Page 1

Stinger® MRT

Getting Started Guide

Part Number: 7820-0969-017

For software version 9.9.0

February 2006

Page 2

Copyright © 2001, 2002, 2003, 2004, 2006 Lucent Technologies Inc. All rights reserved.

This material is protected by the copyright laws of the United States and other countries. It may not be reproduced, distributed, or altered in

any fashion by any entity (either internal or external to Lucent Technologies), except in accordance with applicable agreements, contracts, or

licensing, without the express written consent of Lucent Technologies. For permission to reproduce or distribute, please email your request to

techcomm@lucent.com.

Notice

Every effort was made to ensure that the information in this document was complete and accurate at the time of printing, but information is

subject to change. For latest information, refer to online product documentation at

European Community (EC) RTTE compliance

www.lucent.com/support.

Hereby, Lucent Technologies, declares that the equipment documented in this publication is in compliance with the essential requirements and other relevant provisions of the Radio and Telecommunications Technical Equipment (RTTE) Directive 1999/5/EC.

To view the official Declaration of Conformity certificate for this equipment, according to EN 45014, access the Lucent INS online documentation

library at

Safety, compliance, and warranty Information

http://www.lucentdocs.com/ins.

Before handling any Lucent Access Networks hardware product, read the Edge Access and Broadband Access Safety and Compliance Guide included

in your product package. See that guide also to determine how products comply with the electromagnetic interference (EMI) and network

compatibility requirements of your country. See the warranty card included in your product package for the limited warranty that Lucent

Technologies provides for its products.

Security statement

In rare instances, unauthorized individuals make connections to the telecommunications network through the use of access features.

Trademarks

Lucent, the Lucent logo, and all Lucent brand and product names are trademarks or registered trademarks of Lucent Technologies Inc. Other

brand and product names are trademarks of their respective holders.

Ordering Information

You can order the most up-to-date product information and computer-based training online at http://www.lucentdocs.com/bookstore.

Feedback

Lucent Technologies appreciates customer comments about this manual. Please send them to techcomm@lucent.com.

Lucent Technologies

Page 3

Customer Service

Product and service information, and software upgrades, are available 24 hours a day.

Technical assistance options accommodate varying levels of urgency.

Finding information and software

To obtain software upgrades, release notes, and addenda for this product, log in to

Lucent OnLine Customer Support at http://www.lucent.com/support.

Lucent OnLine Customer Support also provides technical information, product

information, and descriptions of available services. The center is open 24

seven days a week. Log in and select a service.

Obtaining technical assistance

Lucent OnLine Customer Support at http://www.lucent.com/support provides easy

access to technical support. You can obtain technical assistance through email or the

Internet, or by telephone. If you need assistance, make sure that you have the

following information available:

■ Active service or maintenance contract number, entitlement ID, or site ID

Customer Service

hours a day,

■ Product name, model, and serial number

■ Software version or release number

■ Software and hardware options

■ If supplied by your carrier, service profile identifiers (SPIDs) associated with your

line

■ Your local telephone company’s switch type and operating mode, such as AT&T

5ESS Custom or Northern Telecom National ISDN-1

■ Whether you are routing or bridging with your Lucent product

■ Type of computer you are using

■ Description of the problem

Obtaining assistance through email or the Internet

If your services agreement allows, you can communicate directly with a technical

engineer through Email Technical Support or a Live Chat. Select one of these sites

when you log in to http://www.lucent.com/support.

Calling the technical assistance center (TAC)

If you cannot find an answer through the tools and information of Lucent OnLine

Customer Support or if you have a very urgent need, contact TAC. Access Lucent

OnLine Customer Support at http://www.lucent.com/support and click Contact Us

for a list of telephone numbers inside and outside the United States.

Alternatively, call 1-866-LUCENT8 (1-866-582-3688) from any location in North

America for a menu of Lucent services. Or call +1

510-747-2000 for an operator. You

must have an active services agreement or contract.

Stinger® MRT Getting Started Guide iii

Page 4

Page 5

Contents

Customer Service ........................................................................................................iii

About This Guide .............................................................................xvii

What is in this guide ................................................................................................xvii

What you should know............................................................................................xvii

Documentation conventions ....................................................................................xvii

Stinger documentation set ......................................................................................xviii

Chapter 1 Introduction to the Stinger MRT......................................................1-1

The Stinger MRT ...................................................................................................... 1-1

Virtual slot conventions for the Stinger MRT .......................................................... 1-2

Stinger MRT models and optional products............................................................. 1-2

Chapter 2 Preparing for the Installation...........................................................2-1

Selecting an installation site ..................................................................................... 2-1

Before you begin ...................................................................................................... 2-1

Required tools and equipment ................................................................................. 2-2

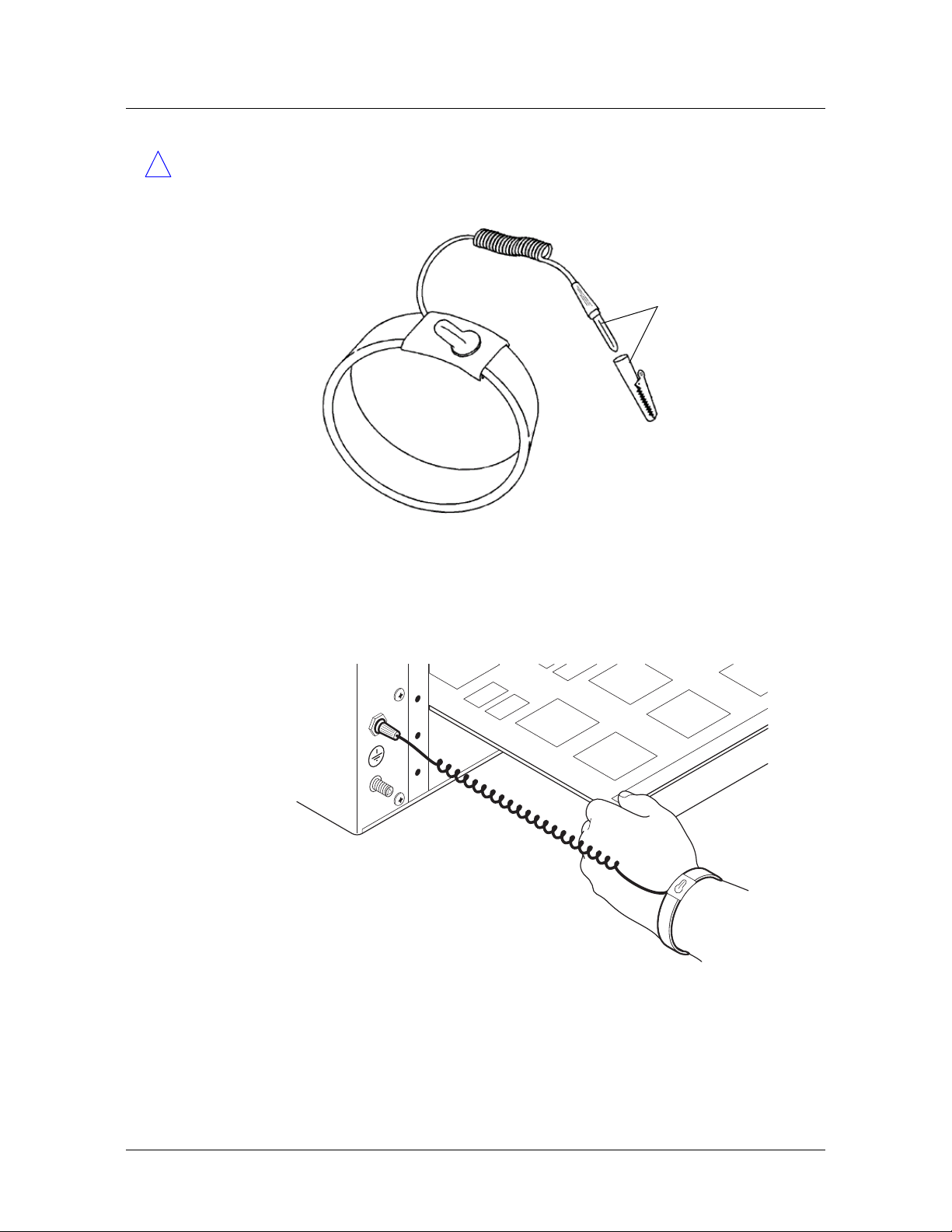

Preventing static discharge damage.......................................................................... 2-2

Use a wrist strap................................................................................................. 2-2

Remove plastics from your work area ............................................................... 2-4

Store components properly ............................................................................... 2-4

Unpacking the Stinger MRT ..................................................................................... 2-4

Verifying the hardware configuration...................................................................... 2-4

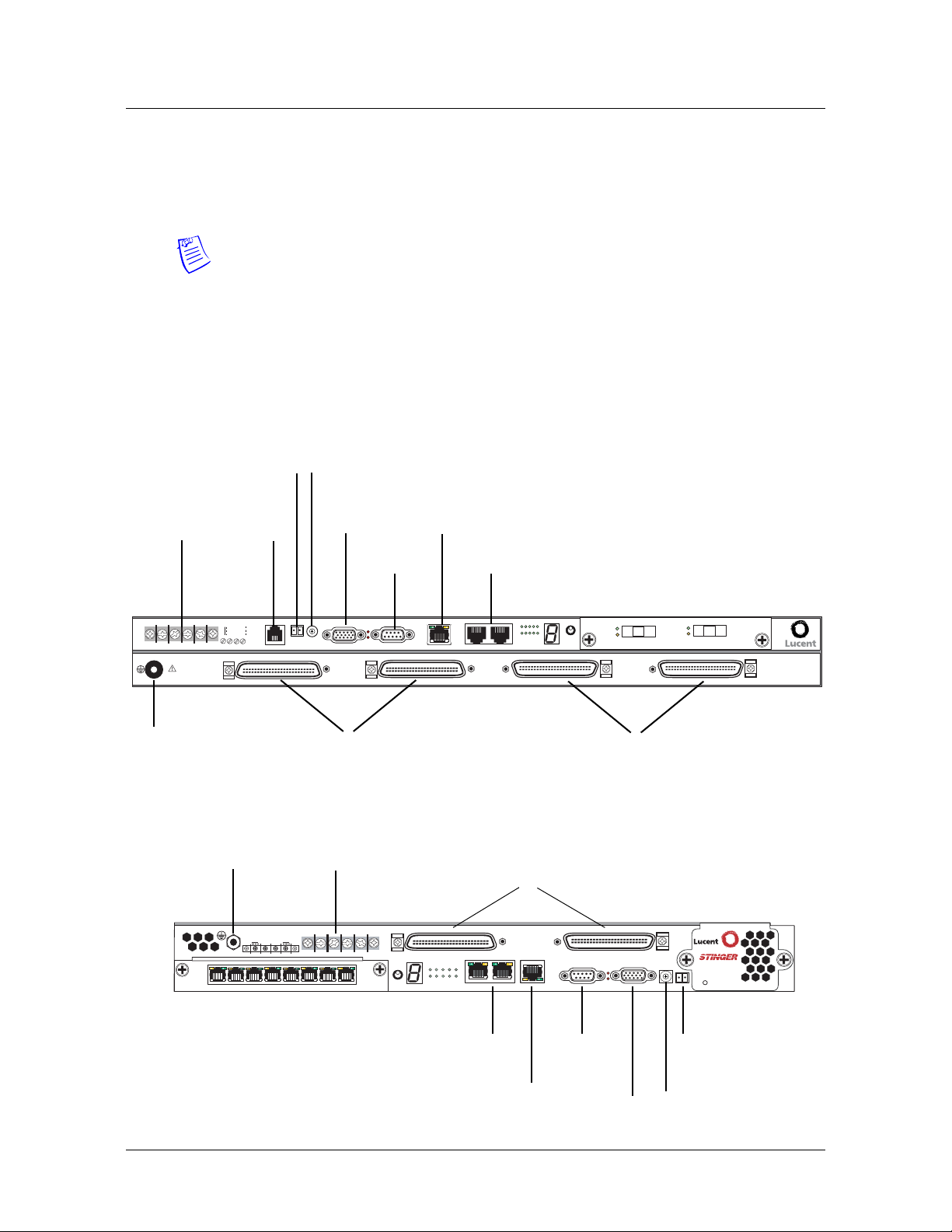

Stinger MRT interfaces ...................................................................................... 2-5

STS-3 cascading connectors ............................................................................... 2-6

Shelf ID switch................................................................................................... 2-6

Trunk module location ...................................................................................... 2-6

OC3/STM1-ATM trunk modules ....................................................................... 2-7

DS3-ATM trunk modules .................................................................................. 2-8

T1 and E1 trunk modules .................................................................................. 2-9

iii

xvii

xvii

xvii

xvii

xviii

1-1

1-1

1-2

1-2

2-1

2-1

2-1

2-2

2-2

2-2

2-4

2-4

2-4

2-4

2-5

2-6

2-6

2-6

2-7

2-8

2-9

Chapter 3 Installing a Stinger MRT ...................................................................3-1

Before you begin ...................................................................................................... 3-1

Identifying and installing mounting brackets .......................................................... 3-1

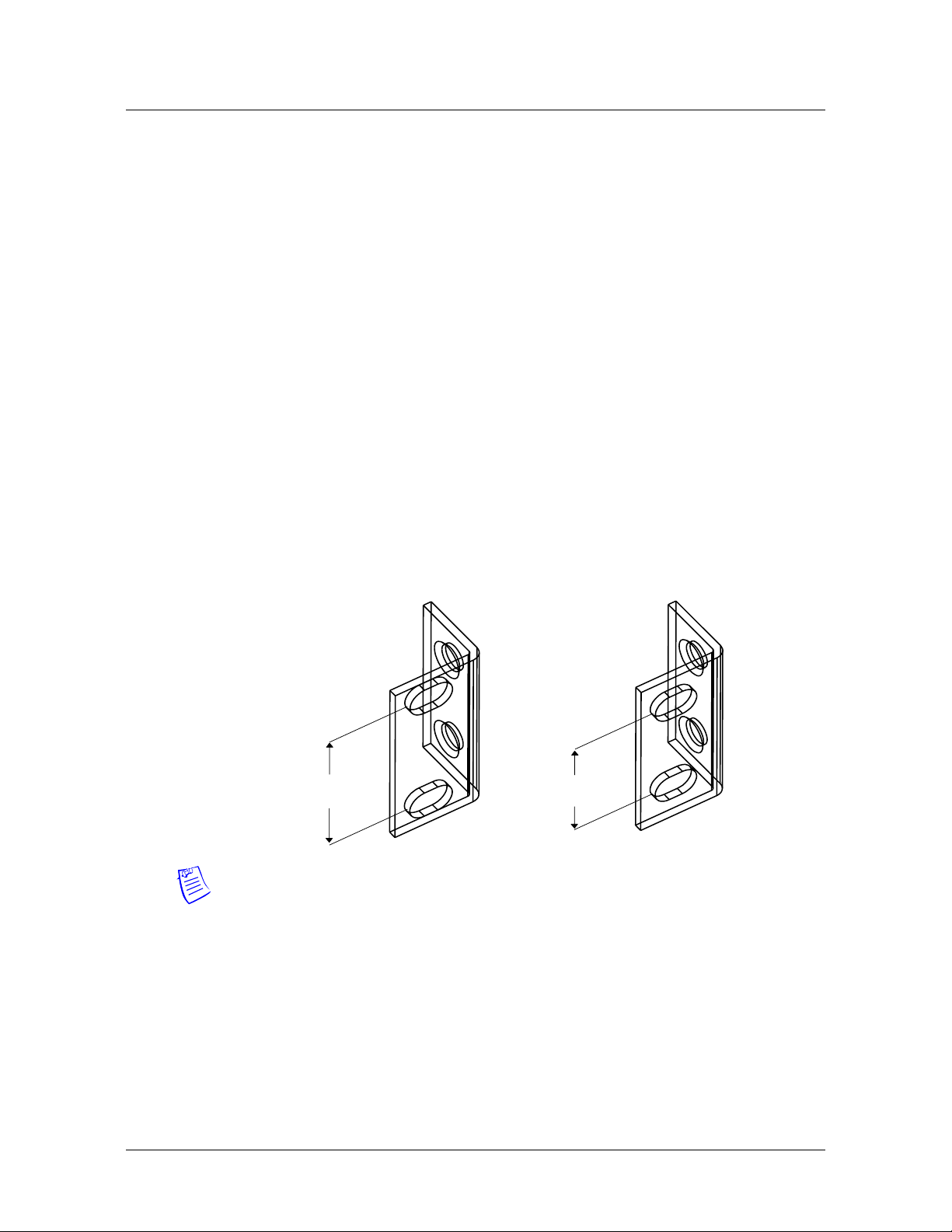

Mounting brackets for the Stinger MRT 23 ....................................................... 3-2

Standard mounting brackets ....................................................................... 3-2

Multi-position brackets ............................................................................... 3-2

Installing mounting brackets on the Stinger MRT 23........................................ 3-33-3

Stinger® MRT Getting Started Guide v

3-1

3-1

3-1

3-2

3-2

3-2

Page 6

Contents

Determining proper alignment of the multi-position brackets ................... 3-3

Installing the mounting brackets................................................................. 3-4

Mounting brackets for the Stinger MRT 19 ....................................................... 3-5

23-inch mounting brackets for the Stinger MRT 19 ................................... 3-5

Installing the 23-inch mounting brackets on the Stinger MRT 19.............. 3-5

19-inch ETSI mounting brackets for the Stinger MRT 19 ........................... 3-6

Installing the 19-inch ETSI mounting brackets on the Stinger MRT 19 ..... 3-7

EIA mounting brackets for the Stinger MRT 19.......................................... 3-8

Installing the EIA mounting brackets on the Stinger MRT 19 .................... 3-9

Mounting the MRT in an equipment rack ............................................................... 3-9

Mounting the Stinger MRT units in a 23-inch rack ........................................ 3-10

Mounting the Stinger MRT 19 in smaller equipment racks ............................ 3-10

Installing and removing trunk modules................................................................. 3-12

Installing a trunk module ................................................................................ 3-12

Removing a trunk module............................................................................... 3-13

MRT cooling ........................................................................................................... 3-13

Replacing the cooling module on the Stinger MRT 19 .......................................... 3-14

Connecting cables to a Stinger MRT unit ............................................................... 3-15

50-pin connectors details................................................................................. 3-16

Connecting the subscriber lines ....................................................................... 3-16

Connecting the POTS lines .............................................................................. 3-18

Disconnecting a 50-pin connector ................................................................... 3-19

Recommended method to disconnect a 50-pin connector........................ 3-19

Alternate method to disconnect a 50-pin connector................................. 3-20

Connecting the STS-3 cascading connections.................................................. 3-20

Connecting the trunk module ......................................................................... 3-22

OC3/STM1-ATM trunk module connections ............................................ 3-22

DS3-ATM trunk module connections ....................................................... 3-22

T1 or E1 trunk module connections.......................................................... 3-23

Network management connections ....................................................................... 3-23

System clocking...................................................................................................... 3-24

Alarm monitoring .................................................................................................. 3-24

Connecting to monitor Stinger MRT alarm status ........................................... 3-24

Connecting a Stinger MRT to monitor the alarm status of other devices........ 3-25

3-3

3-4

3-5

3-5

3-5

3-6

3-7

3-8

3-9

3-9

3-10

3-10

3-12

3-12

3-13

3-13

3-14

3-15

3-16

3-16

3-18

3-19

3-19

3-20

3-20

3-22

3-22

3-22

3-23

3-23

3-24

3-24

3-24

3-25

Chapter 4 Determining the Operating Status ..................................................4-1

Before you begin ...................................................................................................... 4-1

Power requirements ................................................................................................. 4-1

Connecting power to a Stinger MRT unit ................................................................ 4-2

Monitoring backup power to a Stinger MRT ........................................................... 4-3

Turning on power to a Stinger MRT unit................................................................. 4-4

Turning off power to a Stinger MRT unit ................................................................ 4-4

Status lights .............................................................................................................. 4-4

Monitoring the status of the DSL ports .................................................................... 4-7

Chapter 5 Stinger MRT Operational Overview ................................................5-1

Stinger MRT operation as a DSL access multiplexer ................................................ 5-1

Operation with integrated splitters .................................................................... 5-1

Operation without splitters................................................................................ 5-2

Stinger MRT ATM switching overview .................................................................... 5-3

Stinger MRT configuration overview ....................................................................... 5-35-3

vi Stinger® MRT Getting Started Guide

4-1

4-1

4-1

4-2

4-3

4-4

4-4

4-4

4-7

5-1

5-1

5-1

5-2

5-3

Page 7

Contents

Administrative configuration............................................................................. 5-4

Line configuration ............................................................................................. 5-4

Trunk module configuration ............................................................................. 5-4

System clocking modes ...................................................................................... 5-5

Stinger MRT management features.......................................................................... 5-5

Using the command-line interface .................................................................... 5-5

Onboard flash memory and software updates ................................................... 5-6

SNMP support.................................................................................................... 5-6

RADIUS support ................................................................................................ 5-6

Tracking system activity..................................................................................... 5-6

What’s next .............................................................................................................. 5-7

Chapter 6 Configuring Administrative Access, System Timing, and Startup

Settings ........................................................................................6-1

Administrative configuration overview ................................................................... 6-1

Making the initial administrative connection .......................................................... 6-2

Logging into the Stinger MRT .................................................................................. 6-3

Restricting administrative access .............................................................................. 6-3

Changing defaults for serial-port logins............................................................. 6-3

Changing the default admin password .............................................................. 6-4

Setting a Telnet password .................................................................................. 6-5

Providing a basic system IP configuration ................................................................ 6-6

IP address syntax ............................................................................................... 6-6

Netmasks............................................................................................................ 6-6

Subnets .............................................................................................................. 6-6

Assigning the Ethernet IP addresses .................................................................. 6-8

Configuring a default route ............................................................................... 6-9

Additional administrative connections and configuration ....................................... 6-9

Connecting to an Ethernet LAN ...................................................................... 6-10

Verifying a LAN connection for administrators ............................................... 6-10

Connecting to and configuring an external modem ........................................ 6-11

Connecting to and configuring an internal modem ........................................ 6-12

Configuring an internal modem................................................................ 6-12

Administrative terminating PVC connections ................................................. 6-13

Overview of a terminating ATM connection ............................................ 6-13

Overview of terminating PVC settings ...................................................... 6-14

Typical terminating PVC configuration for an administrative connection 6-16

Checking the status of a terminating PVC ....................................................... 6-18

Configuring system clocking (optional) ................................................................. 6-19

Using the BITS clock source............................................................................. 6-19

Loss of BITS signal indications and fall-back............................................. 6-19

Changing the BITS clock source................................................................ 6-20

Using a trunk module clock source ................................................................. 6-21

Configuring trunk ports as eligible clock sources ...................................... 6-21

Typical trunk port clock source configurations ......................................... 6-22

Retaining basic configuration settings for remote administration.......................... 6-22

Storing a partial configuration for restart after clearing NVRAM .................... 6-22

Allowing password information in the default.cfg file .............................. 6-23

Creating the default.cfg file ....................................................................... 6-23

Restarting with a partial configuration ............................................................ 6-24

Saving and loading a backup configuration ........................................................... 6-246-24

5-4

5-4

5-4

5-5

5-5

5-5

5-6

5-6

5-6

5-6

5-7

6-1

6-1

6-2

6-3

6-3

6-3

6-4

6-5

6-6

6-6

6-6

6-6

6-8

6-9

6-9

6-10

6-10

6-11

6-12

6-12

6-13

6-13

6-14

6-18

6-19

6-19

6-19

6-20

6-21

6-21

6-22

6-22

6-22

6-23

6-23

6-24

Stinger® MRT Getting Started Guide vii

Page 8

Contents

Saving the configuration.................................................................................. 6-24

Saving the full configuration to a local file ............................................... 6-25

Saving the configuration to a network host.............................................. 6-25

Restoring the configuration ............................................................................. 6-25

Restoring from a local file ......................................................................... 6-25

Restoring from a network host ................................................................. 6-26

Chapter 7 Configuring the ADSL Line Interfaces .............................................7-1

Configuring ATM ADSL-DMT interfaces ................................................................. 7-1

Overview of the AL-DMT profile ....................................................................... 7-2

ADSL protocol support ...................................................................................... 7-2

Line activation and DMT parameters ................................................................ 7-2

AL-DMT profile ........................................................................................... 7-3

Line-Config subprofile................................................................................. 7-3

Rate-adaptive mode parameters.................................................................. 7-5

Power-level parameters and power spectral density (PSD) ........................ 7-6

Fast and interleaved bit-rate parameters ........................................................... 7-7

Fast-Path-Config subprofile......................................................................... 7-7

Interleave-Path-Config subprofile ............................................................... 7-8

Margin-Config subprofile .......................................................................... 7-10

Configuring call control.......................................................................................... 7-11

Examples of ADSL-DMT interface configuration ................................................... 7-13

Checking the status of an ADSL-DMT interface .................................................... 7-14

Checking status of the physical interface......................................................... 7-15

Obtaining statistics about operations ............................................................... 7-16

Displaying ADSL-DMT port status and nailed groups ..................................... 7-18

ADSL line specifications ......................................................................................... 7-18

6-24

6-25

6-25

6-25

6-25

6-26

7-1

7-1

7-2

7-2

7-2

7-3

7-3

7-5

7-6

7-7

7-7

7-8

7-10

7-11

7-13

7-14

7-15

7-16

7-18

7-18

Chapter 8 Configuring the SHDSL line interfaces ............................................8-1

Configuring SHDSL interfaces .................................................................................. 8-1

Configuring port settings for SHDSL.................................................................. 8-2

Sample SHDSL mode configuration .................................................................. 8-9

Binding two SHDSL ports .................................................................................. 8-9

Displaying SHDSL port status .......................................................................... 8-10

Configuring call control.......................................................................................... 8-11

Checking the status of an SHDSL interface ............................................................ 8-12

Checking the status of the physical interface .................................................. 8-13

Obtaining statistics about operations ............................................................... 8-14

Diagnostic internal, external, and bit error-rate tests ............................................ 8-16

Configuring an internal diagnostic test (IDT) .................................................. 8-18

Configuring a bit-error-rate test (BERT).......................................................... 8-19

Configuring an external diagnostic test (EDT) ................................................ 8-19

Digital loopback......................................................................................... 8-20

Analog loopback........................................................................................ 8-20

Interface standards........................................................................................... 8-21

Embedded Operations Channel (EOC) protocol compliance .......................... 8-21

Chapter 9 Configuring T1 and E1 Trunk Modules............................................9-1

Introducing the T1 and E1 trunk modules............................................................... 9-2

Overview of supported features ............................................................................... 9-29-2

8-1

8-1

8-2

8-9

8-9

8-10

8-11

8-12

8-13

8-14

8-16

8-18

8-19

8-19

8-20

8-20

8-21

8-21

9-1

9-2

viii Stinger® MRT Getting Started Guide

Page 9

Contents

Installing a T1 or E1 trunk module .......................................................................... 9-3

Connecting a T1 or E1 trunk module ...................................................................... 9-3

Interpreting T1 or E1 module status lights ............................................................... 9-4

Profiles associated with a T1 or E1 module.............................................................. 9-4

DS1-ATM profile ...................................................................................................... 9-5

DS1-ATM-Stat profile............................................................................................. 9-11

Slot-Static-Config profile ........................................................................................ 9-14

IMAgroup profile.................................................................................................... 9-15

IMAHW-Config profile ........................................................................................... 9-20

IMA-Group-Stat profile.......................................................................................... 9-21

Connection profile.................................................................................................. 9-25

Configuring T1 or E1 module connections ............................................................ 9-28

Typical UNI configuration................................................................................ 9-29

Typical IMA configuration ............................................................................... 9-30

Typical return to UNI configuration from IMA ............................................... 9-32

Considerations for assigning a nailed group number to a DS1-ATM profile ... 9-33

Commands for checking T1 or E1 IMA performance ............................................ 9-34

Checking line status with the IMAlines command.......................................... 9-34

Checking group status with the IMAgroups command ................................... 9-35

Testing connectivity with the IMA-TPP command .......................................... 9-36

T1 and E1 module specifications ............................................................................ 9-36

Specifications common to T1 and E1 line modules ......................................... 9-36

Specifications unique to T1 line modules ........................................................ 9-38

Specifications unique to E1 line modules ........................................................ 9-39

Compliance with IMA specifications ............................................................... 9-39

Compliance with ATM specifications............................................................... 9-41

9-3

9-3

9-4

9-4

9-5

9-11

9-14

9-15

9-20

9-21

9-25

9-28

9-29

9-30

9-32

9-33

9-34

9-34

9-35

9-36

9-36

9-36

9-38

9-39

9-39

9-41

Chapter 10 Configuring an OC3-ATM Trunk Module ......................................10-1

Installing an OC3-ATM trunk module ................................................................... 10-1

Connecting an OC3-ATM trunk module ............................................................... 10-1

Interpreting OC3-ATM status lights ....................................................................... 10-2

Configuring an OC3-ATM trunk module............................................................... 10-3

Overview of OC3-ATM settings ....................................................................... 10-3

Displaying OC3-ATM status and nailed groups ............................................... 10-5

Changing physical-layer interface settings ...................................................... 10-6

Call control............................................................................................................. 10-6

Example of OC3-ATM configuration ..................................................................... 10-6

Checking OC3-ATM trunk interface status ............................................................ 10-6

Monitoring the OC3 interface.......................................................................... 10-7

Monitoring errors and performance of the SONET payload............................ 10-9

SONET performance and error counters ................................................. 10-10

Performance-Monitoring and Interval-Performance-Monitoring

subprofiles .................................................................................. 10-11

OC3-ATM trunk module specifications................................................................ 10-13

Module specifications .................................................................................... 10-13

Cable specifications ........................................................................................ 10-14

Chapter 11 Configuring a DS3-ATM Trunk Module.........................................11-1

Installing a DS3-ATM trunk module...................................................................... 11-1

Connecting a DS3-ATM trunk module .................................................................. 11-2

Interpreting DS3-ATM status lights ....................................................................... 11-211-2

10-1

10-1

10-1

10-2

10-3

10-3

10-5

10-6

10-6

10-6

10-6

10-7

10-9

10-10

10-11

10-13

10-13

10-14

11-1

11-1

11-2

Stinger® MRT Getting Started Guide ix

Page 10

Contents

Configuring a DS3-ATM trunk module ................................................................. 11-3

Displaying DS3-ATM port status and nailed groups ........................................ 11-5

Setting DS3 framing formats............................................................................ 11-6

Call control............................................................................................................. 11-6

Example of DS3-ATM configuration ...................................................................... 11-6

Checking DS3-ATM trunk interface status ............................................................ 11-7

Traffic aggregation with the DS3-ATM module ..................................................... 11-9

DS3-ATM traffic aggregation connection ........................................................ 11-9

Aggregation failure protection with the DS3-ATM bypass feature................ 11-10

DS3-ATM trunk module specifications ................................................................ 11-10

Appendix A Stinger MRT Intended Use...............................................................A-1

User line interfaces ...................................................................................................A-1

Network interfaces ...................................................................................................A-1

Administrative interfaces .........................................................................................A-2

Appendix B Hosted Operation of Cascaded Stinger MRT units........................ B-1

Introduction to the host management interface ...................................................... B-1

Configuring hosted MRT system operations ............................................................ B-2

Cabling Stinger MRT units together ..................................................................B-3

Configuring the remote shelves.........................................................................B-4

Configuring the host system to operate in master mode ................................... B-5

Enabling the remote shelves in the hosted system............................................B-5

Checking the hosted system topology ............................................................... B-6

Provisioning virtual circuits in the hosted system ............................................. B-7

Restoring a remote shelf to standalone operations............................................ B-8

Traffic management in hosted MRT systems ...........................................................B-8

Deprecated atm-config profile...........................................................................B-8

LIM slot CAC support ........................................................................................ B-9

Hosted MRT system bandwidth and CAC calculations......................................B-9

Upstream traffic shaping in a hosted system ................................................... B-11

Hosted MRT system management..........................................................................B-11

Upgrading hosted MRT system software ......................................................... B-11

Required steps before initializing NVRAM in the host..............................B-12

Automatic upgrade procedure...................................................................B-12

Manual upgrade via loadslave (optional procedure) ............................... B-13

Resetting a hosted system ......................................................................... B-14

Monitoring remote LIMs and connections ...................................................... B-15

Displaying status of remote DSL lines ....................................................... B-15

Displaying shelf-specific ATM connection and signaling information ......B-15

Monitoring the status of remote shelves ......................................................... B-16

Using the remote-shelf-stat profile ........................................................ B-16

Using the remoteshelf command..............................................................B-17

Setting alarms for events on remote shelves ............................................. B-18

Enabling traps for events on remote shelves............................................. B-20

Displaying hosted MRT system topology and statistics .................................... B-22

Displaying the entire topology ..................................................................B-22

Displaying a picture of the topology..........................................................B-24

Displaying the details for a specific shelf ................................................... B-24

Displaying statistics for a specific shelf ...................................................... B-24

Sending an init packet to a remote shelf ................................................... B-26B-26

11-3

11-5

11-6

11-6

11-6

11-7

11-9

11-9

11-10

11-10

A-1

A-1

A-1

A-2

B-1

B-1

B-2

B-3

B-4

B-5

B-5

B-6

B-7

B-8

B-8

B-8

B-9

B-9

B-11

B-11

B-11

B-12

B-12

B-13

B-14

B-15

B-15

B-15

B-16

B-16

B-17

B-18

B-20

B-22

B-22

B-24

B-24

B-24

x Stinger® MRT Getting Started Guide

Page 11

Contents

Appendix C Cables and Connectors .................................................................... C-1

CONSOLE port and cable pinouts ............................................................................C-1

Alarm connector pinouts .........................................................................................C-2

Ethernet interface specifications ..............................................................................C-3

STS-3 (synchronous transport signals-3) connector specifications .......................... C-3

50-pin telephone company connector cable specifications...................................... C-4

Pinouts for subscriber line DSL connections......................................................C-4

Pinouts for POTS connections to a voice switch................................................ C-7

T1 and E1 connector and cable specifications ..........................................................C-9

T1 and E1 connector specifications....................................................................C-9

T1 and E1 cable specifications............................................................................ C-9

T1 or E1 crossover cable: RJ-48C/RJ-48C .................................................C-10

T1 or E1 straight-through cable: RJ-48C/RJ-48C .....................................C-11

T1 or E1 straight-through cable: RJ-48C/DB-15 ....................................... C-12

T1 or E1 crossover cable: RJ-48C/DB-15 .................................................. C-13

T1 or E1 straight-through cable: RJ-48C/Bantam..................................... C-14

T1 or E1 RJ-48C-Loopback plug ............................................................... C-14

C-1

C-1

C-2

C-3

C-3

C-4

C-4

C-7

C-9

C-9

C-9

C-10

C-11

C-12

C-13

C-14

C-14

Appendix D Safety-Related Electrical, Physical, and Environmental

Information .................................................................................D-1

Electrical and electronic information .......................................................................D-1

Electronic and electrical specifications...............................................................D-1

USOC jack and code information ......................................................................D-2

ADSL line ringer equivalence number (REN) ...................................................D-3

EMI compatibility ..............................................................................................D-3

Certifications ......................................................................................................D-4

Minimum ground wire size ...............................................................................D-4

Physical specifications ..............................................................................................D-4

Safety certifications ..................................................................................................D-5

Site specifications .....................................................................................................D-5

Operating environment .....................................................................................D-5

Space requirements ...........................................................................................D-6

D-1

D-1

D-1

D-2

D-3

D-3

D-4

D-4

D-4

D-5

D-5

D-5

D-6

Index .....................................................................................................1

Stinger® MRT Getting Started Guide xi

Page 12

Page 13

Figures

Figure 2-1 Wrist grounding strap ....................................................................... 2-3

Figure 2-2 Wrist strap plugged into a grounding jack ........................................ 2-3

Figure 2-3 Stinger MRT 23 chassis connectors ................................................... 2-5

Figure 2-4 Stinger MRT 19 chassis connectors ................................................... 2-5

Figure 2-5 Stinger MRT 23 trunk module location ............................................ 2-7

Figure 2-6 Stinger MRT 19 trunk module location ............................................ 2-7

Figure 2-7 OC3-ATM trunk module for the MRT 23 chassis ............................. 2-8

Figure 2-8 OC3-ATM trunk module for the MRT 19 chassis ............................. 2-8

Figure 2-9 DS3-ATM trunk module for the MRT 23 chassis .............................. 2-9

Figure 2-10 DS3-ATM trunk module for the MRT 19 chassis .............................. 2-9

Figure 2-11 T1 or E1 trunk module for the MRT 23 chassis ................................ 2-9

Figure 2-12 T1 or E1 trunk module for the MRT 19 chassis ................................ 2-9

Figure 3-1 Stinger MRT 23 mounting brackets .................................................. 3-2

Figure 3-2 Multi-position mounting brackets..................................................... 3-3

Figure 3-3 Determining the mounting position of the multi-position bracket... 3-4

Figure 3-4 Installing mounting brackets............................................................. 3-4

Figure 3-5 23-inch rack mounting brackets for the Stinger MRT 19 ................. 3-5

Figure 3-6 Installing 23-inch brackets on the Stinger MRT 19........................... 3-6

Figure 3-7 19-inch rack mounting brackets for the Stinger MRT 19 ................. 3-7

Figure 3-8 Installing ETSI 19-inch brackets on the MRT 19............................... 3-8

Figure 3-9 EIA rack mounting brackets for the Stinger MRT 19 ........................ 3-8

Figure 3-10 Installing EIA brackets on the MRT 19 ............................................. 3-9

Figure 3-11 Placing Stinger MRT 23 and Stinger MRT 19 chassis in a 23-inch

rack.................................................................................................. 3-10

Figure 3-12 Placing Stinger MRT 19 chassis in a smaller equipment rack ......... 3-11

Figure 3-13 Installing an MRT 23 trunk module................................................ 3-12

Figure 3-14 Installing an MRT 19 trunk module................................................ 3-13

Figure 3-15 Removing the cooling module of a Stinger MRT 19 ....................... 3-14

Figure 3-16 Installing a replacement cooling module ........................................ 3-15

Figure 3-17 50-pin connector security mechanisms........................................... 3-16

Figure 3-18 Connecting the subscriber lines to the Stinger MRT 23 .................. 3-17

Figure 3-19 Connecting the subscriber lines to the Stinger MRT 19 .................. 3-18

Figure 3-20 Connecting the POTS lines.............................................................. 3-19

Figure 3-21 Removing the 50-pin connector (recommended method) ............. 3-20

Figure 3-22 Removing the 50-pin connector (alternate method) ...................... 3-20

Figure 3-23 Connecting the STS-3 cascading connection .................................. 3-21

Figure 3-24 Connecting an OC3-ATM trunk module ........................................ 3-22

Figure 3-25 Connecting DS3-ATM trunk modules ............................................ 3-23

Figure 3-26 Connecting a T1 or E1 trunk module ............................................. 3-23

Figure 4-1 Removing the power terminal shield of a Stinger MRT 23............... 4-2

Figure 4-2 Connecting the -48Vdc power filters on the MRT 23 ....................... 4-3

Figure 4-3 Connecting the -48Vdc power filters on the MRT 19 ....................... 4-3

Figure 4-4 Stinger MRT 23 status light locations................................................ 4-54-5

2-3

2-3

2-5

2-5

2-7

2-7

2-8

2-8

2-9

2-9

2-9

2-9

3-2

3-3

3-4

3-4

3-5

3-6

3-7

3-8

3-8

3-9

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-20

3-20

3-21

3-22

3-23

3-23

4-2

4-3

4-3

Stinger® MRT Getting Started Guide xiii

Page 14

Figures

Figure 4-5 Stinger MRT 19 Status light locations ............................................... 4-5

Figure 4-6 The port group selector switch and group indicator LED.................. 4-7

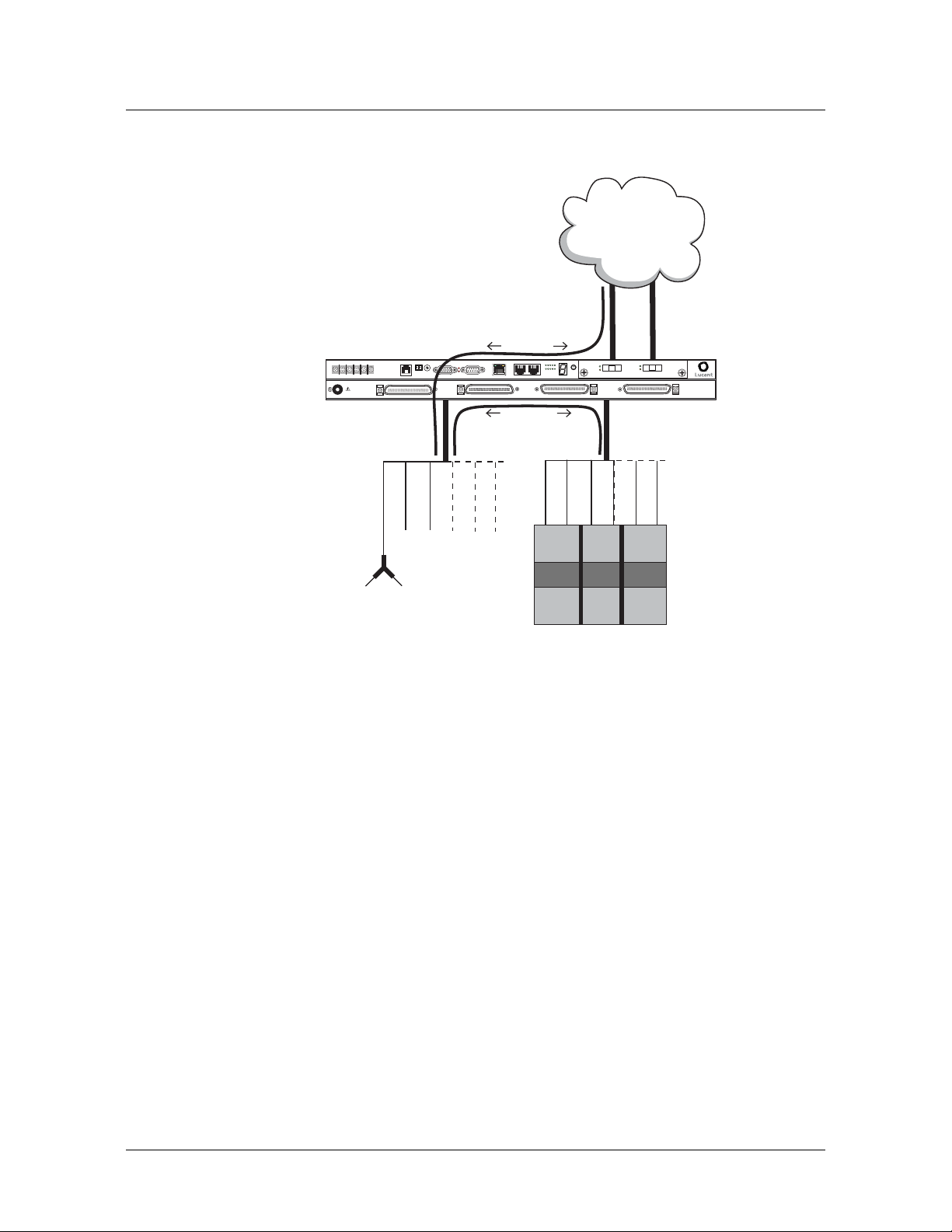

Figure 5-1 Example of DSLAM operations with splitters for POTS service ........ 5-2

Figure 5-2 Example of pure DSLAM operation .................................................. 5-3

Figure 6-1 Serial management connection to the Stinger MRT ......................... 6-2

Figure 6-2 Default netmask for class C IP address .............................................. 6-6

Figure 6-3 Local backbone router to be used as default route............................ 6-9

Figure 6-4 Ethernet connection........................................................................ 6-10

4-5

4-7

5-2

5-3

6-2

6-6

6-9

6-10

Figure 6-5 Administrative connection with a modem to the Stinger MRT

unit.................................................................................................. 6-11

Figure 6-6 Connection for internal modem...................................................... 6-12

Figure 6-7 Terminating ATM connection ......................................................... 6-14

Figure 6-8 Management connection from a remote network .......................... 6-17

6-11

6-12

6-14

6-17

Figure 7-1 Relationship between noise margin parameters and power

adjustments ..................................................................................... 7-10

Figure 7-2 ADSL ATM configuration................................................................ 7-13

Figure 8-1 Digital loopback............................................................................... 8-20

Figure 8-2 Analog loopback.............................................................................. 8-20

Figure 9-1 T1 or E1 trunk module for a Stinger MRT 23 ................................... 9-3

Figure 9-2 Connecting a T1 or E1 trunk module for the MRT 23 ...................... 9-3

Figure 9-3 Connecting a T1 or E1 trunk module for the MRT 19 ...................... 9-3

Figure 9-4 Sample UNI configuration links ...................................................... 9-29

Figure 9-5 Sample IMA configuration links ..................................................... 9-31

Figure 10-1 Connecting an OC3-ATM trunk module for an MRT 23 ................ 10-2

Figure 10-2 Connecting an OC3-ATM trunk module for an MRT 19 ................ 10-2

Figure 10-3 OC3-ATM trunk module................................................................. 10-3

Figure 10-4 SONET layers................................................................................. 10-10

Figure 11-1 Connecting a DS3-ATM trunk module for the Stinger MRT 23 ..... 11-2

7-10

7-13

8-20

8-20

9-3

9-3

9-3

9-29

9-31

10-2

10-2

10-3

10-10

11-2

Figure 11-2 Front panel of the DS3-ATM trunk module for the Stinger

MRT 23............................................................................................ 11-3

Figure 11-3 DS3-ATM traffic aggregation connection ........................................ 11-9

Figure B-1 Hosted MRT system........................................................................... B-3

Figure B-2 SHELF ID switch on a Stinger MRT back panel ................................ B-4

Figure B-3 Sample hosted virtual circuit configuration ...................................... B-7

11-3

11-9

B-3

B-4

B-7

Figure B-4 Slot-level CAC bandwidth calculations performed with default

settings ............................................................................................ B-10

Figure B-5 Port-level CAC sequence (performed only at provisioning time) ... B-11

Figure C-1 USOC RJ-21X 50-pin connector ....................................................... C-4

Figure C-2 RJ-48C/RJ-48C crossover cable. ..................................................... C-10

Figure C-3 RJ-48C/RJ-48C straight-through cable specifications ..................... C-11

Figure C-4 RJ-48C/DB-15 straight-through cable ............................................ C-12

Figure C-5 RJ-48C/DB-15 crossover cable........................................................ C-13

B-10

B-11

C-4

C-10

C-11

C-12

C-13

Figure C-6 RJ-48C/Bantam straight-through cable .......................................... C-14C-14

xiv Stinger® MRT Getting Started Guide

Page 15

Tab le s

Table 1-1 Stinger MRT virtual slots................................................................... 1-2

Table 1-2 Stinger MRT models and optional products ...................................... 1-3

Table 3-1 Alarm connector pinouts for Stinger MRT alarms .......................... 3-25

Table 3-2 Alarm connector pinouts for monitoring the alarm status of remote

devices ............................................................................................. 3-25

Table 4-1 Status lights on the Stinger MRT 23 and MRT 19............................. 4-5

Table 5-1 Location of configuration information .............................................. 5-7

Table 6-1 IP address classes and number of network bits ................................. 6-6

Table 6-2 Decimal subnet masks and prefix lengths ......................................... 6-7

Table 9-1 T1 and E1 trunk module port connector status lights....................... 9-4

Table 9-2 Descriptions of IMA command output............................................ 9-34

Table 9-3 T1 and E1 line module specifications .............................................. 9-36

Table 9-4 T1-specific specifications ................................................................. 9-38

Table 9-5 E1-specific specifications ................................................................. 9-39

Table 9-6 IMA specifications ........................................................................... 9-39

Table 9-7 ATM specifications .......................................................................... 9-41

Table 10-1 DS3-ATM trunk module status lights ............................................. 10-3

Table 10-2 Descriptions of atmtrunks command output .................................. 10-5

Table 10-3 OC3-ATM module specifications................................................... 10-13

Table 10-4 OC3-ATM cable specifications....................................................... 10-14

Table 11-1 DS3-ATM trunk module status lights ............................................. 11-3

Table 11-2 DS3-ATM trunk module specifications ......................................... 11-10

Table B-1 Default allocation of unique nailed-group numbers to remote

shelves ............................................................................................... B-7

Table B-2 New locations for traffic management settings ................................. B-8

Table B-3 Hosted MRT alarm events ............................................................... B-19

Table B-4 Details displayed for each shelf in the topology .............................. B-23

Table B-5 Statistics displayed for a remote shelf ............................................. B-25

Table B-6 Statistics displayed for the host shelf............................................... B-25

Table B-7 Statistics displayed in an open session on the remote shelf ............ B-26

Table C-1 CONSOLE serial port and cable pinouts............................................ C-1

Table C-2 Alarm input pinouts.......................................................................... C-2

Table C-3 RJ-45 connector (normal end).......................................................... C-3

Table C-4 RJ-45 connector (crossover end) ...................................................... C-3

Table C-5 Cable pinouts for the 1-24 LINE or PORTS connector ...................... C-5

Table C-6 Cable pinouts for the 25-48 LINE or PORTS connector.................... C-6

Table C-7 Cable pinouts for the 1-24 POTS connector...................................... C-7

Table C-8 Cable pinouts for the 25-48 POTS connector.................................... C-8

Table C-9 Transmit and receive pins assignments for T1 and E1 trunk

module connectors............................................................................ C-9

Table C-10 RJ-48C/RJ-48C crossover cable specifications ................................ C-10

Table C-11 RJ-48C/RJ-48C straight-through cable specifications..................... C-11

Table C-12 RJ-48C/DB-15 straight-through cable specifications ...................... C-12C-12

1-2

1-3

3-25

3-25

4-5

5-7

6-6

6-7

9-4

9-34

9-36

9-38

9-39

9-39

9-41

10-3

10-5

10-13

10-14

11-3

11-10

B-7

B-8

B-19

B-23

B-25

B-25

B-26

C-1

C-2

C-3

C-3

C-5

C-6

C-7

C-8

C-9

C-10

C-11

Stinger® MRT Getting Started Guide xv

Page 16

Tables

Table C-13 RJ-48C/DB-15 crossover cable specifications.................................. C-13

Table C-14 RJ-48C/Bantam straight-through cable specifications .................... C-14

Table C-15 RJ-48C-Loopback plug specifications.............................................. C-14

Table D-1 Stinger MRT electronic and electrical specifications ......................... D-1

Table D-2 Stinger MRT T1 and E1 module USOC jacks and codes.................... D-2

Table D-3 Ringer equivalence number ratings .................................................. D-3

Table D-4 Stinger MRT minimum ground wire sizes ........................................ D-4

Table D-5 Stinger MRT physical specifications ................................................. D-4

Table D-6 Stinger MRT site specifications.......................................................... D-5

C-13

C-14

C-14

D-1

D-2

D-3

D-4

D-4

D-5

xvi Stinger® MRT Getting Started Guide

Page 17

About This Guide

What is in this guide

This guide explains how to perform the following installation and basic configuration

tasks on a Stinger MRT (Micro-Remote Terminal) unit:

■ Physical installation of a Stinger MRT unit

■ Connection of an administrative terminal to a Stinger MRT

■ Configuration of a Stinger MRT for basic network connectivity

This guide also provides Stinger MRT technical specifications and an operational

overview of the Stinger MRT. When you finish performing the instructions in this

guide, your Stinger MRT will be installed and you will be able to access it via a Telnet

connection for further configuration.

What you should know

Warning Before installing your Stinger MRT unit, be sure to read the safety

instructions in the Edge Access and Broadband Access Safety and Compliance Guide. For

information specific to your unit, see

Physical, and Environmental Information,” in this guide.

Appendix D, “Safety-Related Electrical,

The procedures in this guide require you to understand and follow the safety

practices at your site, as well as those identified in this guide. Before installing any

hardware, check the installation location for adequate temperature, humidity, and

electrical requirements. Work closely with the network manager and other systems

integration personnel to ensure a functional installation.

Documentation conventions

Following are all the special characters and typographical conventions used in this

manual:

Convention Meaning

Monospace text Represents text that appears on your computer’s screen, or that

could appear on your computer’s screen.

Boldface

monospace text

Stinger® MRT Getting Started Guide xvii

Represents characters that you enter exactly as shown (unless

the characters are also in italics—see Italics, below). If you

could enter the characters but are not specifically instructed to,

they do not appear in boldface.

Page 18

About This Guide

Stinger documentation set

Convention Meaning

Italics Represent variable information. Do not enter the words

[ ] Square brackets indicate an optional argument you might add

| Separates command choices that are mutually exclusive.

> Points to the next level in the path to a parameter or menu

Key1+Key2 Represents a combination keystroke. To enter a combination

Press Enter Means press the Enter or Return key or its equivalent on your

themselves in the command. Enter the information they

represent. In ordinary text, italics are used for titles of

publications, for some terms that would otherwise be in

quotation marks, and to show emphasis.

to a command. To include such an argument, type only the

information inside the brackets. Do not type the brackets unless

they appear in boldface.

item. The item that follows the angle bracket is one of the

options that appear when you select the item that precedes the

angle bracket.

keystroke, press the first key and hold it down while you press

one or more other keys. Release all the keys at the same time.

(For example, Ctrl+H means hold down the Ctrl key and press

the H key.)

computer.

Introduces important additional information.

Note

!

Caution

Warning

Warning

Warns that a failure to follow the recommended procedure

could result in loss of data or damage to equipment.

Warns that a failure to take appropriate safety precautions

could result in physical injury.

Warns of danger of electric shock.

Stinger documentation set

The Stinger documentation set consists of the following manuals, which can be found

at http://www.lucent.com/support and http://www.lucentdocs.com/ins:

■ Read me first:

– Edge Access and Broadband Access Safety and Compliance Guide. Contains

important safety instructions and country-specific information that you must

read before installing a Stinger unit.

– TAOS Command-Line Interface Guide. Introduces the TAOS command-line

environment and shows you how to use the command-line interface

xviii Stinger® MRT Getting Started Guide

Page 19

About This Guide

Stinger documentation set

effectively. This guide describes keyboard shortcuts and introduces

commands, security levels, profile structure, and parameter types.

■ Installation and basic configuration:

– Getting Started Guide for your unit. Shows how to install your Stinger chassis

and hardware. This guide shows you how to use the command-line interface

to configure and verify IP access and basic access security on the unit.

The Getting Started Guides for Stinger models with redundant control

modules describe configuration of this feature.

The Stinger MRT Getting Started Guide describes the features and basic

configuration of the trunk modules that are specific to a Stinger MRT.

– Module guides for each type of module designed for the Stinger FS, Stinger

FS+, Stinger LS, or Stinger RT, an individual guide describes the module's

features and provides instructions for configuring the module and verifying

its status.

■ Configuration:

– Stinger ATM Configuration Guide. Describes how to use the command-line

interface to configure Asynchronous Transfer Mode (ATM) operations on a

Stinger unit. The guide explains how to configure permanent virtual circuits

(PVCs), and shows how to use standard ATM features such as quality of

service (QoS), connection admission control (CAC), and subtending.

– Stinger IP2000 Configuration Guide. For Stinger systems with the IP2000

control module, this guide describes how to integrate the system into the IP

infrastructure. Topics include IP-routed switch-through ATM PVCs and RFC

1483 PVCs that terminate on the IP2000, IEEE 802.1Q VLAN, and

forwarding multicast video transmissions on DSL interfaces.

– Stinger Private Network-to-Network Interface (PNNI) Supplement. Provides

quick-start instructions for configuring PNNI and soft PVCs (SPVCs), and

describes the related profiles and commands in the Stinger command-line

interface.

– Stinger SNMP Management of the ATM Stack Supplement. Describes Simple

Network Management Protocol (SNMP) management of ATM ports,

interfaces, and connections on a Stinger unit to provide guidelines for

configuring and managing ATM circuits through any SNMP management

utility.

■ RADIUS: TAOS RADIUS Guide and Reference. Describes how to set up a TAOS unit

to use the Remote Authentication Dial-In User Service (RADIUS) server and

contains a complete reference to RADIUS attributes.

■ Administration and troubleshooting: Stinger Administration Guide. Describes

how to administer the Stinger unit and manage its operations. Each chapter

focuses on a particular aspect of Stinger administration and operations. The

chapters describe tools for system management, network management, and

Simple Network Management Protocol (SNMP) management.

■ Reference:

– Stinger Reference. An alphabetic reference to Stinger profiles, parameters, and

commands.

– TAOS Glossary. Defines terms used in documentation for Stinger units.

Stinger® MRT Getting Started Guide xix

Page 20

Page 21

Introduction to the Stinger MRT

1

The Stinger MRT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Virtual slot conventions for the Stinger MRT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Stinger MRT models and optional products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21-2

The Stinger MRT

The Stinger MRT is a small temperature-hardened version of the Stinger unit,

designed to be installed in outdoor enclosures in remote locations. The operating

temperature of the installation environment can range between -40°F (-40°C) and

149°F (+65°C). (For more information, see

Two types of MRT chassis are available.

■ The Stinger MRT 23—for installation in standard 23-inch racks

■ The Stinger MRT 19—for installation in standard 19-inch racks, or racks with at

least 17.72 inches of space between the mounting rails

Each chassis supports different numbers of DSL lines, and types of DSL service, for

details see

The Stinger MRT chassis have an integrated design, unlike the chassis of larger

Stinger LS and Stinger FS models which have numerous slots that accept different

types of plug-in modules. Plug-in modules for the larger Stinger LS and Stinger FS

support the following functions.

1-1

1-2

“Operating environment” on page D-5.)

“Stinger MRT models and optional products” on page 1-2.

■ General control and configuration of the Stinger unit (control modules)

■ Connection to subscriber lines (line interface modules or LIMs)

■ Protection of the unit from transient subscriber line conditions (line protection

modules or LPMs)

■ Connection to various types of ATM links (trunk modules)

All the hardware and capabilities associated with the control module, LIMs, and

LPMs on the larger Stinger LS and Stinger FS models are integrated into the Stinger

MRT 19 and Stinger MRT 23 chassis.

Depending on bandwidth requirements, a specially designed trunk module that

supports OC3/STM1, DS3, T1, or E1 service can be installed in the Stinger MRT

chassis. Each Stinger MRT chassis is equipped with a pair of STS-3 connectors that

can forward (cascade) traffic through multiple Stinger MRT units in a common

location to a single unit with a trunk module.

Stinger® MRT Getting Started Guide 1-1

Page 22

Introduction to the Stinger MRT

Virtual slot conventions for the Stinger MRT

Some Stinger MRT models also incorporate integrated line splitters to provide

asymmetric digital subscriber line (ASDL) and analog telephone (POTS) service over

a single pair of wires. For chassis details, including model number designations, and

line capabilities, see

Table 1-2.

Virtual slot conventions for the Stinger MRT

The highly integrated Stinger MRT 19 and Stinger MRT 23 use the same TAOS

software as larger Stinger units. In the larger Stinger units TAOS uses the physical slot

number in which modules are installed to access the parameters of those modules

and configure them. In the Stinger MRT, functions are grouped into virtual slots, so

that they can be accessed and configured by the TAOS software in a manner similar

to other Stinger models.

Table 1-1 compares the physical slot locations of modules installed in a Stinger FS

with the virtual slot locations for the same functions integrated into the Stinger MRT.

These virtual slot positions are used in examples throughout this document.

Table 1-1. Stinger MRT virtual slots

Module type Stinger FS location Stinger MRT virtual

location

Line interface module

(LIM)

Control module Slots 8 and 9 Virtual slot 8

Trunk modules Slots 17 and 18 Virtual slot 17 (built-in STS-3)

Slots 1 through 7

Slots 10 through 16

Virtual slot 1

Virtual slot 18 (trunk module)

Stinger MRT models and optional products

Two models of the Stinger MRT 23 are available to support different ADSL line

lengths. The original Stinger MRT 23 was designed for field installations with short

ADSL subscriber loops. This model supports speeds up to 8.128Kbps over 24

American wire gauge (AWG, 0.25 mm²) copper facilities up to 2000 feet, and lower

speeds beyond that distance.

A newer standard-reach version of the MRT 23 supports the standard ADSL

subscriber loop length, identical to the full-sized central office version of the Stinger.

This standard-reach version supports speeds up to 8.128Kbps over 24 AWG (0.25

mm²) copper facilities up to 8000 feet in length, and lower speeds beyond that

distance.

Two models of the MRT 19 are also available. One model of the MRT 19 supports up

to 48 ADSL connections without POTS capability, and another supports up to 36

SHDSL connections.

The two versions of the Stinger MRT 23 can be ordered with different trunk modules

or software options installed for different bandwidth requirements. Trunk modules

for the Stinger MRT 19 models are ordered separately, the base chassis are supplied

with a blank faceplate covering the trunk module slot. Optional software is available

1-2 Stinger® MRT Getting Started Guide

Page 23

Introduction to the Stinger MRT

Stinger MRT models and optional products

that enables additional capabilities of the T1 and E1 trunk module on both models of

the Stinger MRT.

Table 1-2 contains a list of some of the Stinger MRT products that are currently

available. For additional information, contact your Lucent Technologies sales

representative.

Table 1-2. Stinger MRT models and optional products

Product Code Description

MRT-AD-36S

MRT-AD-36S-56K

MRT-AD-36S-SR

MRT-AD-36S-SR-56K

MRT-AD-36S-4T1

MRT-AD-36S-4T1-IMA

MRT-AD-36S-SR-4T

MRT-AD-36S-SR-4T-I

MRT-AD-36S-SR-56K-4T

MRT-AD-36S-SR-56K-4T-I

MRT-AD-36S-8T1

MRT-AD-36S-8T1-IMA

MRT-AD-36S-SR-8T

MRT-AD-36S-SR-8T-I

MRT-AD-36S-SR-56K-8T

MRT-AD-36S-SR-56K-8T-I

MRT-AD-36S-4E1

MRT-AD-36S-4E1-IMA

MRT-AD-36S-SR-4E

MRT-AD-36S-SR-4E-I

MRT-AD-36S-SR-56K-4E

MRT-AD-36S-SR-56K-4E-I

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide with 36 ADSL ports and integrated

POTS splitters and blank panel cover for the trunk

module slot. (Models with -56K designation

indicates an internal 56Kbps analog modem. The

-SR designation indicates standard-reach ADSL

capability.)

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with four T1 ports active

on a T1/E1 trunk module. (The -SR designation

indicates standard-reach ADSL capability. The

-56K designation indicates an internal 56Kbps

analog modem. The -I and -IMA designations

indicate bundled IMA capability.)

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with eight T1 ports

active on a T1/E1 trunk module. (The -SR

designation indicates standard-reach ADSL

capability. The -56K designation indicates an

internal 56Kbps analog modem. The -I and -IMA

designations indicate bundled IMA capability.)

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with four E1 ports

active on a T1/E1 trunk module. (The -SR

designation indicates standard-reach ADSL

capability. The -56K designation indicates an

internal 56Kbps analog modem. The -I and -IMA

designations indicate bundled IMA capability.)

MRT-AD-36S-8E1

MRT-AD-36S-8E1-IMA

MRT-AD-36S-SR-8E

MRT-AD-36S-SR-8E-I

MRT-AD-36S-SR-56K-8E

MRT-AD-36S-SR-56K-8E-I

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with eight E1 ports

active on a T1/E1 trunk module. (The -SR

designation indicates standard-reach ADSL

capability. The -56K designation indicates an

internal 56Kbps analog modem. The -I and -IMA

designations indicate bundled IMA capability.)

MRT-TM-T1E1 Replacement T1/E1 trunk module for a Stinger

MRT 23 chassis.

Stinger® MRT Getting Started Guide 1-3

Page 24

Introduction to the Stinger MRT

Stinger MRT models and optional products

Table 1-2. Stinger MRT models and optional products

Product Code Description

MRT-AD-36S-2OC3

MRT-AD-36S-SR-2OC3

MRT-AD-36S-SR-56K-2OC3

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with two OC3/STM1

ports on an OC3 trunk module. (The -SR

designation indicates standard-reach ADSL

capability. The -56K designation indicates an

internal 56Kbps analog modem.)

MRT-TM-OC3-2 Replacement OC3 trunk module for a Stinger

MRT 23 chassis.

MRT-AD-36S-2DS3

MRT-AD-36S-SR-2DS3

MRT-AD-36S-SR-56K-2DS3

Complete Stinger MRT 23 chassis, 21.5-inch

(54.6cm) wide, equipped with two DS3 ports on a

DS3 trunk module. (The -SR designation indicates

standard-reach ADSL capability. The -56K

designation indicates an internal 56Kbps analog

modem.)

MRT-TM-DS3-2 Replacement DS3 trunk module for a Stinger

MRT 23 chassis.

MRT19-AD-48 Complete Stinger MRT 19 chassis, 17.4-inch

(44.2cm) wide (includes 48 ADSL ports without

splitters, and a blank face plate for the trunk

module slot).

MRT19-SL-36 Complete Stinger MRT 19 chassis, 17.4-inch

(44.2cm) wide (includes 36 SHDSL ports without

splitters, and a blank face plate for the trunk

module slot).

MRT19-TM-OC3-2 OC3 trunk module for the Stinger MRT 19

chassis.

MRT19-TM-DS3-2 DS3 trunk module for the Stinger MRT 19 chassis.

MRT19-TM-T1E1 T1 and E1 trunk module (depending on chassis)

for the Stinger MRT 19.

MRT19-SP-FAN Replacement fan unit for the Stinger MRT 19

chassis.

MRT-SO-8T1E1 Software for upgrading the default 4-port

operation of the T1 and E1 trunk module to 8 T1

or E1 ports.

MRT-SO-IMA Software to enable inverse multiplexing over

ATM (IMA) with the T1 and E1 trunk module.

1-4 Stinger® MRT Getting Started Guide

Page 25

Preparing for the Installation

2

Selecting an installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Required tools and equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Preventing static discharge damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking the Stinger MRT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Verifying the hardware configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Selecting an installation site

Before you choose a setup location for a Stinger MRT unit, read and follow the site

and electrical requirements defined in the Edge Access and Broadband Access Safety and

Compliance Guide.

Select the setup location carefully. Keep in mind that the unit requires proper

ventilation and space for current and future cabling requirements.

Caution At least 1 inch (2.5cm) of clear space must remain on both sides of the MRT

!

chassis to ensure sufficient air flow. The Stinger MRT 23 and Stinger MRT 19 pull air

in from the right side of the chassis and exhaust air from the left side of the chassis.

A Stinger MRT can be mounted in a number of ways, depending on the space that is

available. You can rack-mount the Stinger MRT 23 chassis horizontally in an

equipment rack or outdoor cabinet with mounting rails that are 23 inches (58.42cm)

apart. You can rack-mount the Stinger MRT 19 chassis in an equipment rack or

outdoor cabinet with mounting rails that are 17.72 inches (45.0cm) apart. Optional

mounting hardware is also available for mounting the Stinger MRT 23 chassis

vertically between mounting rails spaced 19 inches (48.26cm) apart, and for wall

mounting both Stinger models. For more information, contact your Lucent

Technologies sales representative.

2-1

2-1

2-2

2-2

2-4

2-4

19

Before you begin

Warning Before installing your Stinger MRT unit, be sure to read the safety

instructions in the Edge Access and Broadband Access Safety and Compliance Guide. Also

read

Appendix D, “Safety-Related Electrical, Physical, and Environmental