Page 1

KMU CONTROLLER

RMC-185

Instruction manual

Page 2

Table of Contents

FCC COMPLIANCE STATEMENT ...................................................................................................... 4

WARNINGS AND PRECAUTIONS .................................................................................................... 4

WARRANTY .................................................................................................................................. 5

STANDARD WARRANTY ............................................................................................................................ 5

THREE YEAR WARRANTY ......................................................................................................................... 5

DISPOSAL ..................................................................................................................................... 5

1. INTRODUCTION ........................................................................................................................ 6

1.1 FEATURES ................................................................................................................................... 6

1.2 DEVICE SETUP ............................................................................................................................. 6

2. CONNECTIONS AND CONTROLS ................................................................................................ 8

2.1 FRONT PANEL – KEYBOARD ............................................................................................................ 8

2.2 REAR PANEL - CONNECTIONS ........................................................................................................ 12

3. MENU SETUP .......................................................................................................................... 13

FN1. EXITS THE MENU (EXIT) .............................................................................................................. 14

FN2. INPUT A SOURCE ASSIGNMENT (INPUT A SOURCE) ............................................................................ 14

FN3. INPUT B SOURCE ASSIGNMENT (INPUT B SOURCE) ............................................................................. 14

FN4. OUTPUT FORMAT SELECTION (OUTPUT FORMAT) .............................................................................. 14

FN5. AUDIO OUTPUT ........................................................................................................................... 15

FN6. GENLOCK SETTING (GENLOCK SET) .................................................................................................. 15

FN7. GENLOCK STATUS DISPLAY (GENLOCK STATUS) ................................................................................... 15

FN8. SELECTION OF SDI 3G TYPE (SDI 3G TYPE) ...................................................................................... 15

FN9. OUTPUT ASSIGN .......................................................................................................................... 15

FN10. LIMIT ....................................................................................................................................... 15

FN11. EXTERNAL MOTION TRIGGER SETTING (TRIGGER SET) ....................................................................... 15

FN12. KMU-100+ FIRMWARE VERSION DISPLAY (KMU-100+ VER.) ......................................................... 15

FN13. DISPLAY OF KMU-100+ FPGA AND PCB BOARD TEMPERATURES (KMU-100+ TEMP) ......................... 15

FN14. RMC-185+ FIRMWARE VERSION DISPLAY (FIRMWARE VER.) ............................................................ 15

4. STORING DIFFERENT DEVICE SETTINGS ................................................................................... 16

5. FRAME MOTION CONFIGURATION .......................................................................................... 17

6. FIRMWARE UPGRADE PROCEDURE ......................................................................................... 19

7. FREQUENTLY-ASKED QUESTIONS ............................................................................................ 22

8. DIMENSIONS .......................................................................................................................... 23

9. SPECIFICATIONS ...................................................................................................................... 23

SERVICE AND SUPPORT .............................................................................................................. 24

Disclaimer of Product and Services

The information offered in this instruction manual is intended as a guide only. At all times, Datavideo Technologies will

try to give correct, complete and suitable information. However, Datavideo Technologies cannot exclude that some

information in this manual, from time to time, may not be correct or may be incomplete. This manual may contain

2

Page 3

typing errors, omissions or incorrect information. Datavideo Technologies always recommend that you double check

the information in this document for accuracy before making any purchase decision or using the product. Datavideo

Technologies is not responsible for any omissions or errors, or for any subsequent loss or damage caused by using the

information contained within this manual. Further advice on the content of this manual or on the product can be

obtained by contacting your local Datavideo Office or dealer.

3

Page 4

FCC Compliance Statement

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

Warnings and Precautions

1. Read all of these warnings and save them for later reference.

2. Follow all warnings and instructions marked on this unit.

3. Unplug this unit from the wall outlet before cleaning. Do not use liquid or aerosol cleaners. Use a damp

cloth for cleaning.

4. Do not use this unit in or near water.

5. Do not place this unit on an unstable cart, stand, or table. The unit may fall, causing serious damage.

6. Slots and openings on the cabinet top, back, and bottom are provided for ventilation. To ensure safe

and reliable operation of this unit, and to protect it from overheating, do not block or cover these

openings. Do not place this unit on a bed, sofa, rug, or similar surface, as the ventilation openings on

the bottom of the cabinet will be blocked. This unit should never be placed near or over a heat register

or radiator. This unit should not be placed in a built-in installation unless proper ventilation is provided.

7. This product should only be operated from the type of power source indicated on the marking label of

the AC adapter. If you are not sure of the type of power available, consult your Datavideo dealer or your

local power company.

8. Do not allow anything to rest on the power cord. Do not locate this unit where the power cord will be

walked on, rolled over, or otherwise stressed.

9. If an extension cord must be used with this unit, make sure that the total of the ampere ratings on the

products plugged into the extension cord do not exceed the extension cord rating.

10. Make sure that the total amperes of all the units that are plugged into a single wall outlet do not exceed

15 amperes.

11. Never push objects of any kind into this unit through the cabinet ventilation slots, as they may touch

dangerous voltage points or short out parts that could result in risk of fire or electric shock. Never spill

liquid of any kind onto or into this unit.

12. Except as specifically explained elsewhere in this manual, do not attempt to service this product

yourself. Opening or removing covers that are marked “Do Not Remove” may expose you to dangerous

voltage points or other risks, and will void your warranty. Refer all service issues to qualified service

personnel.

13. Unplug this product from the wall outlet and refer to qualified service personnel under the following

conditions:

a. When the power cord is damaged or frayed;

b. When liquid has spilled into the unit;

c. When the product has been exposed to rain or water;

d. When the product does not operate normally under normal operating conditions. Adjust only those

controls that are covered by the operating instructions in this manual; improper adjustment of

other controls may result in damage to the unit and may often require extensive work by a qualified

technician to restore the unit to normal operation;

e. When the product has been dropped or the cabinet has been damaged;

f. When the product exhibits a distinct change in performance, indicating a need for service.

4

Page 5

Warranty

Standard Warranty

Datavideo equipment are guaranteed against any manufacturing defects for one year from the date

of purchase.

The original purchase invoice or other documentary evidence should be supplied at the time of any

request for repair under warranty.

The product warranty period beings on the purchase date. If the purchase date is unknown, the

product warranty period begins on the thirtieth day after shipment from a Datavideo office.

Damage caused by accident, misuse, unauthorized repairs, sand, grit or water is not covered under

warranty.

Viruses and malware infections on the computer systems are not covered under warranty.

Any errors that are caused by unauthorized third-party software installations, which are not

required by our computer systems, are not covered under warranty.

All mail or transportation costs including insurance are at the expense of the owner.

All other claims of any nature are not covered.

Cables and batteries are not covered under warranty.

Warranty only valid in the country or region of purchase.

Your statutory rights are not affected.

Three Year Warranty

All Datavideo products purchased after July 1st, 2017 are qualified for a free two years extension to

the standard warranty, providing the product is registered with Datavideo within 30 days of

purchase.

Certain parts with limited lifetime expectancy such as LCD panels, DVD drives, Hard Drive, Solid

State Drive, SD Card, USB Thumb Drive, Lighting, Camera module, PCIe Card are covered for 1 year.

The three-year warranty must be registered on Datavideo's official website or with your local

Datavideo office or one of its authorized distributors within 30 days of purchase.

Disposal

For EU Customers only - WEEE Marking

This symbol on the product or on its packaging indicates that this product must not be

disposed of with your other household waste. Instead, it is your responsibility to

dispose of your waste equipment by handing it over to a designated collection point for

the recycling of waste electrical and electronic equipment. The separate collection and

recycling of your waste equipment at the time of disposal will help to conserve natural

resources and ensure that it is recycled in a manner that protects human health and the

environment. For more information about where you can drop off your waste

equipment for recycling, please contact your local city office, your household waste disposal service or the

shop where you purchased the product.

CE Marking is the symbol as shown on the left of this page. The letters "CE" are the

abbreviation of French phrase "Conformité Européene" which literally means "European

Conformity". The term initially used was "EC Mark" and it was officially replaced by "CE

Marking" in the Directive 93/68/EEC in 1993. "CE Marking" is now used in all EU official

documents.

5

Page 6

1. Introduction

The RMC-185+ is a cost effective physical controller designed specifically for control of the KMU100+ 4K Multi-Camera Processor. The RMC-185+ interfaces with the KMU-100+ via an RS-422

interface.

The RMC-185+ panel style design allows easy control of the KMU-100+ with the hard keys giving

the user quick access to main functions of the KMU-100+. In addition, you can also use the joystick

to move the selected frame view.

That’s Datavideo; sharing the value!

1.1 Features

Remote control of up to eight selected frame views.

Pan, Tilt and Zoom with speed control by joystick.

Storing multiple presets for frame view settings.

Full remote control of the KMU-100+ via RS-422 connection.

An LCD display showing setup menu options.

Two Multiviewer modes (Switcher and KMU modes)

Compact design for easy installation

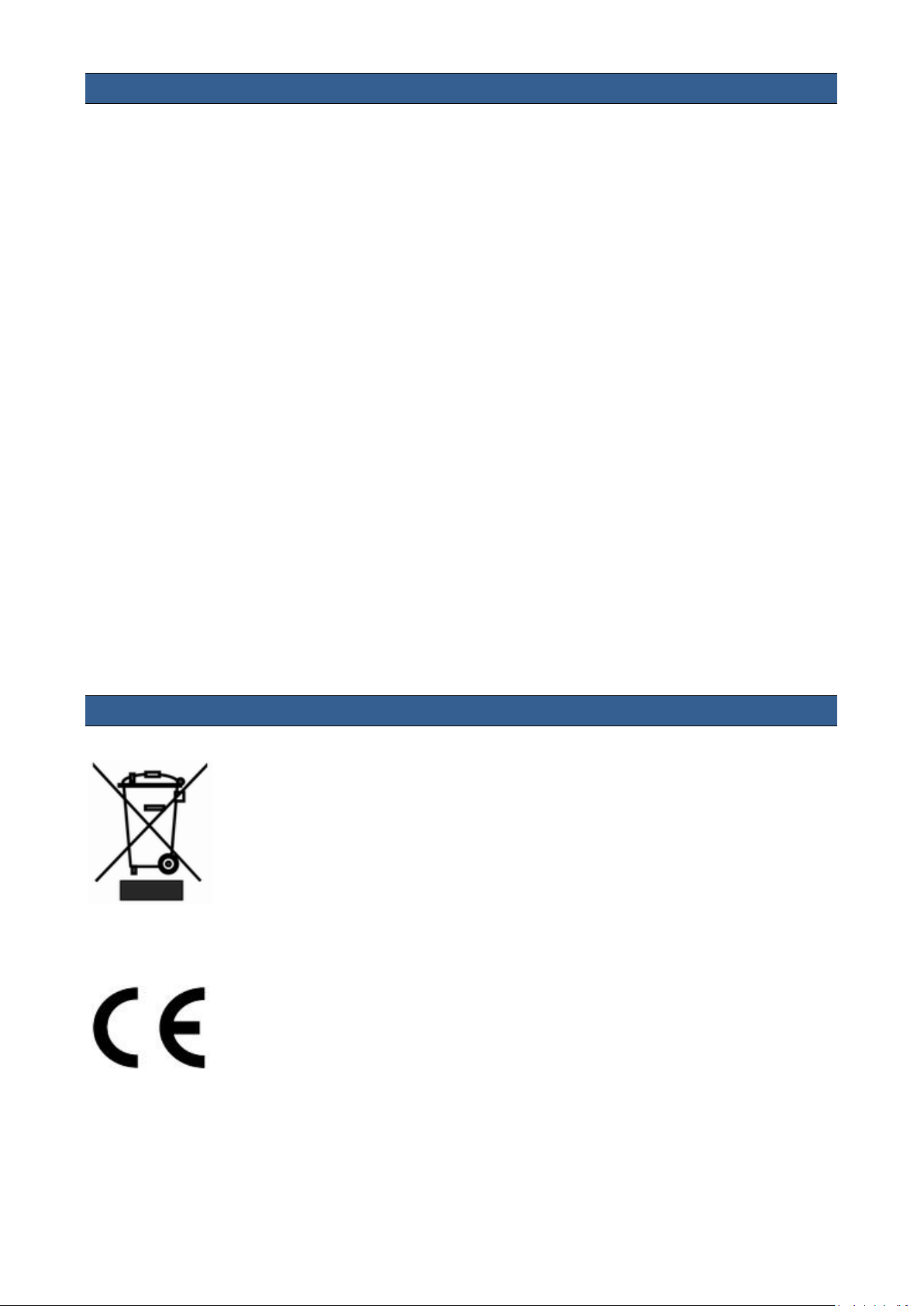

1.2 Device Setup

The RMC-185+ is designed to control the KMU-100+. Therefore, before pairing the RMC-185+ with

the KMU-100+, the user should first ensure that the two devices are installed of the two pieces of

firmware as listed below:

KMU-100+: V1.0.13932

RMC-185+: V1.012

See Firmware Upgrade Procedure in this manual for instructions on how you can install firmware

on RMC-185+. See the KMU-100+ manual for KMU-100+’s firmware upgrade procedure.

Note: The RMC-185 cannot be used to control the KMU-100+.

After the devices have been successfully upgraded to their corresponding firmware, connect the

power to the RMC-185+ through a power cable. After that, the RMC-185+ (RJ-45) is connected to

the KMU-100+ (DSub) using an RJ-45-to-DSub cable. Finally, turn ON the RMC-185+ device switch

to start manipulating your KMU-100+. See the system diagram below for the overall system setup.

Note: The communication protocol between the two devices is RS-422.

6

Page 7

7

Page 8

LCD Display

After the RMC-185+ is booted up, the upper row of

the LCD screen should show “RMC-185 for KMU-

100.”

The bottom left of the LCD screen shows the frame

motion mode and by rotating the knob right below,

you will be able to see the available options listed as

follows:

Single

Loop

PING

TR LOOP

TR PING

TR PING+

Press the knob to select the mode.

The bottom right of the LCD screen shows the frame

motion speed and by rotating the knob right below,

you will be able to change the speed from 1 to 15.

Press the knob the set the speed.

2. Connections and Controls

2.1 Front Panel – Keyboard

8

Page 9

Menu Control Knob

Push the Menu Control Knob to enter and browse

the RMC-185+ configuration menu. Once in the

menu, you can either push the menu knob to select

a specific item or rotate to browse the selected

menu option (or adjust the parameter value of the

selected option).

Certain options of the menu will require the user to

use the two knobs below the LCD screen to adjust

the parameter values and these values can be set by

pushing the corresponding knobs.

PTZ Joystick Control

Note: Before attempting to use the joystick to PAN,

TILT or ZOOM a selected frame, first make sure the

LOCK button is not enabled.

PAN – Move the joystick left or right to pan the

selected frame from left to right or vice versa.

TILT – Move the joystick up or down to tilt the

selected frame up or down.

ZOOM – Twist the joystick clockwise (to the right) or

anti-clockwise (to the left) to have the selected

frame zoom in or out.

LOCK Button

When enabled, the joystick will be in the lock state.

To resume its functional status, simply press the

button once to unlock the joystick.

Speed

The speed at which the selected frame moves can

be chosen by pressing one of the three speed

buttons.

9

Page 10

Multiviewer Mode Select

P/M

The second rightmost P button opens the

multiviewer in KMU Mode, thus displaying

current position of the selected frame.

The rightmost M button enables the Frame

Motion function (playback of the motion from

Start position to End position) of the selected

frame in KMU Mode.

Q

The middle Q button opens the multiviewer in

Switcher Mode as shown in the diagram below.

M

The second leftmost M button opens the

multiviewer in Switcher Mode as shown in the

diagram below.

P

The leftmost P button opens the multiviewer in

Switcher Mode as shown in the diagram below.

The Multiviewer buttons allow you to switch between different display modes.

10

Page 11

Take

Press this Q button will take the preview image to

air.

STORE

Pressing this button enters the RMC-185+ into

either the STORE MODE or Motion Setting Mode.

Store Mode

When activated, this allows the current device

setting to be stored in a chosen Preset Button by

pressing the corresponding Preset Button. Press

again to exit STORE MODE.

Frame Motion Mode

Press the Store button to enter the Motion Setting

Mode (button constantly lit). See Section 5 Frame

Motion Configuration for details.

PRESETS

The preset buttons may be used to store up to four

device settings. Each button corresponds to one

stored device preset. Simply press the button to

recall the saved preset. Once activated, the button

LED will be turned ON.

Frame selection buttons (Top row)

Press one button (1-8) to select an active frame.

After selecting an active frame, you can press the

same button to switch between Start and End

positions.

Motion operation buttons (Bottom row)

Press one button to start motion of an active frame

and the second button press pauses motion. Long

pressing the same button for about 2 seconds will

stop motion. Button LED flashes while the motion is

in progress. When the motion is stopped, the

button LED will stop flashing and turn to constant

lit.

Note: See Section 5 for Frame Motion

Configuration.

11

Page 12

2.2 Rear Panel - Connections

Firmware Upgrade

USB type A port for connection to a computer during the firmware

upgrade process.

RJ-45 port to connect the KMU-100+

The RJ-45 ports are provided on the RMC-185+ rear to connect the

KMU-100+. The communication protocol is RS-422, so use an RJ-45-toDSub cable to connect the RMC-185+ to the RS-422 port located on the

KMU-100+ rear panel.

DC In Socket

Connect the supplied 12V 0.5A PSU to this socket. The connection can

be secured by screwing the outer fastening ring of the DC In plug to the

socket.

Power On/Off Switch

Switches the device ON / OFF.

12

Page 13

Press the MENU button to enter the MENU. The RMC-185+

status or the setup menu options are displayed on the LCD

panel.

Press the dial to select a particular option and rotate the dial

to browse through the option items.

FN1

Exit

FN2

Input A Source

1 x SDI

4 x SDI

HDMI

Clone

FN3

Input B Source

1 x SDI

4 x SDI

HDMI

Clone

FN4

Output Format

PAL

NTSC

PAL 16:9

NTSC 16:9

720p 50

720p 59

720p 60

1080i 50

1080i 59

1080i 60

1080p 25

1080p 29

1080p 30

1080p 50

1080p 59

1080p 60

FN5

Audio Output

Mix

Follow

FN6

Genlock Set

Genlock

Enable

Disable

Termination

Enable

Disable

FN7

Genlock Status

Ref

Present

Loose

Lock

Unlock

Format

Detected video format

Up to 1080p60

3. Menu Setup

13

Page 14

FN8

SDI 3G Type

Type A

Type B

FN9

Output Assign

1~8, PVW, PGM

1~8, PVW, PGM

FN10

Limit

720p

1080p

None

FN11

Trigger Set

Motion No.

1 – 8

Trigger Level

Rising edge

Falling edge

FN12

KMU-100+ Ver.

FPGA / HARDWARE / NIOS / ARM

FN13

KMU-100+ Temp

FPGA Temperature

PCB Board Temperature

FN14

Firmware Ver.

RMC-185+ Firmware Version

FN1. Exits the MENU (EXIT)

Exits the setup menu mode.

FN2. Input A Source Assignment (Input A Source)

In this option, you may select a source for input A image processing. The available interfaces are:

1xSDI – SDI video interface up to 12G (SD is not supported)

4xSDI – quad SDI video

HDMI – HDMI 2.0

Clone – Input B as a source

FN3. Input B Source Assignment (Input B Source)

In this option, you may select a source for input B image processing. The available interfaces are:

1xSDI – SDI video interface up to 12G (SD is not supported)

4xSDI – quad SDI video

HDMI – HDMI 2.0

Clone – Input A as a source

FN4. Output Format Selection (Output Format)

There are many video output formats available for selection. The available video output formats

are listed as follows:

PAL

NTSC

PAL 16:9

NTSC 16:9

720p 50

720p 59

720p 60

1080i 50

1080i 59

1080i 60

1080p 25

14

Page 15

1080p 29

1080p 30

1080p 50

1080p 59

1080p 60

FN5. Audio Output

If Audio Follow is selected, audio settings are described below:

SDI Ch 1 / 2 / 3 / 4: Input A audio

SDI Ch 5 / 6 / 7 / 8: Input B audio

Audio Mix: Input A audio and Input B audio will be simultaneously on the HDMI OUT2 (PGM).

Note: The Audio Mix option will be available only if Mix HDMI OUT2 (PGM) or SDI OUT is set to

PVW / PGM.

FN6. Genlock Setting (Genlock Set)

This option enables/disables the genlock functionality and turns ON/OFF internal 75 Ohm

termination.

FN7. Genlock Status Display (Genlock Status)

Display current genlock status by returning values detected from sync signal.

FN8. Selection of SDI 3G Type (SDI 3G Type)

Enabling of 3G-SDI signal type on output ports (available modes are Type A and Type B).

FN9. Output Assign

This option sets SDI Output 1-8 to either one of 1-8, PVW and PGM.

EX: All SDI Output 1-8 can be set to PGM view.

FN10. Limit

This option limits the minimum size of the motion window.

Note: LIMIT is available for 4K input only.

FN11. External Motion Trigger Setting (Trigger Set)

In this option, you will be able to configure the external motion trigger method. Motion 1-8 can be

controlled by an external device using the level trigger method. You can either set the trigger

method to low level trigger or high level trigger.

FN12. KMU-100+ Firmware Version Display (KMU-100+ Ver.)

Upon entering the KMU-100+ Ver. Option, the KMU-100+ firmware version will be displayed.

FN13. Display of KMU-100+ FPGA and PCB Board Temperatures (KMU-100+ Temp)

In the KMU-100+ Temp option, you will be able to check measured temperatures of the KMU-100+

FPGA and PCB boards.

FN14. RMC-185+ Firmware Version Display (Firmware Ver.)

Upon entering the Firmware Ver. option, the RMC-185+ firmware version will be displayed.

15

Page 16

4. Storing Different Device Settings

The RMC-185+ allows you to store up to four device settings. Follow the procedure below to store

the current device setting to one of the preset buttons.

To store a device setting:

1. Adjust the frame positions using the joystick.

2. Push the STORE button and it will turn red.

3. Press a preset button to save the current device setting.

4. The selected preset button will remain ON for 2-3 seconds and the button LED will be turned

OFF after the device setting is successfully saved.

16

Page 17

1. First enable the rightmost M button of the

MULTIVIEW button row.

2. Press one of the STOP row buttons (buttons 1’

to 8’) to select a frame to adjust its motion

setting.

3. Use the joystick to zoom the frame and adjust

its start position (fine border frame).

4. Press the button (one of the STOP row buttons

1’ to 8’) selected at Step 2 again.

5. Frame Motion Configuration

17

Page 18

5. Use the joystick to zoom the frame and adjust

its end position (thick border frame).

6. Press the STORE button (constantly lit).

7. Use the left knob below the LCD screen to set

the Frame Motion Mode and the right knob to

set the Frame Motion Speed.

8. Press the button (one of the STOP row buttons

1’ to 8’) selected at Step 2 again to trigger the

frame motion.

18

Page 19

6. Firmware Upgrade Procedure

From time to time, Datavideo may release new firmware to either add new features or to fix

reported bugs in the current RMC-185+ firmware. Customers can update the firmware themselves

if they wish or they can contact their local dealer or reseller for assistance should they prefer this

method.

This section describes the firmware update process and it should take approximately few minutes

to complete. Once started, the update process should not be interrupted in any way as this could

result in a non-responsive unit.

Requirement

Latest firmware update files (bootloader and application firmware)

A USB A to USB A cable not longer than 2 meters

A Windows PC with USB 2.0 ports or above

1. Power off the RMC-185+ and use a USB cable (USB A to USB A) to connect the USB firmware

upgrade port on the RMC-185+ rear panel to a USB port on the PC.

2. Press and hold the four buttons indicated with at the same time.

3. With an assistant’s help, one person switches on the RMC-185+ device while another person

presses and holds the buttons indicated with .

4. The user may release the buttons once the RMC-185+ LCD panel displays the following

19

Page 20

information.

5. The RMC-185+ device (RMC-185+_U38) will appear as a removable storage device on the PC as

shown below.

6. Double click the RMC-185_U38 removable storage device and delete the “bootcode.bin” file.

7. Copy and paste the latest bootloader firmware file (bootcode.bin) into the RMC-185_U38

removable storage device.

8. Reboot the RMC-185+ device until the LCD displays the following.

9. Press the MENU key to start the firmware upgrade and do not disconnect the power before the

upgrade is complete.

20

Page 21

10. After the bootloader firmware upgrade is complete, the LCD display will show the following

and the user may proceed to upgrading the application firmware.

11. Remove bootcode.bin from the RMC-185+ device and copy and paste the application firmware

into the RMC-185+ device.

12. Reboot the RMC-185+ device again and the LCD display will now show the following.

13. The RMC-185+ device is now ready for controlling the connected KMU device.

21

Page 22

No.

Problems

Solutions

1.

What is the RJ-45 port used for?

It is used for connecting the RMC-185+ to the

KMU-100+. Please use an RJ-45-to-DSub cable.

The DSub end should be a male connector.

7. Frequently-Asked Questions

This section describes problems that you may encounter while using RMC-185+. If you have any

questions, please refer to related sections and follow all suggested solutions. If problem still exists,

please contact your distributor or the service center.

22

Page 23

RMC-185+ KMU Controller

Firmware Upgrade

USB

Power

DC 12V 0.5A

Dimensions (W x H x D)

310 x 129.98 x 170 (mm)

Net Weight

1.5 Kg

Gross Weight

2.0 Kg

Operating Temperature

0°C to 50°C (32°F to 122°F)

Humidity

10% to 80%

8. Dimensions

All measurements in millimeters (mm)

9. Specifications

23

Page 24

DATAVIDEO WORLDWIDE OFFICES

Service & Support

It is our goal to make owning and using Datavideo products a satisfying experience. Our support sta is available

to assist you to set up and operate your system. Contact your local office for specific support requests. Plus,

please visit www.datavideo.com to access our FAQ section.

China Shanghai

Datavideo Technologies China Co

601,Building 10,No.1228,

Rd.Jiangchang,

Jingan District,Shanghai

Tel: +86 21-5603 6599

Fax:+ 86 21-5603 6770

E-mail: service@datavideo.cn

China Beijing

Datavideo Technologies China Co

No. 812, Building B, Wankai Center,

No.316, Wan Feng Road, Fengtai District,

Beijing, China

Tel: +86 10-8586 9034

Fax:+86 10-8586 9074

E-mail: service@datavideo.cn

China Chengdu

Datavideo Technologies China Co

B-823,Meinian square,No.1388,

Middle of Tianfu Avenue,Gaoxin District,

Chengdu,Sichuan

Tel: +86 28-8613 7786

Fax:+86 28-8513 6486

E-mail: service@datavideo.cn

China Fuzhou

Datavideo Technologies China Co

A1-2318-19 Room,No.8, Aojiang Road,

Taijiang District,Fuzhou,Fujian,China

Tel: 0591-83211756,0591-83210187

Fax:0591-83211262

E-mail: service@datavideo.cn

China Jinan

Datavideo Technologies China Co

902, No. 1 business building,

Xiangtai Square, No. 129,

Yingxiongshan Road, Shizhong District,

Jinan City, Shandong Province, China

Tel: +86 531-8607 8813

E-mail: service@datavideo.cn

Hong Kong

Datavideo Hong K ong Ltd

G/ F.,26 Cross Lane

Wanchai, Hong Kong

Tel: +852-2833-1981

Fax:+ 852-2833-9916

E-mail: info@dat avideo.com.hk

India Noida

Datavideo India Noida

A-132, Sec-63,Noida-201307,

India

Tel: +91-0120-2427337

Fax:+91-0120-2427338

E-mail: sales@datavideo.in

India Kochi

Datavideo India Kochi

2nd Floor- North Wing, Govardhan Building,

Opp. NCC Group Headquaters, Chittoor Road,

Cochin- 682035

Tel: +91 4844-025336

Fax:+91 4844-047696

Netherlands

Data video Technologies Europe B V

Floridadreef 106

3565 AM Ut rech t,

Th e Netherlands

Tel: +31-30-261-9 6-56

Fa x: +31-30-261-9 6-57

E-mail: info@dat av ideo.nl

Singapore

Datavideo Visual Technology(S) Pte Ltd

No. 178 Paya Lebar Road #06-07

Singapore 409030

Tel: +65-6749 6866

Fa x:+65-6749 3266

E-mail:info@datavideovirtualset.com

Singapore

Data video Technologies (S ) PTE Lt d

No. 178 Paya Lebar Road #06-03

Singapore 409030

Tel: +65-6749 6866

Fa x:+65-6749 3266

E-mail:s ales@dat av ideo.sg

Taiwan

Datavideo Technologies Co. Lt d

10F. No. 176, Jian 1st Rd.,Chung Ho

District, New Taipei City 235, Taiwan

Tel: +886-2-8227-2888

Fax:+886-2-8227-2777

E-mail:service@dat avideo.com.tw

United States

Datavideo Corporat ion

7048 Elmer Avenue.

Whittier, C A 90602,

U.S.A.

Tel: +1-562-696 2324

Fax:+1-562-698 6930

E-mail:sales@datavideo.comE-mail: sales@datavideo.in

United Kingdom

Data video U K Limi te d

Brookfield House, Brookfield Industrial

Estate, Peakdale Road, Glossop,

Derbyshire, SK13 6LQ

Tel: +44-1457 851 000

Fa x: +44-1457 850 964

E-mail: sales@dat avideo.co. uk

France

Datavideo France s.a.r.l.

Cité Descartes 1, rue Albert Einstein

Champs sur Marne 774477 –

Marne la Vallée cedex 2

Tel: +33-1-60370246

Fa x: +33-1-60376732

E-mail: info@datavideo.fr

Please visit our website for latest manual update.

www.datavideo.com/product/RMC-185

All the trademarks are the properties of their respective owners. Datavideo Technologies Co., Ltd. All rights reserved 2018

Jul-11.2017

Aug-14.2018

Loading...

Loading...