Page 1

www.lowrance.com

Pub. 988-0064-362

LMF-200

Multi-function Gauge

Installation and Operation

Instructions

Page 2

Copyright © 2006 Lowrance Electronics, Inc.

All rights reserved.

No part of this manual may be copied, reproduced, republished,

transmitted or distributed for any purpose, without prior written

consent of Lowrance Electronics. Any unauthorized commercial

distribution of this manual is strictly prohibited.

Lowrance®

trademark of Lowrance Electronics, Inc. NMEA 2000®

is a registered trademark and LowranceNet ™ is a

is a registered

trademark of the National Marine Electronics Association.

Lowrance Electronics may find it necessary to change or end our

policies, regulations and special offers at any time. We reserve the right

to do so without notice. All features and specifications subject to change

without notice. On the cover: LMF-200.

For free owner's manuals and other information,

visit our web site:

www.lowrance.com

Lowrance Electronics Inc.

12000 E. Skelly Dr.

Tulsa, OK USA 74128-2486

Printed in USA.

Page 3

Table of Contents

Section 1: Introduction............................................................. 1

Section 2: Installation............................................................... 3

Preparation .................................................................................... 3

Recommended Tools and Supplies ........................................... 3

Installation Sequence................................................................ 4

Mounting the Gauge ................................................................. 4

Wiring ............................................................................................ 5

Connecting to a NMEA 2000 Network .................................... 7

Compatibility ............................................................................. 7

Network Backbone and Network Nodes .................................. 7

Adding a Network Node............................................................ 8

Additional Network Information.............................................. 9

Understanding this Manual ....................................................... 10

Up and Down keys .................................................................. 10

Menu key.................................................................................. 10

Menu Commands..................................................................... 10

Instructions = Menu Sequences ............................................. 10

Section 3: Operation................................................................ 11

Boat Setup ................................................................................... 11

Timeout ........................................................................................ 12

Basic Menu .................................................................................. 12

Pages ............................................................................................ 12

Viewing Pages (Page Screen Rotation) ...................................... 13

Page Options................................................................................ 13

Engine Trim............................................................................. 13

Diagnostic ................................................................................ 13

Fuel Manager .......................................................................... 13

GPS Position ............................................................................ 13

Rudder...................................................................................... 13

Single Digital........................................................................... 14

Dual Digital ............................................................................. 14

Gauge ....................................................................................... 14

Synchronizer ............................................................................ 14

Trim Tabs................................................................................. 14

Pages Menu ................................................................................. 14

Add Page .................................................................................. 14

Remove Page............................................................................ 15

Autoscroll ................................................................................. 15

Pop-ups Setup.......................................................................... 16

Stay Time ............................................................................. 16

Pop-up Thresholds............................................................... 17

i

Page 4

Screen........................................................................................... 18

Backlight.................................................................................. 18

Backlight Sync (BL Sync) ....................................................... 18

Contrast ................................................................................... 19

Reverse Video (Rev Video): ..................................................... 19

Audio Setup ................................................................................. 19

Key Sounds .......................................................................... 20

Alarm Sounds ...................................................................... 20

System Setup Menu .................................................................... 20

Bus Devices.............................................................................. 20

Sonar Alarms........................................................................... 21

Timeout .................................................................................... 22

Eng (Engine)/Tank .................................................................. 22

Reset......................................................................................... 22

NMEA Info............................................................................... 23

System Information................................................................. 23

Engine Data............................................................................. 23

Engine Warnings..................................................................... 23

Speed Range ............................................................................ 24

Pressure Range........................................................................ 24

Units......................................................................................... 25

Fuel Setup.................................................................................... 27

Refill Tank (Refill T) ............................................................... 27

Partial Fill (Part Fill).............................................................. 27

Economy Speed (Eco spd) ....................................................... 28

Fuel Remaining Source (FRem Src)....................................... 28

Reset Trip Fuel (Rst trip f) ..................................................... 29

Reset Seasonal Fuel (Rst Seas) .............................................. 29

Customizing Pages ...................................................................... 29

Single Digital........................................................................... 30

Dual Digital ............................................................................. 30

Gauge ....................................................................................... 31

Fuel Manager .......................................................................... 32

Trim Tabs................................................................................. 32

Section 4: EP Configuration & Calibration....................... 33

EP-35 Temperature Configuration ............................................ 33

EP-10 Fuel Flow Configuration ................................................. 35

EP-15 Fluid Level Configuration ............................................... 39

Fluid Level menu .................................................................... 39

Level Warning: .................................................................... 43

Reset......................................................................................... 43

Suzuki Engine Interface Configuration..................................... 44

Calibrating EP Sensors............................................................... 48

ii

Page 5

EP-10 Fuel Flow Calibration...................................................... 48

Fuel Flow Accuracy ................................................................. 48

Refill Tank ........................................................................... 49

Reset Calibration................................................................. 50

Partial Fill............................................................................ 50

EP-15 Fluid Level Calibration ................................................... 51

2-Point Calibration.............................................................. 51

3-Point Calibration:............................................................. 52

5-point Calibration .............................................................. 52

Reset Calibration................................................................. 53

Calibrating Fuel Flow in a Suzuki Engine Interface................ 54

Engine Interface Accuracy...................................................... 54

Refill Tank ........................................................................... 55

Reset Calibration................................................................. 56

Partial Fill............................................................................ 56

Calibrating EP-30 Trim Tabs..................................................... 57

Appendix .................................................................................... 61

iii

Page 6

Notes

iv

Page 7

Section 1: Introduction

Thank you for buying the Lowrance® LMF-200. Your unit is a highquality, multi-function, digital gauge designed to work with a

LowranceNET™ network. This is the NMEA 2000

developed by Lowrance Electronics.

Caution:

Installing LowranceNET NMEA 2000 devices is significantly

different from installing earlier Lowrance components without

NMEA 2000 features. You should read all of the installation

instructions before proceeding.

This gauge will only work with a NMEA 2000 network. It MUST be

connected to a NMEA 2000 network or it WILL NOT function. When

properly installed, the LMF-200 will display information from a variety

of Lowrance Electronic Probe (EP) sensors and other NMEA 2000

devices connected to the network.

®

networking system

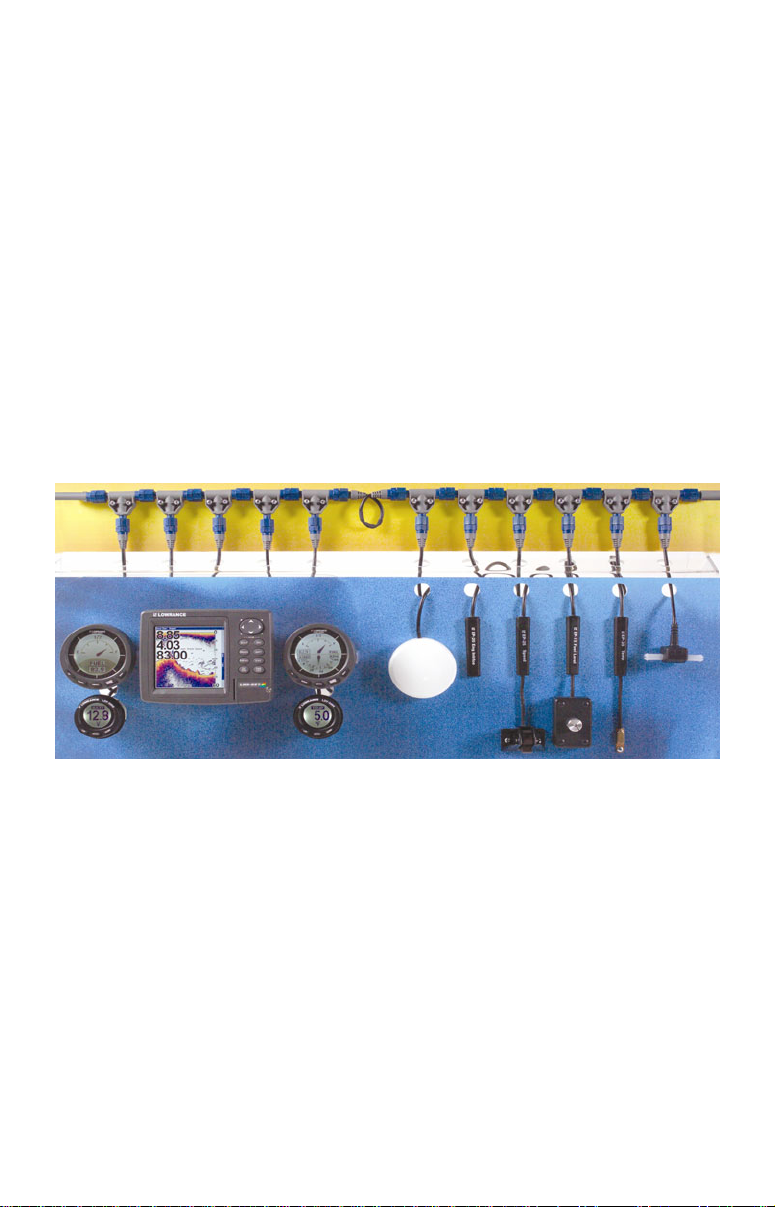

A NMEA 2000 network using LowranceNET components.

All Lowrance NMEA 2000 capable devices are either NMEA 2000

certified or certification is pending. See our web site,

for the latest product status information.

To get started with your Lowrance gauge, first read Section 2:

Installation. It contains instructions for installing the LMF-200. fter

you have read those instructions, install the gauge and any EP sensors

you may have purchased and read the rest of this manual. Each sensor

comes with its own installation instruction sheet, but his manual

describes how the gauge operates with each sensor, and how to

configure and calibrate the sensors. Your gauge includes another

manual, NMEA 2000 Networks General Information, part number 9880154-172, which contains complete instructions for creating or

expanding a NMEA 2000 network.

1

www.lowrance.com,

Page 8

LowranceNET teams up the powerful NMEA 2000 network standard

with a fast-growing, cutting-edge family of Lowrance Electronic Probe

Sensors. At press time, the product line includes the EP-10 Fuel Flow

sensor, EP-15 Fluid Level sensor, Suzuki Engine Interface, EP-25

Speed sensor, Bennett NMEA 2000 Trim Tab sensor, EP-35 Temp

sensor and the EP-35TH Temp sensor. More sensors are on the way,

including the EP-45 Pressure sensor and EP-50 Storage Device.

Log onto

www.lowrance.com from time to time to get the latest product

information, including updated operation manuals, instruction sheets

and software you can download free of charge. When you are ready to

expand your network, see the accessory ordering information on the

back cover of this manual.

NOTICE!

The storage and operation temperature range for your unit is from

-4 degrees to +167 degrees Fahrenheit (-20 degrees to +75 degrees

Celsius). Extended storage or operation in temperatures higher or

lower than specified will damage the liquid crystal display in your unit.

This type of damage is not covered by the warranty. For more

information, contact the factory's Customer Service Department; phone

numbers are inside the manual's back cover.

2

Page 9

Section 2: Installation

Preparation

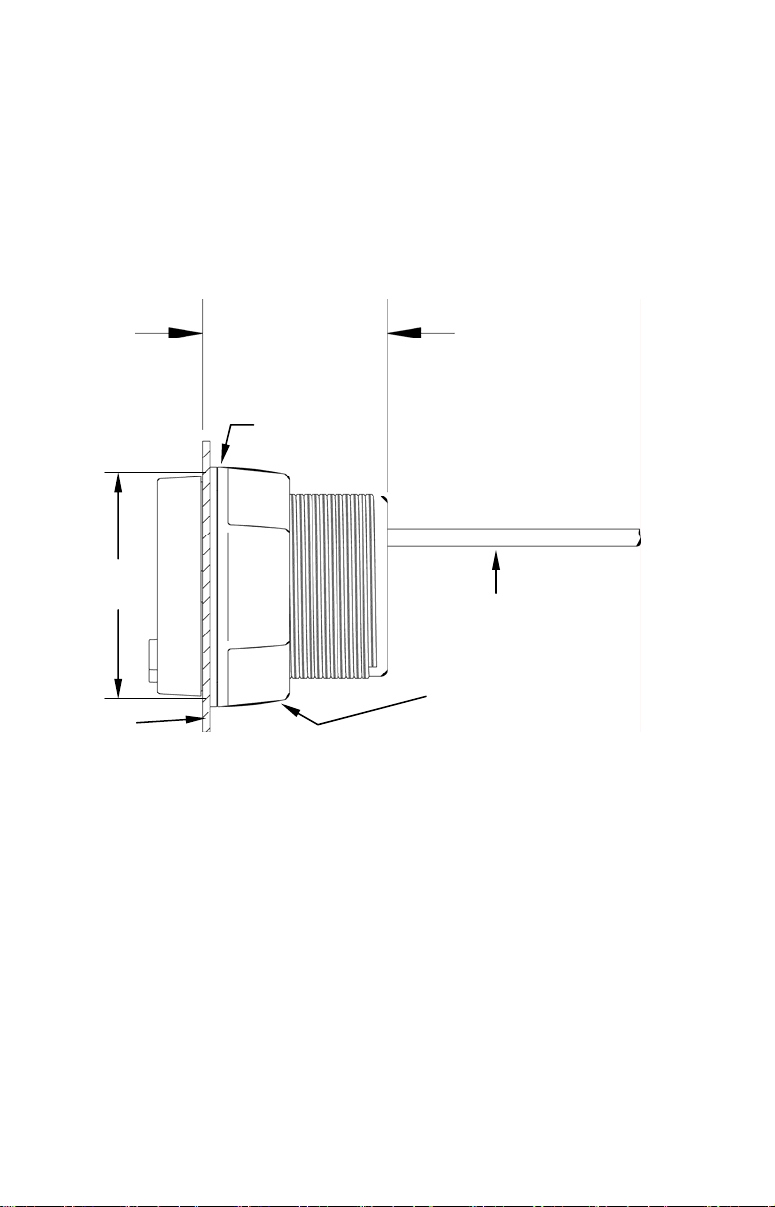

When installed, the gauge will cover an area on the dash 2-3/8" (60.3

mm) in diameter. To mount the unit, first make sure there is at least 23/4" (70 mm) from the front of the dash to any obstruction behind the

dash. The maximum usable dash thickness is 1-1/8" (28.5 mm). Also, be

sure there is room to route the network and buzzer cables. The

following figure shows gauge dimensions.

2-3/4"

(70 mm)

Gasket

2-3/8"

(60.3 mm)

Cables

Threaded mounting collar

Dash

Dash installation, cross-section view.

Caution:

You should read over the entire installation section before

drilling any holes in your vessel!

Recommended Tools and Supplies

Recommended tools for this job include: hole saw, 2 1/8" (54 mm) hole

saw bit, drill, 1/8" (3 mm) drill bit (for starter hole).

Other supplies are not included, unless otherwise indicated. If you need

to route the gauge's network cable connector through a bulkhead, you

will need a drill and a 3/4" drill bit.

If the dash does not have a standard 2-1/8" (54 mm) hole, you will need

a drill or saw to make the hole. Carefully measure the dash thickness

and the hole area before cutting or drilling.

3

Page 10

The buzzer installation requires two cable ties and two wire nuts or

other wire connectors.

If you need to extend any of the buzzer or dash light wires, use a

minimum of 24 gauge wire and wire connectors of your choice. Wire

nuts or electrical tape are required to cap any unused bare wires.

Installation Sequence

You can install this gauge in some other order if you prefer, but we

recommend the installation sequence summarized below:

1. Determine the location for the gauge so you can plan how and where

to route the cables. This will help you make sure you have enough cable

length for the desired configuration.

2. Determine the location of the nearest device on the boat's NMEA

2000 network, along with the route of the gauge's network cable.

3. Determine the location for the alarm buzzer (piezo) and its wire

route.

4. If you want to turn on the gauge's backlight whenever you turn on

your dashboard lights, locate your boat's dash light switch and

determine how to route the gauge's dash light wires to it.

5. Install the gauge in a standard 2-1/8" (54 mm) hole in the dash. If no

2-1/8" (54 mm) hole in the dash, use a hole saw to cut a mounting hole.

6. Connect the buzzer wires and install the buzzer. If desired, connect

the dash light wires to the boat's dash light switch.

7. Connect the network cable to the NMEA 2000 network.

Mounting the Gauge

When you determine the location for the LMF-200, drill a 2-1/8" (54

mm) hole in the dash or use an existing gauge hole. Slide the unit's

cables through the hole from the front side of the dash. Push the LMF200 housing through the hole until it is flush with the dash surface.

Make sure the face of the gauge is aligned correctly.

Next, slide the rubber gasket and plastic-mounting collar over the

cables and onto the back side of the gauge.

4

Page 11

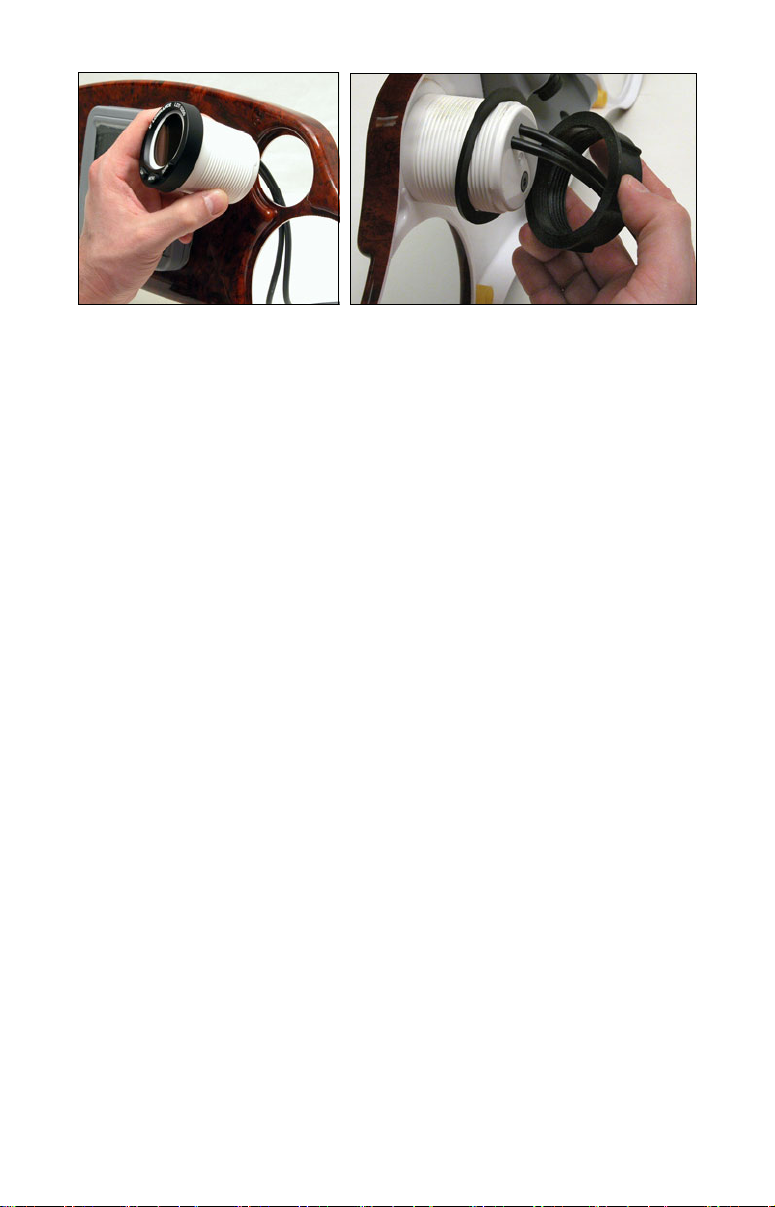

Insert gauge through the hole in the front side of the dash (left). Slide

the rubber gasket over the cables, followed by the plastic collar (right).

Slide the gasket forward so it is flush with the back of the dash, then

screw on the mounting collar, turning it until it is snug against the

gasket and the back of the dash.

Find a buzzer location that is protected from the elements, but that

still allows you hear it. Connect the buzzer wires according to one of

the two wiring diagrams on the following page.

NOTE:

Later model LMF-200 gauges have different color wires, so examine

the wiring diagrams carefully before connecting any wires.

Use two cable ties and attach the buzzer to one or both of the cables at

the back of the gauge or use the adhesive back of the buzzer to stick it

to a flat, clean surface.

If desired, connect the dash light wires as shown in the following

figure. Finish the installation by plugging the network cable into the

network.

Wiring

The LMF-200 draws operating power from the NMEA 2000 network.

The gauge does not have an on/off switch — whenever the network has

power, the LMF-200 is on and drawing current.

5

Page 12

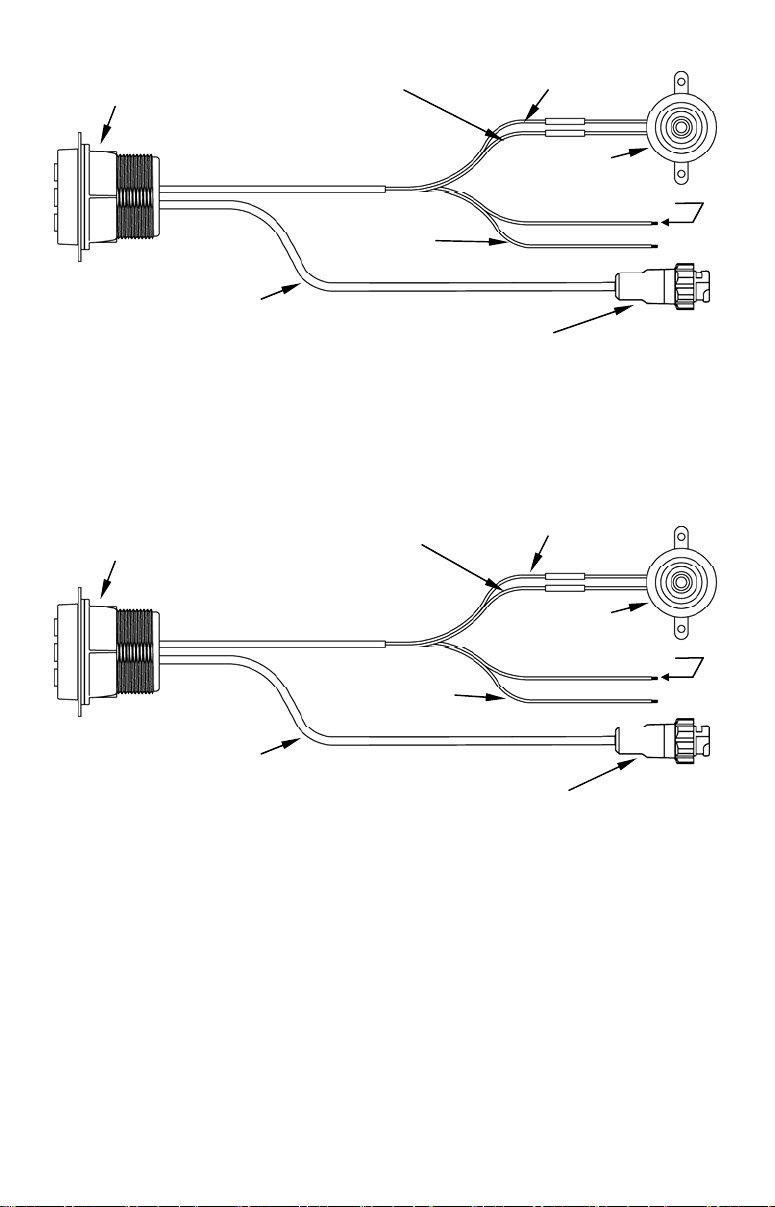

r

r

LMF green wire to

buzzer red wire

Buzze

Dash light red

(to dash light switch)

LMF-200 housing

NMEA 2000

Network cable

LMF-200 white wire to

buzzer black wire

Cap unused wires

with wire nuts or tape.

Dash light black

(to ground)

Female NMEA

2000 T connector

LMF-200 cable connections.

IMPORTANT:

The latest version of the LMF-200 (below) has a different color

scheme for dash light and buzzer wires than those shown in the

diagram above.

LMF-200 housing

LMF-200 yellow wire to

buzzer black wire

Cap unused wires

with wire nuts or tape.

LMF-200 Dash black

(to dash ground)

LMF-200 Blue

wire to buzzer red

Buzze

LMF-200 Dash White

(to dash light switch)

NMEA 2000

Network cable

Latest LMF-200 cable connections.

Female NMEA

2000 T connector

Ideally, the NMEA 2000 network itself is powered from a switch on the

boat's accessory panel, allowing network power to be turned on and off.

To automatically turn on the gauge backlights when you turn on your

other dashboard lights, connect the red dash light wire to the positive

side of the switch controlling the dash lights and connect the black

dash light wire to ground

NOTE:

If multiple gauges are connected to the same NMEA 2000 bus, only

one gauge has to be connected to the dashboard lights for all gauge

6

Page 13

backlights to come on when the dashboard lights are turned on.

The gauge connected to the dashboard lights will send a signal

across the network, causing the other gauges to turn on their

backlights.

Caution:

The bare ends on any unused wires could cause an electrical

short if left exposed. To prevent this, you should cover the

individual wire ends — either by capping them with wire nuts

or wrapping them with electrical tape. (You should cut off the

bare wire before taping off the ends.)

Connecting to a NMEA 2000 Network

A network bus is an installed and operational network cable (backbone)

running the length of your boat, already connected to a power supply

and properly terminated. It provides network connection nodes at

various locations around your boat.

Compatibility

You will easily be able to connect your unit to both red (DeviceNet) and

blue connector networks, regardless of whether your unit has a blue or

red connector network cable. Check the adapter cable segment in the

Setup and Installation of NMEA 2000 Networks, General Information"

that came packed with your unit. If you do not have that document, it

can be downloaded free from the Lowrance web site.

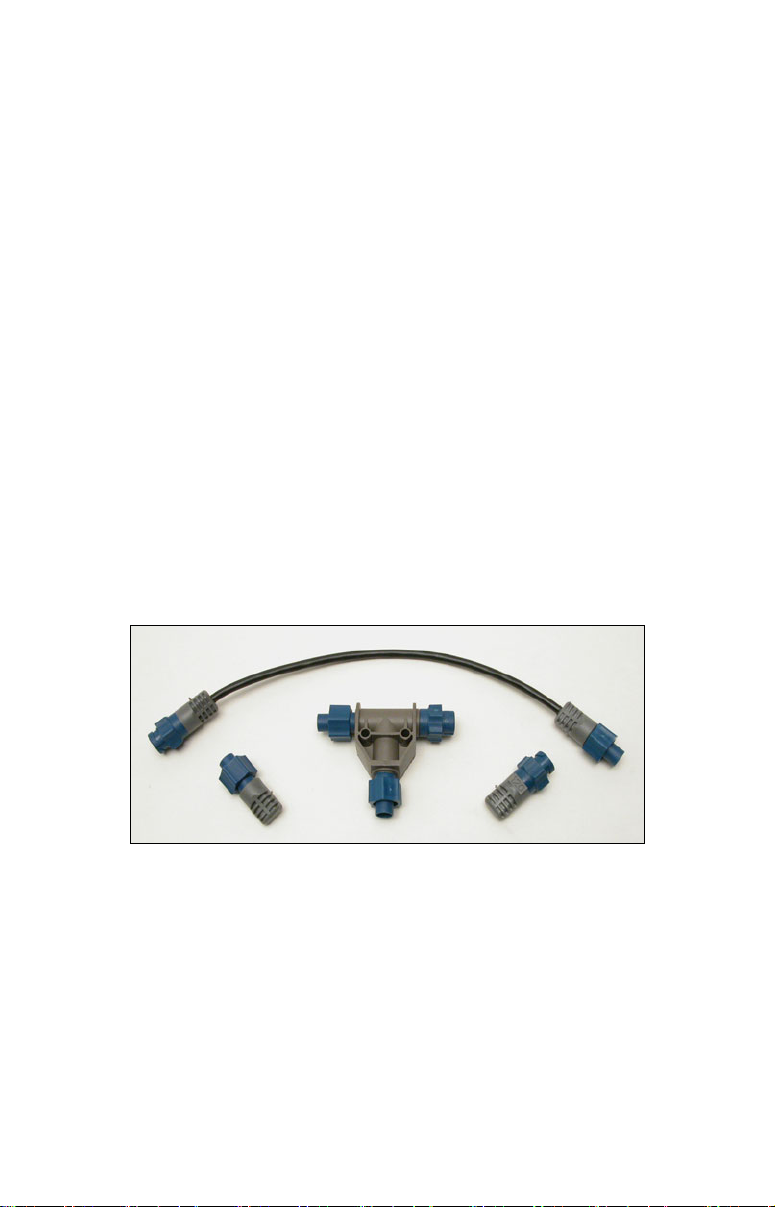

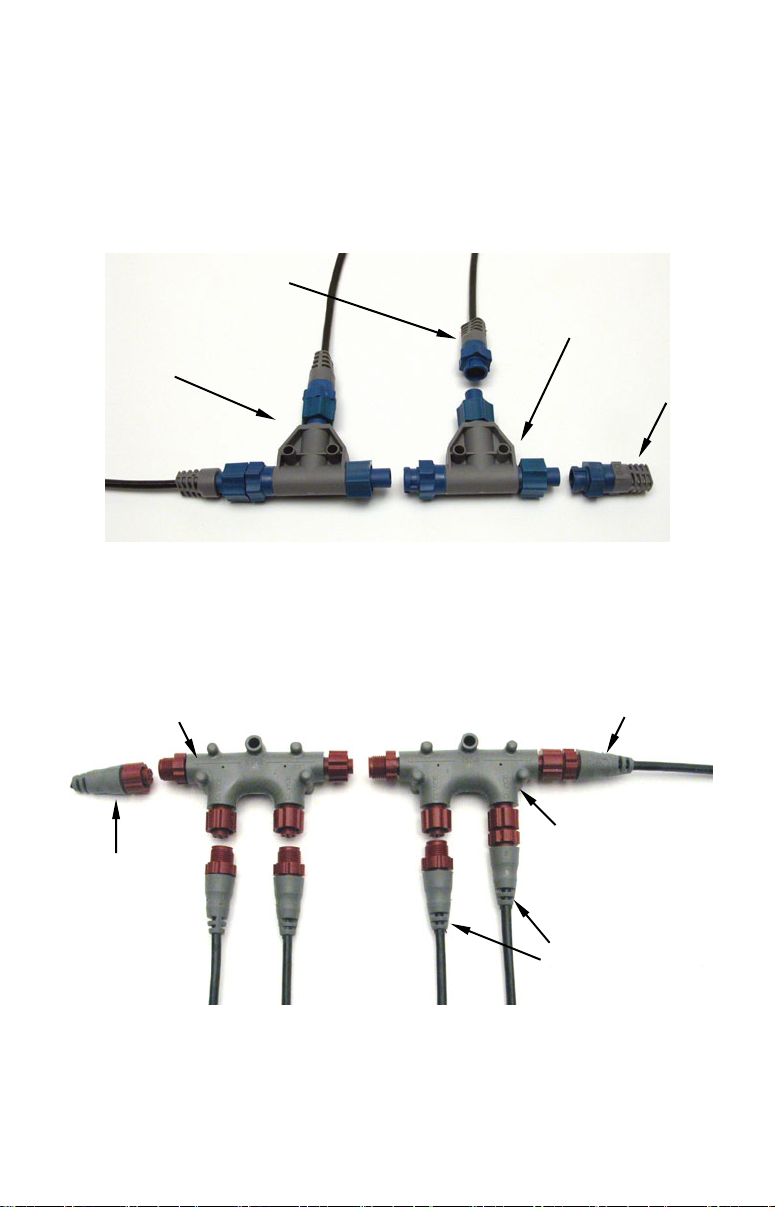

LowranceNET Node Kit for a NMEA 2000 network. Includes a 2 foot

extension cable, T connector, 120-ohm male terminator and 120-ohm

female terminator.

Network Backbone and Network Nodes

A network bus backbone consists of network cabling, terminators and T

connectors. Network nodes are made by fitting T-shaped connectors into

the backbone (using the sockets on the sides) and attaching any network

device to the bottom of the T.

7

Page 14

Adding a Network Node

You can add a node to any existing connection, anywhere along the

network backbone. This connection could be between a T connector and a

terminator, between two T connectors, between a T connector and a

backbone extension cable or between two extension cables. Wherever you

want to add the new node, separate the sockets of the existing connection

and install the T connector between them.

Lowrance or LEI device con-

nects to new T connector.

Existing network

node

Add T-shaped connector to add device

to bus.

Attach

terminator at

end of bus.

Add a new device to a NMEA 2000 bus (above) by attaching a T

connector between two T connectors, between a T connector and the

end terminator, or between two backbone extension cables. The red

connector network (below) is built in the same way. Notice the Double

T connectors on the red connector network.

Add T-shaped or double T connector to add

device to bus (maintaining linear architecture)

Backbone cable

to rest of bus

Existing network

Attach

terminator at

end of bus

node

Devices connect to

Double T connector

If you want to add a node at the end of the backbone (network bus)

remove the terminator from the last connector, like the figure above.

Install the new T connector, then attach the terminator to the side of the

connector.

8

Page 15

NOTE:

If you add an EP-10 Fuel Flow, EP-15 Fluid Level, EP-45 Water

Pressure or EP-50 Storage Device sensor to the network, you must

go through Boat Setup so the engine-tank configuration will be

consistent among the sensors in the LowranceNet. Follow the Boat

Setup procedure in Section 3: Operation.

Additional Network Information

For more detailed information about setting up a NMEA 2000 network,

refer to the "Setup and Installation of NMEA 2000 Networks, General

Information" that came with your unit. If you do not have that

document, it can be downloaded free from the Lowrance web site.

9

Page 16

Understanding this Manual

Most instructions in the manual are listed as numbered steps. Keypad

commands appear as boldface type, making it easy to skim through

instructions and pick out what menu command to use.

Up and Down keys

The Up and Down keys help you navigate through menus, select

(highlight) menu items, and are used to make adjustments to vertical

and horizontal scrollbars. They are referred to as

the manual text.

Menu key

When instructed to press the menu key, menu is shown as

the up and down keys are shown as

UP and DOWN.

Menu Commands

A menu command or a menu option will appear in small capital letters,

like —

SYSTEM SETUP. When you see a word in command text, you are

supposed to take action, by selecting (highlighting) this command or

option from a menu.

Instructions = Menu Sequences

Most functions performed with this unit are described as a sequence of

keystrokes.

Instructions for accessing a menu will look like this:

1. To access the System Setup menu, press

and

DOWN keys to select PAGES and then press MENU.

2. Select

SYSTEM SETUP and press MENU.

UP and DOWN keys in

MENU just as

MENU, use the UP

10

Page 17

Section 3: Operation

The displays and settings in this digital gauge are controlled by a

three-button keypad. The buttons are

key provides access to menus and helps with data entry and command

execution. The

(highlight) menu items.

UP and DOWN keys are used to scroll through and select

LMF-200 keypad.

Boat Setup

When the LMF-200 is turned on the first time the Boat Setup menu

will appear on the screen. You will not be able to proceed without

completing boat setup. If, however, you have

one or more of the following devices — Suzuki

Engine Interface, EP-10 Fuel Flow, EP-15

Fluid Level, EP-45 Pressure Sensor or an EP50 Storage Device — already configured in the

network with the same engine-tank

configuration, you WILL NOT have to go

through boat setup when adding a new gauge

to the network. After adding the gauge to the network, the Boat Setup

menu will be cleared from the screen and the unit will begin normal

operation in 1-2 seconds. If you have more than one gauge on the

network, you will only have to execute Boat Setup for one of the

gauges. When the data is input, it is transmitted over the network and

saved to other units.

NOTE:

If you add an EP-10 Fuel Flow, EP-15 Fluid Level, EP-45 Water

Pressure or EP-50 Storage Device sensor to the network, you must

go through Boat Setup so the engine-tank configuration will be

consistent among sensors on the network.

To execute Boat Setup:

1. With Boat Setup highlighted on the screen, press

Setup menu will appear, allowing you to select an engine-tank

configuration that matches the number of engines and fuel tanks on

UP, DOWN and MENU. The MENU

MENU. The Boat

11

Page 18

your vessel. Boat Setup options include: 1 En/1 Tk, 1 En/2 Tk, 2 En/1

Tk, 2 En/2 Tk, 3 En/1 Tk and 3 En/3 Tk.

2. Select the configuration option that matches number of engines and

tanks on your vessel and press

3. Select the tank you want to set up and press

MENU.

MENU, which will open

the Tank Size window.

4. Use the

will hold and press

UP and DOWN keys to input the number of gallons the tank

MENU. Repeat steps 3 and 4 for each additional

tank. After all tanks have been set up, you will be directed to the main

display.

NOTE:

If you chose the wrong engine-tank configuration during Boat

Setup, you will have to reset your engine-tank configuration to get

back to Boat Setup. See detailed instructions on resetting enginetank configuration on page 22.

Timeout

You will notice there is no exit key in the LMF-200. Its menus time out,

meaning they will be automatically cleared from the screen after a

preset amount of time. There are four intervals from which to choose: 3,

5, 10 and 15 seconds. If, for example, you chose a timeout interval of 15

seconds, the page will be cleared from the screen 15 seconds after the

last button is pushed.

1. To change the Timeout settings, press

to select

2. Highlight

SYSTEM SETUP and press MENU.

TIMEOUT and press MENU. The Timeout menu will open with

MENU, use the UP and DOWN

the four intervals: 3, 5, 10 and 15 seconds.

3. Use the

desired time out setting and press

UP and DOWN keys to highlight the circle to the left of the

MENU. You will be directed back to

the main display.

Basic Menu

The LMF-200 has 10 page screens that can be customized with the data

of your choosing. Each page has its own basic menu. Basic menus vary

from page to page, but all include these standard menu options: Pages,

Screen,

Audio Setup and System Setup. Pages that can be customized

also include Customize on the basic menu.

Pages

Your unit can display up to 16 page screens. You could, for example,

add 10 different pages then add some pages more than once,

customizing them differently each time.

12

Page 19

Viewing Pages (Page Screen Rotation)

The Page Screen Rotation consists of multiple pages that have been set

up for display. Once pages have been added to the page screen rotation,

they can be set to scroll across the screen automatically or manually.

Use the

Pressing the

DOWN key moves the scroll in the other direction. You will use the

UP and DOWN keys to manually scroll pages across the screen.

UP key moves the scroll in one direction. Pushing the

Autoscroll feature to set up pages for automatic scrolling. See page 15

for more detailed information about Autoscroll.

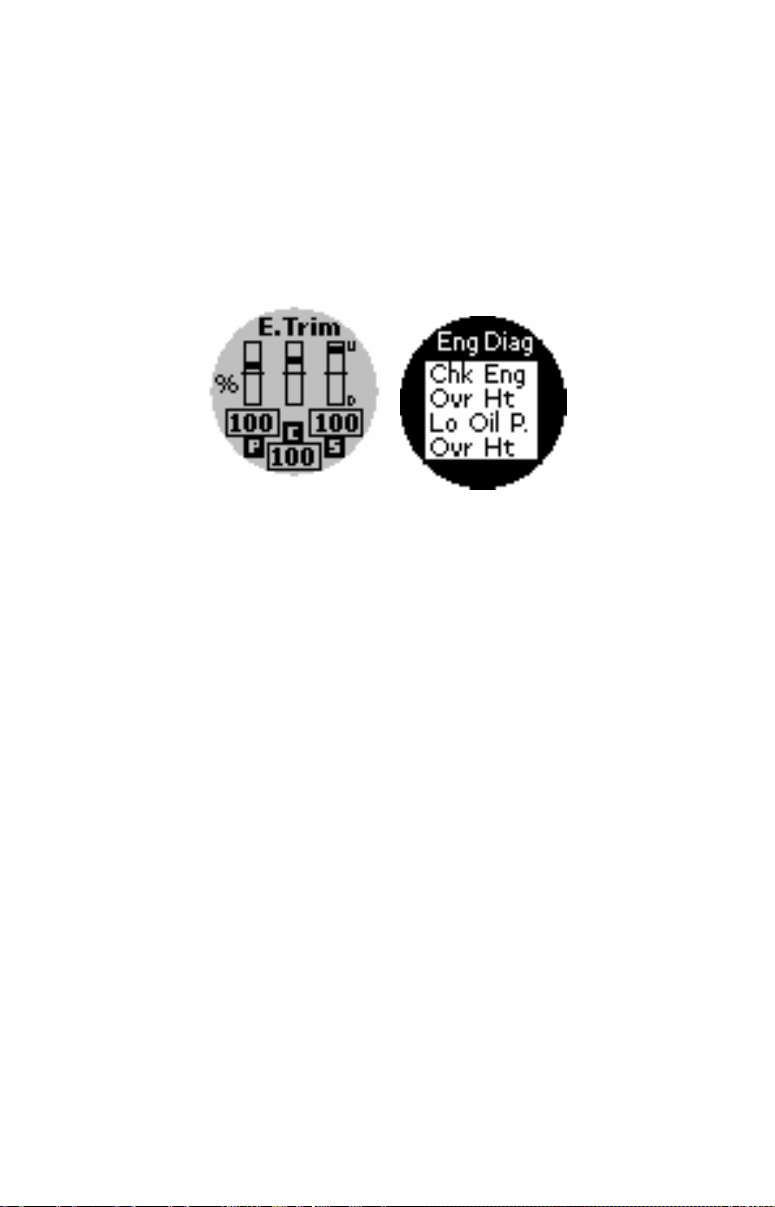

Engine Trim page (left), Engine Diagnotic page (center).

Page Options

The LMF-200 has 9 different pages that may be added to the page

screen rotation. They are: Engine Trim, Engine Diagnostics, Fuel

Manager, GPS Position, Single Digital, Dual Digital, Gauge,

Synchronizer, Trim Tabs and Rudder.

Engine Trim

The Engine Trim page displays engine position data as a percentage. It

cannot be customized.

Diagnostic

The Engine Diagnostic page displays engine performance data. It

cannot be customized.

Fuel Manager

The Fuel Manager page has a digital readout capable of displaying

nine data types, including fuel flow, fuel used and fuel remaining.

GPS Position

The GPS position page displays the boats position in LatitudeLongitude using Degrees-Minutes-Seconds or Degrees-Minutes as units

of measure.

Rudder

The Rudder Page displays the rudder position as an analog gauge and

in degrees. It cannot be customized.

13

Page 20

Single Digital

The Single Digital page consists of a digital data box that can be

customized to display a wide assortment of data, ranging from ALR:V

(Alternate Voltage) and BAT:V (Battery Voltage) to WTR:S (Water

Speed), GND:S (Ground Speed) and Tach (Tachometer).

Dual Digital

The Dual Digital page features two digital data boxes that can be

customized to display a variety of data including, ENG:O:P (Engine Oil

Pressure), ENG:L (Engine Load) and ENG: Hr (Total Engine Hours).

Gauge page (left) monitoring paddle wheel speed; Synchronizer page

(center) with Trim Tabs page (right).

Gauge

The Gauge page consists of a single analog gauge that can be

customized to display a wide assortment of data that includes, Fluid

Level, Engine Voltage, Engine Trim and Water Speed.

Synchronizer

The Synchronizer page displays RPM for two or three engines. It allows

users to synchronize engines for smoother performance. The

Synchronizer page cannot be customized and will NOT be available for

single-engine configurations.

Trim Tabs

The Trim Tab page provides data on the position of the trim tabs, using

degrees or percentages as units of measure.

Pages Menu

The Pages menu can be accessed from any of the page displays. It has

four options: Add Page, Remove Page, Autoscroll and Pop-ups Setup.

Add Page

The Add Page command allows you to add pages to the page screen

rotation. Pages that are not added to the page screen rotation will not

be displayed.

NOTE:

Only pages added to the page screen rotation will be displayed.

14

Page 21

To add a page to the display:

1. Press

MENU, which will open the Pages menu with the following options: Add

MENU, use the UP and DOWN keys to select PAGES and press

Page, Rem Page, Autoscroll and Set Pop-up.

2. Select

3. Select the page you want to display and press

ADD PAGE and press MENU.

MENU. You will be

taken back to the main display, where the page you selected will be

shown.

NOTE:

The LMF-200 can have up to 16 pages in the page screen rotation

at one time. If you try to add a 17th page, the following message

will appear: Pages reached. In that case, you will have to remove a

page before another page can be added to page screen rotation.

Remove Page

The Removing Pages command allows you to remove pages from the

page screen rotation. You will have to scroll the page you want to

remove on to the screen before accessing the Remove Pages command

from the Pages menu.

To remove a page from the display:

1. First, scroll the page you want to remove on to the screen.

2. Press

MENU.

3. Select

MENU, use the UP and DOWN keys to select PAGES and press

REM. PAGE and press MENU. The following message will appear:

Remove current Page?

4. Press

MENU, which will remove the current page and take you back

to the main display.

Autoscroll

Once you have added the pages you want to monitor to the page screen

rotation, you will be able to view them in two ways. You can view pages

manually by using the

ENTER and EXIT keys or use the Autoscroll

function to have pages automatically scroll across the screen at an

interval of your choosing.

To activate Autoscroll:

1. Press

MENU.

2. Highlight

with two options: Off

MENU, use the UP and DOWN keys to select PAGES and press

AUTOSCROLL and press MENU. The Autoscroll menu appears

and Set Time. (Select OFF from the Set Time

menu.)

3. Select

SET TIME and press MENU to open the Set Time menu.

15

Page 22

4. Use the

UP and DOWN keys to set the amount of time (between 1-60

seconds) each page will be displayed before the unit scrolls to the next

page. When the desired time has been entered, press

MENU. You will be

taken back to the main display.

Pop-ups Setup

This feature helps you keep tabs on RPM, Engine Trim, Trim Tab and

Rudder pages by launching a pop up window if thresholds for any of the

data types are exceeded. If, for example, you set the RPM threshold to

500 RPM and choose a 10-second Stay Time, the RPM page will pop up

if there is a change in RPM that exceeds 500 RPM — like decreasing

RPM from 2000 RPM to 1300 RPM. The Pop up will expire 10 seconds

after RPM data stops changing. The gauge will revert to the page it

was showing before the threshold was exceeded.

To set a Pop-Up:

1. Press

MENU. Highlight SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time.

3. Select

PAGES and press MENU to open the Pop-up Pages menu with

four options: RPM, Engine Trim, Trim Tabs and Rudder.

4. Highlight the circle to the left of the desired page or pages and press

MENU, which will place an X in the checkbox.

NOTE:

If you select RPM, you will be taken to the Select Engine menu.

Select the desired engine (Port, Center or Starboard) and press

MENU.

5. Let the menu time out and you will be taken back to the main

display.

Stay Time

The Stay Time command allows you to choose how long a pop up will

remain on the screen once the data stops moving. The Stay Time

setting you choose will affect all four Pop-up Pages.

To set Stay Time:

1. Press

MENU. Highlight SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time.

3. Highlight

STAY TIME and press MENU. Use the UP and DOWN keys to

set the amount of time (between 2-15 seconds) pop up windows will

stay on the screen after they are triggered.

16

Page 23

4. After entering the desired stay time, press

MENU. You will be taken

to the main display.

Pop-up Thresholds

Once you have chosen the pages you want to monitor, you will need to

set a threshold for each page. A pop up will not appear for a page

unless a threshold has been chosen. When a threshold is exceeded, the

pop-up window will appear. If, for example, you set the RPM threshold

to 500 RPM and choose a 10-second Stay on Time, the RPM page will

pop up if there is a change in RPM that exceeds 500 RPM — like

decreasing RPM from 2000 RPM to 1300 RPM. The pop up will expire

10 seconds after the RPM data stops changing. The gauge will revert to

the page it was showing before the threshold was exceeded.

RPM Threshold set up:

Make sure RPM has been selected on the Pop-up Pages menu before

setting a RPM threshold. If it has not been selected on the Pop-up Page

menu, a RPM pop-up will not appear, regardless of the threshold.

1. Press

MENU. Highlight SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time. Select

3. To set the threshold for RPM, highlight

4. Use the

3000 RPM. Press

UP and DOWN keys to select a RPM level between 50 and

MENU and you will be taken back to the main display.

THRESHOLD and press MENU.

RPM and press MENU.

Engine Trim Threshold set up:

Make sure Engine Trim has been selected on the Pop-up Pages menu

before setting an Engine Trim threshold. If it has not been selected on

the Pop-up Page menu, an Engine Trim pop-up will not appear,

regardless of the threshold.

1. Press

MENU. Highlight SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time. Select

3. Select

4. Use the

percent. Press

ENGINE TRIM from the Threshold menu and press MENU.

UP and DOWN keys to choose a threshold between 3 and 50

MENU and you will be taken back to the main display.

THRESHOLD and press MENU.

Trim Tabs Threshold set up:

Make sure Trim Tabs have been selected on the Pop-up Pages menu

before setting a threshold. If Trim Tabs are not selected on the Pop-up

Page menu, a Trim Tab pop-up will not appear, regardless of the

threshold.

17

Page 24

1. Press

MENU. Select SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time. Select

3. Select

TRIM TABS from the Threshold menu and press MENU.

THRESHOLD and press MENU.

4. Use the UP and DOWN keys to choose a threshold between 3 and 50

percent. Press

MENU. You will be taken back to the main display.

Rudder Threshold set up:

Make sure Rudder has been selected on the Pop-up Pages menu before

setting a threshold. If Rudder is not selected on the Pop-up Page menu,

a Rudder pop-up will not appear, regardless of the threshold.

1. Press

MENU. Highlight SET POP-UP and press MENU.

MENU, use the UP and DOWN keys to select PAGES and press

2. The Set Pop-up menu will appear with three options: Pages,

Threshold and Stay Time. Select

3. Select

4. Use the

degrees. Press

RUDDER from the Threshold menu and press MENU.

UP and DOWN keys to choose a threshold between 3 and 40

MENU and you will be taken back to the main display.

THRESHOLD and press MENU.

Screen

The Screen menu allows you to adjust the appearance of the screen.

There are three options in the screen menu: Backlight, Contrast and

Reverse Video.

Backlight

The Backlight feature allows you to brighten or dim the light in the

LMF-200.

To adjust Backlight:

1. Press

MENU. The Screen menu will appear with three options: Backlight,

Contrast and Rev Video.

2. Select

menu with two options: BL Sync and Adjust.

3. To adjust the backlight, select

graphic will appear.

4. Use the

5. Press

Backlight Sync (BL Sync)

By turning on the Backlight Sync function, all the backlight levels for

components on the LowranceNet may be controlled by any of the

gauges or display units in the network. If you adjust the backlight on

MENU, use the UP and DOWN keys to select SCREEN and press

BACKLIGHT and press MENU, which will open the Backlight

ADJUST and press MENU. A flashlight

UP and DOWN keys to set the backlight to a desired level.

MENU to accept the new setting and return to the main display.

18

Page 25

one of the gauges or display units, the backlight levels from the other

gauges and display units will be changed, too. The default setting for

Backlight Sync is On.

1. To turn BL Syn on or off, press

select

SCREEN and press MENU.

MENU, use the UP and DOWN keys to

2. The Screen menu will appear with three options: Backlight, Contrast

and Rev Video. Select

BACKLIGHT and press MENU.

3. The Backlight menu will be displayed with a pair of options: BL Sync

and Adjust. Select

BL SYNC and press MENU.

4. The BL Sync menu has two settings: On and Off. Select the desired

option and press

MENU.

Contrast

The Contrast feature allows you to darken or lighten the display

screen. Unlike the backlight, every gauge's contrast is adjusted

individually. It cannot be synchronized over the network.

To adjust Contrast:

1. To adjust Contrast, press

select

SCREEN.

2. Press

MENU, highlight CONTRAST and press MENU. The Contrast

MENU and use the UP and DOWN keys to

Vertical Adjustment bar will appear.

3. Use the

4. Press

UP and DOWN keys to move the slider bar to a desired level.

MENU to accept the new setting and return to the main display.

Reverse Video (Rev Video):

The Reverse Video function swaps the position of dark and light colors

on the screen. The dark text, on top of a light background, will be

switched to light text on top of a dark background. This feature,

typically, is used to darken the display for nighttime use. Reverse

Video is transmitted over the network, so all gauges will be

synchronized with the same Reverse Video setting (On or Off).

To turn on Reverse Video:

1. Press

MENU.

2. Press

MENU, use the UP and DOWN keys to select SCREEN and press

MENU, highlight REV VIDEO and press MENU. You will notice the

dark and light colors have switched places.

3. To switch back to the previous setting, repeat steps 1 and 2.

Audio Setup

Audio Setup gives you access to the unit's audio functions. There are

two options on the Audio Setup menu: Key Sounds and Alarm Sounds.

19

Page 26

Key Sounds

When Key Sounds are turned on, a tone will sound every time you push

the

UP, DOWN and MENU keys. When you turn off Key Sounds, no tone

will sound when you depress the keys.

To turn Keys Sounds on or off:

1. Press

press

MENU, use the UP and DOWN keys to select AUDIO SETUP and

MENU. The audio menu will appear with two options: Key Sounds

and Alarm Sounds.

2. Highlight the box to the left of Key Sounds and press MENU to turn

on (check) or turn off (uncheck) key sounds. After choosing the desired

setting, the menu will time out, taking you back to the main display.

Alarm Sounds

When an alarm is set and Alarm Sounds are turned on, you will hear a

tone and see a pop-up window when the alarm is triggered. With an

alarm set and Alarm Sounds turned off, you will see a pop-up window,

but no tone will sound.

To turn Alarm Sounds on or off:

1. Press

press

MENU, use the UP and DOWN keys to select AUDIO SETUP and

MENU. The audio menu will appear with two options: Key Sounds

and Alarm Sounds.

2. To turn Alarm Sounds on or off, select

Setup menu and press

MENU to turn on (check) or turn off (uncheck)

ALARM SOUNDS from the Audio

Alarm Sounds. After choosing the desired setting, the menu will time

out, taking you back to the main display.

System Setup Menu

On each page, the System Setup menu contains: Bus Devices, Snr

Alarms, Timeout, Eng/Tank, Reset, NMEA Info, Sys Info, Eng Data,

Engine Warnings, Units and Fuel Manager. The System Setup menus

for Synchronizer, Engine Trim, Single Analog and Trim Tab pages also

include Speed Range and Pressure Range.

Bus Devices

Bus Devices allows you to manage devices on the NMEA 2000 Network.

Accessing devices from the Bus Devices list gives you access to an EP

sensor's internal menu. We will cover that in more detail in Section 4:

EP Configuration and Calibration.

1. Press

press

2. Highlight

network devices, will appear.

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

B. DEVICES and press MENU. The Bus Devices list, a list of

20

Page 27

3. To select an item from the bus devices list, use the

keys to highlight the device and press

MENU. To get back to the main

UP and DOWN

display, let the menu time out. Accessing devices from the Bus Devices

list gives you access to an EP sensor's internal menu. We will cover

that in more detail in Section 4: EP Configuration and Calibration.

4. When you are through with the Bus Devices list, let the menu time

out to be taken back to the main display.

Sonar Alarms

Sonar alarms allow you to set alarms that will alert you as water depth

changes around your vessel. If the depth rises above (Deep Alarm) or

falls below (Shallow Alarm) a depth threshold of your choosing, an

alarm will sound.

To set the Shallow Alarm:

The shallow alarm will sound when your vessel enters water more

shallow than the selected shallow alarm threshold.

1. Press

press

2. Highlight

with two choices: Shallow

3. Select

appear with two options: Off and Set Depth. Select

MENU. (To turn off the Shallow Alarm, repeat Steps 1-3, then select Off

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

SNR ALARMS and press MENU. The Alarm menu will appear

and Deep.

SHALLOW and press MENU. The Shallow Alarm menu will

SET DEPTH and press

from the Shallow menu.)

4. Use the

UP and DOWN keys to set the desired depth. Press MENU and

you will be taken back to the main display.

To set the Deep Alarm:

The deep alarm will sound when your vessel enters water deeper than

the selected deep alarm threshold.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

SNR ALARMS and press MENU. The Alarm menu will appear

with two options: Shallow and Deep.

3. Select

DEEP and press MENU, which will open the Deep menu with

two options: Off and Set Depth. (To turn off the Deep Alarm, repeat

Steps 1-3, then select Off from the Deep menu.)

4. Select

the desired depth and press

SET DEPTH, then use the UP and DOWN keys to set the alarm to

MENU. You will be taken back to the main

display.

21

Page 28

Timeout

You will notice there is no exit key in the LMF-200. Its menus time out,

meaning they will be automatically cleared from the screen after a

preset amount of time. The timeout duration will begin after the last

button is pushed.

1. To change the Timeout settings, press

keys to select

2. Highlight

SYSTEM SETUP and press MENU.

TIMEOUT and press MENU. The Timeout menu will open with

MENU, use the UP and DOWN

four options: 3, 5, 10 and 15 seconds.

3. Choose the desired timeout setting and press

MENU. You will be

taken back to the main display.

Eng (Engine)/Tank

The Engine/Tank configuration menu displays the number of engines

and fuel tanks on the vessel as well as fuel tank capacity. You selected

your engine-tank configuration during Boat Setup. If the selected

configuration is incorrect, you can return to Boat Setup by resetting the

configuration from the Engine/Tank Configuration menu.

To reset Eng/Tank configuration:

1. Press

press

2. Highlight

MENU, use the UP an DOWN keys to select SYSTEM SETUP and

MENU.

ENG/TANK and press MENU. The Engine-Tank configuration

page will appear.

3. Press

reset Eng/Tank. Press

MENU and the following message will appear: Press Menu to

MENU. You will be taken to the Boat Setup

screen.

Reset

The Reset command allows you to switch the LMF-200 back to factory

default settings.

To reset values:

1. Press

press

2. Highlight

Hit Menu to Rst All values. Press

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

RESET and press MENU. The following message will appear:

MENU. You will be taken back to the

main display.

WARNING:

Resetting values is a hard reset. All LMF-200 settings

will be set back to factory defaults. Resetting values,

however, does not affect engine/tank configuration or

the calibration and configuration settings of devices on

the bus.

22

Page 29

NMEA Info

The NMEA information screen displays information about your NMEA

network, including address, instance, serial number and database

version.

To access the NMEA Information screen:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

NMEA INFO and press MENU. The menu will time out and

you will be directed to the main display.

System Information

Access the system information screen to see what version of software

you have in your LMF-200.

To access System Information screen:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

SYS INFO and press MENU. The menu will time out and you

will be taken back to the main display.

Engine Data

The Engine Data feature allows you to select an engine (Port, Center or

Starboard) to be the engine shown on pages that display engine data.

To modify Engine Data:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

ENG DATA and press MENU. The Engine Data menu will

appear with up to three options: Port, Center and Starboard —

depending on the number of engines you chose during Boat Setup.

3. Select the engine to be displayed (Port, Center or Starboard) and

press

MENU. If, for example, you chose the Port engine, the following

confirmation message would appear: Hit Menu to chg to Port.

4. Press

MENU. You will be taken back to the main display. Pages that

display engine data will now show data from the selected engine.

Engine Warnings

The Engine Warnings feature allows you to set an alarm for one or

more engines. There are up to five options in the Engine Alarms menu,

depending on the number of engines chose during Boat Setup. The

options are All Engines, Port, Center, Starboard and Off. The default

setting is All Engines. (If you have a single-engine configuration, the

only options on the Engine Warning menu will be on and off.)

23

Page 30

To set Engine Warnings:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

ENGINE WARNINGS and press MENU. The Engine Warnings

menu will appear with up to five options, depending on the number of

engines chosen during Boat Setup. The options are: All Engines, Port,

Center, Starboard and Off. The default setting is All Engines.

NOTE:

If you choose All Engines, the alarm will be shown for each alarm

engine alarm. If Port, Center or Starboard engines are selected, the

gauge will only show warnings coming from the chosen engine. (To

turn off all engine warnings, highlight

OFF and press MENU. If you

turn off engine alarms, no alarms will be shown for any of the

engines.)

3. Highlight the desired option and press

MENU. You will be taken back

to the main display.

Speed Range

The Speed Range function is included in the System Setup menus of

the following pages: Synchronizer, Gauge and Trim Tab. The Speed

Range feature can make on-screen gauges easier to read by allowing

you to choose a range that will better fit your vessel’s speed

capabilities. If, for example, your vessel's speed range is 0-40, the

unnecessary figures (41-120) will only crowd the gauge display, making

it harder to read. Using the Speed Range feature allows you to

eliminate unnecessary figures from the display, giving it better

resolution. The default Speed Range is 0-40.

To set Speed Range:

1. With the Synchronizer, Engine Trim, Gauge or Trim Tabs page on

the screen, press

SETUP and press MENU.

2. Highlight

MENU. Use the UP and DOWN keys to select SYSTEM

SPD RANGE and press MENU. The Speed Range menu will

appear with three options: 0-40, 0-80 and 0-120.

3. Select the desired speed range and press

MENU. You will be taken

back to the main page. If you want to set speed range for other pages

that support the Speed Range feature, scroll the desired page on the

screen and repeat steps 1-3.

Pressure Range

The Pressure Range screen is included in the System Setup menus of

the following pages: Synchronizer, Gauge and Trim Tab. Pressure

Range can make on-screen gauges easier to read by allowing you to

select a range that will better fit your vessel’s pressure capabilities. If,

24

Page 31

for example, your vessel's water pressure range is 0-30 PSI, the

unnecessary figures (31-100 PSI) will only crowd the gauge display,

making it harder to read.

Using the Pressure Range feature allows you to eliminate unnecessary

figures from the display, giving it better resolution.

To set Pressure Range:

1. With the Synchronizer, Engine Trim, Gauge or Trim Tabs page on

the screen, press

SETUP and press MENU.

2. Select

PRES RNGS and press MENU. The Select Pressure menu will

MENU, use the UP and DOWN keys to select SYSTEM

appear with five options: WTR:P (Water Pressure), Eng:O:P (Engine

Oil Pressure), FUL:P (Fuel Pressure), BST:P (Boost Pressure) and

Trn:O:P (Transmission Oil Pressure).

3. Highlight the desired page and press

MENU. The Pressure Range

menu will appear with four options: 0-30 PSI, 0-60 PSI, 0-80 PSI and 0100 PSI.

4. Choose the desired range and press

MENU. You will be taken back to

the main display. If you want to set the Pressure Range for other pages

that support the Pressure Range feature, scroll

the desired page on to the screen and repeat

Steps 1-4.

Units

You can access the

UNITS menu from the System

Setup menu. It has five units of measure from

which to choose: Speed/Distance,

Temperature, Pressure, Depth, GPS and

Volume.

To change Speed and Distance units:

Temperature menu

with Celsius selected

as the unit of measure

Choosing Speed and Distance from the Change Units menu will allow

you to set the unit of measure for speed and distance to Statute,

Nautical or SI (Metric).

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select SPD/DIST and press MENU,

which will launch the Speed and Distance menu with the following

options: Statute, Nautical and SI (Metric) units.

3. Select one of the three options and press

MENU, which will take you

back to the main display.

25

Page 32

To change Temperature units:

Accessing Temperature from the Change Units menu will allow you to

set the unit of measure for temperature to Fahrenheit or Celsius.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select TEMP and press MENU, which

will launch the Temp menu with two options: Fahrenheit and Celsius.

3. Select the desired setting and press

MENU. You will be taken back to

the main display.

To change Pressure units:

Selecting Pressure from the Change Units menu will allow you to set

the unit of measure for pressure to Imperial/US or SI/Metric.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select PRESSURE and press MENU,

which will open the Pressure menu with two options: Imper (US) and

SI (Metric).

3. Select the desired pressure setting and press

MENU, which will direct

you back to the main display.

To change Depth units:

Choosing Depth from the Change Units menu will allow you to set the

unit of measure for depth to Feet, Fathoms or Meters.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select DEPTH and press MENU, which

will launch the Depth Menu with three options: Feet, Fathoms and

Meters.

3. Select the desired depth setting and press

MENU, which will take you

back to the main display.

To change GPS units:

Selecting GPS Coord from the Change Units menu will allow you to set

the unit of measure for GPS coordinates to Deg/Min or Deg/Min/Sec.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select GPS and press MENU, which

will open the GPS menu with two options: Deg/Min or Deg/Min/Sec.

3. Select the desired GPS unit setting and press

MENU. You will be

directed back to the main display.

26

Page 33

To change Volume units:

Choosing Volume from the Change Units menu will allow you to set the

unit of measure for volume to US Gallons or Liters.

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

UNITS and press MENU. Select VOLUME and press MENU,

which will open the Volume menu with two options: US gallons and

Liters.

3. Select the desired setting and press

MENU, which will take you back

to the main page.

Fuel Setup

Fuel Setup allows you to adjust options that will be used to measure

fuel economy. The following options can be set or reset from the Fuel

Setup menu: Refill Tank (Refill T), Part Fill (Partial Fill), Economy

Speed (Eco spd), Fuel Remaining Source (FRem Src), Reset Trip Fuel

(Rst trip F), Reset Seasonal Fuel (Rst Seas).

Refill Tank (Refill T)

The Refill Tank command ensures your LMF-200 fuel reading is

consistent with the actual amount of fuel in your tank or tanks. Refill

Tank must be used with the EP-10 Fuel Flow, EP-50 Storage Device

and the Suzuki NMEA 2000 Engine Interface. The Refill Tank

command is NOT used when the EP-15 Fluid Level is used to read the

fuel level.

To refill tank:

1. Press

press

2. Select

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Highlight FUEL MNGR and press MENU.

REFILL T and press MENU. The following message will appear:

Hit Menu if Tank filled up.

3. If the tank has been filled, press

MENU, which will take you back to

the main display.

NOTE:

If an EP-10 Fuel Flow or a Suzuki Engine Interface is being used a,

menu will appear giving you the option to calibrate fuel

calculations. We will discuss calibration in Section 4: Configuration

and Calibration.

Partial Fill (Part Fill)

The Partial Fill command helps maintain the accuracy of fuel economy

by allowing you to input the amount of fuel you added to your tank or

tanks. The Partial Fill command can be used with the EP-10 Fuel Flow,

EP-50 Storage Device and the Suzuki NMEA 2000 Engine Interface.

27

Page 34

To use Partial Fill:

1. Press

press

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Highlight FUEL MNGR and press MENU.

2. Highlight PART FILL and press MENU. The Select Tank menu will

appear with up to three options: Port, Center and Starboard. (If you

have one tank, you will be taken directly to the Fuel Quantity window.)

Select the desired engine and press

MENU.

NOTE:

When using the Partial Fill command, you will only be able to input

an amount of fuel less or equal to the fuel used figure. The unit will

not allow you to input a fuel amount greater than the fuel used

figure.

3. The Fuel Quantity window will appear. Use the

to enter the amount of fuel you added to the tank and press

UP and DOWN keys

MENU. You

will be taken back to the main display.

Economy Speed (Eco spd)

The Economy Speed menu allows you to choose what speed source the

LMF-400 will use to calculate Fuel Economy. A NMEA 2000 GPS

module, like the LGC-2000, measures ground speed The EP-25

Paddlewheel and NMEA 2000 Pitot Tube measure water speed.

NOTE:

Ground Speed is the default speed source for Fuel Economy.

To change Economy Speed Source:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Select FUEL MNGR and press MENU.

ECO SPD and press MENU, which will open the Eco spd

menu. The menu has three options: Water Spd (Water Speed), Pitot

Speed and Gnd Spd (Ground Speed). A NMEA 2000 GPS module

measures ground speed, while a paddlewheel, like the EP-25 measures

water speed.

3. Select the desired speed source and press

MENU, which will take you

back to the main display.

Fuel Remaining Source (FRem Src)

The Fuel Remaining source function allows you to select the device

used to measure the amount the fuel remaining in the tank.

NOTE:

If you plan to use a fluid level sensor for a fuel tank, you must

switch the fuel remaining source to Fuel Level. If you want to use

the EP-10 Fuel Flow, EP-50 Storage Device or the NMEA 2000

Suzuki Engine Interface to measure fuel remaining, select

Engine/FFlow from the Fuel Remaining Source menu.

28

Page 35

To change Fuel Remaining Source:

1. Press

press

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Select FUEL MNGR and press MENU.

2. Highlight FREM SRC and press MENU. That will open the FRem Src

menu, which has two options: Eng/FFlow and Fuel level.

3. Select the desired fuel remaining source and press

MENU, which will

take you back to the main display.

Reset Trip Fuel (Rst trip f)

A few sensors, like the Suzuki Engine Interface, EP-10 Fuel Flow and

EP-50 Storage Device keep a running total of fuel used for a trip. By

using the Reset Trip command, you can reset to zero the running total

of fuel used on a trip.

To Reset Trip Fuel (Rst trip f)

1. Press

press

2. Select

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Highlight FUEL MNGR and press MENU.

RST TRIP F (Reset Trip Fuel) and press MENU. The following

message will appear: Hit Menu to Rst Trip F.

3. Press

MENU, which will reset the trip fuel used to zero and take you

back to the main display.

Reset Seasonal Fuel (Rst Seas)

A few sensors, like the Suzuki Engine Interface, EP-10 Fuel Flow and

EP-50 Storage Device keep a running total of fuel used for a season. By

using the Reset Seasonal command, you can reset to zero the running

total of fuel used for a season.

To reset seasonal fuel:

1. Press

press

2. Choose

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU. Highlight FUEL MNGR and press MENU.

RST SEAS and press MENU. If you have more than one engine,

the Select Engine menu will appear with up to four options: All

Engines, Port, Cen (Center) and Stbd (Starboard).

3. Select the desired option and press

MENU. The following message will

appear: Hit Menu to Rst USD:S.

3. Press

MENU, which will take you back to the main display.

Customizing Pages

The customizing pages feature allows you to choose what data will be

displayed and how it will be displayed on select pages. Pages that can

be customized include: Single Digital, Dual Digital, Gauge, Fuel

Manager and Trim Tab pages can all be customized. The Engine Trim,

Engine Diagnostic, GPS Position and Synchronize pages cannot be

customized.

29

Page 36

NOTE:

Before a page can be customized it must be added to the page

display rotation. (See the Adding Pages segment on page 14.) Once

it is in the rotation, scroll it onto the main display to be able to

access its customize menu.

Single Digital

The Single Digital page features a digital dialog box that can be

customized to display the following data types: ALR:V (Alternate

Voltage), BAT:V (Battery Voltage), ENG:T (Engine Temperature),

WTR:P (Water Pressure), ENG:O:P (Engine Oil Pressure), FUL:P (Fuel

Pressure), BST:P (Boost Pressure), TRN:O:P (Transmission Oil

Pressure), ATM:P (Atmospheric Pressure), Temp (Temperature),

Depth, ENG:L (Engine Load), ENG: Hr (Total Engine Hours), FUL:F

(Fuel Flow), ECO (Fuel Economy), FUL: Rm (Fuel Remaining), USD

(Fuel Used), RNG (Fuel Range), USD:Tp (Use Trip Fuel, USD:S (Fuel

Used Seasonal), WTR:S (Water Speed), GND:S (Ground Speed) and

Tach (Tachometer).

To customize the Single Digital page:

1. Use the

UP and DOWN keys to scroll the Single Digital page on to the

main display.

2. Press

3. Highlight the data type you want to display and press

MENU, select CUSTOMIZE and press MENU.

MENU. You

will be taken back to the main display, where the information you

selected will be displayed on the main screen.

Dual Digital

The Dual Digital page has two digital dialog

boxes that can be customized to display the

following data types: ALR:V (Alternator

Voltage), BAT:V (Battery Voltage), ENG:T

(Engine Temperature), WTR:P (Water

Pressure), ENG:O:P (Engine Oil Pressure),

FUL:P (Fuel Pressure), BST:P (Boost Pressure),

TRN:O:P (Transmission Oil Pressure), ATM:P

(Atmospheric Pressure), Temp (Temperature),

Gauge Page

Depth, ENG:L (Engine Load), ENG: Hr (Total

Engine Hours), FUL:F (Fuel Flow), ECO (Fuel Economy), FUL: Rm

(Fuel Remaining), USD (Fuel Used) RNG (Fuel Range), USD:Tp (Used

Trip Fuel), USD:S (Used Seasonal Fuel), WTR:S (Water Speed), GND:S

(Ground Speed) and Tach (Tachometer).

30

Page 37

To customize the Dual Digital page:

1. Use the

UP and DOWN keys to scroll the Dual Digital page on to the

main display.

2. Press

MENU, select CUSTOMIZE and press MENU.

3. The position menu will appear with two options: Top Data or Bottom

Data. Select

4. Highlight the data type you want to display and press

TOP DATA and press MENU, which will open the Data menu.

MENU. This

will take you back to the main display, where the data type you

selected will be displayed in the digital box at the top of the page.

5. Repeat steps 1 and 2, then select

and press

MENU.

6. Highlight the data type you want to display and press

BOT DATA from the position menu

MENU. This

will take you back to the main display, where the data type you

selected will be displayed in the digital box at the bottom of the page.

NOTE:

If a page is customized to show information from a device that is

not connected to the NMEA 2000 network, the data boxes on the

gauge will flash. This indicates the device is not sending data to the

network. This could occur for a variety of reasons, depending on the

device type. If it is a GPS sensor, the GPS unit probably has not

locked on to a satellite yet. If you try to display data from an

unconfigured EP, the gauge will flash.

Gauge

The Gauge page is an analog gauge that can be customized to display

the following data types: WTR:S (Water Speed), GND:S (Ground

Speed), Tach (Tachometer), ALR:V (Alternate Voltage), BAT:V (Battery

Voltage), ENG:T (Engine Temperature), WTR:P (Water Pressure),

ENG:O:P (Engine Oil Pressure), FUL:P (Fuel Pressure) BST:P (Boost

Pressure), TRN:O:P (Transmission Oil Pressure), ATM:P (Atmospheric

Pressure), Temp (Temperature) and Fluid Lev (Fluid Level).

To Customize the Gauge Page:

1. Use the

UP and DOWN keys to scroll the gauge page on to the main

display.

2. Press

MENU, select CUSTOMIZE and press MENU, which will open the

Data menu.

3. Highlight the data type you want to display and press

MENU. This

will take you back to the main display, where the data you selected will

be displayed on an analog gauge.

31

Page 38

Fuel Manager

The Fuel Manager page can be customized to display the following data

types: GND:S (Ground Speed), Ful:F (Fuel Flow), ECO (Fuel Economy),

Ful:Rm (Fuel Remaining), USD (Fuel Used), RNG (Fuel Range),

USD:Tp (Trip Fuel Used), USD:S (Fuel Used Seasonal) and WTR:S

(Water Speed).

To Customize the Fuel Manager Page:

1. Use the UP and DOWN keys to scroll through the pages until the Fuel

Manager page is displayed.

2. Press

MENU, select CUSTOMIZE and press MENU, which will open the

Data menu.

3. Highlight the desired data type and press

MENU. You will be directed

back to the main display, where the data type you selected will be on

the display.

Trim Tabs

The Trim Tab page can be customized to display

Trim Tab position in percentages or degrees.

To Customize Trim Tabs:

1. Use the

UP and DOWN keys to scroll through

the pages until the Trim Tabs page is displayed.

2. Press

3. The Trim Tab Detail menu will open with two

options: Percentage (Pct) or Degrees (Deg).

4. Select the desired unit of measure and press

MENU, select CUSTOMIZE and press MENU.

Trim Tabs page

MENU. The Trim Tab

page will show trim tab position in the unit of measure you chose.

32

Page 39

Section 4: EP Configuration &

Calibration

To configure items connected to the LowranceNET network, press

MENU and select SYSTEM SETUP. Highlight B. DEVICES and press MENU,

which will open the Bus Devices list, a list of devices on the network.

Bus Devices works as the device manager for the bus, allowing you to

configure and unconfigure devices and set and reset critical values such

as alarms and calibration.

If you configure or reconfigure a sensor, you are assigning or

reassigning its configuration name in the LMF-200 to a different sensor

location on the boat.

NOTE:

The Suzuki Engine Interface, EP-10 Fuel Flow, EP-15 Fluid Level,

EP-35 Temperature Sensor and EP-50 Storage Device are the only

devices that can be configured through the Bus Devices list.

The following items can be configured, unconfigured or reconfigured:

Temperature (UnCfg Tmp), Fuel Flow (UnCfg FF) and Fluid Level

(UnCfg FL) sensors. When they are shown on the bus devices list as

UnCfg Tmp, UnCfg FF and the UnCfg FL, they are unconfigured.

You can have multiple Temperature sensors and Fluid Level Tanks,

but will have no more than three Fuel Flows to configure since the

LMF-200 supports a maximum of three engines on a vessel.

NOTE:

If you configure the desired sensors and are not satisfied with the

results, you may clear the configuration settings for each sensor

individually, by resetting values from the sensor's configuration

menu. Remember, ONLY the sensor you select from the Bus

Devices list will be set back to its defaults.

EP-35 Temperature Configuration

The EP-35 Temperature sensor has three configuration options: Inside,

Outisde and Water. An unconfigured temperature sensor will appear

on the Bus Devices list as UnCfg Temp.

To configure EP-35 Temp Sensor:

1. Press

press

2. Highlight

Devices list, a list of devices on the network, will appear.

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

B. DEVICES and press MENU. After a few moments the Bus

33

Page 40

3. Highlight

UNCFG TEMP and press MENU. The following message will

appear: Hit Menu to Cfg Temp Sns.

4. Press

MENU to be taken to the Selecting Temp menu, which will have

three options: Inside, Outside and Water.

5. Highlight one of the Temp options and press

MENU. The temp sensor

has now has been configured. You will automatically be directed to the

Bus Devices list.

To unconfigure EP-35 temp sensor:

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

B. DEVICES and press MENU, which will open the Bus Devices

list.

3. Select a temp sensor from the Bus Devices list and press

MENU. The

Configuration Options menu will appear with two choices: Unconfig

(Unconfigure) and Reconfig (Reconfigure).

4. Select

UNCONFIG and press MENU. The following message will appear:

Hit Menu to Unset Device Name.

5. Press

MENU to unconfigure the sensor and be directed back to the

Bus Devices list, where the temp you unconfigured will be listed as

Uncfg Temp.

To reconfigure an EP-35 temp sensor:

To reconfigure a sensor, there must be a configuration name available

(Water, Outside or Inside. In the following example, there are three

configured temps, one each for inside, outside and water temp. If you

try to reconfigure a sensor when the desired configuration name

(Water, Outside and Inside) is in use, a Name Already Selected message

will appear.

If all three temps are configured, which means there is no name

configuration available, follow the first set of instructions. If the desired

configuration name is available, follow the second set of instructions.

The steps below will show you how to switch the configuration of a

water temp to an outside temp.

If all temps configured (Configuration name unavailable):

1. Press

press

2. Highlight

MENU, use the UP and DOWN keys to select SYSTEM SETUP and

MENU.

B. DEVICES and press MENU, which will open the Bus Devices

list.

3. Highlight

WTR TEMP on the Bus Devices list and press MENU, which

will launch the Configuration Options menu.

34

Page 41

4. Select

UNCONFIG and press MENU. The following message will appear:

Hit Menu to Unset Device Name.

5. Press

MENU to unconfigure the sensor and be directed back to the

Bus Devices list, where the temp you unconfigured (Water Temp) will

be listed as Uncfg Temp.

6. Highlight

OUT T (Outside Temp) and press MENU. The configuration

options menu will appear.

7. Select

Highlight

RECONFIG and press MENU to open the Selecting Temp menu.

WATER and press MENU. You will be taken back to the Bus