DIGITAL PHOTO PRINTER

DPP-EX5

SERVICE MANUAL

V olume 1 1st Edition

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! A VERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING

This unit has no power switch.

When installing the unit, incorporate a readily

accessible disconnect device in the fixed wiring, or

connect the power cord to a socket-outlet which must

be provided near the unit and easily accessible, so that

the user can turn off the power in case a fault should

occur.

WARNUNG

Dieses Gerät hat keinen Netzschalter.

Beim Einbau des Geräts ist daher im Festkabel ein

leicht zugänglicher Unterbrecher einzufügen, oder das

ß

Netzkabel mu

befindlichen, leicht zugänglichen Wandsteckdose

verbunden werden, damit sich bei einer

Funktionsstörung die Stromversorgung zum Gerät

jederzeit unterbrechen läßt.

mit einer in der Nähe des Geräts

DPP-EX5 V1

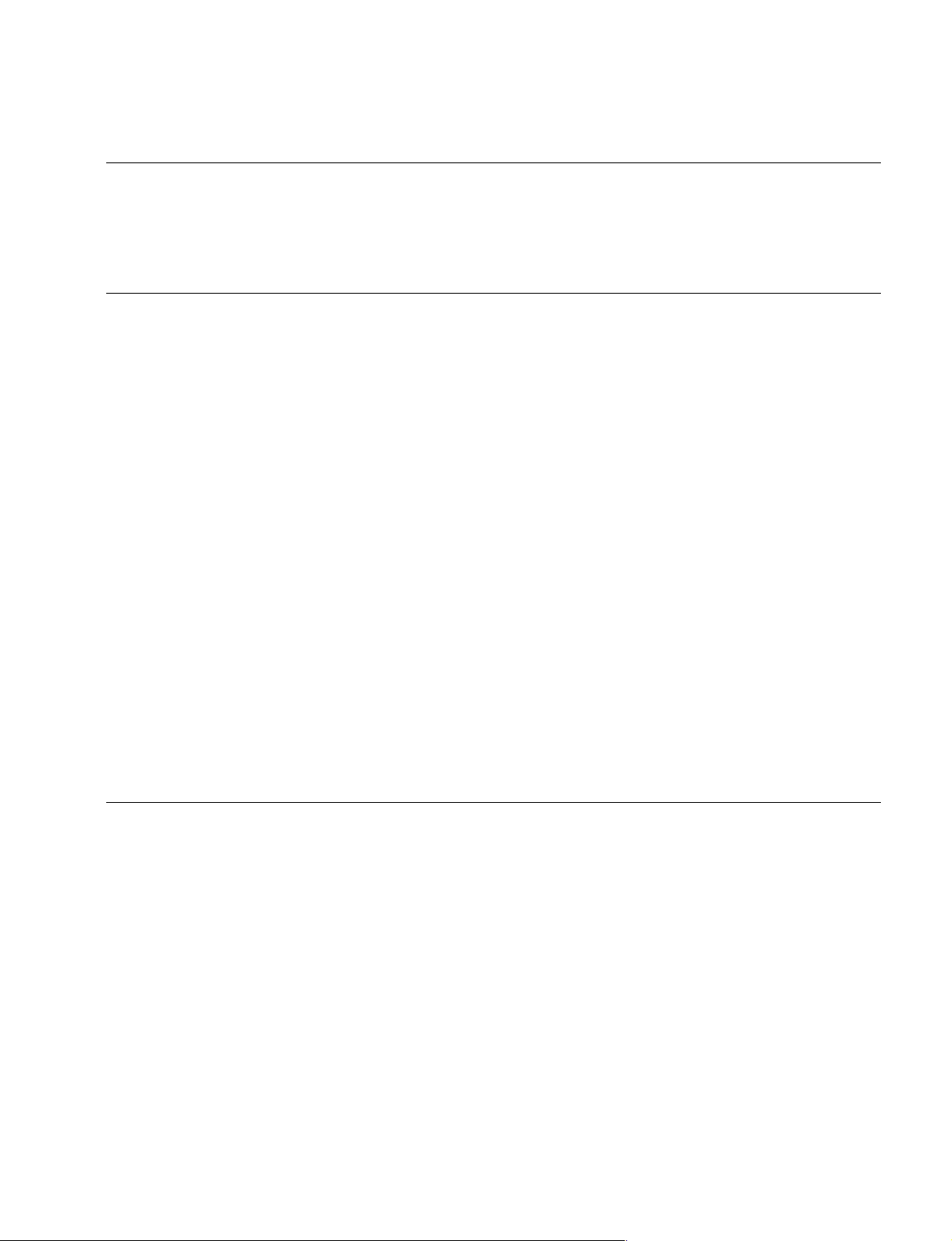

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 3

Related manuals......................................................................................................... 3

Trademarks ................................................................................................................ 3

1. Service Information

1-1. Main Parts Location ....................................................................................1-1

1-1-1. Main Block Location..................................................................1-1

1-1-2. Board Location ...........................................................................1-1

1-1-3. Sensor Location and Function Description ................................1-2

1-2. Removal and Installation of Cabinet........................................................... 1-4

1-2-1. Panel (L) .....................................................................................1-4

1-2-2. Panel (R).....................................................................................1-4

1-2-3. Panel (TOP) Assembly............................................................... 1-5

1-2-4. Front Door ..................................................................................1-5

1-2-5. Cabinet (L) .................................................................................1-6

1-3. Rewriting the Serial Number (when Replacing the DK-44 Board) ............1-6

2. Replacement of Main Parts

2-1. Replacement of Boards ............................................................................... 2-1

2-1-1. SW-44 Board.............................................................................. 2-1

2-1-2. DK-44 Board ..............................................................................2-1

2-1-3. UV-44 Board ..............................................................................2-2

2-1-4. MD-44 Board .............................................................................2-2

2-1-5. JD-44 Board ...............................................................................2-3

2-1-6. PE-44 Board ...............................................................................2-4

2-1-7. RM-44 Board ............................................................................. 2-5

2-2. Switching Regulator.................................................................................... 2-6

2-3. Paper Eject Guide Assembly.......................................................................2-7

2-4. E Chassis Assembly ....................................................................................2-7

2-5. Paper Feed Frame Assembly.......................................................................2-8

2-6. DC Fan ........................................................................................................ 2-8

2-7. Thermal Head.............................................................................................. 2-9

2-8. Ferrite Holder ..............................................................................................2-9

2-9. Stepping Motor..........................................................................................2-10

2-10. E Capstan Roller .......................................................................................2-10

DPP-EX5 V1

1

3. Service Mode

3-1. Density Adjustment during Thermal Head Replacement ...........................3-2

3-2. Confirmation and Adjustment of Video Output Level ...............................3-7

4. Troubleshooting

4-1. Electrical Troubleshooting ..........................................................................4-1

4-2. Error Display ...............................................................................................4-2

4-3. Upgrade .......................................................................................................4-5

4-3-1. Firmware ....................................................................................4-5

4-3-2. Upgrade ......................................................................................4-5

4-3-3. Upgrading method...................................................................... 4-6

4-4. Mechanical Troubleshooting.......................................................................4-7

2

DPP-EX5 V1

Purpose of this manual

Related manuals

Manual Structure

This manual is the service manual Vol. 1 of Digital Photo Printer DPP-EX5.

This manual describes the information on maintenance and the service information

such as service information, parts replacement, service mode and troubleshooting.

In addition to this “Service Manual Vol. 1”, this unit is provided with the manual

below.

..

. Service Manual Vol. 2 (Not supplied for products.)

..

Part No.: 9-955-370-21

This manual describes the semiconductors, spare parts, block diagrams, schematic

diagrams, and board layouts of this unit.

..

. Operating Instruction (Supplied for products.)

..

Part No.: 3-207-119-14

These manuals describe the information required for the actual management and

operation of this unit.

Trademarks

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

service manual for the corresponding unit. The service manual contains a complete list of all semiconductors and their ID Nos., and thus should be used together

with the CD-ROM.

Part number: 9-968-546-XX

Trademarks and registered trademarks used in this manual are follows.

. Memory Stick is a registered trademark of SONY Corporation.

DPP-EX5 V1

3

y

1-1. Main Parts Location

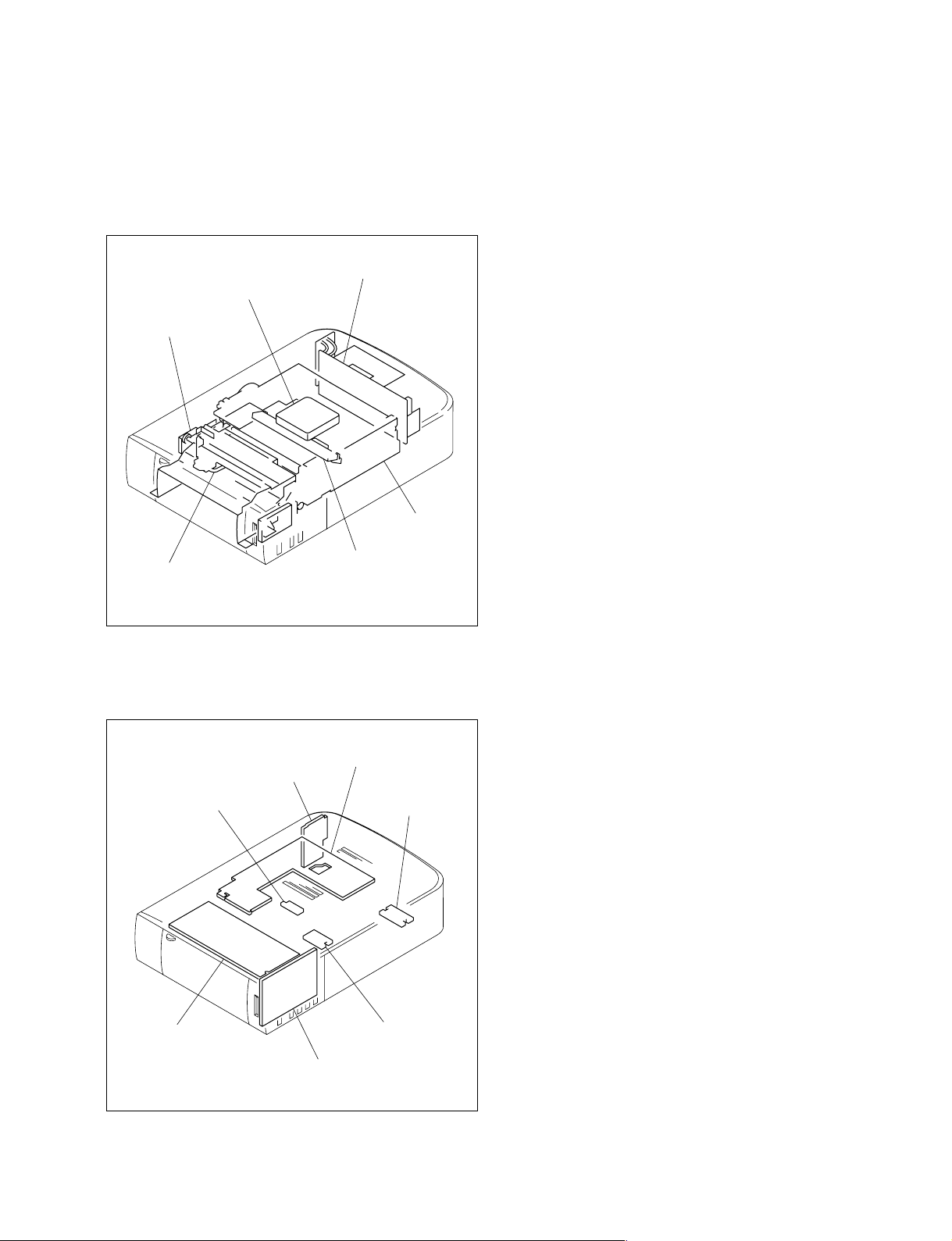

1-1-1. Main Block Location

Switching regulator

DC fan

Paper eject

guide assembly

Thermal head

Paper feed

frame assembl

Section 1

Service Information

E chassis

assembly

1-1-2. Board Location

UV-44 board

RM-44 board

DK-44 board

MD-44 board

JD-44 board

PE-44 board

SW-44 board

DPP-EX5 V1

1-1

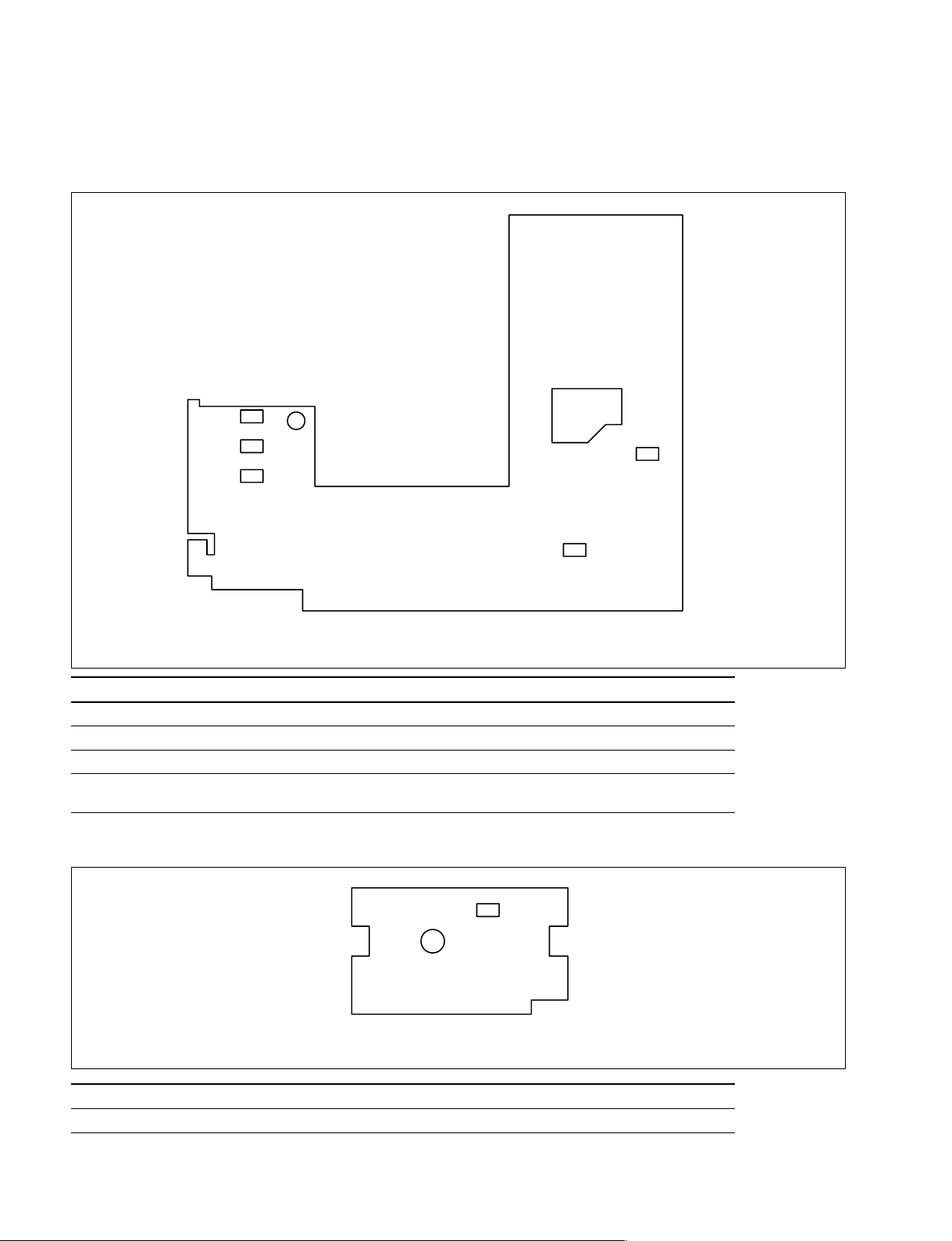

1-1-3. Sensor Location and Function Description

MD-44 board

PH901

PH902

PH905

D901

PH903

PH904

MD-44 board (Side A)

Ref. Name Type Function

PH903, 904 Mode position sensor Reflective x2 Detection of DC motor position

PH901, 902 Ribbon code sensor Reflective x2 Detection of ribbon type

D901 Ribbon mark sensor LED Detection of ribbon position

PH905 Ribbon in sensor Reflective x1 Detection of presence or absence

of ribbon cassette

JD-44 board

PH961

JD-44 board (Side A)

Ref. Name Type Function

PH961 Jamming dead sensor Reflective x1 Detection of paper position

1-2

DPP-EX5 V1

PE-44 board

PH971

PE-44 board (Side A)

Ref. Name Type Function

PH971 Paper edge sensor Reflective x1 Detection of paper position

Detection of paper type

RM-44 board

Q981

RM-44 board (Side A)

Ref. Name Type Function

Q981 Ribbon mark sensor Photo transistor Detection of ribbon position

DPP-EX5 V1

1-3

)

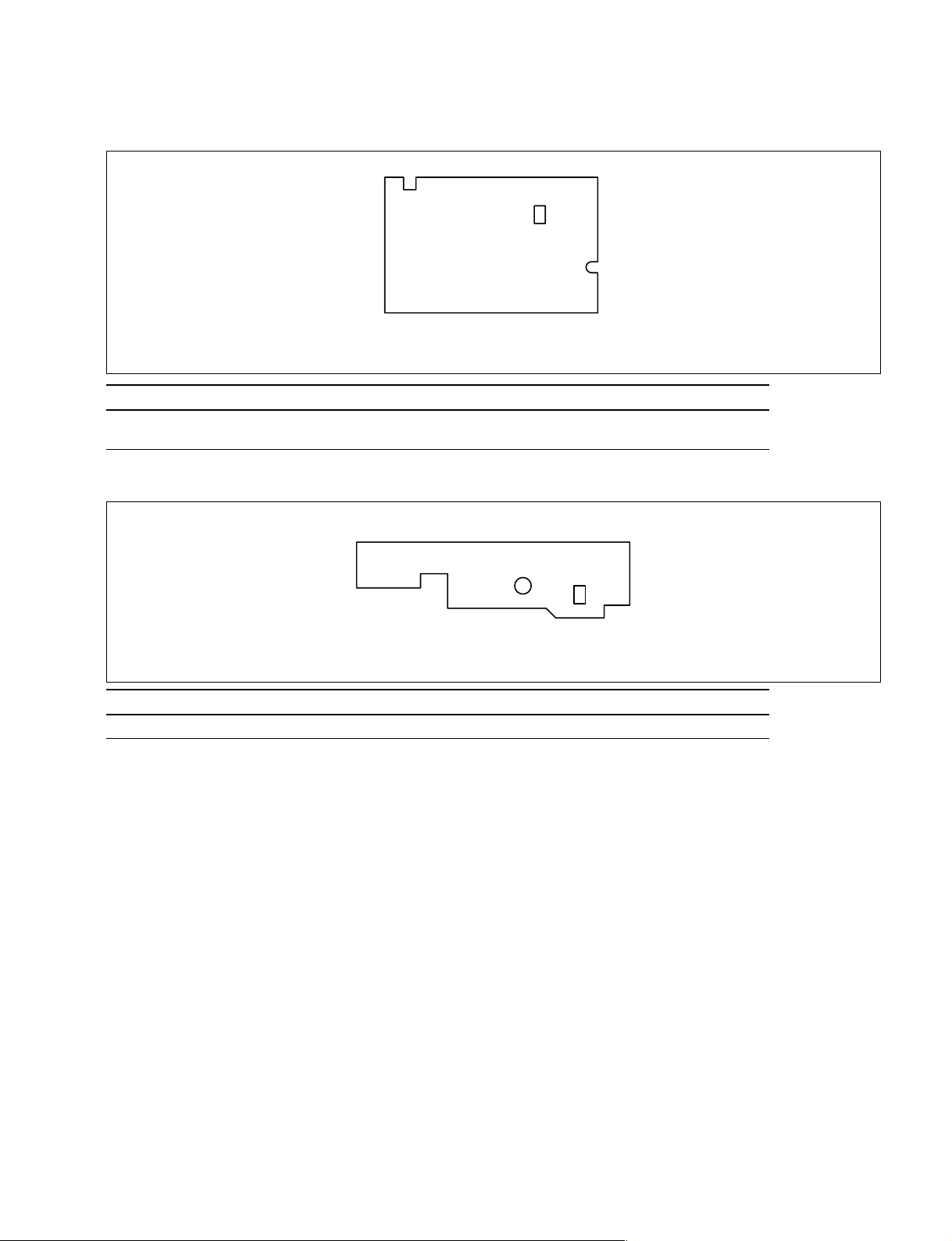

1-2. Removal and Installation of Cabinet

1-2-2. Panel (R)

1-2-1. Panel (L)

1. Open the ribbon door in the direction indicated by the

arrow A, then remove the one screw.

2. Move the panel (L) in the direction indicated by the

arrow and remove the nine hooks, then remove the

panel (L).

Ribbon door

A

BVTP

2.6x8

B

1. Open the ribbon door in the direction indicated by the

arrow A, then remove the one screw.

2. Move the panel (R) in the direction indicated by the

arrow and remove the twelve hooks, then remove the

panel (R).

Ribbon door

Hooks

BVTP

2.6x8

Hooks

Panel (R)

A

B

Hooks

Hooks

Hooks

Hooks

Panel (L

3. Attach the panel (L) in the reverse order of step 1 to 2.

3. Attach the panel (R) in the reverse order of step 1 to 2.

1-4

DPP-EX5 V1

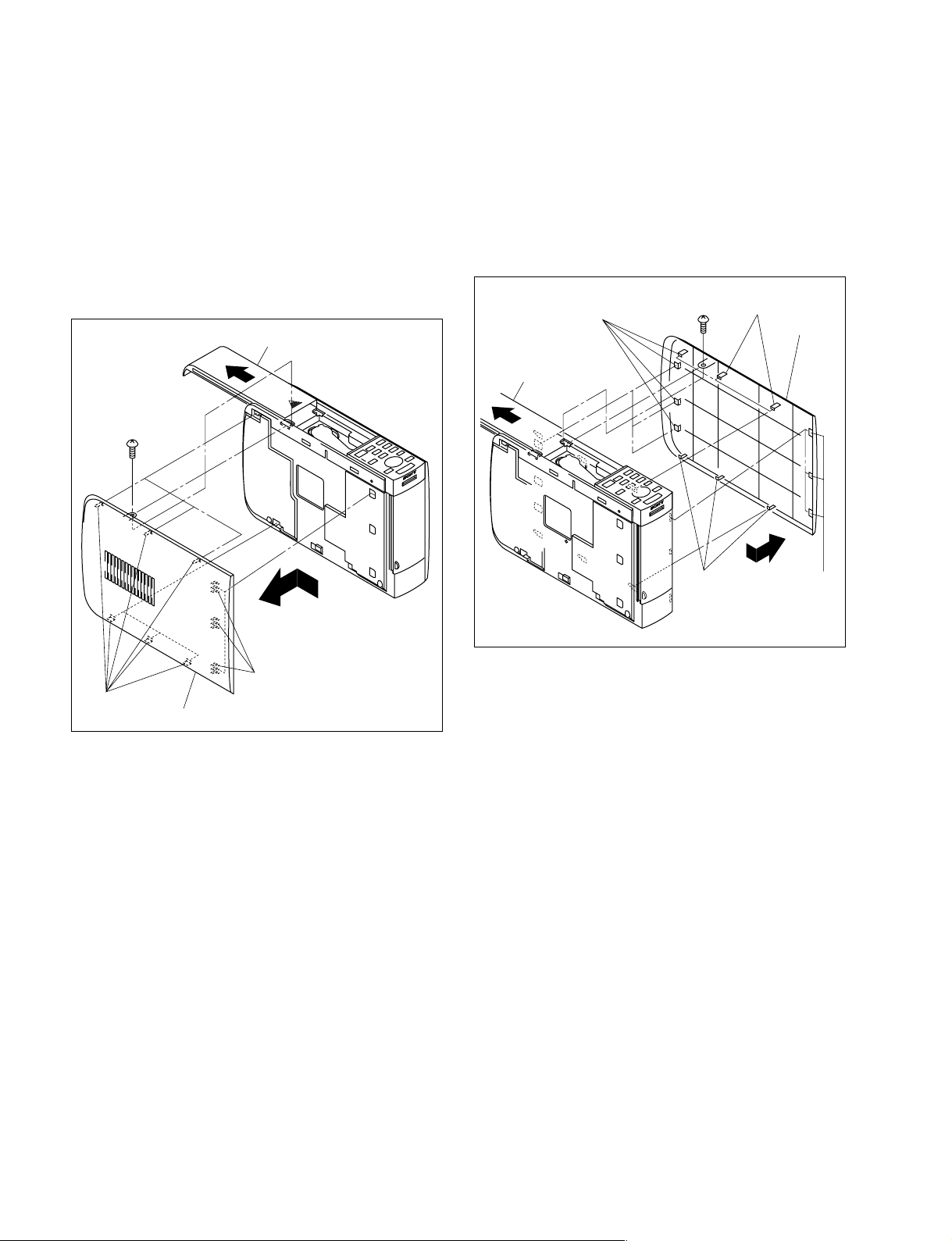

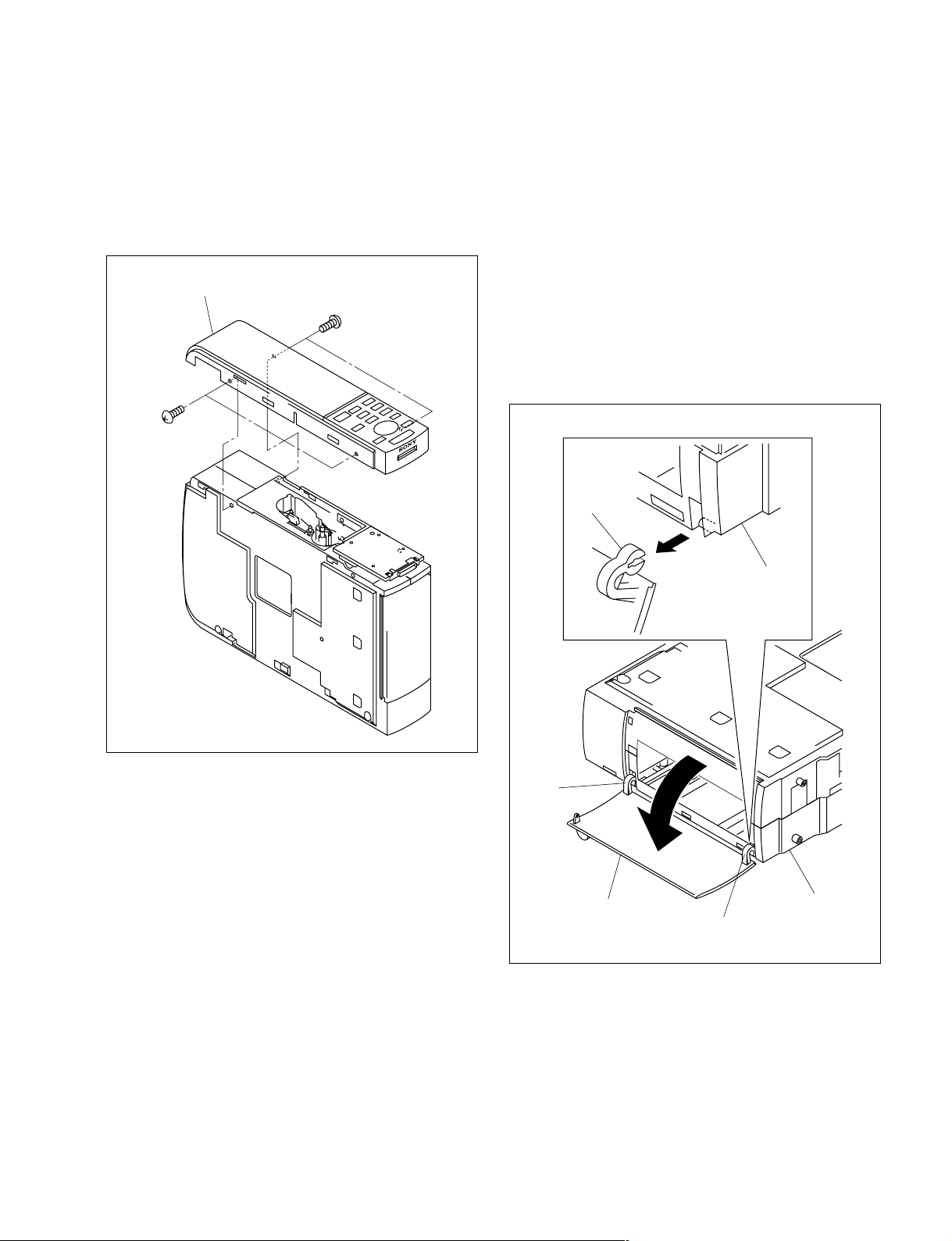

1-2-3. Panel (TOP) Assembly

1-2-4. Front Door

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the four screws, then remove the panel (TOP)

assembly.

Panel (TOP) assembly

BVTP 2.6x8

BVTP 2.6x8

n

When removing the front door, be careful not to break the

two hooks of the front door.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Open the front door in the direction indicated by the

arrow A.

4. Pull the front door in the direction indicated by the

arrow B and remove the two hooks, then remove the

front door from the cabinet R.

Hook

B

Cabinet R

4. Attach the panel (TOP) assembly in the reverse order

of steps 1 to 3.

DPP-EX5 V1

Hook

A

Front door

Hook

Cabinet R

5. Attach the front door in the reverse order of steps 1 to

4.

1-5

1-2-5. Cabinet (L)

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly. (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the two screws and expand the portion A of

the cabinet (L) in the direction indicated by the arrow

B to remove the two hooks.

7. Remove the cabinet (L) in the direction indicated by

the arrow C.

Cabinet (L)

BVTP 3x20

Hook

B

1-3. Rewriting the Serial Number (when

Replacing the DK-44 Board)

n

A serial number must be written in a new DK-44 board

when the DK-44 board is replaced.

Rewrite the serial number according to the procedure

below.

Equipment required

. Personal computer (that can copy a file to a memory

stick)

. Memory stick (to which no data is copied)

. Text file for rewriting serial number (File name:

058USBSN.txt)

n

Consult a Sony’s Sales Office for how to acquire the text

file for rewriting a serial number.

Hook

Portion A

Portion A

B

C

8. Attach the cabinet (L) in the reverse order of steps 1 to

7.

Preparation (before replacing the DK-44 board)

1. Make a note of a USB’s (eight-digit) serial number in

the test mode.

2. Create a “SONY\DPPSV” folder in the memory stick

and copy a 058USBSN.txt text file to it.

3. Open the text file copied in step 2 and enter the serial

number written in step 1 using a half-size numeric

character.

Write

1. Turn on the power of DPP-EX5.

2. Press the MENU button, ENTER button, and power

button simultaneously and start the test mode. (Refer

to Section 3.)

The test menu is then displayed.

3. Install the memory stick supplied in “Preparation” in

DPP-EX5.

4. Move the cursor to the “USB S/N” button and press

the ENTER key.

After about one second, the screen becomes dark and

the test menu is displayed again. The write operation

is then completed.

5. Confirm that the numeric characters below USB S/N

are those written in step 1 of “Preparation”.

1-6

DPP-EX5 V1

Section 2

BVTT

2.6x5

Flexible flat cable

Flexible

flat cable

CN251

DK-44 board

CN201

Replacement of Main Parts

2-1. Replacement of Boards

2-1-1. SW-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the three screws (BTP 2x6) and one precision

screw (P 2x5), then remove the SW-44 board.

5. Disconnect one flexible flat cable from the connector

(CN2002) on the SW-44 board.

6. Remove the two hooks from the holes of the SW-44

board, then remove the MS guide in the direction

indicated by the arrow.

Precision P 2x5

BTP 2x6

CN2002

Flexible flat cable

SW-44 board

Holes

Hooks

2-1-2. DK-44 Board

n

Before replacing the DK-44 board, check the serial number

in the service mode and make a note of it.

The serial number is used when writing a serial number in

a new DK-44 board.

Refer to section 1-3 for how to rewrite the serial number.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section 1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Disconnect two flexible flat cables from the

connectors (CN251 and CN201) on the DK-44 board.

9. Remove one screw, then remove the DK-44 board in

the direction indicated by the arrow.

MS guide

7. Install the SW-44 board in the reverse order of steps 1

to 6.

DPP-EX5 V1

10. Install the DK-44 board in the reverse order of steps 1 to 9.

2-1

2-1-3. UV-44 Board

2-1-4. MD-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. Remove one screw (BVTP 2.6x8), then remove the

UV fixing plate.

12. Remove the UV cover from the UV-44 board.

13. Remove the two precision screws (P 2x5) and

disconnect one flexible flat cable from the connector

(CN3001) on the UV-44 board, then remove the UV44 board.

UV cover

UV fixing plate

UV-44 board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Disconnect the seven harnesses from the connectors

(CN903, CN904, CN905, CN906, CN908, CN909 and

CN910) and two flexible flat cables from the

connectors (CN901 and CN907) on the MD-44 board.

9. Remove the three screws, then remove the MD-44

board.

Flexible

flat cable

Harnesses

Harness

CN906

CN905

CN904

CN908

BVTT

2.6x5

CN910

Harnesses

Precision P 2x5

Flexible flat cable

CN3001

BVTP

2.6x8

CN909

BVTT

2.6x5

MD-44 board

CN903

CN907

Harness

CN901

Flexible

flat cable

10. Install the MD-44 board in the reverse order of steps 1

to 9.

14. Install the UV-44 board in the reverse order of steps 1

to 13.

2-2

DPP-EX5 V1

2-1-5. JD-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the MD-44 board. (Refer to Section 2-1-4.)

9. Remove one screw, then remove the JD-44 board.

10. Disconnect one harness from the connector (CN961)

on the JD-44 board.

Harness

P2x3

CN961

JD-44 board

11. Install the JD-44 board in the reverse order of steps 1

to 10.

DPP-EX5 V1

2-3

2-1-6. PE-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. While pushing the hook of the paper feed frame

assembly in the direction indicated by the arrow A,

remove the PE-44 board in the direction indicated by

the arrow B.

12. Disconnect one harness from the connector (CN971)

on the PE-44 board.

Paper feed

frame assembly

Paper feed

frame assembly

E chassis

assembly

Harness

Hook

B

A

PE-44 board

CN971

13. Install the PE-44 board in the reverse order of steps 1

to 12.

2-4

DPP-EX5 V1

2-1-7. RM-44 Board

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. Remove the MD-44 board. (Refer to Section 2-1-4.)

12. Remove the paper feed frame assembly. (Refer to

Section 2-5.)

13. Remove the four hooks, then remove the paper guide

assembly from the paper feed frame assembly.

14. Remove the two hooks of the paper feed frame

assembly in the direction indicated by the arrow A,

then remove the RM-44 board in the direction

indicated by the arrow B.

15. Disconnect one harness from the connector (CN981)

on the RM-44 board.

Harness

CN981

Hook

Paper feed

frame assembly

Hook

RM-44 board

Hook

B

Hook

A

A

RM-44 board

Paper guide

assembly

Hook

Paper feed

frame assembly

Hook

16. Install the RM-44 board in the reverse order of steps 1

to 15.

DPP-EX5 V1

2-5

2-2. Switching Regulator

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the front door. (Refer to Section 1-2-4.)

5. Remove the cabinet (L). (Refer to Section 1-2-5.)

6. Remove one screw, then remove the earth lug from the

E chassis assembly.

7. Disconnect one harness from the connector (CN2) on

the switching regulator.

8. Remove the switching regulator in the direction

indicated by the arrow.

9. Attach the switching regulator in the reverse order of

steps 1 to 8.

m

. When attaching the switching regulator, be sure to

securely attach it to the three grooves of the PS

cover.

. When attaching the switching regulator, be sure to

securely hook the harness and earth lug in the notch

of the PS cover.

Grooves

Earth lug

PS cover

Switching

regulator

BVTT

2.6x5

PS cover

Groove

Switching

regulator

Harness

CN2

Cabinet (R)

2-6

E chassis assembly

Harness

Earth lug

Notch of

PS cover

DPP-EX5 V1

2-3. Paper Eject Guide Assembly

2-4. E Chassis Assembly

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the two screws, then remove the DK holder.

10. Remove the two screws (BVTP 2.6x8) and one screw

(BVTT 2.6x5).

11. Remove the two hooks in the direction indicated by

the arrow, then remove the paper eject guide assembly.

BVTT

2.6x5

Paper eject

guide assembly

BVTP

2.6x8

DK holder

BVTT

2.6x5

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the three screws, then remove the E chassis

assembly.

E chassis

BVTP

BVTP

2.6x8

2.6x8

assembly

Hook

Hook

12. Attach the paper eject guide assembly in the reverse

order of steps 1 to 11.

DPP-EX5 V1

11. Attach the E chassis assembly in the reverse order of

steps 1 to 10.

2-7

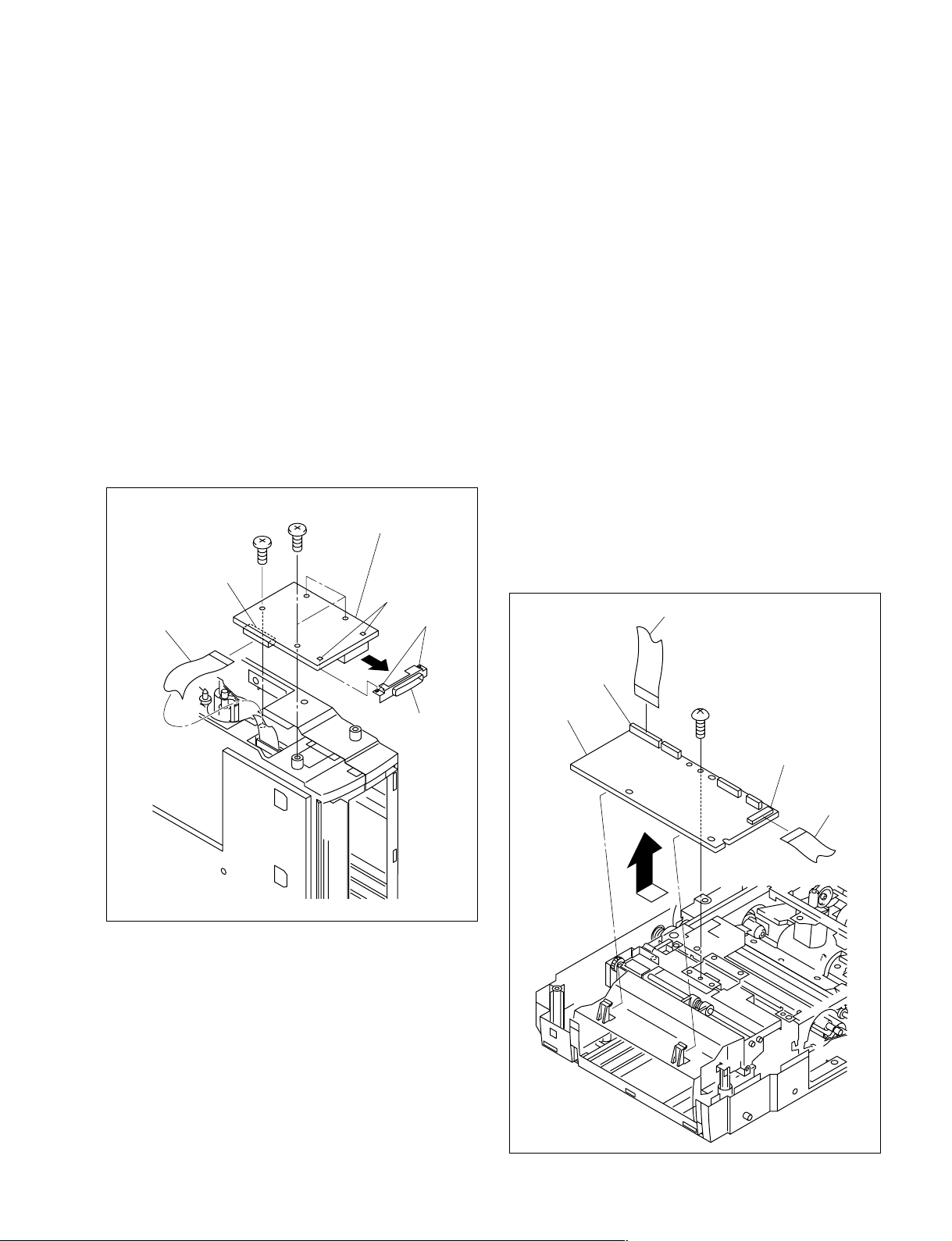

2-5. Paper Feed Frame Assembly

2-6. DC Fan

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section 1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-4.)

11. Remove the two screws (BVTP 2.6x8) and two screws

(BVTT 2.6x5), then remove the SW earth plate (2)

and paper feed frame assembly in the direction

indicated by the arrow.

BVTP

Paper feed

frame holder

2.6x8

SW earth

plate (2)

BVTT

2.6x5

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the two screws and disconnect one harness

from the connector (CN903) on the MD-44 board, then

remove the DC fan.

Harness

CN903

MD-44 board

PS 3x10

DC fan

E chassis

Paper feed

frame assembly

BVTP

2.6x8

assembly

12. Attach the paper feed frame assembly in the reverse

order of steps 1 to 11.

m

. When attaching the paper feed frame assembly, be sure

to attach it while repressing the R pendulum lever

assembly in the direction indicated by the arrow.

. When attaching the paper feed frame assembly, be sure to

securely insert the four hooks of the E chassis assembly

into the four holes of the paper feed frame assembly.

8. Attach the DC fan in the reverse order of steps 1 to 7.

2-8

DPP-EX5 V1

2-7. Thermal Head

Ferrite holder

Flexible

flat cable

Flexible

flat cable

Ferrite bead

(Large)

Ferrite bead

(Small)

DK-44 board

CN253 CN202

2-8. Ferrite Holder

n

After removing the thermal head, check that center shim is

attached.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the MD-44 board. (Refer to Section 2-1-4.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. Remove the DC fan. (Refer to Section 2-6.)

12. Pull out the portion A of the connectors on the thermal

head in the direction indicated by the arrow, then

disconnect the two flexible flat cables.

13. Remove the two screws, then remove the thermal

head.

14. Remove the center shim from the thermal head.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Disconnect the two flexible flat cables from the

connectors (CN202 and CN253) on the DK-44 board.

8. Remove the two ferrite beads and disconnect the two

flexible flat cables from the ferrite holder.

PSW

2.6x6

E chassis assembly

Flexible flat cables

A

Connector

A

Thermal head

Center shim

15. Attach the thermal head in the reverse order of steps 1

to 14.

9. Attach the ferrite holder in the reverse order of steps 1

to 8.

DPP-EX5 V1

2-9

2-9. Stepping Motor

2-10. E Capstan Roller

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. Remove the two screws and disconnect one harness

from the connector (CN905) on the MD-44 board, then

remove the stepping motor.

BVTT

2.6x5

Harness

Stepping motor

CN905

n

When replacing the E capstan roller, platen roller or pinch

roller, be extremely careful not to touch the roller with bear

hands or dirty gloves.

1. Remove the panel (L). (Refer to Section 1-2-1.)

2. Remove the panel (R). (Refer to Section 1-2-2.)

3. Remove the panel (TOP) assembly (Refer to Section

1-2-3.)

4. Remove the SW-44 board. (Refer to Section 2-1-1.)

5. Remove the front door. (Refer to Section 1-2-4.)

6. Remove the cabinet (L). (Refer to Section 1-2-5.)

7. Remove the ferrite holder. (Refer to Section 2-8.)

8. Remove the DK-44 board. (Refer to Section 2-1-2.)

9. Remove the paper eject guide assembly. (Refer to

Section 2-3.)

10. Remove the E chassis assembly. (Refer to Section 2-

4.)

11. Remove the MD-44 board. (Refer to Section 2-1-4.)

12. Remove the paper feed frame assembly. (Refer to

Section 2-5.)

13. Remove the stepping motor. (Refer to Section 2-9.)

14. Remove the two screws, then remove the reinforcing

plate (L).

15. Remove the four screws, then remove the E

transmission gear assembly.

MD-44 board

12. Attach the stepping motor in the reverse order of steps

1 to 11.

2-10

E transmission

BVTT

2.6x5

BVTT

2.6x5

Reinforcing plate (L)

gear assembly

BVTT

2.6x5

DPP-EX5 V1

16. Remove the R pendulum lever assembly.

Pinch roller

E capstan roller

Roller bearing

Roller

bearing

B

A

A

C

17. Remove one screw, then remove the CP shaft earth

and two roller bearings.

18. Rotate the two roller bearings in the direction indicated

by the arrow A, then remove them.

19. Move the platen roller in the direction indicated by the

arrow B, then remove the platen roller in the direction

indicated by the arrow C.

20. Rotate the two roller bearings in the direction indicated

by the arrow, then remove them.

21. Move the E capstan roller in the direction indicated by

the arrow B, then remove it in the direction indicated

by the arrow C.

BVTT

2.6x5

CP shaft earth

A

R pendulum

lever assembly

Roller bearing

Platen roller

B

A

Roller

bearing

C

22. Attach the E capstan roller in the reverse order of steps

1 to 21.

DPP-EX5 V1

2-11

Operation panel

Section 3

Service Mode

Power

Input select

Effect

Menu

Paper error indicator

Cartridge error indicator

Picture

Print

Auto print

Creative print

Cancel

Enter

Arrow

Activation

1. Connect the power cord to DPP-EX5 (hereafter referred to as this unit) and connect the video cable,

connected to a monitor, to the VIDEO OUT terminal of this unit.

2. Turn on the power while pressing the Menu and Enter keys simultaneously.

3. Release the keys when the service mode screen (shown in Fig. 3-1) appears on the monitor screen.

DPP-EX5 V1

Fig.3-1

3-1

3-1. Density Adjustment during Thermal Head Replacement

Before replacing the thermal head, print a test pattern (gray pattern) as the reference of density using an

old head or normal unit.

n

For the test pattern print of an old head, use the thermal head that is not damaged as a whole due to black

and white stripes.

Procedure

1. Set the ribbon and paper.

n

Use the set paper below.

Small-size photo paper SVM-30SS

2. Enter the service mode, move the \ mark to “Mechanic Test” using Direction keys, and press the

Enter key. (Fig. 3-2)

Fig.3-2

3. Press the Print key when the screen (shown in Fig. 3-3) is displayed on the monitor screen. This

unit initiates the print of a density confirmation pattern (gray).

Fig.3-3

3-2

DPP-EX5 V1

4. Press the Cancel key when the printing is completed.

5. When the screen shown in Fig. 3-2 is displayed on the monitor screen, turn off the power and

disconnect the power cord from this unit.

6. Replace the thermal head.

m

. When replacing the thermal head, confirm the resistance value of old and new heads and find the

difference in the resistance value.

. The resistance value is described beside the head.

7. After the thermal head is replaced, connect the power cord and enter the service mode again. At that

time, confirm that a \ mark is located in “Print Calibrate” on the monitor screen and press the Enter

key. (Fig. 3-4)

Fig.3-4

8. Confirm the display in parentheses in the lower-left position when the screen (shown in Fig. 3-5) is

displayed on the monitor screen. (An example of the screen is R2-4.)

The print voltage after replacement is determined by the difference between the display in

parentheses and the head resistance value in step 6.

n

The voltage applied to the head is changed by the head resistance value. The change in a voltage is

adjusted in two levels.

DPP-EX5 V1

3-3

For eight steps (R1 to R8) (Fig. 3-5)

In this case, R1 has the lowest resistance value of a head. The difference in a resistance value is

approximately 290 Z for each step.

Fig.3-5

For seven steps (R1 to R7) (Fig. 3-6)

In this case, R1 has the lowest resistance value of a head. The difference in a resistance value is

approximately 73 Z for each step.

3-4

Fig.3-6

DPP-EX5 V1

(Example)

Assume that the first display is (R2-4) and that the difference between the display and head resistance

value is 350 Z (the resistance value of a new head is higher). The display after replacement is (R3-

5).

(Since the difference the display and head resistance value is 290 Z or more, the step of R

automatically increase by one step. The step of a numeric character also increases by one step

because of 350 _ 290 = 60. For the step of a numeric character, the width of one step is

approximately 73 Z. Therefore, the step of the numeric character increases or decreases by one step

if the difference is 36 to 37 Z or more.)

9. Move a \ mark using Direction keys so that it is located in Rx (x = 1 to 8) obtained by the difference

between the display and head resistance value. (In Fig. 3-7, a \ mark is located in R3.)

Press the Print key when the \ mark is moved to the determined “Rx” position.

10. Printing is initiated and the screen (shown in Fig. 3-8) is displayed on the monitor screen.

Fig.3-7 Fig.3-8

11. After the printing is completed, move the \ mark to the determined numeric character (“5” because

of (R3-5) in this example) using Direction keys and press the Enter key. (Fig. 3-9)

Fig.3-9

DPP-EX5 V1

3-5

12. The screen (Shown in Fig. 3-10) is displayed on the monitor screen.

Fig.3-10

n

At that time, confirm that the display below “Print Calibrate” is the determined numeric character

(R3-5 in this example).

13. Print a density confirmation pattern (gray) again according to the method in steps 2 to 4.

Confirm that the print result is equal to the density of a test pattern as reference.

If fine adjustment is required, perform steps 7 and later again and increase or decrease the numeric

character in step 11.

m

To increase the density, increase the numeric character.

To decrease the density, decrease the numeric character.

14. Set the screen to the initial screen of the service mode, turn off the power, and disconnect the power

cord from the printer.

3-6

DPP-EX5 V1

3-2. Confirmation and Adjustment of Video Output Level

n

Connect the equipment below when confirming and adjusting the level of a video output signal.

Equipment required

. Monitor television (with S video input)

. Oscilloscope (with a band of more than 30 MHz)

. 75 Z terminator

Connection diagram

DPP-EX5

Monitor TV

S1

Video

output

GND

75 Z terminator

GND

Oscilloscope

DPP-EX5 V1

3-7

Procedure

1. Switch S1 to the monitor TV side.

Fig.3-11

2. Enter the service mode, move the \ mark to “YC out level” using Direction keys, and press the

Enter key. (Fig. 3-11)

3. A color-bar signal is displayed on the monitor.

4. Switch S1 to the oscilloscope side.

5. Adjust using Direction keys (Use ↑ and ↓ keys.) so that the video output level (SYNC to 100%

white) and burst level satisfy the specifications.

Video output level (Use ↑ and ↓ keys.)

Specifications: 1 ±0.05 V p-p

n

key: Increases the level.

↑

key: Decreases the level.

↓

6. Confirm that the video output level and burst level satisfy the specifications and press the Enter key.

7. Switch S1 to the monitor TV side.

8. When the monitor screen returns to the screen shown in Fig. 3-11, turn off the power and disconnect

the power cord from this unit.

3-8

DPP-EX5 V1

Section 4

Troubleshooting

4-1. Electrical Troubleshooting

Trouble: No video signal is output. (No monitor screen is displayed on the monitor.)

Remedy: . Confirm the flat cable (DKUV) and connector.

. Confirm IC201 and IC202 on the DK-44 board and the peripheral circuit.

. Confirm that the input select key is set to “Memory Stick”.

n

Confirm the flexible flat cable (13-pin) and connector when a video signal is not output.

Trouble: No Memory Stick image can be read.

Remedy: . Confirm that the input select key is set to Memory Stick.

. Confirm the flat cable (DKSW) and connector.

. Confirm CN2001 on the SW-44 board and the peripheral circuit.

. Confirm IC101 on the DK-44 board and the peripheral circuit.

. Confirm that an image is based on the compatible file format.

. Confirm the Memory Stick operates correctly.

Trouble: A printer is not recognized by the personal computer.

Remedy: . Confirm the flexible flat cable (DKUV) and connector.

. Confirm IC3001 on the UV-44 board and the peripheral circuit.

. Confirm IC101 on the DK-44 board and the peripheral circuit.

Trouble: No buttons on the operation panel can be operated.

Remedy: Confirm the flat cable (DKSW) and connector.

DPP-EX5 V1

4-1

4-2. Error Display

In this unit, the “status of mechanical deck” can be displayed in the service mode.

Activation

1. Connect the power cord to DPP-EX5 (hereafter referred to as this unit) and connect the video cable,

connected to a monitor, to the VIDEO OUT terminal of this unit.

2. Turn on the power while pressing the Menu and Save keys simultaneously.

3. Release the keys when the service mode screen (shown in Fig. 4-1) appears on the monitor screen.

Fig.4-1

Status display of mechanical deck

1. Enter the service mode, move the \ mark to “Print Status” using Direction keys (shown in Fig. 4-2),

and press the Enter key.

2. The monitor screen is displayed. (Fig. 4-3)

*** PrintStatus EEPROM Data ***

Now: 404F 0000 2000 0000 000A 000A 0000 EB00

Last: 4053 0000 2000 0000 000A 000A 0000 EB00

01: 4064 9308 B501 0100 0005 0004 0000 2C02

02: 4070 9308 B501 0100 010F 010A 0000 2C02

03: 4060 9308 B501 0100 0491 048C 0000 2C02

04: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

05: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

06: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

07: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

08: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

09: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

10: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

Fig.4-2

Fig.4-3

4-2

DPP-EX5 V1

Viewing the status display screen

*** PrintStatus EEPROM Data ***

Now: 404F 0000 2000 0000 0491 048C 0000 EB00

Last: 4053 0000 2000 0000 0491 048C 0000 EB00

01: 4064 9308 B501 0100 0005 0004 0000 2C02

02: 4070 9308 B501 0100 010F 010A 0000 2C02

03: 4060 9308 B501 0100 0491 048C 0000 2C02

04: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

05: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

06: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

07: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

08: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

09: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

10: FFFF FFFF FFFF FFFF FFFF FFFF FFFF FFFF

CAB

Fig.4-4

Displays the present status

Displays the status obtained when the

power was turned off previously

Displays that no writing in FFFF portions

A:

Displays the total number when printing would be performed (Hexadecimal digit)

B:

Displays the total number when printing can be completed (Hexadecimal digit)

C:

Error status (Refer to the detail of status in this section)

n

To confirming whether the contents of occuring error, make sure to read the nearest value at C portion

compare with the value of present status at A portion into 01: to 10: on the screen.

DPP-EX5 V1

4-3

Detail of status

1 Error & ribbon code

Bit76543210

Name PES4 PES3 PES2 PES1 PES0 RM2 RM1 RM0

Contents Print error status Ribbon code

Print error status

PES4 PES3 PES2 PES1 PES0 Decimal State

0 0 0 0 0 0 No error

0 0 1 0 0 4 No ribbon

0 0 1 0 1 5 Ribbon completed

0 0 1 1 1 7 Ribbon code error

0 1 0 0 0 8 No paper

0 1 0 0 1 9 Paper completed

0 1 0 1 0 10 Paper length error (Long)

0 1 0 1 1 11 Paper length error (Short)

0 1 1 0 0 12 Remaining paper

1 0 0 0 0 16 Sensor or PE error (Jamming)

1 0 0 0 1 17 Sensor or JD error (Jamming)

1 0 0 1 0 18 Head error

1 0 0 1 1 19 Mode motor error

1 0 1 0 0 20 Stepping motor error or jamming

1 0 1 0 1 21 Transition error

1 0 1 1 0 22 Ribbon error

1 1 1 1 1 31 Others

Ribbon code

RC2 RC1 RC0 Decimal State

0 0 0 0 Reserved

0 0 1 1 Reserved

0 1 0 2 Reserved

0 1 1 3 Reserved

1 0 0 4 Small size

1 0 1 5 Post card size

1 1 0 6 Long size

1 1 1 7 Reserved

4-4

DPP-EX5 V1

4-3. Upgrade

n

Download the latest firmware and technical memo from the home page of GSP.

4-3-1. Firmware

The firmware of this unit is stored in IC102 (flash memory) on the DK-44 board. The firmware can be

upgraded using a Memory Stick by employing flash memory for program storage memory.

4-3-2. Upgrade

Upgrade when requiring the improvement in a function (the version of firmware).

DPP-EX5 V1

4-5

4-3-3. Upgrading method

Procedure

1. Copy the latest firmware (together with the downloaded and extracted folder) to the route directory of

a Memory Stick.

2. Insert the Memory Stick containing the latest firmware into the Memory Stick slot of this unit and

connect the power cord to the printer.

3. Press the POWER key while pressing the Menu and Print keys simultaneously.

4. Release the Menu , Print and Power keys when the buzzer “beeps”.

5. After completion is confirmed (The print LED then blinks at approximately two minutes), disconnect

the power cord from the printer and remove the Memory Stick from the printer.

6. Connect the power cord to the printer and then connect the video cable, connected to the monitor

television, to the video output terminal of the printer.

7. Press the POWER key while pressing the Menu and Save keys simultaneously.

8. Release the Menu , Save and POWER keys when the service mode screen below is displayed on

the screen of the monitor television.

9. Confirm that the “Check Sum” value displayed at the bottom of the monitor screen is the same as the

technical memo value.

10. Press the POWER key, disconnect the power cord and video cable from the printer.

Example of monitor screen (The Check Sum value is an example.)

4-6

Fig.4-5

DPP-EX5 V1

4-4. Mechanical Troubleshooting

The troubles caused by a mechanical deck can be mainly classified into the following.

1. Any paper cannot be fed normally. (Paper feed/eject trouble)

2. Any ink ribbon cannot be fed normally. (Ribbon trouble)

3. Printing cannot be performed normally. (Print trouble)

The cause and remedy of each trouble are described below.

1. Paper feed/eject trouble

Trouble: . No paper is ejected from the paper feed tray.

. Paper is ejected from the paper feed tray, but it stops halfway.

Cause: Perform the mode transition operation in MECHANIC TEST and confirm whether the UP

plate operation is normal. (Tap MODE RESET)

Normal: The chassis assembly is abnormal.

Abnormal: The paper feed block (K (paper feed) frame assembly) is abnormal.

Remedy: . Clean (wipe with dry cloth) if the paper feed roller and separation roller are dirty due to an

abnormal paper feed block.

. Replace the K (paper feed) frame assembly if the paper feed roller and separation roller are

not dirty.

. Replace the chassis assembly if it is abnormal (the mode gear is damaged).

Trouble: . Paper is fed normally, but it is ejected as blank paper.

. Multiple sheets of paper are fed continuously. (Multiple paper feed)

Cause: Incorrect paper detection.

Remedy: . Confirm the fixing state of the PE-44 and JD-44 boards. Replace the PE-44 and JD-44

boards if the state is normal.

Trouble: Paper is folded inside a printer and cannot be taken out. (Paper jamming)

Cause: . Abnormal ribbon cassette.

. Abnormal paper feed block. (e.g., Separation plate deformation and damage)

Remedy: . Remove the mechanical deck block from the lower cabinet and eliminate the paper.

. Replace the K (paper feed) frame assembly if the paper feed block is abnormal.

n

The ribbon cassette is judged to be abnormal when no abnormality is detected in a paper feed

block. Confirm the ribbon cassette. (e.g., Ribbon rewind and counter wind)

DPP-EX5 V1

4-7

2. Ribbon trouble

Trouble: The ribbon is wound round the capstan roller and cannot be taken out. (Ribbon jamming)

Cause: . Abnormal ribbon cassette

. Abnormal installation position of ribbon guide

. Abnormal chassis assembly (Deterioration in take-up reel clutch torque or ribbon path

abnormality due to chassis deformation)

Remedy: . Remove the mechanical deck block from the lower cabinet, turn the gear engaged with the

stepping motor gear, and eliminate the ribbon.

. Confirm that the ribbon guide is fixed in clockwise direction with the heat sink and in the

non-floating state.

(If the ribbon guide is not fixed in the conditions above)

Loosen the fixing screw and fix the ribbon guide again.

. Replace the chassis assembly if it is abnormal.

3. Print trouble

Trouble: . Paper is not fed from the paper feed tray.

. Abnormality is detected at equal pitch intervals in the paper feed direction of the printed

side.

n

An abnormal point can be confirmed according to the interval of a pitch.

. Pitch interval of 18.8 mm: Pinch roller abnormality

. Pitch interval of 20.4 mm: Capstan roller abnormality

. Pitch interval of 37.7 mm: Platen roller abnormality

Cause: . Adhesion of dust or grease

. Adhesion defect (in case of a pinch roller and platen roller)

. Welding defect (in case of a capstan roller)

Remedy: . Remove the mechanical deck block from the lower cabinet and clean each roller. (For the

dust adhering to the capstan roller, eliminate it using a gum tape.)

Trouble: A stripe is detected in the paper feed direction of the printed side.

Cause: . Adhension of foreign objects to the thermal head surface

. Broken thermal head

. Flaw and scar on ribbon guide

. Flaw and burr on the printed side of paper path of K (paper feed) frame assembly

Remedy: Clean the paper feed path using the cleaning kit supplied with this unit. When the trouble

persists even after cleaning, replace other faulty parts that may cause the trouble.

4-8

DPP-EX5 V1

SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before

releasing the set to the customer :

Check the metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC

leakage. Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to

any exposed metal part having a return to

chassis, must not exceed 3.5 mA. Leakage

current can be measured by any one of three

methods.

1. A commercial leakage tester, such as the

Simpson 229 or RCA WT -540A. Follow the

manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The

Data Precision 245 digital multimeter is

suitable for this job.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 5.25 V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM

that is suitable. Nearly all battery operated

digital multimeters that have a 20 V AC range

are suitable. (See Fig. A)

DPP-EX5 V1

To Exposed Metal

Parts on Set

0.15 µF 1.5 k

Fig A. Using an AC voltmeter to check AC leakage.

Z

Earth Ground

AC

voltmeter

(5.25V)

DPP-EX5 (UC, CE, KR, CN) E

9-955-370-11

Printed in Japan

Sony Corporation 2002. 10 22

B&P Company ©2002

Loading...

Loading...