Page 1

Quick Guide

xPONENT® for FLEXMAP 3D® Software

Version 4.2

Page 2

©

Luminex Corporation, 2012. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, or translated into any language or computer language,

in any form or by any means without prior express, written consent of Luminex Corporation.

LUMINEX CORPORATION

12212 Technology Boulevard

Austin, Texas 78727-6115

U.S.A.

Voice: (512) 219-8020

Fax: (512) 219-5195

xPONENT® for FLEXMAP 3D® Software Version 4.2 Quick Guide

89-00002-00-402 Rev. A

July 2012

Luminex Corporation (Luminex) reserves the right to modify its products and services at any

time. This guide is subject to change without notice. Although prepared to ensure accuracy,

Luminex assumes no liability for errors or omissions, or for any damages resulting from the

application or use of this information.

The following are trademarks of Luminex Corporation: Luminex®, xMAP®, xTAG®,

xPONENT®, Luminex® SD™, Luminex® XYP™, MAGPIX®, FLEXMAP 3D®, MagPlex

®

Microspheres, MicroPlex®.

All other trademarks, including ProClin®, Cheminert®, Windows® Pentium® and Dell® are

trademarks of their respective companies.

xPONENT™ for FLEXMAP 3D

ii

®

Page 3

Table of Contents

StartingxPONENT®...............................................................................................................................1

Start-up Indicators .................................................................................................................................1

Common Daily Activities .................................................................................................................1

Software Overview ................................................................................................................................2

System Monitor ...............................................................................................................................3

Initial Startup .........................................................................................................................................4

Adjusting the Sample Probe Height ................................................................................................5

Revive After Storage Routine .........................................................................................................7

Initialize the System ........................................................................................................................7

Initialize the System ..............................................................................................................................8

Run, Save, and Print Reports .........................................................................................................9

Create a Protocol ................................................................................................................................10

Creating a Kit .......................................................................................................................................13

Create a Batch ....................................................................................................................................14

View Batches .......................................................................................................................................14

Shut Down the Instrument ...................................................................................................................15

Technical Support .........................................................................................................................15

iii

Page 4

xPONENT™ for FLEXMAP 3D

iv

®

Page 5

StartingxPONENT

• On the PC desktop, click the Luminex® xPONENT® icon, or click Start > All Programs >

Luminex > xPONENT > Luminex xPONENT.

• If you have a trial license, contact Luminex® Technical Support to obtain a full license, or

click OK in the dialog box to continue.

• If this is the first time you have started the software, the User License Agreement may

display. Read the license agreement. Select I accept the terms of this license

agreement, then click OK.

NOTE: For safety and legal information, refer to the xPONENT® for

FLEXMAP 3D ® Hardware Version 4.2 User Manual that you

received with your instrument.

Start-up Indicators

When you turn on the Luminex® FLEXMAP 3D® instrument, the following start-up indicators

occur:

• The blue light and power supply fan turn on

• The compressor and MAC valve cycle on (MAC valve makes a distinct sound)

• Immediately, the sample valve cycles (distinct sound)

• Immediately, the probe actuator cycles

• Immediately, the right syringe pump takes a stroke

• Immediately, the exhaust fans turn on

• The left syringe pump takes a stroke

• Drip to waste occurs

• The sample valve cycles again approximately 15 to 30 seconds after the left syringe pump

completes stroke

®

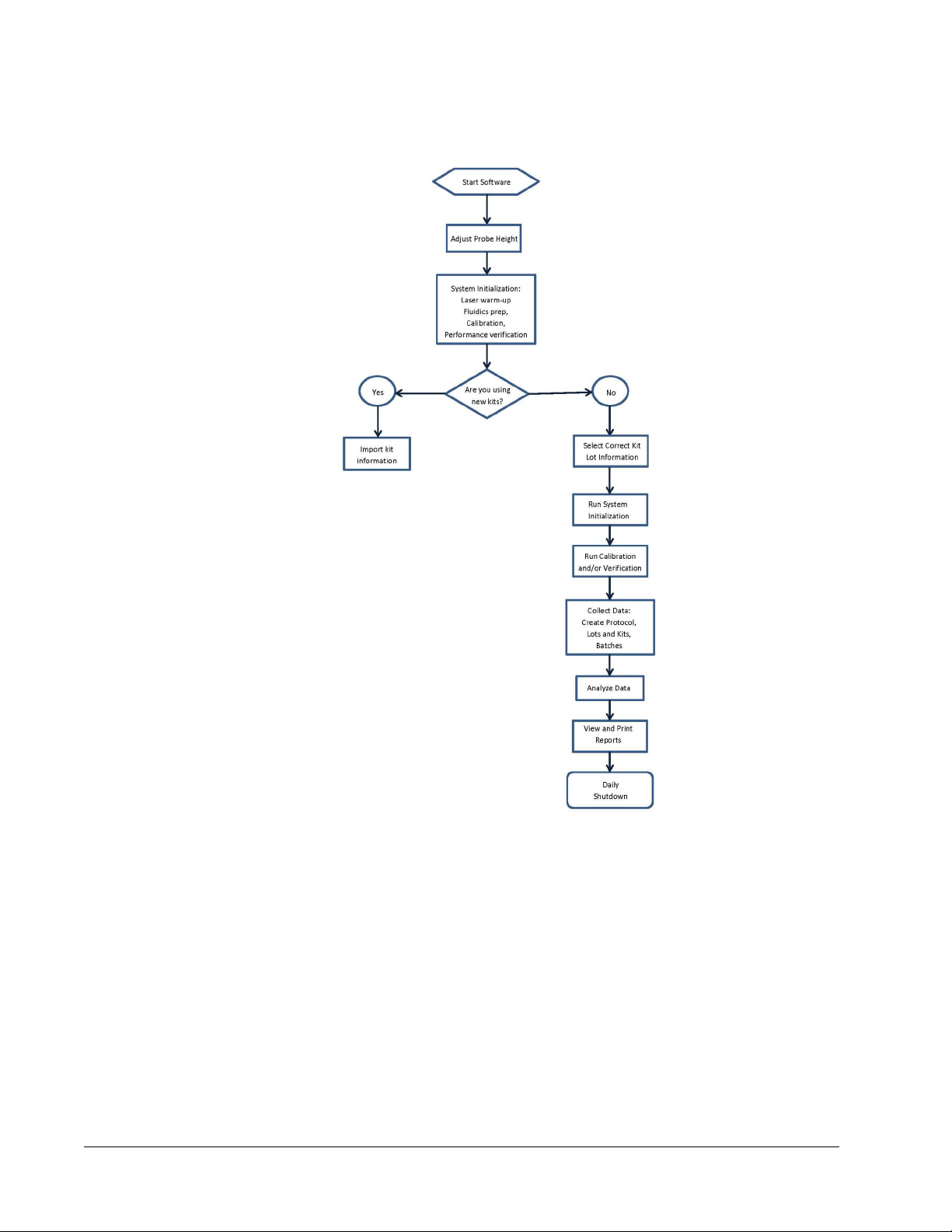

Common Daily Activities

This flowchart illustrates the flow of common daily tasks. For more information about any

task, see the Luminex® FLEXMAP 3D® Installation and Hardware User Manual or the

xPONENT® for FLEXMAP 3D®Software User Manual .

1

Page 6

Software Overview

xPONENT® software is organized into a series of pages. As you click each page, applicable

tabs open on the left-hand side of the window.

xPONENT® opens to the Home page. You can access most tasks from the Home page.

xPONENT® includes the following pages:

Home - Access most commonly used features

Samples - Import or enter sample data (optional)

Batches - Set up batches

xPONENT™ for FLEXMAP 3D

2

®

Page 7

Results - Analyze previously acquired batches; view current and saved reports

Protocols - Displays protocols, Stds & Ctrls, and Lot information.

Maintenance - Calibrate, verify, and maintain the application

Admin - Perform administrative tasks

Log Off - Log out of software

Help - Access help file

System Monitor

The System Monitor is displayed at the bottom of all xPONENT® windows. It displays the

physical state of the Luminex® system. Values are reported directly from the Luminex

system.

1 System Status button 2 Connection Status 3 Check Cal/Ver Ok

4 Command Display 5 Progress Bar and buttons 6 Stop button

7 Pause button 8 Eject button 9 Delta Cal Temp Status

10 Sheath Pressure 11 XY Status 12 Laser Status

13 Region Event Status 14 Total Events Status 15 Warm Up button

®

3

Page 8

System Status Button - This button has two functions: When clicked, it opens the system

log. It also displays the current status of the system. If there are no warnings or errors, the

System Status button is green with a check mark. If there is a warning, out of calibration

condition, or other important user notification, the button is yellow with an exclamation point.

Connection Display - Displays the connection status.

Cal/Ver Ok - This will be lit up if the calibrations and verifications are connected. When you

click the Cal/Ver button, it takes you to Maintenance > System Setup.

Command Display - Displays the following:

• The command currently running.

• The system state (i.e. running, idle, etc.).

• Date and time.

Progress - Displays a bar graph showing the progress of the current command or routine; if

the command or routine is finished, it displays a full progress bar and the command status as

Complete.

Pause - Pauses the system after the current command completes. Pause does not stop the

system in the middle of running a command. You cannot run another command while the

system is paused. Pause the system before stopping it so that it will finish the current

command, store the pending batch and then resume exactly where it left off.

Stop - Stops the system, regardless of command status. Use this only if it does not matter

whether the data from the current well is lost.

Eject - Ejects the plate. Once the plate is ejected, the Eject button changes to Retract.

Retract retracts the plate, and the Retract button changes back to Eject.

Delta Cal Temp - Displays the difference in temperature in degrees Celsius between the

current reading and the reading when the system was calibrated. If the temperature is out of

tolerance, this shows a high or low arrow. When clicked, it opens the Auto Maint tab.

Sheath Pressure - Displays the sheath pressure in psi. A high or low arrow is displayed if the

pressure is trending up or down versus the calibration pressure it turns yellow. When clicked,

it opens the System Info tab.

XY Status - Displays the current location of the command and the temperature of the plate

heating block in degrees Celsius. When clicked, it opens the Probe & Heater tab.

Laser Status - Displays the laser status, including the time remaining until you must warm

up the laser again. The Laser status box is blue. The button turns yellow when the lasers are

turned off and about ten minutes before they turn off. Clicking the Warm Up button restarts

the active clock for the laser.

Region Events Status - Displays the number of bead events detected per second that are

classified in a region.

Total Events Status - Displays the number of total events detected per second.

Warm Up Button - Starts or schedules a warmup.

Initial Startup

When you turn on the system for the first time, perform the following procedures:

1. Adjusting the Sample Probe Height

2. System Initialization

xPONENT™ for FLEXMAP 3D

4

®

Page 9

Adjusting the Sample Probe Height

Adjust the sample probe height to ensure that the probe drops far enough into the well to

acquire sample.

NOTE: Ensure that there is no liquid in the wells or reservoirs before

adjusting the sample probe height.

NOTE: When you adjust and save the probe height settings for all three

areas under a plate name, all areas retain the adjustment.

WARNING: Correct sample probe height is critical to successful sample

acquisition and calibration. Problems with the sample probe

height can lead to fluid leaks and inhibit sample acquisition.

1. On the Home page, click Probe and Heater under Daily Activities. The Probe &

Heater tab opens.

2. Select a plate in the Plate Type list.

• 96-well and 384-well Hard Bottom Plates - No disk is required. Ensure that the well

location is selected on the plate image. Use well D6 for the 96-well plate and well H12

for the 384-well plate (a green pin marks the location). To change the well location,

click on the desired well in the plate image.

• 96-well Filter or Mylar Bottom Plate - Place one (5.08) alignment disk into a well.

Ensure that the well location is selected on the plate image. Luminex® recommends

using well D6 for 96-well plates.

• 384-well Filter or Mylar Plate - Use the Probe Height Adjustment Tool (not supplied).

NOTE: You can order the Probe Height Adjustment Tool (P/N CN-0298-01)

at http://www.luminexcorp.com/Products/ORDERING-

INFORMATION

3. Verify that the microtiter is not warped. Warped plates can lead to incorrect probe height

adjustment.

4. Click Eject to eject the plate carrier.

NOTE: If using a strip-well plate, ensure that a strip is present in the

selected well location, prior to calibration.

5. Place the plate on the plate holder with A1 in the top left corner. Place the off-plate

reagent block on the plate carrier. Place a well-strip (provided with the Calibration and

the Performance Verification kits) in column S1 of the block.

NOTE: Make sure there is no liquid in the plate or the off plate reagent

block.

6. Click Retract to retract the plate carrier.

5

Page 10

7. Type a name for the plate in the Plate Name box, or select a saved plate from the Plate

Name list.

NOTE: If a saved plate is selected the results of the new calibration will

override the previous calibration.

8. In the Plate section, click D6 for the 96-well plate. Click H12 for the 384-well plate.

9. In the Reservoir section, click RB1.

10. In the Strip-Wells section, click SD1.

11. Click Auto Adjust Height. The probe automatically adjusts itself and saves it to the plate

you selected.

NOTE: The probe height is automatically set to 0.49 mm. The probe

automatically adjusts this distance from the bottom of the plate or

calibration disks.

NOTE: When you adjust and save the probe height settings for all three

WARNING: Correct sample probe height is critical to successful sample

CAUTION: Ensure that the probe height is set correctly before calibrating

xPONENT™ for FLEXMAP 3D

6

under a plate name, all areas retain the adjustment.

acquisition and calibration. Problems with the sample probe can

lead to fluid leaks and inhibit sample acquisition.

the system.

®

Page 11

Revive After Storage Routine

NOTE: The Revive After Storage routine is necessary when the system

has been idle for more than a week.

After you have adjusted the sample probe height, run the Revive After Storage (Luminex)

routine.

1. Open the Maintenance page, then the Cmds & Routines tab.

2. Select Revive After Storage (Luminex) from the Routine Name drop-down list. The

Revive After Storage routine performs the following commands:

• Warmup

• Backflush (x2)

• Drain RA2 (x3)

• Alcohol Flush RB1 (x2)

• Backflush

• Wash RA1 (x3)

3. Add 70% isopropanol or 70% ethanol to reservoir RB1 on the off-plate reagent block as

indicated on the Cmds & Routines tab. Add DI Water to reservoir RA1.

NOTE: The drain reservoir (RA2) should be empty.

4. Click Run.

After the Revive After Storage routine is complete, run the System Initialization routine.

Initialize the System

xPONENT® enables you to customize system initialization using one of these three options:

• Laser warm-up, fluidics prep, calibration, performance verification

• Laser warm-up, fluidics prep, performance verification

• Warm-up fluidics prep

NOTE: Verify the system daily and calibrate weekly to check system integrity

and to ensure that calibration is still valid.

To run the system initialization routine:

1. On the Home page, click System Initialization.

2. Select the performance verification kit from the Performance Verification Kit list.

3. Select the calibration kit from the Calibration Kit list.

4. Vortex the xMAP calibrator, verification, and fluidics containers for 30 seconds to ensure

homogeneity. Do not dilute xMAP calibrator, verification, or fluidics agents.

5. Click Eject on the status bar.

6. Place the off-plate reagent block on the plate holder. Load a strip well into the block.

7

Page 12

7. Load wells with at least five drops of the Calibration, Verification, and Fluidics beads, as

indicated on the plate image and in the kit insert instructions.

NOTE: To ensure you get the necessary bead count, invert the calibrator

and verifier vials perpendicular to the plate as you add drops to the

wells. This ensures the maximum fluid drop size is dispensed into

the wells.

8. Click Retract.

9. Click Run.

Initialize the System

xPONENT® enables you to customize system initialization using one of these three options:

• Laser warm-up, fluidics prep, calibration, performance verification

• Laser warm-up, fluidics prep, performance verification

• Warm-up fluidics prep

NOTE: Verify the system daily and calibrate weekly to check system integrity

and to ensure that calibration is still valid.

To run the system initialization routine:

1. On the Home page, click System Initialization.

2. Select the performance verification kit from the Performance Verification Kit list.

3. Select the calibration kit from the Calibration Kit list.

xPONENT™ for FLEXMAP 3D

8

®

Page 13

4. Vortex the xMAP calibrator, verification, and fluidics containers for 30 seconds to ensure

homogeneity. Do not dilute xMAP calibrator, verification, or fluidics agents.

5. Click Eject on the status bar.

6. Place the off-plate reagent block on the plate holder. Load a strip well into the block.

7. Load wells with at least five drops of the Calibration, Verification, and Fluidics beads, as

indicated on the plate image and in the kit insert instructions.

NOTE: To ensure you get the necessary bead count, invert the calibrator

and verifier vials perpendicular to the plate as you add drops to the

wells. This ensures the maximum fluid drop size is dispensed into

the wells.

8. Click Retract.

9. Click Run.

Run, Save, and Print Reports

xPONENT® can provide information in six different report types:

• Batch

• Protocol

• Calibration and Verification

• Performance Verification

• System Log

• Advanced (User)

It can also format your batch or multibatch results in a variety of export formats.

9

Page 14

To run, print, and/or save a report:

1. Open the Results page.

2. Click the Reports tab.

3. In the Report drop-down list, select the report that you want to view.

4. In the Type drop-down list, select the type of report you want to view.

NOTE: Select dates if applicable.

5. Select the item for which you want to generate the report. If you are creating a Batch

Report, select the analytes to include in the report.

6. Click Generate.

7. Click Print to print the report, or Save to save the report as a PDF file.

Create a Protocol

You can create protocols with four types of analysis:

Quantitative - Analyzes unknown data generated with a standard curve.

Qualitative - Analyzes unknown data generated with cutoff ranges based on one standard.

Allele Call - Analyzes data generated as either heterozygotes or homozygotes, based on

specific cutoff ratios.

None - Used when analysis of the data will be carried out in another program. (xPONENT

reports are unavailable for data acquired with a protocol of type “none”.)

xPONENT™ for FLEXMAP 3D

10

®

®

Page 15

You can create each quantitative, qualitative, and allele call protocols using one product

composed of a definable number of standards and controls.

There are three steps to creating a protocol. All three are accessible from the Protocols

page, Protocols tab. The three steps are:

• Define settings.

• Select the analysis type.

• Define the plate layout.

To create a protocol:

1. Open the Protocols page.

2. Click Create New Protocol. The Settings tab opens.

3. Type the protocol name, version, and manufacturer.

4. Type the following information in the Acquisition Settings panel:

• Sample volume (10-200μL)

• XY heater temperature (35-60°C)

• Timeout (1-250 seconds)

• Bead Type

• Plate name

• DD gating

• Reporter Gain

5. Select the analysis type (Qualitative, Quantitative, Allele Call, or None), and enter the

number of standards and controls.

11

Page 16

6. Select Fit of all Standards or Mean of Replicates.

7. Select Analyze results while acquiring samples if you want to view real-time analysis.

8. Click Next to open the Select Analytes tab. Select analytes by clicking the bead

number. The table allows you to name the analyte and to select the analysis type, the

units to be measured, and the count.

9. Click Change to change the analysis settings.

10. Click Next. The Plate Layout tab opens.

xPONENT™ for FLEXMAP 3D

12

®

Page 17

11. Add standards, controls, unknowns, and maintenance steps to the plate layout.

12. Click Save to save the protocol.

Creating a Kit

To create a kit:

1. Open the Protocols page, then open the Protocols tab.

2. Select the protocol that you want to use for the kit, then click New Std/Ctrl. The Std/Ctrl

Details tab opens.

3. Type the name of the kit in the Name box, the lot number in the Std/Ctrl Kit Lot# box,

the expiration date using MM/DD/YYYY format in the Expiration box, and the

manufacturer in the Manufacturer box.

4. Click Apply Std Lot if you want to apply a standard lot. The Select Lot dialog box

opens. Click a lot and select OK.

5. Click Apply Ctrl Lot to apply a control lot. The Select Lot dialog box opens. Select a lot

and click OK.

6. Alternatively, type the appropriate information in the Assay Standard Information and

Assay Control Information sections. The number of standards, controls, or both in

these sections is defined in the protocol. If your batch uses controls, select Expected,

Low or High from the Show Value options. Use the Apply Values arrows to apply

values down or across the range of analytes.

7. Click Save.

13

Page 18

Create a Batch

There are three batch creation options:

• Create a New Batch from an Existing Protocol (uses a protocol; described in this

section).

• Create a New Batch from a New Protocol

• Create a New Multi-batch (runs multiple batches at one time).

To create a new batch from an existing protocol:

1. Open the Batches page.

2. Click Create a New Batch from an Existing Protocol.

3. Type the batch name in the Batch Name box.

4. Type a description of the batch in the Enter Optional Description box.

5. Click the protocol you want to use in the Select a Protocol list. If the protocol you select

uses standards and/or controls, the active reagents are shown on the bottom of the

screen. Verify that these are the correct standards and controls.

6. Click Next.

• If the protocol you selected uses standards and controls, the Stds & Ctrls tab opens.

View the details of the active reagents and verify that they are correct; apply different

assay standards and controls, or manually enter new information. Click Next. The

Plate Layout tab opens. Confirm that the plate layout conforms to your specific assay

instructions.

• If the protocol you selected does not use standards and/or controls, the Plate Layout

tab opens. Confirm that the plate layout conforms to your specific assay instructions.

Continue with step 6.

7. On the Plate Layout tab, add samples to the plate layout if needed.

8. Click Run Batch to begin batch acquisition, or click Save to save the batch information to

the Pending Batch list, to be run at a later time.

NOTE: If the batch spans more than one plate, the tray ejects automatically

View Batches

You can observe and analyze current and previously run batches on the Results page.

To view batch data:

1. Open the Results page.

xPONENT™ for FLEXMAP 3D

14

when all defined wells have been acquired. A dialog box prompts

you to insert the next plate.

®

Page 19

2. Select the Current Batch or Saved Batches tab.

3. If you want to open a saved batch, highlight the batch and click Open.

Shut Down the Instrument

Run the daily shutdown routine to prevent clogs and crystallization of salt in the sample

probe. Clogs and crystallization of salt in the sample probe may cause problems with

calibration, verification, and data acquisition; they may also cause sample splashing. Shut

down the system properly to ensure system integrity.

1. On the Home page, click Shutdown. The Auto Maint tab opens, with System

Shutdown selected.

2. Fill the labelled area of the off-plate reagent block (RB2) with a 10-20% household

bleach and water solution.

3. Add deionized water to the labelled area of the off-plate reagent block (RA1).

4. Click Run.

Technical Support

On the Web

For more information, visit the Luminex FAQ page at http://www.luminexcorp.com/support/.

You can access the Technical Support website using a user name and password at https://

esupport.luminexcorp.com/OA_HTML/jtflogin.jsp.

15

Page 20

By Phone Inside the U.S. and Canada

Contact Luminex Technical support at:

• Toll Free: 1-877-785-BEAD (-2323)

• Fax: 512-219-5114

By Phone Outside the U.S. and Canada

Contact Luminex Technical support at:

• International Toll Free: +800 2939 4959

• Direct Phone: +1 512-381-4397

• Fax: +1 512-219-5114

Email

Email questions to support@luminexcorp.com.

xPONENT™ for FLEXMAP 3D

16

®

Loading...

Loading...