Page 1

www.lowrance.com

Pub. 988-0151-221

LMF-400

Multi-function Gauge

Installation and Operation

Instructions

Page 2

Copyright © 2005 Lowrance Electronics, Inc.

All rights reserved.

No part of this manual may be copied, reproduced, republished,

transmitted or distributed for any purpose, without prior written

consent of Lowrance Electronics. Any unauthorized commercial

distribution of this manual is strictly prohibited.

Lowrance Electronics may find it necessary to change or end our

policies, regulations and special offers at any time. We reserve the right

to do so without notice. All features and specifications subject to change

without notice. On the cover: LMF-400 shown.

For free owner's manuals and other information,

visit our web site:

www.lowrance.com

Lowrance Electronics Inc.

12000 E. Skelly Dr.

Tulsa, OK USA 74128-2486

Printed in USA.

Page 3

Table of Contents

Section 1: Introduction ............................................................ 3

Section 2: Installation .............................................................. 5

Preparation ................................................................................... 5

Recommended Tools and supplies............................................ 5

Mounting the Unit ........................................................................ 5

Connecting to a NMEA 2000 Network..................................... 6

Network Nodes.......................................................................... 7

Adding a Network Node............................................................ 7

Additional Network Information.............................................. 8

Section 3: Operation ................................................................. 9

Boat Setup..................................................................................... 9

Pages ........................................................................................... 10

Engine Trim ............................................................................10

Diagnostics .............................................................................. 10

Fuel Manager .......................................................................... 10

GPS Position ........................................................................... 11

Single Analog .......................................................................... 11

Dual Analog............................................................................. 11

Quad Analog............................................................................ 11

Single Digital .......................................................................... 11

Dual Digital............................................................................. 12

Quad Digital............................................................................ 12

Synchronizer ........................................................................... 12

Trim Tabs ................................................................................ 12

Viewing options........................................................................... 12

Basic Menu.................................................................................. 12

Adding Pages........................................................................... 13

Removing Pages ...................................................................... 13

Page Scrolling.......................................................................... 14

Pop-Ups Setup......................................................................... 14

Screen .......................................................................................... 15

Audio Setup................................................................................. 16

System Setup .............................................................................. 17

Bus Devices .............................................................................17

To Reset Values:.................................................................. 17

Section 4: EP Configuration & Calibration ....................... 19

Temperature Sensors.............................................................. 20

To Unconfigure a temp sensor:........................................... 20

To Configure a temp sensor:............................................... 20

To Reconfigure a temp sensor: ........................................... 20

Fuel Flow (Port, Center and Stbd) ......................................... 21

1

Page 4

Fluid Level .................................................................................. 22

To unconfigure Fluid Level:.................................................... 23

Calibrate.................................................................................. 25

Reset Values............................................................................ 25

GPS Module, Paddle Wheel Speed and Trim Tabs ...............25

Calibration of EP Devices........................................................... 26

Partial Fill ........................................................................... 28

Trim Tabs ................................................................................ 28

Section 5: Advanced Operation............................................ 31

Customizing Pages...................................................................... 31

Single Analog .............................................................................. 31

Dual Analog................................................................................. 32

Quad Analog................................................................................ 32

Single Digital .............................................................................. 33

Dual Digital................................................................................. 34

Quad Digital................................................................................ 35

Trim Tabs .................................................................................... 35

GPS Position ............................................................................... 36

Fuel Manager.............................................................................. 36

Fuel Setup ............................................................................... 36

Adjust Calibration............................................................... 36

Fuel Remaining Source....................................................... 36

Reset Seasonal .................................................................... 37

Refill Tank........................................................................... 37

Partial Fill ........................................................................... 37

Economy Speed Source .......................................................37

Reset Trip Fuel ....................................................................... 37

System Setup Menu.................................................................... 38

Engine Displayed ................................................................ 38

Bus Devices ......................................................................... 38

Sonar Alarms .......................................................................... 38

Engine/Tank Configuration ................................................ 39

Reset Values: ....................................................................... 40

System Information ................................................................ 40

Speed Range ........................................................................ 40

Pressure Range ................................................................... 40

Change Units ..............................................................................41

Speed and Distance............................................................. 41

Temperature........................................................................ 41

Pressure............................................................................... 41

Depth ...................................................................................41

GPS Coordinates ................................................................. 42

Volume................................................................................. 42

2

Page 5

Section 1: Introduction

Thank you for buying the Lowrance LMF-400! Your unit is a highquality, multi-function, digital gauge designed to work with a

LowranceNET network. This is the NMEA 2000

developed by Lowrance Electronics.

Caution:

Installing LowranceNET NMEA 2000 devices is significantly

different from installing earlier Lowrance components without

NMEA 2000 features. You should read all of the installation

instructions before proceeding.

This gauge will only work with a NMEA 2000 network. It MUST be

connected to a NMEA 2000 network or it WILL NOT function. When

properly installed, the LMF-400 will display information from a variety

of Lowrance Electronic Probe (EP) sensors connected to the network.

networking system

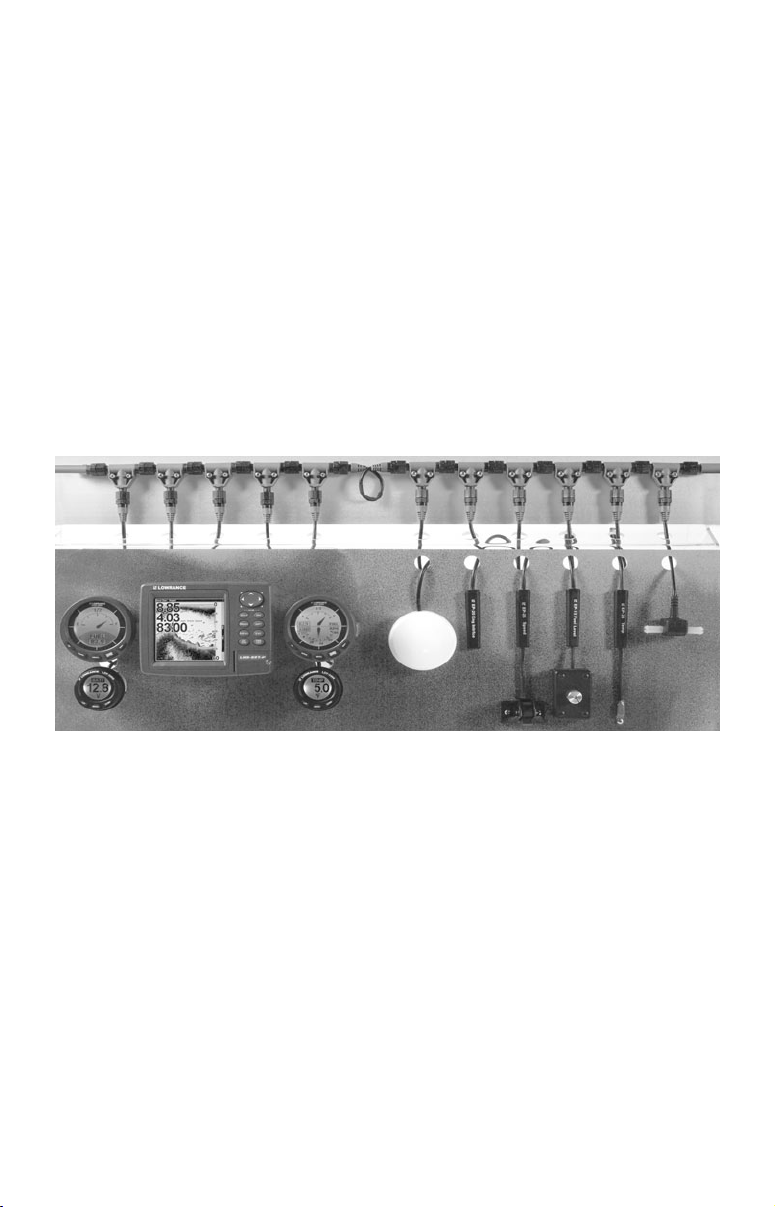

A NMEA 2000 network using LowranceNET components.

All Lowrance NMEA 2000 capable devices are either NMEA 2000

certified or certification is pending. See our web site,

for the latest product status information.

To get started with your Lowrance gauge, first read the installation

section. It contains instructions for installing the LMF-400.

After you've read those instructions, install the gauge and any EP

sensors you may have purchased, then read the rest of this manual.

Each sensor comes with its own installation instruction sheet, but this

manual describes how the gauge operates with each sensor, and how to

calibrate the sensors. The more you know about the gauge, the better it

will work for you.

Your package also includes another manual, part 988-0154-172, which

contains complete instructions for creating or expanding a NMEA 2000

network.

3

www.lowrance.com,

Page 6

LowranceNET teams up the powerful NMEA 2000 network standard

with a fast-growing, cutting-edge family of Lowrance Electronic Probe

Sensors. At press time, the product line includes the EP-10 Fuel Flow,

EP-15 Fluid Level, EP-20 Engine interface, EP-25 Speed, EP-35 Temp

and EP-45 Water Pressure sensors.

And what's more exciting, there are others on the way! Be sure to log

onto

www.lowrance.com from time to time for the latest developments,

including updated operation manuals and instruction sheets you can

download free of charge. When you're ready to expand your network,

see the accessory ordering information on the back cover of this

manual.

NOTICE!

The storage and operation temperature range for your unit is from

-4 degrees to +167 degrees Fahrenheit (-20 degrees to +75 degrees

Celsius). Extended storage or operation in temperatures higher or

lower than specified will damage the liquid crystal display in your unit.

This type of damage is not covered by the warranty. For more

information, contact the factory's Customer Service Department; phone

numbers are inside the manual's back cover.

4

Page 7

Section 2: Installation

Preparation

The design of the LMF-400 allows convenient mounting in the dash of

your boat, or it can be mounted on any flat panel at least four inches in

diameter.

To mount the LMF-400 in the dash, first make sure there is sufficient

clearance behind the panel in the desired location. Also, see that there is

adequate room to connect power and transducer cables. At least 3-1/2 inches

are needed behind the surface of the dash to clear all connectors and wiring.

Recommended Tools and supplies

Recommended tools for this job include: hole saw, drill, drill bit (for

starter hole). Required supplies for this job include: "U" bracket, lock

washers and wing nuts (included).

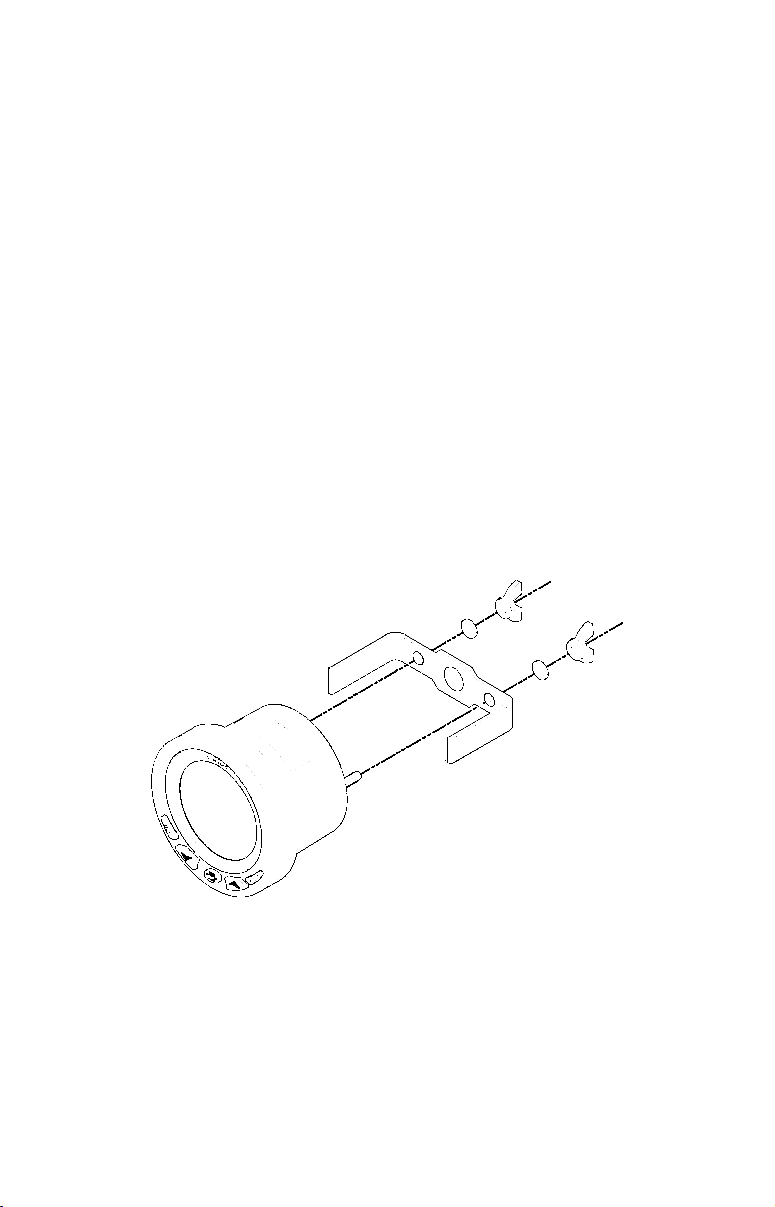

Mounting the Unit

Cut a 3-3/8 inch diameter mounting hole with a hole saw. A "U" bracket

is supplied to hold the sonar to the dash. Place it over the threaded

studs on the back of the unit and secure it with the lock washers and

nylon wing nuts provided with the unit.

Secure unit to the dash using "U" bracket as shown.

The bracket is designed to secure the unit to a dash with a thickness of

2 mm. If your dash is thicker than 2 mm, the "U" bracket will be too

long. Simply place washers or spacers between the unit and the bracket

until you can tighten the wing nuts and secure the unit in place. Once

the unit is in place, you need to connect it to a power supply, to the

speaker (provided) and the LowranceNET.

5

Page 8

Yellow wire:

Piezo ground

Blue wire:

LMF-400

Housing

LMF-400 with power cable wiring and NMEA 2000 Cable Connection.

Piezo positive

White wire:

Dash light

positive

Black wire:

Dash light

ground

LMF-400

NMEA

2000

Network

Cable

Connecting to a NMEA 2000 Network

A network bus is an installed and operational network cable (backbone)

running the length of your boat, already connected to a power supply

and properly terminated. Such a bus provides network connection

nodes at various locations around your boat.

This is similar to the telephone wiring in a house. If you pick up a

phone in your living room, you can hear someone talking into the phone

in the bedroom.

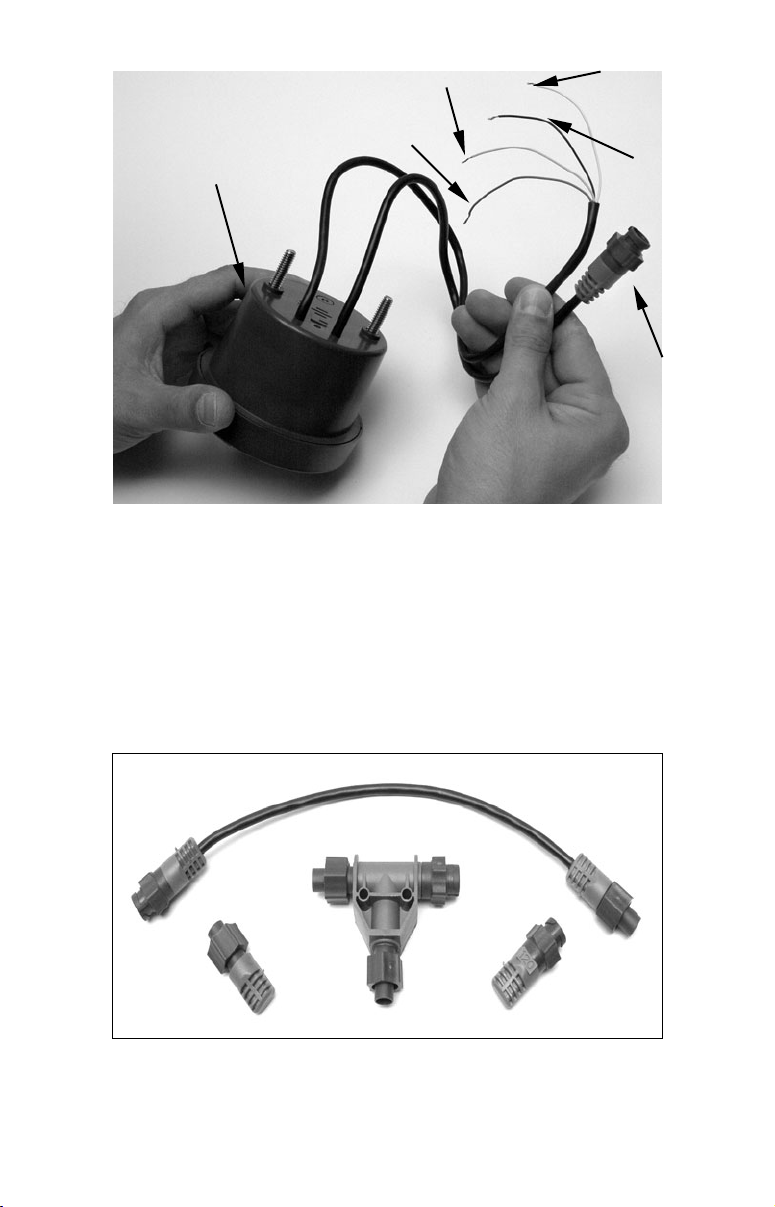

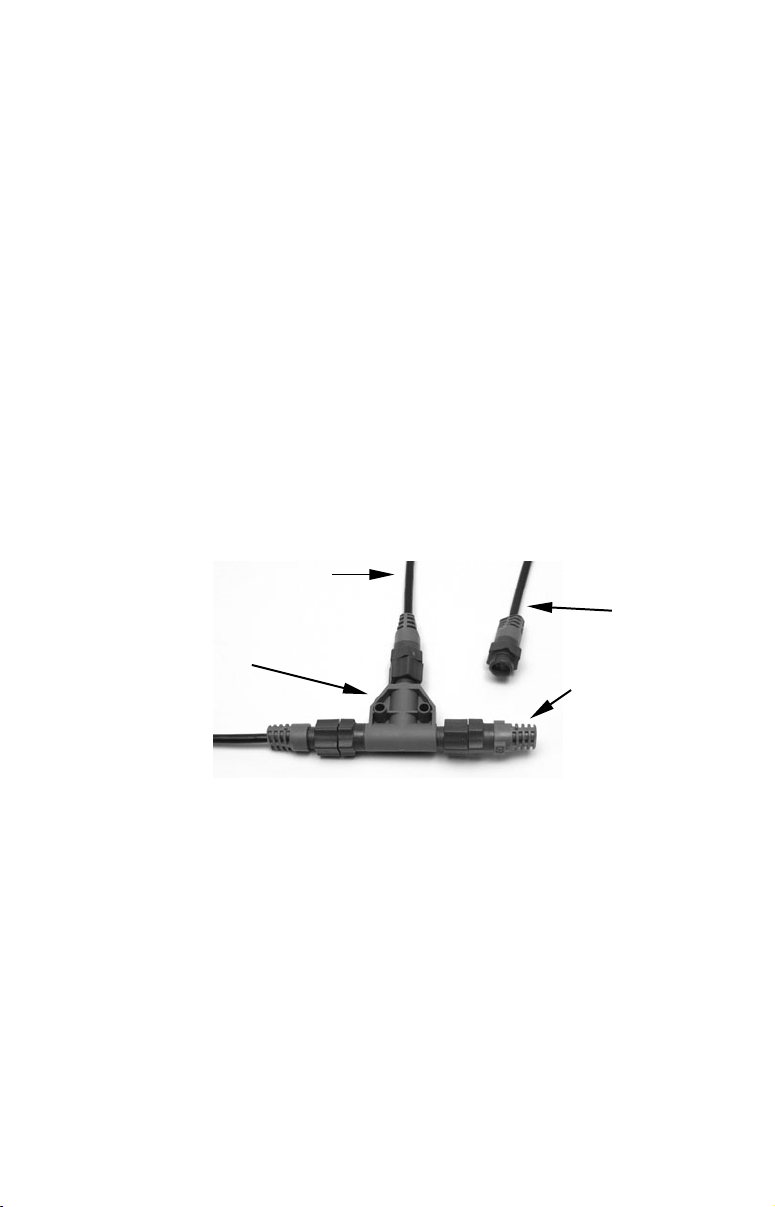

LowranceNET Node Kit for a NMEA 2000 network. Includes a 2 foot

extension cable, T connector, 120-ohm male terminator and 120-ohm

female terminator.

6

Page 9

For complete instructions on setting up a new NMEA 2000 network or

expanding an existing one, see the other document packed with your

gauge, "Setup and Installation of NMEA 2000 Networks, General

Information" part number 988-0154-172. If that document is missing, it

can be downloaded free from the Lowrance web site.

Network Nodes

A network bus is built of network nodes spread along a backbone.

Network nodes are made by fitting T-shaped connectors into the

backbone (using the sockets on the sides), and attaching a display unit or

sensor at the bottom of the "T."

Using our telephone example, the T connectors are similar to telephone

jacks. The backbone is like the phone wiring running through a house.

Phones in a house must be connected to each other to communicate, and

in the same way only sensors and display units plugged into the NMEA

network can share information.

Connections found in the middle of the bus will have one or more of these

T-shaped connectors with the backbone cables plugged into both sides.

Connections at the end of a network will have the backbone plugged into

one side, and a terminator plugged into the other, as shown in the

following figure.

Cable from

sensor or

display unit

LEI or Lowrance

device needs an

open T.

T connector

Backbone cable

(to rest of bus)

NMEA 2000 network node located at the end of a NMEA 2000 bus.

Terminator at

the very end

of the bus

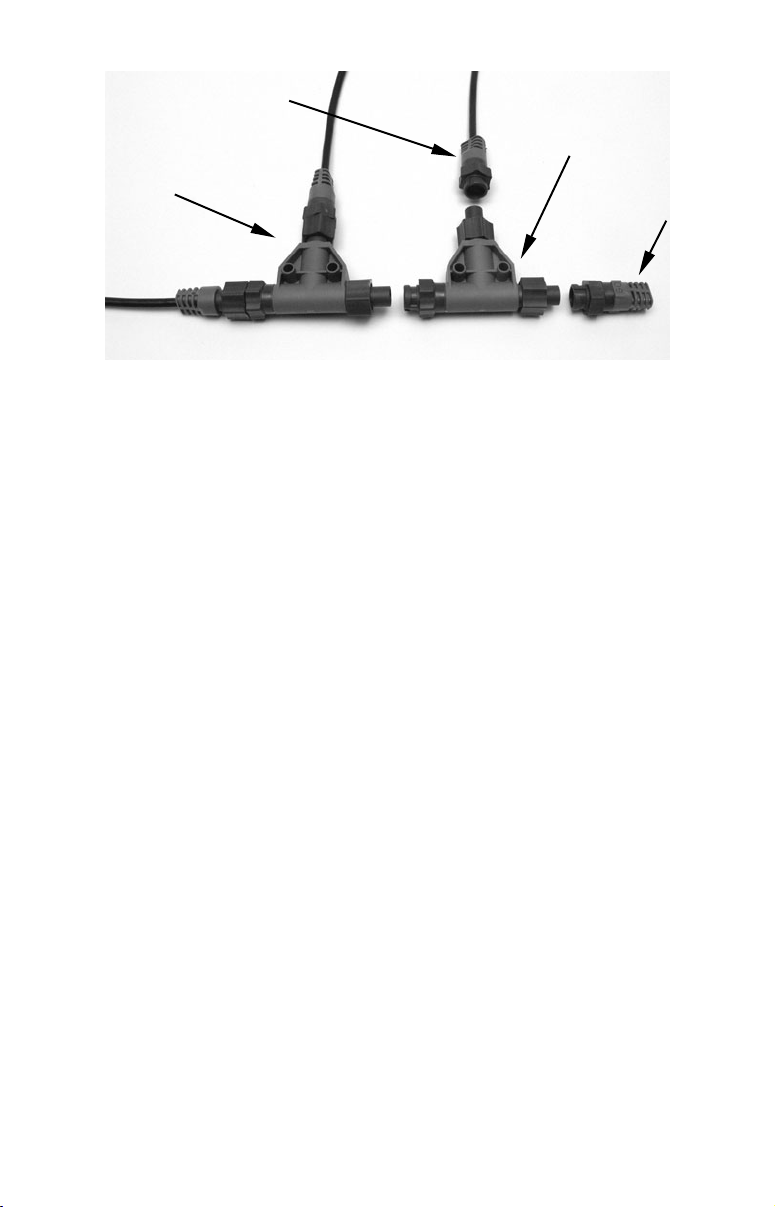

Adding a Network Node

You can add a node anywhere along the network backbone where a

connection already exists. This connection could be at the end of the

network (between a T connector and a terminator), between two T

connectors, between a T connector and a backbone extension cable, or

between two extension cables. Wherever you want to add the new node,

simply separate the sockets of the old connection and attach your new T

connector between them.

7

Page 10

Lowrance or LEI device con-

nects to new T connector.

Existing network

node

Add a new device to a NMEA 2000 bus by attaching a T connector

between two T connectors, between a T connector and the end

terminator, or between two backbone extension cables.

Add T-shaped connector to add device

to bus.

Attach

terminator at

end of bus.

If you want to add a node at the end of the line (as shown in the previous

figure), remove the terminator from the very last connector, securely

attach the new T connector, and then attach the terminator on the new

connector. Either method will allow you to add a device.

Additional Network Information

Further instructions on creating or expanding a LowranceNET network

are illustrated in the NMEA 2000 network setup booklet, part number

988-0154-172, which came packed with this manual.

8

Page 11

Section 3: Operation

The displays and settings in this digital gauge are controlled by a fivebutton keypad. The buttons are

EXIT. The MENU key calls up the basic menu, which allows you to set up

as many as 16 pages for display. The

scroll through and highlight menu items. The

referred to as the

ENTER key) allows you to scroll forward through a

series of pages and is used to select items from menus. The

used to close menus and scroll backward through a series of pages.

LMF-400 keypad.

Boat Setup

When the LMF-400 powers up for the first time, the screen will show

the

Boat Setup menu. You will not be able to proceed without

completing Boat Setup, which requires you to program into the unit the

number of engines and gas tanks on your vessel. Boat Setup will only

appear again if you reset Engine/Tank configuration, add certain EP

sensors or if configuration is lost.

To complete Boat Setup:

1. With Boat Setup highlighted, press

allowing you to choose the number of engines and fuel tanks on your

vessel. The Boat Setup menu options are: 1 Eng/1 Tank, 1 Eng/2 Tank,

2 Eng/1 Tank, 2 Eng/2 Tanks, 3 Eng/1 Tank or

2. Choose the option that applies to your vessel and press ENTER. After

setting the engine/tank configuration, you will need to enter the size of

each tank via the Set Tank Size menu. It will appear with up to three

options, depending on the number of tanks you chose during Boat

Setup. The options are: Port Tank, Stbd Tank and Cen Tank.

3. Select the tank you want to set up and press

the Setting Tank Size window. If you selected one tank during Boat

Setup, you will be taken directly to the Setting Tank Size Window.

UP, DOWN, MENU, PAGES/ENTER and

UP and DOWN keys are used to

PAGES/ENTER key (also

EXIT key is

ENTER. A menu will appear,

3 Eng/3 Tanks.

ENTER. That will launch

9

Page 12

4. Use the

hold and press

UP and DOWN keys to enter how many gallons the tank will

ENTER.

Press EXIT and repeat steps 3 and 4 for each of the remaining tanks.

5. After all tanks on your vessel have been setup, press EXIT repeatedly

to be directed back to the main display.

NOTE:

If your LMF-400 was already installed on your boat you likely will

not have to complete boat setup. But, if you would like to go

through the setup, take a look at the following instructions.

1. Press

Select

MENU, scroll down to SYSTEM SETUP, then press ENTER.

ENG/TANK CFG and press ENTER|ENTER.

2. The following message will appear: Press Enter to Reset

Eng/Tank Cfg. Press

directed to the Boat

press

ENTER to access the engine/tank configuration menu.

ENTER to reset the configuration and be

Setup screen. From the Boat Setup screen,

Pages

Pages are the backbone of the LMF-400. They give you the power to

mix and match data that will be displayed on the screen. Once you have

picked pages that meet your preferences, the 400's multi-functionality

really kicks in, allowing you to customize pages with the data most

important to you. We'll take a closer look at customizing pages in

Section 5: Advanced Operation.

The LMF-400 has the capability to support up to 16 pages, which

means you can add pages you find most helpful more than once,

customizing each one differently.

Engine Trim (from left to right), Diagnostics, Fuel Manager and GPS

Module page.

Engine Trim

Monitors position of the boat’s engine in either percentages or degrees.

Diagnostics

Monitors engine performance, notifying you if a problem arises.

Fuel Manager

Fuel Manager page has three digital readouts capable of displaying:

Fuel Flow, Fuel Economy, Fuel Remaining, Fuel Range, Trip Fuel

Used, Seasonal Fuel, Paddle Wheel Speed, Pitot Speed and GPS Speed.

10

Page 13

GPS Position

The GPS position page displays the boater’s position in LatitudeLongitude, using Degrees-Minutes-Seconds or Degrees-Minutes as

units of measure.

Single Analog (from left to right), Dual Analog, Quad Analog and

Single Digital page.

Single Analog

The single analog page displays an analog gauge that can show: Alt

Voltage, Battery Voltage, Engine Temp, Atmospheric Pressure,

Temperature, Fluid Level, PaddleWheel Speed, Pitot Speed, GPS Speed

and Tachometer.

Dual Analog

The Dual Analog page shows a pair of analog gauges that can display:

Alt Voltage, Battery Voltage, Engine Temperature, Atmospheric

Pressure, Temperature, Fluid Level, Paddle Wheel Speed, Pitot Speed,

GPS Speed and Tachometer.

Quad Analog

The Quad Analog page displays four analog gauges that can monitor:

Alt Voltage, Battery Voltage, Engine Temperature, Atmospheric

Pressure, Temperature, Paddle Wheel Speed, Pitot Speed, GPS Speed

and Tachometer.

Single Digital

The Single Digital page displays a digital gauge that can monitor: Alt

Voltage, Battery Voltage, Engine Temperature, Atmospheric Pressure,

Temperature, Depth, Engine Load, Total Engine Hours, Fuel Flow,

Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel Speed, Pitot

Speed, GPS Speed and Tachometer.

11

Page 14

Dual Digital (from left to right), Quad Digital, Synchronizer and Trim

Tabs page.

Dual Digital

The Dual Digital page features a pair of digital gauges which can

display: Alt Voltage, Battery Voltage, Engine Temp, Atmospheric

Pressure, Temperature, Depth, Engine Load, Total Engine Hours, Fuel

Flow, Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel

Speed, Pitot Speed, GPS Speed and Tachometer.

Quad Digital

The Quad Digital page has four digital gauges capable of displaying:

Alt Voltage, Battery Voltage, Engine Temperature, Atmospheric

Pressure, Temperature, Depth, Engine Load, Total Engine Hours, Fuel

Flow, Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel

Speed, Pitot Speed, GPS Speed and Tachometer.

Synchronizer

The Synchronizer page will show RPM for up to three engines, allowing

users to synchronize the engines for smoother performance.

Trim Tabs

The Trim Tab page monitors the position of the Trim Tabs using either

percentages or degrees as units of measure.

Viewing options

The pages may be viewed on the screen in one of two ways. You can

scroll through them manually by using the

ENTER and EXIT keys or set

them to scroll automatically via the Page Scrolling function. We'll

explore Page Scrolling in greater detail later in this section.

NOTE:

The

ENTER and EXIT keys work together to help you scroll through

pages on the main display. Pressing the

in one direction. Pushing the

EXIT key moves the scroll in the other

ENTER key moves the scroll

direction.

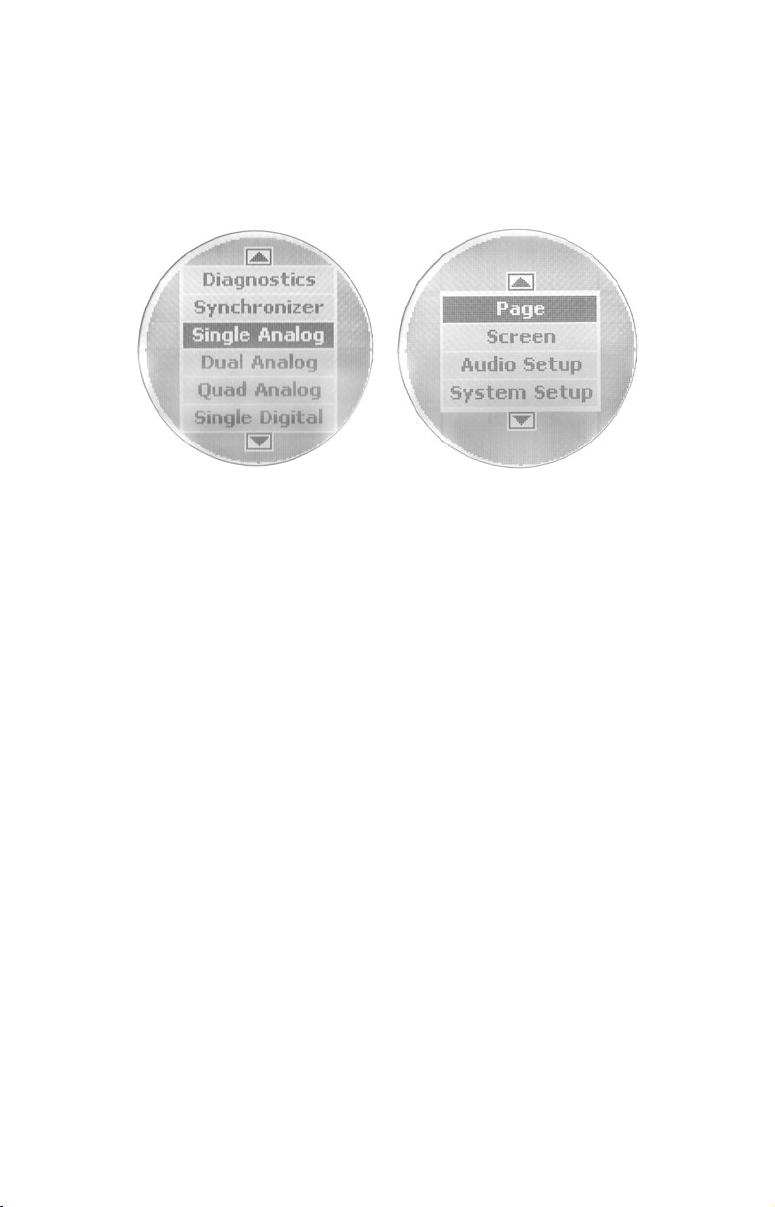

Basic Menu

Each page has its own menu. The menus vary somewhat from page to

page, but all include these basic menu categories: Page, Screen, Audio

Setup and

System Setup.

12

Page 15

The pages may be displayed one at a time or in a timed scroll set at an

interval of your choosing via the page

scrolling setting.

NOTE:

The System Setup menu is the lone basic menu category that

differs slightly from page to page, depending on the page being

displayed. We'll delve into that later in this section.

Scrolling list of page options (left) with basic menu categories (right).

Adding Pages

To add a page to the display:

1. Press

four options: Add Page, Remove Page, Page Scrolling and

MENU, select PAGES and press ENTER. A menu will pop up with

Pop-Ups

Setup.

2. Select

ADD PAGE and press ENTER. Use the UP and DOWN keys to

scroll through the list.

3. You can select the page you want to display by pressing

ENTER when

the desired page is highlighted. An adding page prompt will appear

asking you to press the

ENTER key to add the page.

4. Press ENTER to add the page, which will take you back to the main

display, where the page you selected will be on the screen.

5. If you choose not to add the selected page, press

EXIT repeatedly to

return to the main display.

Removing Pages

To remove a page from the display:

1. Press

2.

Choose REMOVE PAGE and press ENTER. You won't have a list to choose

MENU, select PAGES and press ENTER.

from, like when we added a page. You will only be able to remove the

page that was on the main display when you pressed the

MENU key.

The following prompt will appear: Press Enter to Remove current Page.

3. Press

ENTER, which will return you to the main display.

4. If you decide not to remove the selected page, press EXIT repeatedly

to return to the main display.

13

Page 16

Page Scrolling

Once you have added the pages you want to monitor, you'll have two

ways to view them on the display. You can scroll through the pages

manually by using the

ENTER and EXIT keys or utilize the Page

Scrolling function to automatically scroll through the pages at an

interval of your choosing.

To activate Page Scrolling:

1. Press

MENU, select PAGES and press ENTER.

2. Select PAGE SCROLLING and press ENTER. The Page Scrolling menu will

appear with two settings: Off

and Set Time.

3. To set the scrolling interval, choose SET TIME and press ENTER.

4. Use the UP and DOWN keys to select an interval between one and 60

seconds. At the bottom of the Set Time display will be a message, Press

Enter when finished. After you are satisfied with the selected interval,

press

ENTER.

To turn off Page Scrolling:

To get back into the Page Scrolling menu, repeat the steps you used to

activate Page Scrolling.

But this time, when you access the Page Scrolling menu, select

OFF

instead of SET TIME.

Pop-Ups Setup

Pop-Ups Setup is accessed from the basic menu by selecting

pressing

options will appear: RPM, Engine Trim, Trim Tabs and

ENTER. Scroll down to Pop Ups Setup and press ENTER. Four

Stay-on Time.

PAGES and

The Pop-Ups feature makes it possible for you to be alerted when the

category you selected (RPM, Engine Trim, Trim Tabs) exceeds a

threshold of your choosing. When a threshold is exceeded, the main

page for the category will pop up on the main display for a preset

duration. You can choose how long the page will be displayed via the

Stay-on Time option.

RPM: If you highlight

will appear: Off and Set Threshold. Select

or highlight Set Threshold and press

RPM and press ENTER, a pair of menu options

OFF to turn off a RPM pop up

ENTER, to set a RPM threshold.

The threshold for RPM ranges from 50 to 3,000 RPM.

Engine Trim: If you select

options will appear: Off and Set

Engine Trim pop up or highlight Set Threshold and press

ENGINE TRIM and press ENTER, a pair of menu

Threshold. Select Off to turn off an

ENTER, to set

an Engine Trim threshold. The threshold for Engine Trim ranges from

3% to 50%.

Trim Tabs: If you choose

options will appear: Off and Set Threshold. Select

TRIM TABS and press ENTER, a pair of menu

OFF to turn off a Trim

14

Page 17

Tab pop up or highlight Set Threshold and press

ENTER, to set a Trim

Tab threshold. The threshold for Trim Tabs ranges from 3% to 50%.

Stay-on Time: By highlighting Stay-on Time you are able choose how

long the RPM, Engine Trim and Trim Tab pages will be displayed when

their respective thresholds have been exceeded. To set the duration of

each display, highlight

STAY-ON TIME and press ENTER. The Set Time

menu will appear, giving you the option to select a duration between 2

and 15 seconds. You need only set the Stay-on Time duration once since

it will affect all three categories (RPM, Engine Trim and Trim Tabs).

Basic menu with Screen highlighted (left). Screen option menu

(center) with Set Backlight window (right).

Screen

To access the Screen menu:

1. Press

from which to choose: Backlight, Contrast

Adjusting Backlight:

1. Select

backlight. A vertical adjustment bar will appear on the Set Backlight

window. If more than one gauge is on the bus, it will automatically

adjust the other gauge to the same setting.

2. Use the

3. Press

main display.

Adjusting Contrast:

You can adjust the Contrast in the same manner as the Backlight.

1. Select

Contrast Adjust window.

2. Use the

3. Press

to the main display.

MENU, choose SCREEN and press ENTER. There are three options

and Reverse Video.

BACKLIGHT and press ENTER to adjust the brightness of the

UP and DOWN keys to set the backlight to a desired level.

EXIT to return to the Screen menu or ENTER to get back to the

CONTRAST from the Screen menu and press ENTER to launch the

UP and DOWN keys to move the slider bar to a desired level.

EXIT to return to the Screen menu or press ENTER to get back

15

Page 18

Contrast is highlighted on the Screen menu (left). The Contrast Adjust

window (center). Reverse Video highlighted on Screen menu (right).

The easiest way to change the look of the display is to utilize the

Reverse Video command, commonly used for nighttime viewing.

To select Reverse Video:

1. From the screen menu, highlight

REVERSE VIDEO and press ENTER.

You'll notice the dark and light colors have been swapped for one

another. The white text, which was on top of a dark background, now

has been switched to dark text on top of a white background. If more

than one gauge in on the bus, it will automatically adjust the other

gauge to the same setting.

2. To toggle back to the previous setting, return to the Screen menu,

select

REVERSE VIDEO and press ENTER.

3. Press

EXIT|EXIT to return to the main display.

Audio Setup highlighted on the basic menu (left). Audio

Setup menu (center) with Key Sounds menu (right).

Audio Setup

To modify audio settings:

1. Press

appear with two options: Key Sounds and Alarm Sound.

Adjusting Key Sounds:

2. Select

MENU, highlight AUDIO SETUP, then press ENTER. A menu will

KEY SOUNDS and press ENTER.

16

Page 19

3. Select

ON or OFF and press ENTER, which will take you back to the

main display.

4. If you choose to keep the current setting, press

EXIT to return to the

Audio Setup menu

Adjusting Alarm Sounds:

1. To turn on or turn off Alarm Sounds, select

Audio Setup menu and press

2. Select

ON or OFF and press ENTER, which will take you back to the

ENTER.

ALARM SOUNDS from the

main display.

3. If you choose to keep the current setting, press

AUDIO SETUP menu.

4. Press

EXIT repeatedly to return to the main display.

EXIT to return to the

System Setup

On each page, the System Setup menu contains, Engine Displayed,

Change Units, Bus Devices, Sonar Alarms, Eng/Tank Configuration,

Reset Values

To access the System Setup menu, press

DOWN keys to highlight SYSTEM SETUP, then press ENTER. We’ll discuss

the System Setup menu in more detail in the Advanced Operation

section.

Bus Devices

One of the more significant commands in the System Setup menu is the

Bus Devices command. It allows you to run a system check for all

devices connected to the LowranceNet.

1. To run a system check for devices connected to the NMEA 2000

LowranceNet, press

BUS DEVICES and press ENTER. After a Searching for Bus Devices

message comes up, a list of all devices attached to the LowranceNET —

the Bus Devices list — will appear.

NOTE:

If you modify settings and are not satisfied with the results, you

can reset the gauge to its factory default settings via the Reset

Values command.

To Reset Values:

1. Press

2. Scroll down to

will appear: Press Enter to reset all values.

3. Press

and System Information.

MENU and use the UP and

MENU, select SYSTEM SETUP and press ENTER. Choose

MENU, highlight SYSTEM SETUP and press ENTER.

RESET VALUES and press ENTER. The following message

ENTER to reset the values.

17

Page 20

WARNING:

Resetting values is a factory hard reset. All settings will

be wiped out.

NOTE:

Resetting values does not affect engine/tank configuration or the

calibration and configuration settings of devices on the bus.

18

Page 21

Section 4: EP Configuration &

Calibration

To configure items linked into the LowranceNET networking system,

MENU and select SYSTEM SETUP. Highlight BUS DEVICES and press

press

ENTER, which will bring up the message, Searching Bus Devices. Once

all devices are detected, a list of the devices (Bus Devices list) will be

displayed.

The Bus Devices command acts as the device manager for the bus,

allowing you to configure and unconfigure devices and set and reset

critical values such as alarms and calibration.

Bus Devices highlighted in the System Setup menu (left). Searching

Bus Devices window (center) with Bus Devices list (right).

NOTE:

Devices will vary in name and number depending on what has been

connected to the LowranceNET. The number of temp sensors

attached to the network will match the number that comes up on

the Bus Devices list.

If you configure or reconfigure a sensor, you're assigning or reassigning

its designation in the LMF-400 to a different sensor location on the

boat.

The following items can be configured, unconfigured or reconfigured:

Temperature Sensors (UnCfg Temp), Fuel Flow Sensors (UnCfg F

Flow) and Fluid Level (UnCfg F Level). When UnCfg Temp, UnCfg F

Flow and the UnCfg Fluid Level appear on the bus devices list it shows

they are unconfigured. Proceed through this section to configure each

one. You can have multiple Temperature sensors and Fluid Level

Tanks, but will have no more than three Fuel Flows to configure since

the LMF-400 supports a maximum of three engines.

The GPS Module and Paddle Wheel Speed do not need to be configured.

Engines and tanks are configured through the System Setup menu.

Trim Tabs are configured through the Pages menu, which will be

addressed later in this section.

19

Page 22

NOTE:

If you configure the desired sensors and are not satisfied with the

results, you may clear the configuration settings for each sensor

individually, by resetting values from the sensor's configuration

menu. Remember, ONLY the sensor you select from the Bus

Devices list will be set back to its defaults. To reset the LMF-400 to

its defaults, you must select

Menu. We'll take a closer look at the

RESET VALUES from the System Setup

RESET VALUES command later in

this section.

To get to the configuration menu:

1. Press

2. Highlight

detected in the network will be listed. Use the

MENU, select SYSTEM SETUP and press ENTER.

BUS DEVICES and press ENTER. After a few moments, items

UP and DOWN keys to

scroll through the list.

3. To configure an item in the list, highlight the item and press

ENTER.

Temperature Sensors

When temperature sensors are selected from the Bus Devices menu,

the temp sensor configuration menu comes up with two choices:

UNCONFIGURE or RECONFIGURE.

To Unconfigure a temp sensor:

1. After selecting a temp sensor from the Bus Devices list and pressing

ENTER, choose UNCONFIGURE from the configuration menu and press

ENTER. The following message will appear: Hit Menu to UnCfg Temp

Sns.

2. Press

ENTER to unconfigure the sensor and be directed back to the

Bus Devices list.

To Configure a temp sensor:

1. If you highlight

UNCFG TEMP and press ENTER, a window will pop up

asking if you want to configure the sensor.

2. Press

ENTER to be taken to the Selecting Temp menu.

3. Highlight one of the Temp options (Temp1, Temp 2, Temp 3, etc.) on

the Selecting Temp menu and press

ENTER. The UnCfg temp now has

been configured as the Temp you selected. You automatically will be

redirected to the Bus Devices list.

To Reconfigure a temp sensor:

If you want to reconfigure a sensor, but all the sensors linked to the

LowranceNET are already configured, you must first unconfigure a

sensor, so its name will be available. Otherwise a Name Already

Selected message will appear.

20

Page 23

In the following example, we want to swap the configuration of Temp 2

and Temp 1. We will first unconfigure Temp 2, then reconfigure Temp 1

as Temp 2. We'll finish by configuring UnCfg Temp (formerly Temp 2)

as Temp 1.

1. Highlight

TEMP 2 on the Bus Devices list and press ENTER, which will

launch the temp sensor configuration menu.

2. Choose

UNCONFIGURE and press ENTER. The following message will pop

up: Hit Menu to UnCfg Temp Sns.

3. Press

4. Select

RECONFIGURE and press ENTER. That will direct you to the Temp

ENTER, and you will be taken back to the Bus Devices list.

TEMP 1 from the Bus devices menu and press ENTER. Choose

Selection menu.

5. Select

TEMP 2 and press ENTER, which will take you back to the Bus

Devices list.

6. Now highlight

UNCFG TEMP from the Bus Devices list and press ENTER,

which will call up the Selecting Temp menu. Choose one of the Temp

options (Temp 1, Temp 3, etc.) and press

ENTER. You will be returned to

the Bus Devices list.

NOTE:

To run a system check for devices connected to the NMEA 2000

network, select

ENTER. A Searching Bus Devices message comes up, followed by a

BUS DEVICES from the System Setup menu and press

list of all devices attached to the LowranceNET — the Bus Devices

list. To select an item from the bus devices list, use the

DOWN keys to scroll through the list. Highlight the desired category

and press

ENTER.

UP and

Fuel Flow (Port, Center and Stbd)

Port Fuel Flow (Port Fflow), Center Fuel Flow (Cen Fflow) and

Starboard Fuel Flow (Stbd Fflow) all share the same internal

configuration menu, which includes: Change Engine (for two or more

engines only), Fuel Warning, Unset Engine and Reset Values. After

selecting a Fuel Flow (Port, Center or Stbd) from the Bus Device list

and pressing

ENTER, the following options will appear in the menu.

To Unconfigure Fuel Flow:

See Unset Engine below.

To Configure Fuel Flow:

1. From the Bus Devices list, highlight

UNCFG F FLOW and press ENTER.

That will launch the following message: Hit Menu to Cfg Flow Sns.

2. Press

ENTER to proceed with configuration.

21

Page 24

To Change Engine (Reconfigure; active only with multiple-engine setting):

1. From a fuel flow menu, select

CHANGE ENGINE and press ENTER. That

will call up an internal menu with three options: Port, Center and

Starboard. When you select one of the three options a message appears:

Changing Device Settings. When the LowranceNET has been scanned

and all devices have been detected, you will be directed back to the Bus

Device list.

To set Fuel Warning:

1. Highlight FUEL WARNING and press ENTER, which opens a menu with

the following options: Low Level or High Level.

2. After choosing either

Level Warning window will appear. It will be set to

When setting a Fuel Warning, you should choose

HIGH LEVEL or LOW LEVEL and pressing ENTER, a

OFF by default.

LOW LEVEL, which will

warn you when the fuel level drops below a preset percentage of the

tank's capacity.

3. To set the Fuel Warning level, use the

desired percentage and press

ENTER. You then will be directed back to

UP and DOWN keys to select a

the Bus Devices list.

To Unset Engine (Unconfigure):

1. After highlighting UNSET ENGINE and pressing ENTER, a message will

pop up: Press Ent to Unconfig Dev Instance.

2. Press ENTER and you will be directed back to the Bus Devices list.,

where UnCfg F Flow will now be displayed.

To Reset Values:

1. Choose RESET VALUES, press ENTER and a message will be displayed:

Press Enter to Reset Device Values.

2. Press

ENTER to reset the device values to the default settings.

NOTE:

By resetting values from the configuration menu, ONLY the device

selected from the Bus Devices list will be set back to its defaults.

When you Reset Values, the calibration on the device is reset. But

when you unconfigure a device, its calibration is unaffected.

WARNING:

If you reset any EP, that EP will lose all configuration

and calibration.

Fluid Level

Up to three tanks for each Fluid Level category (Fuel, Fresh Water, Oil,

Black Water, Waste Water and Live Well) can be supported by the

LMF-400. On the Bus Devices list, the fuel tanks will be displayed as

Fuel Tank (P) for portside, Fuel Tank (C) for center and Fuel Tank (S)

for starboard.

22

Page 25

If you have one tank it will be shown as Fuel Tank. Other tanks will be

displayed as Blackwater Tank, Freshwater Tank, Oil Tank, Live Well

Tank and Waste Water Tank. If you have more than one of the tank

types above, it will be displayed as Blk Wtr 1, 2, 3, Live Well 1, 2, 3, etc.

If the tank or tanks have not been configured, they will be listed as

Unfcg F Level.

To unconfigure Fluid Level:

1. Choose a configured Fluid Level from the Bus Devices list and press

ENTER.

2. Highlight UNCONFIGURE and press ENTER, which will launch the

following message: Press Enter to Unconfigure Device.

3. Press

ENTER and you will be returned to the Bus Devices list where

you now will see UnCfg F Level on the devices list.

To Configure Fluid Level:

1. Select

which will launch the following message: Press

UNFCG F LEVEL from the Bus Devices list and press ENTER,

ENTER to configure

Fluid Level Sensor.

2. Press

ENTER and a menu will be called up with these configuration

options: Fuel, Fresh Water, Waste Water, Live Well, Oil and Black

Water. You can have up to three tanks for each category.

NOTE:

The gauge must be set to Fuel Level for the Fuel Remaining Source

to display fuel level sensor information properly. For more

information on the topic, see Fuel Remaining source under Fuel

Setup in Section 5, Advanced Operation.

To configure Fuel:

1. Highlight FUEL from the list of configuration options and press ENTER.

The number of options on the menu will vary with the number of tanks

you selected during Boat Setup. See Boat Setup on the first page of

Section 3: Operations.

If you have three tanks, a menu will appear with these options: Port

Tank, Cen (Center) Tank and

Stbd (Starboard) Tank.

2. Highlight one of the three tank options and press ENTER, which will

take you back to the Bus Devices list. If you have more than one tank,

one of the following will now be on the list: Fuel Tank (P), Fuel Tank

(C), Fuel Tank (S). If you have one tank, Fuel Tank will be on the list.

To configure Fresh Water:

1. Choose FRESH WATER from the list of configuration options and press

ENTER. A window will appear prompting you to input the tank number.

2. Enter the tank number (1, 2 or 3) and press ENTER. That will launch

a tank size window.

23

Page 26

3. Use the

hold and press

UP and DOWN keys to enter how many gallons the tank will

ENTER. You will then be directed back to the Bus

Devices list.

To configure Waste Water:

1. Highlight WASTE WATER from the list of configuration options and

press

ENTER. A window will appear prompting you to input the tank

number.

2. Enter the tank number (1,2 or 3) and press

ENTER, which will launch

a tank size window.

3. Use the

hold and press

UP and DOWN keys to enter how many gallons the tank will

ENTER. The Changing Device Settings window will

appear. You will then be directed back to the Bus Devices list.

To configure Live Well:

1. Choose LIVE WELL from the list of configuration options and press

ENTER, which will launch a window prompting you to input the tank

number.

2. Enter the tank number (1,2 or 3) and press

ENTER, which will launch

a tank size window.

3. Use the

ENTER. You will then be directed back to the Bus Devices list.

To configure Oil:

UP and DOWN keys to enter the size of the tank and press

1. Highlight OIL from the list of configuration options and press ENTER,

which will launch a menu with these options: Port Tank, Cen Tank

and

Stbd Tank.

2. Select a tank and press

ENTER, which will call up a Setting Tank

Size window.

3. Use the

will hold and press

UP and DOWN keys to enter the number of gallons the tank

ENTER. You will then be returned to the Bus

Devices List.

To configure Black Water:

1. Highlight BLACK WATER from the list of configuration options and

press

ENTER, which will launch a window prompting you to input the

tank number.

2. Enter the tank number (1, 2 or 3) and press

ENTER, which will call

up a tank size window.

3. Use the

hold and press

UP and DOWN keys to enter how many gallons the tank will

ENTER. You will then be directed back to the Bus

Devices list.

To Reconfigure Fluid Level:

1. Select a configured Fluid Level (Fuel Tank, Oil Tank, Black Water

Tank, Waste Water Tank, Fresh Water Tank, Live Well Tank) from the

Bus Devices list and press

ENTER.

24

Page 27

A menu will be displayed with the following options: Level Warning,

Unconfigure, Reconfigure, Calibrate and Reset Values.

To set Level Warning:

1. Select

LEVEL WARNING and press ENTER, which will open a menu with

two options: Low Level or High Level.

2. Choose one of the levels (Low or High) and a box will appear,

allowing you to set the warning level you selected to Off or to a desired

percentage.

NOTE:

If you configure a tank for fuel, you should choose a

LOW LEVEL

warning, which will warn you when the fuel level drops below a

preset percentage of the tank's capacity. Fresh Water and Oil also

should be set for Low Level. If you configure a tank for Black Water

or Waste Water, you should configure the Level Warning to the

LEVEL. For example, if the High Level warning is set to 3 quarters of

HIGH

a tank, you will be notified before the tank's capacity has been

exceeded, allowing you to dump the tanks before they fill up.

3. Use the

desired level and press

UP and DOWN keys to set the warning percentage to a

ENTER, then you will be returned to the Bus

Devices list.

Calibrate

See detailed information on Calibration later in this section.

Reset Values

1. Highlight

ENTER. The following message will appear: Hit Menu to Rst Values.

RESET VALUES on the Tank configuration menu and press

2. Press ENTER to reset the Tank device configuration values to the

default setting. This will remove any calibration previously set.

NOTE:

By resetting values from the configuration menu, ONLY the device

selected from the Bus Devices list will be set back to its defaults.

When you Reset Values, the calibration on the device is reset. But

when you unconfigure a device, its calibration is unaffected.

WARNING:

If you reset any EP, that EP will lose all configuration

and calibration.

GPS Module, Paddle Wheel Speed and Trim Tabs

The remaining items from the Bus Devices list, GPS Module, Paddle

Wheel Speed and Trim Tab Sensors do not need to be configured. If you

highlight GPS Module or Paddle Wheel Speed and press

ENTER, the

following message should appear: Device Working Properly.

25

Page 28

Trim Tab Sensors: highlighting Trim Tab Sensors and pressing ENTER,

will launch the following message: Press Enter to Reset Device Values.

To reset the Trim Tab Sensor settings to the default setting, press

ENTER.

Calibration of EP Devices

Calibrating Fluid level is an important step to ensuring the status of

your tank is correctly transmitted over the NMEA 2000 bus.

For example: if you have an odd-shaped tank, like one that is wider at

the top than at the bottom, the float inside the tank will tell you there

is a half tank of gas when it reaches the midpoint of the tank,

regardless of the tank’s actual capacity below the midpoint. That could

cause you to run out of gas more quickly than expected. Whether the

tank is configured for Fuel, Fresh Water, Waste Water, Black Water or

Oil, calibrating the Fluid Level protects you from unpleasant surprises.

NOTE:

To run a system check for devices connected to the NMEA 2000

network, select

ENTER. A Searching Bus Devices message comes up, followed by a

list of all devices attached to the LowranceNET — the Bus Devices

list. To select an item from the bus devices list, use the

DOWN keys to scroll through the list. Highlight the desired category

and press

To calibrate a tank:

1. Press

MENU, select SYSTEM SETUP and press ENTER.

2. From the System Setup menu, highlight

to bring up the Bus Devices list.

3. From the devices list, highlight the fluid level source you want to

calibrate, press

appear with three calibration options: 2 point, 3 point and 5 point.

To execute

2-Point Calibration: there will be a pair of settings in the 2-

point calibration menu: Empty Level and Full Level. 2-Point calibration

is best for rectangular or square shaped tanks that allow the fuel level

sensor to provide an accurate reading of the fuel level at the top and

bottom of the tank.

1. Choose the level (

tank's current fuel level and press

If you choose F

Set Tank to Full Level Press Enter.

2. Press

3. Press

ENTER and you will be taken back to the 2-point menu.

EXIT to return to the Bus Devices list.

BUS DEVICES from the System Setup menu and press

UP and

ENTER.

BUS DEVICES and press ENTER

ENTER, select CALIBRATE and press ENTER. A menu will

EMPTY OR FULL LEVEL) that corresponds with your

ENTER.

ULL LEVEL, the following message will appear: Calibrating

26

Page 29

To execute 3-Point Calibration: there will be three options in the 3-point

calibration menu: Empty Level, Half Level and Full Level. 3-point

calibration is designed for tanks that vary in shape from the top to the

bottom, leading to an inaccurate fuel level sensor reading, in the

narrower, bottom portion of the tank.

1. Choose the level

tank's current fuel level and press

following message will appear: Calibrating Set Tank to Half

(EMPTY, HALF OR FULL LEVEL) that corresponds with your

ENTER. If you choose half level, the

Level Press

Enter.

2. Press

3. Press

To execute 5-point Calibration: there will be five options in the 5-point

ENTER and you will be taken back to the 3-point menu.

EXIT to return to the Bus Devices list.

calibration menu: Empty Level, 1 Qtr Level, Half Level, 3 Qtr Level

and Full Level. 5-point calibration is designed for the most uniquely

formed tanks that vary greatly in shape from top to bottom, making an

accurate fuel level sensor reading impossible without calibration.

1. Choose the level (

corresponds with your tank's current fuel level and press

EMPTY, 1 QTR, HALF, 3 QTR or FULL LEVEL) that

ENTER. If you

chose 3-quarter level, the following message will appear: Calibrating

Set Tank to 3 Qtr Press Enter.

2. Press

3. Press

ENTER and you will be directed back to the 5-point menu.

EXIT to return to the Bus Devices list.

Fuel Flow

If using the EP-10 Fuel Flow as the Fuel Remaining source, you must

tell the unit when you add fuel or fill the tank. If just adding fuel, but

not topping off the tank, use the

PARTIAL FILL option and enter the

amount of fuel added.

WARNING:

Be sure to carefully follow these instructions, otherwise

fuel calibration could be inaccurate, resulting in

incorrect Fuel Flow, Fuel Remaining, Fuel Economy and

Fuel Range readings.

If you are topping off the tank, but do not want or need to calibrate the

unit, select the

FILL TANK option and choose NO on the Calibrate option.

To calibrate the EP-10 Fuel Flow, you must use the Refill Tank option.

1. First, fill up the vessel's tank, but do not recalibrate, just input that

the tank has been refilled.

2. Once you have burned at least 5 gallons of fuel, fill up the tank

again, carefully noting how much fuel was added to top off the tank.

The amount of fuel added should be very close to the amount of Fuel

27

Page 30

Used shown by the gauge. If the difference between these two figures is

greater than 5 percent, then you need to recalibrate the unit.

3. To do this, after entering the tank has been refilled, select

RECALIBRATE option.

YES on the

4. Then enter in the amount of fuel added to fill the tank. The

calibration is calculated by comparing the actual fuel used to the

calculated fuel used. It is vital to get an accurate reading on the actual

fuel used and the amount of fuel added to fill the tank the second time.

On multiple engine installations with a single tank configuration, only

one engine should be run when calibrating the EP-10 Fuel Flow. This is

the only way to know how much fuel has gone through the EP-10 Fuel

Flow you want to calibrate.

Refill Tank

1. After you have filled the gas tank, scroll through the pages until the

Fuel Manager page is on the main display. Press

2. Highlight

3. Scroll down the menu to

FUEL SETUP and press ENTER.

REFILL TANK and press ENTER, which will call

MENU.

up the following message: ReCalibrate? A menu will be below the

message with two options: Yes or No.

4. Highlight

YES and press ENTER, which will launch the Filled Fuel

Quantity window.

5. Use the

the tank and press

UP and DOWN keys to enter the number of gallons you put in

ENTER to finalize the calibration. You will be

directed back to the Fuel Setup menu.

Partial Fill

1. Scroll through the pages until the Fuel Manager page is on the

screen, then press

2. Highlight

3. Scroll down to

MENU.

FUEL SETUP and press ENTER.

PARTIAL FILL and press ENTER, which will launch the

Adding Fuel Window.

4. Use the

the tank, then press

UP and DOWN keys to enter the amount of fuel you added to

ENTER. You will be directed back to the Fuel Setup

menu.

Trim Tabs

If the Trim Tabs have not been calibrated or have been reset, the

display will flash between 0 and 100. This is normal prior to the trim

tabs being calibrated for the first time.

Trim Tabs can only be calibrated from the Trim Tabs page. If the page

is not present in the scrolling page display, add the Trim Tab page by

following the Adding Pages instructions in Section 3: Operation.

28

Page 31

1. Scroll through the displayed pages until the Trim Tab page is on the

main display.

2. Press

MENU, select CALIBRATE TAB and press ENTER, which will launch

the following message: Bring Tabs Full Up Press Enter.

3. Adjust the position of the Trim Tabs to the Full Up Position and

ENTER. A second message will appear: Run Tabs Full DN (Down).

press

4. Move the Trim Tabs into the full down position. The Trim Tabs are

now calibrated. Recalibration can be performed at any time and as

many times as necessary by following the step by step trim tab

calibration instructions listed in this section.

Trim Tabs menu (left). When calibrating Trim Tabs, the Full Up

message (center) appears first. It is followed by the Run Tabs Full

Down message (right).

29

Page 32

Notes

30

Page 33

Section 5: Advanced Operation

Customizing Pages

In this section, we're going to take a look at how each of the pages can

be customized.

NOTE:

In order to access a page-specific menu make sure the desired page

is on the display when you press the menu button. The page menus

have a lot of similarities, but many have specific menu categories

that only will appear on the basic menu if accessed while that page

is on the main screen. For example, if you wanted to access the Fuel

Manager menu, then you must scroll through the pages until the

Fuel Manager page is displayed on the screen before pressing

MENU.

Basic menu with Customize highlighted.

Single Analog

A single gauge display, the Single Analog page may be customized to

monitor any of the following: Alt Voltage, Battery Voltage, Engine

Temp, Atmospheric Pressure, Temperature, Fluid Level, PaddleWheel

Speed, Pitot Speed, GPS Speed and Tachometer.

To customize the Single Analog page:

1. Scroll through the pages set for display by pushing the

key.

2. Once the Single Analog page is displayed, press

CUSTOMIZE and press ENTER.

3. Scroll through the device list and highlight the category you want to

monitor, then press

displayed on the screen.

ENTER. The information you selected will be

31

ENTER or EXIT

MENU, select

Page 34

NOTE

The System Setup menu for all three analog gauges feature Speed

Range and Pressure Range. A more detailed description of Speed

Range and Pressure range may be found under System Setup later

in this section.

Single Analog page (left) with Dual Analog page (right).

Dual Analog

A pair of analog gauges, the Dual Analog page may be customized to

show information from any of the following: Alt Voltage, Battery

Voltage, Engine Temperature, Atmospheric Pressure, Temperature,

Fluid Level, Paddle Wheel Speed, Pitot Speed, GPS Speed and

Tachometer.

To customize the Dual Analog page:

1. Scroll through the pages set for display by pushing the

ENTER or EXIT

key.

2. Once the Dual Analog page is displayed, press MENU, select CUSTOMIZE

and press ENTER.

3. A menu prompt will appear giving you the option to customize the

Top Gauge or the Bottom Gauge. Use the

highlight the desired gauge and press

ENTER.

UP and DOWN keys to

4. Scroll through the device list and highlight the category you want to

monitor, then press

ENTER. This will take you back to the menu

prompt. If you want to customize the other portion of half of the gauge

repeat the steps above, otherwise press

EXIT, EXIT. The information you

selected will be displayed on the screen.

Quad Analog

A display featuring four analog gauges, the Quad Analog page

supports: Alt Voltage, Battery Voltage, Engine Temperature,

Atmospheric Pressure, Temperature, Paddle Wheel Speed, Pitot Speed,

GPS Speed and Tachometer.

32

Page 35

To Customize the Quad Analog page:

1. Scroll through the pages set for display by pushing the

ENTER or EXIT

key.

2. Once the Quad Analog page is displayed, press MENU, select

CUSTOMIZE and press ENTER.

3. A menu prompt will appear giving you the option to customize the

gauge on the Top Left, Top Right, Bottom Left or Bottom Right.

4. Use the

customize and press

UP and DOWN keys to highlight the gauge you want to

ENTER.

5. Scroll through the device list and highlight the desired item, then

press

ENTER. This will take you back to the gauge menu prompt. If you

want to customize any of the other gauges, repeat the steps above,

otherwise press

EXIT, EXIT. The information you selected will be

displayed on the main screen.

NOTE:

If a page is customized to show information from a device that is

working improperly or is not connected to the NMEA 2000 network,

the data boxes on the gauge will flash. This indicates the device is

not sending data to the Bus. This could occur for a variety of

reasons, depending on the device type. If it is a GPS sensor, the

GPS unit probably has not locked on to a satellite yet and may take

a few moments to acquire a position. All other EP sensors need to

be configured, which may be done via Bus Devices in the System

Setup menu.

Quad Analog page (left) with Single Digital page (right).

Single Digital

The single digital page displays a single digital gauge that can display:

Alt Voltage, Battery Voltage, Engine Temperature, Atmospheric

Pressure, Temperature, Depth, Engine Load, Total Engine Hours, Fuel

Flow, Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel

Speed, Pitot Speed, GPS Speed and Tachometer.

33

Page 36

To customize the Single Digital page:

1. Scroll through the pages set for display by pushing the

ENTER or EXIT

key.

2. Once the Single Digital page is displayed, press

CUSTOMIZE and press ENTER.

MENU, select

3. Scroll through the device list and highlight the category you want to

monitor, then press

ENTER. The information you selected will be

displayed on the main screen.

Dual Digital

The Dual Digital page features a pair of digital gauges which can

monitor: Alt Voltage, Battery Voltage, Engine Temp, Atmospheric

Pressure, Temperature, Depth, Engine Load, Total Engine Hours, Fuel

Flow, Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel

Speed, Pitot Speed, GPS Speed and Tachometer.

To customize the Dual Digital page:

1. Scroll through the pages set for display by pushing the

key.

2. Once the Dual Digital page is displayed, press

MENU, select CUSTOMIZE

and press ENTER.

3. A menu prompt will appear give you the option to customize Top

Data or Bottom Data. Use the

you want to change and press

UP and DOWN keys to highlight the data

ENTER.

4. Scroll through the list and highlight the category you want to

monitor, then press

ENTER. This will take you back to the menu

prompt. If you want to customize the other data, repeat the steps

above, otherwise press

EXIT, EXIT. The information you selected will be

displayed on the main screen.

ENTER or EXIT

Dual Digital page (left) with Quad Digital page (right).

34

Page 37

Quad Digital

The Quad Digital page has four digital gauges capable of displaying:

Alt Voltage, Battery Voltage, Engine Temperature, Atmospheric

Pressure, Temperature, Depth, Engine Load, Total Engine Hours, Fuel

Flow, Fuel Economy, Fuel Remaining, Fuel Range, Paddle Wheel

Speed, Pitot Speed, GPS Speed and Tachometer.

To Customize the Quad Digital page

:

1. Scroll through pages set for display by using the ENTER or EXIT key.

2. Once the Quad Digial page is displayed, press MENU, select CUSTOMIZE

and press ENTER.

3. A menu prompt will appear giving you the option to customize Data

Box 1, Data Box 2, Data Box 3 or Data Box 4.

4. Use the

customize and press

UP and DOWN keys to highlight the data box you want to

ENTER.

5. Scroll through the device list and highlight the category you want to

monitor, then press

ENTER. This will take you back to the menu

prompt. If you want to customize any of the other boxes, repeat the

steps above, otherwise press

EXIT|EXIT. The box you customized will

display the data you selected.

Trim Tabs

The Trim Tab page can display Trim Tabs position in percentages and

degrees, giving boaters precise control of Trim Tab position.

To Customize Trim Tabs:

1. Scroll through the pages set for display, pressing

Trim Tab page is on the main display.

2. Select

CUSTOMIZE and press ENTER.

3. There will be two choices: Percentage or Degrees.

4. Choose the desired unit of measure and press ENTER. The Trim Tab

page displays position information in the unit of measure you chose.

MENU when the

Trim Tabs page (left), GPS Module page (center) and Fuel Manager

Page (right).

35

Page 38

GPS Position

Displays user position in Latitude/Longitude.

Fuel Manager

The Fuel Manager page has three digital readouts capable of

displaying: Fuel Flow, Fuel Economy, Fuel Remaining, Fuel Range,

Trip Fuel Used, Seasonal Fuel, Paddle Wheel Speed, Pitot Speed and

GPS Speed. While on the Fuel Manager page, press

Fuel manager menu, which contains the following options: Customize,

Fuel Setup, Pages, Screen, Audio Setup and System Setup.

NOTE

If you have multiple engines, you must go into System Setup and

select Engine Displayed. Here you can select the engine you want to

set up. The Fuel Management page shows the engine you selected

at the bottom of the page.

To Customize the Fuel Manager Page:

1. Scroll through pages set for display using the

2. Once the Fuel Manager page is displayed, press

CUSTOMIZE and press ENTER.

3. The menu prompt will appear with the follow options: Top Data,

Center Data and Bottom Data. Use the

the data box you want to customize and press

UP and DOWN keys to highlight

ENTER.

4. Scroll through the list and highlight the desired item, then press

ENTER. This will take you back to the menu prompt. If you want to

customize other data, repeat the steps above, otherwise press

EXIT. The information you selected will be displayed on the screen.

Fuel Setup

1. To access the Fuel Setup menu, press

MENU while viewing the Fuel

Manager page, which will bring up the Fuel Manager page menu.

2. Select

FUEL SETUP, then press ENTER.

The Fuel Setup menu contains the following categories: Adjust

Calibration, Fuel Remaining Source, Reset Seasonal, Refill Tank,

Partial Fill, Eco Speed Source and

Reset Trip Fuel.

Adjust Calibration

1. From the Fuel Setup menu, select

2. Use the

adjustment, then press

UP and DOWN keys to input the desired calibration

ENTER.

ADJUST CAL and press ENTER.

Fuel Remaining Source

The Fuel Remaining Source menu prompts you to choose what sensor

will be used to monitor your fuel level. There are two options: Engine

Fuel Flow and

Fluid Level Sensor.

36

MENU to access the

ENTER and EXIT keys.

MENU, select

EXIT,

Page 39

From the Fuel Setup menu, select

FUEL REM SRC and press ENTER.

1. Highlight your preference — ENG/FFLOW or FLUID LEV SNSR — and press

ENTER. Press EXIT repeatedly to get back to the main display.

Reset Seasonal

The LMF-400 has the capability to track fuel usage not only for trips,

but also for entire seasons. The reset seasonal option allows you to

reset the running tally of seasonal fuel usage to zero.

1. From the Fuel Setup menu, select

RST SEASONAL and press ENTER. The

following message will appear: Press Enter to reset Seasonal Fuel.

2. Press

ENTER to reset seasonal fuel or press EXIT to return to the Fuel

Setup menu.

Refill Tank

The Refill Tank category gives you the option of re-calibrating after you

have filled the fuel tank.

1. From the Fuel Setup menu, select

REFILL TANK and press ENTER. The

following message will appear: Press Enter after refilling the fuel tank.

If you choose to recalibrate, a window will pop up, asking you to enter

the amount of fuel you put into the tank. Use the

enter the fuel amount and press

ENTER.

UP and DOWN keys to

Partial Fill

Partial Fill helps maintain the accuracy of the Fuel Remaining and

Fuel Range figures, by allowing you to input into the unit the amount

of fuel added to the tank.

1. From the Fuel Setup menu, select

PARTIAL FILL and press ENTER. An

Adding Fuel window will appear.

2. Use the

the tank and press

UP and DOWN keys to enter the amount of fuel you added to

ENTER.

Economy Speed Source

Economy Speed source allows you to select the speed source that will be

factored into the Fuel Economy equation.

1. From the Fuel Setup menu, select

ECO SPEED SRC and press ENTER,

which will call up the Economy speed Source menu with the following

options: Paddle Wheel Speed, Pitot Speed andGPS Speed.

2. Select one of the three options and press

ENTER, which will take you

back to the Fuel Management display. Paddle Wheel Speed is best

suited for low speeds, while Pitot Speed will work best at high speeds.

GPS Speed works well at both high and low speeds.

Reset Trip Fuel

Reset Trip Fuel allows you to reset to zero the running tally of how

much fuel you have used on a particular trip.

37

Page 40

1. From the Fuel Setup menu, select

RST TRIP FUEL and press Enter,

which will launch the following message: Press Enter to Reset Trip

Fuel.

2. Press

EXIT repeatedly to return to the main display.

ENTER, which will take you back to the Fuel Setup menu. Press

System Setup Menu

To get to the System Setup menu, press MENU, then scroll down to

System Setup and press

Engine Displayed, Bus Devices, Sonar Alarms, Eng/Tank

Configuration, Reset Values, System Information and Change Units.

Engine Displayed

The Engine Displayed command allows you to monitor up to three

engines on your vessel.

ENTER. The System Setup menu contains:

Basic menu with System Setup highlighted (left). System Setup menu

(right) with Engine Displayed selected.

1. After accessing the System Setup menu, highlight ENGINE DISPLAYED

and press ENTER. A menu will appear with the following options: Port,

Center and Starboard. This is important when viewing information like

Fuel Management, RPM and Engine Voltage.

2. Select the engine you would like to monitor and press

ENTER.

Bus Devices

1. To run a system check for devices connected to the NMEA 2000

network, choose

ENTER. After a Searching for Bus Devices message comes up, a list of

BUS DEVICES from the System Setup menu and press

all devices attached to the LowranceNET — the Bus Devices list — will

appear.

Sonar Alarms

1. If you would like to set Deep or Shallow Sonar Alarms, select

ALARMS from the System Setup menu and press ENTER. An alarm menu

SONAR

will pop up with two choices: Shallow or Deep.

38

Page 41

2. In this example, we'll select

SHALLOW and press ENTER. A small menu

will appear, giving you the option to turn off the alarm or set the depth.

3. Select

SET DEPTH and press ENTER.

4. Use the UP and DOWN keys to select the desired depth and press

ENTER. To set the Deep alarm, press EXIT, select DEEP from the alarms

menu and press the

Sonar Alarms highlighted on System Setup menu (left). Sonar Alarms

menu (center); Reset Values selected on System Setup menu (right).

ENTER key.

5. Choose SET DEPTH, then use the UP and DOWN keys to set the alarm to

the desired depth. Press

ENTER|EXIT|EXIT to return to the System

Setup menu.

Engine/Tank Configuration

1. From the System Setup menu, scroll down to

ENTER. Boat Setup will be highlighted. Press ENTER, which will bring

ENG/TANK CFG and press

up the following message: Press Enter to reset Eng/Tank Cfg. Press

ENTER.

3. The Boat Setup title bar will appear on the screen. Press

ENTER to

access the Boat Setup menu. The Boat Setup menu options are: 1 Eng/1

Tank, 1 Eng/2 Tank, 2 Eng/1 Tank, 2 Eng/2 Tanks, 3 Eng/1 Tank or 3

Eng/3 Tanks.

4. Choose the option that applies to your vessel and press

ENTER, which

will bring up the Set Tank Size menu. It will appear with up to three

options, depending on the number of tanks you chose during Boat

Setup. The options are: Port Tank, Stbd Tank and Cen Tank.

(If you

selected one tank during Boat Setup, you won't see any of these options.

You will be taken directly to the Setting Tank Size Window.)

5. Select the tank you want to set up and press

ENTER, which will

launch the Setting Tank Size window.

6. Use the

hold and press

UP and DOWN keys to enter how many gallons the tank will

ENTER.

Press EXIT and repeat steps 3 and 4 for each of the remaining tanks.

7. After all tanks on your vessel have been setup, press EXIT repeatedly

to be directed back to the main display.

39

Page 42

Reset Values:

1. Press

2. Scroll down to

MENU, highlight SYSTEM SETUP and press ENTER.

RESET VALUES and press ENTER. The following message

will appear: Press Enter to reset all values.

3. Press

ENTER to reset the values.

NOTE:

Resetting Values will not clear Engine/Tank configuration or the

settings of EP sensors previously calibrated or configured.

System Information

The system information screen provides information about the version

and build of the software in your LMF-400.

1. To access system information, select

Setup menu and press

ENTER. The system information will be

SYSTEM INFO from the System

displayed on the screen.

NOTE:

The System Setup menu for all three analog gauges feature Speed

Range and Pressure Range.

Speed Range

1. To access the Speed Range menu, press

MENU when a single, dual or

quad analog page is on the main display.

2. Scroll down to

3. Select Speed Range and press

SYSTEM SETUP and press ENTER.

ENTER. The Speed Range menu has

three options: 0-40, 0-80 and 0-120.

4. Choose the desired range and press

ENTER, which will take you back

to the main display.

Pressure Range

1. To access the Pressure Range menu, press Menu when a single, dual

or quad analog page is on the main display.

2. Scroll down to

3. Select Pressure Range and press

SYSTEM SETUP and press ENTER.