Page 1

Page 1

Lotus Service Notes Introduction

CONTENTS

ELISE & EXIGE; 2004 M.Y. ONWARDS; WITH 1ZZ/2ZZ ENGINE

Section

Technical Data - Engine TDP

- Vehicle TDQ

Chassis AH

Bodycare & Repair BQ

Body Fittings BR

Front Suspension CI

Rear Suspension DH

Engine & Engine Management - Lotus supplement EH

- Toyota 1ZZ/2ZZ engine repair manual *

* see separate manual B120T0327J

- Toyota 2ZZ-GE engine supplement #

# see separate manual C120T0327J

Engine Management EMP

Transmission - Lotus supplement FJ

- Toyota C64 transmission repair manual ~

~ see separate manual D120T0327J

- Toyota C56 transmission repair manual ^

^ see separate manual TBA

Wheels & Tyres GH

Steering HG

Brakes JJ

Engine Cooling KH

Fuel System - Except North America LJ

- North America LK

Electrics MP

Maintenance & Lubrication OI

Air Conditioning, Heating & Ventilation PL

Clutch QH

Passive Restraint (North America) WD

Supplement - Exige Supercharged (S/C) Exige S/C

Supplement - 2-Eleven 2-Eleven

Page 2

Page 2

Lotus Service Notes Introduction

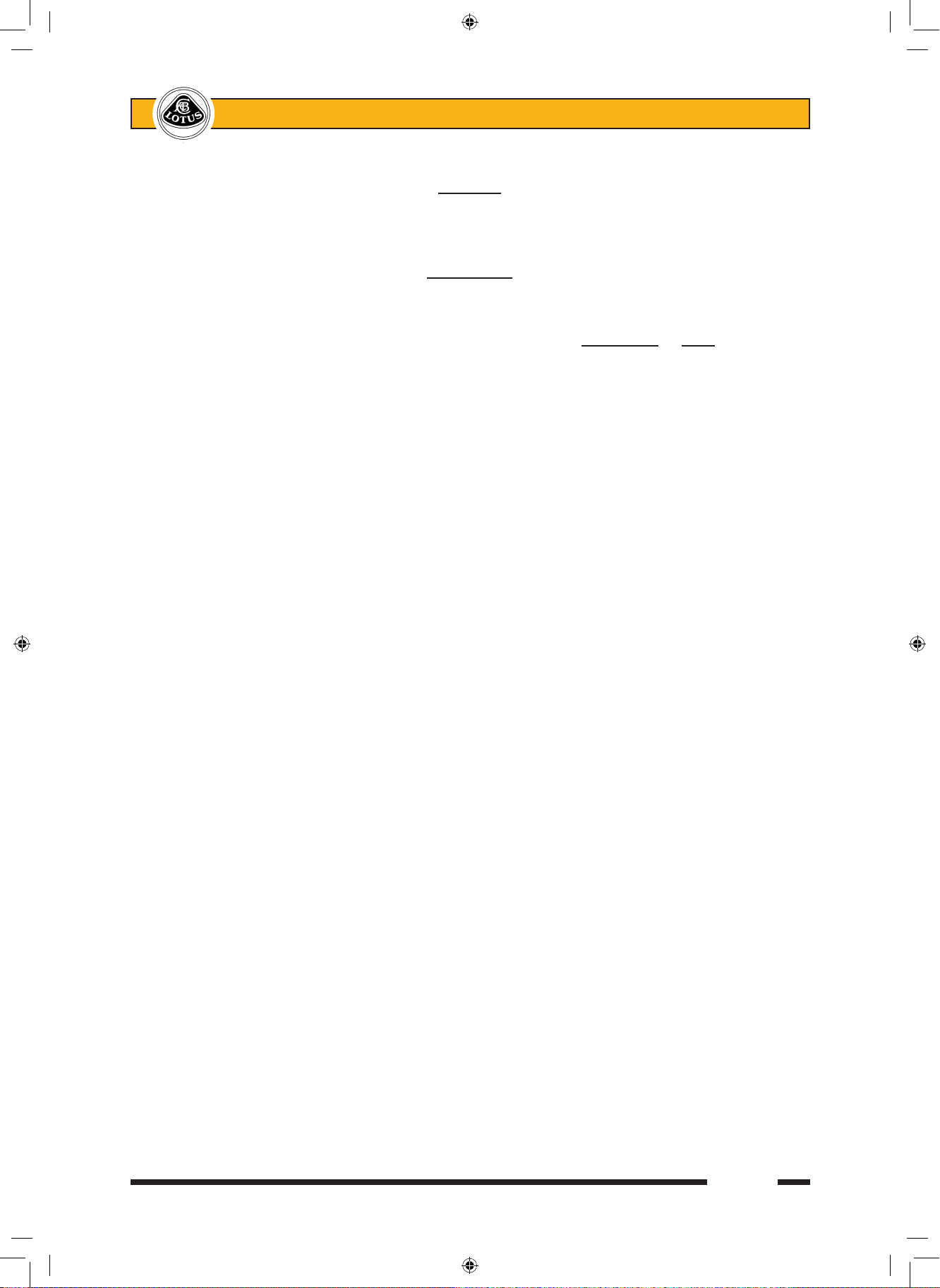

VEHICLE IDENTIFICATION NUMBER & ENGINE NUMBER

The Vehicle Identification Number (V.I.N.) is stamped on the chassis in the right hand front wheelarch

area, viewable with the front wheels turned to right full lock, and is also printed on a label stuck to the inside

of the chassis sideframe alongside the driver's seat. The engine number is marked on a vertical patch at the

right hand side of the rear face of the cylinder block, adjacent to the clutch housing.

Both numbers should always be quoted with any vehicle enquiries, as Factory records are filed against

V.I.N., and specification change points are identified by V.I.N. or engine number. The vehicle licence number

should be considered irrelevant, since it may not accurately reflect vehicle age, and may also be changed during the car’s life.

The V.I.N. comprises 17 characters, coded in accordance with European Economic Community (EEC)

and National Highway Traffic Safety Association (NHTSA) directives. For change point identification in Service

Notes, Service Bulletins and Service Parts Lists, typically, only characters 10 (model year), and 14 to 17 (serial

number) will be quoted.

'2004 M.Y. onwards

V.I.N. ON

CHASSIS

ohs119a

V.I.N. LABEL

ohs104 ENGINE NUMBER ohs133

Assembly

Plant Model

Vehicle Type H = Hethel 2 = 2-Eleven

Manufacturer 111 = Elise Check B = Shah 3 = Elise

Identifier Code 123 = 2-Eleven Digit Alam 8 = Exige

S C C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Engine Type Restraint Model Year Chassis/Body Serial

L = Motorsport A = Active belts 4 = 2004 A = LHD Fed.

Number

N = 2ZZ s/c 255 C = Dual S.I.R. 5 = 2005 C = RHD

P = 2ZZ n.a. + active belts 6 = 2006 D = LHD

V = 2ZZ s/c 7 = 2007 F = U.K. SVA RHD

Y = 1ZZ 8 = 2008 G = U.K. SVA LHD

9 = 2009 H = Motorsport*

A = 2010 J = Motorsport*

L = LHD Fed. a.c.

* Track only. Not M = LHD Can. a.c.

approved for road use N = RHD a.c.

P = LHD a.c.

Page 3

Page 3

Lotus Service Notes Introduction

MODEL HISTORY MILESTONES

Elise 111R Introduction: January 2004

VIN character 4 = P; Character 13 = 3; Serial number from 0970

Note that the serial number sequence is shared with other Elise variants.

Changes from previous model include: Toyota powertrain with 1.8 litre VVTL-i engine and 6-speed transmission. Twin exhaust tailpipes exiting through centre of diffuser. Larger fuel tank with new pump. Revised

chassis rail rear ends, new rear subframe, revised seat belt mounting frame backstays. Revised rear suspension wishbones, springs and dampers. ABS brake control with vacuum servo. Revised front bonnet grilles

and access covers.

2004 Exige Introduction: March 2004

VIN character 4 = P; Character 13 = 8; Serial number from 1092

Note that the serial number sequence is shared with other Elise variants.

Differences compared with Elise 111R include: Restyled front and rear clamshells with roof scoop, new

tailgate panel and strut mounted rear aerofoil. Front body splitter panel. Re-styled road wheels, wider on the

front, and Yokohama A048 tyres.

2005 M.Y. Elise for North America: May 2004

VIN character 10 = 5; Character 12 = L; Serial number from 0001

Note that the serial number sequence is shared with other Elise variants when '05 M.Y. is adopted for

those models later in the year.

Differences compared with Elise 111R include: Driver and passenger airbags, pyrotechnic seat belt pretensioners; Re-styled fascia and dashboard structure; Front speakers moved onto top surface of fascia, stowage pockets incorporated into dashboard end panels, fixed windscreen demist vents. Engine start button in

driver's side switch panel. Revised springs and dampers, Yokohama AD07 tyres. Side marker lamps on front

and rear wheelarch lips. Revised fuel system with fuel filler flap.

Lotus Sport Exige 240R: March 2005

Limited edition of 50 units produced as post registration official factory conversions of '05 Exige by the

Lotus Sport workshops at Hethel, for U.K. and certain overseas territories. The car is not identifiable from the

VIN coding.

Differences compared to standard Exige include: 243 bhp engine upgrade using Eaton M62 supercharger

with integral by-pass valve, air/air chargecooler and 5th fuel injector. Re-programmed ECU. Accusump.

Stiffened springs & Ohlins adjustable dampers. Adjustable front anti-roll bar. Chassis rear brace kit. Forged

5-spoke widened roadwheels & Yokohama A048 tyres. Motorsport brake pads, braided hoses, yellow callipers,

Castrol SRF brake fluid. Sport Yellow body colour with black wheels, or Sport Black body with silver wheels.

Black interior with yellow inserts. 4-point harnesses, T45 roof hoop and backstays.

2006 M.Y. Introduction: September 2005

VIN character 10 = 6; Serial number restarts at 0001, common to all variants.

Introduction of USA Exige and Canadian Elise.

5-speed Elise remains unchanged.

Differences between 6-speed '06 Elise and '05 include; Electronic throttle control (using no mechanical

cable). Optional Lotus Traction Control (LTC) or Limited Slip Differential (LSD) with LTC. Standard fit Yokohama

AD07 tyres on non-USA cars. Optional forged wheels with new 6.0 in front size. LED rear lamp clusters incorporating reflectors (formerly separate), and commonised USA type CHMSL. ProBax seat foams. New body

colours. USA & Canadian Elise; revised fuel tank and evap. loss system. Canadian Elise uses daytime running

lights and clutch down start allow switch. USA Exige similar to non-USA, but with USA airbag interior.

Sports Racer: October 2005

Special paint versions of '06 M.Y. 111R in either Ardent Red with triple Monaco White stripes, or Nightfall

Blue with twin Monaco White stripes. Combined total of 199 units with unique build plate on sill. Forged wheels

(6J on front), AD07 tyres, sport suspension, twin front oil coolers, LTC. Black leather interior with red or blue

stitching, and red or blue 'Elise' embroidered into head restraints. Sports Racer decals.

Page 4

Page 4

Lotus Service Notes Introduction

Exige Cup 190 & 240: January 2006

Limited number of competition oriented naturally aspirated (190) or supercharged (240) models produced

as post registration official factory conversions of '06 Exige by the Lotus Sport workshops at Hethel for U.K.

and certain overseas territories. Not identifiable from VIN coding.

Differences compared to 240R (see above) include: Electronic throttle, high flow port injectors (no 5th).

Cup 240 fitted with torque sensing LSD with LTC. Cup 190 uses friction plate LSD. Standard Exige wheels in

'Hi-power' silver. Race cars fitted with FIA 6-point roll cage, remote kill switch, extinguisher system. Standard

body colours.

Exige S: February 2006

VIN character 4 = V

Factory built type approved supercharged Exige. Not USA.

Differences to standard Exige include: 221 PS supercharged engine similar to 240R but using electronic

throttle, smooth flow inlet adaptor, standard injectors without 5th injector, modified downpipe, optimised muffler

with single oval tailpipe. Enlarged roof duct inlet for chargecooler. Body colour splitter, scoops and aerofoil.

'Exige S' decal on rear transom, 'S' on front quarter panels.

USA Lotus Sport Elise: March 2006

Limited edition of 50. Saffron Yellow with twin Storm Titanium stripes. Saffron Yellow centre console. Yel

low highlighted sports seats, 'carbon' door trim inserts. Harness bar, T45 seat belt mounting frame. Motorsport

mats, stalks, winders and parking brake sleeve. Traction control, supersport suspension, black forged wheels,

Yokohama A048s, braided brake hoses, silicone fluid, motorsport clutch. Lotus Sport decals and Union flags.

Lotus Sport chassis plate.

2007 M.Y. & Elise S Introduction: June 2006

VIN character 10 = 7; Serial number restarts at 0001, common to all variants.

VIN character 4 identifies engine type. Elise S = Y

Differences between '07 Elise/Exige and '06 include: Elise 111R renamed Elise R; New sealed headlamp

units; raised LOTUS lettering on rear transom; additional screen pillar seal; Alpine audio; improved HVAC ducting. New model Elise S uses 1ZZ-FE engine producing 100 kW, with variable inlet timing but fixed valve lift,

plastic inlet manifold, revised intake snorkel, revised exhaust manifold and downpipe, smaller tailpipes within

standard trims. Elise S also uses new C56 5-speed transmission and 6-spoke roadwheels sharing styling of

standard '01 model wheels.

USA Exige S: October 2006

The specification of the USA Exige S is that of the standard USA Exige and option packs, apart from the

engine, which is as non-USA Exige S with the following exceptions: High flow port injectors, specific engine

programming, 223 PS, 223 Nm. Carry-over features from the non-USA Exige S include exhaust downpipe and

optimised muffler with single oval tailpipe, roof air intake funnel mouth.

Exige S British GT Special Edition: November 2006

Celebrating Lotus Sport Cadena’s 2006 British GT3 Team Championship victory.

Differences to standard Exige S include: Torsen LSD & Lotus Traction Control. Chassis rear brace kit.

T45 roof hoop & stays. Braided brake hoses. Level 1 sports exhaust. Forged 7-bifurcated spoke silver wheels.

Lotus Sport black metallic body colour with Sport yellow & Arctic silver quad stripes, supplier decals on sills,

Lotus Sport visor strip, Cadena decals on front wings, GT3 decal on rear clam, GT3 winners decal with unique

build number on rear quarter panel, Lotus Sport build plate with build number. 4-point harnesses, black/yellow

door trims and unique black/yellow trimmed seats. Optional a.c. Optional GT pack available as post registration

official factory conversion by Lotus Sport workshops at Hethel for U.K. and certain overseas territories, includes:

High flow injectors, different ECU & unique calibration for 243 bhp, Accusump, 2-way adjustable Ohlins dampers

with uprated springs, 308mm front discs & 4-piston A.P. callipers, Pagid pads, Castrol SRF brake fluid.

Page 5

Page 5

Lotus Service Notes Introduction

USA Low Speed Damage Mitigation: January 2007

From ‘07 USA VIN serial no. 1579.

To meet USA safety legislation, modifications made to Elise/Exige: Front; armatures and foam inserts

added between crash structure and clamshell. Rear; bumper panel housing foam pads either side of licence

plate, narrower rear grilles, reinforced boot floor and diffuser support panel, stiffened diffuser. Some elements

commonised for all markets.

Lotus Sport Exige Cup 255: January 2007

Produced as post registration official factory conversions of '07 Exige S by the Lotus Sport workshops at

Hethel for certain territories, excluding U.K. and USA. Not identifiable from VIN coding.

Based on Exige Cup 240 (see above) with following differences: Power increase to 255 PS by; unique

ECU calibration, enlarged chargecooler, extended roof duct, larger air cleaner and intake spout, uprated fuel

pump. A.P. Racing 4 piston alloy front callipers, 308mm front discs.

2-Eleven Introduction: May 2007

VIN character 6/7/8 = 123; Character 13 = 2

Extreme, minimalist, track focussed Elise variant based on Exige Cup 255 powertrain componentry, but

using new chargecooler arrangement. Produced in small numbers for U.K. and certain overseas territories. In

U.K. only, SVA road going version available. All other territories only for track use, in LHD or RHD.

New body with no doors or roof. Aeroscreen. Rear aerofoil in two versions. FIA compliant roll over bar.

Chassis rear brace, unique front top wishbones and steering arms, optional Ohlins suspension. Accusump,

twin front oil coolers. Standard LTC, optional variable LTC & Launch Control. Uprated clutch. Odyssey battery.

Limited warranty for SVA cars. Extensive options list.

USA Elise Limited Edition 'Type 72D'

Limited edition of 50 cars to commemorate the 35th anniversary of Lotus' F1 1972 World Championship

victory with the type 72D.

Phantom black body colour with hand painted gold pinstriping. Rear body spoiler, black diffuser. Gold

laurel leaf decal on front quarters, gold 'Elise' and 'Type 72D' decals, gold raised LOTUS lettering, gold/black

nosebadge, gold fuel filler cap. Gold Exige 8 split-spoke wheels with Yokohama A048 tyres and sports suspension. Black & gold seats and interior trim details with Limited Edition plaque. Scale model crash helmet.

Page 6

Page 6

Lotus Service Notes Introduction

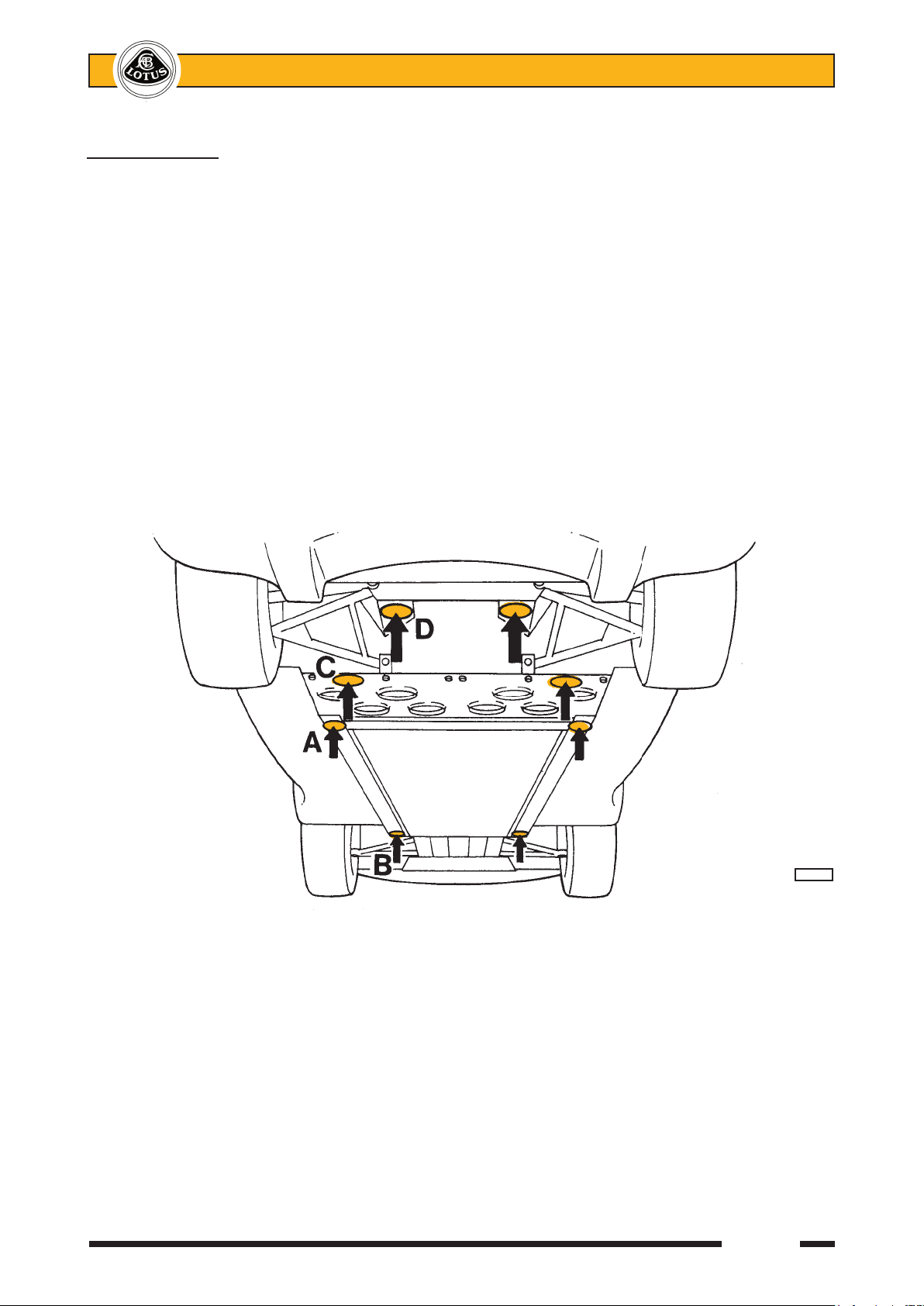

ENGINE BAY UNDERTRAY/DIFFUSER

For certain service operations, it may by necessary to remove the engine bay undertray and/or diffuser

panel. The panels contribute to the aerodynamic performance of the car, and also help to keep the engine bay

clean. Do not run the car without the panels fitted.

3 screws to licence 1 screw each side

plate plinth to grille panel

b275b

Diffuser panel

3 screws

each side

Single screw each to tank bay

side to clamshell panel

Undertray

front edge

M8 button head slots into

(2) to subframe 5 screws M8 button head chassis

undertray (2) to lower

to diffuser link brackets

Page 7

Page 7

Lotus Service Notes Introduction

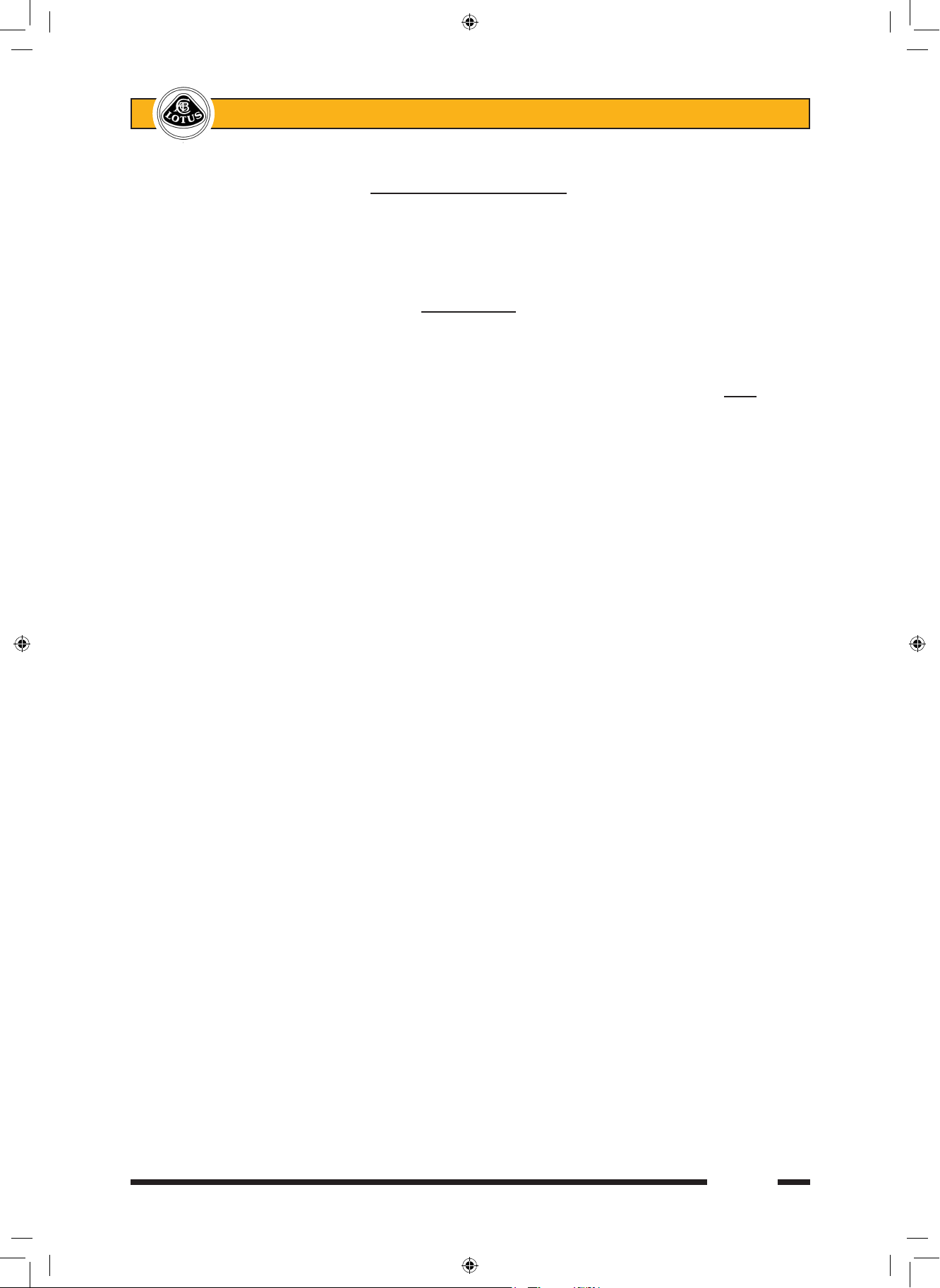

JACKING POINTS

Care must be taken when using a lifting jack or hoist to position the device only in one of the the areas

shown in the illustration, with a suitable rubber or timber pad protecting the chassis from surface damage. If a

4-point lift is to be used, the engine bay undertray/diffuser panel (if fitted) must first be removed. When using

a 4-point lift, it is strongly recommended that for optimum stability and safety, positions B and D are used.

A; Identified by a blue sticker. Beneath crossmember ahead of fuel tank bay. To be used one side at a time

for wheel changing - lifts both wheels on one side. Do not use with a four point garage lift.

B; Beneath the front end of the right or left hand main chassis rail, behind the front wheelarch. Garage use

with 4-point lift in conjunction with (C).

C; The engine undertray/diffuser panel must first be removed. Beneath the outboard end of the chassis

crossmember ahead of the rear wheelarches. Take care to position the jack between the fixing screws

for the fuel tank bay perforated undershield. Garage use with 4-point lift in conjuction with (B).

D; The engine undertray/diffuser panel must first be removed. Beneath the rear subframe, close to the lower

wishbone rearmost mountings.

Jacking at any other point may damage the chassis or body structure and/or jeopardise safety.

ohs49sn

Page 8

Page 1

Lotus Service Notes Section TDP

TECHNICAL DATA - ENGINE

SECTION TDP

Page

General .................................................................................................................... 2

Cylinder Block .......................................................................................................... 2

Cylinder Head .......................................................................................................... 3

Valves & Springs ...................................................................................................... 3

Camshafts ................................................................................................................ 3

Pistons ..................................................................................................................... 3

Connecting Rods ...................................................................................................... 3

Crankshaft ............................................................................................................... 3

Oil Pump .................................................................................................................. 3

Coolant Thermostat .................................................................................................. 3

sn_tdp_engine_cyclone.indd 1 03/07/2006 14:59:41

Page 9

Page 2

Lotus Service Notes Section TDP

GENERAL

Type designation - All except Elise S 2ZZ-GE

- Elise S 1ZZ-FE

Configuration & no. of cylinders in-line 4 Capacity 1796 cm3 1794 cm³

Bore 82.00 mm 79.00 mm

Stroke 85.00 mm 91.50 mm

Camshafts Chain driven DOHC Valves 4VPC in pentroof chambers

Valve control - inlet Variable timing & lift Variable timing

- exhaust Variable lift Valve timing - inlet - low & medium speed - open 33° BTDC to all speeds 48° BTDC

to 10° ATDC to 5° BTDC

- close 15° ATDC to all speeds 12° ATDC

58° ATDC to 55° ATDC

- high speed - open 58° BTDC to

15° BTDC

- close 54° ABDC to

97° ABDC

- exhaust - low & medium speed - open 14° BBDC all speeds 42° BBDC

- close 34° ATDC all speeds 2° ATDC

- high speed - open 36° BBDC

- close 60° ATDC

Compression ratio 11.5:1 10.0:1

Compression pressure (250 rpm) - new 1400 kPa (203 psi) 1500 kPa (218 psi)

- service limit 1000 kPa (145 psi) Firing order 1,3,4,2 Spark plugs NGK IFR6A11 NGK BKR5EYA-11

Spark plug gap 1.1 mm 1.0 ± 0.05 mm

Maximum continuous engine speed 8000 rpm 6,800 rpm

Maximum transient engine speed 8500 rpm 7,000 rpm

Idle speed 850 rpm Ignition system Direct ignition using individual H.T. coils

for each cylinder

Fuel system Fully sequential indirect fuel injection,

Lotus T4 controller

Fuel requirement (minimum) Unleaded 95 RON Peak power (1999/99/EC) 141 kW (192 PS) 100 kW (136 PS)

@ 7,800 rpm @ 6,200 rpm

Peak torque (1999/99/EC) 181 Nm 172 Nm

@ 6,800 rpm @ 4,200 rpm

Exhaust emissions - CO 0.42 g/km 0.23 g/km

- HC 0.078 g/km 0.050 g/km

- NOx 0.0121 g/km 0.0217 g/km

- HC + NOx 0.0792 g/km 0.0717 g/km

- CO2 208 g/km 196 g/km

CYLINDER BLOCK

Material Aluminium alloy, Aluminium alloy,

MMC cylinder bores cast iron liners

Deck face flatness tolerance 0.05 mm Cylinder bore diameter 82.000 - 82.013 mm 79.000 - 79.013 mm

sn_tdp_engine_cyclone.indd 2 03/07/2006 14:59:41

Page 10

Page 3

Lotus Service Notes Section TDP

CYLINDER HEAD 2ZZ-GE 1ZZ-FE

Material Aluminium alloy Head face flatness tolerance 0.05 mm Reface limit No machining -

VALVES & SPRINGS

Valve seat angle in head 45° Valve face angle 44.5° Cold valve clearance (between cam & follower) - inlet 0.10 - 0.16 mm 0.15 - 0.25 mm

- exhaust 0.24 - 0.30 mm 0.25 - 0.35 mm

Valve guide standout 15.3 - 15.7 mm 8.7 - 9.1 mm

Valve spring free length - inlet 46.4 mm 45.9 mm

- exhaust 46.5 mm 45.9 mm

CAMSHAFTS

End float - new 0.04 - 0.14 mm 0.04 - 0.10 mm

- service limit 0.15 mm 0.11 mm

PISTONS

Diameter - @ 90° to pin, 12 mm from bottom edge 81.975 - 81.993 mm

- @ 90° to pin, 25 mm from top edge 78.925 - 78.935 mm

Ring gap, 110 mm from block top face - std. - no.1 0.25 - 0.35 mm -

- no.2 0.35 - 0.50 mm -

- oil rail 0.15 - 0.40 mm -

- max. - no.1 1.1 mm -

- no.2 1.2 mm -

- oil rail 1.1 mm Ring groove clearance 0.030 - 0.070 mm -

CONNECTING ROD

Small end bush inside diameter 20.011 - 20.023 mm 20.012 - 20.021 mm

Big end side clearance 0.16 - 0.34 mm -

CRANKSHAFT

Crankshaft endfloat - new 0.04 - 0.24 mm -

- service limit 0.30 mm Main journal diameter 47.988 - 48.000 mm Crankpin diameter 44.992 - 45.000 mm 43.992 - 44.000 mm

Max. taper & out of round, journals & crankpins 0.02 mm -

OIL PUMP

Oil pressure - idle, running temperature 39 kPa (6 psi) min. 29 kPa (4 psi) min.

- 3,000 rpm, running temperature 300 - 540 kPa (45 - 80 psi)

Outer rotor to housing clearance - new 0.13 - 0.18 mm -

- service limit 0.33 mm Inner rotor tip clearance - new 0.06 - 0.18 mm -

- service limit 0.33 mm Rotor end float - new 0.03 - 0.08 mm -

- service limit 0.16 mm -

COOLANT THERMOSTAT

Valve opening temperature 80 - 84°C Valve lift at 90°C 10 mm Header tank pressure cap 108 kPa Cap opening pressure 93 - 123 kPa -

sn_tdp_engine_cyclone.indd 3 03/07/2006 14:59:41

Page 11

Page 4

Lotus Service Notes Section TDP

sn_tdp_engine_cyclone.indd 4 03/07/2006 14:59:41

Page 12

Page 5

Lotus Service Notes Section TDP

sn_tdp_engine_cyclone.indd 5 03/07/2006 14:59:41

Page 13

Lotus Service Notes Section TDQ

TECHNICAL DATA - VEHICLE

SECTION TDQ

Page

Dimensions ........................................................................................................ 2

Capacities .......................................................................................................... 2

Wheels & Tyres ................................................................................................... 3

Front Suspension ................................................................................................. 3

Rear Suspension ................................................................................................. 4

Electrical ............................................................................................................. 5

Transmission ....................................................................................................... 5

Clutch .................................................................................................................. 6

Brakes ................................................................................................................. 6

Steering ............................................................................................................... 6

Fuel Consumption ............................................................................................... 6

Page 1

Page 14

Lotus Service Notes Section TDQ

DIMENSIONS

Overall length - Elise 3785 mm

- Exige 3797 mm

Overall width - exc. mirrors - Elise 1719 mm

- Exige 1727 mm

- inc. mirrors 1850 mm (approx.)

Overall height (at kerb weight) - Elise 1117 mm

- Exige 1159 mm

Wheelbase 2300 mm

Track - front 1457 mm

- rear 1507 mm

Ground clearance (mid-laden) - except std. USA 130 mm

- std. USA 135 mm

Front overhang - Elise 783 mm

- Exige 805 mm

Rear overhang - Elise 702 mm

- Exige 692 mm

Approach angle (at kerb) 13.5°

Departure angle (at kerb) 23°

Unladen weight - 111R/Elise R - total 860 kg >

(lightest) - front 327 kg > incl. full fuel tank

- rear 533 kg >

- Elise S - total 862 kg }

(lightest) - front 328 kg } incl. full fuel tank

- rear 534 kg }

- USA Elise - total 912 kg )

(heaviest) - front 344 kg ) incl. full fuel tank

- rear 568 kg )

- non-USA Exige - total 875 kg >

- front 328 kg > incl. full fuel tank

- rear 547 kg >

- non-USA Exige S- total 935 kg }

- front 355 kg } incl. full fuel tank

- rear 580 kg }

- USA Exige - total 920 kg )

- front 350 kg ) incl. full fuel tank

- rear 570 kg )

Max. weight - 111R/R, Exige - total 1166 kg >

- front 443 kg > incl. occupants & luggage

- rear 723 kg >

- Elise S - total 1126 kg }

- front 428 kg } incl. occupants & luggage

- rear 698 kg }

- USA Elise - total 1162 kg )

- front 441 kg ) incl. occupants & luggage

- rear 721 kg )

- non-USA Exige S- total 1199 kg >

- front 456 kg > incl. occupants & luggage

- rear 743 kg >

Trailer towing Not permissible

CAPACITIES

Engine oil - refill inc. filter 4.4 litre

(+ 3.5 litre if front mounted oil coolers are drained)

High/low dipstick mark difference 1.5 litre

Transmission oil 2.3 litre

Fuel tank 43.5 litre

Page 2

Page 15

Lotus Service Notes Section TDQ

Coolant 12 litre

Refrigerant 550 g

Rear luggage compartment 50 kg/112 litre

WHEELS & TYRES

Tyres

Type - Elise std. - prior '06 Bridgestone Potenza RE040

- from '06 Yokohama Advan Neova AD07

- USA Elise Yokohama Advan Neova AD07

- Elise option, Exige Yokohama A048

Size - front - Elise std. 175/55 R16 80W

- USA Elise 175/55 R16 80W

- Elise option, Exige 195/50 R16 84W

- rear - Elise std. - RE040 225/45 R17 90W

- AD07 225/45 R17 91W

- USA Elise - AD07 225/45 R17 91W

- Elise option, Exige - A048 225/45 R17 90W

Pressure (cold) - front 1.8 bar (26 lb/in²)

- rear 2.0 bar (29 lb/in²)

Winter Tyres

Type - front Pirelli 210 Snowsport

- rear Pirelli 240 Snowsport

Size - front 195/50 R16

- rear 215/45 R17

Pressure (cold) - front 1.8 bar (26 lb/in²)

- rear 1.9 bar (27.5 lb/in²)

Tyre studding Not permitted

Tyre chains Pewag Neon X3-NX373

fitted only on rear winter tyres

Wheels

Type - Elise 111R/R/USA Cast alloy, 8 spoke

- Elise S Cast alloy, 6 spoke

- Exige std. Cast alloy, 8 Y-spoke

- Elise/Exige option Forged alloy, 7 split-spoke

Size - front - Elise std. 5.5J x 16

- Elise option 6.0J x 16 (forged + AD07)

- Elise option, Exige 6.5J x 16 (forged + A048)

- rear 7.5J x 17

Wheel bolt torque 105 Nm (77 lbf.ft)

FRONT SUSPENSION

Type Independent. Upper and lower wishbone; co-axial

coil spring/telescopic damper unit; anti-roll bar

Steering axis inclination 12 ° nominal

Geometry specification - Standard Elise:

Mid-laden ride height (reference height for geometry check)

- USA Elise from VIN 3013 & 111R/R/S - front 130 mm below front end of chassis siderail

- rear 130 mm below rear end of chassis siderail

- USA Elise prior VIN 3013 - front 135 mm below front end of chassis siderail

- rear 135 mm below rear end of chassis siderail

Castor - optimum + 3.8°

- tolerance range + 3.5° to + 4.1°; max. side/side 0.35°

Page 3

Page 16

Lotus Service Notes Section TDQ

Camber - optimum - 0.1°

- tolerance range + 0.1° to - 0.3°; max. side/side 0.2°

Alignment - optimum Zero

- tolerance range 0.5 mm toe out, to 0.7mm toe-in overall

Geometry specification - Sportpack Elise, Exige:

Mid-laden ride height (reference height for geometry check)

- front 130 mm below front end of chassis siderail

- rear 130 mm below rear end of chassis siderail

Castor - optimum + 3.8°

- tolerance range + 3.5° to + 4.1°; max. side/side 0.35°

Camber - optimum - 0.3°

- tolerance range - 0.1° to - 0.5°; max. side/side 0.2°

Alignment - optimum Zero

- tolerance range 0.5 mm toe out, to 0.5 mm toe-in overall

Geometry specification - Supersportpack Elise, Exige:

Mid-laden ride height (reference height for geometry check)

- front 120 mm below front end of chassis siderail

- rear 120 mm below rear end of chassis siderail

Castor - optimum + 3.8°

- tolerance range + 3.5° to + 4.1°; max. side/side 0.35°

Camber - optimum - 0.2°

- tolerance range + 0.1° to - 0.3°; max. side/side 0.2°

Alignment - optimum Zero

- tolerance range 0.5 mm toe out, to 0.7 mm toe-in overall

REAR SUSPENSION

Type Independent. Upper and lower wishbone; co-axial

coil spring/telescopic damper.

Geometry specification - Standard Elise:

Mid-laden ride height (reference height for geometry check)

- USA Elise from VIN 3013 & 111R/R/S - front 130 mm below front end of chassis siderail

- rear 130 mm below rear end of chassis siderail

- USA Elise prior VIN 3013 - front 135 mm below front end of chassis siderail

- rear 135 mm below rear end of chassis siderail

Camber - optimum - 1.8°

- tolerance range - 1.6° to - 2.0°; max.side/side 0.2°

Alignment - optimum 1.2 mm toe-in each side

- tolerance range 1.2 to 1.8mm toe-in each side

max.side/side 0.3 mm

Geometry specification - Sportpack Elise, Exige:

Mid-laden ride height (reference height for geometry check)

- front 130 mm below front end of chassis siderail

- rear 130 mm below rear end of chassis siderail

Camber - optimum - 1.8°

- tolerance range - 1.6° to - 2.0°; max.side/side 0.2°

Alignment - optimum 1.5 mm toe-in each side

- tolerance range 1.2 to 1.8 mm toe-in each side

max.side/side 0.3 mm

Geometry specification - Supersportpack Elise, Exige:

Mid-laden ride height (reference height for geometry check)

- front 120 mm below front end of chassis siderail

- rear 120 mm below rear end of chassis siderail

Page 4

Page 17

Lotus Service Notes Section TDQ

Camber - optimum - 2.5°

- tolerance range - 2.0° to - 2.7°; max.side/side 0.2°

Alignment - optimum 1.8 mm toe-in each side

- tolerance range 1.5 to 2.0 mm toe-in each side

max.side/side 0.3 mm

ELECTRICAL

Light Bulbs Wattage Type

Headlamps - prior '07 - main beam 55 H7

- dip beam 55 H1

- from '07 - main beam 55 H7U

- dip beam 55 H7U

Driving lamps 55 H3

Front side/parking lamps 5 W5W

Side repeater lamps 5 WY5W amber

Front turn indicators 21 PY21w amber

Rear turn indicators - prior '06 21 H21 )

Stop/Tail lamps - prior '06 4/21 P21/4w )

Stop lamps (USA) - prior '06 21 H21 ) '06 onwards use

Tail lamps - prior '06 5 R5W ) LED clusters

Tail/turn lamps (USA) - prior '06 4/21 P21/4w )

Fog/Tail lamps - prior '06 4/21 P21/4w

Reversing lamp - prior '06 21 H21

Turn lamps (non-USA) - from '06 16 W16W

Reverse lamps - from '06 16 W16W

High mounted stop lamp 2.5 16 x LED

Licence plate lamps 5 C5W

Interior lamp 5 W5 W

System voltage/polarity 12V negative earth

Alternator 85A

Battery - non USA - type Yuasa 063/3

- cranking power (SAE) 380A

- reserve capacity 70 minutes

- dimensions (mm) L 207, W 175, H 175

- USA - type Delco 19001598

- BCI code 26R-6YR

- cranking power 550 amps @ -18°C

- reserve capacity 80 minutes

TRANSMISSION

Gearbox - all except Elise S 6-speed manual incl. final drive

- Elise S 5-speed manual incl. final drive

Differential - standard Open, bevel gear

- option Torsen type LSD with Lotus Traction Control

Gear Ratio Final Drive mph(km/h)/1000 rpm

5-speed 6-speed 5-speed 6-speed 5-speed 6-speed

First 3.17 : 1 3.17 : 1 ) 5.36 (8.62) 5.1 (8.2)

Second 1.90 : 1 2.05 : 1 ) 8.73 (14.1) 7.7 (12.4)

Third 1.39 : 1 1.48 : 1 ) 4.31 : 1 4.53 : 1 12.0 (19.2) 10.7 (17.2)

Fourth 1.03 : 1 1.17 : 1 ) 16.2 (26.0) 13.6 (21.8)

Fifth 0.82 : 1 0.92 : 1 ) 20.4 (32.8) 17.3 (27.8)

Sixth - 0.81 : 1 ) - 19.4 (31.3)

Reverse 3.25 : 1 3.25 : 1 )

Page 5

Page 18

Lotus Service Notes Section TDQ

CLUTCH

Type Single dry plate. Diaphragm spring cover.

Hydraulic release.

Friction plate diameter 215 mm

Diaphragm finger clearance 1.00 mm

Diaphragm finger height - new 37.5 - 32.1 mm

- service limit 42.75 mm

Friction plate thickness - new 7.4 - 6.9 mm

- service limit 5.6 mm

Rivet depth - new 1.00 mm

- service limit 0.20 mm

Friction plate run-out - new 0.80 mm

- service limit 1.00 mm

Pressure plate warp - service limit 0.15 mm

BRAKES

Brake discs Cast iron, curved vane ventilated, cross-drilled discs

on all four wheels.

Calipers - front A.P. Racing, aluminium alloy body, one pair of

opposed pistons

- rear Brembo, cast iron, single piston sliding rear calipers

Disc size - front & rear 288 mm

Operation Tandem master cylinder with vacuum servo and

Kelsey Hayes EBC430 Anti-lock system

Parking brake Cable operation of rear calipers, self adjusting for

pad wear .

STEERING

Type Rack and pinion

Turns, lock to lock 2.8

Gear ratio 15.8:1

Rack height plate 6 notch

FUEL CONSUMPTION 1ZZ-GE 2ZZ-GE

1999/100/EC - urban 1 1.3 l/100km 12.1 l/100km

- extra urban 6.5 l/100km 6.8 l/100km

- combined 8.3 l/100km 8.8 l/100km

Page 6

Page 19

Page 1

Lotus Service Notes Section AH

CHASSIS

SECTION AH

Sub-Section Page

General Description AH.1 3

Chassis Straightness Check AH.2 4

Rear Subframe AH.3 5

sn_ah_cyclone.indd 1 03/03/2006 10:51:12

Page 20

Page 2

Lotus Service Notes Section AH

ELISE CHASSIS UNIT

Seat belt mounting

frame steel roof hoop

Composite Scuttle Seat mounting

crash structure beam extrusion Seat belt mounting

frame backstay

Door hinge

mounting

Sill extrustion

Main siderail

Fuel tank bay Steel rear subframe

a29b

sn_ah_cyclone.indd 2 03/03/2006 10:51:13

Page 21

Page 3

Lotus Service Notes Section AH

AH.1 - GENERAL DESCRIPTION

The chassis frame of the Lotus Elise is constructed primarily from aluminium alloy extrusions and formed

alloy sheet, with the various sections bonded together using an epoxy adhesive with secondary drive-in fasten

ers. The basic chassis unit includes the passenger cell, front suspension mountings, fuel tank housing, and mid

mounted engine bay, with a fabricated sheet steel rear subframe bolting to the rear of the engine bay to provide

rear suspension mountings and rear body support. A tubular steel seat belt mounting frame is bolted to the top of

the chassis structure and incorporates a roof hoop for additional occupant protection. The cabin rear bulkhead,

body sills (inc. 'B' posts), front energy absorbing crash structure and scuttle/windscreen mounting frame, are all

constructed from glass fibre composite and are bonded to the chassis structure using an elastomeric adhesive.

The front and rear outer body clamshells are each constructed from glass fibre composite mouldings, fixed to

the body and chassis structure with threaded fasteners to facilitate service access and economic repair.

Two main chassis siderail extrusions, 210mm deep and 100mm wide, run along each side of the passenger

compartment between the front and rear suspension mountings, splaying outwards towards the rear before

curving inwards around the fuel tank bay and terminating at each side of the engine bay in a vertical section to

provide engine mounting platforms and a flange to which the rear subframe is attached. To enhance cockpit

access, the height of the siderails is reduced in the door area, and internal reinforcement added in order to

maintain beam strength and torsional rigidity.

Running along the underside of the siderails from the front suspension crossmember to the fuel tank bay

are sill extrusions which carry the cockpit floor panel. The single skin floor panel is swaged for stiffness, and

is reinforced by a ribbed transverse extrusion running across the inside of the tub, which also provides for the

seat mountings. Behind the passenger cell, the siderails are linked by a pair of transverse crossmembers

which are used in conjunction with a folded sheet upper panel to form an open bottomed fuel tank cell with a

detachable, screw fixed, closing panel with swaged lightening holes. Note that this lower panel contributes to

the structural integrity of the chassis, such that the vehicle should not be operated without it fitted.

The rear ends of the siderails are joined behind the engine bay by a galvanised sheet steel fabricated

subframe which provides mountings for the rear suspension pivots nad damper abutment, engine rear stabiliser

and exhaust muffler.

At the front of the passenger compartment, four transverse extrusion beams are used to provide mountings

for the front suspension pivots, and house the steering rack, with an upright section used each side to anchor

the top of the spring/damper unit. Five interlinked extruded floor sections together with additional extrusions,

connect the transverse beams to form an open topped space to house the heater/a.c. unit. An extruded scuttle beam links the tops of the siderails at the front of the cockpit, and is reinforced by a panel extending to the

steering rack crossmember. These elements are used to mount the steering column and pedal box, with a

vertical extrusion fixed to each end of the scuttle beam to carry the door hinge pillar.

To the front end of the chassis is bonded a glass fibre composite 'crash structure' which incorporates

tubular sections designed to dissipate collision energy and control the rate of deceleration sustained by the

occupants. Ducting and mountings for the horizontally positioned engine cooling radiator are also incorporated

in this structure.

The bonded and rivetted alloy chassis structure described above is considered a non-serviceable single

unit, jig built to fine tolerances, to which no structural repairs are approved. Superficial, cosmetic, or non-structural

localised damage may be cosmetically repaired as necessary, but in the case of accident damage resulting in

significant bending, tearing or distortion of the aluminium chassis, such that the specified suspension geometry cannot be achieved by the standard range of suspension adjustment provided, the recommended repair

is to renew the partial body assembly, which comprises the chassis, rear subframe and the seat belt mounting

frame together with jig bonded composite rear bulkhead, body sills, windscreen frame and crash structure.

Also included are the radiator feed and return pipes in the chassis siderails, and those pipes and cables routed

through the sills, including the heater and a.c. pipes, battery cable, clutch and brake pipes, and brake servo

and oil cooler hoses.

sn_ah_cyclone.indd 3 03/03/2006 10:51:13

Page 22

Page 4

Lotus Service Notes Section AH

AH.2 - CHASSIS STRAIGHTNESS CHECK

In the absence of visual damage, the chassis may be checked for twist or distortion by utilising the tooling

holes in the underside of the main side rails. If computer processed laser measuring equipment is not avail

able, manual checks can be made with reference to an accurately level ground plane, e.g. an accurately set

and maintained suspension geometry ramp/lift. Position the car on the lift, and proceed as follows:

1. Identify the tooling holes in the lower surface of each chassis main side rail. At the front end, between the

suspension wishbone pivots, and at the extreme rear end of each rail.

2. Measure the height of each tooling hole above the reference plane and use jacks to adjust the height of

the chassis in order to equalise any three of these dimensions.

3. Measure the deviation of the fourth dimension from the other three.

Maximum service deviation = ± 2.0 mm.

4. Repeat operations (2) and (3) for each combination of corners to result in four values for the 'fourth' dimen

-

sion deviation. If any one of these exceeds the service specification, the chassis should be considered

damaged and replaced by a partial body assembly.

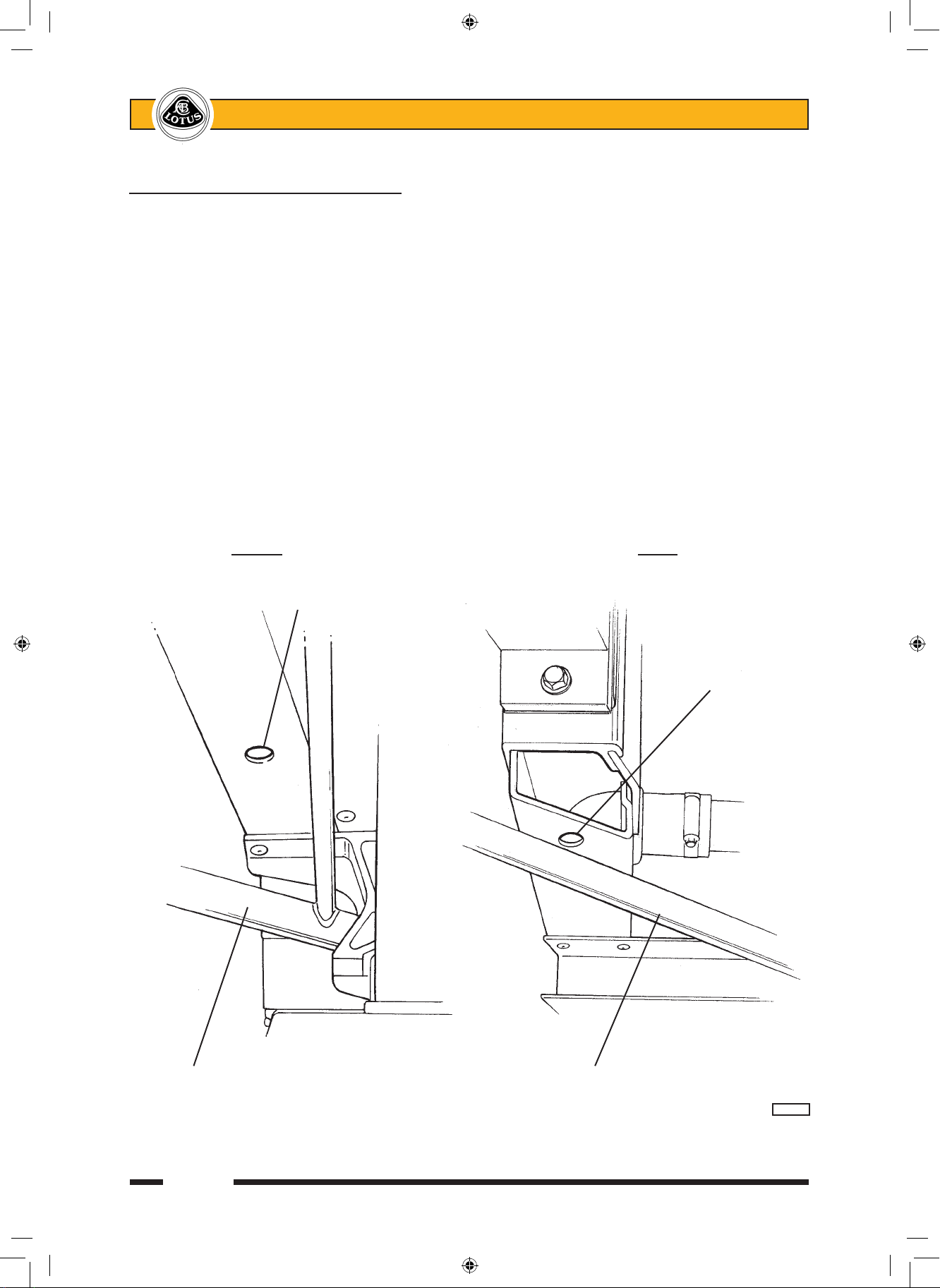

FRONT REAR

Tooling hole

Tooling

hole

Front wishbone Rear wishbone

a27/27a

sn_ah_cyclone.indd 4 03/03/2006 10:51:14

Page 23

Page 5

Lotus Service Notes Section AH

AH.3 - REAR SUBFRAME

The rear ends of the chassis siderails are linked by a fabricated sheet steel subframe which provides

mountings for the rear body section, rear suspension pivots, engine rear stabiliser, exhaust muffler and seat

belt mounting frame struts. The subframe is secured to the siderails by two M12 bolts at each side, with an

anti-corrosion shim plate interposed.

To remove rear subframe

1. Remove the rear clamshell (see section BR).

2. Remove exhaust heatshields, catalytic converter and muffler.

3. Disconnect the parking brake cables, wheel speed sensor harnesses and rear brake hydraulics. Release

the driveshafts from the hubs, and remove both rear suspension assemblies complete, providing alterna

-

tive support for the driveshafts.

4. Disconnect the inertia switch, and release from the subframe the oxygen sensor harness, wheel speed

sensor harnesses and brake pipes.

5. Release the engine rear stabiliser mounting from either the subframe or transmission.

6. Release the roof hoop backstays from the subframe. Remove the two bolts each side securing the sub

-

frame to the chassis flange and withdraw the subframe from the car.

Fitting rear subframe

When bolting the subframe at each side to the chassis rail rear flange, ensure that the anti-corrosion

shim plate is interposed. The lower fixing bolts should be inserted from the rear, using a washer and Nyloc nut

inside the chassis extrusion. Apply Permabond A130 (A912E7033V) to the threads of the upper bolts before

fitting from the front into the weldnuts in the subframe. Tighten all four bolts to 86 Nm. Continue re-assembly

in reverse order to disassembly.

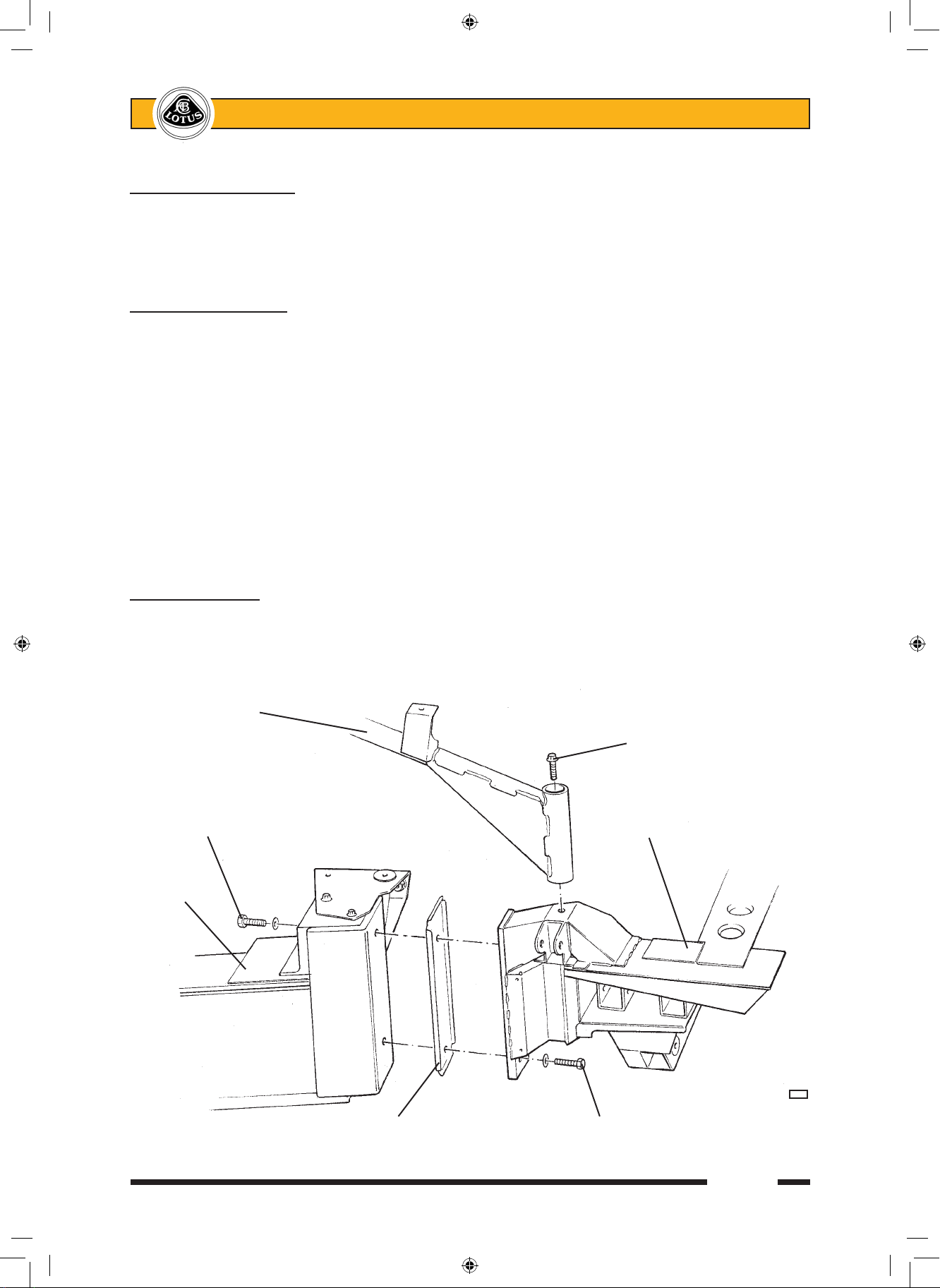

Seat belt mounting

frame backstay

Backstay to subrame

fixing bolt

Subframe upper

mounting bolt Rear subframe

Chassis

a30

Anti-corrosion shimplate Subframe lower mounting bolt

sn_ah_cyclone.indd 5 03/03/2006 10:51:14

Page 24

Page 1

Lotus Service Notes Section BQ

BODYCARE & REPAIR

SECTION BQ

Sub-Section Page

General Description BQ.1 3

Lotus Composite Body Features BQ.2 3

Bodycare BQ.3 4

Accident Damage Assessment BQ.4 5

Body Panel Bonding Materials BQ.5 6

Replacement of Bonded-On Panels - General BQ.6 9

Front Crash Structure BQ.7 10

Windscreen Frame BQ.8 12

Sill Panels BQ.9 16

Rear Bulkhead BQ.10 17

sn_bq_cyclone.indd 1 03/03/2006 10:53:38

Page 25

Page 2

Lotus Service Notes Section BQ

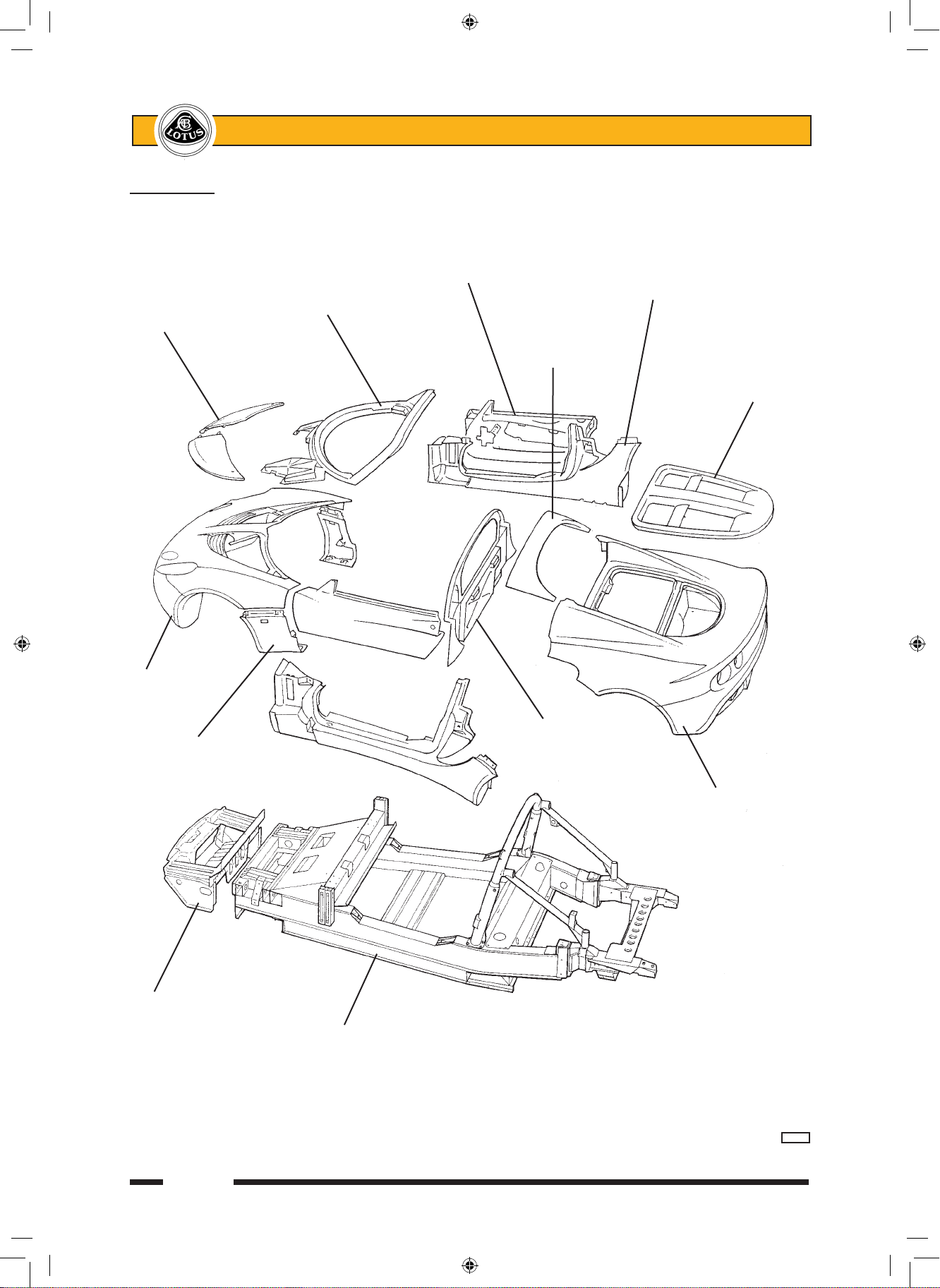

Body Panels

Door

shell

Windscreen Sill panel

Front access frame

panel Rear

window

shroud

Engine

cover lid

Front

clamshell

Cabin rear

Door hinge bulkhead

cover panel

Rear clamshell

Front crash

structure

Chassis frame

b277b

sn_bq_cyclone.indd 2 03/03/2006 10:53:38

Page 26

Page 3

Lotus Service Notes Section BQ

BQ.1 - GENERAL DESCRIPTION

The body panels of the Lotus Elise are constructed of composite materials, with the external panels not

being required to contribute to chassis rigidity. The panels are attached to the aluminium chassis and/or other

body panels either by elastomeric polyurethane adhesive, or in the case of the front and rear clamshells, are

bolted on for ease of dis-assembly and access to chassis parts. The composite mouldings are manufactured

by one of several processes (see later) dependent on application, with a nominal thickness of 2.2 - 2.5 mm.

The windscreen frame incorporates foam beams to create closed box sections for optimum strength and a

‘crash structure’ bonded to the front of the chassis incorporates longitudinal box sections to provide specific

crush characteristics and absorb crash impact by progressive collapse. This structure also acts as a mounting

and duct for the engine cooling radiator which is mounted horizontally on its top surface.

BQ.2 - LOTUS COMPOSITE BODY FEATURES

Composite structures have the ability to absorb high impact loads by progressive collapse, with impact

damage being localised. In vehicle accidents this feature protects the occupants from injurious shock loads and

greatly reduces the danger of entrapment by deformation of steel body panels. This behaviour also facilitates

repair by either replacing the damaged bonded or bolt on panels, and/or integrating a replacement section

with the undamaged area, using recognised approved methods which restore the panel to its original condition

without residual strain or distortion.

The manufacturing process enables the thickness of composite mouldings to be varied in order to provide

efficient structures of high strength and low weight. Composites will not corrode, so the strength of composite

components is retained regardless of age, unless physical damage is sustained. On the Elise, the body construction features an assembly of mouldings to form a single piece for the whole of the nose and front wings,

and a similar assembly for the whole of the rear body aft of the doors. These two 'clamshells' are fixed using

threaded fasteners to permit easy removal for access to chassis or powertrain components, or to allow simple

and economic accident repair. Other composite mouldings include the door shells, sills, front compartment

lid, windscreen frame and rear bulkhead, some panels being bonded to the aluminium alloy chassis with an

elastomeric adhesive.

A composite panel may return to its original shape after deflection, but beyond a certain level of flexibility,

such treatment may result in the formation of surface cracks which may not be immediately apparent due to

the masking effect of the paint film. A steel panel similarly treated would become dented or deformed. The

cracking may be confined to the surface layer with no reduction in panel strength, but if the damage is more

severe the composite structure below the surface may be weakened. Localised repairs can be made in either

case. Possible causes of surface cracking include:

- Vehicle collision;

- Sitting, leaning heavily or pushing on the body or any composite panel;

- Knocking doors against obstructions when opening;

- Dropping objects onto a panel;

- Allowing unrestrained items to roll about in a luggage compartment;

- Fitting a front access panel or closing the engine cover onto projecting objects, e.g. luggage or tools;

- Applying excessive force to parts attached to composite panels e.g. mirrors, locks, aerial etc. (inc. action

byvandals).

- Incorrect jacking.

The composite body panels of the Elise are manufactured by one of several processes dependent on the

requirements of the panel concerned:

- The front and rear clamshells, sill panels, windscreen frame, door outer panels, hard top roof outer panel

and front crash structure are produced by Injection Compression System Resin Transfer Moulding (ICS

RTM), whereby a mix of polyester resin and glass fibres is injected into a heated, chrome steel surfaced,

closed mould. After filling, the gap between the two halves of the mould is then reduced in order to compress the moulding and ensure complete material flow and consistent structural quality. Panel thickness

is a nominal 2.2 mm. The absence of the 'gel coat' used with other processes results in much greater

resistance to surface damage, and minimum surface preparation for before painting.

sn_bq_cyclone.indd 3 03/03/2006 10:53:38

Page 27

Page 4

Lotus Service Notes Section BQ

- The front access panels, engine cover lid, door hinge panels, door and roof inners and rear window shroud

are produced from Low Pressure Sheet Moulding Compound (LPSMC), whereby flat sheets of composite

material are formed using heated, chrome steel surfaced moulds to produce panels with a nominal thickness of 2.5 mm.

- A third process is used for the cabin rear bulkhead, bootbox and radiator mounting panel where the panel

surface is not primarily visible. These panels are produced by a Polyurethane Structural Reaction Injection Moulding (PU SRIM) process.

- Body panels unique to the Exige model, including front and rear clamshells, door hinge cover panels and

tailgate panel, are 'hand lay' composite mouldings with a nominal thickness of 2.5 mm.

Whichever production process applies, conventional composite repair techniques can be used to rectify

structural or surface damage whenever repairs can be determined as being more economic than panel replacement.

BQ.3 - BODYCARE

The acrylic enamel paint finish of the Elise is extremely resistant to all normal forms of atmospheric attack.

Following the simple maintenance procedure summarised below will help retain the gloss, colour and protective

properties of the paint throughout the life of the vehicle. However, car finishes are not immune to damage, and

amongst the more common causes of deterioration are:

- Atmospheric contaminants; dust, soot, ash, and acidic or alkaline aerosol mist can chemically attack

paint.

- Abrasion; blowing sand and dust, or a dirty washing cloth.

- Tree sap and insect fluids; can form a water-insoluble polymer that adheres to the paint.

- Bird excrement; highly acidic or alkaline, they can chemically etch the paint. Wash off immediately.

- Leaves; contain tannic acid which can stain light finishes.

- Impact damage; granite chippings thrown up from poor or recently dressed road surfaces can subject the

body to severe localised impact, and result in paint chips, especially around the vulnerable frontal panels.

Do not follow other vehicles too closely in such circumstances.

Washing

Lotus recommends that the car be hand washed, using the following instructions:

Many contaminants are water soluble and can be removed before any harm occurs by thorough washing

with plenty of lukewarm water, together with a proprietary car wash additive (household detergent and washing

up liquid can contain corrosive salts, and will remove wax and accelerate oxidation). Frequent washing is the

best safeguard against both seen and invisible contaminants. Wash in the shade, and use a cotton chenille

wash mitt or a sponge rinsed frequently to minimise entrapment of dirt particles. Use a straight back and forth

washing motion to avoid swirled micro scratches, and rinse thoroughly.

In order to minimise degradation from road salt, the underside of the chassis should be rinsed with clean

water as soon as possible after driving on treated roads. Many fuel filling stations offer pressure washing facilities ideal for this purpose, but to not use on the painted bodywork or soft top roof.

Soft Top Roof:

1. Careful vacuuming of the soft top before washing may be helpful in removing excess dust and other foreign

particles.

2. Wash in partial shade rather than strong sunlight, and wet the whole car before tackling the soft top.

3. Using only clean lukewarm water and a sponge (a chamois or cloth will leave lint, and a brush may abrade

the threads) wash the entire top uniformly. Do NOT use a detergent, which may affect the waterproofing

properties of the material.

4. Rinse the whole car to remove all soap from the fabric and to prevent streaking on the car bodywork.

5. Remove surface water with a sponge and allow to air dry in direct sunlight. Ensure that the roof is fully dry

before stowing, as prolonged stowage of a wet or damp roof will promote rotting of the fabric.

Keeping the soft top clean by regular washing will enhance the life and maintain the appearance of the

roof, and facilitate subsequent cleaning. The use of stronger cleansers should be left to professionals experi-

sn_bq_cyclone.indd 4 03/03/2006 10:53:39

Page 28

Page 5

Lotus Service Notes Section BQ

enced in handling this type of fabric as discoloration and degradation of the special protective inner layer may

result. The application of wax finishes, dressings or preservatives will cause stains which are difficult to remove

and therefore should be avoided.

Paintwork Polishing

Eventually some loss of gloss, and an accumulation of traffic film, will occur. At this stage, after normal

washing, the application of a good quality liquid polish will restore the original lustre of the paint film. Higher

gloss of the paint finish, and added protection against contamination, can be obtained by the use of a wax

polish; however, this can only be used successfully on a clean surface, from which the previous application has

been removed with white spirit or a liquid polish cleaner.

Ventilation

Water lying on the paint surface for a lengthy period will eventually penetrate the paint film. Although the

effects will not be visible immediately, a deterioration in the protective properties of the paint film will ultimately

result. It is not recommended to store a wet car in a poorly ventilated garage. If good ventilation cannot be

provided, storage outside on a hard standing or under a carport is to be preferred.

BQ.4 - ACCIDENT DAMAGE ASSESSMENT

The repair method to be employed in the rectification of accident damage to composite panels, is to be

assessed reletive to the particular panel and its method of attachment:

Bolt-on Panels: - Front Clamshell;

- Rear Clamshell;

- Door Shells;

- Front Body Access Panels;

- Engine Cover Lid;

- Door Hinge Cover Panels;

- Rear Window Shroud;

- Hard Top Roof.

These panels are secured by threaded fasteners and are easily removed for access to the back of any

damaged area for repair by conventional composite techniques. Instructions for the removal and refitment of

these panels are contained in section BR.

Bonded-on Panels: - Windscreen Frame;

- LH & RH Sill Panels;

- Front Crash Structure;

- Rear Bulkhead

These panels are bonded to the chassis or to other panels using a flexible polyurethane adhesive which

must be cut before the panel may be removed. In some cases, it may be necessary to partially remove another

panel before the subject panel can be released. It is not generally economic to attempt to remove a bonded

panel intact for later re-fitment.

The integrity of the front crash structure is crucial to the safety of the car in a frontal collision, and it is rec-

ommended not to attempt any major repair of this component. The damaged structure should be cut from the

front of the chassis, and a new assembly bonded into position. The shape and positioning of the windscreen

frame is crucial to the fit of the windscreen and sealing of the soft top roof, such that the only repairs which

should be considered for this panel are cosmetic and superficial; any structural damage should entail panel

replacement.

The sill panels include the ‘A’ and ‘B’ posts, and involve much labour time to replace. Localised repairs

should be performed whenever possible, although access to the inside surface of some parts of the panels is

not freely available.

Note that if damage is such as to require replacement of the chassis, replacement chassis assemblies are

provided only as a 'partial body assembly' which includes jig bonded front crash structure, windscreen frame,

side sills and rear bulkhead. The roof hoop and rear subframe are also included, as are the pipes, hoses and

cables routed through the sills.

sn_bq_cyclone.indd 5 03/03/2006 10:53:39

Page 29

Page 6

Lotus Service Notes Section BQ

BQ.5 - BODY PANEL BONDING MATERIALS

The materials used for bonding the body panels are manufactured by Dow Chemical, and in order to

maintain the structural integrity of the vehicle, and in the case of the front crash structure, the safety, it is most

important to use only the specified materials. The surface preparation and cleaning and priming operations are

crucial to the performance of the adhesive, and must be followed in detail. The products to be used depend on

the surface (substrate) onto which they are applied, and the following list identifies each application:

Anodised aluminium (e.g. chassis and components)

Cleaner: Betawipe VP 04604 Lotus part no. A082B6150V

Primer: Betapnme 5404 Lotus part no. A082B6337V

Adhesive: Betaseal 1701 Lotus part no. A082B6281F

or Betamate E2400 Lotus part no. A082B8415V

Unpainted or painted composite

Cleaner: Betaclean 3900 Lotus part no. A100B6008V

Primer: Betaprime 5404 Lotus part no. A082B6337V

Adhesive: Betaseal 1701 Lotus part no. A082B6281F

or Betamate E2400 Lotus part no. A082B8415V

Zinc plated and passivated steel

Cleaner: Beatclean 3900 Lotus part no. A100B6008V

Primer: Betaprime VP 01706 A+B Lotus part no. A100B6070V

Adhesive: Betaseal 1701 Lotus part no. A082B6281F

Glass

Cleaner: Betawipe VP 04604 Lotus part no. A082B6150V

Primer: Betaprime 5001 Lotus part no. A100B6009V

Adhesive: Betaseal 1701 Lotus part no. A082B6281F

or Betamate E2400 Lotus part no. A082B8415V

Uncoated Lexan/Perspex

Cleaner: Abrasion & dry wipe

Primer: Betapnme 5404 Lotus part no. A082B6337V

Adhesive: Betaseal 1701 Lotus part no. A082B6281F

or Betamate E2400 Lotus part no. A082B8415V

Residual adhesive (i.e. rebonding to surface after cutting off old panel)

Cleaner, primer

& re-activator: Betawipe 4000 Lotus part no. A082B6355V

Adhesive: Betaseal 1701 Lotus part no. A082B6281 F

or Betamate E2400 Lotus part no. A082B8415V

Applicator Bottle

An applicator bottle is available for use with some cleaners and primers, and has a disposable felt pad

which should be changed regularly to minimise surface contamination:

Applicator bottle: A000Z1071F

Cap: A082B6353S

Felt pad: A082B6354S

Product Usage

BETAWIPE VP 04604 (A082B6150V):

Description: Activator and cleaning agent used to promote adhesion to the substrate surface. Supplied in

a 250ml aluminium container with a YELLOW coloured cap.

Application: - Wipe on/wipe off type.

- Pour Betawipe VP 04604 into applicator bottle, and immediately refit the yellow cap onto the

container.

sn_bq_cyclone.indd 6 03/03/2006 10:53:39

Page 30

Page 7

Lotus Service Notes Section BQ

- Push the applicator head onto the bottle, and fit the felt pad.

- Wet out the felt pan by inverting the applicator bottle and gently squeezing the sides.

- Wipe the pad over the substrate surface using minimal pressure to wet the surface.

- Immediately wipe off the activated/cleaned surface using a clean fibre free cloth, and dis-

card.

Notes: - If the substrate is very dirty, first wipe off the surface with a clean fibre free cloth and dis-

card.

- Do not leave the caps off Betawipe containers. A milky colour indicates moisture absorption,

and the material should be discarded.

- Only decant a sufficient quantity of Betawipe for the job concerned, and never pour material

back into the container from the applicator bottle.

- Change the felt pad at regular intervals to reduce surface contamination.

BETACLEAN 3900 (A100B6008V)

Description: Degreaser and cleaning agent used for the removal of contamination from the substrate surface.

Supplied in 1 litre aluminium container with a BLACK coloured cap.

Application: - Wipe on/wipe off type.

- When substrate is very dirty, first wipe off the surface with a clean fibre-free cloth and dis-

card.

- Dampen a fibre-free cloth with Betaclean 3900, and immediately replace the black cap.

- Thoroughly clean the substrate surface with Betaclean and discard the cloth.

- Wipe off the substrate with a clean fibre-free cloth and discard.

BETAWIPE 4000 (A082B6355V)

Description: Cleaning agent which acitvates the old adhesive layer to accept new adhesive. Supplied in 250

ml aluminium containers with a BLUE cap.

Application: - The residual adhesive bead should be cut with a scalpal to leave an even thickness of ap-

proximately 1 to 2 mm.

- Dampen a fibre-free cloth with Betawipe 4000 and immediately replace the blue cap.

- Thoroughly clean the substrate surface with Betawipe and discard the cloth. Do not wipe

off.

- Allow 2 - 3 minutes flash off time before applying adhesive.

BETAPRIME 5001 (A100B6009V)

Description: Adhesion promotor used to maximise the performance of the bonding between the cleaned

and/or activated surface and the adhesive compound. Supplied in 250 ml aluminium container

with GREEN coloured cap.

Application: - Two steel balls inside the container are provided to assist mixing of the contents when shaken.

Prior to decanting Betaprime 5001, shake the container for at least 60 seconds to disperse the

solid content of the material into suspension.

- Pour the primer into the applicator bottle and immediately replace the green cap.

- Wet out the felt pan by inverting the applicator bottle and gently squeezing the sides.

- Wipe the pad over the activated/cleaned substrate surface to apply a continuous film of

primer.

- Allow to dry for a minimum of 15 minutes before applying adhesive. If adhesive is not applied

with 72 hours, wipe on/wipe off with Betawipe VP 04604.

Notes: - The appearance of the primed areas should be deep black in colour with no streaks or

voids.

To achieve this appearance, apply in smooth continuous uni-directional movement, not short

backward and forward movements. The latter technique results in inconsistent film build.

Rework any poor areas after 5 minutes (tack time), applying in the same direction.

- Replace the felt pad if moisture absorption results in hardening.

- Never return unused Betaprime back into the aluminium container.

sn_bq_cyclone.indd 7 03/03/2006 10:53:39

Page 31

Page 8

Lotus Service Notes Section BQ

BETAPRIME 5404 (A082B6337V)

Description: Adhesion promotor used to maximise the performance of the bonding between the cleaned

and/or activated surface and the adhesive compound. Supplied in 250 ml aluminium container

with RED coloured cap.

Application: - Two steel balls inside the container are provided to assist mixing of the contents when shaken.

Prior to decanting Betaprime 5404, shake the container for at least 60 seconds to disperse the

solid content of the material into suspension.

- Pour the primer into the applicator bottle and immediately replace the green cap.

- Wet out the felt pan by inverting the applicator bottle and gently squeezing the sides.

- Wipe the pad over the activated/cleaned substrate surface to apply a continuous film of

primer.

- Allow to dry for a minimum of 15 minutes before applying adhesive. If adhesive is not applied

with 24 hours, re-activate by applying a further coat of Betaprime 5404.

Notes: - The appearance of the primed areas should be deep black in colour with no streaks or

voids.

To achieve this appearance, apply in smooth continuous uni-directional movement, not short

backward and forward movements. The latter technique results in inconsistent film build.

Rework any poor areas after 5 minutes (tack time), applying in the same direction.

- Replace the felt pad if moisture absorption results in hardening.

- Never return unused Betaprime back into the aluminium container.

BETAPRIME VP 01706 A+B (A100B6070V)

Description: Adhesion promotor used to maximise the performance of the bonding between the cleaned

and/or activated surface and the adhesive compound. Supplied in 250 ml aluminium containers

of component A and component B.

Application: - Thoroughly shake component A container to disperse solid material. Remove the lid from the

component A container and scrape any sediment from the botton of the container. Replace the

container lid and thoroughly shake again to disperse the solid content.

- Pour the required amount of component A into a clean container, and add the same volume

of component B. Replace lids immediately. Thoroughly mix the two components for 45 seconds

minimum.

- Leave the mixed components to stand for 30 MINUTES. (Discard if unused after 8 hours)

- Pour the pnmer into the applicator bottle and wet out the felt pan by inverting the bottle and

gently squeezing the sides.

- Wipe the pad over the cleaned substrate surface to apply a continuous THIN film of primer:

A thin, almost transparent film is all that is required. No attempt should be made to attain a

completely opaque covering.

- Allow to dry for a minimum of 4 HOURS, before applying adhesive.

Notes: - To achieve a continuous thin film of VP 01706, apply in a smooth continuous uni-directional

movement, not short backward and forward movements. The latter technique results in inconsistent film build.

- Replace the felt pad if moisture absorption results in hardening.

- Never return unused Betaprime back into the aluminium container.

BETASEAL 1701 (A082B6281F)

Description: One component moisture curing adhesive, providing high strength, permanently elastic bonds

between various substrates. Supplied in 300 ml aluminium cartridge.

Application: - Remove the cartridge end ensuring there is no damage to the reinforcing sleeve.

- Pierce the neck of the cartridge and screw on the applicator nozzle. Cut the nozzle end to the

required diameter and shape.

- Fit the cartridge into an air assisted gun, and extrude a smooth, even and continuous bead

of Betaseal to the previously prepared substrate.

- Assemble the joint within 5 MINUTES.

Notes: - If the adhesive has to be touched or manipulated for any reason, use only wetted fingers.

sn_bq_cyclone.indd 8 03/03/2006 10:53:40

Page 32

Page 9

Lotus Service Notes Section BQ

BETAMATE E2400 (A082B8415V - 220ml, A100B6258V - 450ml)

Description: Two component chemically curing adhesive, providing high strength, permanently elastic bonds

between various substrates. Supplied in 220 and 450 ml aluminium cartridges.

Application: - An electrically driven Betagun Mk 11 is required to mix and extrude Betamate E2400. Refer

to the operating instructions supplied with the gun.

- Extrude a smooth, even and continuous bead of Betamate to the previously prepared sub-

strate.

- Assemble the joint within 5 MINUTES.

Notes: - If the adhesive has to be touched or manipulated for any reason, use only wetted fingers.

BQ.6 - REPLACEMENT OF BONDED-ON PANELS - GENERAL

Bonded body panels are secured using the Gurit-Essex products ‘Betaseal’ or ‘Betamate’, which are flex

ible polyurethane adhesives which must be cut in order for a panel to be removed. The recommended method

of adhesive cutting is with the use of a pneumatic tool such as the Chicago Pneumatic CP838 PneuNife which

uses a range of differently shaped cutting knives to which is imparted a vibrating action. This tool may also be

used to remove windscreens.

Supplier: Chicago Pneumatic, Utica, New York 13501, USA.

Catalogue no.: CP838 Pneu-Nife

Recommended air pressure: 60 - 90 PSIG (4.0 - 6.2 bar)

Tool air inlet: 1/4” NPTF, 3/8” mm. hose size

Air gun

Betaseal cartridge

bj43

sn_bq_cyclone.indd 9 03/03/2006 10:53:40

Page 33

Page 10

Lotus Service Notes Section BQ

It is not generally practical to remove a bonded panel intact, for later refitment. Consequently, when

necessary, the panel can be cut away for better access to the bonded joint. It is not necessary to remove all

traces of sealant from the joint faces on the remaining panels or chassis, but any remaining sealant must be

securely bonded and no thicker than 1 mm or the fit and joint gaps will be upset. It is essential always to follow

the cleaning/priming/bonding operations meticulously if sufficiently strong and durable bonds are to be obtained.

Always use the specified materials.

BQ.7 - FRONT CRASH STRUCTURE

The front crash structure consists of an upper and lower moulding bonded together and supplied only

as an assembly. It is bonded to the front face of the chassis, and is braced by an alloy undershield screwed

to the bottom front edge of the chassis, and to each lower side of the crash structure. The unit also acts as a

ducting for the engine cooling radiator and a.c. condenser (if fitted) which are mounted horizontally on its top

surface in a bolted-on composite radiator housing. Longitudinal tubes formed in the construction are designed

to produce a particular crush characteristic in order to control the rate of deceleration of the vehicle occupants

in a frontal collision.

Operating handle

Compressed air inlet

Vibrating cutting blade

bj46

Crush tubes Radiator aperture

Crash structure

Airflow to

climate chamber

via cut outs

in tubes

Chassis front face

p84a

sn_bq_cyclone.indd 10 03/03/2006 10:53:41

Page 34

Page 11

Lotus Service Notes Section BQ

To remove the crash structure:

- Remove the front clamshell (see sub-section BR.5).

- Remove the front undershield by releasing the three screws securing each lower side of the structure to

the shield, and the three screws securing the shield to the front lower edge of the chassis.

- Drain the coolant and remove the radiator and pipework (see section KH).

- Remove the driving lamps (if fitted) from the crash structure, along with the towing strut, horn, alarm siren

and wiring harness.

- Use a seal cutting knife to cut the bond between the structure and the front face of the chassis. For access

to some of the bonding areas, it may be necessary to cut away some parts of the structure, rendering the

unit unsuitable for refitment. Take care not to damage the surface of the chassis when cutting the adhe-

sive.

It is not necessary to remove all traces of old adhesive from the chassis, but a uniform surface must be

available for the new adhesive bead. The remaining adhesive must be securely bonded and be cut with

a scalpal blade to leave an even thickness of 1 - 2 mm.

Prepare the new structure for bonding:

- Dry fit the new structure to the chassis, and check that a good fit is achieved. Fettle the structure or remove

old adhesive as necessary until the fit is satisfactory.

- Re-activate the surface of the old adhesive on the chassis using Betawipe 4000 (see sub-section BQ.5),

and clean and prime the bonding area on the new crash structure using Betaclean 3900 and Betaprime

5404 (see sub-section BQ.5).

Bonding surface on chassis

Composite crash

structure

b278a

sn_bq_cyclone.indd 11 03/03/2006 10:53:41

Page 35

Page 12

Lotus Service Notes Section BQ

- Apply a bead of Betaseal/mate adhesive (see sub-section BQ.5) to the bonding surface in the manner

shown.

- Fit the structure to the chassis and press into position to spread the adhesive. Use several clamps around

the joint flange to retain the structure until the adhesive has cured; This will take approximately 4 hours

dependent on atmospheric conditions, with a longer period required in dry atmospheres.

- Fit the undershield, radiator (see sub-section KH.4), front clamshell (see sub-section BR.5) and remaining

parts.

BQ.8 - WINDSCREEN FRAME

The windscreen frame is a single ICSRTM moulding with hollow, foam filled sections, and incorporates a

forward extending buttress at each side to brace the frame against the front chassis. A separate dash baffle

panel is used to bridge the space between frame underside and chassis scuttle, and provide for the routing of

climate control pipework and air ducting, and other services.

Application of

adhesive bead

Betaseal bead

b279

Windscreen frame

Dash baffle panel

Demist air duct

Face level

vent duct

Chassis scuttle

Heater pipe

b282b

sn_bq_cyclone.indd 12 03/03/2006 10:53:41

Page 36

Page 13

Lotus Service Notes Section BQ

The shape of the frame is critical to the windscreen fit, and structural repairs to the frame itself are not

recommended. It is not generally economic to attempt to remove the windscreen frame intact for refitment,

as the elastomeric adhesive bonding the frame to the chassis requires cutting with a reciprocating knife, and

access to the joints is sometimes obscured. The recommended procedure is to cut the frame as necessary to

allow its removal without damage to the dash baffle panel. If the sills are to remain fitted, it will be necessary

to carry out some minor work on the screen buttress to sill panel joint, where a panel overlap occurs.

To Replace Windscreen Frame

1. Remove the front wheelarch liners and front clamshell (see sub-section BR.5), and for improved access,

the two doors.

2. Remove the windscreen (see sub-section BR.14).

3. Remove the instrument binnacle and fascia top panel (see sub-section BR.13), and release the fixings

between dash upper extrusion and screen frame.

4. Release the brake hose/pipe connector at the front end of each buttress on the windscreen frame. Release

all harnesses and other components from the windscreen frame buttresses as necessary.

5. Remove the wiper motor mechanism from the windscreen frame.

6. Use a sealant cutting tool to cut the bond between the windscreen frame buttresses and chassis, and

between the frame and 'B' posts, and between the frame underside and dash baffle panel. Remove the

windscreen frame.

7. Cut the adhesive securing the drainage gutter around the front of the frame, to allow transfer to the new

frame.

8. If the dash baffle panel is to be replaced, the clutch pipe and climate control cables must be released and

threaded through the panel before cutting the adhesive.

Primer band on chassis

Heater pipe grommet

Primer band on baffle

Dash baffle panel

Foam strip

b283b

sn_bq_cyclone.indd 13 03/03/2006 10:53:42

Page 37

Page 14

Lotus Service Notes Section BQ

9. To fit a new dash baffle:

- Ensure the heater feed and return pipes are fitted.

- Dry fit the panel and mark up the bonding surface on the chassis scuttle.

- Prepare and re-activate the surface of the old adhesive on the chassis using Betawipe 4000 (see

BQ.5).

- Clean and prime the upper and lower bonding faces on the new baffle panel using Betaclean 3900 and

Betaprime 5404 (see sub-section BQ.5).

- Apply a bead of Betaseal/mate adhesive (see sub-section BQ.5) to the baffle lower flange.

- Position the panel and press along the length of the joint to ensure sufficient spread of adhesive. Clamp

the panel in position until the adhesive cures.

- Apply self adhesive foam strip A082U6065V to each vertical end face of the baffle panel, wrapping over

onto the top edge and along to the primed surface. Apply a second strip up each vertical face.

10. Prepare the old adhesive bead on the chassis for fitment of the windscreen frame by removing excess

sealant from all the bonding areas on the chassis, sill panels and dash baffle to leave a consistent and

level bonding surface for the new frame. It is not necessary to remove all traces of old adhesive, but a

uniform surface must be available for the new adhesive bead. The remaining adhesive must be securely

bonded and be cut with a scalpal blade to leave an even thickness of 1 - 2 mm.

11. Fit the wiper motor assembly and windscreen washer jets to the windscreen frame.

12. If necessary, fit a new roof side rail latch plate to the windscreen header rail - it is not recommended to

refit a bracket due to the requirement for high surface quality on the bracket.

- If applicable, completely remove any old adhesive from the header rail taking care not to damage the com

-