Page 1

Installation & Parts Manual

V-7 Valves

Installation: M400-10

www.lcmeter.com

Page 2

Table of Contents

Description Page Number

General Information ...............................................2

Application Class Description ................................2

Specifications .........................................................3

How V-7 Valves Work.............................................3

Accessories............................................................4

New Installations ....................................................5

Retrofit Installations ...............................................5-7

Setting the Dwell ....................................................8

Setting Zero Shut-off ..............................................9

Disassembling........................................................10-11

Reassembling ........................................................11

Illustrated Parts Breakdown ...................................12-15

!!

! WARNING

!!

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury,

or death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

Publication Updates and Translations

The most current English versions of all Liquid Controls

publications are available on our website,

www.lcmeter.com. It is the responsibility of the Local

Distributor to provide the most current version of LC

Manuals, Instructions, and Specification Sheets in the

required language of the country, or the language of the

end user to which the products are shipping . If there

are questions about the language of any LC Manuals,

Instructions, or Specification Sheets, please contact your

Local Distributor.

General Information

Liquid Controls V-7 Valves are designed for a wide range

of applications and flow rates and have minimum

pressure loss. Careful engineering and construction

ensure smooth, accurate, and controlled operation.

The V-7 Series mechanically actuated piston valves are

available in 1½” and 2” sizes, and are designed for

mounting on the meter outlet to provide tight shut-off with

smooth and easy operation regardless of system line

pressure. The valves may be manually operated or

connected via a mechanical linkage to a preset counter

on the meter for singe-stage closure (for low flow

applications) or two-stage closure with dwell period to

eliminate hydraulic shock. The valves are indexible in

90º increments for up, down, or side facing outlet.

Applications Class Description

Refined petroleum products 1

Aviation and jet fuel 2

Variety of products including: liquid sugars, sweeteners, syrups, & vegetable oils 3

Treated waters & solvents where no red metals are allowed 4

Chlorinated solvents 7

Acidic pH liquids including: nitric, phosphoric, glacial acetic acids, citric juices, & vinegar 8

Crude Oil 14

Oil-based & Water-bases latex products, polyester, resins, herbicides, & nitrogen fertilizers 15

General Solvents, 200 proof alcohol 16

Batch process water meter service 20

Alkaline pH Liquids including: latex products, adhesives, & liquid fertilizers 27

Herbicides 30

Sodium Hydroxide solutions, high sulfur crude oil, & alkaline pH liquids 37

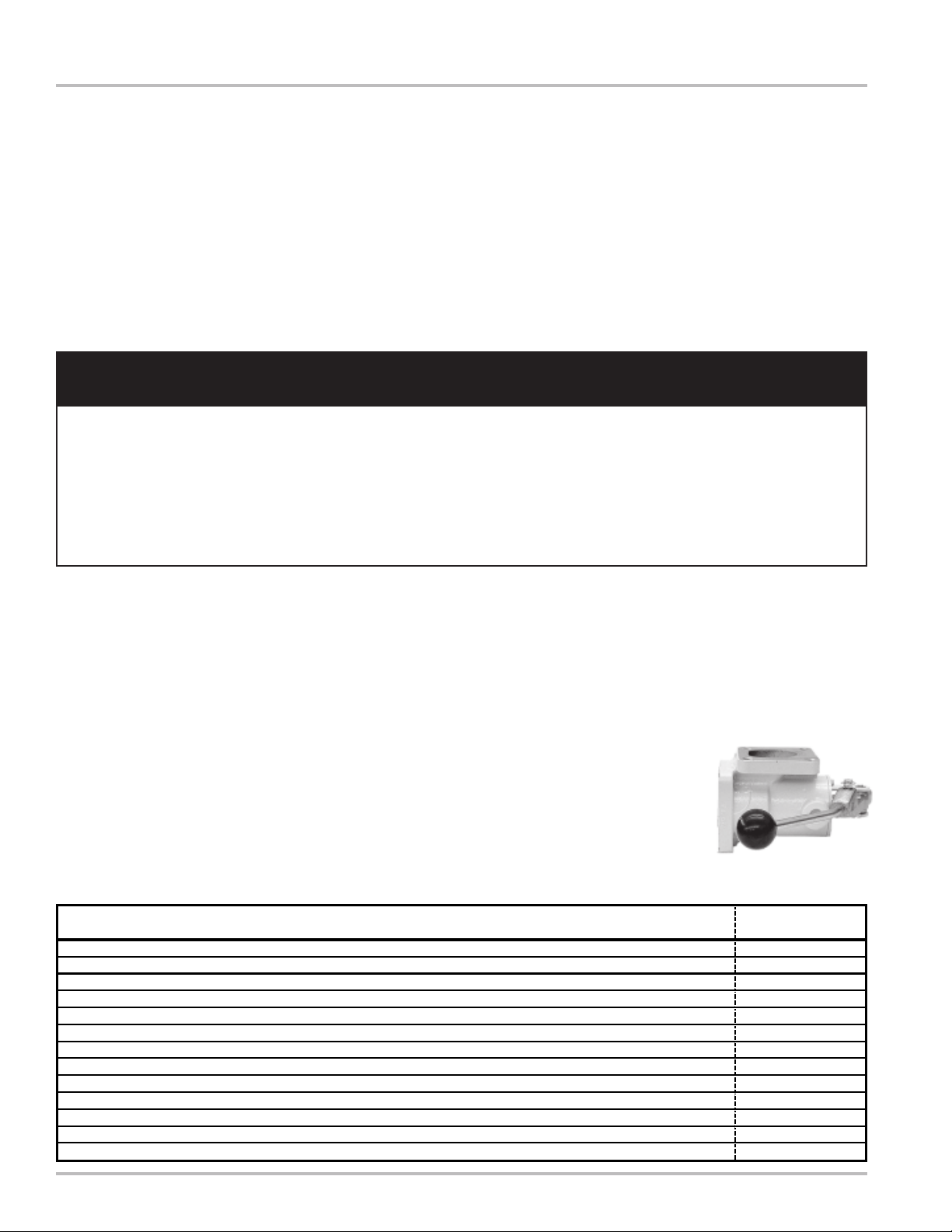

V-7 Series valves offer the important advantage of a

pressure-balanced dashpot design that ensures precise

valve response and soft closure at shut-off. Operation is

smooth and easy regardless of the line pressure since

the vector forces are directed at right angles to the valve

opening mechanism and are never in opposition to it.

Depending on the preset, the

valve may be operated as either

a two-stage valve with dwell

period shut-off or as a singlestage valve with abrupt shut-off.

Single stage valves are

recommended when the

application flow rates are low.

Figure 1: V-7 Valve

Class

Number

2

Page 3

Specifications

Model

V-7 (A2600 Series)

Used with M-5, M-7 & M-10 Meters

A2621 1½" & 2" 1, 2, 14

A2623 1½" & 2"

A2631 1½" & 2" 1, 3, 14, 15

A2651 1½" & 2" 3, 4, 14, 15, 16

A2652 1½" & 2" 1, 2, 16, 20

A2655 1½" & 2" 1, 30

A2684 1½" & 2" 20

A2690 1½" & 2" 20

A2693 1½" & 2" 20

A2670 1½" & 2" 7, 37

A2671 1½" & 2" 7, 27

A2672 1½" & 2" 7, 27, 37

A2681 1½" & 2" 8

A2682 1½" & 2" 8

Body & Seal Material

Aluminum with Viton Seal

Aluminum with Teflon Seal

Aluminum with Viton Seal

Aluminum with Viton Seal

Aluminum with Buna N Seal

Aluminum with Viton & Teflon Seal

Brass with Viton Seal

Brass with Viton Seal

Brass with Teflon Seal

Cast Iron with Viton Seal

Cast Iron with Teflon Seal

Cast Iron with Viton Seal

Stainless Steel with Viton Seal

Stainless Steel with Teflon Seal

Companion

Flanges

Working

Pressure

150 PSI

(10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

Application

Class*

1, 2, 3, 4, 14, 15,

16, 30

How V-7 Valves Work

Inside the valve housing, a cylindrical bore connects the

valve inlet and outlet. Contained within the bore is a

piston assembly. Measured liquid exiting the meter outlet

is blocked from entering the valve inlet by the piston and

seal.

As the meter operator shifts the handle to the open

position, a mechanical linkage connecting the valve to

the preset counter trip ring causes a latch to engage and

hold the valve open allowing liquid to flow.

In the open position, the valve handle assembly

compresses the piston spring and pulls the piston shaft

and the piston away from the valve inlet. As the piston is

pulled away, it disconnects from the inlet seal, allowing

liquid to flow.

In most metering applications, closing the valve is a twostage process. At a predetermined dwell period, the

preset counter, while counting down to “0”, releases a

latch mechanism, allowing the valve linkage to close to

approximately 10% of full flow. This initial closing causes

the piston inside the valve to slide toward the inlet,

restricting product flow.

As liquid is blocked by the piston, some product passes

through the dashpot washer bleed holes, creating the

hydraulic balance feature of V-7 Valves that allows the

valve to close slowly and smoothly. The dwell period

prevents hydraulic shock while permitting the preset

counter to register the remaining flow.

As the preset counter reaches “0”, the preset counter trip

ring disengages from the dwell position to the fully closed

position. This action releases the valve handle and relaxes

the piston spring, permitting the piston to contact the inlet

ring seal and complete its closure, stopping product flow.

This process is illustrated in Figure 2.

Figure 2: Valve Operation

3

Page 4

V-7 Valves

Figure 3a: Cast Iron or Aluminum

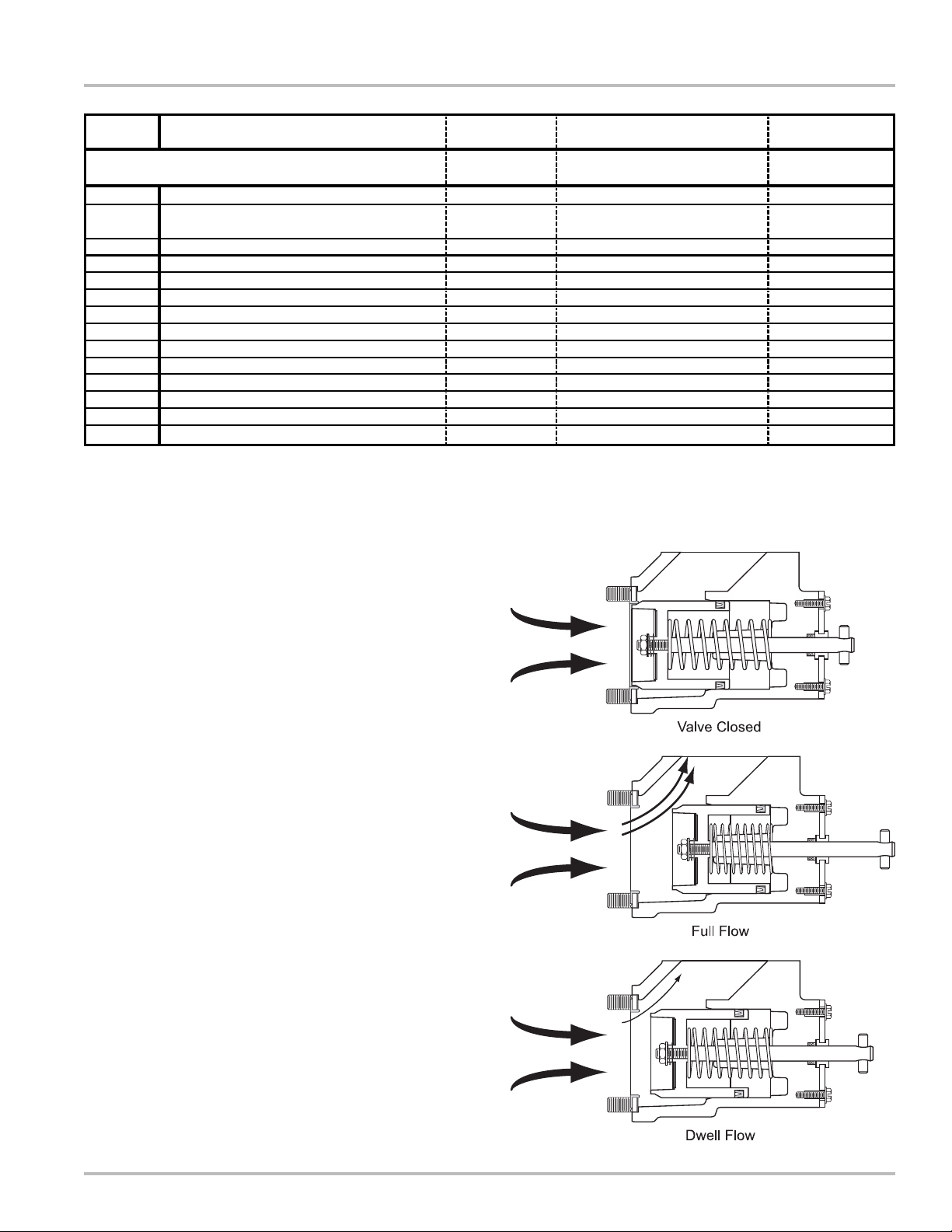

Accessories

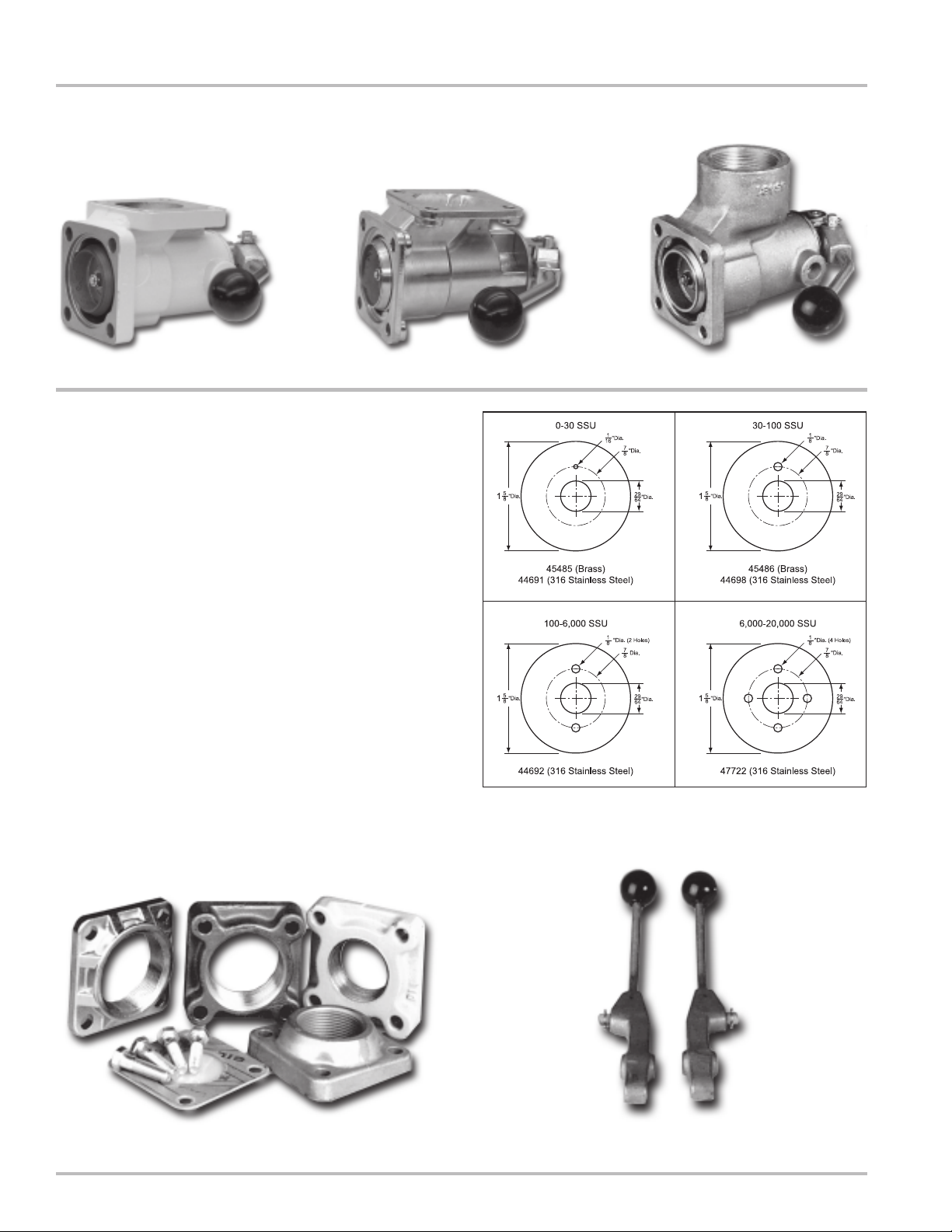

Dashpot Washers

V-7 Valves are offered with a variety of dashpot washers.

They are available in either brass or stainless steel

construction material. Four different bleed orifice

configurations (Figure 4) are available to ensure proper

closure regardless of viscosity. For viscosities greater

than 20,000 SSU, do not use a dashpot washer.

Flanges

Flanges (Figure 5) are offered in 1½ and 2 inch BSPT

and NPT sizes and weld types. Materials of construction

are aluminum, brass, cast iron, and stainless steel.

Teflon, Viton, and Buna seals and gaskets are available.

Linkage and Valve Handles

Valve handle (Figure 6) and linkage assemblies are

accessories used when normal manual ON and OFF

valve operation is desired. Different handle and linkage

configurations can be ordered separately for field

installations.

Figure 3c: BrassFigure 3b: Stainless Steel

Figure 4: Dashpot Washers

Figure 6: Left and Right Valve HandlesFigure 5: Flanges

4

Page 5

New Installations

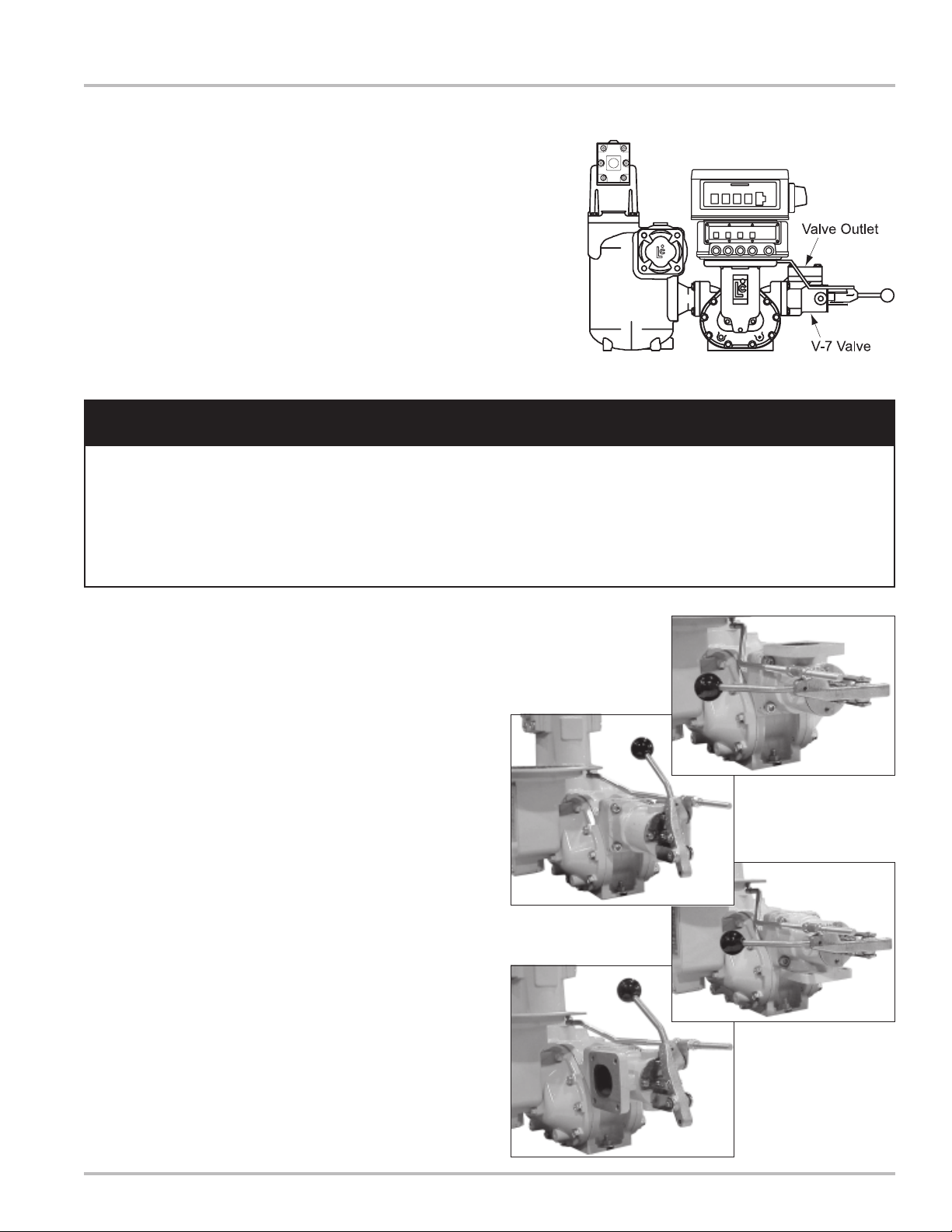

When ordered with a new metering system, the V-7

Series Valve is supplied mounted to the outlet side of the

meter as shown to the right. A liquid line must be

connected to the flange on the outlet side of the valve or

to the accompanying air check valve. The flange

connection on the V-7 valve is 1½” or 2” BSPT or NPT or

weld type.

!!

! WARNING

!!

Relieve Internal Pressure

All internal pressure must be relieved to zero pressure before

disassembly or inspection of the meter or any of the meter accessories.

V-7 Valves - Installation

Figure 7: V-7 Valve installed

Serious injury or death from fire or explosion could result from

maintenance of an improperly depressurized and evacuated system.

Retrofit Installations

Depending on the existing configuration, adding a V-7

Valve may require modification of the outlet piping.

After the internal pressure is relieved from the system,

the outlet line can be disconnected from the meter. The

new valve assembly can then be connected to the outlet

side of the positive displacement meter.

Installing the Valve

V-7 valves can be mounted in four possible positions

(Figures 8a-8d) depending on the required direction of

the valve output. The output can be front or back, top or

bottom. Standard valve position is configured with a top

outlet connection for flow from left to right and a horizontal

handle with an offset linkage assembly.

Positioning the Seal Ring

Each V-7 Valve is supplied with a seal ring. The inner

seal lip faces the valve housing and not the meter. Place

the seal on the valve and mount the valve to the meter

using the four bolts provided. Thread the four bolts into

the meter housing but do not tighten.

Figure 8a:

Standard Top

Facing Outlet

Figure 8b: Rear

Facing Outlet

Figure 8c:

Bottom Facing

Outlet

Figure 8d: Front

Facing Outlet

5

Page 6

V-7 Valves - Installation

Retrofit Installations (continued)

Attaching the Valve Handle

There are several options for valve handles. Systems

which do not use a preset use a faucet valve kit (Part

Number A2755).

For systems which use a preset, curved valve handles

are offered for left-to-right or right-to-left flow, or a straight

handle may be used. The valve handle options are listed

in the table below.

1. Line up the hole in the valve handle with the holes in

the lift bracket.

2. Insert the valve handle shaft through the lift bracket

and valve handle. Secure with one retaining ring on

each side of the lift bracket.

3. Insert the roller chain link into the valve shaft and

valve handle.

4. Slide the flat link over the ends of the roller chain

link. Secure the roller chain link with the retaining

clip.

The valve piston should be flush or slightly drawn into

the valve to ensure proper installation. Use a screwdriver

handle (Figure 10) or a wooden dowel to prop the valve

handle in the open position. This action will compress

the piston spring, drawing the piston into the housing

and allowing the valve to mount flush to the meter. With

the valve propped open, tighten the four bolts in crossing

pattern.

Figure 11 shows the valve handle mounted two different

ways. The valve on the left is opened by pulling on the

handle, the valve to the right by pushing on the handle.

Regardless of the valve or handle orientation, the link

pivot stub must face up in order to properly install the

linkage assembly.

Figure 9: Valve Handle Views

Figure 10: Handle Propped Open

Figure 11: Handle Orientations

V-7 Valve Handles for Aluminum, Brass, & Cast Iron Valves

Part Number Description

43614 Valve Handle Assembly, Curved, Right-to-Left Flow

43617 Valve Handle Assembly, Curved, Left-to-Right Flow

44685 Valve Handle Assembly, Straight

V-7 Valve Handles for Stainless Steel Valves

Part Number Description

46335 Valve Handle Assembly, Straight

45336 Valve Handle Assembly, Curved, Right-to-Left Flow

45337 Valve Handle Assembly, Curved, Left-to-Right Flow

6

Page 7

Installing the Linkage Assembly

Linkage assemblies are used with presets. The linkage

provides the connection between the valve handle and

the preset trip ring mounted on the mechanical register.

V-7 Valves - Installation

The linkage assembly is selected based on the meter/

register configuration. Linkage assemblies are available

in either straight or offset styles. These are listed in the

table below.

1. Mount the linkage assembly to the preset ring by

threading the threaded end of the ball joint into the

preset ring. Attach the linkage end to the ball joint

(Figure 13a).

2. Mount the other end of the linkage assembly to the

valve handle. Remove the retaining ring from pivot

stud on the valve handle to accomplish this.

3. Place the linkage bracket over onto the pivot stud

ensuring that the flat side of the linkage bracket is

facing the valve handle (Figures 13b & c). Secure

using the retaining ring.

Proceed with setting the dwell.

Figure 12: Linkage Assemblies

Ball Joint

Figure 13a

Figure 13b

Figure 13d: Linkage Installed

V-7 Valve Linkage Assemblies for Aluminum, Brass, & Cast Iron Valves

Part Number Style Description

49925 Offset For use on M-7 meters with TVC & V-R Preset

A2712 Straight Linkage Assembly for LC Preset

A2714 Offset Linkage Assembly for LC Preset

A2728 Offset Right-to-Left Flow with TVC & LC Preset

A2730 Straight For all Meters with a Counter Extension & LC Preset

V-7 Valve Linkage Assemblies for Stainless Steel Valves

Part Number Style Description

49922 Offset Stainless Steel for use with M-5 & M-7 Meters with V-R Preset

A2725 Straight Stainless Steel Linkage Assembly for LC Preset

A2726 Offset Stainless Steel Linkage Assembly for LC Preset

Figure 13c:

Retaining Ring

& Pivot Stud

7

Page 8

V-7 Valves

Setting the Dwell

Correct linkage adjustments avoid hydraulic shock.

Hydraulic shock occurs when a volume (mass) of liquid

moving at a high rate through a pipeline is stopped by a

valve that is suddenly closed. When the flow stops

abruptly, the mass of liquid acts as a battering ram,

causing a shock effect within the metering system. The

meter housing and internal parts receive the full impact

since the valve is located at the meter outlet. The greater

the mass, length of pipeline or velocity, the greater the

hydraulic shock and the greater the damage possibilities.

To prevent damage from hydraulic shock, a slow closure,

two-stage valve and preset should be used with the meter.

In some instances, mass, length of pipeline, or velocity

are of such a magnitude that using a two-stage valve is

ineffective. In this case, an impact absorbing, air

cushioning device should be used as an added

accessory.

The linkage between the valve and preset can be

adjusted to increase or decrease product flow during the

dwell period. To make adjustments shift the valve handle

to the slow flow or dwell setting. (See the preset counter

manual for more detail).

Figure 14: Linkage Adjustment

Turn the two 9/16 inch linkage nuts (Figure 14) located

on either side of the bracket to adjust the linkage for

proper dwell.

• On a right to left flow meter the nuts are moved to

the right to increase dwell flow and moved to the left

to decrease dwell flow.

• On a left to right flow meter the opposite is true.

Moving the nuts to the right decreases dwell flow

and moving nuts to the left increases dwell flow.

While adjusting the nuts, it is important to hold the linkage

rod firmly so that it does not move.

Proper adjustment is obtained when the far right wheel

of the preset counter (Figure 15) slows to a readable

rate and the characteristic dwell hiss is heard. Dwell

hiss is a low, resonating sound caused by slow moving

product through the valve.

When this is accomplished, tighten the adjusting nuts

ensuring that the linkage bracket is free to move, but

there is little slop between the linkage bracket and the

adjusting nuts.

Figure 15: Preset Counter

8

Page 9

Adjusting Zero Shut-off (LC Preset)

Because of the interaction between the valve and the

preset counter, some adjustment may be needed to the

preset counter so that components work at optimum

efficiency. Preset Counters assembled with meters at

the factory are adjusted for proper shut-off timing. Due

to meter system variations, such as flow rate and

viscosity, it may be necessary to make zero shut-off

adjustments.

At least two test runs should be completed before any

adjustments are made. On all presets, make a test run

using a value large enough to permit the meter to reach

its normal flow rate. If it is determined after testing that

an error in zero shut-off is indicated, correct the zero

shut-off in the following manner.

1. Start by removing the eight screws that hold the bezel

to the preset counter.

2. Remove the bezel (Figure 16a).

V-7 Valves

Figure 16a: Bezel Removal

3. Press the preset button directly below the units wheel

until the set screw appears in the opening.

4. Use a screwdriver to loosen the set screw on the

notch ring located on the left side of the units wheel

(Figure 16b). This allows for the repositioning of the

notch ring and units wheel.

5a. Early Shut-off

To correct an early shut-off, hold the notch ring in

place (Figure 16c) and move the numbers wheel

down enough to correct the misalignment.

5b. Late Shut-off

To correct a late shut-off, hold the notch ring in place

(Figure 16c) and move the numbers wheel up enough

to correct the misalignment.

6. After each adjustment, carefully tighten the set screw.

Take care not to strip the threads with excessive

torque.

7. After running two test runs, the zero should be

centered in the window. If not, reset the notch ring

and repeat the procedure.

Figure 16b: Set Screw & Notch

Ring

8. Ensure that the set screw is tight and remount the

bezel.

Figure 16c: Set Screw Adjustment

9

Page 10

V-7 Valves

Disassembling the Valve

!!

! WARNING

!!

Relieve Internal Pressure

All internal pressure must be relieved to zero pressure before

disassembly or inspection of the meter or any of the meter accessories.

Serious injury or death from fire or explosion could result from

maintenance of an improperly depressurized and evacuated system.

To perform maintenance on a V-7 valve, or to repair a V7 valve, it must be removed from the meter. Note the

orientation of the valve so that it can be replaced in the

proper orientation. Drain all the fluid from the metering

system prior to valve removal.

1. Remove the four screws and washers holding the

valve to the meter.

2. Remove the valve from the piping connection.

NOTE: The valve piston is under pressure exerted by

the valve compression spring. Exercise caution when

disassembling the valve.

3. Place the valve on a flat surface with the valve piston

facing down (Figure 17a).

4. Remove the retaining clip from the connection link.

A screwdriver may be needed to pry the retaining

clip off (Figure 17b).

5. Press down on the valve housing so that the valve

piston is forced into the valve, pushing the valve shaft

and handle away from the valve housing.

6. While keeping pressure on the valve, remove the

two pieces of the connection link (Figure 17c-d).

7. Slowly release the valve until the compression spring

exerts no pressure. As the valve housing is lifted,

the piston assembly and compression spring should

easily slide out of the housing (Figure 17e). The

piston and seals may now be inspected, cleaned and

replaced as needed.

Figure 17a

Figure 17b

Figure 17c

Figure 17e: Piston Assembly Removed

10

Figure 17d

Page 11

Disassembling the Valve (continued)

Disassembling the Piston Assembly

8. Use a 7/16” wrench to remove the nut from the valve

shaft (Figure 18a).

9. Remove the nut, washer, spring, dashpot washer,

and piston from the valve shaft (Figure 18b).

Reassembling the Valve

1. Place the piston on the valve shaft.

2. Place the dashpot washer, spring, and washer on

the valve shaft and secure by placing the nut on the

end of the valve shaft.

V-7 Valves

3. Place the compression spring into the valve housing.

4. Insert the valve shaft and piston assembly into the

valve housing. The piston will rest on the

compression spring.

5. Place the assembly on a flat surface with the piston

facing down.

6. Press down on the valve housing, compressing the

compression spring and forcing the end of the valve

shaft to protrude out of the valve housing.

7. While keeping pressure on the valve assembly, insert

the link connector through the valve shaft opening

and the valve handle opening.

8. When the link connector in completely inserted

through these two elements, place the flat end of the

link connector over the two studs and secure with

the retaining clip.

When reassembly of the V-7 valve is complete, it may be

returned to service. Follow the installation instructions

which begin on Page 5.

Figure 18a: Piston Assembly

Figure 18b: Piston Assembly Disassembled

11

Page 12

Illustrated Parts Breakdown - V-7 Aluminum Valves

A2655 Shown

Item No. Description Part No.

110 Valve Housing 43605

133 Piston 43607

220 Piston Sub-Assembly 49808

318 Lift Bracket 43652

337 Roller Chain Link 07103

354 Lower Seal Ring 43626

370 Valve Shaft 43612

380 Dashpot Washer Spring 43620

382 Compression Spring 43678

453 O-Ring (2) 09275

465 Quad Ring, Viton 07832

516 Sleeve Bearing 07102

532 Self Locking Nut 06050

553 Valve Handle Shaft 45345

564 Retaining Ring (2) 07304

572 Retaining Ring 06044

606 Screw, #10-24 x .625 (4) 09079

626 Screw, .375-16 x 1.25 (4) 06991

724 Flat Washer 06635

727 Dashpot Washer (See Page 4)

738 Flat Washer (4) 04607

Model

Num be r

It e m No. Par t No .

110

133

220

318

337

354

370

380

382

388

424

446

453

465

516

532

553

564

572

606

626

724

738

780

A2621 A2623 A2631 A2651 A2652 A2655

43605 44695 43605 43605 43605 43605

44658 43607 43602 43602 43602 43607

N/S 4980 8 N/S N/S N/S 49808

43652 43652 43652 43652 43652 43652

07103 07103 07103 07103 07103 07103

43626 43674 43626 43626 43608 43626

43612 43612 43612 43612 43612 43612

43620 43620 N/A 43620 43620 43620

N/A 43678 43678 43678 43678 43678

N/A 0694 3 N/A N/A N/A N/A

N/A 4581 8 N/A N/A N/A N/A

N/A 4469 6 N/A N/A N/A N/A

09275 N/A 09275 09275 07443 09275

07822 07832 07253 07253 06848 07832

07102 07102 07102 07102 07102 07102

06050 06050 06050 06050 06050 06050

45345 45345 45345 45345 45345 45345

07304 07304 07304 07304 07304 07304

N/A 0604 4 N/A N/A N/A 06044

09079 09079 09079 09079 09079 09079

06991 06991 06991 06991 06991 06991

06635 06635 N/A 06635 06635 06635

04607 04607 04607 04607 04607 04607

N/A 4367 2 N/A N/A N/A N/A

*N/S = Not for Sale

12

Page 13

Illustrated Parts Breakdown - V-7 Brass Valves

A2690 Shown

Item No. Description Part No.

110 Valve Housing 45481

133 Piston 45483

220 Piston Sub-Assembly N/S*

310 Valve Orifice Plate 45099

318 Lift Bracket 43652

337 Roller Chain Link 07103

354 Lower Seal Ring 43626

370 Valve Stem 45484

380 Dashpot Washer Spring 43620

382 Compression Spring 43678

453 O-Ring (2) 09275

465 Quad Ring 07253

516 Sleeve Bearing 07102

532 Stop Nut 07401

553 Valve Handle Shaft 45345

564 Retaining Ring (2) 07304

572 Retaining Ring 07925

606 Screw, #10-24 x .625 (4) 07295

626 Screw, .375-16 x 1.25 (4) 07690

738 Flat Washer (4) 06166

724 Flat Washer 06635

Model

Number

Item No.

110 N/S* 45481 N/S

133 45483 45483 45454

220 N/S N/S N/S

310 45099 45099 45099

318 43652 43652 43652

337 07103 07103 07103

354 43626 43626 43674

370 45484 45484 45484

380 43620 43620 43620

382 43678 43678 43678

388 N/A N/A 44696

424 N/A N/A 45818

446 N/A N/A 06943

453 09275 09275 N/A

465 07253 07253 07832

516 07102 07102 07102

532 07401 07401 07401

553 45345 45345 45345

564 07304 07304 07304

572 N/A 07925 06044

573 07925 N/A 07925

606 07295 07295 07295

626 07690 07690 07497

738 04607 06166 04607

724 06635 06635 06635

780 N/A N/A 43672

A2684 A2690 A2693

Part No.

*N/S = Not for Sale

13

Page 14

Illustrated Parts Breakdown - V-7 Cast Iron Valves

A2672 Shown

Item No. Description Part No.

110 Valve Housing 44689

133 Piston 44690

220 Piston Sub-Assembly N/S*

318 Lift Bracket 43652

337 Roller Chain Link 07103

354 Lower Seal Ring 43674

370 Valve Shaft 43612

380 Dashpot Washer Spring 43620

382 Compression Spring 43678

388 Compression Spring 44696

424 Flange Gasket 45818

446 V-Ring Seal 06943

465 Seal, Teflon 07832

512 Sleeve Bearing 07464

516 Sleeve Bearing 07102

532 Self Locking Nut 06050

553 Valve Handle Shaft 45345

564 Retaining Ring (2) 07304

572 Retaining Ring 06044

606 Screw, #10-24 x .625 (4) 07295

626 Screw, .375-16 x 1.25 (4) 07319

724 Flat Washer 06635

738 Flat Washer (4) 04607

780 Flat Washer 43672

Model

Number

Item No.

110 44682 44682 44689

133 44684 44690 44690

220 N/S N/S N/S

318 43652 43652 43652

337 07103 07103 07103

354 43626 43626 43674

370 43612 43612 43612

380 43620 43620 43620

382 43678 43678 43678

388 N/A N/A 44696

424 N/A N/A 45818

446 N/A N/A 06943

453 09275 09275 N/A

465 07253 07832 07832

512 07464 07464 07464

516 07102 07102 07102

532 06050 06050 06050

553 45345 45345 45345

564 07304 07304 07304

572 N/A 06044 06044

606 07295 07295 07295

626 07319 07319 07319

724 06635 06635 06635

738 04607 04607 04607

780 N/A N/A 43672

A2670 A2671 A2672

Part No.

*N/S = Not for Sale

14

Page 15

Illustrated Parts Breakdown - V-7 Stainless Steel Valves

A2682 Shown

Item No. Description Part No.

133 Piston 48567

208 Valve Housing N/S*

220 Piston Sub-Assembly N/S

318 Lift Bracket 45339

337 Roller Chain Link (2) 45342

354 Lower Seal Ring 43626

370 Valve Shaft 48566

380 Dashpot Washer Spring 43620

381 Spacer (2) 45343

382 Compression Spring 43678

383 Bearing 45340

388 Bushing 48565

424 Flange Gasket 45818

446 Seal 09244

461 O-Ring, Teflon 09246

463 O-Ring, Teflon 49881

465 Seal, Teflon 07832

532 Self Locking Nut 06050

550 Valve Shaft (2) 45346

553 Valve Handle Shaft 45345

561 Retaining Ring (4) 07524

564 Retaining Ring (2) 07523

570 Retaining Ring 42606

572 Retaining Ring 06044

606 Screw, #10-24 x .625 (4) 07521

626 Screw, .375-16 x 1.25 (4) 07497

724 Flat Washer 06635

738 Flat Washer (4) 06166

781 Lock Washer (4) 07121

Model

Number

Item No.

110 N/S* N/S

133 48567 48567

208 N/S N/S

220 N/S N/S

318 45339 45339

337 45342 45342

354 43626 43674

370 48566 48566

380 43620 43620

381 45343 45343

382 43678 43678

383 45340 45340

388 48565 48565

424 N/A 45818

446 09256 09244

*N/S = Not for Sale

A2681 A2682

Part No.

Model

Number

Item No.

461 09246 09246

463 49881 49881

465 07832 07832

532 06050 06050

550 45346 45346

553 45345 45345

561 07524 07524

564 07523 07523

570 42606 42606

572 06044 06044

606 07521 07521

626 07497 07497

724 06635 06635

738 06166 06166

781 07121 07121

A2681 A2682

Part No.

15

Page 16

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2006 Liquid Controls

Pub. No. 48405

(06/06)

Loading...

Loading...