

After the Revive After Storage routine is complete, run the System Initialization routine.

System Initialization

xPONENT for MAGPIX contains a pre-defined routine to prepare the analyzer for data

acquisition. This section describes calibration and performance verification of the system.

Calibrator magnetic beads are used to normalize the settings for the reporter channel and

classification channels. Verification magnetic beads are used to verify calibration and optical

integrity of the system. Fluidics beads are used to assess well-to-well carryover.

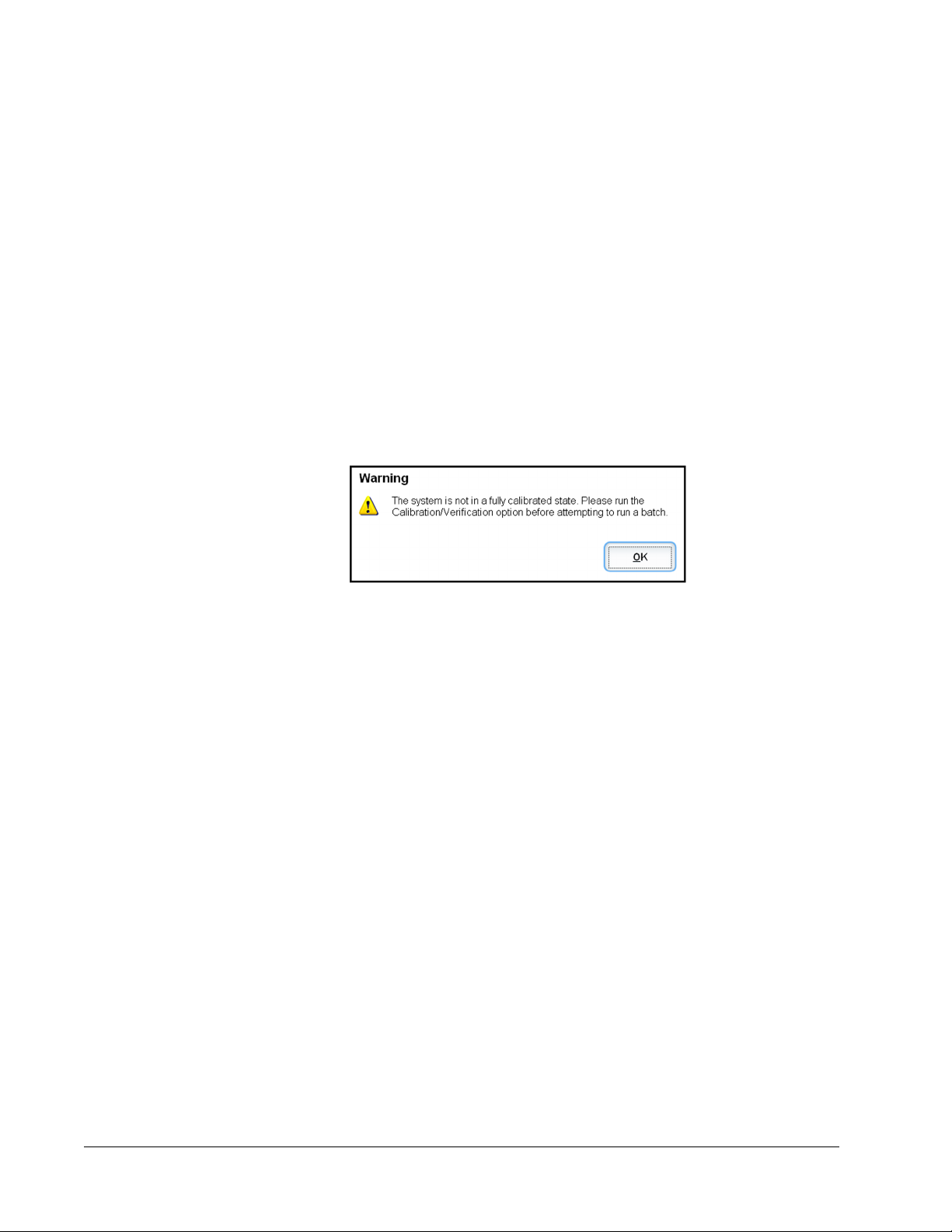

If the system is not fully calibrated, a warning message opens.

Once calibrated, the values remain until you recalibrate. You can track system calibration and

verification results through the Calibration and Verification report. Target value information

for calibration and verification beads is available on the Luminex website at http://

www.luminexcorp.com/Support/index.htm.

Calibrate your system at least once a week using the Calibration/Verification button on the

Auto Maint tab of the Maintenance page. In addition, recalibrate the system if any of the

following things occur:

• The delta calibration temperature exceeds ± 5° C.

• You move the instrument.

• You experience sample acquisition problems.

• The instrument undergoes hardware maintenance, such as replacement of a part.

Verify the system daily using the Performance Verification button on the Auto Maint tab of

the Maintenance page. Refer to your assay kit instructions for additional calibration

frequency requirements.

Before you can calibrate the system, you must import MAGPIX calibrator and verification

bead lot information. Do this using the Lot Management tab of the Maintenance page. This

information is available on the CD that accompanies the Performance Verification Kit and

Calibration Kit, and is also available on the Luminex website at http://www.luminexcorp.com/

Support/index.htm.

xPONENT for MAGPIX 4.2 Software User Manual

12

Page 26

Running the System Initialization Routine

1. On the Home page, click System Initialization under Daily Activities. The Auto Maint

tab opens. On the Auto Maint tab, the System Initialization option is automatically

selected.

2. Verify that the correct lot kit is displayed in the Calibration and Performance

Verification drop down field and that the correct reagents (for example, VER and

Fluidics reagents) have been added to the off-plate reagent block.

3. Fill reservoir RB1 3/4 full of 70% isopropanol or ethanol.

4. Verify that the Rinse reservoir RD1 is empty.

5. Click Retract.

6. Click Run.

Daily Activities

System Initialization - Perform a system initialization routine.

NOTE: Luminex recommends weekly calibration and daily verification. For

Shutdown - Perform the shutdown routine.

Probe and Heater - Adjust the probe height or plate heater.

Drive Fluid Lot - Enter the Drive Fluid lot number, which is printed on the box in which the

fluid container was shipped. This information is optional.

Create a New Batch from a new Protocol - Creates a new batch from a new protocol by

opening the Settings tab of the Batches page. You can create protocols while creating a

batch, and can save the protocol before or after you run the batch.

Create a New Batch from the highlighted Protocol below - Creates a new batch using a

selected protocol from the Installed Protocols list. This button displays the same fields as

the Create a new batch from existing Protocol button on the Batches page.

Scroll - Use the up and down arrows to scroll through the list of installed protocols.

View - Opens the Settings tab of the Protocols page to view the selected protocol. This tab

enables viewing the settings, analytes, and plate layout for the selected protocol.

Sys Info - Opens the System Info tab of the Maintenance page. If the instrument is

connected and powered on, the System Information page displays licensing information, the

instrument serial number, the date of the last Calibration, Verification, Fluidics tests, and

other important information.

Reports - Opens the Reports tab of the Results page.

daily use, verify your System Initialization setting is set to Fluidics

Prep and Performance Verification in the Admin System Setup tab.

Refer to Maintenance Page for detailed maintenance instructions.

Return to the Home page at any time by clicking Home at the top of the screen.

Shutting Down the Analyzer

Run the daily shutdown routine to prevent clogs and crystallization of salt in the sample

probe. Clogs and crystallization of salt in the sample probe can cause problems with

calibration, verification, and data acquistion; they can also cause sample splashing. Shut

down the system properly to ensure system integrity.

Introduction

13

Page 27

1. On the Home page, click Shutdown. The Auto Maint tab opens, with System

Shutdown selected.

2. Click Eject.

3. Fill reservoir RA1 with 3/4 of DI water.

4. Fill reservoir RC1 with 3/4 of 10%-20% household bleach solution.

5. Verify that reservoir RD1 is empty.

6. Click Retract.

7. Click Run.

Logging Off and Exiting

To log off and exit xPONENT:

1. Click Logoff at the top of the page.

2. When the Confirm dialog box opens, click OK. This opens the Log In page, with Exit on

the left tab.

3. Click Exit to exit the application.

Using Online Help

English-language help is available at all times while you are using xPONENT. To display

online help for the page or tab in which you are currently working, click the blue “i” icon at the

upper-right of the xPONENT window. This opens a help window with information specific to

that page or tab.

xPONENT for MAGPIX 4.2 Software User Manual

14

Page 28

To display system-level help, click the blue question mark at the top of the xPONENT

window, then click Contents and Index. The online help opens, where you can navigate to

any available topic.

To display quick start information, click the blue question mark at the top of the xPONENT

window, then click Quick Start. This displays information about the basic steps to start the

system.

To display software information, click the blue question mark at the top of the xPONENT

window, then click About Luminex xPONENT. The xPONENT information dialog box opens,

displaying the software version information.

Luminex Support

Luminex Website

Additional information is available on the Luminex website. FAQs are available at http://

www.luminexcorp.com/Support/index.htm.

You can access the Technical Support Website using a user name and password at https://

oraweb.luminexcorp.com/OA_HTML/jtflogin.jsp.

Contacting Technical Support

Luminex Technical Support representatives are ready to help you. If the question or problem

relates to materials from the assay kit, contact the kit provider directly.

Luminex Technical Support is available to users in the U.S. and Canada by calling

1-877-785-BEAD (2323). Users outside of the U.S. and Canada can contact us at +1

512-381-4397. Inquiries may also be sent by email to support@luminexcorp.com.

Software Packages

Multiple levels of user access can be licensed for xPONENT.

Basic - Allows instrument control.

Additional features for which you can obtain a license:

• Secure - Includes all of the Basic functions as well as administrator-controlled user

permission levels.

• 21 CFR Part 11 - Includes all of the Secure package features as well as the option to

require electronic signatures to perform certain tasks. (Electronic signatures are listed in

the system log.)

• Automation - Includes the ability to communicate with external hardware.

• Allele - Enables you to use allelic ratios.

Introduction

15

Page 29

• Remote Web Monitoring - Enables you to view alerts and system status using a

webpage.

• LIS - Enables the system to communicate with an external Laboratory Information System

(LIS) database. The LIS package enables you to export and import patient result data in

ASTM file format.

You must have an instrument control license to operate the instrument.

For more information about purchasing upgraded packages, or to obtain specific package

documentation, contact your vendor.

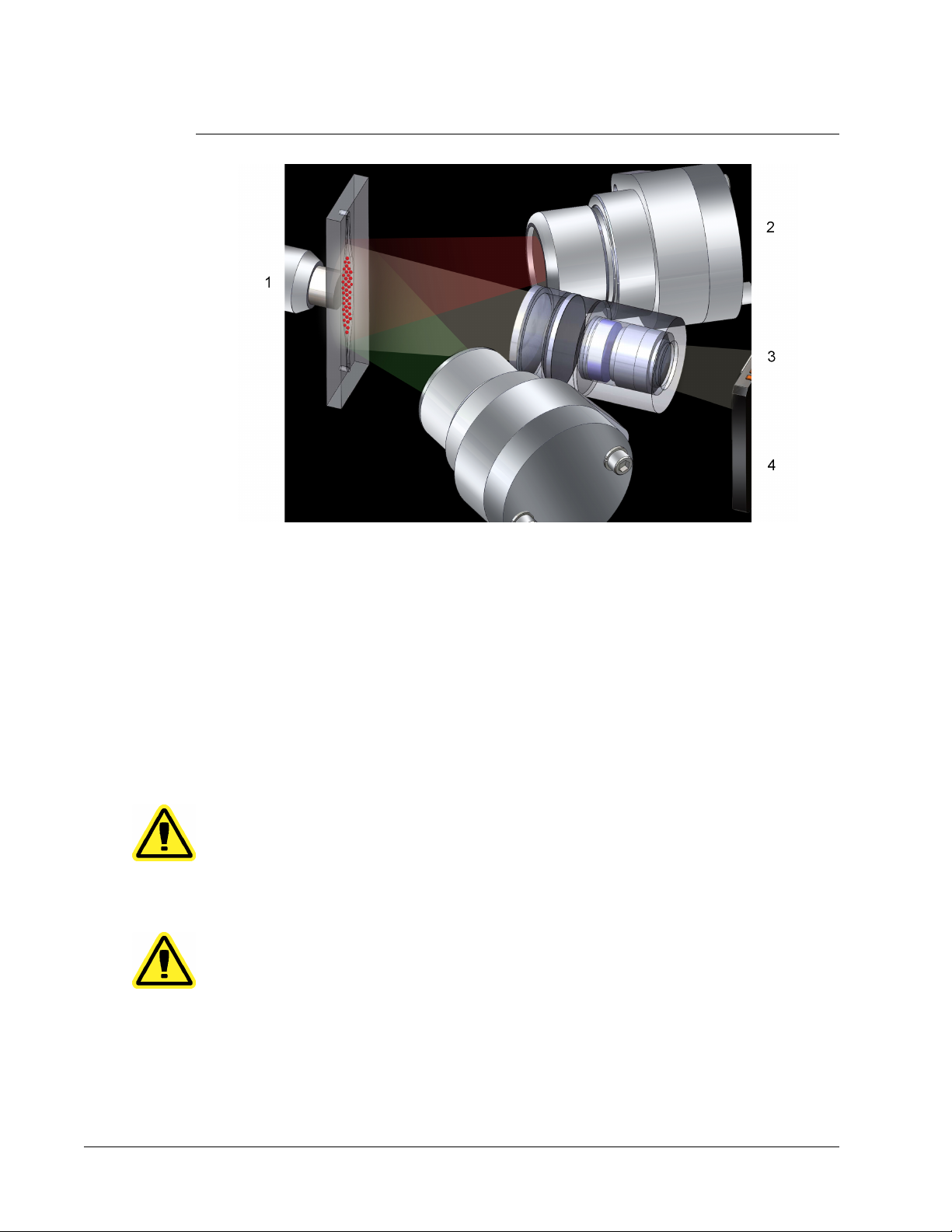

MAGPIX Technology

The MAGPIX system operates by using magnetic beads (microspheres) that are coated with

a reagent specific to a particular bioassay, enabling the capture and detection of specific

analytes from a sample. The sample mixture is aspirated by the sample probe and conveyed

via Drive Fluid into the camera chamber, where the beads are pulled down into a monolayer

by the magnet, immobilized, and imaged. Within the chamber, beads are exposed to a red

LED and a green LED, which excite both the internal dyes that identify each bead’s color

signature and the reporter fluorescence from the surface of the beads. The red LED is

responsible for classifying the beads. The CL1 and CL2 filters function to categorize the

beads based on color signature and place them properly on the bead map as well as throw

out any doublets that may exist. The green LED with the RP1 filter excites the reporter

fluorescence, which identifies the quantity of analyte captured for each bead region. The

beads are then flushed to the waste container, clearing room for the next sample.

Calibration is important to ensure that the optical system functions effectively and that

different Luminex MAGPIX systems report similar results. Calibrating the MAGPIX system

normalizes the settings for the classification channels (CL1 and CL2) and the reporter

channel (RP1). Use the Luminex MAGPIX Calibration Kit to accomplish this.

Following calibration, use the Luminex MAGPIX Performance Verification Kit to check all of

the optical channels in the system for correct calibration. It is essential to verify every time

you calibrate. If there is a problem with optical integrity or fluidics, MAGPIX may pass

calibration but fail performance verification. The Luminex MAGPIX Performance Verification

Kit includes reagents to verify the calibration and optical integrity for the Luminex MAGPIX

system as well as reagents to verify the fluidics channels using observations of bead count

and well-to-well carryover.

xPONENT for MAGPIX 4.2 Software User Manual

16

Page 30

FIGURE 2.

LED Image-Based Analysis

1 Beads in chamber

2 Red LED (635 nm)

3 CCD Imager

4 Green LED (525 nm)

Running Assays with MAGPIX

General Guidelines

WARNING: Modifying or deleting xPONENT system files can cause

degradation of system performance. Repair modified or deleted

xPONENT system files by uninstalling and re-installing the

xPONENT software. Luminex recommends that you contact

Luminex Technical Support before uninstalling and reinstalling

xPONENT.

WARNING: Using unauthorized third-party software with xPONENT

software can result in corruption or failure of the xPONENT

software. Use third-party software at your own risk. The

operation of the system software is validated only when it runs

alone on the dedicated PC.

NOTE: If you are using a screen saver on the PC on which xPONENT is

installed, xPONENT prevents it from activating. A dialog box opens

each time xPONENT is launched, recommending that the screen

saver and any power management settings be turned off.

Introduction

17

Page 31

CAUTION: This system contains electrical and mechanical components that,

if handled improperly, are potentially harmful. Adhere to standard

laboratory safety practices.

CAUTION: Protection provided by the equipment can be impaired or the

warranty voided if the Luminex system is used in a manner not

specified by Luminex documentation or Luminex Corporation.

Biological Samples

CAUTION: Human and animal samples may contain biohazardous

infectious agents. Where exposure to potentially biohazardous

material—including aerosol—exists, follow appropriate biosafety

procedures and use personal protective equipment such as

gloves, gowns, laboratory coats, face shields, or mask and eye

protection. Use ventilation devices. Observe all local, state, and

federal biohazard handling regulations when disposing of

biohazardous waste material.

Dilute concentrated biological samples, such as plasma or serum, at least 1:5 with reagents

as part of assay setup or as a final dilution step to reduce the chance of system clogs. If you

are running a MagPlex® kit, follow the dilution instructions in the kit’s product insert.

Bead (Microsphere) Handling

MagPlex beads come in various configurations. To reduce foaming and precipitation, avoid

agitating the beads until you are ready to vortex and use them. Beads settle and must be

resuspended by vortexing before use. In addition:

• Multiple pipetting from the original container can affect bead concentrations.

• Protect MagPlex beads from light at all times to prevent photobleaching. Photobleaching

effects are cumulative. To maintain the integrity of the beads, minimize their exposure to

light during your development and manufacturing phases.

• Store MagPlex beads at 2°- 8°C.

NOTE: Refer to the product information sheet that accompanies your

MagPlex beads or for additional information.

Repetitive MagPlex Bead Measurements

In a MagPlex assay, the reporter signal is the result of the assay. Due to small bead size,

MagPlex bead suspension exhibits near solution-phase reaction kinetics. This means that

each set of beads used for a particular assay shows a statistically even distribution of

reporter molecules bound to the surface of each bead. The fluorescence signal of reporter

molecules bound to the surface of each bead set is measured and used to determine the

result of each assay in a multiplex. During data acquisition, numerous beads of each set are

analyzed and the median statistic is computed for that set by xPONENT. The more beads of

a set measured, the more confidence that can be given for that particular measurement.

Luminex recommends that you use R-Phycoerythrin as your reporter fluorophore.

If you are running a calibration and verification kit, follow the kit's product insert or use the

software protocol provided.

xPONENT for MAGPIX 4.2 Software User Manual

18

Page 32

Classification and Reporter Fluorochromes

MagPix beads in the calibration kit are used to autofocus the camera and calibrate the CL1,

CL2, and RP1 channels. The beads in the verification kit are a mix of 6 different regions that

cover the range of the 50-plex map. Both calibration and verification beads are triple-dyed,

and the fluorescence signal of these dyes enables classification of each bead set.

TABLE 1.

Region Region Region

MC10012 MC10013 MC10014

MC10015 MC10018 MC10019

MC10020 MC10021 MC10022

MC10025 MC10026 MC10027

MC10028 MC10029 MC10030

MC10033 MC10034 MC10035

MC10036 MC10037 MC10038

MC10039 MC10042 MC10043

MC10044 MC10045 MC10046

MC10047 MC10048 MC10051

MC10052 MC10053 MC10054

MC10055 MC10056 MC10057

MC10061 MC10062 MC10063

MC10064 MC10065 MC10066

MAGPIX Active Bead Regions (by Region)

MC10067 MC10072 MC10073

MC10074 MC10075 MC10076

MC10077 MC10078

Fluidics 1 and Fluidics 2

Although it undergoes a wash step in between wells, the probe can be susceptible to carryover from well-to-well. Fluidics 1 contains one bead set. Fluidics 2 contains a buffer solution

and a different control bead. The function of this maintenance procedure is to measure how

much (as a percentage) of the first bead set in Fluidics 1 is found in the well where Fluidics 2

has been loaded.

Sample Volume

Sample volumes range in size from 20 µL to 200 µL. Ensure that approximately 25 µL more

than the sample volume remains in the well after aspiration. This amount may vary

depending on the type of plate used. Your sample volume must be large enough to prevent

aspirating air into the fluid line when acquiring sample, and small enough to prevent spill-over

Introduction

19

Page 33

when the analyzer flushes the sample lines after sample acquisition and expels

approximately 75 µL of sample back into the well.

Examples

• If you use a sample volume of 50 µL and aspirate 50 µL, you acquire air bubbles.

• If you use a sample volume of 200 µL and a standard sample pickup of 50 µL, the well

overflows when the analyzer washes the sample lines after acquisition and expels fluid

back into the well, because the amount of fluid expelled back into the well is approximately

75 µL.

CAUTION: Sample volume is critical to the proper functioning of your

MAGPIX instrument. Aspirating too few beads can result in

insufficient bead count or insignificant data results. Aspirating too

many beads can result in saturation of the chamber and prevent

proper bead classification, which may also result in low bead

counts or inconclusive data.

This formula quantifies the volume restrictions on the assay design:

Total well volume (µL) - Sample uptake volume (µL) + 75 (µL) <Maximum Well Volume (µL)

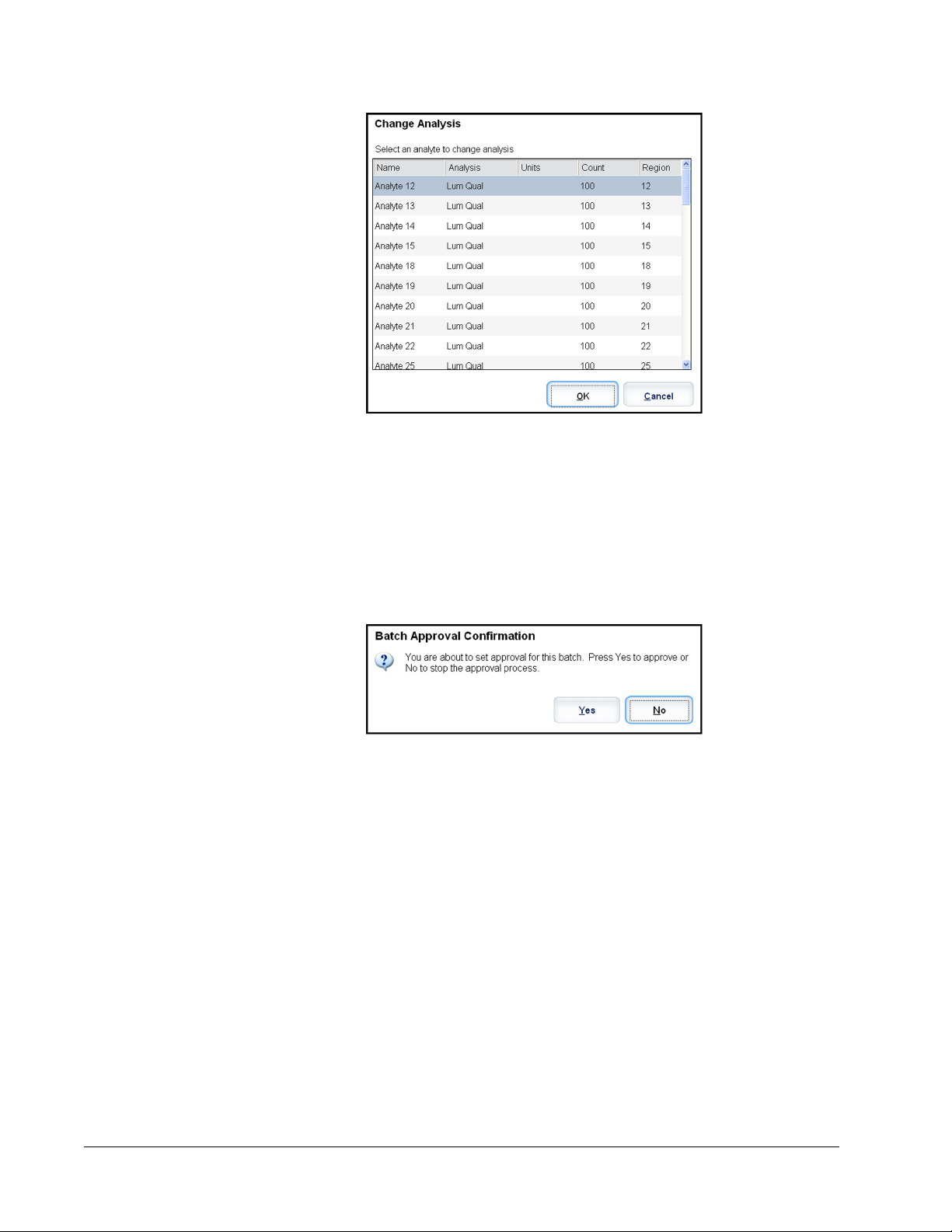

Where: