Lowrance X85, X75 User Manual

X-75X-75

X-75

X-75X-75

andand

and

andand

X-85X-85

X-85

X-85X-85

INSTALLATION AND OPERATION

INSTRUCTIONS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

INTRODUCTION.............................................................................................................................1

INSTALLATION - BRACKET ..........................................................................................................1

POWER CONNECTIONS ...............................................................................................................2

SPEED/TEMPERATURE SENSORS ............................................................................................. 3

CONNECTORS ...............................................................................................................................6

TRANSDUCER INSTALLATION.....................................................................................................7

20° TRANSDUCER INSTALLATION .......................................................................................... 8

8° TRANSDUCER INSTALLATION ...............................................................................................14

KEYBOARD BASICS..................................................................................................................... 20

OPERATION .................................................................................................................................. 21

POWER/LIGHTS............................................................................................................................21

MENUS .......................................................................................................................................... 21

DUAL FREQUENCY OPERATION ................................................................................................21

MODES ..........................................................................................................................................23

WINDOWS .....................................................................................................................................24

REPROGRAM WINDOW GROUPS ..............................................................................................25

AUTOMATIC ..................................................................................................................................26

SENSITIVITY .................................................................................................................................27

RANGE ..........................................................................................................................................28

UPPER AND LOWER LIMITS .......................................................................................................29

ZOOM ............................................................................................................................................30

GRAYLINE® ..................................................................................................................................31

CHART SPEED ............................................................................................................................. 32

FISH ID ..........................................................................................................................................33

FISHTRACK™ ...............................................................................................................................33

CHART SETUP..............................................................................................................................34

CHART CURSOR......................................................................................................................34

DISPLAY ZOOM BAR ...............................................................................................................35

DISPLAY ZONE BAR ................................................................................................................35

DIGITAL SONAR .......................................................................................................................35

ALARMS ........................................................................................................................................36

DEPTH ALARMS.......................................................................................................................36

ZONE ALARM ...........................................................................................................................38

FISH ALARM .............................................................................................................................38

ADJUST CHART SURFACE CLARITY .........................................................................................38

ADVANCED SIGNAL PROCESSING (ASP) .................................................................................39

SYSTEM SETUP ...........................................................................................................................40

AUDIO/DISPLAY .......................................................................................................................40

SYSTEM INFORMATION .......................................................................................................... 40

UNITS OF MEASURE ...............................................................................................................40

TEMPERATURE GRAPH .......................................................................................................... 41

RESET DISTANCE LOG ........................................................................................................... 41

PRESET OPTIONS ...................................................................................................................41

KEEL OFFSET ..........................................................................................................................41

CALIBRATE SPEED .................................................................................................................42

SIMULATOR ..............................................................................................................................42

WINDOWS SUMMARY..................................................................................................................43

TROUBLESHOOTING ................................................................................................................... 44

WARRANTY ..................................................................................................................................47

Copyright © 1998, Lowrance Electronics, Inc.

All rights reserved.

All features and specifications subject to change without notice. Lowrance Electronics

may find it necessary to change or end our shipping policies, regulations, and special

offers at any time. We reserve the right to do so without notice. All screens in this manual

are simulated.

INTRODUCTION

The X-75 and X-85 are the latest members of the Lowrance family that

combines a high performance sonar with a wide, high definition screen.

Using menu features and “soft-key” operation, these units are also easy to

use. The wide screen shows the underwater world with high resolution and

detail. The display and keyboard are also lighted for night operation. They

have digital boat speed, surface water temperature, and distance travelled

(log) screens. (Requires optional ST-TBK speed/temperature sensor for

both speed and temperature screens.)

The optional SAM-50HPD gives these units 50 kHz capability.The 3000

watt transmitter in the SAM-50HPD plus the low frequency gives the units

far more depth penetration. This, along with the wider cone angle transducers, makes 50 kHz operation ideal for ocean and Great Lakes use.

SPECIFICATIONS

Dimensions................................................ 4.94"H x 6.10"W x 2.71"D

Transmitter Frequency .............................. 192 kHz

X-75 Transmitter Power............................. 600 watts (p-p, typical)

75 watts (RMS, typical)

X-85 Transmitter Power............................. 3000 watts (p-p, typical)

375 watts (RMS, typical)

Display ...................................................... Supertwist LCD

240 vertical x 240 horizontal

57,600 total pixels

INSTALLATION

MOUNTING

Install the unit in any convenient location, provided there is clearance

behind the unit when it is tilted for the best viewing angle. Holes in the

bracket base allow wood screw or through-bolt mounting. You may need

to place a piece of plywood on the back of thin fiberglass panels to secure

the mounting hardware. Make certain there is enough room behind the unit

to attach the power and transducer cables.

The gimbal bracket will also accept the GBSA-1 swivel bracket adapter

that lets you rotate the unit a full 360°.

The smallest hole that allows one power or transducer connector to pass

through is 3/4". After the hole is drilled, push the transducer connector up

through the hole first, then drop the power cable down through it.

After the cables have been routed, fill the hole with a good marine sealing

compound. Offset the bracket to cover the hole. Route the power cable

through the slot. Break out one of the holes in the back of the bracket for

the transducer cable.

FRONT

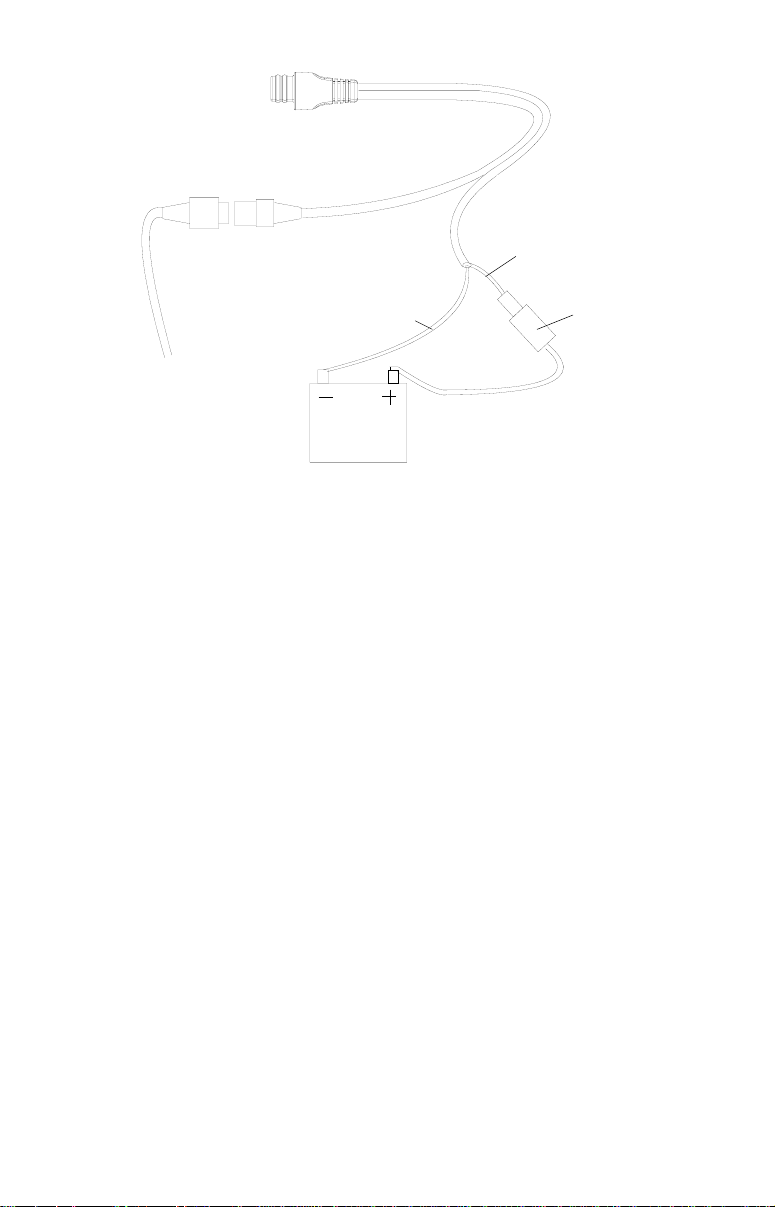

POWER CONNECTIONS

The unit works from a twelve-volt battery system. For the best results,

attach the power cable directly to the battery. You can attach the power

cable to an accessory or power buss, however you may have problems

with electrical interference. Therefore, it’s safer to go ahead and attach the

power cable directly to the battery. If the cable is not long enough, splice

#18 gauge wire onto it. The power cable has two wires, red and black. Red

is the positive lead, black is negative or ground. Make certain to attach the

in-line fuse holder to the red lead

as close to the power source as possible.

For example, if you have to extend the power cable to the battery or power

buss, attach one end of the fuse holder directly to the battery or power buss.

This will protect both the unit and the power cable in the event of a short.

It uses a 3-amp fuse.

IMPORTANT!

Do not use this product without a 3-amp fuse wired into the power cable!

Failure to use a 3-amp fuse will void your warranty.

If you’re installing a speed/temperature sensor, read it's mounting instructions. Route the sensor’s cable to the power cable and plug it into the

connector marked “SPEED/TEMP CABLE”

To Sonar

Unit

POWER CONNECTIONS

RED

WIRE

TO SPEED/TEMP

OR TEMP SENSORS

(Not included)

BLACK

WIRE

12 VOLT

BATTERY

3 amp

FUSE

SPEED/TEMPERATURE SENSORS

This unit accepts up to three temperature sensors which can monitor

surface water, live well, air, and virtually any other temperature. You do

need to be careful when purchasing the temperature sensors, however.

Each temperature sensor has its own "address". The sensors are labeled

"Water", "T-2" (or Temp-2), and "T-3" (or Temp-3). If you want two (or

more) temperature readings, you'll need to use the proper sensors. For

example, you can't use two T-3 sensors. The sensors that will fit these units

are:

TS-1BK One sensor for "Water" temperature display.

TS-2BK One sensor for "T-2" temperature display.

TS-3BK One sensor for "T-3" temperature display.

TS-12BK Two sensors for "Water" and "T-2" temperature displays.

ST-TBK One speed sensor and one temperature sensor for

"Speed" and "Water" displays.

You can combine these sensors in many combinations. See the list on the

following page for temperature and speed sensor combinations.

Sensor Chart

(Note: Do not use these sensors in any other combination.)

ST-TBK = 1 speed sensor and 1 temperature display

ST-TBK + TS-2BK = 2 temp sensors and one speed sensor

ST-TBK + TS-2BK + TS-3BK = 3 temp sensors and one speed sensor

TS-1BK = 1 temperature sensor

TS-12BK = 2 temperature sensors

or

TS-1BK + TS-2BK = 2 temperature sensors

TS-12BK + TS-3BK = 3 temperature sensors

or

TS-1BK + TS-2BK +TS-3BK = 3 temperature sensors

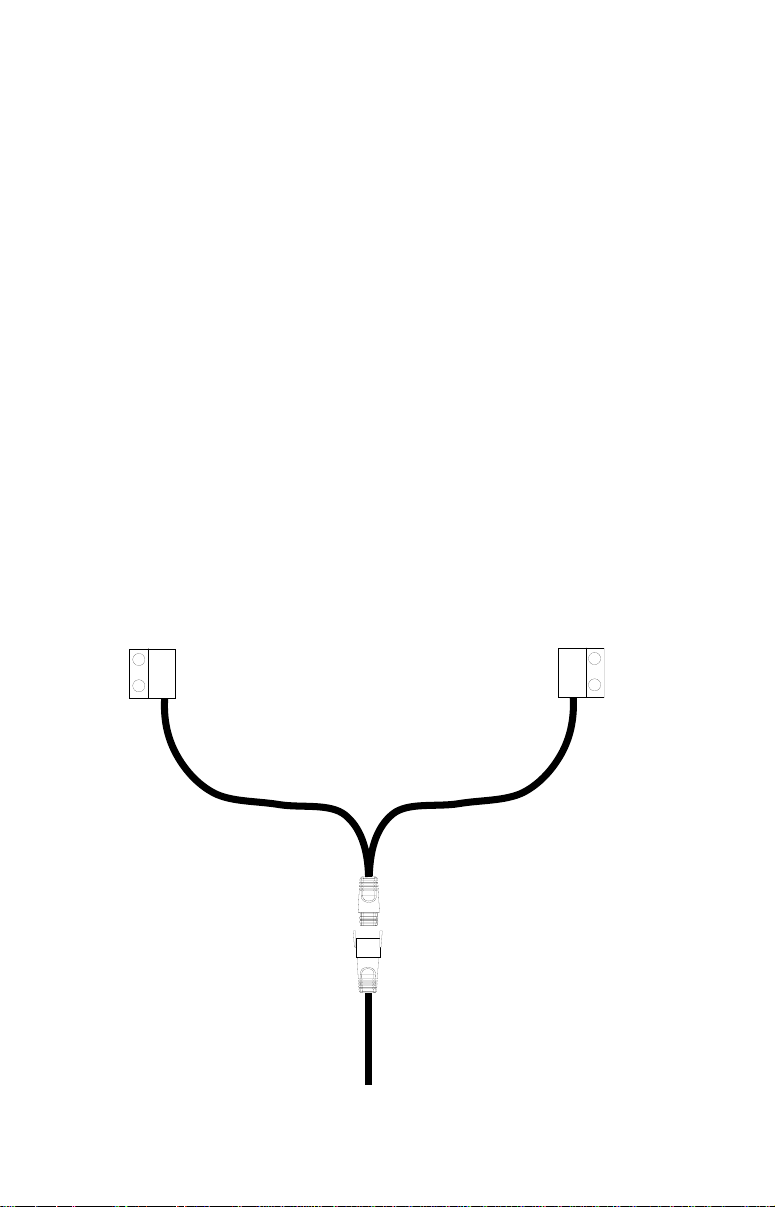

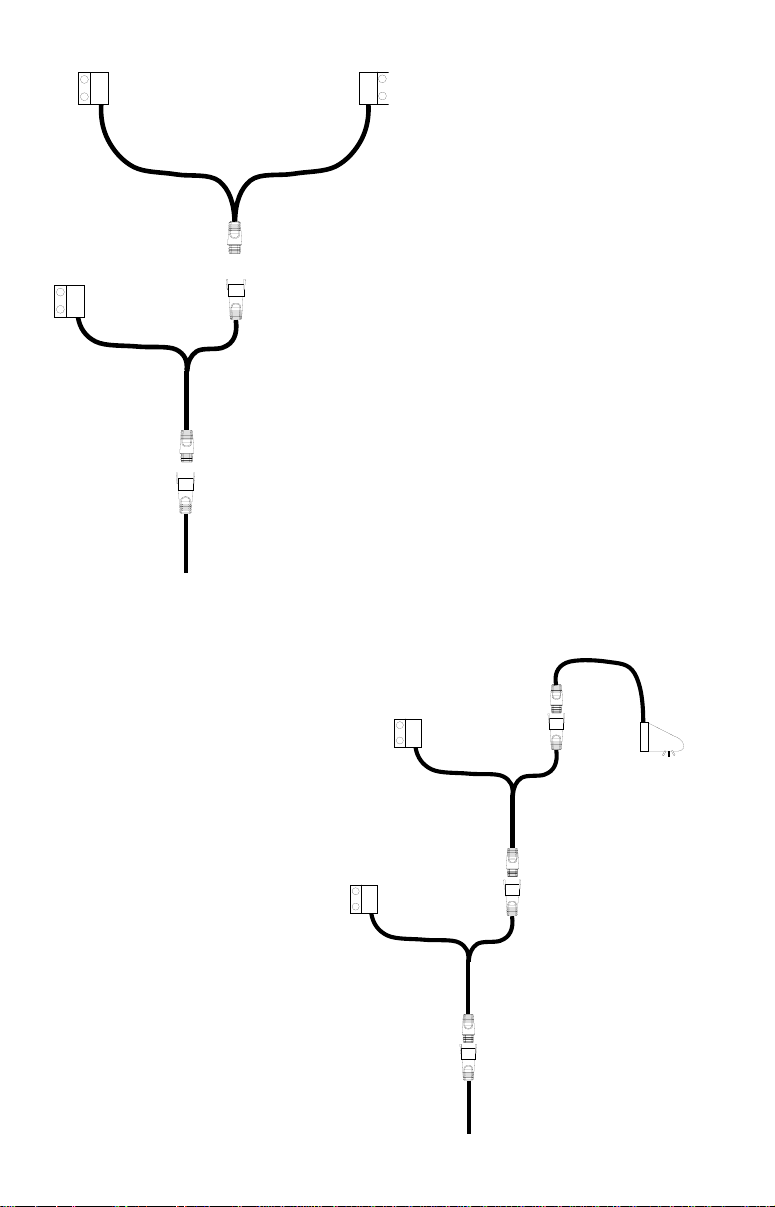

Here's some sample wiring diagrams:

Two Temperature Sensors

(Water and T-2)

TS-12 BK

POWER CABLE

TS-3 BK

TS-12 BK

Three Temperature Sensors

(Water, T-2, and T-3)

POWER CABLE

ST-TBK

Three Temperature Sensors

plus Speed

(Water, T-2, T-3, and Speed)

TS-2 BK

TS-3 BK

POWER CABLE

LOWRANCE

192 kHz TRANSDUCER

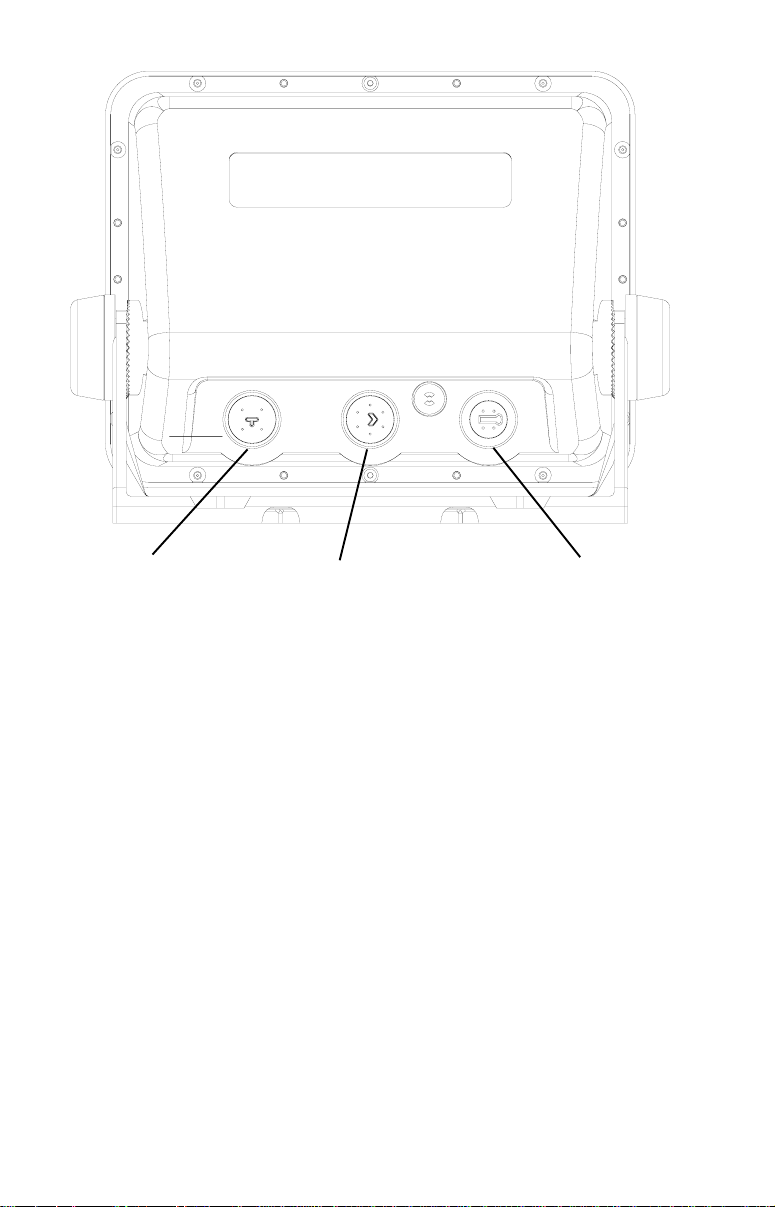

CONNECTORS

The diagram above shows the three connectors on the back of the sonar

unit. Looking at the back of the unit, the 192 kHz transducer connector is

at the far left. Plug the 192 kHz transducer in here. The center connector

is for the power cable. The connector at the far right is for a serial cable that

is included with the SAM-50HPD. This is the cable that allows the SAM to

communicate with the sonar unit. See the SAM-50HPD's installation

manual for more information.

POWER TO SAM-50HPD

(NOT INCLUDED)

Transducer Installation

Some of the models covered by this manual have a transom-mount

transducer included. There two different transducers that could be

packed with your unit. One is a 20° cone angle "Skimmer" transducer

that can be mounted on the transom or epoxied inside certain boats to

"shoot-thru" the hull. The other transducer is an 8° cone angle "Skimmer" transducer that is transom-mounted only.

The 8° transducer has a “kick-up” mounting bracket helps prevent damage if the transducer strikes an object while the boat is moving. If the

transducer does “kick-up”, the bracket can easily be pushed back in

place without tools.

Read this manual carefully before attempting the installation. Determine

which of the mounting positions is right for your boat. Use extreme care

if mounting the transducer inside the hull, since once it is epoxied into

position, the transducer usually cannot be removed. Remember, the

transducer location is the most critical part of a sonar installation.

Location - General - All Transducers

1. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is to be mounted inside the hull,

then the chosen location must be in the water at all times. If the

transducer is not placed in a smooth flow of water, interference will

show on the sonar’s display in the form of random lines or dots

whenever the boat is moving.

2. The transducer should be installed with it’s face pointing straight

down, if possible.

3. If the transducer is mounted on the transom, make certain it doesn’t

interfere with the trailer or hauling of the boat. Also, don’t mount it

closer than approximately one foot from the engine’s lower unit. This

will prevent cavitation interference with the propeller. Typically, the

transducer should be mounted as deep in the water as possible. This

increases the chance that it will be in the water in high speed and

reduces the possiblity of air bubble interference.

4. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps, and areators

can be displayed on the sonar’s screen. Use caution when routing

the transducer cable around these wires.

Shoot-thru-hull v.s. Transom Mounting

(20° Transducer Only)

Typically, shoot-thru-hull installations give excellent high speed operation and good to excellent depth capability. There is no possibility of

damage from floating objects. It can't be knocked off when docking or

loading on the trailer.

However, the shoot-thru-hull installation does have its drawbacks. One,

some loss of sensitivity does occur, even on the best hulls. This varies

from hull to hull, even from different installations on the same hull. This

is caused by differences in hull layup and construction. Two, the angle

of the transducer cannot be adjusted for the best fish arches. This can

be a problem on some hulls that sit with the bow high when at rest or at

slow trolling speeds. Follow the procedure listed in the shoot-thru-hull

installation section in this manual to determine if you can satisfactorily

shoot through the hull.

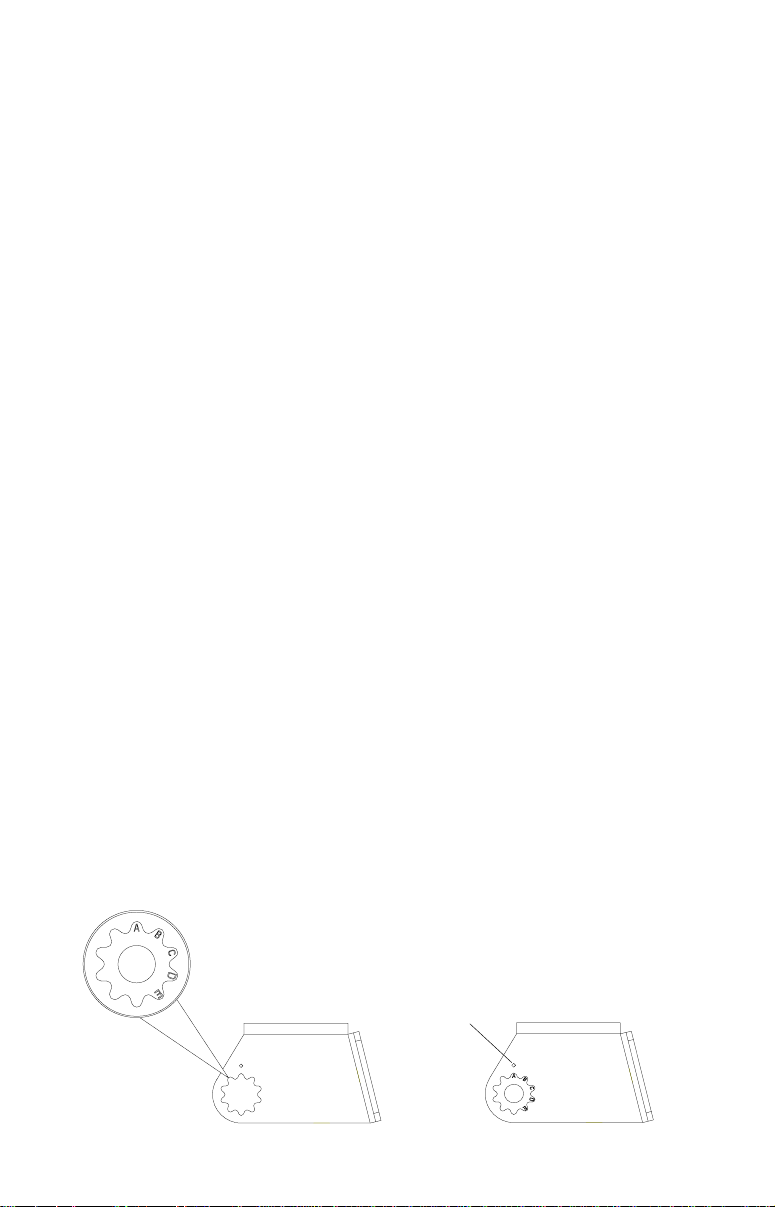

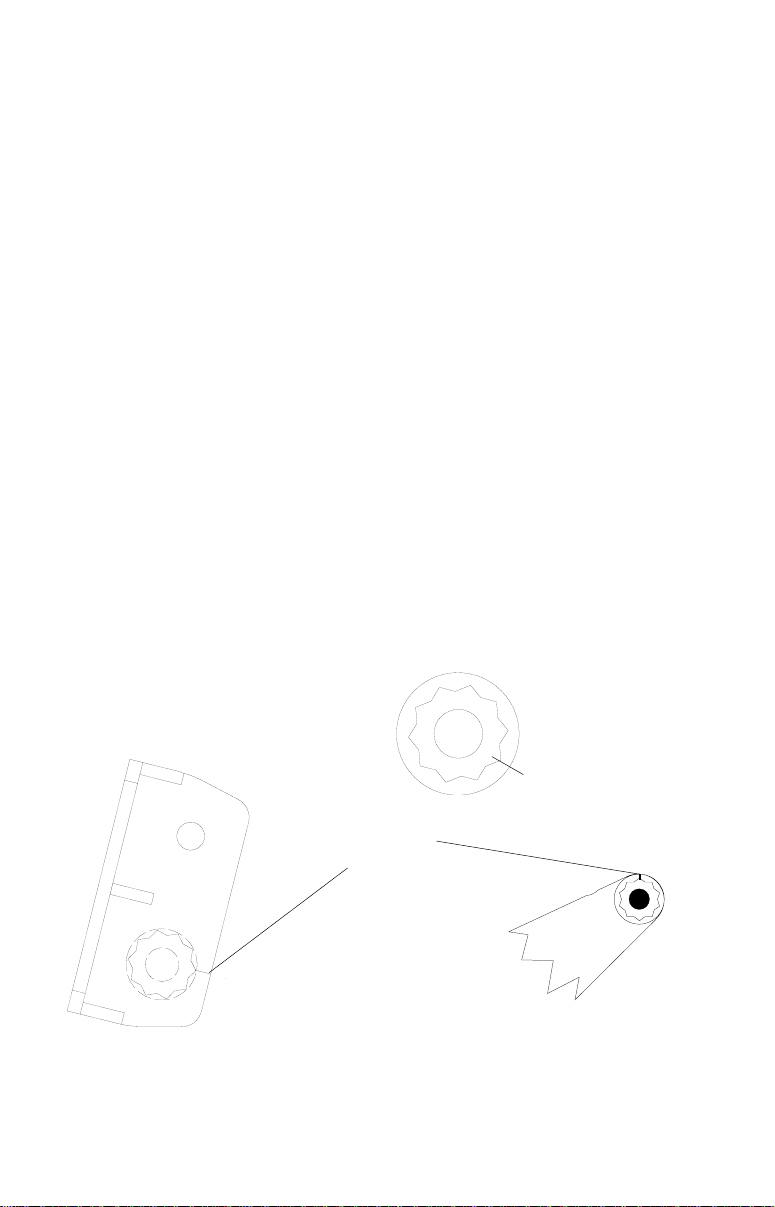

Transducer Assembly and Mounting - 20° Transducer Only

The best way to install this transducer is to loosely assemble all of the

parts first, place the transducer’s bracket against the transom and see if

you can mov e the transducer so that it’s parallel with the ground.

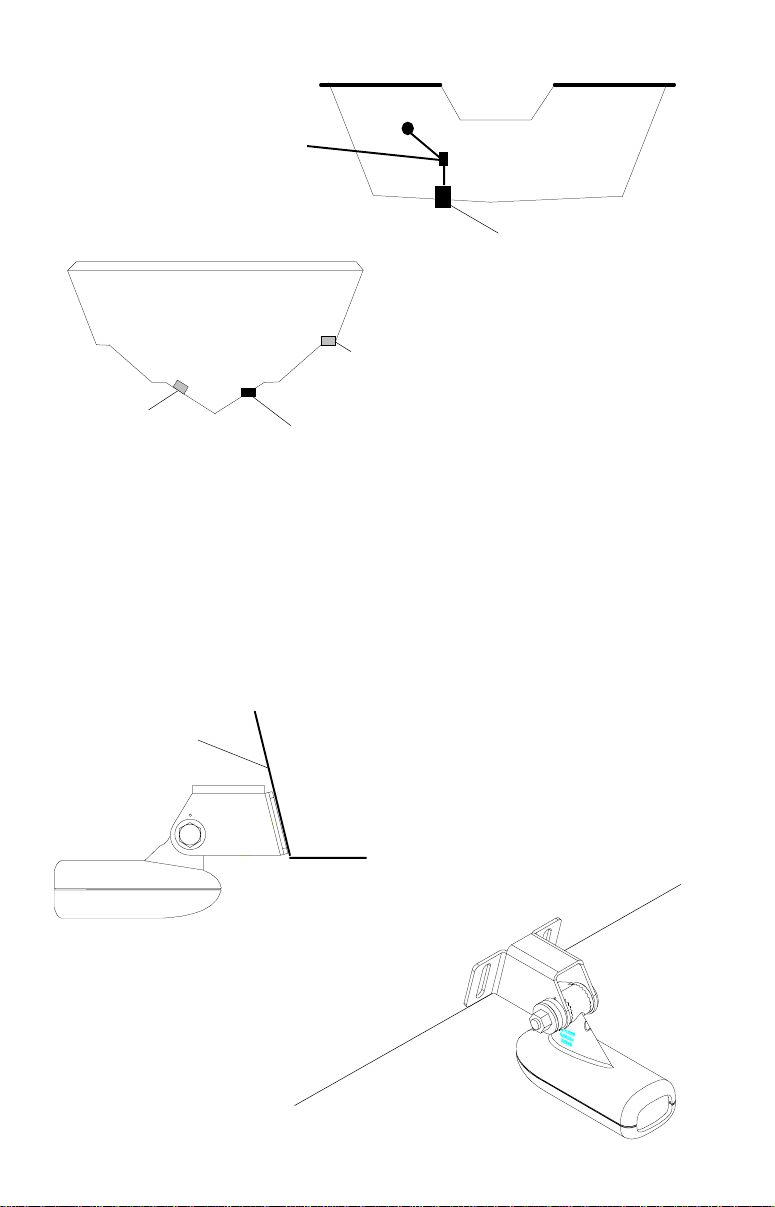

1. Press the two small plastic ratchets into the sides of the metal brac ket

as shown below. Notice there are letters molded into each ratchet.

Place each ratchet into the brack et with the letter “A” aligned with the

dot stamped into the metal brack et. This position sets the tr ansducer’s

coarse angle adjustment for a fourteen (14) degree transom. Most

outboard and stern-drive transoms have a f ourteen degree angle.

DOT

2. Slide the transducer between the two ratchets. Temporally slide the

bolt though the transducer assembly and hold it against the transom.

Looking at the transducer from the side, chec k to see if it will adjust so

that its face is parallel to the ground. If it does, then the “A” position is

correct for y our hull. If the tr ansducer’s f ace isn’t parallel with the ground,

remove the transducer and r atchets from the bracket. Place the ratchets into the holes in the brack et with the letter “B” aligned with the dot

stamped in the brack et. Reassemble the transducer and bracket and

place them against the transom. Again, chec k to see if y ou can mo v e

the transducer so it’s parallel with the ground. If you can, then go to

step 3. If it doesn’t, repeat step 2, but use a different letter until y ou can

place the transducer on the transom correctly.

RATCHETS

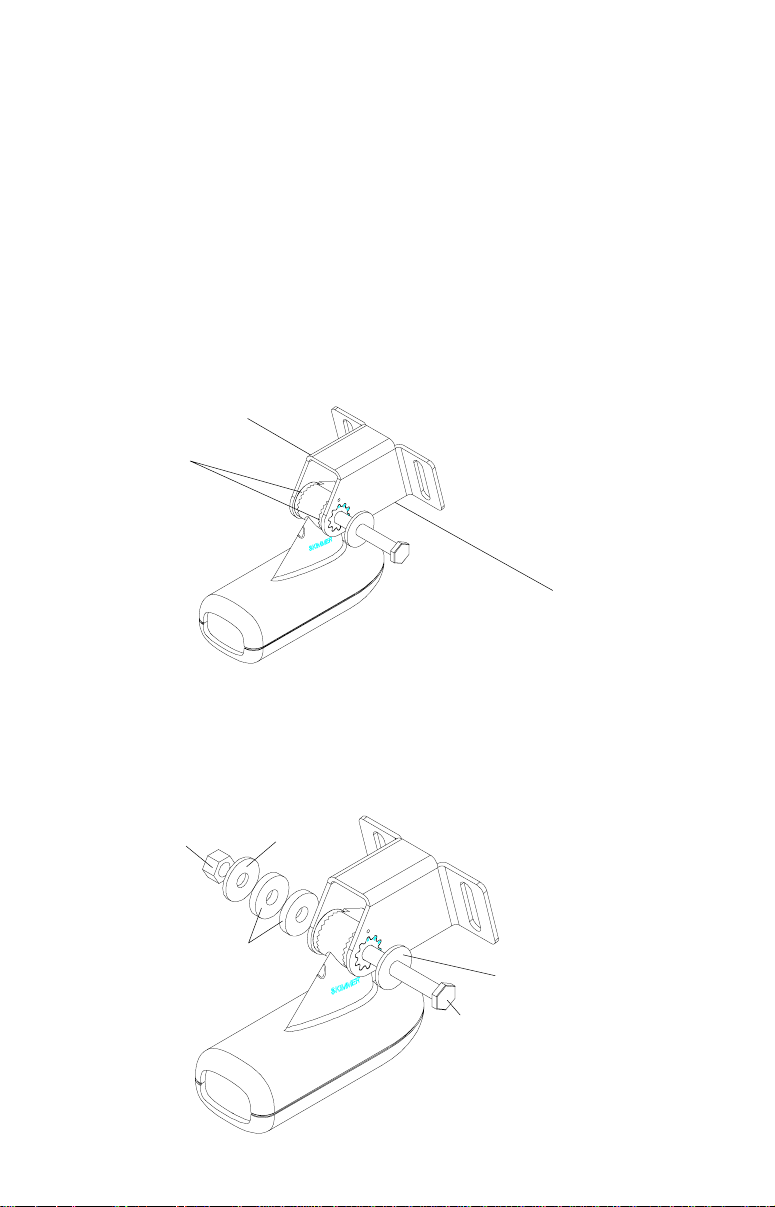

3. Once you determine the correct position for the ratchets, assemble

the transducer as shown at left. Don't tighten the lock nut at this time .

METAL

NUT

WASHER

RUBBER

WASHERS

METAL

WASHER

BOLT

CAUTION!CAUTION!

CAUTION!

CLAMP THE TRANSDUCER CABLE TOCLAMP THE TRANSDUCER CABLE TO

CLAMP THE TRANSDUCER CABLE TO

CLAMP THE TRANSDUCER CABLE TOCLAMP THE TRANSDUCER CABLE TO

TRANSOM NEAR THE TRANSDUCER. THISTRANSOM NEAR THE TRANSDUCER. THIS

TRANSOM NEAR THE TRANSDUCER. THIS

TRANSOM NEAR THE TRANSDUCER. THISTRANSOM NEAR THE TRANSDUCER. THIS

WILL HELP PREVENT THE TRANSDUCERWILL HELP PREVENT THE TRANSDUCER

WILL HELP PREVENT THE TRANSDUCER

WILL HELP PREVENT THE TRANSDUCERWILL HELP PREVENT THE TRANSDUCER

FROM ENTERING THE BOAT IF IT ISFROM ENTERING THE BOAT IF IT IS

FROM ENTERING THE BOAT IF IT IS

FROM ENTERING THE BOAT IF IT ISFROM ENTERING THE BOAT IF IT IS

KNOCKED OFF AT HIGH SPEED.KNOCKED OFF AT HIGH SPEED.

KNOCKED OFF AT HIGH SPEED.

KNOCKED OFF AT HIGH SPEED.KNOCKED OFF AT HIGH SPEED.

POOR ANGLEPOOR ANGLE

POOR ANGLE

POOR ANGLEPOOR ANGLE

CAUTION!CAUTION!

POOR LOCATIONPOOR LOCATION

POOR LOCATION

POOR LOCATIONPOOR LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATION

GOOD LOCATIONGOOD LOCATION

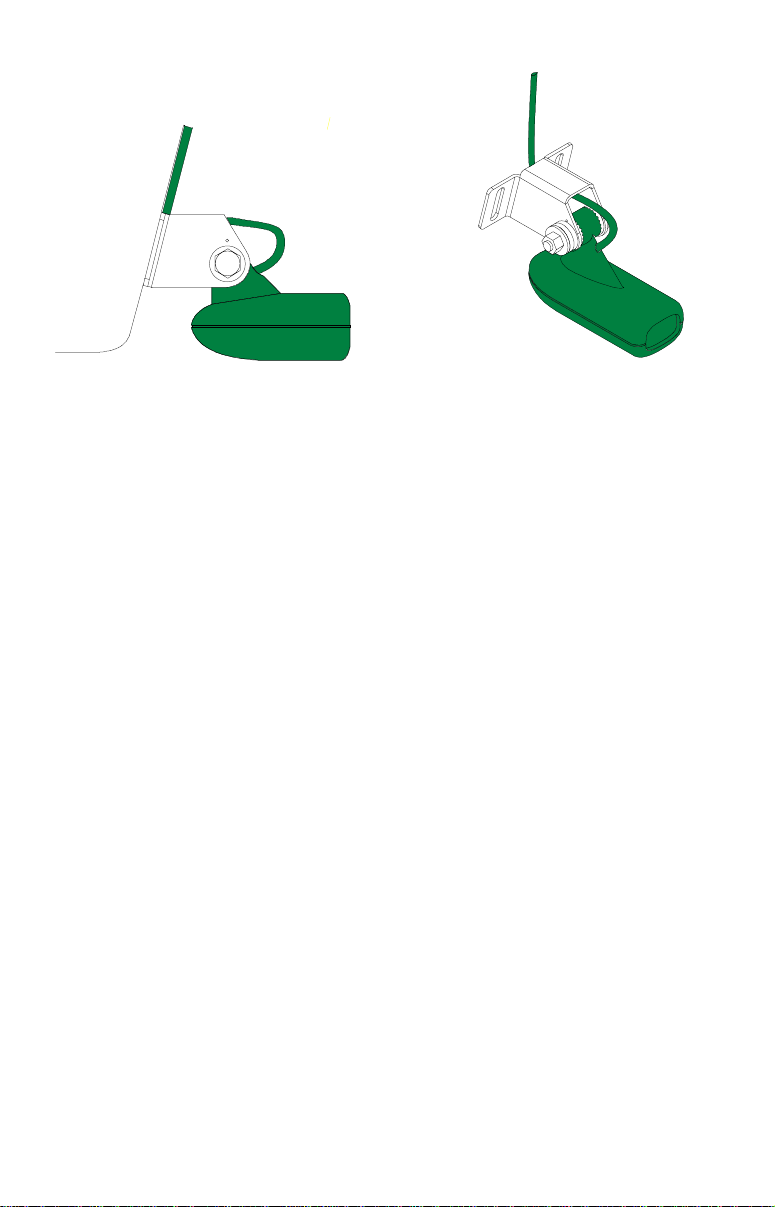

4. Hold the transducer and bracket assembly against the transom. The

transducer should be roughly parallel to the ground. The bottom of the

transducer brack et should be in line with the bottom of the hull.

let the bracket extend below the hull!

Mark the center of the slots for

Don't

the mounting holes. Drill two 5/32" holes in the marked locations for

the #10 screws supplied with the transducer.

TRANSOM

SIDE VIEW

5. Remove the transducer from the bracket and re-assemble it with the

cable passing through the bracket over the bolt as shown above. Attach the transducer to the transom. Slide the transducer up or down

until it’ s aligned properly on the transom as shown abov e. Tighten the

brack et’s mounting scre ws. Adjust the transducer so that it’ s parallel to

the ground and tighten the lock nut until it touches the flat w asher, then

add 1/4 turn.

won’t “kick-up” if it strikes an object in the w ater.

6. Route the transducer cable to the sonar unit. Make certain to leave

some slack inthe cable at the tr ansducer as shown abo ve . If possib le ,

route the transducer cable a way from other wiring on the boat. Electrical noise from the engine’s wiring, bilge pumps, VHF radio wires and

cables, and aerators can be pic ked up by the sonar . Use caution when

routing the transducer cable around these wires.

Clamp the transducer cable to the transom close to the transducer. This

can prevent the transducer from entering the boat if it is knocked off at

high speed.

7. Make a test run to determine the results. If the bottom is lost at high

speed, or if noise appears on the display, tr y sliding the transducer

bracket down. This puts the transducer deeper into the water, hopefully below the turbulence causing the noise. Don't allow the transducer brack et to go below the bottom of the hull!

Don’t over tighten the loc k nut!

IMPORTANT!

If you do , the tr ansducer

SHOOT-THRU-HULL

(20° Transducer Only)

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass

layers. The sonar signal must pass through solid fiberglass. A successful transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood, or foam) between layers of fiberglass if

the material is removed from the chosen area. For example, some

manufacturers use a layer of fiberglass, then a core of balsa wood,

finishing with an outer layer of fiberglass. Removing the inner layer of

fiberglass and the balsa wood core exposes the outer layer of fiberglass.

The transducer can then be epoxied directly to the outer layer of fiberglass. After the epoxy cures, the hull is watertight and structurally sound.

Remember, the sonar signal must pass through solid fiberglass. Any air

bubbles in the fiberglass or the epoxy will reduce or eliminate the sonar

signals.

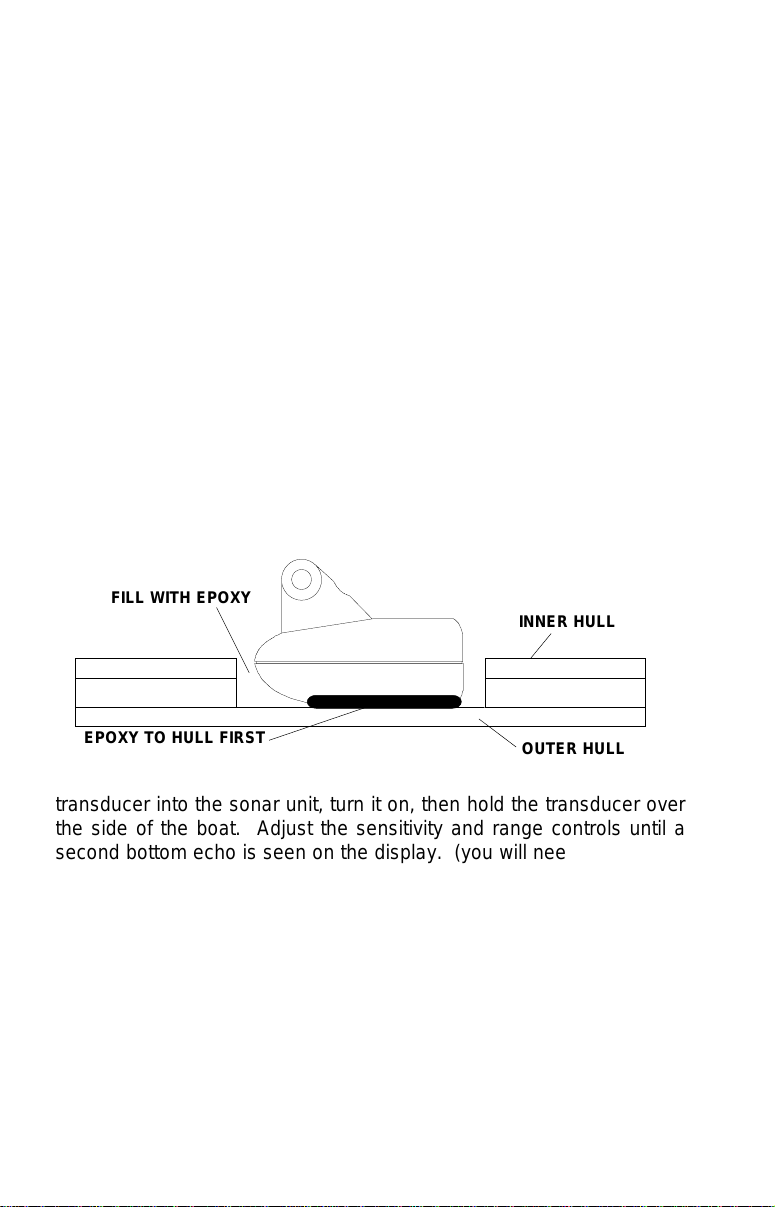

To choose the proper location for thru-hull mounting, anchor the boat in

60 feet of water. Add a little water to the sump of the boat. Plug the

FILL WITH EPOXY

INNER HULL

EPOXY TO HULL FIRST

OUTER HULL

transducer into the sonar unit, turn it on, then hold the transducer over

the side of the boat. Adjust the sensitivity and range controls until a

second bottom echo is seen on the display. (you will need to turn both

automatic and ASP off.) Don’t touch the controls once they’ve been set.

Next, take the transducer out of the water and place it in the water in the

sump of the boat. Observe the sonar signal to see if there is a noticeable decrease in sensitivity. The second bottom signal may disappear

and the bottom signal may decrease in intensity. Move the transducer

around to find the best location. If the sensitivity control has to be

increased greatly to compensate, then the transducer should be

mounted on the outside of the hull. If not, then mark the location that

shot through the hull the best and follow the instructions on the next

pages for a shoot-thru-hull mounting.

TRANSDUCER LOCATION

(HIGH SPEED)

TRANSDUCER LOCATION

(TROLLING SPEED)

Shoot-thru-hull Installation

(20° Transducer Only)

1. Make certain the area is clean, dry, and free of oil or grease, then

sand both the inside surface of the hull and the face of the transducer

with 100 grit sandpaper. The surface of the hull must be flat so the entire

transducer face is in contact with the hull prior to bonding.

SPREAD EPOXY HERE

SAND THIS SURFACE

2. Follow the instructions on the epoxy package and mix it thoroughly.

Do not mix it too fast, as it will cause bubbles to form in the epoxy.

Apply a small amount on the face of the transducer as shown above,

then spread a small amount onto the sanded area on the hull. Place the

transducer into the epoxy, twisting and turning it to force any air bubbles

out from under the transducer face. The face of the transducer should be

parallel with the hull, with a minimum amount of epoxy between the hull

and transducer. After the epoxy dries, route the cable to the sonar unit.

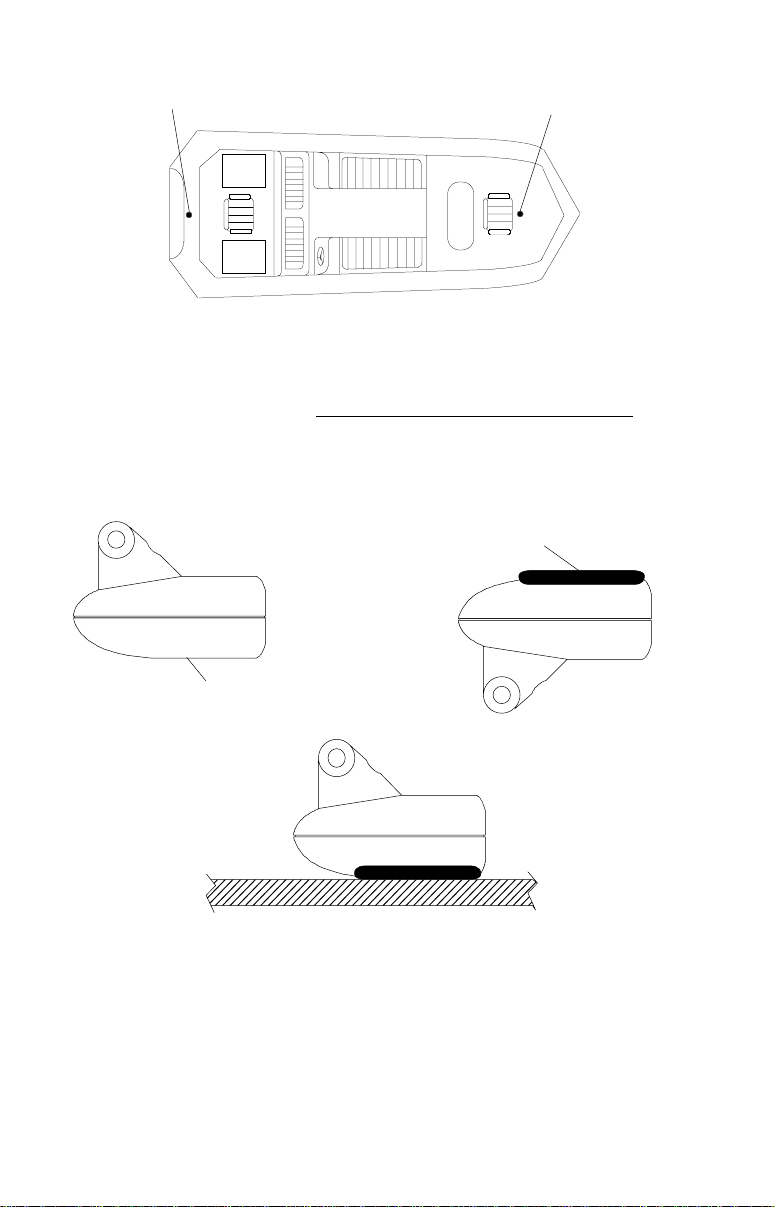

TRANSDUCER INSTALLATION - 8° Transducer Only

The 8° transducer is designed for transom mount only. It can be installed

on any outboard or stern-drive powered boat. Do not use this transducers on an inboard powered boat.

Please read these instructions carefully before installing your transducer. The transducer mounting location is the most critical part of a

sonar installation. If it isn’t done properly, the sonar can’t perform to its

potential.

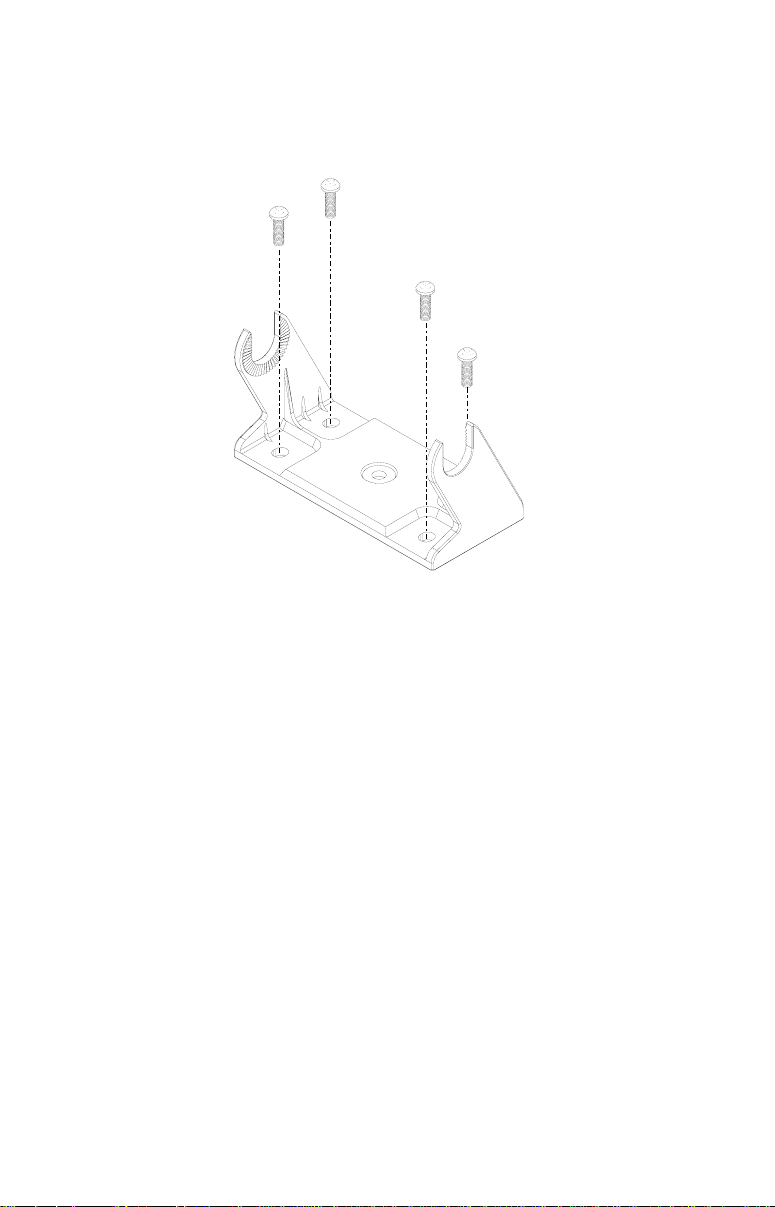

ASSEMBLY

1. Locate the four ratchets in the transducer's hardware package. Note

there are letters engraved into one side of each ratchet. These are for

the coarse angle adjustment. A standard transom angle is 14 degrees. By aligning a letter on the ratchet to the alignment mark on the

the transducer bracket, the correct transducer angle can be attained.

Once you've determined the correct angle, press one ratchet on each

side of the transducer and one ratchet on each transducer bracket as

shown below.

RATCHET

F

E

A

B

C

D

ALIGNMENT

LETTERS

ALIGNMENT

MARKS

F

A

E

D

B

C

TRANSDUCER

TRANSDUCER

BRACKET

Loading...

Loading...