Lowrance electronic X125 User Manual

www.lowrance.com

Pub. 988-0151-171

X125, X126DF, X135, X136DF

Fish-finding & Depth Sounding Sonars

Operation Instructions

Copyright © 2003 Lowrance Electronics, Inc.

All rights reserved.

Lowrance

®

is a registered trademark of Lowrance Electronics, Inc.

Navionics

is a registered trademark of Navionics, Inc.

Lowrance Electronics may find it necessary to change or end our

policies, regulations and special offers at any time. We reserve the right

to do so without notice. All features and specifications subject to change

without notice. All screens in this manual are simulated. On the cover:

X136DF shown. Other models covered in the manual are similar.

For free owner's manuals and other information,

visit our web site:

www.lowrance.com

Lowrance Electronics Inc.

12000 E. Skelly Dr.

Tulsa, OK USA 74128-2486

Table of Contents

Sec. 1: Read Me First! ...............................................................1

Capabilities and Specifications: X125, X126DF, X135, X136DF.. 2

How Sonar Works ......................................................................... 3

How to Use this Manual: Typographical Conventions................ 4

Sec. 2: Installation & Accessories .......................................... 7

Preparations.................................................................................. 7

Transducer Installation................................................................ 7

Recommended Tools and Supplies ........................................... 8

Selecting a Transducer Location.................................................. 8

How Low Should You Go?......................................................... 9

Shoot-Thru-Hull vs. Transom Mounting ................................... 10

Transom Transducer Assembly and Mounting ......................... 10

Trolling Motor Bracket Installation (Single-Frequency only) .. 16

Transducer Orientation and Fish Arches.................................. 17

Shoot-Thru-Hull Preparation and Installation ......................... 17

Speed/Temperature Sensors ................................................. 20

Sensor Chart ............................................................................... 21

Optional Speed Sensor Installation ....................................... 22

Power Connections...................................................................... 23

Mounting the Unit: Bracket, In-Dash or Portable .................... 25

Face Cover................................................................................... 29

Sec. 3: Basic Sonar Operation............................................... 31

Keyboard ..................................................................................... 31

Power/Lights (Turn Unit On and Off) ....................................... 32

Menus .......................................................................................... 32

Main Menu .............................................................................. 32

Sonar Menu ............................................................................. 34

Pages ........................................................................................... 35

Basic Sonar Quick Reference ............................................... 38

Sonar Operations ........................................................................ 39

Fish Symbols vs. Full Sonar Chart ........................................ 41

Other Free Training Aids ....................................................... 42

Sec. 4: Sonar Options & Other Features ............................43

ASP (Advanced Signal Processing) ......................................... 43

Alarms ......................................................................................... 44

Depth Alarms .......................................................................... 44

Zone Alarm .............................................................................. 45

Fish Alarm............................................................................... 46

Brightness ................................................................................... 46

Calibrate Speed........................................................................... 46

Chart Speed................................................................................. 47

Contrast....................................................................................... 48

i

Depth Cursor............................................................................... 48

Depth Range - Automatic ........................................................... 48

Depth Range - Manual................................................................ 49

To Turn Auto Depth Range on Again: ................................... 49

Depth Range - Upper and Lower Limits ................................... 49

FasTrack .................................................................................. 51

Fish I.D. (Fish Symbols & Depths) ......................................... 51

FishTrack ................................................................................. 53

FishReveal ............................................................................... 54

Frequency (Change Transducer Frequency) .............................56

Grayline

..................................................................................... 57

HyperScroll .............................................................................. 59

Noise Rejection............................................................................ 59

Overlay Data ............................................................................... 59

To Change Displayed Data Font Size: ................................... 60

Ping Speed & HyperScroll....................................................... 61

Pop-Up Help................................................................................ 62

Reset Options .............................................................................. 63

Reset Water Distance ................................................................. 63

Screen Contrast and Brightness ................................................ 63

Sensitivity & Auto Sensitivity.................................................... 64

To Turn Auto Sensitivity Back on:......................................... 66

Set Keel Offset ............................................................................66

Set Language .............................................................................. 67

Software Version Information.................................................... 67

Sonar Chart Mode....................................................................... 68

Sonar Chart Display Options ..................................................... 68

Full Sonar Chart ..................................................................... 69

Split Zoom Sonar Chart.......................................................... 70

Split Frequency Sonar Chart (X126DF and X136DF only) .. 70

Digital Data/Chart .................................................................. 71

Customizing the Digital Data/Chart Screen...................... 72

Flashgraf ................................................................................. 73

Sonar Simulator.......................................................................... 73

Stop Chart ................................................................................... 74

Surface Clarity............................................................................ 74

Transducer Type (X126DF and X136DF only) .......................... 75

Units of Measure......................................................................... 76

Upper and Lower Limits ............................................................ 76

Zoom & Zoom Bar ....................................................................... 76

Zoom Pan..................................................................................... 77

Sec. 5: Sonar Troubleshooting..............................................79

Sec. 6: Supplemental Material.............................................. 85

ii

Section 1: Read Me First!

How this manual can get you out on the water, fast!

Welcome to the exciting world of digital sonar! We know you're anxious

to begin finding fish, but we have a favor to ask. Before you grab your

unit and begin installing it, please give us a moment or two to explain

how our manual can help you get the best performance from your compact, wide-screen, fish finder.

First, we want to thank you for buying a Lowrance sonar. Whether

you're a first time user or a professional fisherman, you'll discover that

your unit is easy to use, yet capable of handling demanding sonar

tasks. You won't find another sonar unit with this much power and this

many features for this price!

Our goal for this book is to get you on the water fast, with a minimum

of fuss. Like you, we'd rather spend more time boating or fishing and

less time reading the manual!

So, we designed our book so that you don't have to read the whole thing

from front to back for the information you want. At the start (or end) of

each segment, we'll tell you what content is coming up next. If it's a

concept you're already familiar with, we'll show you how and where to

skip ahead for the next important topic. We've also made it easy to look

up any tips you may need from time to time. Here's how:

The manual is organized into 6 sections. This first section is an introduction to the sonar unit. It tells you the basics you need to know before you can make the unit look below the surface to find some fish.

Section 2 will help you install your unit and the transducer. We'll also

tell you about some of the available accessories.

Section 3 covers Basic Sonar Operation. It will show you how easy it is

to run your sonar, right out of the box. This section features a one-page

Sonar Quick Reference. (If you've already jumped ahead and fig-

ured out how to install the unit yourself, and you just can't wait

any longer, turn to the Quick Reference on page 38 and head

for the water with your sonar unit!)

After you've gained some experience with your sonar, you'll want to

check out Section 4, which discusses more advanced Sonar Options and

Other Features.

When you come to a sonar menu command on the unit's screen, you can

look it up in the manual by skimming over the table of contents or index,

just flipping through Section 3 or scanning through the sonar options in

Section 4.

1

If you're having difficulty with your sonar, you can find an answer to

the most common problems in Section 5, Sonar Troubleshooting.

Finally, in Section 6, we offer Supplemental Material, including a list of

warranty and customer service information.

Now, if you're into the fine details, glance over the next segment on

specifications to see just how much sonar power your unit contains. It's

important to us (and our power users), but, if you don't care how many

watts of power the unit has, skip ahead to important information on how

sonar works, on page 3.

Capabilities and Specifications: X125, X126DF, X135, X136DF

General

Display: ............................. 5.0" (12.7 cm) diagonal high contrast Film

SuperTwist; programmable to viewing preference.

Resolution:...................... 480 pixel x 480 pixel resolution ; 230,400 to-

tal pixels. 16-level grayscale definition.

Backlighting:.................. X136DF and X135:

White LED backlit screen and keypad.

X126DF and X125:

Amber LED backlit screen and keypad.

Input power:................... 10 to 15 volts DC.

Case size:......................... 5.4" H x 6.9" W x 3.4" D (13.8 x 17.6 x 8.6

cm); sealed and waterproof; suitable for

saltwater use.

Back-up memory: .......... Built-in memory stores sonar records for

decades.

Languages:...................... 10; menu languages selectable by user.

Sonar

Frequency:...................... 50/200 kHz for X126DF and X136DF; 200

kHz for X125 and X135.

Transducers: .................. A dual-frequency Skimmer

transducer with

built-in temperature sensor is packed with

the X126DF and X136DF. It has 35°/12° cone

angles. A single-frequency with built-in temperature sensor is packed with the X125 and

X135. It has a 20° cone angle. Transducers

operate at speeds up to 70 mph (61 kts).

2

Transmitter: ................... X136DF, X135 and X126DF:

4,000 watts peak-to-peak/500 watts RMS.

X125:

2,400 watts peak-to-peak/300 watts RMS.

Sonar sounding

depth capability: ........... X136DF: 2,500 feet (762 meters).

X126DF: 1,700 feet (518 meters).

X135: 1,000 feet (305 meters).

X125: 800 feet (244 meters).

Actual capability depends on transducer configuration and installation, bottom composition and water conditions. All sonar units

typically read deeper in fresh water than in

salt water.

Depth display:................ Continuous display .

Audible alarms: ............. Deep/shallow/fish/zone.

Automatic ranging:....... Yes, with instant screen updates.

Auto bottom track:........ Yes.

Zoom bottom track: ...... Yes.

Split-screen zoom:......... Yes.

Surface water temp: ..... Yes.

Speed/distance log: ....... Optional (requires optional speed sensor).

NOTICE!

The storage temperature range for your unit is from -4 degrees to +167

degrees Fahrenheit (-20 degrees to +75 degrees Celsius). Extended stor-

age in temperatures higher or lower than specified will damage the liquid crystal display in your unit. This type of damage is not covered by

the warranty. For more information, contact the factory's Customer

Service Department; phone numbers are listed on the last page.

How Sonar Works

Sonar has been around since the 1940s, so if you already know how it

works, skip ahead to the next segment on the typographical conventions

used in this manual. But, if you've never owned a sonar fish finder, this

segment will tell you the under water basics.

Sonar is an abbreviation for SOund NA

ogy developed during World War II for tracking enemy submarines.

(Lowrance developed the world's first transistorized sportfishing sonar in

vigation and Ranging, a technol-

3

1957.) A sonar consists of a transmitter, transducer, receiver and display. In simple terms, here's how it finds the bottom, or the fish:

The transmitter emits an electrical impulse, which the transducer converts into a sound wave and sends into the water. (The sound frequency

can't be heard by humans or fish.) The sound wave strikes an object

(fish, structure, bottom) and bounces back to the transducer, which

converts the sound back into an electrical signal.

The receiver amplifies this return signal, or echo, and sends it to the

display, where an image of the object appears on the scrolling sonar

chart. The sonar's microprocessor calculates the time lapse between the

transmitted signal and echo return to determine the distance to the

object. The whole process repeats itself several times each second.

How to use this manual: typographical conventions

Many instructions are listed as numbered steps. The keypad and arrow

"keystrokes" appear as boldface type. So, if you're in a real hurry (or

just need a reminder), you can skim the instructions and pick out what

menu command to use by finding the boldface command text. The following paragraphs explain how to interpret the text formatting for

those commands and other instructions:

Arrow Keys

The arrow keys control a horizontal line depth cursor on the sonar

screen. The arrow keys also help you move around the menus so you

can execute different commands. They are represented by symbols like

these, which denote the down arrow key, the up arrow, the left arrow

and the right arrow: ↓ ↑ ← →.

Keyboard

The other keys perform a variety of functions. When the text refers to a

key to press, the key is shown in bold, sans serif type. For example, the

"Enter/Icons" key is shown as

MENU.

ENT and the "Menu" key is shown as

Menu Commands

A menu command or a menu option will appear in small capital letters,

in a bold sans serif type like this:

DEPTH CURSOR. These indicate that you

are to select this command or option from a menu or take an action of

some kind with the menu item. Text that you may need to enter or file

names you need to select are show in italic type, such as data type.

4

Instructions = Menu Sequences

Most functions you perform with the sonar unit are described as a sequence of key strokes and selecting menu commands. We've written

them in a condensed manner for quick and easy reading.

For example, instructions for turning on the Fish ID feature would

look like this:

1. From the Sonar Page, press

2. Press → to

FISH SYMBOLS|ENT|EXIT|EXIT.

MENU|↓ to SONAR FEATURES|ENT.

Translated into complete English, step 1 above would mean: "Start on

the Sonar Page. Press the Menu key then repeatedly press (or press and

hold) the down arrow key to scroll down the menu and select (highlight)

the Sonar Features menu command. Then press the Enter key."

Step 2 would mean: "Press the right arrow key to select (highlight) the

Fish ID symbols command. Next, press the Enter key, then press the

Exit key twice."

5

Notes

6

Section 2:

Installation & Accessories

Preparations

You can install the sonar system in some other order if you prefer, but

we recommend this installation sequence:

Caution:

You should read over this entire installation section before drilling any holes in your vessel!

1. Determine the approximate location for the sonar unit, so you can

plan how and where to route the cables for the transducer and power.

This will help you make sure you have enough cable length for the desired configuration.

2. Determine the approximate location for the transducer and its cable

route.

3. Determine the location of your battery or other power connection,

along with the power cable route.

4. Install the transducer and route the transducer cable to the sonar

unit.

5. Install the power cable and route it to the sonar unit.

6. Mount the sonar unit.

Transducer Installation

These instructions will help you install your Skimmer

transom, on a trolling motor or inside a hull. These instructions cover

both single- and dual-frequency Skimmer transducers. Please read all

instructions before proceeding with any installation.

The smaller single-frequency Skimmers typically use a one-piece,

stainless steel mounting bracket. The larger dual-frequency Skimmers

typically use a two-piece, plastic mounting bracket. The trolling motor

mount uses a one-piece plastic bracket with an adjustable strap.

These are all "kick-up" mounting brackets. They help prevent damage if

the transducer strikes an object while the boat is moving. If the transducer does "kick-up," the bracket can easily be pushed back into place

without tools.

Read these instructions carefully before attempting the installation.

Determine which of the mounting positions is right for your boat. Use

7

transducer on a

extreme care if mounting the transducer inside the hull, because once it

is epoxied into position, the transducer usually cannot be removed.

Remember, the transducer installation is the most critical part

of a sonar installation.

Recommended Tools and supplies

If you prefer the option of routing the cable through the transom, you

will need a 1" drill bit. A transom mount requires use of a high quality,

marine grade above- or below-waterline caulking compound. The following installation types also call for these recommended tools and required supplies (supplies are not included):

Single-frequency transom installations

Tools include: two adjustable wrenches, drill, #29 (0.136") drill bit, flathead screwdriver. Supplies: none.

Dual-frequency transom installations

Tools: two adjustable wrenches, drill, #20 (0.161") drill bit, flat-head

screwdriver. Supplies: four, 1" long, #12 stainless steel slotted wood

screws.

Single-frequency trolling motor installations

Tools: two adjustable wrenches, flat-head screwdriver. Supplies: plastic

cable ties.

Shoot-through hull installations

Tools: these will vary depending on your hull's composition. Consult your

boat dealer or manufacturer. Supplies: 100 grit sandpaper, good quality

epoxy adhesive.

Selecting a Transducer Location

1. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is to be mounted inside the hull,

then the chosen location must be in the water at all times. If the

transducer is not placed in a smooth flow of water, interference

caused by bubbles and turbulence will show on the sonar's display in

the form of random lines or dots whenever the boat is moving.

NOTE:

Some aluminum boats with strakes or ribs on the outside of the

hull create large amounts of turbulence at high speed. These boats

typically have large outboard motors capable of propelling the boat

at speeds faster than 35 mph. Typically, a good location on aluminum boats is between the ribs closest to the engine.

2. The transducer should be installed with its face pointing straight

down, if possible.

8

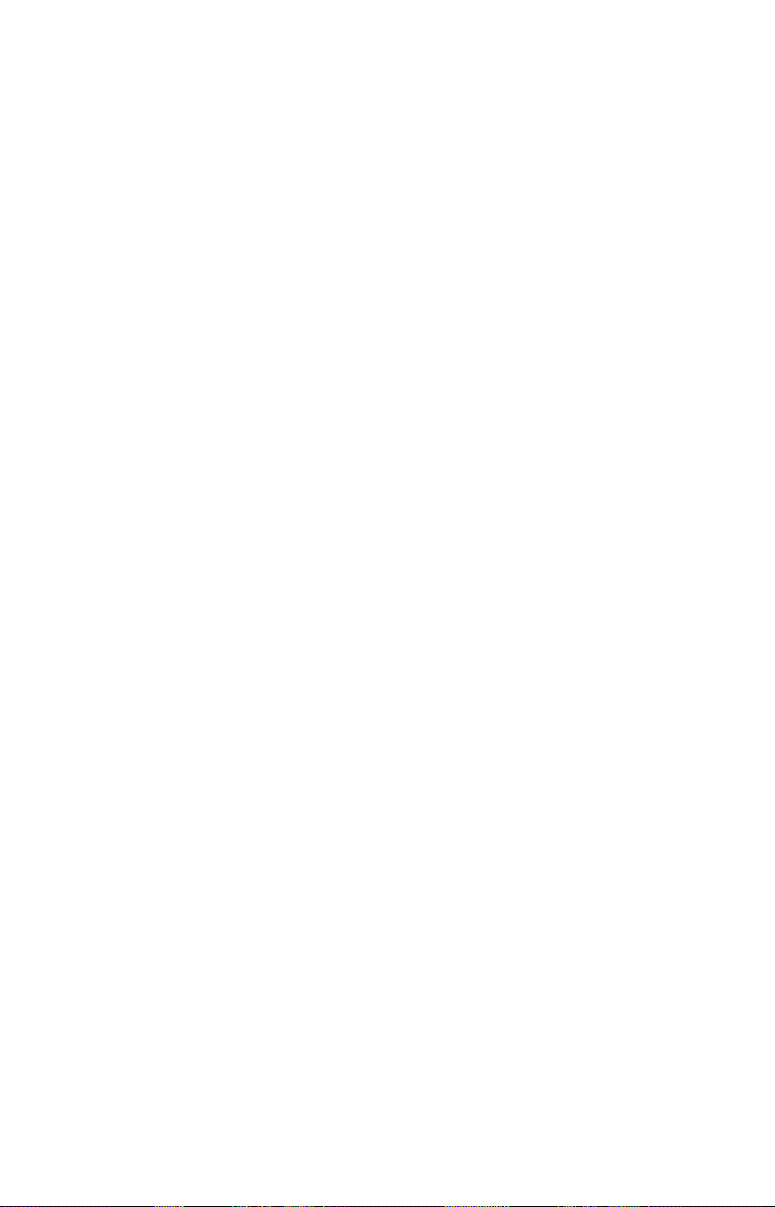

3. If the transducer is mounted on the transom, make sure it doesn't

prevent the transducer from

location

Transom

centerline

interfere with the trailer or hauling of the boat. Also, don't mount it

closer than approximately one foot from the engine's lower unit. This

will prevent cavitation (bubble) interference with propeller operation.

4. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps and aerators

can be displayed on the sonar's screen. Use caution when routing the

transducer cable around these wires.

CAUTION: Clamp the transducer cable to transom near

the transducer. This will help

entering the boat if it is

knocked off at high speed.

Good location

Poor location

Good

Poor angle

Good and poor transducer locations.

Good location

How low should you go?

For most situations, you should install your Skimmer transducer so

that its centerline is level with the bottom of the boat hull. This will

usually give you the best combination of smooth water flow and protection from bangs and bumps.

Transducer

Hull bottom

Align transducer centerline with hull bottom.

However, there are times when you may need to adjust the transducer

slightly higher or lower. (The slots in the mounting brackets allow you

to loosen the screws and slide the transducer up or down.) If you fre-

9

quently lose bottom signal lock while running at high speed, the transducer may be coming out of the water as you cross waves or wakes.

Move the transducer a little lower to help prevent this.

If you cruise or fish around lots of structure and cover, your transducer

may be frequently kicking up from object strikes. If you wish, you may

move the transducer a little higher for more protection.

There are two extremes you should avoid. Never let the edge of the

mounting bracket extend below the bottom of the hull. Never let the

bottom – the face – of the transducer rise above the bottom of the hull.

Shoot-thru-hull vs. Transom Mounting

Typically, shoot-thru-hull installations give excellent high speed operation and good to excellent depth capability. There is no possibility of

damage from floating objects. It can't be knocked off when docking or

loading on the trailer.

However, the shoot-thru-hull installation does have its drawbacks.

First, some loss of sensitivity does occur, even on the best hulls. This

varies from hull to hull, even from different installations on the same

hull. This is caused by differences in hull lay-up and construction.

Second, the transducer angle cannot be adjusted for the best fish

arches. This can be a problem on some hulls that sit with the bow high

when at rest or at slow trolling speeds. Follow the procedure listed in

the shoot-thru-hull installation section at the end of this lesson to determine if you can satisfactorily shoot through the hull.

TRANSOM TRANSDUCER ASSEMBLY AND MOUNTING

The best way to install these transducers is to loosely assemble all of the

parts first, place the transducer's bracket against the transom and see if

you can move the transducer so that it's parallel with the ground.

The following instructions sometimes vary depending on the mounting

bracket that came with your transducer. Single-frequency Skimmers

come with a one-piece stainless steel bracket, while dual-frequency

Skimmers come with a two-piece plastic mounting bracket. Use the set of

instructions that fits your model.

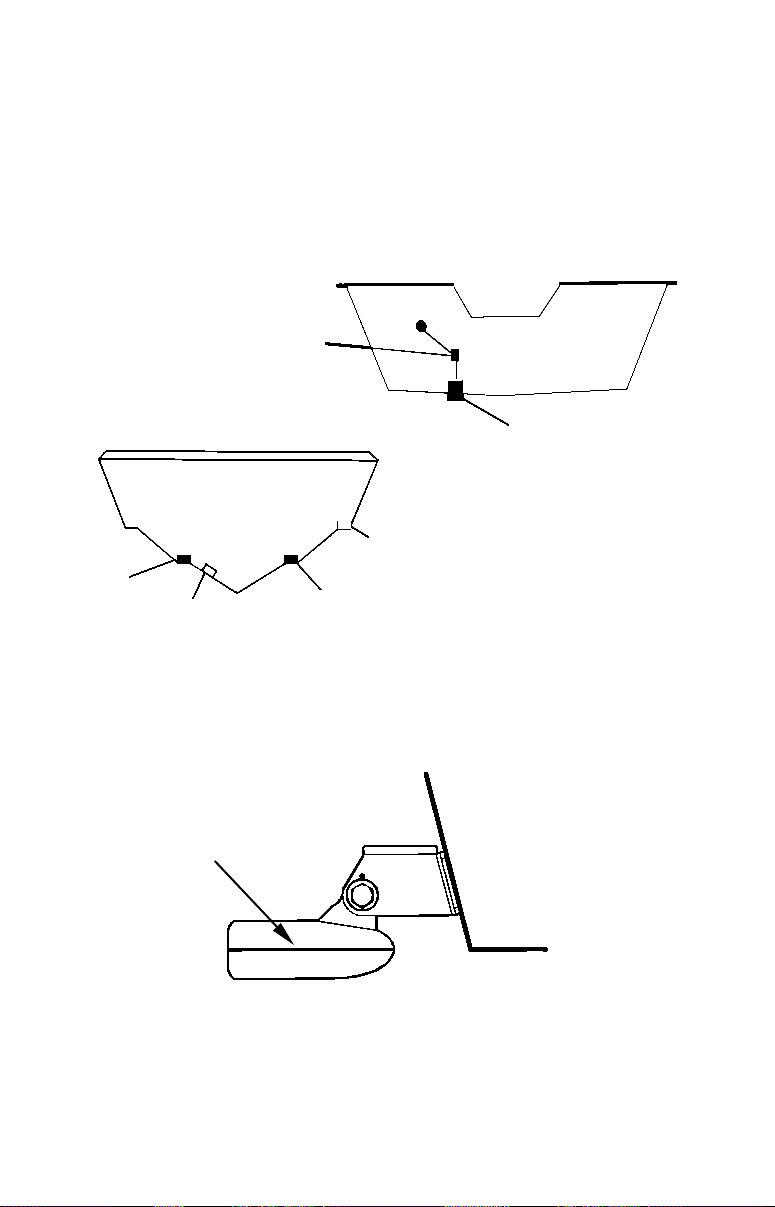

1. Assembling the bracket.

A. One-piece bracket: Press the two small plastic ratchets into the

sides of the metal bracket as shown in the following illustration. Notice

there are letters molded into each ratchet. Place each ratchet into the

bracket with the letter "A" aligned with the dot stamped into the metal

bracket. This position sets the transducer's coarse angle adjustment for a

14° transom. Most outboard and stern-drive transoms have a 14° angle.

10

Dot

Align plastic ratchets in bracket.

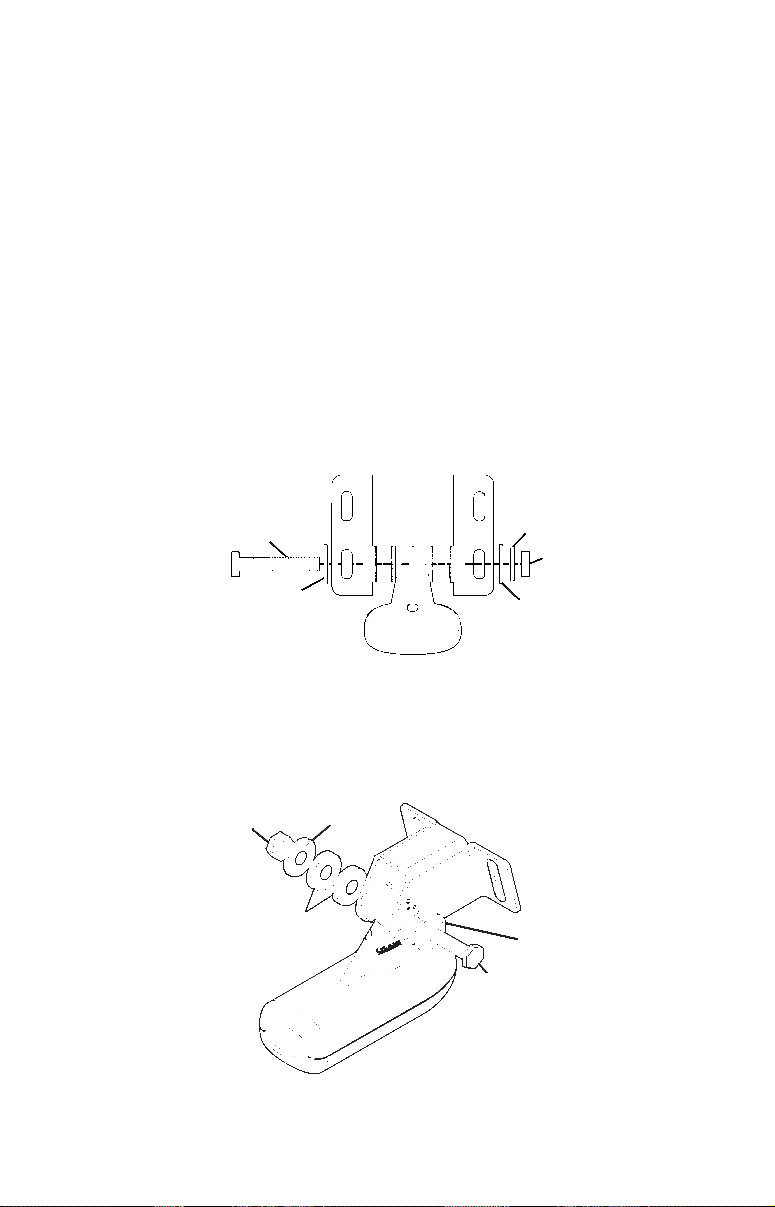

B. Two-piece bracket: Locate the four plastic ratchets in the transducer's hardware package. Press two ratchets into the sides of the plastic bracket and two on either side of the transducer as shown in the following illustrations. Notice there are letters molded into each ratchet.

Place the ratchets into the bracket with the letter "A" aligned with the

alignment mark molded into the bracket. Place the ratchets onto the

transducer with the letter "A" aligned with the 12 o'clock position on

the transducer stem. These positions set the transducer's coarse angle

adjustment for a 14° transom. Most outboard and stern-drive transoms have a 14° angle.

Alignment letters

Alignment

positions

Transducer

Transducer bracket

Insert and align ratchets.

11

Transducer

bracket

Transducer

Ratchet

Add ratchets to bracket and transducer.

Ratchet

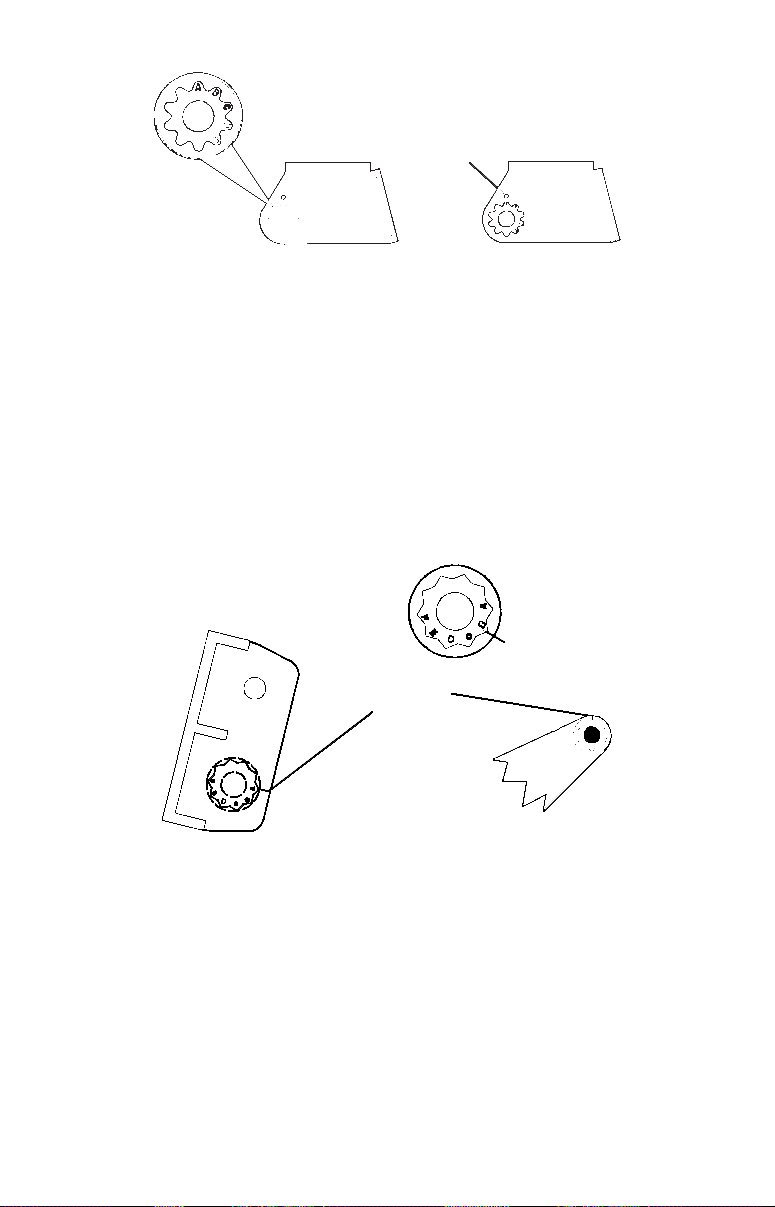

2. Aligning the transducer on the transom.

A. One-piece bracket: Slide the transducer between the two ratch-

ets. Temporarily slide the bolt though the transducer assembly and

hold it against the transom. Looking at the transducer from the side,

check to see if it will adjust so that its face is parallel to the ground.

If it does, then the "A" position is correct for your hull.

If the transducer's face isn't parallel with the ground, remove the

transducer and ratchets from the bracket. Place the ratchets into the

holes in the bracket with the letter "B" aligned with the dot stamped

in the bracket.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's

parallel with the ground. If you can, then go to step 3A. If it doesn't,

repeat step 2A, but use a different alignment letter until you can

place the transducer on the transom correctly.

Ratchets

Insert bolt and check transducer position on transom.

12

B. Two-piece bracket: Assemble the transducer and bracket as shown

Flat washer

in the following figure. Temporarily slide the bolt though the transducer

assembly but don't tighten the nut at this time. Hold the assembled

transducer and bracket against the transom. Looking at the transducer

from the side, check to see if it will adjust so that its face is parallel to

the ground. If it does, then the "A" positions are correct for your hull.

If the transducer's face isn't parallel with the ground, remove and

disassemble the transducer and ratchets. Place the ratchets into the

bracket holes with the letter "B" aligned with the bracket alignment

mark. Place them on the transducer aligned with the 12 o'clock position on the transducer stem.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's

parallel with the ground. If you can, then go to step 3B. If it doesn't,

repeat step 2B, but use a different alignment letter until you can

place the transducer on the transom correctly.

Bolt

Flat washer

Assemble transducer and bracket.

Lock washer

Nut

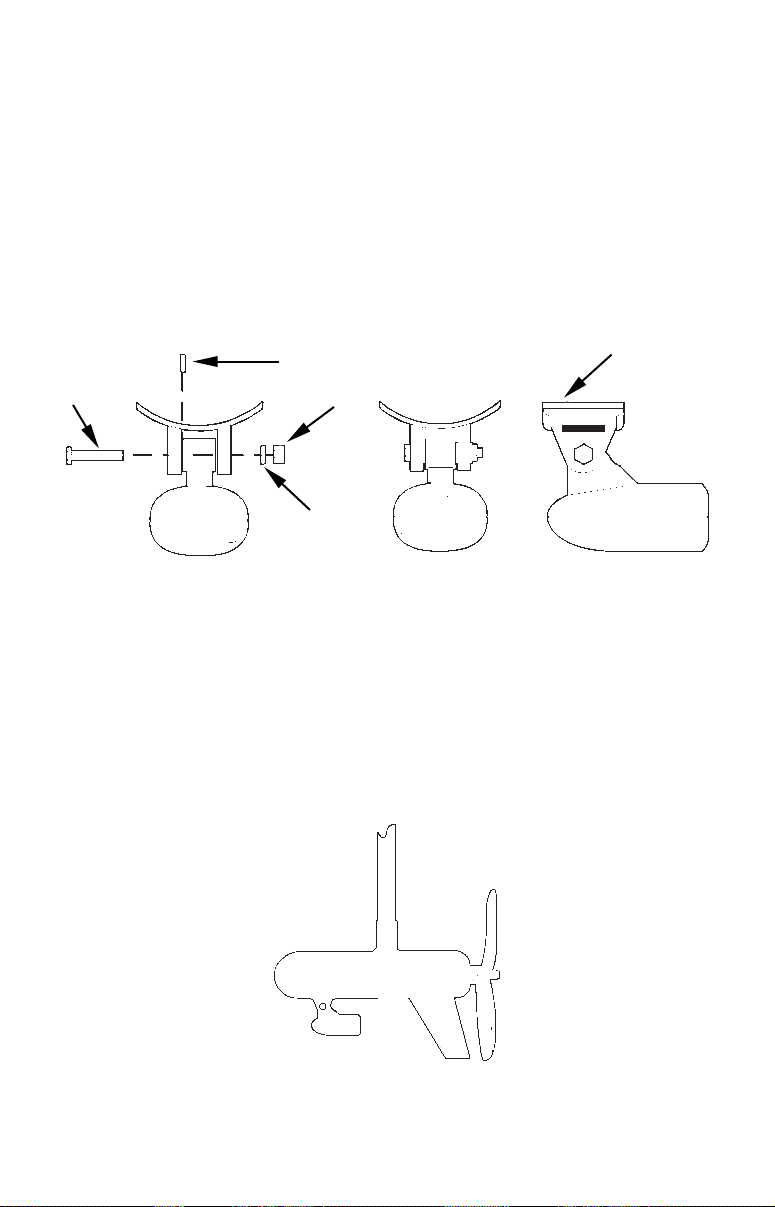

3. Assembling the transducer.

A. One-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the following figure. Don't tighten the lock nut at this time.

Metal

Nut

Rubber

washers

Assemble transducer and bracket.

washer

Metal washer

Bolt

13

B. Two-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the figure in step

2B. Don't tighten the lock nut at this time.

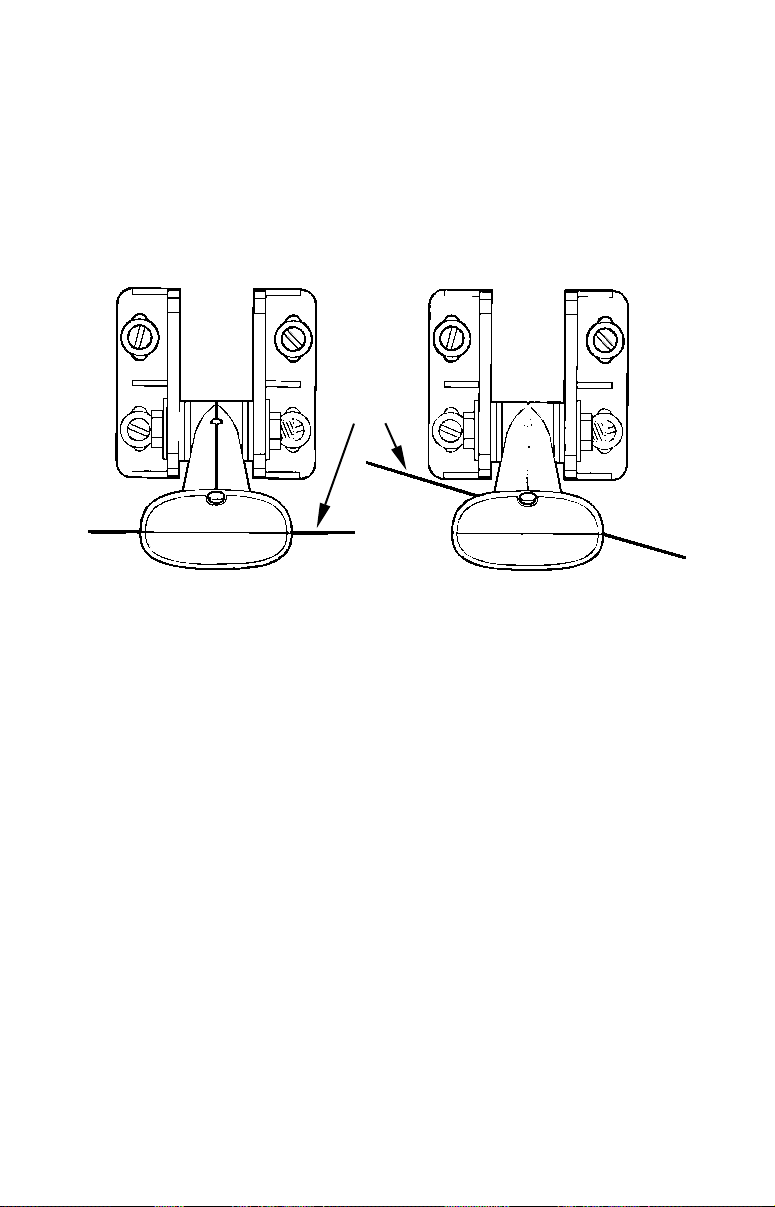

4. Drilling mounting holes.

Hold the transducer and bracket assembly against the transom. The

transducer should be roughly parallel to the ground. The transducer's centerline should be in line with the bottom of the hull. Don't

let the bracket extend below the hull!

Mark the center of each slot for the mounting screw pilot holes. You

will drill one hole in the center of each slot.

Drill the holes. For the one-piece bracket, use the #29 bit (for the #10

screws). For the two-piece bracket, use the #20 bit (for the #12 screws).

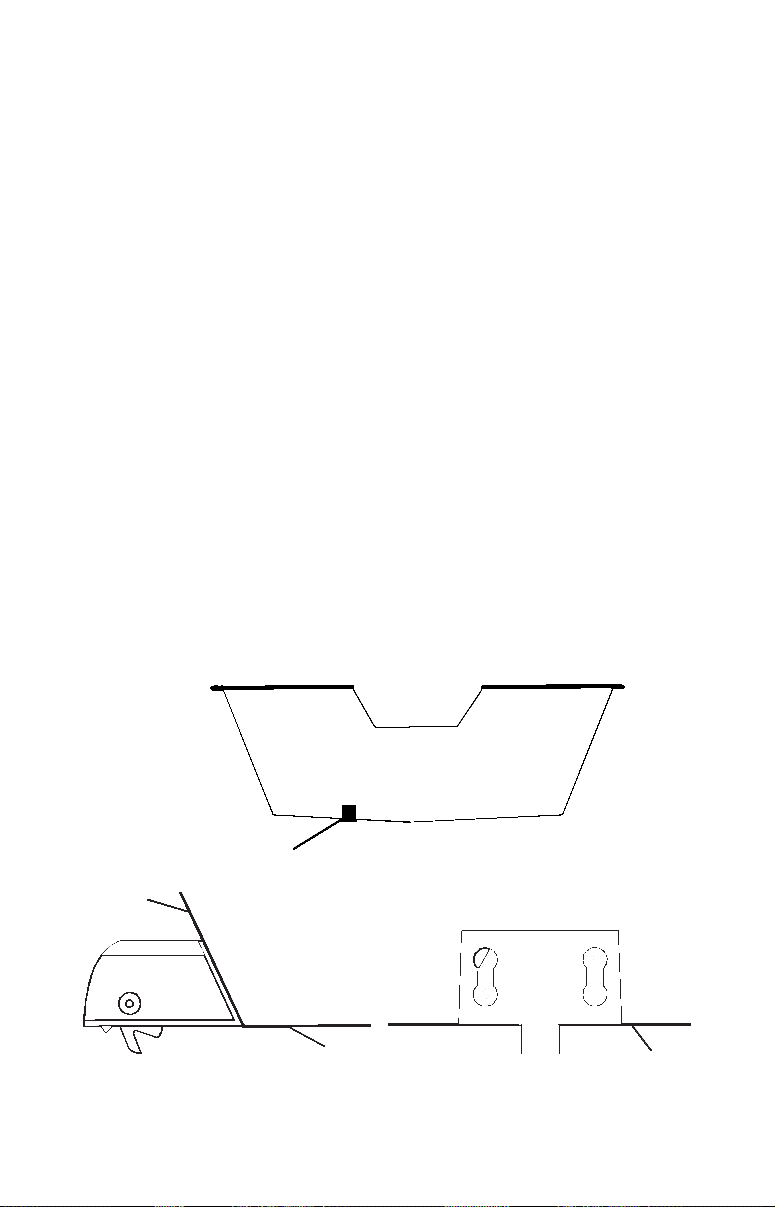

Transom

Transom

Position transducer mount on transom and mark mounting holes.

Side view shown at left and seen from above at right.

5. Attaching transducer to transom.

A. One-piece bracket: Remove the transducer from the bracket and

re-assemble it with the cable passing through the bracket over the

bolt as shown in the following figures.

For single-frequency Skimmer, route cable over bolt and through

bracket. Side view shown at left and seen from above at right.

14

Both bracket types: Attach the transducer to the transom. Slide the

Flat-bottom hull

transducer up or down until it's aligned properly with the bottom of

the hull as shown in the preceding and following figures. Tighten the

bracket's mounting screws, sealing them with the caulking compound.

Adjust the transducer so that it's parallel to the ground and tighten

the nut until it touches the outer washer, then add 1/4 turn. Don't

over tighten the lock nut! If you do, the transducer won't "kick-up" if

it strikes an object in the water.

Bottom

of

hull

Deep-"vee" hull

Align transducer centerline with hull bottom and attach transducer to

transom. Rear view of dual-frequency Skimmer shown.

6. Route the transducer cable through or over the transom to the sonar

unit. Make sure to leave some slack in the cable at the transducer. If

possible, route the transducer cable away from other wiring on the

boat. Electrical noise from the engine's wiring, bilge pumps, VHF radio

wires and cables, and aerators can be picked up by the sonar. Use caution when routing the transducer cable around these wires.

WARNING:

Clamp the transducer cable to the transom close to the

transducer. This can prevent the transducer from entering the boat if it is knocked off at high speed.

If you need to drill a hole in the transom to pass the connector through,

the required hole size will be 1".

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline sealant used for the mounting screws.

15

7. Make a test run to determine the results. If the bottom is lost at

Flat washer

high speed, or if noise appears on the display, try sliding the transducer bracket down. This puts the transducer deeper into the water,

hopefully below the turbulence causing the noise. Don't allow the

transducer bracket to go below the bottom of the hull!

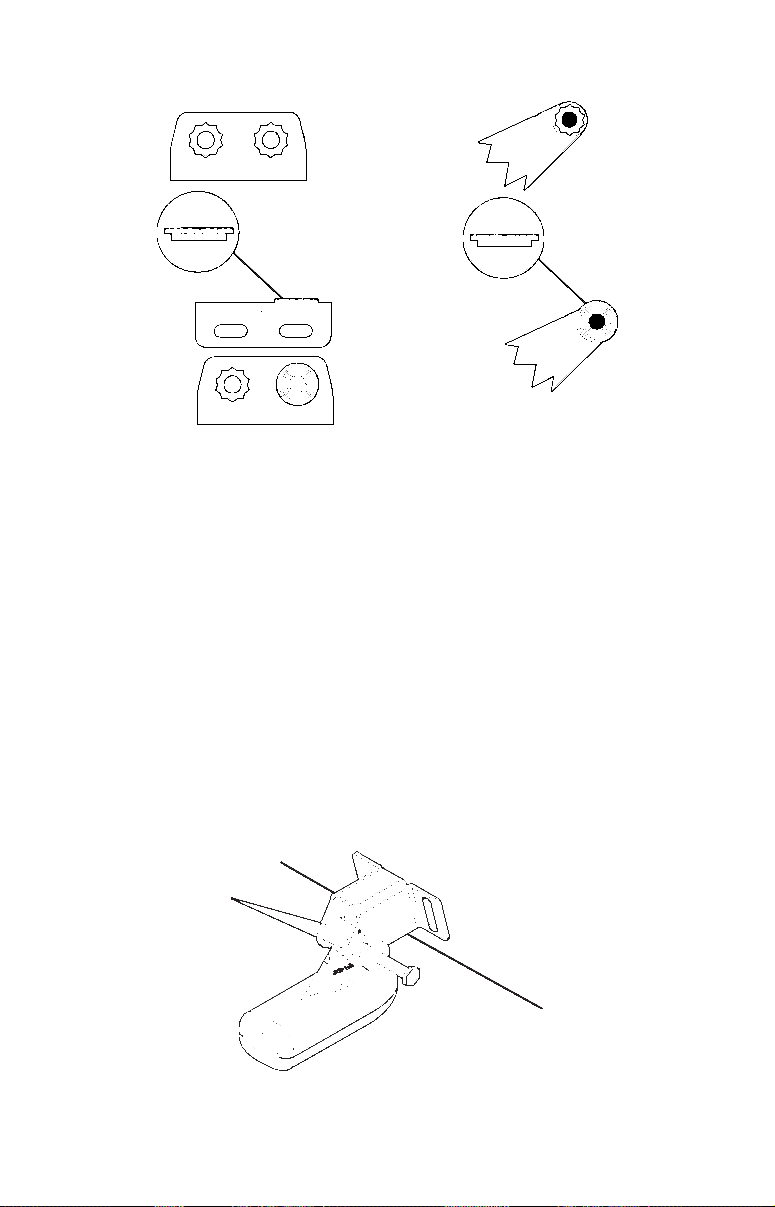

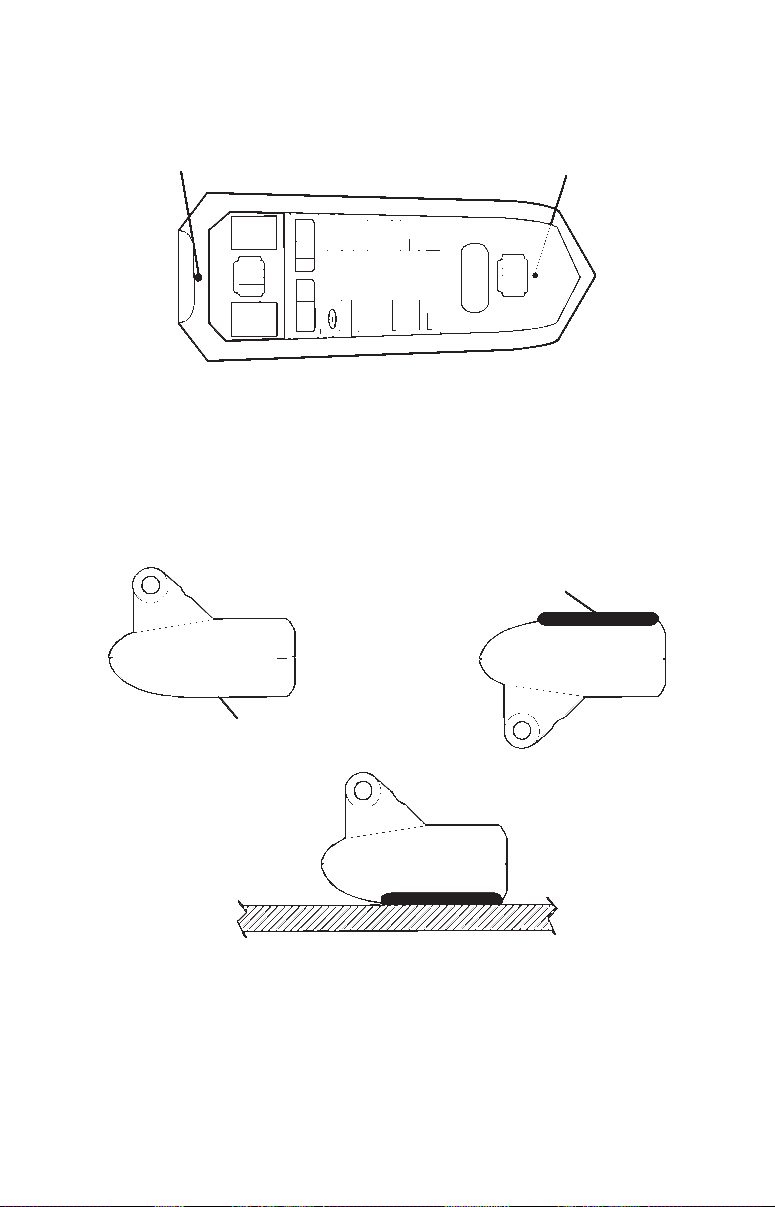

TROLLING MOTOR BRACKET INSTALLATION

(single-frequency only)

1. Attach the optional TMB-S bracket to the transducer as shown in the

following figure, using the hardware supplied with the transducer.

(Note: The internal tooth washer is supplied with the TMB-S.)

TMB-S bracket

Bolt

Internal tooth washer

Nut

Attach motor mounting bracket to transducer.

2. Slide the adjustable strap supplied with the TMB-S through the slot

in the transducer bracket and wrap it around the trolling motor. Position the transducer to aim straight down when the motor is in the

water. Tighten the strap securely.

3. Route the transducer cable alongside the trolling motor shaft. Use

plastic ties (not included) to attach the transducer cable to the trolling motor shaft. Make sure there is enough slack in the cable for the

motor to turn freely. Route the cable to the sonar unit and the transducer is ready for use.

Transducer mounted on trolling motor, side view.

16

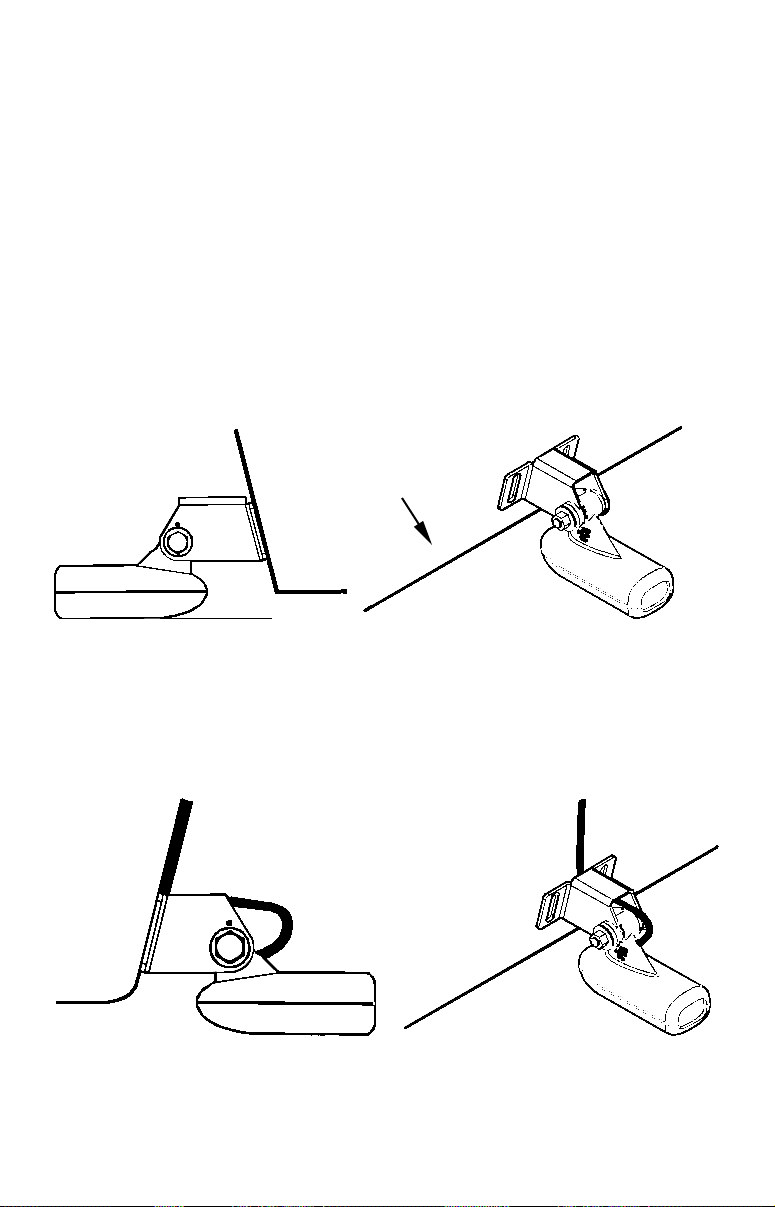

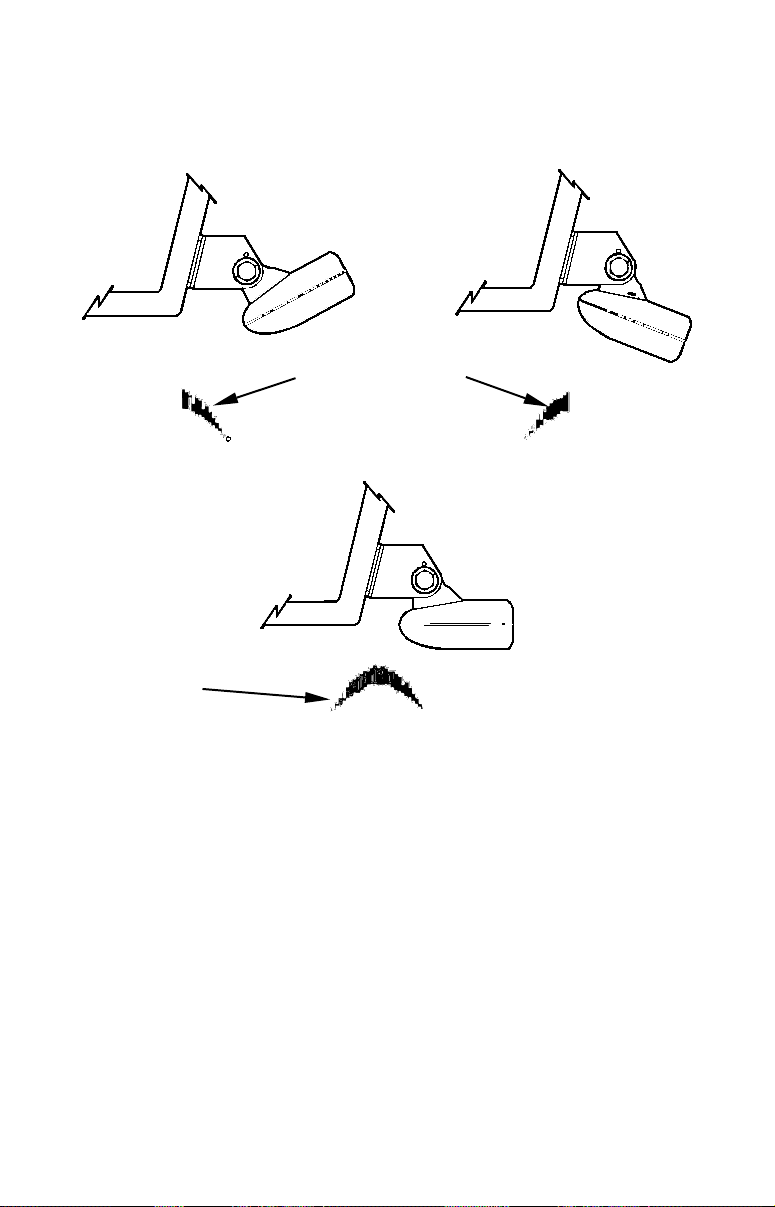

TRANSDUCER ORIENTATION AND FISH ARCHES

If you do not get good fish arches on your display, it could be because

the transducer is not parallel with the ground when the boat is at rest

in the water or at slow trolling speeds.

Partial fish arches

Transducer aimed

too far back

Transducer aimed

too far forward

Full fish arch

Proper transducer angle

Transducer angles and their effects on fish arches.

If the arch slopes up – but not back down – then the front of the transducer is too high and needs to be lowered. If only the back half of the

arch is printed, then the nose of the transducer is angled too far down

and needs to be raised.

NOTE:

Periodically wash the transducer's face with soap and water to remove any oil film. Oil and dirt on the face will reduce the sensitivity

or may even prevent operation.

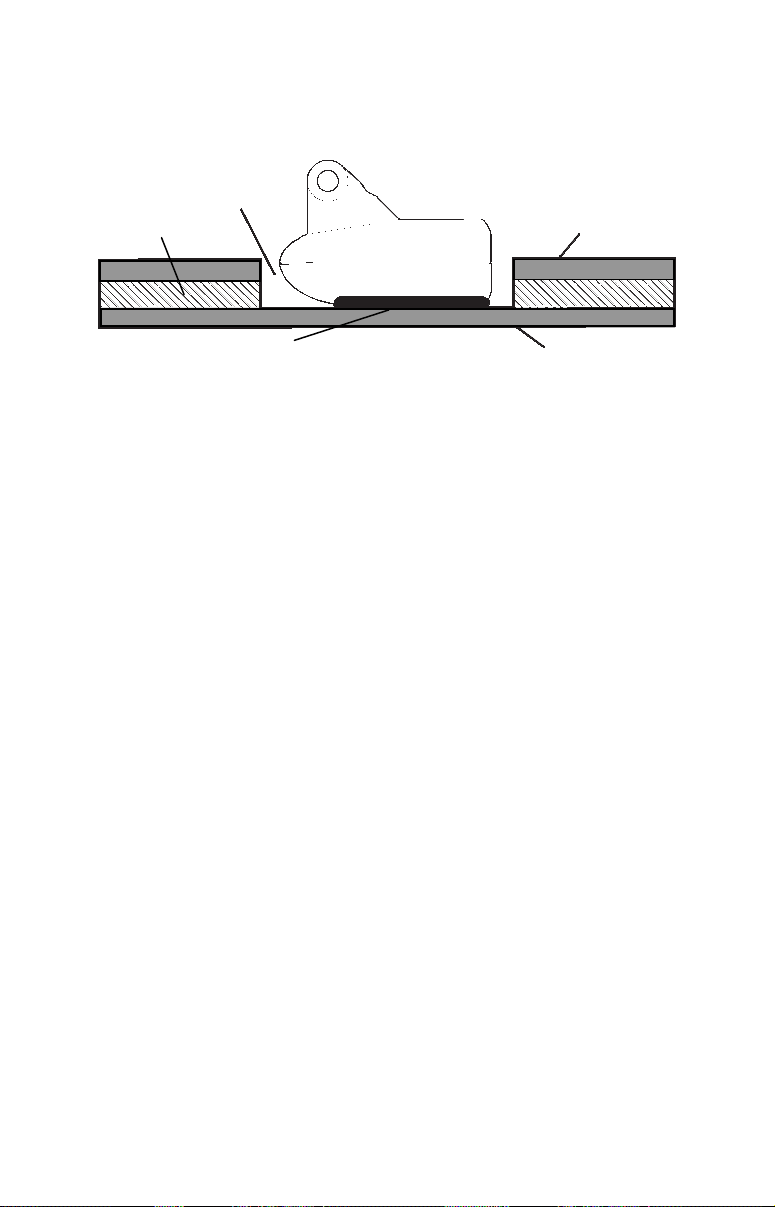

SHOOT-THRU-HULL PREPARATION

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass layers. The sonar signal must pass through solid fiberglass. A successful

17

transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood or foam) between layers of fiberglass if

the material is removed from the chosen area.

Fill with polyester resin

Flotation material

Inner hull

Epoxy to hull first

Epoxy the transducer to a solid portion of the hull.

Outer hull

For example, some (but not all) manufacturers use a layer of fiberglass,

then a core of balsa wood, finishing with an outer layer of fiberglass.

Removing the inner layer of fiberglass and the balsa wood core exposes

the outer layer of fiberglass. The transducer can then be epoxied directly to the outer layer of fiberglass. After the epoxy cures, the hull is

watertight and structurally sound. Remember, the sonar signal must

pass through solid fiberglass. Any air bubbles in the fiberglass or the

epoxy will reduce or eliminate the sonar signals.

WARNING:

Do not remove any material from your inner hull unless

you know the hull's composition. Careless grinding or

cutting on your hull can result in damage that could sink

your boat. Contact your boat dealer or manufacturer to

confirm your hull specifications.

To choose the proper location for thru-hull mounting, anchor the boat in

60 feet of water. Add a little water to the sump of the boat. Plug the

transducer into the sonar unit, turn it on, then hold the transducer over

the side of the boat. Adjust the sensitivity and range controls until a second bottom echo is seen on the display. (You will need to turn off both

automatic and ASP.) Don't touch the controls once they've been set.

Next, take the transducer out of the water and place it in the water in

the sump of the boat. Observe the sonar signal to see if there is a noticeable decrease in sensitivity. The second bottom signal may disappear and the bottom signal may decrease in intensity.

Move the transducer around to find the best location. If the sensitivity

control must be increased greatly to compensate, then the transducer

should be mounted on the outside of the hull. If not, then mark the lo-

18

cation that shot through the hull the best and follow the instructions on

the following pages for a shoot-thru-hull mounting.

Transducer location

(high speed)

Shoot-thru-hull transducer locations for

high speed or trolling speed operation.

Transducer location

(trolling speed)

Shoot-thru-hull Installation

1. Make sure the area is clean, dry and free of oil or grease, then sand

both the inside surface of the hull and the face of the transducer with

100 grit sandpaper. The surface of the hull must be flat so the entire

transducer face is in contact with the hull prior to bonding.

Spread epoxy here

Sand this surface

Epoxy transducer to hull.

2. Follow the instructions on the epoxy package and mix it thoroughly.

Do not mix it too fast, because it will cause bubbles to form in the epoxy. Apply a small amount on the face of the transducer as shown

above, then spread a small amount onto the sanded area on the hull.

19

Place the transducer into the epoxy, twisting and turning it to force

any air bubbles out from under the transducer face. The face of the

transducer should be parallel with the hull, with a minimum amount

of epoxy between the hull and transducer. After the epoxy dries,

route the cable to the sonar unit.

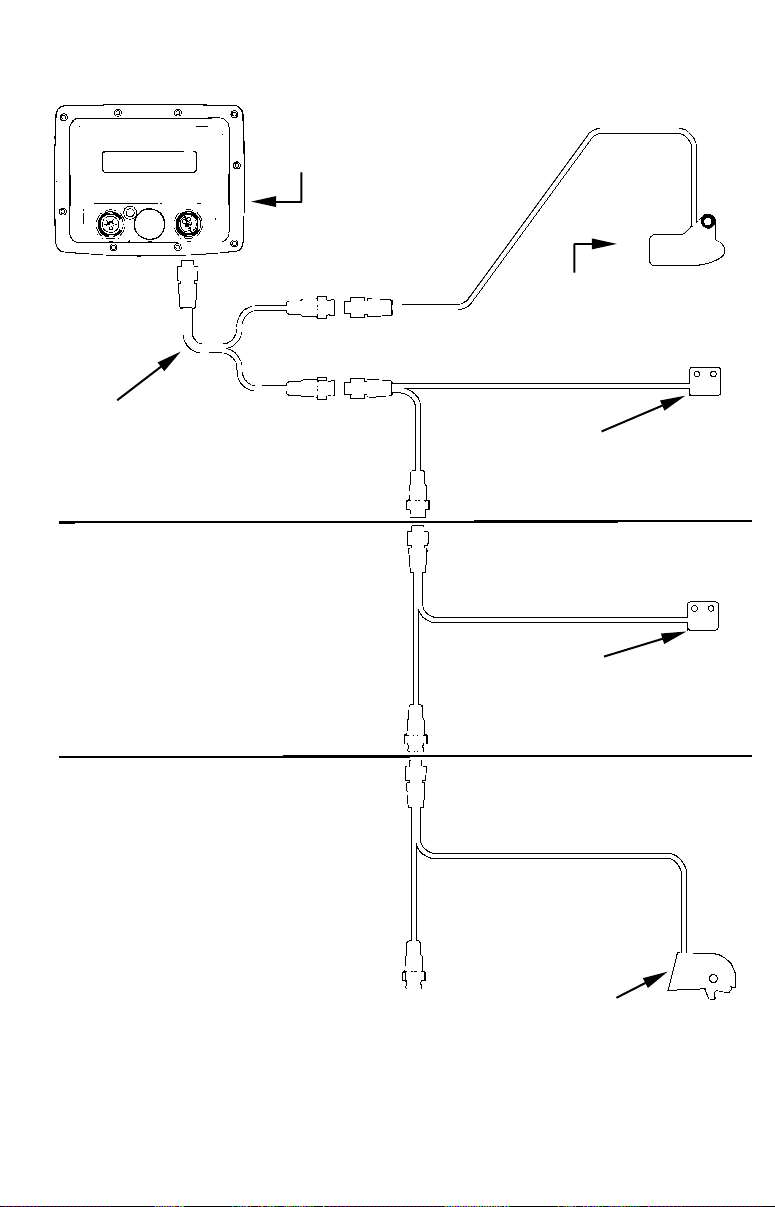

Speed/Temperature Sensors

This unit accepts up to three temperature sensors which can monitor

surface water, live well, bait well and virtually any other temperature.

If you want to use more than one temperature sensor or a speed sensor,

you must purchase the optional MY-4X adapter cable. You also need to

be careful when purchasing the temperature sensors, because each

temperature sensor has its own fixed electronic "address." The sensors

are labeled "Water," "T-2" (or Temp-2) and "T-3" (or Temp-3).

The first "Water" temperature sensor is built into the transducer. This

is the sensor that measures surface water temperature. If you want two

(or more) temperature readings from other locations, you'll need to use

the proper sensors. For example, you can't use two additional T-3 sensors. The sensors that fit this unit are:

• TS-1X This sensor will over-ride the temperature sensor

built into the transducer and over-ride the temperature sensor in a ST-TGY combination sensor. (This sensor is not recommended.)

• TS-2X One sensor for "T-2" temperature display.

• TS-3X One sensor for "T-3" temperature display.

• SP-X One speed sensor for "Speed" display.

• ST-TGY This combination sensor will provide speed and

temperature readings, but the temperature

reading will be displayed as the "Water" temperature because it will over-ride the temperature sensor in the transducer. (This sensor is

not recommended.)

See the wiring diagram on the following page for temperature and

speed sensor combinations.

20

MY-4X

Cable

Three-temperature

sensor installation

Sensor Chart

Sonar unit

rear view

Two-temperature

sensor installation

Temperature

sensor built into

transducer

TS-2X

temperature sensor

TS-3X

temperature sensor

Three-temperature sensor

installation with speed

SP-X speed sensor

21

Optional Speed Sensor Installation

All the units in this series can display speed and distance traveled, but

only the X126DF and X136DF come packed with a speed sensor. If you

wish to purchase an optional additional sensor for your unit, refer to

the accessory ordering information inside the back cover of this manual. The following instructions describe how to install the speed sensor.

Recommended tools for this job include: drill, 7/8" drill bit, 1/8" drill bit for

pilot holes, screwdriver. Required supplies for this job include: four #8

stainless steel wood screws (3/4" long), high quality, marine grade above-

or below-waterline caulking compound.

First find a location on the boat's transom where the water flow is smoothest. Don't mount the sensor behind strakes or ribs. These will disturb the

water flow to the speed sensor. Make sure the sensor will remain in the

water when the boat is on plane. Also make sure the location doesn't interfere with the boat's trailer. Typically, the sensor is mounted about one foot

to the side of the transom's centerline.

Once you've determined the proper location for the unit, place the sensor on the transom. The bottom of the bracket should be flush with the

hull's bottom. Using the sensor as a template, mark the hull for the

screws' pilot holes. Drill four 1/8" holes, one in each end of the slots.

Mount the sensor to the hull using #8 stainless steel wood screws (not

included). Use a high quality, marine grade above- or below-waterline

caulking compound to seal the screws. Make sure the sensor is flush

with the bottom of the hull and tighten the screws.

Good location

Stern view showing good location for mounting sensor on transom.

Transom

Bottom of hull

Speed sensor mounting configuration:

side view (left) and rear view (right.)

Bottom of hull

22

If the base of the transom has a radius, fill the gap between the transom and the sensor with the caulking compound. This will help ensure

a smooth water flow.

Route the sensor's cable through or over the transom to the sonar unit.

If you need to drill a hole in the transom to pass the connector through,

the required hole size is 7/8".

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline sealant used for the screws.

The sensor is now ready for use. Connect the sensor to the in-line connector on the MY-4X adapter cable. If you have any questions concerning the installation of the sensor, please contact your local boat dealer.

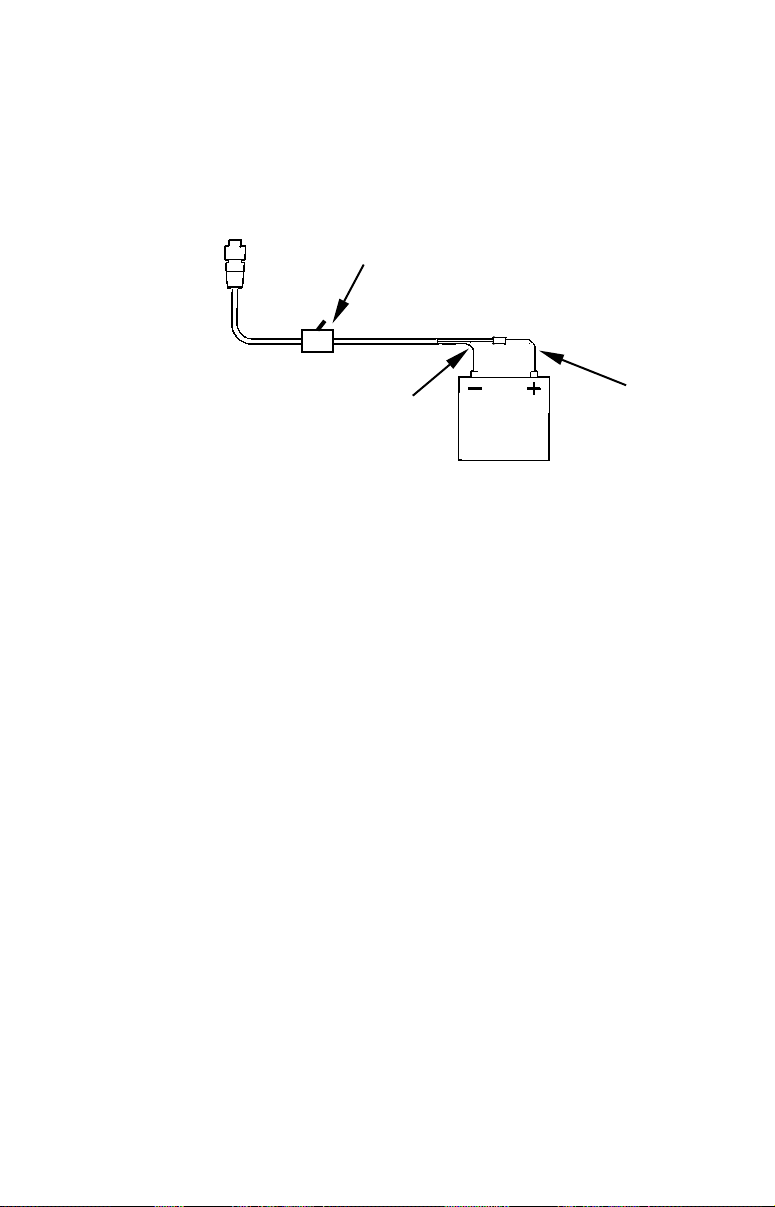

Power Connections

The unit works from a 12-volt battery system. For the best results, attach the power cable directly to the battery. You can attach the power

cable to an accessory or power buss, however you may have problems

with electrical interference. Therefore, it's safer to go ahead and attach

the power cable directly to the battery.

CAUTION:

When using the unit in a saltwater environment, we strongly recommend that you shut off the power supply to the power cable when

the unit is not in use. When the unit is turned off but still connected

to a power supply, electrolysis can occur in the power cable plug.

This may result in corrosion of the plug body along with the electrical contacts in the cable and the unit's power socket.

In saltwater environments we recommend you connect the power

cable to the auxiliary power switch included in most boat designs.

If that results in electrical interference, or if such a switch is not

available, we recommend connecting direct to the battery and installing an inline switch. This will let you shut off power to the

power cable when the unit is not in use. When you are not using

the unit, you should always shut off power to the power cable, especially when the power cable is disconnected from the unit.

If possible, keep the power cable away from other boat wiring, especially the engine's wires. This will provide the best isolation from electrical noise. If the cable is not long enough, splice #18 gauge wire onto

it. The power cable has two wires, red and black. Red is the positive

23

lead, black is negative or ground. Make sure to attach the in-line fuse

3 amp fuse

holder to the red lead as close to the power source as possible.

For example, if you have to extend the power cable to the battery or

power buss, attach one end of the fuse holder directly to the battery or

power buss. This will protect both the unit and the power cable in the

event of a short. It uses a 3-amp fuse.

Optional power off switch for

saltwater installations

To unit

Black wire

12 volt

battery

Power connections for the sonar unit.

Red wire with

CAUTION:

Do not use this product without a 3-amp fuse wired into the power

cable! Failure to use a 3-amp fuse will void your warranty.

This unit has reverse polarity protection. No damage will occur if the

power wires are reversed. However, the unit will not work until the

wires are attached correctly.

An optional 8-foot, CA-4 external power cable with a cigarette lighter

adapter is available from Lowrance.

24

Loading...

Loading...