Lukas LH2 User Manual

Operating instructions

Hydraulic Tools

Hand pump LH1 / LH2

and accessories

84129/2430-85 GB

Issue 04.2009

replaces 03.2008

(Translation of the original operating instructions)

2

Contents Page

1. Danger classes 4

2. Product safety 4

3. Proper use 7

4. Main components of the hand pump 8

5. Functional description 9

5.1 Base pump 9

5.2 Adapter blocks 9

6. Mounting of base plates and valve blocks 10

6.1 Basics for mounting base plates and valve blocks 11

6.2 Base plates 12

6.3 4/3-way valve 13

6.4 2-way distribution valve 14

6.5 Oil distributor with pressure gauge connection 15

7. Connection options for hydraulic equipment 16

7.1 Direct connection into the pump head

(only in operation with single-acting cylinders) 16

7.2 Quick-disconnect couplings 17

7.3 Screwed joint couplings 17

7.4 Direct connection into the valve block 17

7.5 Direct connection into the oil distributor block 19

8. Commissioning 20

7.6 Direct connection into the base plate 20

8.1 Unlocking the pump 21

8.2 Bleeding the pump 21

9. Operation 22

9.1 Notes for a secure operation of the hand pump 22

9.2 Hand pump (basic pump) 22

9.3 Hand pump with base plate 22

9.4 Hand pump with 4/3-way valve 23

9.5 Hand pump with 2-way distribution valve 23

9.6 Hand pump with oil distributor and pressure gauge 24

9.7 Shutdown / storage 24

3

10. Transport 24

11. Maintenance and repair 24

11.1 Basic requirements 24

11.2 Maintenance 26

11.3 Hydraulic uid change or adding hydraulic uid 27

11.4 Care 27

11.5 Repair (hand pump) 28

11.6 Repair (accessories) 34

11.7 Repair (couplings and decals) 36

12. Troubleshooting 37

13. Technical data 40

13.1 Data of the hand pumps 40

13.2 Hydraulic uid recommendation 42

13.3 Operating and storage temperature ranges 42

14. Notes 43

4

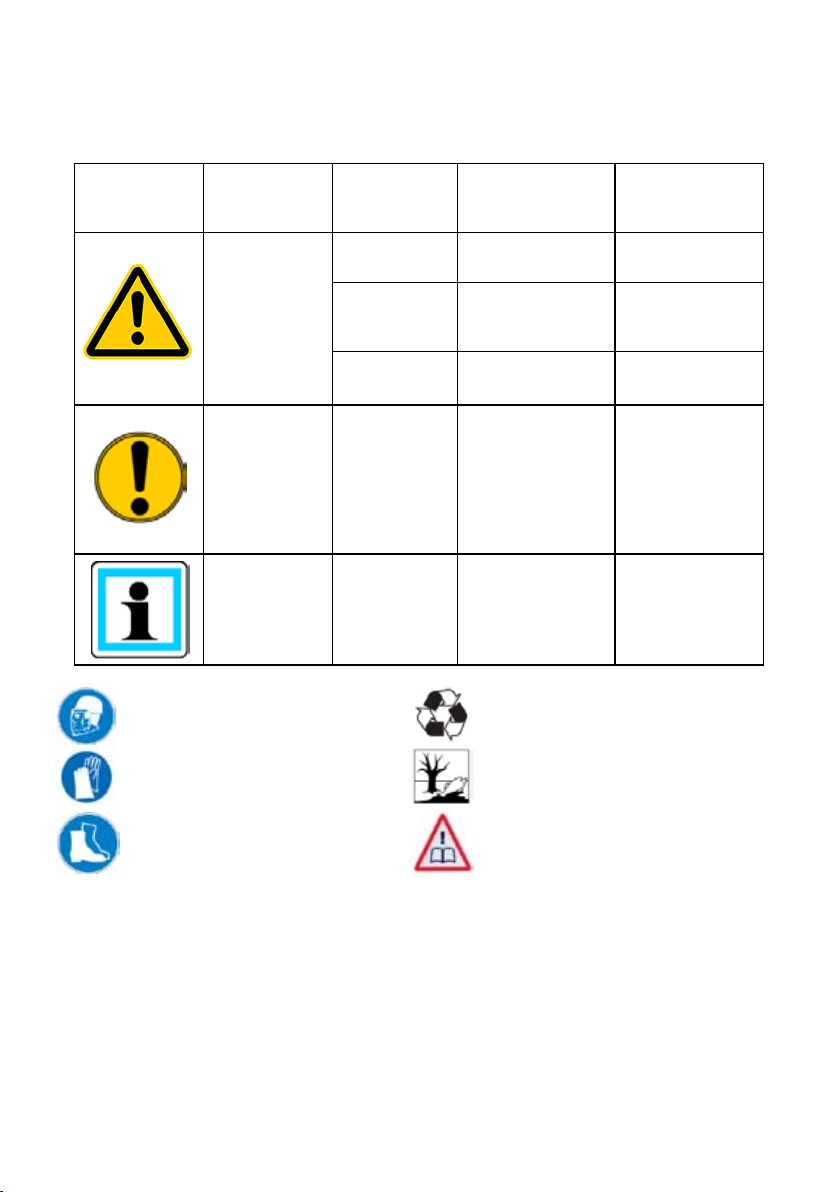

Danger classes1.

We distinguish between various categories of safety instructions. The table shown below

shows you the overview, via the assignment of symbols (pictograms) and signal words, of

the concrete danger and the possible consequences.

Pictogram

Wear helmet with face guard

Damage /

injury to

human

device

- NOTE

Key word Denition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

CAUTION!

Proper recycling

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to device /

environment

Advice for

application and

other important /

useful information

and advice

Death or major

injury

Potential death or

major injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surrounding

materials

No injury /

damage to

persons /

environment /

equipment

Wear protective gloves

Wear safety shoes

Protect the environment

Read and follow operating

instructions

Product safety2.

LUKAS products are developed and produced in order to ensure the best performance and

quality with proper use.

The safety of the operator is the most important consideration in the product design.

In addition, the operating instructions are to help in using the LUKAS products safely.

In addition to the operating instructions, all generally applicable, statutory and other

binding rules for accident prevention and for environmental protection must be heeded and

disseminated.

The device must only be operated by educated persons who are trained in safety technology,

since otherwise there is a risk of injury.

5

We advise all users before using the device to carefully read through the operating instructions

and to follow the instructions contained therein without exception.

We also recommend that you get instructed by a qualied trainer in the use of the product.

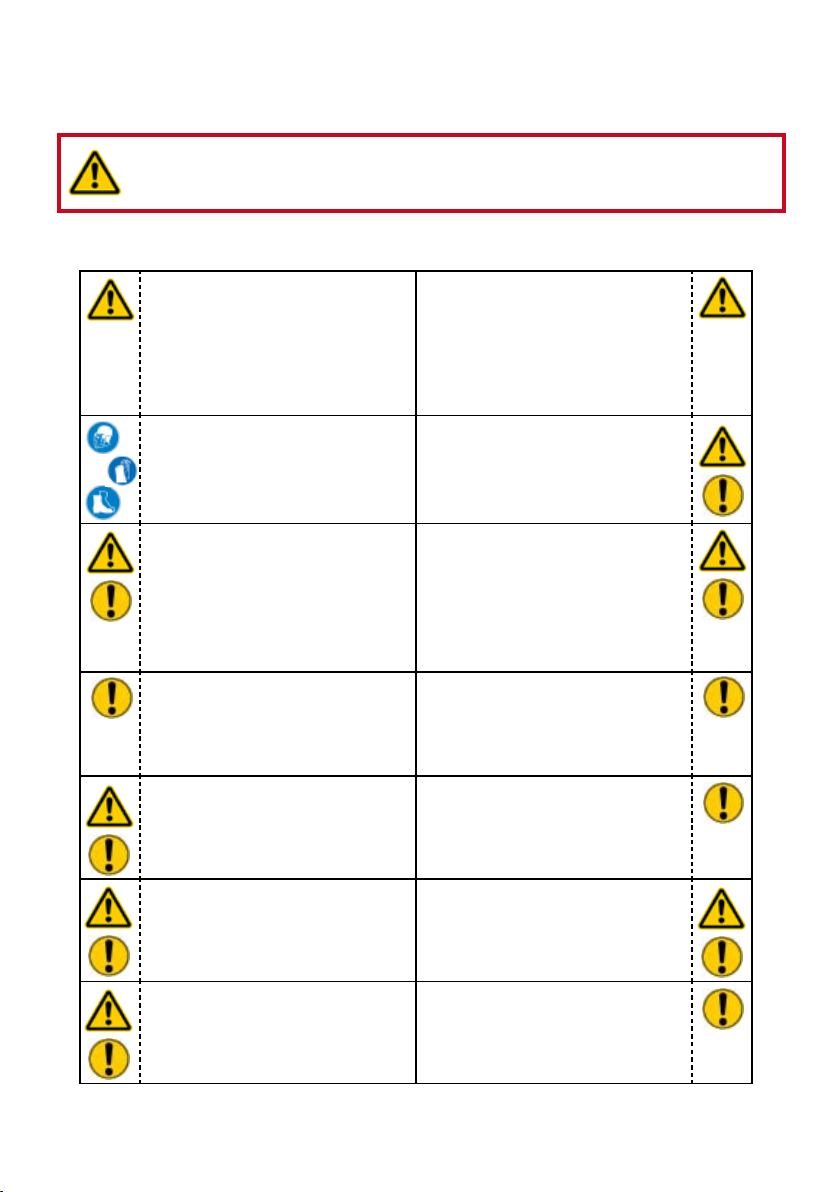

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

devices must also be heeded!

Even if you have already received instruction, you should read the following safety instructions

again.

Make sure that no body parts

or clothing get between the

openly visible moving parts of

the device.

Wear protective clothing,

protective helm with visor,

safety shoes and protective

gloves.

Immediately report changes

that occur (including changes

in operating behavior) to

the appropriate persons/

departments! If necessary,

immediately shut down and

secure the device!

Check the device for visible

defects or damage before and

after use.

Working under loads is

prohibited if they are raised

exclusively with hydraulic

devices. If this work is

unavoidable, sufcient

mechanical supports are

additionally required.

In the event of malfunctions,

shut down the device

immediately and secure it. You

should have the malfunction

repaired immediately.

Heed all safety instructions

and hazard warnings on the

device and in the operating

instructions.

Make sure that all safety

covers are present on the

device and in proper working

condition.

Safety equipment must never

be disabled!

Check all lines, hoses and

screwed connections for leaks

and externally visible damages

and repair immediately!

Escaping hydraulic uid can

lead to injuries and res.

Do not make any changes

(add-ons or conversions)

on the device without the

approval of LUKAS.

All safety instructions and

hazard warnings on the device

are to be kept intact and in a

legible condition.

Any work procedure that

detracts from the safety and/

or stability of the device should

be abandoned!

The maximum permissible

operating pressure must not

be changed.

6

Before switching on/engaging

the device or while operating

the device, it must be ensured

that no one is endangered by

the operation of the device.

When working in the vicinity

of live components and lines,

take appropriate measures for

preventing current transfers or

high voltage ashovers to the

device.

Prevent electrostatic

discharge, which has the

possible consequence of spark

formation, when handling the

device.

The device is lled with

hydraulic uid. These hydraulic

uids can be detrimental to

health if they are swallowed

or their vapours are inhaled.

Direct contact with the skin

should be avoided for the

same reason. Also, when

handling hydraulic uids, note

that they can negatively affect

biological systems.

Make sure there is adequate

lighting while working.

Always keep these operating

instructions easily accessible

at the site where the device is

used.

Observe all intervals that

are prescribed or specied

in the operating instructions

for recurring tests and/or

inspections.

For repairs only original

LUKAS accessories and spare

parts are to be used.

Make sure that you do not

get caught in the hose loops

and trip when working with or

transporting the device.

When the hand pumps are set

up, care needs to be taken

that they are not impaired by

extremely strong temperature

changes.

When operating and/or storing

the device, make sure that the

function and the safety of the

device are not impaired by

strong external temperature

differences or that the device

is damaged. Keep in mind that

the device can also heat up

when it is continuously used.

Before transporting the device,

always check to see that the

accessories are positioned

securely to prevent the

possibility of an accident.

Make sure you properly

dispose of all removed parts,

leftover hydraulic uid, leftover

oil and packing materials.

7

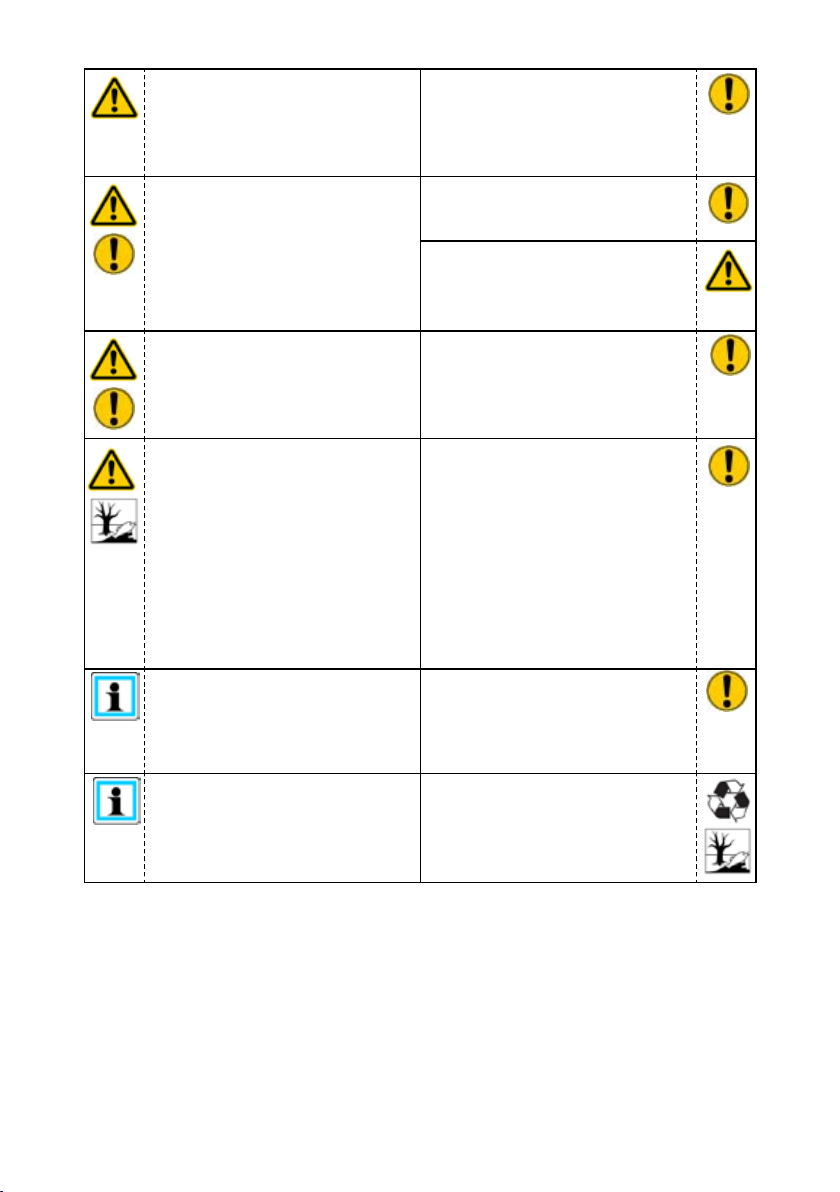

WARNING / CAUTION / ATTENTION!

The device is specied exclusively for the purpose represented in the operating

instructions (see Chapter "Proper use"). Any use that differs or goes beyond this is

considered improper. The manufacturer/supplier shall not be held liable for damages

resulting from improper use. The risk shall be borne solely by the user.

Proper use also includes heeding the operating instructions and complying with the inspection

and maintenance requirements.

Never work in a fatigued or intoxicated state!

Proper use3.

The LUKAS hand pump is used for the operation of devices of the LUKAS Hydraulic tools.

They can be used as an additional or replacement drive source along with the LUKAS

hydraulic unit (e.g. in areas at risk for explosion).

Use with equipment of other manufacturers is possible, but requires technical testing and

approval of LUKAS on a case-by-case basis.

WARNING / CAUTION / ATTENTION!

Always note the product limitations with respect to operating pressure, load limit

values and operating conditions. The operating pressure should not be higher

than the lowest maximum operating pressure of any system components.

The operating pressure should NEVER be set higher than that which is specied

in the "Technical Data" chapter. A higher setting may cause property damage

and/or injuries.

Make sure that the usable capacity of the hand pump (see chapter "Technical

Data") is sufcient for operating the connected cylinders or devices.

The required hydraulic uid operating quantity can be found in the chapter

"Technical Data" or in the operating instructions of the devices to be operated.

Accessories and spare parts for the hydraulic equipment can be obtained from your

authorised LUKAS dealer!

8

Main components of the hand pump4.

5

4

7

6

1 Hand relief valve

2 Port P

3 Return port T

4 Vent / ll cap

5 Pump lever

6 Reservoir

7 Lock

3

2

1

9

Functional description5.

5.1 Base pump

All LUKAS hand pumps of this series are two-speed, i.e. they have two operating speeds:

• A high speed in the low pressure range (LP) for fast extension of the cylinder or device

while unloaded

• A low speed in the high pressure range (HP) for controlled extension of the cylinder or

device while loaded

The switch from low pressure (LP) to high pressure (HP) is automatic at the factory setting

for changeover pressure (see chapter "Technical Data").

A pressure port "P" with a G1/4" thread and a return port "T" with an M10 thread (usually

closed) are directly available as ports on the pump.

With the basic pump it’s only possible to operate single-acting cylinders or devices.

To use other connections or double-acting cylinders or hydraulic devices, you will have to

mount adapter blocks (see chapter “adapter blocks”.

In some of the offered LUKAS hand pumps this adapter blocks are part of the shipment

and they are already mounted.

5.2 Adapter blocks

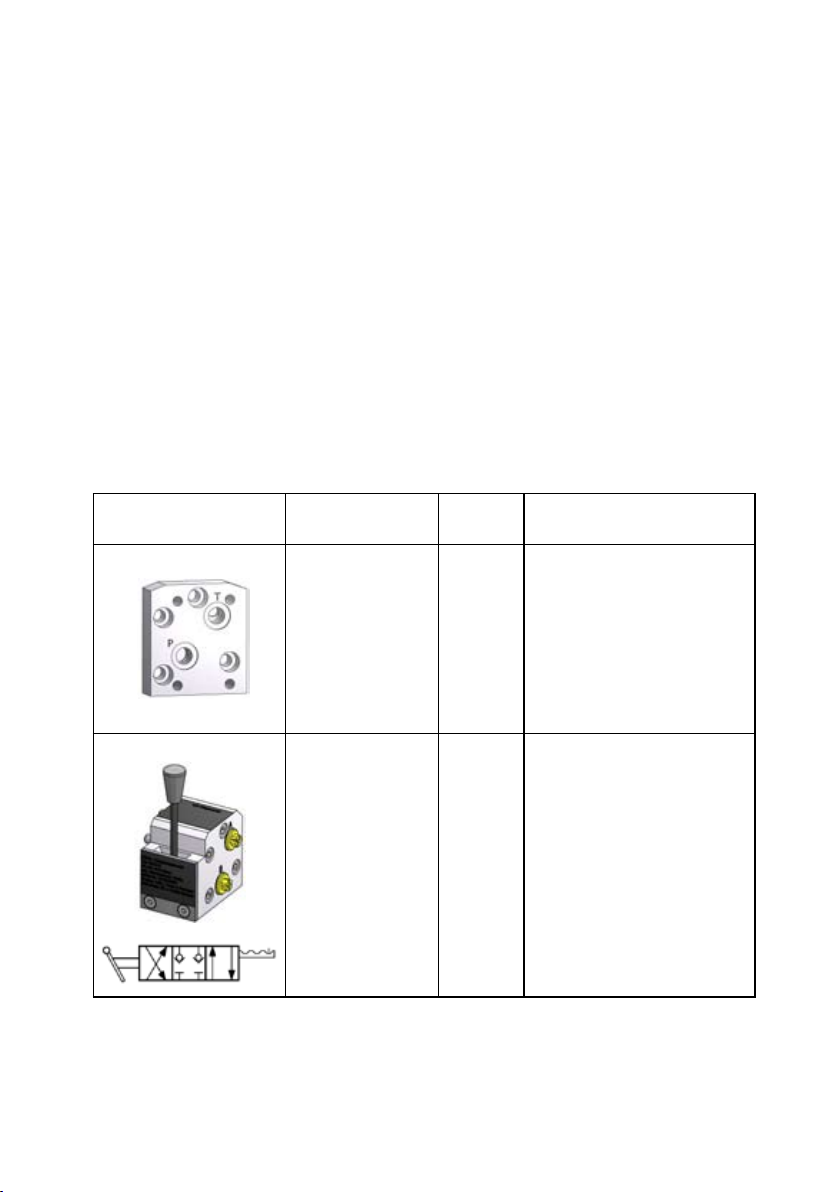

Adapter kit Ref. no. Weight

[kg]

Base plate 841297410 0,3 Add-on of a second return

Function / application

port (G1/4”) on the pump.

The base plate is a basic

requirement to mount valve

blocks and oil distributors

on the pump.

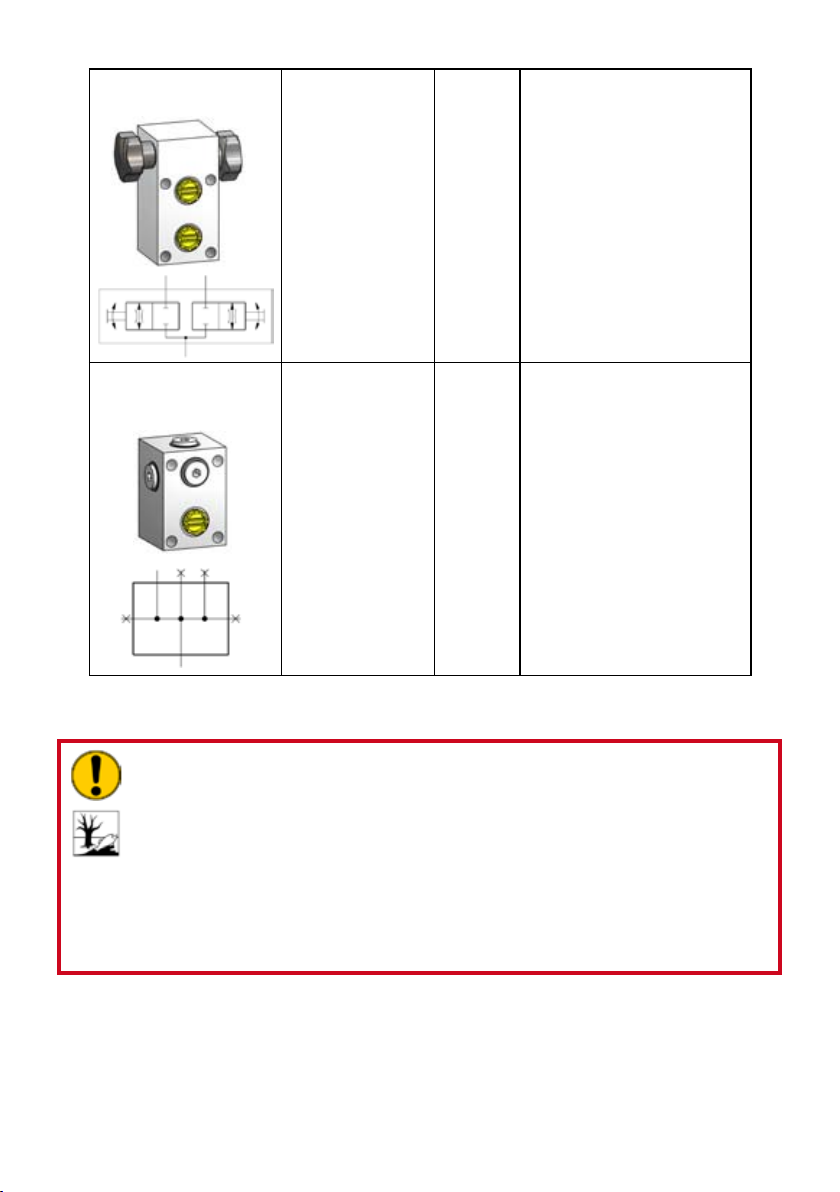

4/3-way valve 841297310 1,5 Control valve to extend

and retract double-acting

cylinders / hydraulic

devices.

10

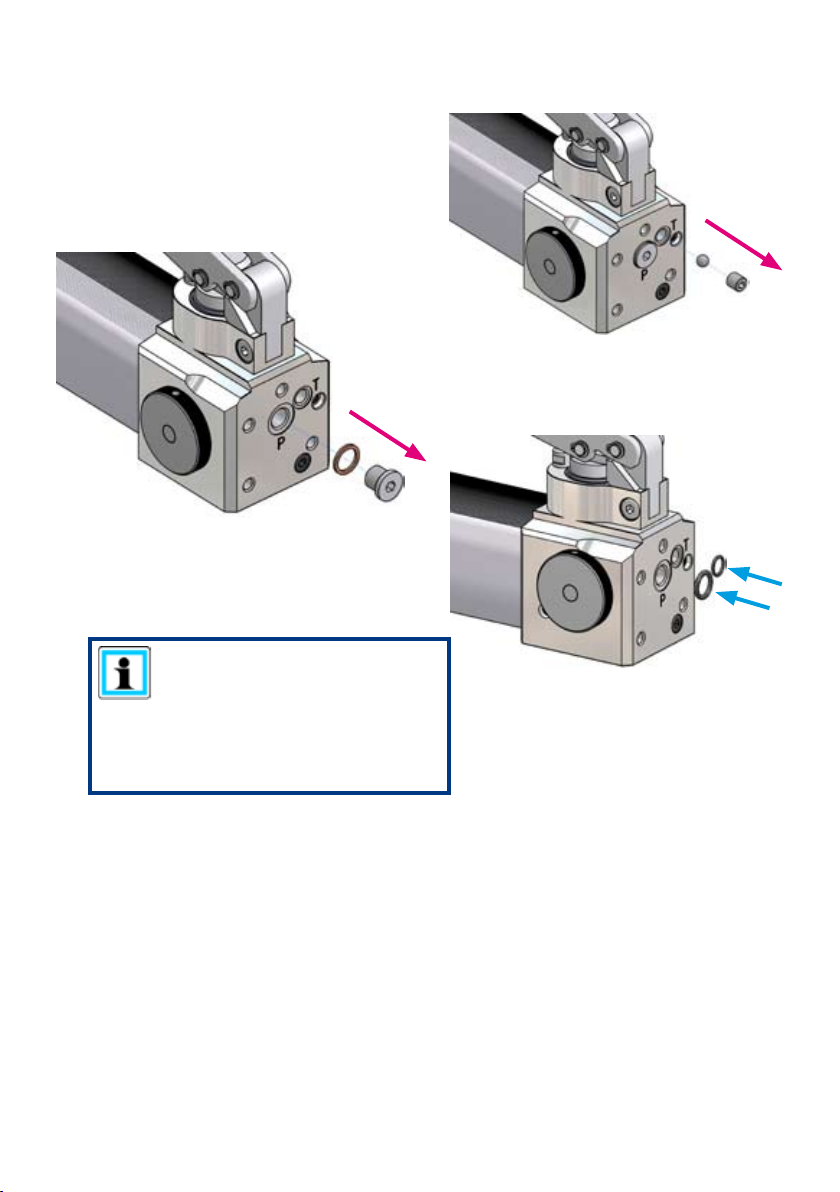

2-way-distribution

valve N2W

841489903 2,1 Distribution valve to divide

one oil ow into two ows.

By closing or opening the

valve screw, the partial

ows could be regulated

and harmonized.

(Base plate is a basic

requirement)

Oil distributor with

pressure gauge

connection N4M

841489905 1,4 By use of the oil distributor

one oil ow can be divided

into 5 ows. The distributor

has 4 pressure ports

(G1/4”) and one pressure

gauge port (G1/4”).

(Base plate is a basic

requirement)

Mounting of base plates and valve blocks6.

ATTENTION!

When mounting base plates and valve blocks, hydraulic uid can leak from

the pump. To make sure that the quantity of the leaking uid is as small as

possible, the hand pump should be in a vertical position with the hydraulic

ports facing upwards, while mounting base plates and valve blocks

Make sure to store all plugs, screw plugs and/or dust caps in a way that

prevents them from getting dirty or lost.

Especially you will have to take care that the eventually leaking hydraulic uid

is being collected completely and being disposed professionally!

11

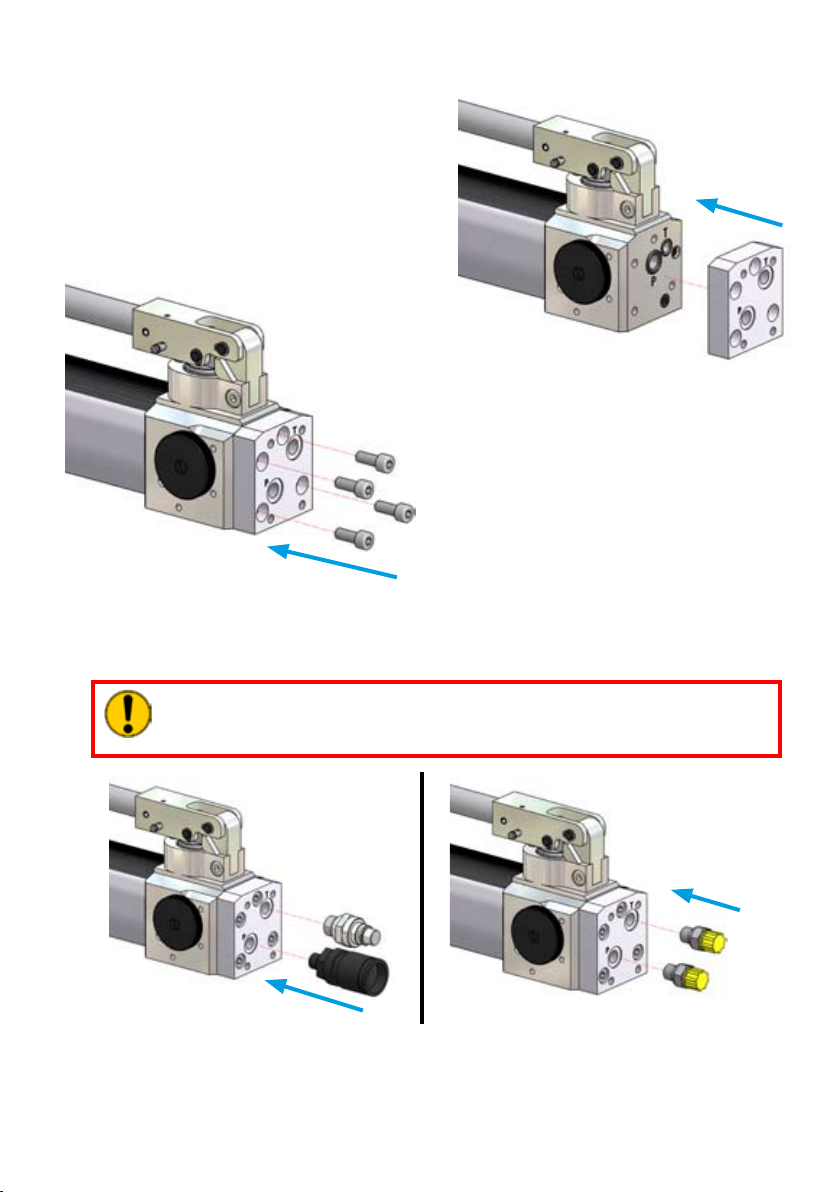

6.1 Basics for mounting base plates and valve blocks

1. Remove the closing screw of the return port

“T” and the ball behind.

2. Remove the closing screw of the pressure

line port “P” and the sealing ring behind.

3. Put the o-rings into the designated groovings

of the ports “T” and “P” .

Take care, that the surfaces are clean and

dust-free.

NOTE:

The o-rings are always part of the

mounting kits of the designated

adapter kits!

(The appropriate mounting kits

could be found in the spare parts

lists.)

12

6.2 Base plates

1. Put the base plate onto the pump head, so

that the boreholes “T” and “P” of the base

plates matches with the ports of the pump

head

Take care, that the surfaces are clean and

dust-free.

2. Put the 4 screws into the designated

boreholes and tighten them with a torque

of 20 Nm.

3. When you are connecting the hose assemblies directly to the hand pump, you will have

to mount appropriate designated couplings, ttings or closing screws to the ports “P” and

“T”. (tightening torque M

= 40 Nm)

A

ATTENTION!

After the end of the assembly close all hydraulic lines by using closing screws

and/or dust protection caps, to prevent the hand pump from impurities.

13

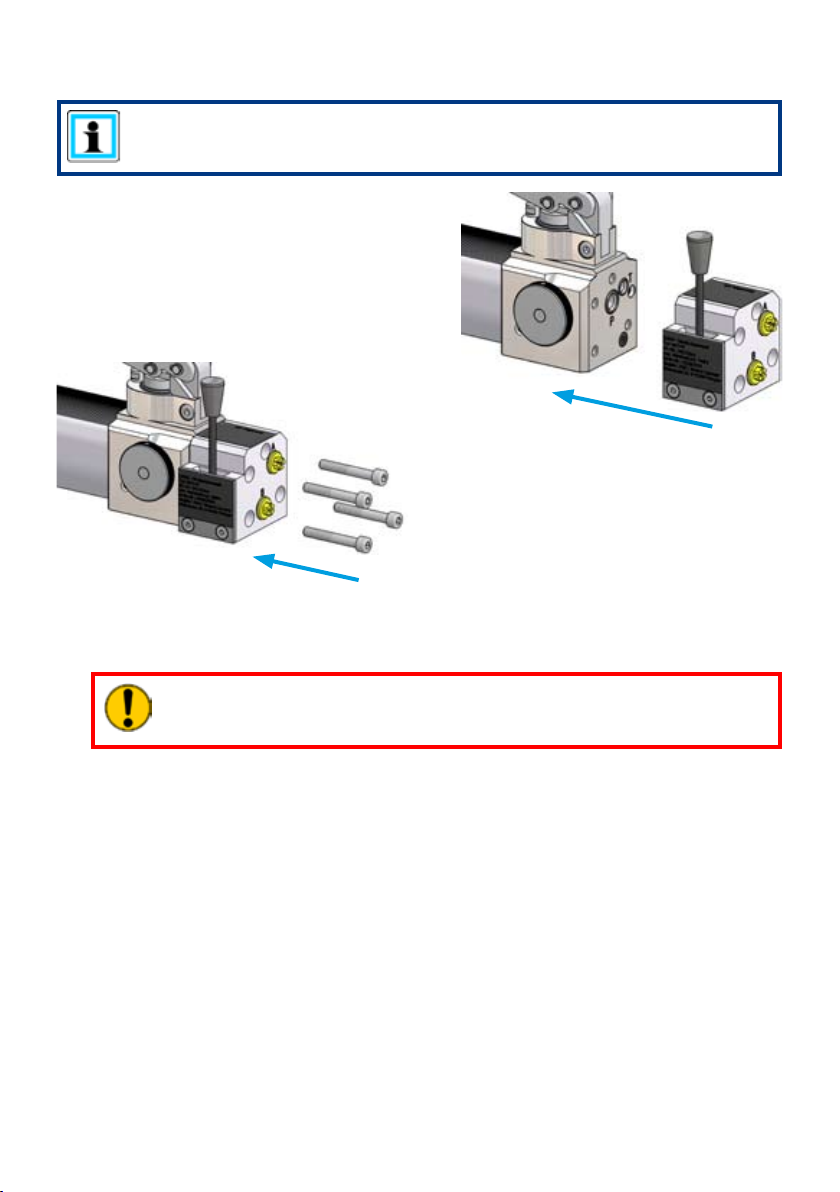

6.3 4/3-way valve

NOTE:

The article description and reference number of all listed position numbers could

be found in the spare parts lists.

1. Put the 4/3-way valve onto the pump head,

so that the boreholes “T” and “P” of the base

plates matches with the ports of the pump

head

Take care, that the surfaces are clean and

dust-free.

2. Put the 4 screws (Pos. 6.1) into the

designated boreholes and tighten them

with a torque of 20 Nm.

3. Now screw on the appropriate designated couplings, ttings or closing screws, to seal

the hand pump again.

(tightening torque M

= 40 Nm)

A

ATTENTION!

After the end of the assembly close all hydraulic lines by using closing screws

and/or dust protection caps, to prevent the hand pump from impurities.

14

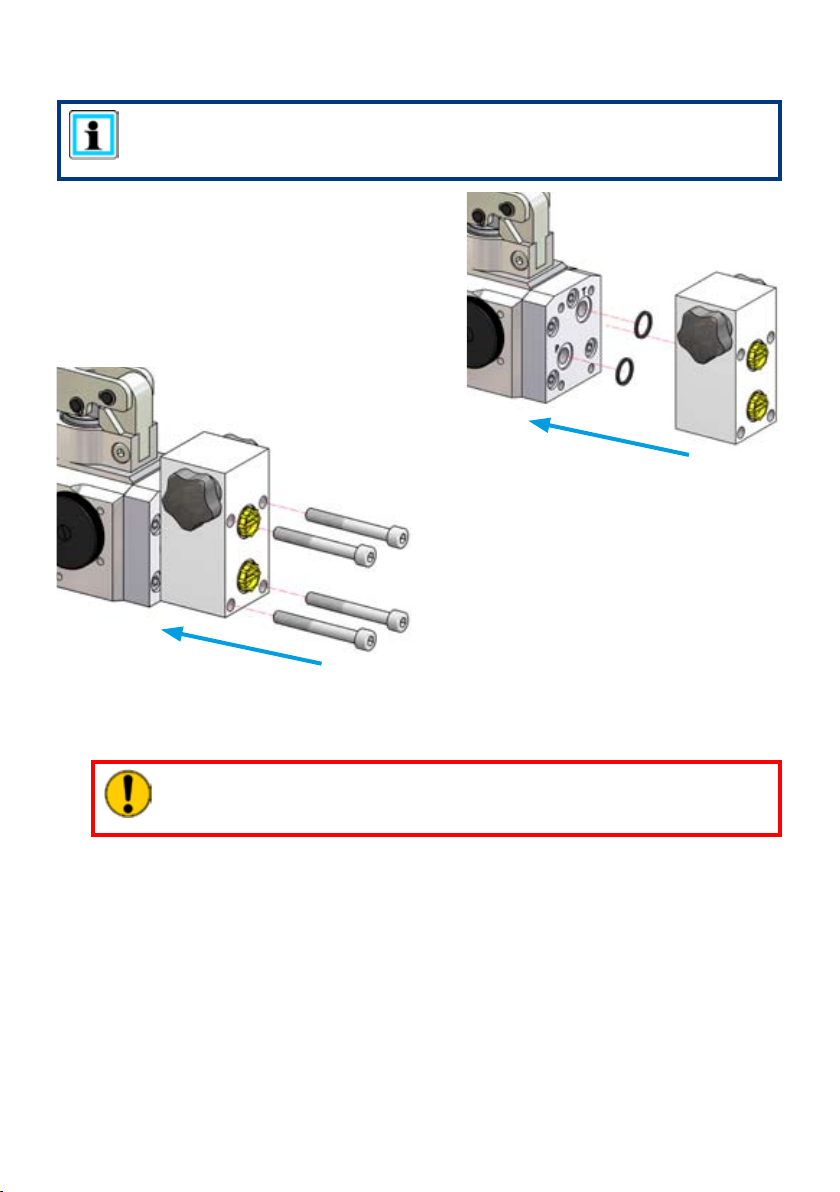

6.4 2-way distribution valve

NOTE:

To mount the 2-way distribution valve, rst the base plate without closing

screws, ttings and couplings has to be mounted.

1. Put the sealing rings and the 2-way

distribution valve onto the pump head, so

that the boreholes “T” and “P” of the 2-way

distribution valve matches with the ports of

the base plate / pump head.

Take care, that the surfaces are clean and

dust-free.

2. Put the 4 screws into the designated

boreholes and tighten them with a torque

of 32 Nm.

3. When you are connecting the hose assemblies directly to the hand pump, you will have

to mount appropriate designated couplings, ttings or closing screws to the ports “P” and

“T”. (tightening torque M

= 40 Nm)

A

ATTENTION!

After the end of the assembly close all hydraulic lines by using closing screws

and/or dust protection caps, to prevent the hand pump from impurities.

Loading...

Loading...