Page 1

INSTALLATION & OPERATION

MANUAL

T650N SERIES

CRYOGENIC TRUCK TO TAL IZER

DOC #: MN-650.DOC

Page 2

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 2 DOC# MN-650

Page#

INTRODUCTION ........................................................................................................................... 3

MODEL T650N Dimensional Information ................................................................................... 16

TABLE OF CONTENTS

General ..................................................................................................................................... 3

Theory of Operation .................................................................................................................. 3

Testing ...................................................................................................................................... 3

Calibration ................................................................................................................................. 3

Temperature Compensation-Optional ....................................................................................... 3

INSTALLATION ............................................................................................................................ 4

Inspection ................................................................................................................................. 4

Physical .................................................................................................................................... 4

Electrical ................................................................................................................................... 4

Signal ........................................................................................................................................ 4

Field Termination ...................................................................................................................... 4

Initial System Start Up Procedure ............................................................................................. 5

Switch, Adjustment, and Display Descriptions .......................................................................... 5,6

CALIBRATION .............................................................................................................................. 6

Sensitivity .................................................................................................................................. 6

Calibration Factor...................................................................................................................... 6,7

“0-1” Function For Calibration ................................................................................................... 7,8

CALIBRATION FACTOR .............................................................................................................. 8

Field Correction ........................................................................................................................ 8

Calibration Factor-Change of Calibration Engineering Units ..................................................... 8

Temperature Compensation ..................................................................................................... 8,9

MODEL 820 TEMPERAT URE COMPENSATOR ......................................................................... 10

Introduction ............................................................................................................................... 10

Theory of Operation .................................................................................................................. 10

System Setup and Installation .................................................................................................. 11

Calibration ................................................................................................................................. 11

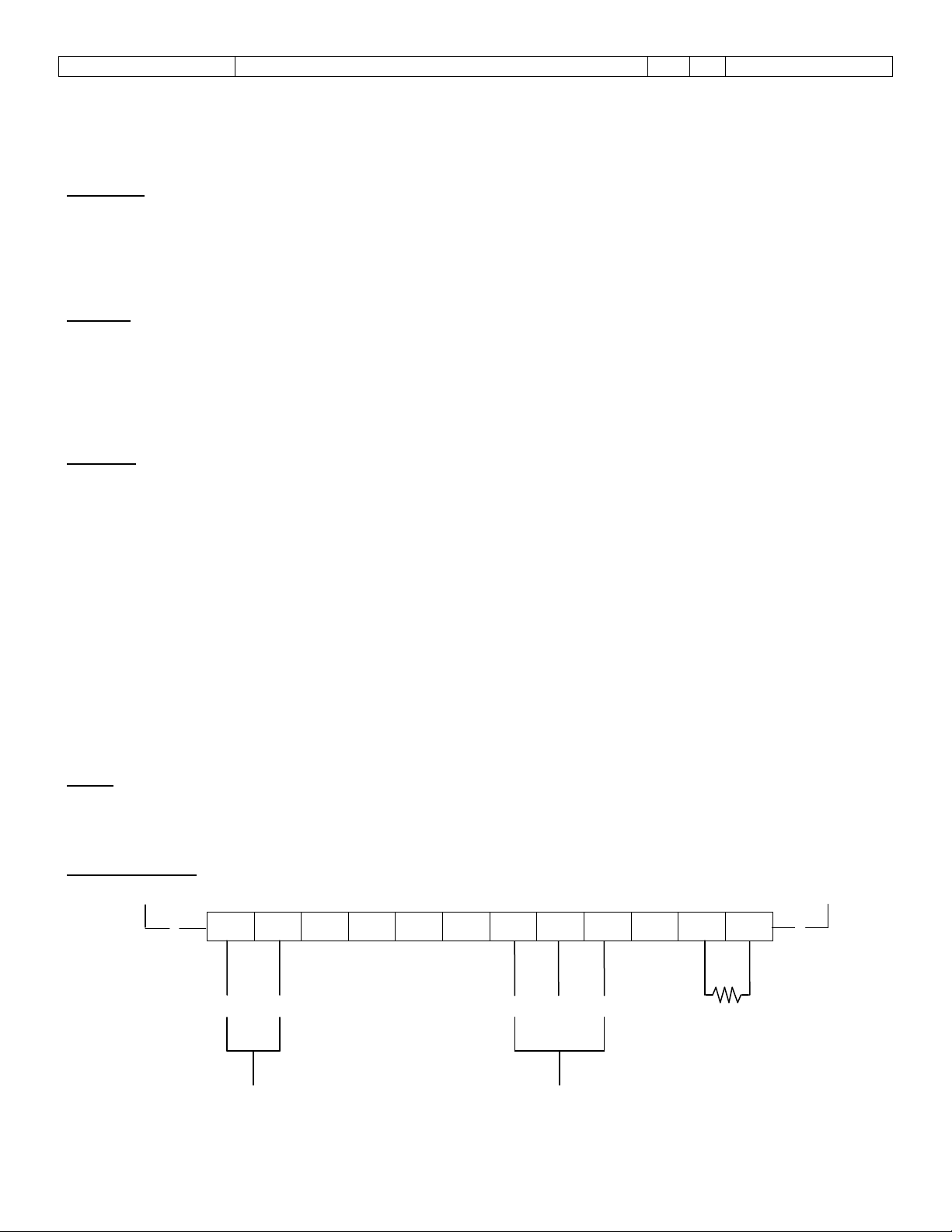

Model 820 Connection Diagram ............................................................................................... 12

SYSTEM TROUBLESHOOTING ................................................................................................... 13

Procedures ............................................................................................................................... 13

Troubleshooting Diagram .......................................................................................................... 14

MODEL T650N Internal Illustration ............................................................................................. 15

Page 3

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 3 DOC# MN-650

INTRODUCTION

General

The Model T650N Truck Totalizer provides flow totalization in any engineering unit. The totalized flow is displayed via

an accumulating 8 digit Liquid Crystal Display (LCD) electronic counter and an 8 digit resettable LCD.

Negatives previously associated with LCD’s - poor cold temperature performance, night clarity & condensation, which

is a byproduct of heaters, and incandescent lighting - have been eradicated with incorporation of a low temperature

coefficient LCD (-30

develop a precise, reliable totalizer.

Theory of Operation

The T650N initially amplifies & shapes the incoming pulses generated by the turbine’s response to flow. The amplified

pulse train is then scaled and divided to produce a totalized display in the desired engineering unit – gallons, liters,

pounds, SCF, m

sequence. A manual reset function is available if so desired.

Testing

A single switch “System Test” function enables maintenance personnel to quickly and effectively troubleshoot a system

failure, thereby reducing costly maintenance time. “System Test” provides a visual diagnostic indication of every

critical function of the T650N. With few exceptions, the system failure will be identified by the fault isolation LED’s of

the “System Test”.

Calibration

Field calibration is accomplished by incorporating a calibration factor based on the K-Factor of the turbine. A divider

switch provides a divisional increment of 10X from 1-10,000. The calibration factor is inserted using 4 BCD switches &

the 0-1 dip switch. The calibration factor range is .0001-1.9999. Verification of the electronics accuracy can be

accomplished by conventionally utilizing an external oscillator or by depressing the “System Test” switch which applies

a calibrated 500 Hz input signal to the system.

Temperature Compensation – Optional

A microprocessor based temperature compensation system designed to correct flow information based on product

temperature is available for use in the T650N. The Model 820 Temperature Compensator accommodates up to 8

different products (field selectable via a rotary switch) and accurately calculates the selected product density

acknowledging the non-linearity of the temperature probe and the product.

Installation of the Model 820 Temperature Compensator provides access to wireless I.R. communication for data

transfer to the Model SP824 portable ticket printer and provides an output for addition of a PCM-100 module for Pump

Control.

After market installation of temperature compensation requires minimal expertise and takes less than 15 minutes to

accomplish. By installing the 820 TC module, one connector to the 650 factoring board and the flip of a switch,

compensated totalization is accomplished.

o

C) and electroluminescent backlighting. The latest technological advances have been used to

3

, etc. The “power on reset” feature insures that the display is reset to zero during the initial po wer up

Page 4

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 4 DOC# MN-650

BLK

WHT

SHD

B

12 VDC

POWER

2-WIRE

RTD

INSTALLATION

Inspection

All units are completely assembled, tested and inspected at the factory prior to shipment. Upon receipt of the unit, a

visual inspection should be conducted to detect any damage that may have occurred during shipment. If the packing

case is damaged, notify the local carrier at once regarding his liability. A report should be made to the distributor.

Carefully remove the equipment from the packing and inspect for damaged or missing parts.

Physical

The T650N Flow Converter should be mounted as practically as possible taking into account display visibility,

accessibility, etc. Ideally the T650N should be securely mounted using ONLY the supplied shock mounts on a stand

positioning the Flow Converter 12-18” above the deck, clear of overhead pipes and as remote from the pump motor as

possible. Although the T650N enclosure integrity is watertight at manufacture, adherence to these guidelines will

significantly enhance the trouble-free operation of the unit.

Electrical

The T650N is designed to operate on the 12 VDC power system of the transport and is “polarity insensitive”. Both the

+ and – power inputs should be obtained in the pump control box. To facilitate testing without having to activate the

entire pumping system, + power input should be derived from the unswitched 12V input to the pump control box.

Every effort should be made to keep the proximity of the Flow Converter’s input power leads to the pump motor’s

winding leads as isolated as practically possible within the pump control box. In the event a transport doesn’t have a

pump control box, as is the norm in CO

front of the trailer connected to the 12 VDC accessory or Light Circuit.

DO NOT ATTEMPT TO OBTAIN POWER BY SPLICING INTO THE LIGHT CIRCUIT LOCATED NEAR THE METER:

LINE DROPS AND FLUCTUATIONS MAY AFFECT THE UNIT’S OPERATION.

DO NOT CONNECT A JUMPER FROM THE T650N ENCLOSURE TO THE TRAILER CHASSIS AND DO NOT

REPLACE THE SHOCK MOUNTS WITH SOLID “LOOK ALIKES” AVAILABLE IN HARDWARE STORES; THEY

HAVE SOLID MOUNTING STUDS AND ARE NOT ISOLATING STUDS AS PROVIDED BY THE SPONSLER

COMPANY.

Signal

The standard T650N signal cable is a 2 wire shielded cable with an MS3102 connector termination which is the

industry standard interface for 2 pole pickup coils. The shielding is single ended and should not be altered.

Field Termination

1 2 3 4 5 6 7 8 9 10 11 12

WHT

, 2 wires should be routed to the trailer’s power junction box located at the

2

BLK

WHT

BLK

A

SIGNAL

Page 5

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 5 DOC# MN-650

Initial System Start Up Procedure

Assure all Field Terminations are complete, correct and secure. Turn on the T650N and observe that 8 zeros are

displayed and the LCD back lighting is on. Depress res et if externa l reset opt ion was selecte d.

Refer to DWG. # SCI-T650N-REV C-TC-INT

Open the T650N enclosure and depress “System Test” S9. All LED indicators of the 10 position bar graph D1-D10

should be illuminated except D3 if “1” is selected by “0-1” Switch S2. Also observe that both the LCD counters

increment equally. D4, 5, 6, & 7 will blink. Each LED indicates a specific T650N function. The indicators are

extensively discussed in the Description Section and in the Troubleshooting Section which should be referenced in the

event of a failure of the T650N.

Switch, Adjustment, and Display Descriptions

S1 - Power Switch: 3 Amp DPDT; switches fused input power to the logic circuits of the factoring and

display boards.

S2 - “0-1” Switch: 2 position D.I.P.; permits increased calibration accuracy when the calibration factor

begins with a ‘1’ such as .015979 (Refer to example #3).

S3-6 - Factoring Switches: 10 position (0-9) BCD rotary; inserts the desired calibration factor digitally with S3 as

the MSD & S6 as the LSD.

S7 - Divider Switch: 5 position rotary; provides the proper divider for decimal point placement in the

calibration factor.

Position 1=1, 2=10, 3=100, 4=1000, 5=10000

S8 - Reset Switch: Single pole, momentary pushbutton; resets display and all logic circuits when

depressed and released.

S9 - System Test: Single pole, momentary pushbutton; activates LED bar graph and injects 500 Hz signal

to increment LCD counters while depressed.

S10 - Display Test: Single pole, momentary pushbutton; injects signal to increment large LCD while

depressed.

S11 - Display Decimal Point: Display Blanking & Backlight Control: 2 position, 4 pole D.I.P.

S11-1: displays 10ths Decimal Point when in ‘1’ position

S11-2: displays 100ths Decimal Point when in ‘2’ position

S11-3: display blanks when in ‘3’ position and power “OFF”

S11-4: extinguishes backlight when in ‘4’ position and power “OFF”.

S12 - TC Selector: 2 position D.I.P.; permits by-pass of the temperature compensation module. Positions

0=w/o TC; 1=TC incorporated.

R1 - S ensitivity Adjustment: Single turn potentiometer; establishes input signal amplitude required to initiate the

count sequence.

CCW = minimum sensitivity CW = maximum sensitivity

Page 6

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 6 DOC# MN-650

Engineering Units

K-Factor

Bar Graph - 10 position LED; activated while S9 (system test) is depressed to indicate status of specific functions

of the T650N circuitry.

D1 - normally illuminated; extinguished if either the pickup coil or the signal cable shorts.

D2 - normally illuminated; extinguished if either the pickup coil or the signal cable opens.

D3 - illuminated if S2 is in “0” position; extinguished if S2 is in “1” position.

D4 - normally flashing; nonflashing if mechanical counter output signal is absent.

D5 - normally flashing; nonflashing if factoring board output signal is absent.

D6 - normally flashing; nonflashing if display board oscillator is not functioning.

D7 - normally flashing; nonflashing if system test oscillator is not functioning.

D8 - normally illuminated; extinguished if 12 volts is absent.

D9 - normally illuminated; extinguished if 5 volts on factoring board is absent.

D10 - normally illuminated; extinguished if 5 volts on display board is absent.

D11 - Power indicator, LED; illuminated if switched fused input power is present.

D12 - TC Range Alarm, LED; illuminated if temperature compensation is incorporated and temperature for

the selected product is out of range.

J5 - Jumper: installed if external manual reset is incorporated.

J6 - Jumper: installed if power on reset is incorporated.

CALIBRATION

Sensitivity

The Sensitivity adjust (R1) should be adjusted at the lowest expected flow rate. Turn R1 completely counterclockwise;

slowly adjust R1 clockwise until the display increments; then increase R1 slightly clockwise again. In the normal R1

position, the arrow indicator will be in the 11 o’clock position.

Calibration Factor

The Calibration Factor is derived by taking the reciprocal of the meter’s “K-Factor” (pulses per gallon or other

engineering unit).

It is desired that zero not be dialed as the first digit on the factor switches. The CF, in most cases, will start with at

least one zero. The divider switch (S7) on the factoring board will allow dividing by 1, 10, 100, 1000, or 10000 to move

the decimal the required digits.

C.F. =

Page 7

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 7 DOC# MN-650

S7 POSITION

DIVIDER

500 X Time In Seconds X Calibration Factor

Divider

500 X 120 X .4348

100

Hz X Time In Seconds X Calibration Factor

Divider

(41,381,600 X .1257)

for a difference of 166.7 SCF

10

1

2

3

4

5

Example #1: K-Factor = 230 pulses per gallon

Engineering Units = Gallons

1/230 = .0043478

Set S7 in Position 3 (100 divider; moves decimal right 2 places)

Set S3 at 4, S4 at 3, S5 at 4, S6 at 8 (Rounding 4

Set S2 on “0” position

Accuracy: Using the “System Test” the electronic accuracy can be verified incorporating the following

formula for a timed test.

QTY. Displayed =

Example #2: Time = 2 Minutes (120 sec.), CF = .4348, Divider = 100

QTY. Displayed =

1

10

100

1000

10000

(does not move decimal)

(moves decimal right 1 place)

(moves decimal right 2 places)

(moves decimal right 3 places)

(moves decimal right 4 places)

th

digit)

= 260.88 = 261

Universal Formula –

QTY. Displayed =

“0-1” Function for Calibration:

The “0-1” function provides a greater degree of accuracy when totalization encompasses a large quantity such as SCF

produced in a 24 hour period.

Example #3: Assume a turbine flowmeter has a K-Factor of 79.58 pulses per SCF and a product demand of

520,000 SCF is the customer’s daily usage.

A delivery of 520,000 SCF = 41,381,600 total pulses (520,000 X 79.58).

C.F. = 1/79.58 = .012566

Without the “0-1” function

S7 in Position #2 (10 divider; moves decimal right 1 place)

S3 at 1, S4 at 2, S5 at 5, S6 at 7 (rounding the fourth digit)

S2 in “0” position

The meter would indicate a total quantity of 520,166.7 SCF

Page 8

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 8 DOC# MN-650

(41,381,600 X .2566) + 41,381,600

for a difference of 1 SCF

Actual Total

Meter Total

3.785

230

500 X Time in Seconds X CF

Divider

(

)

Incorporating the “0-1” function:

S7 in Position #3 (100 divider; moves decimal right 2 places) Decimal must move to the right of the 1

digit.

S3 at 2, S4 at 5, S5 at 6, S6 at 6

S2 in “1” position

The meter would indicate a total quantity of 520,001.2 SCF

100

CALIBRATION FACTOR

Field Correction

To adjust the calibration factor to reflect the actual response of the turbine to the operating conditions, apply the

following formula:

New Calibration Factor =

Example #4: Actual Total = 50

Meter Total = 52

C.F. = .4000

50/52 X .400 = New Calibration Factor

.9615 X .4000 = .3846

Insert .3846 into S3 – S6 respectively

In the above example .9615 denotes that the meter is operating 3.85% fast & multiplying the present calibration factor

(.4000) by the ratio of Actual Total: Meter Total (.9615) reduces the calibration factor 3.85%.

Calibration Factor – Change of Calibration Engineering Units

Assume that rather than gallons, liters are the desired engineering unit.

Example #5: K-Factor = 230 pulses per gallon

Liters = 3.785 per gallon

= Calibration Factor

= .016456 for display of liters

Set S7 at 3 (100 divider; moves decimal right 2 places)

Set S2 at 1 (incorporates “0-1” function)

Set S3 at 6, S4 at 4, S5 at 5, S6 at 6

Temperature Compensation:

The temperature compensator is discussed in detail in the attached Model 820 Supplement. The Model 820

Temperature Compensator digitally converts a resistive temperature representation to a density correction factor that

corrects for variations in mass related to temperature. Incorporation of the following formula provides a means to

verify field accuracy.

X Calibration Factor

Quantity Displayed =

X (Temperature Correction Factor)

Page 9

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg 9 DOC# MN-650

(500 X 60 X .5279)

100

(15837)

100

=

158.37

X (1.0529)

Hz X Time in Seconds X CF

Divider

(

)

Use the “System Test” S9 (Injects 500 Hz signal).

Example #6:

Calibration Factor = .5279 Time = 60 seconds

Divider = 100 T.C. Factor = 1.0529

Substituting: Quantity Displayed =

=

= 166.7

The Temperature Correction Factor (T.C.F.) is referenced at the Normal Boiling Point (NBP). The example above

indicates that the product temperature is below the NBP in that the T.C.F. > 1. Likewise, if the product temperature is

above the NBP, the T.C.F. will be < 1.

Universal Formula:

Quantity Displayed =

X (1.0529)

X (1.0529)

X (Temperature Correction Factor)

Page 10

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

10

DOC# MN-650

DELAY TIME

(minutes)

LOX & LIN

10

ALL OTHERS

1

LOX, LIN, & LAR

12

M820-VO1-7

ALL PRODUCTS

5

ANY OTHER VERSION HAS NO TIME DELAY BUILT IN

MODEL 820 TEMPERAT URE COMPENSATOR

Introduction

The Model 820 Temperature Compensator is a highly sophisticated electronic temperature compensation system

designed to correct flow information based on product temperature. Inserted between the signal source and recording

electronics, the temperature compensator will automatically add or subtract pulses from the pulse train based on

temperature of the product being delivered. The Model 820 is designed to accommodate up to 8 different products

(field selectable via a rotary switch) with the density and non-linearity of the temperature probe and each product being

acknowledged. Data transfer via wireless (IR) communications is available to print product selection, temperature,

correction factor and accumulated corrected total on the Model SP824 Portable Ticket Printer.

Theory of Operation

As product flows through the pipeline, a turbine located in the product spins and electrical pulses are generated and

sent to the temperature compensator. The number and frequency of these pulses corresponds to the amount of

product flow and the flow rate.

As the product in the pipeline heats or cools, the density and volume of the product change. When the volume of

product changes, the turbine spins faster or slower since the turbine flowmeter is a volumetric measuring device even

though the AMOUNT (measured by weight) of product is not changed. Model 820 performs its function first by

amplifying and conditioning signals from a pickup coil or other small signal device. The temperature of the product is

then read via an RTD temperature probe. Model 820 then adds or subtracts incoming pulses based on the

temperature/density of the product and the product’s correction curve.

As long as the product flowing past the temperature sensor is within range for the product, the temperature

compensator will automatically correct for the density of the product. If the product is not within the correct

temperature range, or the temperature probe fails, the compensator will turn on the alarm LED and modify the

temperature correction factor (TCF).

The TCF is modified based on the jumper installed at the jumper option block of the 820 (Ref. Drawing SCI-820CONN-VOL-9-01 & Table “OPTION JUMPER” on the next page). If no jumper is installed, the correction factor will be

set for no compensation (TCF = 1.00). If the “B” jumper is installed, the 820 will stop accepting incoming pulses during

alarm condition, resulting in no count during an alarm condition. If the “C” jumper is installed, the compensator reverts

to ‘alarm’ temperature and corresponding TCF for the selected product (Ref the ‘Model 820 EPROM’ table for a listing

of products, temperature compensation range, and default alarm temperature).

The pump control output is used in conjunction with the PCM-100 module to disable the pump when the product is

above the proper temperature for delivery. If the 820 detects a complete temperature probe failure (temperature

reading above 200

after the temperature probe detects that the product is within the correct temperature range for delivery may be

activated by installing jumper ‘D’. This enabled delay allows the entire system to reach temperature before delivery is

allowed. Once the pump is enabled, the product temperature may go out of range for 10 seconds before the pump is

disabled. Once the pump is disabled, the initial delay time will be imposed before the pump is again enabled.

The delay times are based on the EPROM version installed on the Model 820 and the product selection. The following

table lists each version and the associated time delays (The EPROM installed on the 820 will be labeled with the

version).

o

C), the pump will be enabled so as not to prevent delivery. A timer to continue to disable the pump

EPROM PRODUCT

M820-VO1-9

M820-VO1-8

LAR 15

ALL OTHERS 5

Page 11

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

11

DOC# MN-650

POSITION

PRODUCT

LOW LIMIT

REF TEMP

ALARM TEMP

HI LIMIT

0

Oxygen

-200.00

-183.11

-168.00

-140.50

1

Nitrogen

-210.00

-195.930

-182.00

-155.30

2

Argon

-189.00

-186.046

-168.00

-140.50

3

CO2

-40.050

-16.388

-6.30

-6.30

4

N2O

-51.087

-34.679

15.30

15.30

5

Calif. CO2

-40.00

-25.817

-7.00

-7.00

6

MAPP

-17.871

15.384

50.50

15.50

7

LPG

-40.00

15.384

49.50

49.50

9

Self test

Jumper

Description

A

(*do not install) Momentarily shorted in probe calibration mode starts the dip switch

verification test.

B

C

When the alarm LED is on... If the jumper is installed the compensator reverts to the

1.00) and will output the actual temperature without modification.

D

System Setup and Installation

The Temperature Compensator has been calibrated for the RTD and tested in the factory. Once the unit is installed,

the product selector switch must be set to the correct position for the product being delivered.

The following table summarizes the various positions of the product selector switch and the corresponding product.

MODEL 820 OPTION ‘IC’ EPROM

8

The following table summarizes the option jumpers and their functions. NOTE: Only one jumper should be installed!

Calibration

To calibrate the unit, first set the product selector switch to position 8 (calibrate). Next replace the temperature probe

with a 100 ohm .1 resistor and observe the (-) and (+) LED’s on the PCB. If the (-) LED is on, turn the calibrate pot

clockwise until the LED goes off. If the (+) LED is on, turn the calibrate pot counterclockwise until the LED goes off.

Once both LED’s are off, the unit is calibrated properly and is ready for use.

NOTE: Be sure to set the product selector switch back to the correct position for the product being delivered

Calibrate &

switch test

When this jumper is installed the unit will not totalize if the alarm LED is on.

‘alarm’ temperature and corresponding TCF for the product selected. If the ‘C’ jumper is

not installed, the compensator will set the correction factor for no compensation (TCF =

When jumper is installed the pump control time delays will be activated.

OPTION JUMPERS

Page 12

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

12

DOC# MN-650

IR INTERFACE

SERIAL PORT

S

J4

J3

PROBE CALIBRATION POT

P0

+LED

- LED

ALARM LED

SIGNAL INPUT LED

SIGNAL OUTPUT LED

J2

D0D2D3

D4

D1

FUNCTION

ALARM OUTPUT GROUND

TEMP PROBE

TEMP PROBE

SIGNAL INPUT (SIG 2)

SIGNAL INPUT (SIG 1)

ALA RM O UTPUT

OUTPUT GROUND

OUTPUT SIGNAL

8

7

6

5

4

3

2

1

J2

-

+

DC POWER

D

C

B

A

PRODUCT SE L ECTOR

0 = LOX

1 = LIN

2 = LAR

3 = LCO

2

4 = N2O

5 = CCO

2

6 = MAPP

7 = LPC

8 = CALIBRATE

PROBE

OPTION JUMPERS:

B = INS TAL L F O R NO COUNT

IN ALARM

C = INSTALL TO REVERT TO

“ALARM” TEMPERATURE

AND TCF FOR PRODUCT

D = INSTALL TO ACTIVATE

PUMP CUTOUT TIME

0

DATE DRAWING NUMBER

SPONSLER CO., INC.

MODEL 820 CONNE CTION DIAGRAM VOL-9 OPTIONS

7-9-96

SCI-820-CONN-VOL-9-01

PUMP CONTROL

OUTPUT

MODEL 820

CURVE IC

M820-VO1-9

EPROM

NOTES:

“C” JUMPER SHOULD ALWAYS BE INSTALLED TO

ENABLE SP825 DATA TRANSMISSION

“B” & “D” MAY BE INSTALLED AS NEEDED TO ENABLE

FUNCTIONS AS LISTED

12/01 ADDED NOTES

Page 13

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

13

DOC# MN-650

SYSTEM TROUBLESHOOTING

Procedures:

When a failure is believed to exist, the following procedure will aid in expediting the isolation of the failure.

1. Check all wiring for secure and accurate connections. Ref. DRAWING # T650NIR-1

2. Check that sensitivity (R1) setting is mid-range (11 o’clock), and depress S9. Observe all LED’s

and the displays.

3. Follow the troubleshooting diagram (next page) for the following:

SYMPTOM

No Display

Display “ON” – No Count

Display Counts – No Accumulative Count

This test is designed to troubleshoot the 820 Temperature Compensator after the 650D and 650F Boards have

been proved functional (unit functions correctly when S12 is in W/O TC position).

Refer to Drawings: SCI-820-CONN-VOL-9-01

T650NIR-1

Troubleshooting Diagram

Preliminary Checks:

1. Probe Cable: Check continuity between Pin A and W HT wire; Pin B and BLK wire.

Check NO SHORT between Pin A and Pin B or between Pin A or Pin B and the

connector.

Insure that the probe cable wires are securely attached at J1-11 and J1-12.

2. Probe: Check resistance between Pin A and Pin B

If the RTD is at ambient temperature, resistance range 100 to 110

If the RTD is immersed in liquid product at delivery temperature:

LOX resistance range 18 to 42

LIN resistance range 16 to 37

LAR resistance range 23 to 42

CO

If the resistance reading is NOT within the specified range, replace the RTD

3. Insure that interconnect wiring harness is installed properly and securely at 650F J2-A and 820 J2 and

J4.

4. Insure that the 820 Product Selector Switch (SO) is in proper position for product being measured.

5. Check placement of jumper on 820 PCB. Ref DRAWING # SCI-820-CONN-VOL-9-01. If installed at

‘B’, the unit will not count while the temperature is out of range for the selected product. The alarm LED

will be “ON” if the temperature is out of range.

6. Set S12 in W/TC position. Turn Power “ON”. Display is “ON”; D11 is “ON”; D12 is “OFF” (Probe is

immersed in liquid product). Depress S9. If D3 and D4 don’t flash (unit does not count), proceed to

Troubleshooting Chart (next page).

resistance range 84 to 96

2

Page 14

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

14

DOC# MN-650

GO TO STEP 15

NO GO

1) SW ITCH S12 TO W/T. C.

2) DEPRESS S9 FOR 15 SEC

OBSERVE DISPLAY N2 = 53 COUNTS

O2 = 58 COUNTS

AR = 57 COUNTS

CO2 = 59 COUNTS

CCO2 = 57 COUNTS

REPLACE

650F & D

NO GO

1) SW ITCH S12 TO W/O T.C.

2) SET S3, 4, 5, 6 TO 7777

3) DEPRESS S9 FOR 15 SEC.

OBSERVE S8 DISPLAYED

12

NO GO

REPLACE

650F & D

REPLACE T.C.

SWITCH S12 TO W/O T.C., DEPRESS S9

OBSERVE DISPLAY COUNTS

NO GO

NO GO

GO

11

REFER TO TURBINE

ASSY. DRAWING

REBUILD

TURBINE

'COUNTS'

OPEN DISCHARGE VALVE PERMITTING VAPOR

BLOW BY - OBSERVE DISPLAY COUNTS

SYSTEM

COUNT

10

DEPRESS S9 - OBSERVE

DISPLAY COUNTS

REPLACE

PROBE CABLE

'ON'

D0 & D2 'ON' PROBE CABLE SHORTED

D0 & D3 ‘ON’ PROBE CABLE ‘OPEN’

9

T.C. ASSY

DISCONNECT RTD & CONNECT TEMP RANGE

PLUG - OBSERVE D0, D2, D3 ‘OFF’

(AL) (-) (+)

8

REPLACE

650F & D

D6, D7 'OFF' (NOT FLASHING)

D8, D9 ‘OFF’

SWITCH S1 2 TO W /T.C.

REPLACE T.C.

'FLASHING

'

NO GO

REPLACE

650F & D

7

D4. D5 'OFF' (NOT FLASHING)

1) SW ITCH S12 TO W/O T.C.

2) DEPRESS S9, OBSERVE D4,

D5 ‘FLASHING’

REPLACE

650F & D

REPLACE

P/U COIL

REPLACE

SIGNAL CABLE

'OFF'

NO GO

NO GO

'ON'

6

5) CONNECT J1

6) TURN POWER ‘ON’

OBSERVE D1, D2 ‘ON’

4) CONNECT P/U COIL

J1-7 (WHT) → J1-8 (BLK)

1800-2100Ω WARM

AS LOW AS 250Ω COLD

J1-9 (SHD) → J1-7 OR 8 = ∞Ω

D1,2 'OFF'

1) TURN POWER ‘OFF’

2) DISCONNECT J1

3) DISCONNECT P/U COIL

J1-7 (WHT)

→ PIN ‘A’ = 0 Ω

J1-8 (BLK) → PIN ‘B’ = 0 Ω

J1-9 (SHD) → J1-7 or 8 = ∞Ω

J1-7 (WHT) → J 1-8 (BLK) = ∞Ω

NO GO

5

DEPRESS S9, OBSERVE

D1-D10 ‘ON’ OR FLASHING

DIAGNOSTIC LED'S

17

18

16

GO TO STEP 5

OK

REPLACE T.C.

BLOWN

DISCONNECT J2

OBSERVE FUSES

FUSES

BLOWN

O.K

YES

CHANGE DEFECTIVE FUSE

REPLACE S1

POWER SWITCH

NO

CHECK J1-5,6

FOR 12 VDC

BLOWN

GO

CHECK FUSES

F1 & F2

'OFF'

POWER CIRCUITS

REPLACE

650F & D

'ON'

DEPRESS S9, OBSERVE

D8, 9, 10 ‘ON’

4

3

2

1

'

OFF'

'ON'

TURN POWER 'ON' & OBSERVE THAT

THE DISPLAY IS EITHER ‘ON’ OR ‘OFF’

ON TC ASSY CHECK THAT: JU7 INSTALLED,

PRODUCT SELECTOR IN CORRECT POSITION

& IF EQUIPPED SENSITIVITY=11 O’CLOCK

CHECK SENSITIVITY ADJUST

ON T650F=11 O’CLOCK

CHECK AND SECURE ALL

ELECTRICAL CONNECTIONS

‘IT DOESN'T WORK"

1) CONNECT J1

2) CLOSE & SECURE LID

NO GO

REPLACE

RTD

15

1) TURN POWER ‘OFF’

2) DISCONNECT J1

3) DISCONNECT TEMP RANGE PLUG

4) CONNECT RTD

J1-11 (WHT) → J1-12 (BLK) =

114.4Ω = 98.6 °F

20.25Ω = -320 °F

25.75Ω = -298 °F

24.50Ω = -303 °F

90.0Ω = -10° F

RTD TES T

BASIC CONCEPTS

1) DISPLAY ‘ON’

2) ALL DIAGNOSTIC LEDS ‘ON’ OR ‘FLASHING’

3) ALL T.C. RANGE LEDS ‘OFF’

4) DISPLAY COUNTS

5) SYSTEM ACCURACY

6) VAPOR BLOW BY GENRATES COUNT

T.C. 100Ω CALIBRATION PROCEDURE

A) DISCONNECT RTD

B) INSTALL TEMP CAL PLUG

C) SET PRODUCT SELECTOR ON T.C. TO #8

D) CALIBRATION ADJUSTMENT D2 ‘ON’ (-) ADJUST UNTIL D2 ‘OFF’

D3 ‘ON’ (+) ADJUST UNTIL D3 ‘OFF’

E) DISCONNECT TEMP CAL PLUG

F) CONNECT RTD

G) RETURN PRODUCT SELECTOR ON T.C. TO

CORRECT PRODUCT

0 = O

2

1 = N

2

2 = A

R

JU7

D0

D2

D3

TEMPERATURE

COMPENSATOR

BOARD

SENSITIVITY

W/O TC

W/TC

SYSTEM TEST

CW

FACTORING BOARD

F1

S12

R1

S9

J2-A

D1-D10

J3-A

F2

J1

S3S4S5

S6

REV C

123456789

10

11

12

PROCEED TO

STEP FOR

OFF LED

'ON' OR FLASHING

PROCEED TO

STEP 9

TROUBLESHOOTING DIAGRAM

REPLACE T.C.

14

13

COUNTS

ACCURACY

TEST

GO

GO

‘OFF’

PRODUCT

SELECTOR

0 - 0

2

1 - N

2

2 - A

R

CAL 100Ω ADJUST

(ALARM)

(-)

(+)

Page 15

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

15

DOC# MN-650

Page 16

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

16

DOC# MN-650

SPON SLER C O . , I NC .

SPONSLER CO., INC.

MFG DATE

Dimensional Information

4 1/2"

11 3/4"

6"

MODEL T650N

TC RANGE

ALARM

POWER

FLOW MEASURING DEVICES AND CONTROLS

2363 SANDIFER BLVD., W ESTMINSTER S.C. 2 9693, 864-647 -2065

9"

POWER

©2009

Pub. No. MN-650-R1

(09/09)

FLOW MEASURING DEVICES AND CONTROLS

2363 SANDIFER BLVD., WESTMINSTER SC 29693

POWER

MODEL

SERIAL #

10 7/8"

Loading...

Loading...