Lull 1044C-54 Operation Manual

Operator & Safety Manual

Keep this manual with machine at all times.

Model 1044C-54 Series II

Before S/N 0160037900

31200070

Revised

February 23, 2009

An Oshkosh Corporation Company

Revision Log

Revision Log

March 9, 2005 - A - Original Issue of Manual

REVISION LOG

July 12, 2005 - B - Revised pages 6, 23, 24, 27 & inside rear cover.

February 23, 2009 - C - Revised covers and pages c, 30 & 31.

a

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes without prior notification. Contact JLG Industries, Inc. for updated information.

Operator Qualifications

The operator of the machine must not operate the machine until this manual has been read, training is accomplished and operation of the machine has been completed under the supervision of an experienced and qualified operator. Operation within the U.S.A. requires training per OSHA 1910.178.

Operators of this equipment must possess a valid, applicable driver’s license, be in good physical and mental condition, have normal reflexes and reaction time, good vision and depth perception and normal hearing. Operator must not be using medication which could impair abilities nor be under the influence of alcohol or any other intoxicant during the work shift.

In addition, the operator must read, understand and comply with instructions contained in the following material furnished with the telehandler:

•This Operator & Safety Manual

•Telehandler Safety Manual

•All instructional decals and plates

•Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable Employer, Industry and Governmental rules, standards and regulations.

Modifications

Any modification to this machine must be approved by JLG.

b

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries, Inc. or the local authorized JLG representative for information regarding safety-related bulletins which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this machine. Contact JLG Industries, Inc. to ensure that the current owner records are updated and accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG products have been involved in an accident involving bodily injury or death of personnel or when damage has occurred to personal property or the JLG product.

FOR:

•Accident Reporting and Product Safety Publications

•Current Owner Updates

•Questions Regarding Product Applications and Safety

•Standards and Regulations Compliance Information

•Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office (Addresses on back cover)

In USA

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

Outside USA

Phone: +1-717-485-6591

ProductSafety@JLG.com

Other Publications Available

Illustrated Parts Manual ...................................... |

31200069 |

Service Manual ................................................... |

31200079 |

c

Read This First

This Page Intentionally Left Blank

d

TABLE OF CONTENTS

Revision Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . a

Read This First. . . . . . . . . . . . . . . . . . . . . . . . . . . . . b

Operator Qualifications . . . . . . . . . . . . . . . . . . . . b

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . b

Other Publications Available . . . . . . . . . . . . . . . . c

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Danger, Warning, & Caution: What They Mean . .1

Safety Standard . . . . . . . . . . . . . . . . . . . . . . . . . .1

Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operators Protective Structure . . . . . . . . . . . . . . .1

Refueling Safety . . . . . . . . . . . . . . . . . . . . . . . . . .2

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . .2

Vehicle Stability . . . . . . . . . . . . . . . . . . . . . . . . . .2

Starting Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . .3

Before Operating the Machine . . . . . . . . . . . . . . . . .8

Check the Equipment . . . . . . . . . . . . . . . . . . . . . .8

Know the Work Area . . . . . . . . . . . . . . . . . . . . . .8

Plan Your Work . . . . . . . . . . . . . . . . . . . . . . . . . .9

Safe Vehicle Operation . . . . . . . . . . . . . . . . . . . .9

Know the Rules . . . . . . . . . . . . . . . . . . . . . . . . . .9

Protect Yourself . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mount and Dismount Properly . . . . . . . . . . . . . .10

Instruments and Controls. . . . . . . . . . . . . . . . . . . .12

Gauges and Lights . . . . . . . . . . . . . . . . . . . . . . .12

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . .13

Throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Brake Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Drive Lockout Override Foot Switch . . . . . . . . . .14

Park Brake Control . . . . . . . . . . . . . . . . . . . . . . .14

Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Direction Control. . . . . . . . . . . . . . . . . . . . . 15

Speed Range Selection . . . . . . . . . . . . . . . 15

Neutral Lock . . . . . . . . . . . . . . . . . . . . . . . . 15

Shutdown Override Switch . . . . . . . . . . . . . . . . .15

Transmission Declutch Switch . . . . . . . . . . . . . .16

Steer Mode Selector . . . . . . . . . . . . . . . . . . . . .16

Front Wheel Steer Mode . . . . . . . . . . . . . . 17

Round Steer Mode . . . . . . . . . . . . . . . . . . . 17

Oblique Steer Mode . . . . . . . . . . . . . . . . . . 17

Synchronizing (Straightening) the Wheels . 17

Joystick Controls . . . . . . . . . . . . . . . . . . . . . . . .19

General Description . . . . . . . . . . . . . . . . . . 19

Front Joystick . . . . . . . . . . . . . . . . . . . . . . . 19

Rear Joystick . . . . . . . . . . . . . . . . . . . . . . . 20

Auxiliary Controls . . . . . . . . . . . . . . . . . . . . 22

Tilting Carriage Control. . . . . . . . . . . . . . . . 22

Boom Angle Indicator . . . . . . . . . . . . . . . . . . . . .23

Boom Extension Indicator . . . . . . . . . . . . . . . . .23

Transfer Carriage Extension Indicator . . . . . . . .23

Frame Level Indicator . . . . . . . . . . . . . . . . . . . .23

Frame Tilt Control . . . . . . . . . . . . . . . . . . . . . . .24

Outrigger Controls . . . . . . . . . . . . . . . . . . . . . . .24

General Operating Procedures . . . . . . . . . . . . . . .26

Starting Procedures . . . . . . . . . . . . . . . . . . . . . .26

Shutdown Procedures . . . . . . . . . . . . . . . . . . . .26

Traveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Follow Safe Operating Procedures . . . . . . . . . .27

Lift the Load Safely . . . . . . . . . . . . . . . . . . . . . .27

Transport the Load Safely . . . . . . . . . . . . . . . . .27

Safely Placing the Load . . . . . . . . . . . . . . . . . . .28

Elevated or Overhead Placement. . . . . . . . 28 Lifting Personnel . . . . . . . . . . . . . . . . . . . . . . . .29 Quick Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Disconnecting an Attachment . . . . . . . . . . . 30 Connecting an Attachment . . . . . . . . . . . . . 31

Stability Systems. . . . . . . . . . . . . . . . . . . . . . . . . . .32

System Safety . . . . . . . . . . . . . . . . . . . . . . . . . .32

Rear Oscillation Lock System . . . . . . . . . . . . . .32

Drive Lockout Override . . . . . . . . . . . . . . . . . . .32

Theory of Normal Operation . . . . . . . . . . . . 32

General Description, Drive

Lockout Override System . . . . . . . . . . . . . . 33

Operation of the Drive

Lockout Override System . . . . . . . . . . . . . . 33

Boom/Transfer Extend Lock System . . . . . . . . .34

Fluid & Lubricant Specifications . . . . . . . . . . . . . .36

General Fluid and Lubricant Specifications

36

Engine Oil Specifications . . . . . . . . . . . . . . . . . .36

John Deere Engines . . . . . . . . . . . . . . . . . . 36

Transmission Oil Specifications . . . . . . . . . . . . .37

Fuel Requirements . . . . . . . . . . . . . . . . . . . . . . .37

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

John Deere Engines . . . . . . . . . . . . . . . . . . 37

Service/Lubrication Schedule . . . . . . . . . . . . . . . .38

Sample Load Chart . . . . . . . . . . . . . . . . . . . . . . . . .40

i

TABLE OF CONTENTS

ii

SAFETY

DANGER, WARNING, & CAUTION: WHAT THEY MEAN

Hazards are identified by the “Safety Alert Symbol” and followed by a signal word: Danger, Warning, or Caution.

DANGER

DANGER

The signal word “DANGER” indicates an imminently hazardous situation which, if not avoided, will result in death or serious personal injury.

WARNING

WARNING

The signal word “WARNING” indicates a potentially hazardous situation which, if not avoided, could result in death or serious personal injury.

CAUTION

CAUTION

The signal word “CAUTION” indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

The signal word “CAUTION”, used without the safety alert symbol, indicates a potentially hazardous situation which, if not avoided, may result in property damage.

SAFETY STANDARD

The ASME/ANSI B56.6 safety standard for rough terrain forklift trucks defines safety requirements relating to the design, operation, and maintenance of these vehicles.

DECALS

The decals on the vehicle provide instructions for safe and correct operation.

Never make modifications affecting safe operation or capacity without the expressed written approval of JLG.

When JLG approved modifications are made, the user is responsible for seeing that appropriate decals, load charts, and instructions are changed.

All plates and decals must be in place and legible at all times.

OPERATORS PROTECTIVE

STRUCTURE

This vehicles Operators Protective Structure is equipped with a Roll-Over Protective Structure (ROPS) to guard the operator if the vehicle tips over. The Falling Object Protective Structure (FOPS) is built into the ROPS. The FOPS protects the operator from falling objects.

Despite the protection of the ROPS/FOPS, it cannot protect the operator from every possible hazard. Do not consider the ROPS/FOPS a substitute for safe practices and good common sense.

Any modification to a ROPS/FOPS, such as welding or drilling holes in the structural members for mounting brackets, will affect the ROPS/FOPS capability to provide the required protection.

Any modification or repair without the specific written approval of JLG will void the ROPS/FOPS certification. Contact your authorized JLG dealer before making any modifications or repairs. Failure to do so may void the ROPS/FOPS certification.

1

SAFETY

REFUELING SAFETY

Never smoke near the vehicle during refueling.

Do not permit anyone to be on the vehicle during refueling.

Spilled fuel must be completely absorbed or evaporated before starting the engine.

Make sure the fuel cap is in place before starting the engine.

Never use an open flame when checking the fuel level in the tank.

Never fill the fuel tank with the engine running. Make sure you have adequate ventilation during fueling.

PERSONAL SAFETY

Wear all the protective clothing and personal safety devices issued to you or called for by job conditions.

You may need…

•A hard hat

•Safety shoes

•Safety glasses, goggles, or face shield

•Heavy gloves

•Hearing protection

•Reflective clothing

•Wet weather gear

•Respirator or filter mask

Avoid entanglement hazards. Do not wear clothing or jewelry that could catch on machinery. Keep your hands, hair, feet and clothing away from moving parts. Always keep your hands and feet inside the cab.

Know the pinch points and rotating parts on the vehicle.

Always know where to get assistance in case of an emergency. Know how to use a first aid kit and fire extinguisher.

VEHICLE STABILITY

Your JLG vehicle is proven to be stable when properly operated. However, improper operation, faulty maintenance, unauthorized modifications, or poor housekeeping may cause instability.

Some Conditions that Affect Stability:

•Ground and surface conditions.

•Surface grade.

•Weight and configuration of the attachment.

•Improper tire inflation and ballast content.

•Operator judgement.

•Excessive tilting of the fork carriage or other attachments, with an elevated load, can cause vehicle instability. The amount of allowable tilt is governed by conditions such as boom elevation, weight of load, and terrain.

STARTING SAFETY

Before Starting the Engine…

Important: Warn all others in the area that you are going to start the vehicle.

1.Check underneath and around the vehicle and make sure all personnel are clear.

2.Be properly seated and seat belt secured.

3.Set the park brake.

4.Make sure shift selector is locked in the NEUTRAL position.

5.Apply the brakes.

2

OPERATION SAFETY

Safe operation is the responsibility of the operator.

Improper use of the vehicle can lead to dangerous situations for yourself, those around you, the vehicle and the work area. You must have safe working habits and be aware of hazardous working conditions.

Thoroughly read and understand this entire manual. Follow all safety rules and practices explained in this manual.

The vehicle must be checked every day or at the start of each shift. See “Check the Equipment” on page 8.

To meet the requirements of different operating conditions, JLG offers optional lighting packages for your vehicle. Do not operate the vehicle if it is not equipped with lights when conditions require them. If your vehicle is not equipped with the proper lights, contact your authorized JLG dealer for available lighting packages.

If operating in an enclosed or partially enclosed environment, make sure there is enough ventilation. Engine exhaust fumes can be deadly to you and those around you if precautions are not taken. Questions about the air quality in the working environment and sampling methods should be directed to a qualified person.

W1008

Never operate the vehicle controls while you are outside the cab. You must be properly seated in the cab before operating any controls.

Before Leaving the Cab…

•Bring the vehicle to a full stop.

•Apply the park brake.

•Lower the boom.

SAFETY

Before Leaving the Vehicle Unattended…

•Stop the engine.

•Block the wheels if parked on an incline.

•Lower the boom.

The vehicle is considered “attended” when the operator is less than 25 feet from the vehicle and it remains in the operator’s view.

The vehicle is considered “unattended” when the operator is 25 feet or more from the vehicle and the vehicle is in the operator’s view, or whenever the vehicle is not in the operator’s view.

W1009

Never stand or walk under a raised boom. Do not allow others to do so.

W1007

Never allow passengers on the vehicle.

3

SAFETY

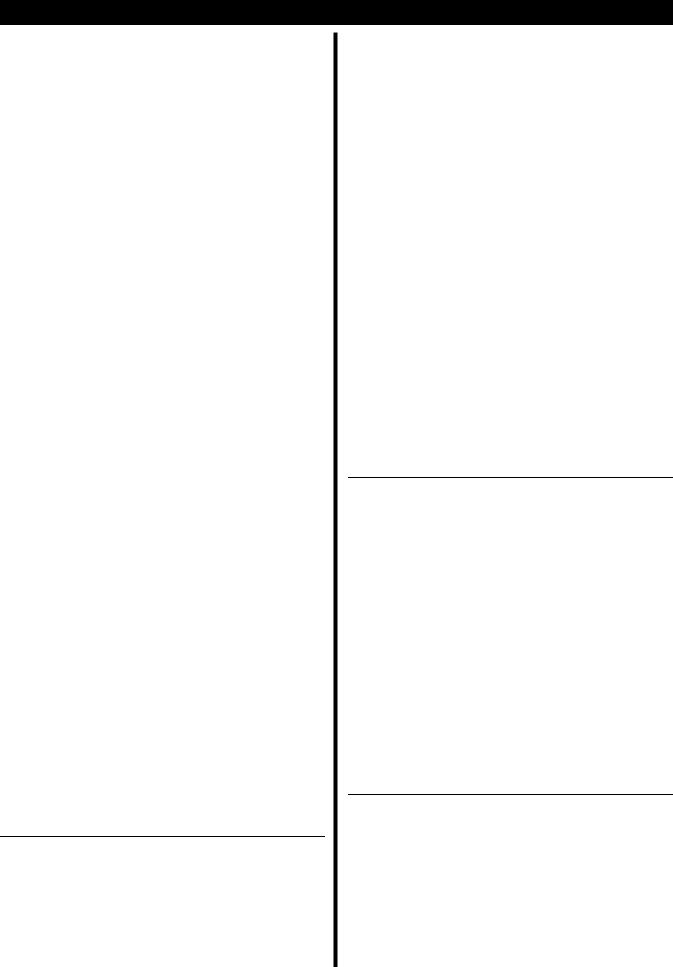

W1011

Always check clearances under power lines and overhead structures before driving under them.

DO NOT operate the vehicle near energized power lines. Always contact the electrical power company when operating near power lines. The lines should be moved, insulated, disconnected, or de-energized and grounded before operating in the area. Keep all parts of the vehicle at least 10 feet away from power lines. Contacting electrical power lines WILL result in death or serious personal injury!

DANGER

DANGER

KEEP ALL PARTS OF

MACHINE AT LEAST 10

FEET FROM POWER

LINES. CONTACTING

ENERGIZED POWER

LINES WILL CAUSE

DEATH OR SERIOUS

PERSONAL INJURY!

W1010

Always check for enough overheard clearance for the boom.

W1017

Ensure that correct tire pressure and tire ballast levels are maintained.

W1014

Never attempt to discharge a load by stopping the vehicle suddenly.

W1013

Never lift a load using one fork.

4

W1016

Never place loads that exceed scaffold capacity or subject scaffold to unnecessary “shock” loads.

W1015

Never stack a load on uneven ground.

W1019

Always be aware of load width.

SAFETY

W1021

Drive carefully and avoid sudden stops and changes of direction.

W1020

Ensure that the load is stable and secure. Check to see that there are no loose articles that may fall off the fork.

W1022

Don’t overload the vehicle.

W1023

Never add unauthorized counterweights.

5

SAFETY

W1024

Always pick up the load at its center of gravity.

W1026

Avoid parking on slopes. If it is necessary to park on a slope, set the parking brake and block the wheels.

When Traveling On Inclines…

•Tilt the attachment back and raise only enough to clear the ground.

•Avoid turning. If it cannot be avoided, turn slowly and with extreme caution.

•Travel straight up and down grades.

•When loaded and traveling up or down grades, travel only with the load uphill.

•When unloaded, travel only with the forks or attachment downhill.

•Proceed slowly and with extreme caution.

•Do not travel across excessively steep slopes.

W1043

The vehicle can be levelled side to-side a total of 10° in each direction (18% grade). Any slope or grade that exceeds this is considered excessively steep.

W1018

Drive slow and carry the load as low as possible.

When Traveling on Roadways…

•Make sure the vehicle is equipped with all necessary lights and safety signs required for traveling on roadways.

•Observe all traffic laws and speed limits.

•Keep to the correct side of the roadway.

•Keep a safe distance from other vehicles.

•Maintain control of the vehicle at all times.

•Yield the right-of-way to pedestrians and emergency vehicles.

•Do not pass another vehicle at intersections, blind spots, or other dangerous locations.

•Avoid running over loose objects and debris.

6

SAFETY

Additional Safety Instructions:

•Maneuver the vehicle carefully. Do not cause the load to shift or the vehicle to tip.

•Slow down for wet and slippery surfaces and changes in terrain.

•Turn the steering wheel smoothly and slow down when turning.

•Do not make sharp turns at high speeds.

•Take special care when traveling without a load. The vehicle is more susceptible to tipping over on its side.

•Do not continue to operate the vehicle if an unsafe condition is found. Stop the vehicle and report the condition to the designated authority.

•Never make repairs or adjustments unless you are authorized to do so.

•Always keep your hands and feet inside the cab.

•Never reach into the boom or attachments.

•Understand the limitations of the vehicle and drive safely.

•Watch for pedestrians, especially when backing up or turning and where pedestrians may step into the path of the vehicle.

•The vehicle may add to the overall sound level of the work area. Give consideration to the sound exposure of those working around you.

•If a fuel leak is found, do not operate the vehicle until the problem is fixed.

•When approaching areas where vision is obstructed, always slow down and sound the horn.

•Report all accidents involving personnel, building structures, and equipment to your supervisor or as directed.

•Use caution when operating on ramps, platforms, trenches, and other similar surfaces.

•Keep a clear view of the terrain and where the vehicle is heading. Watch out for other vehicles, people, and structures.

•Where the load will obstruct the operator's vision, it is recommended that the vehicle be operated in reverse, looking backwards in the direction of travel. Travel at a slower speed and get someone to direct you.

•Avoid excessively steep slopes or unstable surfaces. If you must drive on a slope, level the vehicle, keep the load low and proceed with extreme caution. Do not, under any circumstances, drive across excessively steep slopes.

•Do not block access to fire lanes or fire equipment.

•Do not jump! If a vehicle ever becomes unstable and starts to tip over: Brace yourself and stay with the vehicle, Keep your seat belt fastened, Hold on firmly and lean away from the point of impact.

•Never tamper with, modify, or bypass the stability systems installed on your JLG vehicle. Never disconnect or bypass pressure switches or proximity switches.

Do not disconnect or bypass proximity switches.

Bypassing proximity switches may result in death or serious personal injury !

W1056

See “Stability Systems” on page 32 for more information on the stability systems installed on your vehicle.

7

Loading...

Loading...