Page 1

Installation & Parts Manual

V-15, V -30, VS-3, and VS-4 Valves

Installation: M400-20

www.lcmeter.com

Page 2

Table of Contents

Description Page Number

General Information ..................................................................... 2

Specifications............................................................................... 3

Application Class Description ...................................................... 3

V-15 & V-30 Valves ...................................................................... 4-10

General ........................................................................... 4

New Installations ............................................................. 5

Retrofit Installations......................................................... 6-7

Disassembling................................................................. 7-8

Reassembling ................................................................. 8

Setting the Dwell ............................................................. 9

Setting Zero Shutoff ........................................................ 10

VS-3 & VS-4 Valves ..................................................................... 11-15

General ........................................................................... 11

New Installations ............................................................. 12

Retrofit Installations......................................................... 13

Disassembling................................................................. 14

Reassembling ................................................................. 15

Illustrated Parts Breakdown......................................................... 16-23

V-15 Valve .......................................................................26-17

V-30 Valve .......................................................................18-19

VS-3 Valve....................................................................... 20-21

VS-4 Valve....................................................................... 22-23

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our website, www.lcmeter.com.

It is the responsibility of the Local Distributor to provide the most current version of LC Manuals, Instructions, and

Specification Sheets in the required language of the country, or the language of the end user to which the products are

shipping . If there are questions about the language of any LC Manuals, Instructions, or Specification Sheets, please

contact your Local Distributor.

!!

WARNING WARNING

!

WARNING

!!

WARNING WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury,

or death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

General Information

Liquid Controls valves are designed for a wide range of

applications and flow rates and have minimum head loss.

Careful engineering and construction ensure smooth,

accurate, and controlled operation.

The V-Series mechanically actuated piston valves are

available in 3” and 4” sizes, and are designed for

mounting on the meter outlet to provide tight shut-off with

smooth and easy operation regardless of system line

pressure. The valves may be manually operated or

connected via a mechanical linkage to a preset counter

on the meter for singe-stage closure (for low flow

applications) or two-stage closure with dwell period to

eliminate hydraulic shock. The valves are indexible in

90º increments for up, down, or side facing outlet.

2

Page 3

Specifications

r

Model

V-15 (A-3600 Series)

A3610 3" 1, 16

A3611 3" 1, 3, 14

A3612 3" 1, 16

A3620 3" 3, 4, 14, 15

A3622 3" 2, 14, 15

A3624 3" 2

V-30 (A-4600 Series)

A4610 4" 1, 14, 16

A4611 4" 1, 3, 14

A4612 4" 1, 14, 16

A4622A 4" 2

A4623 4" 1, 3, 4, 15

A4624 4" 2

Model

VS-3 (A-36500 Series)

A36501 3" 1, 16

A36502 3" 14

A36521 3" 16

A36522 3" 7

A36551 3" 1

A36552 3" 1

A36572 3" 27, 37

A36582 3" 7, 27

VS-4 (A-46500 Series)

A46501 4" 1, 14, 16

A46502 4" 14

A46521 4" 16

A46522 4" 14

A46551 4" 14

A46552 4" 14

Body & Seal Material

Aluminum with Vit on Seal

Aluminum with Vit on Seal

Aluminum with Teflon S eal

Aluminum with Vit on Seal

Aluminum with Teflon S eal

Aluminum with Vit on Seal

Aluminum with Vit on Seal

Aluminum with Vit on Seal

Aluminum with Teflon S eal

Anodized Aluminum with Tef l on Seal

Aluminum with Vit on Seal

Aluminum with Vit on Seal

Body & Seal Material

Steel with Viton Seal, 275# Flange

Steel with Viton Seal, 275# Flange

Steel with Teflon Seal, 275# Flange

Steel with Teflon Seal, 275# Flange

Steel with Viton Seal, 300# Flange

Steel with Viton Seal, 300# Flange

Steel with Viton Seal, 150# FF

Steel with Teflon Seal, 150# FF

Steel with Viton Seal, 275# Flange

Steel with Viton Seal, 275# Flange

Steel with Teflon Seal, 275# Flange

Steel with Viton Seal, 275# Flange

Steel with Viton Seal, 300# Flange

Steel with Viton Seal, 300# Flange

Companion

Flanges

Companion

Flanges

Working

Pressure

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

150 PSI (10.3 BAR)

Working

Pressure

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

300 PSI (20.7 BAR)

Application

Class*

Application

Class*

Applications Class Description

Refined petroleum products

Aviation and jet fuel

Variety of products including: liquid sugars, sweeteners, syrups, & vegetable oils

Treated waters & solvents where no red metals are allowed

Chlorinated solvents

Crude Oil

Oil-based & Water-bases latex products, polyester, resins, herbicides, & nitrogen fertilizers

General Solvents, 200 proof alcohol

Alkaline pH Liquids including: latex products, adhesives, & liquid fertilizers

Sodium Hydroxide solutions, high sulfur crude oil, & alkaline pH liquids

Class

Numbe

1

2

3

4

7

14

15

16

27

37

3

Page 4

V-15 & V -30 Valves

General

V-15 valves are designed for use on M-15 and M-25

positive displacement flowmeters; V-30 valves are for use

on M-30, M-40, and M-60 positive displacement

flowmeters.

V-15 & V-30 valve operation is smooth and easy

regardless of the line pressure since the vector forces

are directed at right angles to the valve opening

mechanism and are never in opposition to it.

Depending on the preset, the valve may be operated as

either a two-stage valve with dwell period shut-off or as

a single-stage valve with abrupt shut-off. Single stage

valves are recommended when the application flow rates

are low.

How V-15 & V-30 Valves Work

Inside the valve housing, a cylindrical bore connects the

valve inlet and outlet. Contained within the bore is a

piston assembly . Measured liquid exiting the meter outlet

is blocked from entering the valve inlet by the piston and

seal.

As the meter operator shifts the handle to the open

position, a mechanical linkage connecting the valve to

the preset counter trip ring causes a latch to engage and

hold the valve open allowing liquid to flow.

In the open position, the valve handle assembly

compresses the piston spring and pulls the piston shaft

and the piston away from the valve outlet. As the piston

is pulled away, it disconnect s from the inlet seal, allowing

liquid to flow.

Figure 1: V-15 & V-30 Valves

In most metering applications, closing the valve is a twostage process. At a predetermined dwell period, the

preset counter, while counting down to “0”, releases a

latch mechanism, allowing the valve to close to

approximately 10% of full flow. This initial closing causes

the piston inside the valve to slide toward the outlet,

restricting product flow.

As liquid is blocked by the piston, some product passes

through the valve. The dwell period prevents hydraulic

shock while permitting the preset counter to register the

remaining flow.

As the preset counter reaches “0”, the preset counter

trip ring disengages from the dwell position to the fully

closed position. This action releases the valve handle

and relaxes the piston spring, permitting the piston to

contact the outlet ring seal and complete its closure,

stopping product flow.

Figure 2: Valve Operation

4

Page 5

Accessories

Flanges

Flanges are offered in 3 and 4 inch BSPT and NPT sizes

and weld types. Material of construction is aluminum.

Teflon, Viton, and Buna seals and gaskets are available.

Linkage and Valve Handles

Valve handle and linkage assemblies (Figure 3) are

accessories used when normal manual ON and OFF

valve operation is desired. Different handle and linkage

configurations can be ordered separately for field

installations.

There are two valve handle options. When using a

mechanical preset, the 40984 curved handle (provided

as part of the linkage assembly) is used with both the V 15 and V-30 valves. For applications without a preset,

the A3750 faucet valve handle kit is used.

Unlike the V-7 Valves, the V-15 and V-30 linkage

assemblies come complete with the 40984 handle. The

available Linkage Assemblies for V-15 and V-30 valves

are listed in the table below.

V-15 & V-30 Valves

Figure 3: Linkage Assemblies

V-15 Valve Linkage Assemblies

Part Number Style Description

A3710 Offset Linkage Assembly for LC Preset

A3711 Offset Linkage Assembly for LC Preset

A3712 Offset For use with M-15 with a V-R Preset & Microswitch

A3718 Offset For use with M-30 Class 7 Meters with LC Preset

A3730 Offset For use with M-15 through M-60 & MS-15 through MS-75 Spec with LC Preset

V-30 Valve Linkage Assemblies

Part Number Style Description

A4710 Offset Linkage Assembly for LC Preset

A5712 Offset For use with M-60 and MS-30 without a Counter Extension

Installation

New Installations

When ordered with a new metering system, the V-15 or

V-30 Series Valve is supplied mounted to the outlet side

of the meter as shown in Figure 4. A liquid line must be

connected to the flange on the outlet side of the valve or

to the accompanying check valve. The flange connection

on the V-15 valve is 3” BSPT or NPT. The flange

connection on the V-30 valve is 4” BSPT or NPT. Weldtype flanges are available as an option.

V-15 Valve

Figure 4: V-15 Valve Installed

5

Valve Outlet

Page 6

V-15 & V-30 Valves - Installation

Retrofit Installations

!!

! WARNING

!!

Relieve Internal Pressure

All internal pressure must be relieved to zero pressure before

disassembly or inspection of the meter or any of the meter accessories.

Serious injury or death from fire or explosion could result from

maintenance of an improperly depressurized and evacuated system.

Depending on the existing configuration, adding a V-15

or V-30 V alve may require modification of the outlet piping.

After the internal pressure is relieved from the system,

drain all the fluid from the flowmeter and accessories.

The outlet line can then be disconnected from the

flowmeter.

Installing the Valve

The V-15 or V-30 valve is installed on the outlet side of

the flowmeter. The valve may be installed in one of four

orientations as shown in Figure 5. Determine the

orientation desired and then attach the flowmeter using

the four bolts and washers provided. Tighten the bolt s in

a crossing pattern.

Installing the Linkage Assembly

The handle and linkage assembly is provided with the V15 and V-30 Valves. The handle and linkage may need

to be repositioned depending on the valve orientation.

Refer to Figure 5 to determine the handle and linkage

positions based on the valve orientation.

Rear Facing Outlet

Front Facing Outlet

The valve handle mounts on either side of the valve shaft.

Mount the valve handle to the valve shaft and tighten.

With the handle securely mounted to the valve shaft, the

linkage assembly can be connected to the preset ring

located under the mechanical register.

The linkage assembly connects to the preset ring via the

ball joint extension (Figure 6a). The ball joint extension

is mounted using the screw and nut provided.

Bottom Facing Outlet

Top Facing Outlet

Figure 5: Valve Orientations

6

Page 7

Retrofit Installations (continued)

Mount the ball joint extension to the preset ring by

threading the screw into one of the holes at the back of

the register assembly. Thread the nut in place on the

screw.

With the ball joint extension secure on the preset ring,

attach the linkage assembly (Figure 6b). The linkage

assembly may require adjustment in order to mount to

the ball joint extension. If this is the case, either loosen

the handle and reposition on the valve shaft, or loosen

the nuts at the handle pivot (Figure 6c).

Once the handle and linkage assembly is secure,

proceed with setting the dwell and zero shut-off as

described on Pages 9-10.

Disassembling the Valve

The V-15 & V-30 Valves are under pressure from the

compression spring. The safest method for opening the

valve for service or maintenance is to place the valve on

a flat surface with the valve outlet facing down.

V-15 & V -30 Valves - Installation

Figure 6a: Ball Joint Figure 6b: Linkage Attached to

Ball Joint

Figure 6c: Handle Pivot

1. Loosen the four bolts (Items 610 & 611) located on

the valve cap (Item 124). The compression spring

will exert a force on the cap and push it up.

2. When the four bolts are almost completely removed,

check to see if the compression spring is still exerting

a force on the cap. If not, remove the four bolts and

washers completely . If there is still force on the cap,

remove two screws from opposite sides of the cap.

While bracing the cap with one hand, remove the

other two bolts and carefully release the cap until

the compression spring exerts no force.

3. Note the orientation of the cap and valve handle.

Remove the cap (Item 124). The internal

components are attached to the cap and will come

out of the valve housing with the cap.

4. T o disassemble the cap assembly , it will be necessary

to remove the four cotter pins which hold the cup

(Item 133) to the links on each side of the cup. This

is only necessary when replacing the compression

spring or the cup.

5. T o replace the dashpot washer , remove the retaining

ring on the end of the guide shaft.

Figure 7: V-15 Valve

Cotter Pins

Retaining Ring

Figure 8: Piston

7

Page 8

V-15 & V-30 Valves - Reassembly

Disassembling the Valve (continued)

6. Reposition the valve assembly so that the outlet side

is facing up.

7. Remove the two screws (Item 615) that hold the guide

(Item 138) and seal in place and remove the guide

and seal.

The valve shaft (Item 368) is not removable, but it is not

necessary to remove it in order to inspect or replace the

O-Rings and bearings of the valve shaft.

8. Remove the retaining ring (Item 564) from one side

of the valve shaft.

9. Remove the shaft seal (Item 270), the bearing (Item

140) the O-Ring (Item 455), the inner bearing (Item

260) and the O-Ring (Item 450).

10. Inspect and replace these components as needed.

Figure 9: V-15 Valve Guide

11. Repeat steps 8-10 for the other side of the valve shaft.

Reassembling the Valve

For reassembly, refer to Figures 7 & 10 or the parts

breakdown on Pages 17 & 19.

1. Place the seal (Item 354) into the valve housing.

2. Place the guide (Item 138) into the valve outlet.

3. Secure the seal and guide using the two screws

(Items 615). Tighten the screws.

4. Turn the valve so that the outlet faces down.

5. Reassemble the valve by placing the dashpot washer

and retaining ring on the end of the guide shaft.

6. Place the complete cap assembly on the valve

housing remembering to orient the valve handle in

the same position as it was prior to disassembling.

7. Insert the four screws and washers into the valve

Figure 10: V-15 Valve Cap

cap and tighten by alternately tightening each screw

a few turns so that the cup (Item 133) slides evenly

over the guide (Item 138).

8. When the cap rests against the valve housing evenly ,

tighten all four screws in a crossing pattern.

9. If the valve shaft components were removed for

inspection or replacement, reassemble the valve

shaft components following the drawing above.

10. Insert the O-Ring (Item 450), the Inner bearing (Item

260), the next O-Ring (Item 455), the next bearing

(Item 140), the shaft case seal (Item 270) and secure

with the retaining ring (Item 564).

This completes reassembly. The valve may be placed

back in service. Refer to Pages 6 & 7 for installation

instructions.

8

Page 9

Setting the Dwell

Correct linkage adjustments avoid hydraulic shock.

Hydraulic shock occurs when a volume (mass) of liquid

moving at a high rate through a pipeline is stopped by a

valve that is suddenly closed. When the flow stops

abruptly, the mass of liquid acts as a battering ram,

causing a shock effect within the metering system. The

meter housing and internal parts receive the full impact

since the valve is located at the meter outlet. The greater

the mass, length of pipeline or velocity, the greater the

hydraulic shock and the greater the damage possibilities.

T o prevent damage from hydraulic shock, a slow closure,

two-stage valve and preset should be used with the meter .

In some instances, mass, length of pipeline, or velocity

are of such a magnitude that using a two-stage valve is

ineffective. In this case, an impact absorbing, air

cushioning device should be used as an added

accessory.

The linkage between the valve and preset can be

adjusted to increase or decrease product flow during the

dwell period. T o make adjustment s shift the valve handle

to the slow flow or dwell setting. (See the preset counter

manual for more detail).

V-15 & V -30 Valves - Installation

Figure 11: Linkage Adjustment

Turn the two 9/16 inch linkage nuts (Figure 11) located

on either side of the bracket to adjust the linkage for

proper dwell.

• On a right to left flow meter the nuts are moved to

the right to increase dwell flow and moved to the left

to decrease dwell flow.

• On a left to right flow meter the opposite is true.

Moving the nuts to the right decreases dwell flow

and moving nuts to the left increases dwell flow.

While adjusting the nuts, it is important to hold the linkage

rod firmly so that it does not move.

Proper adjustment is obtained when the far right wheel

of the preset counter (Figure 12) slows to a readable

rate and the characteristic dwell hiss is heard. Dwell

hiss is a low, resonating sound caused by slow moving

product through the valve.

When this is accomplished, tighten the adjusting nuts

ensuring that the linkage bracket is free to move, but

there is little slop between the linkage bracket and the

adjusting nuts.

Figure 12: Preset Counter

9

Page 10

V-15 & V-30 Valves - Installation

Adjusting Zero Shutoff (LC Preset)

Because of the interaction between the valve and the

preset counter, some adjustment may be needed to the

preset counter so that components work at optimum

efficiency. Preset Counters assembled with meters at

the factory are adjusted for proper shut-off timing. Due

to meter system variations, such as flow rate and

viscosity, it may be necessary to make zero shut-off

adjustments.

At least two test runs should be completed before any

adjustments are made. On all presets, make a test run

using a value large enough to permit the meter to reach

its normal flow rate. If it is determined after testing that

an error in zero shut-off is indicated, correct the zero

shut-off in the following manner.

1. Start by removing the eight screws that hold the bezel

to the preset counter.

2. Remove the bezel (Figure 13a).

Figure 13a: Bezel Removal

3. Press the preset button directly below the units wheel

until the set screw appears in the opening.

4. Use a screwdriver to loosen the set screw on the

notch ring located on the left side of the units wheel

(Figure 13b). This allows for the repositioning of the

notch ring and units wheel.

5a. Early Shutoff

To correct an early shut-off, hold the notch ring in

place (Figure 13c) and move the numbers wheel

down enough to correct the misalignment.

5b. Late Shut-off

T o correct a late shut-of f, hold the notch ring in place

(Figure 13c) and move the numbers wheel up enough

to correct the misalignment.

6. After each adjustment, carefully tighten the set screw.

Take care not to strip the threads with excessive

torque.

7. After running two test runs, the zero should be

centered in the window. If not, reset the notch ring

and repeat the procedure.

Figure 13b: Set Screw & Notch

Ring

8. Ensure that the set screw is tight and remount the

bezel.

Figure 13c: Set Screw Adjustment

10

Page 11

General

VS-3 valves are designed for use on MS-30 and MS-40

steel case, positive displacement flowmeters; VS-4

valves for use on MS-75 steel case, positive displacement

flowmeters.

VS-3 & VS-4 valve operation is smooth and easy

regardless of the line pressure since the vector forces

are directed at right angles to the valve opening

mechanism and are never in opposition to it.

Depending on the preset, the valve may be operated as

either a two-stage valve with dwell period shut-off or as

a single-stage valve with abrupt shut-off. Single stage

valves are recommended when the application flow rates

are low.

How VS-3 & VS-4 Valves Work

Inside the valve housing, a cylindrical bore connects the

valve inlet and outlet. Contained within the bore is a

piston assembly . Measured liquid exiting the meter outlet

is blocked from exiting the valve outlet by the piston and

seal.

VS-3 & VS-4 Valves

Figure 14: VS-3 & VS-4 Valves

As the meter operator shifts the handle to the open

position, a mechanical linkage connecting the valve to

the preset counter trip ring causes a latch to engage and

hold the valve open allowing liquid to flow.

In the open position, the valve handle assembly

compresses the piston spring and pulls the piston shaft

and the piston away from the valve outlet. As the piston

is pulled away , it disconnects from the outlet seal, allowing

liquid to flow.

In most metering applications, closing the valve is a twostage process. At a predetermined dwell period, the

preset counter, while counting down to “0”, releases a

latch mechanism, allowing the valve to close to

approximately 10% of full flow. This initial closing causes

the piston inside the valve to slide toward the outlet,

restricting product flow.

As liquid is blocked by the piston, some product passes

through the valve. The dwell period prevents hydraulic

shock while permitting the preset counter to register the

remaining flow.

As the preset counter reaches “0”, the preset counter

trip ring disengages from the dwell position to the fully

closed position. This action releases the valve handle

and relaxes the piston spring, permitting the piston to

contact the outlet ring seal and complete its closure,

stopping product flow.

Figure 15: Valve Function

11

Page 12

VS-3 & VS-4 Valves - Installation

Accessories

Flanges

Flanges are offered in 3 and 4 inch BSPT and NPT sizes

and weld types. Material of construction is steel. Teflon,

Viton, and Buna seals and gaskets are available.

Linkage and Valve Handles

Valve handle and linkage assemblies are accessories

used when normal manual ON and OFF valve operation

is desired. Different handle and linkage configurations

can be ordered separately for field installations.

VS-3 Valve Linkage Assemblies

Part Number Style Description

A3730 Offset For use with M-15 through M-60 & MS-15 through MS-40

A5712 Offset For use with M-60 and MS-30 without a Counter Extension

VS-4 Valve Linkage Assemblies

Part Number Style Description

A4710 Offset Linkage Assembly for LC Preset

The VS-3 and VS-4 linkage assemblies come complete

with a handle. The available Linkage Assemblies for VS3 and VS-4 valves are listed in the table below.

Installation

New Installations

When ordered with a new metering system, the VS-3 or

VS-4 Series V alve is supplied mounted to the outlet side

of the meter as shown in Figure 16. A liquid line must be

connected to the flange on the outlet side of the valve or

to the accompanying check valve as shown in the figure

to the right. The flange connection on the VS-3 valve is

3” BSPT or NPT. The flange connection on the VS-4

valve is 4” BSPT or NPT . W eld-type flangers are available

as an option.

Valve

Outlet

Figure 16: VS Valve Installed

12

VS-3 Valve

Page 13

Retrofit Installations

!!

! WARNING

!!

Relieve Internal Pressure

All internal pressure must be relieved to zero pressure before

disassembly or inspection of the meter or any of the meter accessories.

Serious injury or death from fire or explosion could result from

maintenance of an improperly depressurized and evacuated system.

Depending on the existing configuration, adding a VS-3

or VS-4 Valve may require modification of the outlet

piping.

After the internal pressure is relieved from the system,

drain all the fluid from the flowmeter and accessories.

The outlet line can then be disconnected from the

flowmeter.

Installing the Valve

The VS-3 or VS-4 valve is installed on the outlet side of

the flowmeter. The valve may be installed in one of four

orientations. Determine the orientation desired and then

attach the flowmeter using the four bolts and washers

provided. Tighten the bolts in a crossing pattern.

VS-3 & VS-4 Valves - Installation

Once the handle and linkage assembly is secure,

proceed with setting the dwell and zero shut-off as

described on Pages 9-10.

Installing the Linkage Assembly

The handle and linkage assembly is provided with the

VS-3 and VS-4 Valves. The handle and linkage may

need to be repositioned depending on the valve

orientation.

The valve handle mounts on either side of the valve shaft.

Mount the valve handle to the valve shaft and tighten the

handle screw. With the handle securely mounted to the

valve shaft, the linkage assembly can be connected to

the preset ring under the mechanical register.

The linkage assembly connects to the preset ring via the

ball joint extension (Figure 17a). The ball joint extension

is mounted using the screw and nut provided.

Mount the ball joint extension to the preset ring by

threading the screw into one of the holes at the back of

the register assembly. Thread the nut in place on the

screw.

With the ball joint extension secure on the preset ring,

attach the linkage assembly (Figure 17b). The linkage

assembly may require adjustment in order to mount to

the ball joint extension. If this is the case, either loosen

the handle and reposition on the valve shaft, or loosen

the nuts at the handle pivot (Figure 17c).

Figure 17a: Ball Joint

Figure 17b: Linkage Attached to Ball Joint

Figure 17c: Handle Pivot

13

Page 14

VS-3 & VS-4 Valves - Disassembling

Disassembling the Valve

The VS-3 & VS-4 Valves are under pressure from the

compression spring. The safest method for opening the

valve for service or maintenance is to place the valve on

a flat surface with the valve outlet facing down.

1. Loosen the four bolts (Item 61 1) located on the valve

cap (Item 124). The compression spring will exert a

force on the cap and push it up.

2. When the four bolts are almost completely removed,

check to see if the compression spring is still exerting

a force on the cap. If not, remove the four bolts and

washers completely . If there is still force on the cap,

remove two screws from opposite sides of the cap.

While bracing the cap with one hand, remove the

other two bolts and carefully release the cap until

the compression spring exerts no force.

3. Note the orientation of the cap and valve handle.

Remove the cap (Item 124). The internal

components are attached to the cap and will come

out of the valve housing with the cap.

4. T o disassemble the cap assembly , it will be necessary

to remove the four cotter pins which hold the cup

(Item 133) to the links on each side of the cup. This

is only necessary when replacing the compression

spring or the cup.

5. To replace the dashpot washer (Item 727), remove

the retaining ring (Item 559) from the end of the guide

shaft.

6. Four screws (Item 627) and lock washers (Item 745)

secure the guide (Item 138) and seals in place.

These screws are accessed from the opening

created when the cap (Item 124) and components

were removed. Remove these four screws and

washers to inspect and replace components as

necessary.

The valve shaft (Item 368) is very difficult to remove, but

it is not necessary to remove it in order to inspect or

replace the O-Rings and bearings of the valve shaft.

7. Remove the retaining ring (Item 564) from one side

of the valve shaft.

8. Remove the shaft seal (Item 270), the bearing (Item

140) the O-Ring (Item 456), the inner bearing (Item

260) and the O-Ring (Item 451).

9. Inspect and replace these components as needed.

Figure 18: VS-3 Valve

Figure 19: VS-3 Cap Assembly

10. Repeat steps 7-9 for the other side of the valve shaft.

14

Page 15

VS-3 & VS-4 Valves - Reassembling

Reassembling the Valve

For reassembly, refer to Figures 18 & 19 or the parts

breakdown on Pages 21 & 23.

1. Place the O-Ring (Item 455) on the guide (Item 354).

2. Place the upper seal (Item 453) and the bonded seal

ring (Item 354) onto the guide (Item 138).

3. Place the two retainer ring guides (Item 139) on the

guide.

4. Place the guide (Item 138) into the valve.

5. Secure this assembly using the four screws (Items

627) and lock washers (Item 745).

6. Reassemble the valve by placing the dashpot washer

and retaining ring on the end of the guide shaft.

7. Place the complete cap assembly on the valve

housing remembering to orient the valve handle in

the same position as it was prior to disassembling.

8. Insert the four screws and washers into the valve

cap and tighten by alternately tightening each screw

a few turns so that the cup (Item 133) slides evenly

over the guide (Item 138).

9. When the cap rests against the valve housing evenly ,

tighten all four screws in a crossing pattern.

10. If the valve shaft components were removed for

inspection or replacement, reassemble the valve

shaft components following the drawing to the right.

1 1. Insert the O-Ring (Item 451), the Inner bearing (Item

260), the next O-Ring (Item 456), the next bearing

(Item 140), the shaft case seal (Item 270) and secure

with the retaining ring (Item 564).

This completes reassembly. The valve may be placed

back in service. Be sure to check for leaks. Refer to

Pages 12 & 13 for installation instructions.

15

Page 16

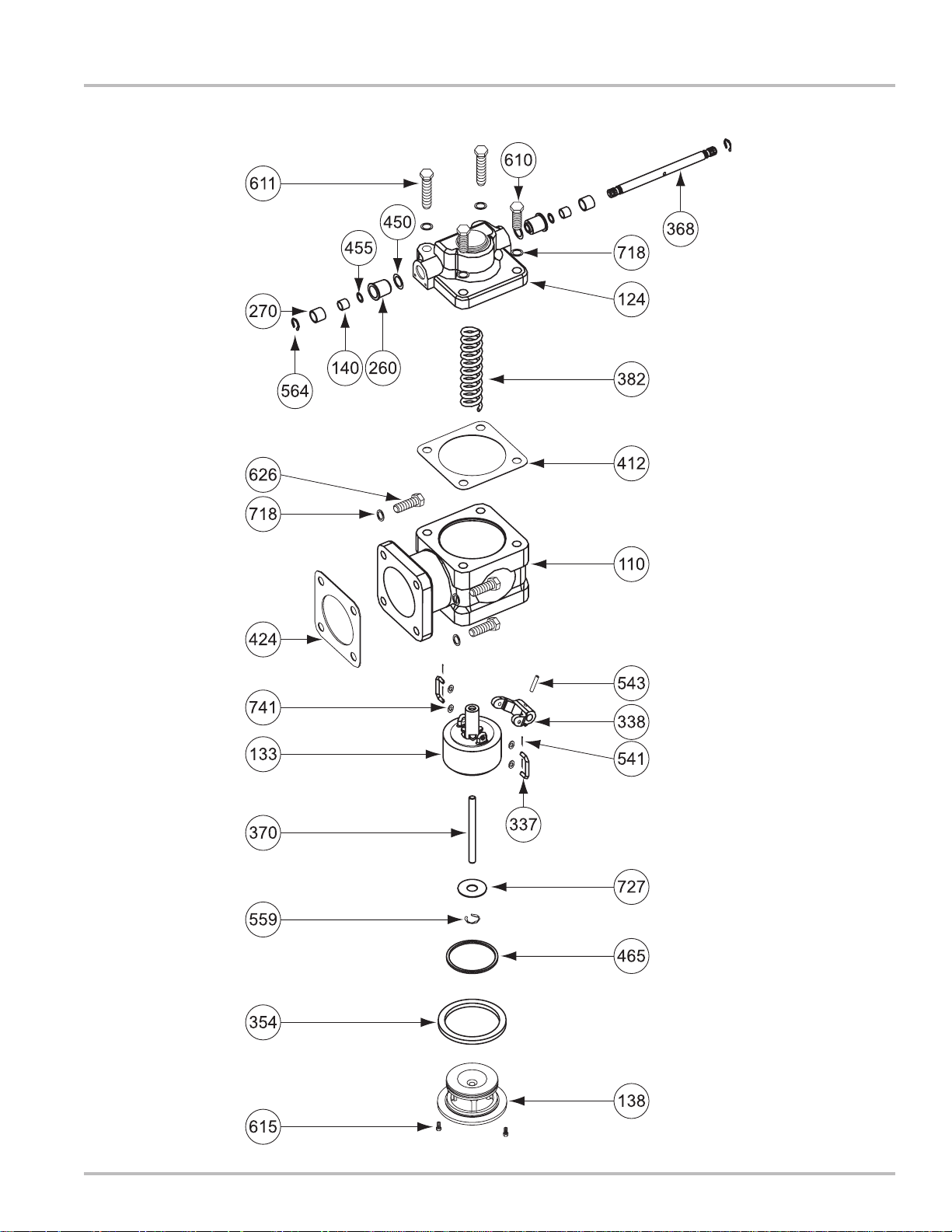

Illustrated Parts Breakdown - V-15 Valves

Item No. Description Part No.

110 Housing 40731

124 Valve Cap 43985

133 Cup 43529

138 Guide 43953

140 Bearing (2) 09050

260 Inner Bearing (2) 47889

270 Shaft Case Seal (2) 47891

337 Link (2) 43534

338 Link Arm 43533

354 Seal Ring 40736

368 Valve Shaft 40746

370 Guide Shaft 40737

382 Compression Spring 40735

412 Cap Casket 40738

424 Flange Gasket 40871

450 O-Ring (2) 09046

455 O-Ring (2) 09311

465 Upper Seal Ring 40742

541 Cotter Pin (4) 04005

543 Tapered Groove Pin 06822

559 Retaining Ring 04001

564 Retaining Ring (2) 04003

610 Screw, .500-13 x 1.50 (2) 06057

611 Screw, .500-13 x 2.25 (2) 00244

615 Screw, #10-24 x .375 (2) 06819

626 Screw, .500-13 x 1.50 (4) 06057

718 Flat Washer (8) 04685

727 Dashpot Washer 40944

741 Flat Washer (4) 06818

Model No. A3610 A3611 A3612 A3620 A3622 A3624

Item No.

110 40731 40731 40731 40731 40731 40731

124 43985 43985 43985 43985 43985 43985

133 43529 43998 43529 43529 43529 43529

138 43953 43953 43978 43953 43978 43953

140 09050 09050 09050 09050 09050 09050

260 47889 47889 47889 47889 47889 47889

270 47891 47891 47891 47891 47891 47891

337 43534 43534 43534 43534 43534 43534

338 43533 43533 43533 43533 43533 43533

354 40736 40736 43982 40736 43982 40736

368 40746 40746 40746 40746 40746 40746

370 40737 40737 40737 40737 40737 40737

382 40735 40735 40735 43535 43535 43535

412 40738 46070 40738 46070 40738 40738

424 40871 46069 40871 N/A 40871 40871

450 09046 09046 09047 09046 09047 09046

455 09311 09311 09045 09311 09045 09311

465 40742 40742 07209 40742 07209 40742

541 04005 04005 04005 06936 06936 06936

543 06822 06822 06822 06822 06822 06822

559 04001 N/A 04001 06820 06820 06820

564 04003 04003 04003 06821 06821 06821

572 N/A N/A 07207 N/A 07207 N/A

610 06057 06057 06057 06057 06057 06057

611 00244 00244 00244 00244 00244 00244

615 06819 06819 06819 06819 06819 06819

626 06057 06057 06057 06057 06057 06057

718 04685 04685 04685 04685 04685 04685

727 40944 N/A 43521 43521 43521 43521

741 06818 06818 06818 06818 06818 06818

Part No.

*N/S = Not for Sale

16

Page 17

A-3610 Shown

Illustrated Parts Breakdown - V-15 Valves

17

Page 18

Illustrated Parts Breakdown - V-30 Valves

Item No. Description Part No.

11 0 Housing Sub-Assembly 40931

124 Valve Cap 43976

133 Cup 43528

138 Guide 43956

140 Bearing (2) 09050

260 Inner Bearing Guide (2) 47889

270 Shaft Case Seal (2) 47892

337 Link (2) 43525

338 Link Arm 43524

354 Seal Ring 46239

368 Valve Shaft 40987

370 Guide Shaft 40967

382 Compression Spring 40942

412 Flange Gasket (2) 40704

450 O-Ring (2) 09048

455 O-Ring (2) 09311

465 Upper Seal Ring 40969

541 Cotter Pin (4) 04005

543 Tapered Groove Pin 06822

559 Retaining Ring 04001

564 Retaining Ring (2) 04003

610 Screw, .625-11 x 1.75 (6) 04762

611 Screw, .625-11 x 2.50 (2) 06466

615 Screw, #10-24 x .375 (2) 06819

718 Flat Washer (8) 04764

727 Dashpot Washer 40944

741 Flat Washer (4) 06818

Model No. A4610 A4611 A4612 A4622AA4623 A4624

Item No.

110 40931 40931 40931 40931 40931 40931

124 43976 43976 43976 43976 43976 43976

133 43528 43734 43528 43528 43528 43528

138 43956 43956 43979 43979 43956 43956

140 09050 09050 09050 09050 09050 09050

260 47889 47889 47889 47889 47889 47889

270 47892 47892 47892 47892 47892 47892

337 43525 43525 43525 43525 43525 43525

338 43524 43524 43524 43524 43524 43524

354 46239 46239 43981 43981 46239 46239

368 40987 40987 40987 40987 40987 40987

370 40967 40967 40967 40967 40967 40967

382 40942 43526 40942 43526 43526 43526

412 40704 46072 40704 40704 46072 40704

450 09048 09048 09049 09049 09048 09048

455 09311 09311 09045 09045 09311 09311

465 40969 40969 07202 07202 40969 40969

541 04005 06936 04005 06936 06936 06936

543 06822 06822 06822 06822 06822 06822

559 04001 N/A 04001 06820 06820 06820

564 04003 06821 04003 06821 06821 06821

572 N/A N/A 07203 07203 N/A N/A

610 04762 04762 04762 04762 04762 04762

611 06466 06466 06466 06466 06466 06466

615 06819 06819 06819 06819 06819 06819

626 N/A N/A N/A N/A 04762 04762

718 04764 04764 04764 04764 04764 04764

727 40944 N/A 40944 43521 43521 43521

741 06818 06818 06818 06818 06818 06818

Part No.

*N/S = Not for Sale

18

Page 19

A-4610 Shown

Illustrated Parts Breakdown - V-30 Valves

19

Page 20

Illustrated Parts Breakdown - VS-3 Valves

Item No. Description Part No. Item No. Description Part No.

11 0 Housing Sub-Assembly N/S*

124 Cap Sub-Assembly 45533

133 Cup 43528

138 Machined Guide 45530

139 Retainer Ring Guide (2) 45521

140 Bearing (2) 09050

260 Inner Bearing Guide (2) 47890

270 Shaft Case Seal (2) 47893

337 Link (2) 43525

338 Link Arm 43524

354 Seal Ring 46239

368 Cap Shaft 45507

370 Guide Shaft 40967

382 Compression Spring 40942

420 Flange Gasket 07261

450 O-Ring 07504

451 O-Ring (2) 09048

Model No. A36501 A36502 A36521 A36522 A36551 A36552 A36572 A36582

Part No.

*N/S = Not for Sale

Item No.

110 N/S* N/S N/S N/S N/S N/S N/S N/S

124 45533 45533 45533 45533 45533 45533 45533 45533

133 43528 45528 43528 45528 43528 45528 45528 45528

138 45530 45529 N/S* 45526 45530 45529 45529 45526

139 45521 45521 45521 45521 45521 45521 45521 45521

140 09050 09050 09050 09050 09050 09050 09050 09050

260 47890 47890 47890 47890 47890 47890 47890 47890

270 47893 47893 47893 47893 47893 47893 47893 47893

337 43525 43525 43525 43525 43525 43525 43525 43525

338 43524 45531 43524 45531 43524 45531 45531 45531

354 46239 46239 43981 43981 46239 46239 46239 43981

368 45507 45507 45507 45507 45507 45507 45507 45507

370 40967 40967 40967 40967 40967 40967 40967 40967

382 40942 40942 40942 40942 40942 40942 40942 40942

390 N/A N/A N/A N/A N/A N/A N/A 07269

420 07261 07261 07261 07261 07262 07262 07261 07261

450 07504 07504 07608 07608 07504 07504 07504 07608

451 09048 09048 09049 09049 09048 09048 09048 09049

453 40969 40969 07202 07202 40969 40969 40969 07202

455 07611 07611 07612 07612 07611 07611 07611 07612

456 09311 09311 09045 09045 09311 09311 09311 09045

533 07212 07212 07212 07212 06985 06985 07212 07212

541 04005 04005 04005 04005 04005 04005 04005 04005

543 06822 06822 06822 06822 06822 06822 06822 06822

559 04001 04001 04001 04001 04001 04001 04001 04001

564 04003 04003 04003 04003 04003 04003 04003 04003

572 N/A N/A 07203 07203 N/A N/A N/A 07203

611 07255 07255 07255 07255 07255 07255 07255 07255

614 07293 07293 07293 07293 N/S N/S 07293 07293

627 07613 07613 07613 07613 07613 07613 07613 07613

650 45241 45241 45241 45241 45242 45242 45249 45249

718 07256 07256 07256 07256 07256 07256 07256 07256

727 40944 40944 40944 40944 40944 40944 40944 40944

741 04789 04789 04789 04789 04789 04789 04789 04789

745 06174 06174 06174 06174 06174 06174 06174 06174

453 Upper Seal Ring 40969

455 O-Ring 07611

456 O-Ring (2) 09311

533 Nut, .625-11 (4) 07212

541 Cotter Pin (4) 04005

543 Tapered Groove Pin 06822

559 Retaining Ring 04001

564 Retaining Ring (2) 04003

611 Screw, .750-10 x 2.25 (4) 07255

614 Screw, .625-11 x 2.75 (4) 07293

627 Screw, .250-20 x .625 (4) 07613

650 Stud, Nut, Gasket Kit 45241

718 Flat Washer (4) 07256

727 Dashpot Washer 40944

741 Flat Washer (4) 04789

745 Lock Washer (4) 06174

20

Page 21

A-36501 Shown

Illustrated Parts Breakdown - VS-3 Valves

21

Page 22

Illustrated Parts Breakdown - VS-4 Valves

Item No. Description Part No.

11 0 Housing Sub-Assembly N/S*

124 Cap Sub-Assembly 45533

133 Cup 43528

138 Machined Guide 45530

139 Retainer Ring Guide (2) 45521

140 Bearing (2) 09050

260 Inner Bearing Guide (2) 47890

270 Shaft Case Seal (2) 47893

337 Link (2) 43525

338 Link Arm 43524

354 Seal Ring 46239

368 Cap Shaft 45507

370 Shaft Guide 40967

382 Compression Spring 40942

420 Flange Gasket 07263

450 O-Ring 07504

451 O-Ring (2) 09048

453 Upper Seal Ring 40969

455 O-Ring 07611

456 O-Ring (2) 09311

533 Nut, .625-11 (8) 07212

541 Cotter Pin (4) 04005

543 Tapered Groove Pin 06822

559 Retaining Ring 04001

564 Retaining Ring (2) 04003

611 Screw, .750-10 x 2.25 (4) 07255

614 Screw, .625-11 x 2.75 (8) 07293

627 Screw, .250-20 x .625 (4) 07613

650 Stud, Nut, Gasket Kit 45248

718 Flat Washer (4) 07256

727 Dashpot Washer 40944

741 Flat Washer (4) 04789

745 Lock Washer (4) 06174

Model No. A46501 A46502 A46521 A46522 A46551 A46522

Item No.

110 N/S* N/S N/S N/S 45524 45524

124 45533 45533 45533 45533 45533 45533

133 43528 45528 43528 45528 43528 45528

138 45530 45529 45527 45526 45530 45529

139 45521 45521 45521 45521 45521 45521

140 09050 09050 09050 09050 09050 09050

260 47890 47890 47890 47890 47890 47890

270 47893 47893 47893 47893 47893 47893

337 43525 43525 43525 43525 43525 43525

338 43524 45531 43524 45531 43524 45531

354 46239 46239 43981 43981 46239 46239

368 45507 45507 45507 45507 45507 45507

370 40967 40967 40967 40967 40967 40967

382 40942 40942 40942 40942 40942 40942

420 07263 07263 07263 07263 N/S N/S

450 07504 07504 07608 07608 07504 07504

451 09048 09048 09049 09049 09048 09048

453 40969 40969 07202 07202 40969 40969

455 07611 07611 07612 07612 07611 07611

456 09311 09311 09045 09311 09311 09311

533 07212 07212 07212 07212 06985 06985

541 04005 04005 04005 04005 04005 04005

543 06822 06822 06822 06822 06822 06822

559 04001 04001 04001 04001 04001 04001

564 04003 04003 04003 04003 04003 04003

572 N/A N/A 07203 07203 N/A N/A

611 07255 07255 07255 07255 07255 07255

614 07293 07293 07293 07293 N/S N/S

627 07613 07613 07613 07613 07613 07613

650 45248 45248 45248 45248 45243 45243

718 07256 07256 07256 07256 07256 07256

727 40944 40944 40944 40944 40944 40944

741 04789 04789 04789 04789 04789 04789

745 06174 06174 06174 06174 06174 06174

Part No.

*N/S = Not for Sale

22

Page 23

A-46501 Shown

Illustrated Parts Breakdown - VS-4 Valves

23

Page 24

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2007 Liquid Controls

Pub. No. 48854B

(02/07)

Loading...

Loading...