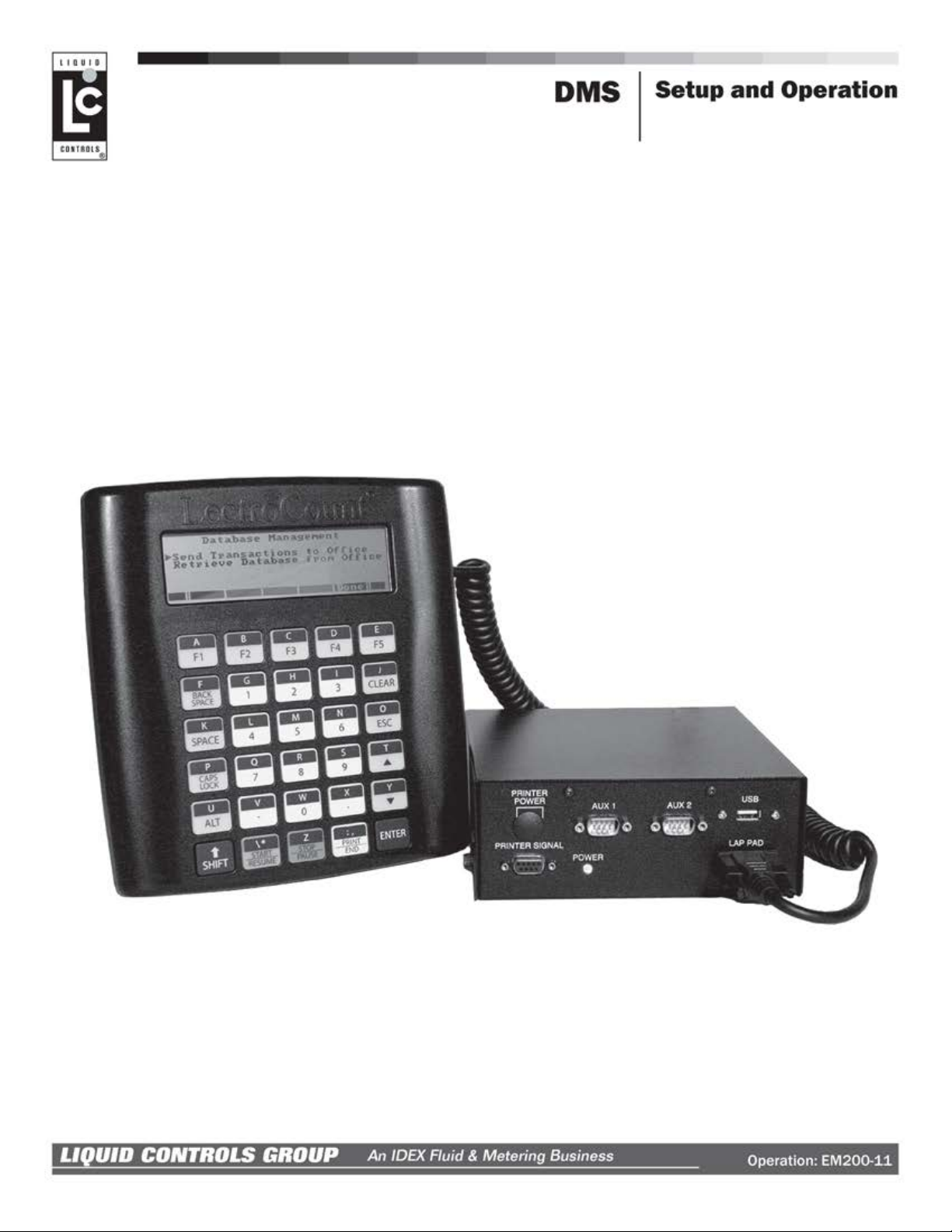

Page 1

Page 2

Table of Contents

Introduction

Software License Agreement............................. 3

DMS i1000 i1000 Overview ............................... 4

DMS i1000 i1000 System Components............. 5

Specications .................................................... 6

DMS i1000 Lap Pad .......................................... 7

Navigating DMS i1000 Lap Pad ........................ 8

Field Edit and List Box Windows ....................... 9

DMS i1000Menu

System Utilities ................................................ 12

Data Application List ........................................ 16

Database Management ................................... 17

LCR Host

Main Menu ....................................................... 20

Setup Network ................................................. 21

Setup Network Port ......................................... 24

System Parameters ......................................... 26

Congure LCR ................................................. 28

General Setup ................................................. 29

System Calibration .......................................... 32

Product Calibration .......................................... 37

Single-Point Calibration ................................... 44

Multi-Point Calibration ..................................... 45

Diagnostics ...................................................... 48

Security............................................................ 49

Factory Setup .................................................. 50

Save Conguration .......................................... 51

Load Conguration .......................................... 52

LCR Host Delivery

Preset and Delivery ......................................... 54

Device Not Found ............................................ 59

Machine Status ................................................ 60

Printer Status ................................................... 61

Delivery Status ................................................ 62

Delivery Code .................................................. 63

LCP File Server

Setup LCP File Server ..................................... 66

File Management ............................................. 69

Software Menu Maps

Software Menus - DMS i1000Menu................. 72

Software Menus - LCRHost ............................. 73

Software Menus - LCP File Server .................. 82

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our web site, www.

lcmeter.com. It is the responsibility of the local distributor to provide the most current version of LC

manuals, instructions, and specication sheets in the required language of the country, or the language

of the end user to which the products are shipping. If there are questions about the language of any LC

manuals, instructions, or specication sheets, please contact your local distributor.

! WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualied personnel trained in the proper application, installation, and maintenance of

equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury, or death from

re and/or explosion, or other hazards that may be associated with this type of equipment.

2

Page 3

Software License Agreement

Read this license carefully. You agree that by using the eldized software package, you have agreed to the software

license terms and conditions. This agreement constitutes complete and entire agreement between you and Liquid

Controls with respect to this product.

1. Liquid Controls hereby grants to Licensee a nonexclusive

license to use DMS i1000 Menu, LCP File Server,

FleetConnect Ofce, and LCR Host Software (hereinafter

referred to as “Licensed Software”)

2. Under the License granted herein, Licensee may use the

eldized machine readable (executable code) copy of the

Software, including any subsequent updates which may

be provided. Licensee shall not, without Liquid Controls’

prior written consent, (a) rent, lease, lend, sublease or

otherwise transfer the materials hereunder; (b) remove or

obscure proprietary or copyright notices which may be set

forth on the Licensed Software; or (c) alter, decompile, or

disassemble the program.

3. One (1) copy of the Licensed Software, including any

software distributed on disks may be made for backup

purposes only. No other copies may be made or used

without the written consent of Liquid Controls.

4. Title. No title to ownership of any Licensed Software is

transferred to the Licensee.

5. Upgrades. License upgrades may become available for

the Licensed Software. Any cost associated with such

upgrades will solely be determined by Liquid Controls.

6. Warranty. Liquid Controls makes and licensee receives

no warranty express or implied and there are expressly

excluded all warranties of merchantability and tness for

a particular purpose.

8. Termination. Liquid Controls may terminate this software

license granted hereunder and require return of the

Licensed Software if Licensee fails to comply with these

license terms and conditions.

9. Licensee acknowledges that it has read this agreement,

understands it, and agrees to be bound by its terms, and

further agrees that this is the complete and exclusive

statement of the agreement between Liquid Controls

and Licensee, which supersedes and merges all prior

proposals, understandings, and all other agreements, oral

or written, between the parties relating to this agreement.

This agreement may not be modied or altered except by

written instrument duly executed by both parties.

10. This Agreement and performance hereunder shall be

construed and interpreted under the laws of the State of

Illinois.

11. If any provision of this agreement is invalid under any

applicable statute or rule of law, it is to that extent to be

deemed omitted.

12. Licensee may not assign or sublicense, without the

prior written consent of Liquid Controls, its rights, duties,

or obligations under this Agreement to any person or entity

in whole or in part.

13. The waiver or failure of Liquid Controls to exercise in

any respect any right provided herein shall not be deemed

a waiver of any further right hereunder.

7. Limitation of Liability. Licensee shall have the sole

responsibility for adequate protection and backup of its

data in connection with the Licensed Software. In no event

shall Liquid Controls be liable for (a) special, indirect or

consequential damages; (b) any damages whatsoever

resulting from loss of use, data, or profits, product,

inaccurate input or work delays, or any direct property

damage arising out of or in connection with this agreement

or the use or performance of the Licensed Software.

3

Page 4

DMS i1000 i1000 Overview

LectroCount Data Management System

DMS i1000Menu

LCRHost DMS i1000 Delivery LCP File Server

DMS i1000 Ofce Program

LectroCount DMS i1000 is a “Data Management System”

comprised of a DMS i1000 Module, DMS i1000 Lap

Pad, and function specic software applications. The

DMS i1000 Module is a hardware component which the

LectroCount registers, printer, DMS i1000 Lap Pad, and

power supply are connected.

The DMS i1000 software components consist of a system

operating software, DMS i1000Menu, LCRHost, DMS

i1000 Delivery, and LCP File Server. The DMS i1000

software applications are function specic.

DMS i1000Menu: An application which allows an operator

ability to switch between LCRHost, DMS i1000

Delivery, and LCP File Server. DMS i1000Menu also

provides ability to transfer and receive information

from a DMS i1000 Ofce program.

LCRHost: An application providing an operator ability to

setup LCR Networks, calibrate LectroCount LCR and

LCR-II electronic registers, and make deliveries.

DMS i1000 Delivery: An application providing an operator

ability to select customers from a customized list,

make deliveries, record/track deliveries, review

shift information, and transmit completed delivery

information to a DMS i1000 Ofce Program using a

USB ash memory.

DMS i1000 Ofce Program: This program runs on an

ofce computer. It is used to congure the DMS i1000

Delivery application an operator will use while making

deliveries, as well as customization of a delivery ticket.

It is also responsible for converting data les between

ofce software formats and the DMS i1000 Module.

DMS i1000 Delivery component of the LectroCount

DMS i1000 Data Management System is an application

designed to record and maintain delivery information.

DMS i1000 Delivery is not covered in this publication.

Instead, this publication covers the DMS i1000Menu,

LCRHost, and LCP File Server applications. These

applications are accessed via the DMS i1000 Lap Pad.

The DMS i1000 Lap Pad is a terminal interface device

with a display having up to eight lines of information. It

attaches directly to the DMS i1000 Module.

DMS i1000Menu instruction (page 11).

LCRHost instruction (page 18).

LCF File Server instruction (page 65).

DMS i1000 Delivery instructions are covered in the

LectroCount DMS i1000 Operator’s Manual: 500344.

Other LectroCount DMS i1000 publications include:

LCP File Server: An application providing an operator

ability to access files of the DMS i1000 Module

from other computer systems in a manner similar to

Windows® Explorer. Files on other devices running

LCP File Server are also accessible.

Windows® is a registered trademark of Microsoft Corporation.

• LectroCount DMS i1000 Installation Manual: 500343

• Quick Reference Card: 500345.

• Ofce Installation & Operation Manual: 500346.

NOTE: LC software is copyright protected and may not be

duplicated under any circumstances without authorization

from Liquid Controls.

4

Page 5

DMS i1000 i1000 System Components

Typical vehicle delivery system components:

Metering System

Metering system is typically mounted to the back or

side of the delivery vehicle and measures the ow of

product being delivered. Components of this system

can include the meter, electronic register, strainer, air

eliminator, and control valve.

DMS i1000 Module

DMS i1000 Module provides connections for the

printer, DMS i1000 Lap Pad, electronic registers,

and a USB ash memory (optional). Powered from

the vehicle’s accessory panel and often mounted on

support brackets in the cab of the vehicle.

M-10 Meter with LectroCount LCR-II Electronic

Register, Optical Air Eliminator, Hi Capacity Strainer,

and E-7 Valve.

DMS i1000 Module

DMS i1000 Lap Pad

DMS i1000 Lap Pad is the user interface device which

allows initial set up and calibration of the system and

an interface for daily deliveries.

Printer

Printer is used to print out a record of the delivery. This

ticket is typically a multi-layer ticket providing a copy

with the customer and a copy retained for physical

record of the delivery.

DMS i1000 Lap Pad

Epson Slip Printer

Support Brackets

5

Page 6

Specications

DMS i1000 Lap PadDMS i1000 Module

Enclosure

Dimensions

6.875” W x 2.625” H x 7.25” L

Material

Powder painted steel

Operating Voltage

+9 to 30 VDC, less than 3A

Temperature Rating

-13° to 158°F (-25° to 70°C)

Microprocessor

133 MHz, 486

Memory (Primary Hard Drive)

Internal ash memory

Housing

Lightweight, high impact, molded plastic.

Housing Rating

NEMA 3, IP54

Display

LCD, dot matrix, 240 x 64 pixels, backlit.

5.2” wide, 1.55” tall; 8 rows, 30 characters per row.

Keyboard

6 row, 5 column membrane with tactile metal dome

switch contacts and silicon rubber overlay.

Supply Current

150 mA maximum

Temperature

-13°F to 158°F (-25° to 70ºC)

Vibration

2 g between 10-150 sinusoidal sweep cycle. 20

sweep cycles per axis.

Electrostatic Discharge

IEC801-2

8 kV for air discharges

6 kV for contact discharges

Electromagnetic Susceptibility

IEC 801-3

3 V/m 26-500 MHz

1 V/m 500-1000 MHz

Interface

RS-232 at 115,200 baud rate

6

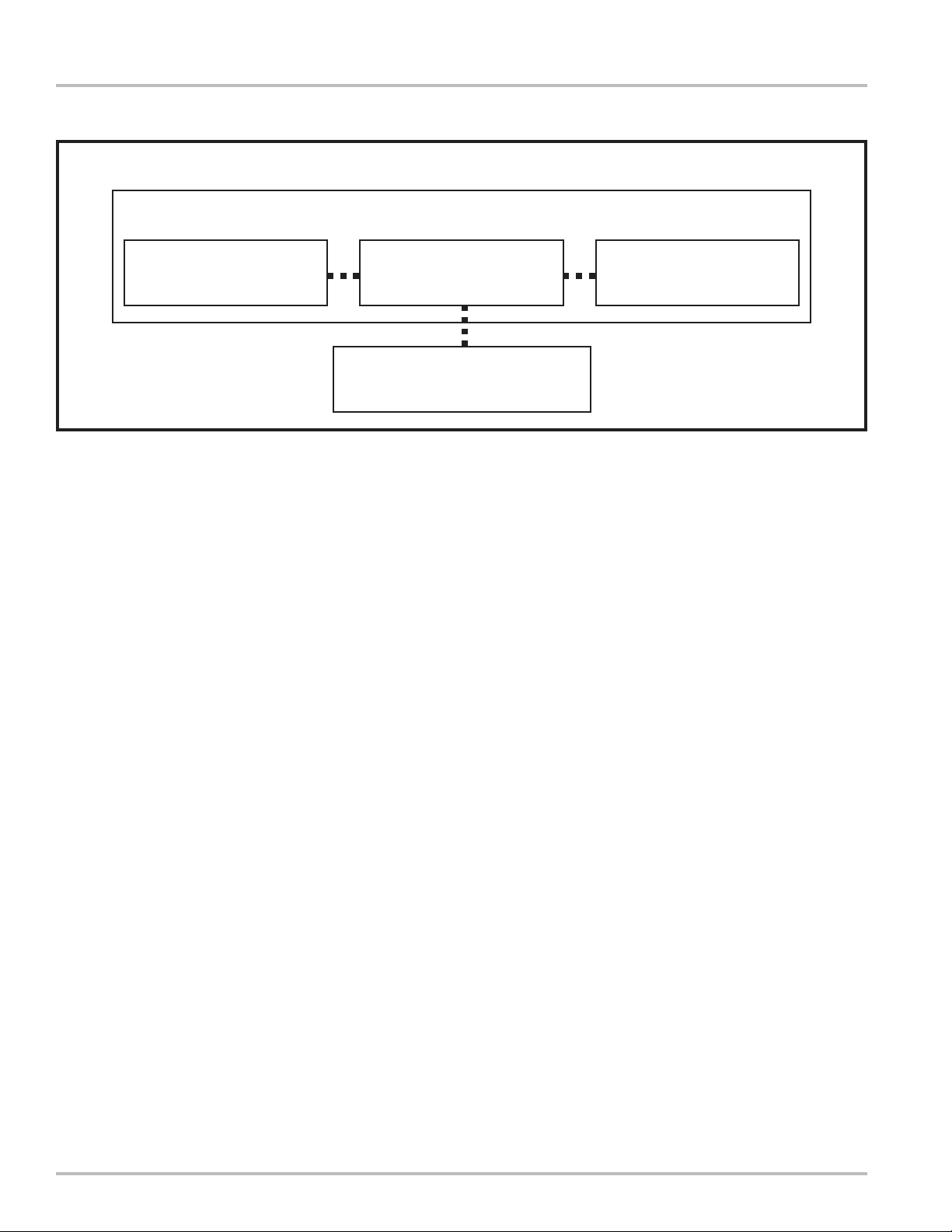

Page 7

DMS i1000 Lap Pad Setup

DMS i1000 Lap Pad Setup

DMS i1000 Lap Pad Setup v.1.00

(c) Liquid Controls LLC 2005

Adjust Contrast with and

Backlight:

Blink Cursor?

Auto Repeat:

CR and LF as Graphic?

Press ESC to exit.

DMS i1000 Lap Pad Setup Screen

On

Yes

Off

Yes

The DMS i1000 i1000 Lap Pad is the user interface

device for the DMS i1000 i1000. In the DMS i1000 i1000

Lap Pad Setup screen, you can change the settings for

the lap pad’s operation and display. While this screen is

loaded, the DMS i1000 i1000 Lap Pad is off line with the

DMS i1000 i1000.

To access the DMS i1000 i1000 Lap Pad Setup:

Press and hold the ALT and ENTER keys

simultaneously.

In the setup screen, the active eld is displayed in reverse

video. For example, in the example to the left, Adjust

Contrast is the active option. Pressing ENTER drops the

active eld to the next item. From the bottom option, the

active eld simply wraps back to the top option.

Adjust Contrast with and

Alters the DMS i1000 i1000 Lap Pad display for optimal

viewing. The up arrow increases the contrast; the down

arrow decreases the contrast.

Backlight:

Turns the light behind the display on and off. Use either

arrow key to change the setting.

DMS i1000 i1000 Lap Pad

Blink Cursor?

Switches the cursor display between solid and blinking.

If set to Yes, the blink rate is 250 ms.

Auto Repeat:

Enables or disables auto repeat when a key is held down.

If set to On, the character being held down will start to

repeat after 250 ms and repeat again every 50 ms.

CR and LF as Graphic?

This option is used to turn the CR/LF graphic on or off.

This eld should be set to Yes, when used with a DMS

i1000 i1000 application. If the Lap Pad is being used as

a standard terminal device, for example, processing DOS

command lines, this eld should be set to No.

Exiting the Lap Pad Setup

Press ESC to exit the DMS i1000 i1000 Lap Pad setup

and reestablish communication with the host computer

(DMS i1000 i1000). The values entered will be retained

each time the unit is powered up.

7

Page 8

DMS i1000 Lap Pad Navigation

Navigating the DMS i1000 Lap Pad

The DMS i1000 i1000 Lap Pad has an 8-line, 30

character per line display. Screen layouts vary according

to function. Some screen lines are xed, and some lines

can be modied. Since there are so many unique screens

throughout the suite of DMS i1000 i1000 application

software, the setup and operation manuals for DMS i1000

i1000 application software will layout each screen and

explain screen navigation according to function.

Line 1:

A xed standard eld. The screen title, LOAD TRUCK,

is displayed on the left, and the time, 14:45:07, is

displayed to the right. If there is more than one screen

necessary for a screen title, the screen number will

be displayed between the title and the time (Example

(1/3)).

Lines 2 - 7:

Line 1

Line 2

Line 3

Line 4

Line 5

Line 6

Line 7

Line 8

ACCOUNT INFORMATION

1111113

Albert Constantine

Presets

Miscellaneous Fees

Discounts

Price and Tax

Util

F1 F2 F3 F4 F5

DMS i1000 Lap Pad Display Layout

Back

(2/3)

2

$25.00

0

Fwd

A list of conguration options or DMS i1000 i1000

commands that can be selected using the pointer.

Using the up and down arrows on the DMS i1000

i1000 Lap Pad, the pointer moves up and down along

the left side of the options. The ENTER key selects

the option to the right of the pointer.

Line 8:

The commands assigned to the function keys (F1 -

F5) on the top row of the DMS i1000 i1000 Lap Pad

keyboard. These commands open new screens,

scroll through screens of the same title, and provide

navigation options. This manual will define the

commands available on every screen.

DMS i1000 i1000 Lap Pad

8

Page 9

SETUP NETWORK

Network#:

Name:

Network Name

|_ |

Home <-- Ins --> End

F1 F2 F3 F4 F5

Field Edit Window

Home (F1) moves the cursor to the rst position

Ins (F3) toggles between insert mode and over-write mode

F2 and F4 moves the cursor one space to the left or right

End (F5) moves the cursor to the last position in the eld

SHIFT must be held down to type in letters

BACK SPACE erases the character to the left of the cursor

CLEAR erases all characters in a eld edit window

ESC backs out of the window without making changes

ENTER accepts the characters inside the eld edit window

Field Edit and List Box Windows

Field Edit and List Box Windows

There are two editable fields in DMS i1000 i1000

applications: eld edit windows and list box windows.

Field edit windows appear above the function commands

(line 8) as a box in which alpha-numeric characters can

be entered. List box windows also appear above the

function commands (line 8), as a box with a list of options.

Both elds are titled in the upper left corner of the eld

and surrounded by a border. In the example to the upper

right, the eld edit window title is Customer Name. In the

example to the lower right, the list box window is titled

Button ID.

Field Edit Window

Field edit windows allow you to key unique information into

the DMS i1000 i1000. Using the keys of the DMS i1000

i1000 Lap Pad, you can type alpha-numeric characters

into the window, and DMS i1000 i1000 will assign them

to the eld (in the upper right example Customer Name).

While the eld edit window is in the display, the function

keys (F1 - F5) will provide tools to help you maneuver the

cursor inside the window. When you are nished keying

in your information, press the ENTER key to accept and

exit the eld edit window.

Product Type

Aviation

Distillate

Gasoline

Methanol

LPG

Lube Oil

Home PgUp Find PgDn End

List Box Window

Home (F1) sends the pointer to the rst item in the list

PgUp (F2) and PgDn (F4) scrolls forward or backward through the

list by full screens

Find (F3) opens a eld edit window into which parameters can be

entered for a search

End (F5) jumps to the end of the list

ENTER accepts the option to the right of the pointer

The (F#) function keys are activated only if there are more than

six options

Parameters for each specic eld edit window will be

dened throughout this manual.

List Box Window

List box windows display a searchable list of options for

you to choose from. Use the DMS i1000 i1000 Lap Pad

arrow keys to scroll the (pointer) up and down the list.

Press the ENTER key to select the option to the right of

the pointer. If there are more than six options and the list

will continue to another screen, the function keys (F1 - F5)

will provide navigational tools to accelerate the search.

9

Page 10

10

Page 11

DMSMenu Application

11

Page 12

System Utilities

Screen 1: Program Initialization

For newly installed LectroCount DMS i1000 systems,

DMS i1000Menu will launch the rst time the system is

powered up. The display to the right will appear on the

DMS i1000 Lap Pad prompting the operator to press Util

(F1) to advance to the System Utilities menu.

NOTE: If DMS i1000Menu is not displayed upon initial

startup, press ALT and ESC together to access DMS

i1000Menu. Press Util (F1) to advance to Screen 2a

shown below.

Screen 2a: System Utilities (1/3)

System Utilities consists of three screens. To advance

through these screens, press Next (F1). To exit this menu,

press Exit (F5).

Move pointer to Language and press ENTER to open a

list box window with options for the language to be used

by DMS i1000Menu. Move pointer to desired option and

press ENTER to accept.

Press Vers (F4) to open DMS i1000 Version Display

(shown below) which contains version numbers of the

application and supporting software libraries. There are

a minimum of six applications, it will be necessary to

scroll up and down to view all installed application version

numbers.

Data Management System v1.00

Welcome to the DMS i1000!

To set up your system, go to

SYSTEM UTILITIES by pressing

the F1/Util key.

Util

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Date Format:

DMS i1000 Date:

DMS i1000 Time:

MM/DD/YY

12/11/05

16:00:31

Next Vers Exit

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Version Display

Shows current version numbers of all installed applications

and supporting software libraries. Use PgDn (F4) to scroll

down to view version numbers.

DMS i1000 Date Format:

MM/DD/YY

Language

English

DMS i1000 Menu 1.02

(c) Liquid Controls LLC

ROM-DOS (c) Datalight Inc.

Support SDKs

PgDn End

12

Page 13

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Password

| |

Home <-- Ins --> End

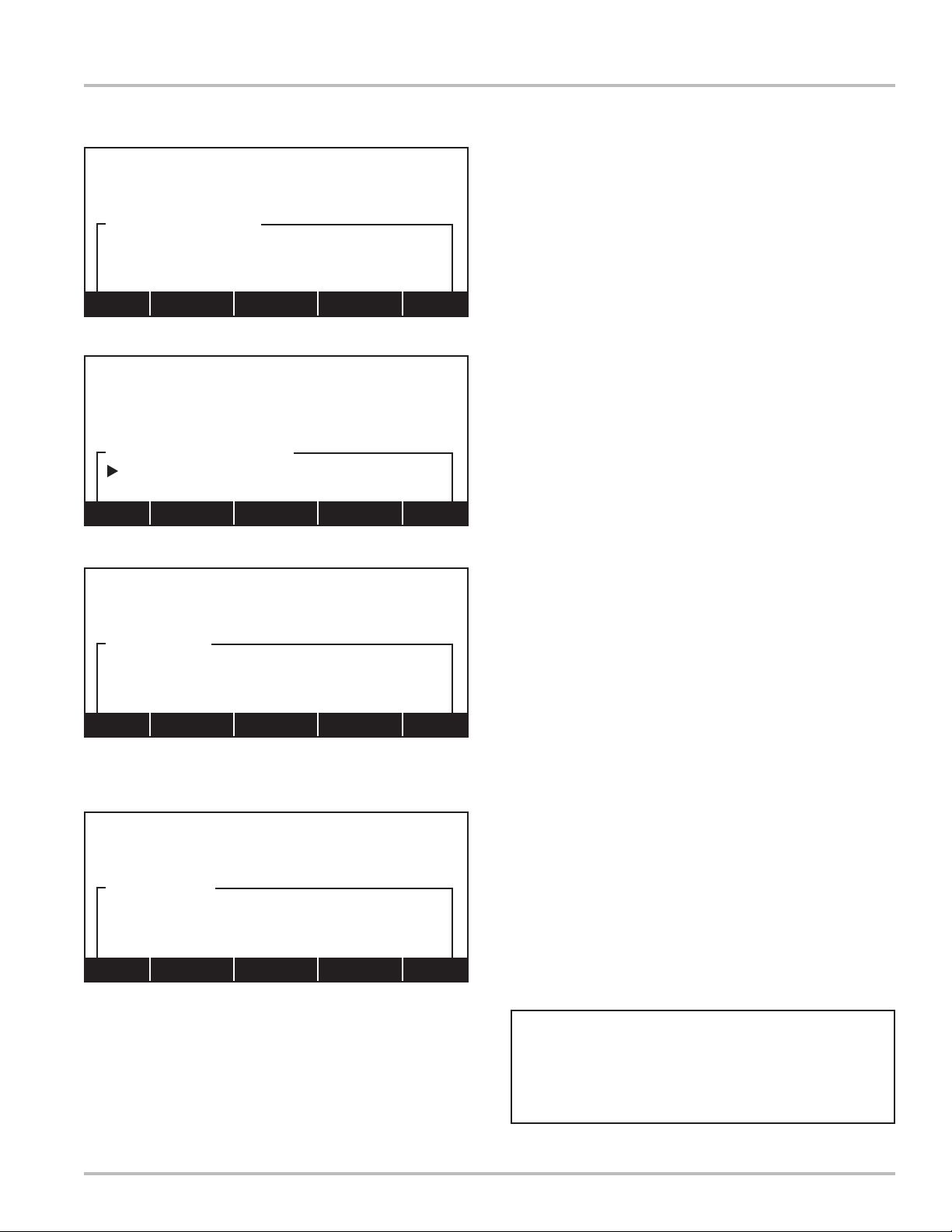

System Utilities

Screen 2a: System Utilities (1/3)

System Utilities contain system critical information, an

option is provided to lock out this menu using a password.

Move pointer to DMS i1000 Password and press ENTER

to open a eld edit window.

Enter a password in the space provided. This can be

an alpha-numeric string of up to ten characters. Next,

press ENTER to accept password and close eld edit

window. Once password is entered, it will be required to

regain access to the System Utilities menu as well as

LCRHost and LCP File Server. Retain this password in

a safe place.

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Date Format

MM/DD/YY

DD/MM/YY

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Date

|12-11-05|

Home <-- Ins --> End

SYSTEM UTILITIES

Language:

(1/3)

English

DMS i1000 Password:

DMS i1000 Time

Move pointer to DMS i1000 Date Format and press

ENTER to open a list box window with options:

MM/DD/YY (month/day/year)

DD/MM/YY (day/month/year)

Move pointer to desired option and press ENTER to

accept.

Move pointer to DMS i1000 Date and press ENTER

to open a eld edit window. Enter date to be used by

LectroCount DMS i1000 and press ENTER to accept.

Three characters can be used as a separator: period (.),

dash (-), and colon (:).

Move pointer to DMS i1000 Time and press ENTER

to open a eld edit window. Enter time to be used by

LectroCount DMS i1000 and press ENTER to accept.

Press Next (F1) to advance to Screen 2b on page 14.

|16:00:31|

Home <-- Ins --> End

NOTE: It will be assumed that the operator can

now readily navigate list box windows and eld edit

windows. Therefore, these windows will no longer

be shown for the remainder of this section.

13

Page 14

System Utilities

Screen 2b: System Utilities (2/3)

Startup Caps Lock is used to designate whether the DMS

i1000Menu should boot with caps lock on or off. Press

ENTER to open a list box window with options Off or On.

Startup Insert Flag is used to designate whether the DMS

i1000Menu should boot with the system set to insert or

overwrite. Press ENTER to open a list box window with

options Off or On.

Ofce Node Address allows operator to specify LCP node

address used by an ofce computer when communicating

with a wireless transmitter. This can be any number in the

range from 0 to 255. Leave this set to 0.

Ofce Path is used to identify a path to where transaction

and database les are located on an ofce computer

when a wireless transmitter is in use. This can be an

alpha-numeric string up to 244 characters in length. As

an example:

C:\ or

C:\DMS i1000 or

C:\DMS i1000\DATA or

C:\SOURCE\DMS i1000

SYSTEM UTILITIES

Startup Caps Lock:

Startup Insert Flag:

Ofce Node Address:

Ofce Path:

USB Path:

C:\SOURCE\DMS i1000

D:\DMS i1000

(2/3)

Off

Off

255

Next Prev Exit

Leave this eld blank.

USB Path is used to identify path to where transaction

and data base les are located on the DMS i1000 USB

ash memory. This eld can be an alpha-numeric string

up to 244 characters in length. As an example:

D:\ or

D:\DMS i1000 or

D:\DMS i1000\DATA

Press Next (F1) to advance to Screen 2c on page 15.

Press Prev (F2) to return to Screen 2a on page 13.

Press Exit (F5) to exit System Utilities menu and advance

to Screen 3 on page 16. Screen 1 may not appear again

during normal operation.

14

Page 15

(3/3)SYSTEM UTILITIES

Upgrade DMS i1000 Software

Prev Exit

System Utilities

Screen 2c: SYSTEM UTILITIES (3/3)

Upgrade DMS i1000 Software is a function that enables

operator to upgrade system software of a LectroCount

DMS i1000 Module. Press ENTER to open a list box

window with options Yes or No.

Move pointer to Yes and press ENTER. Software on

the USB ash memory will load to ash memory of DMS

i1000 Module.

Press Exit (F5) to exit System Utilities menu and advance

to Screen 3 on page 16. Screen 1 may not appear again

during normal operation.

15

Page 16

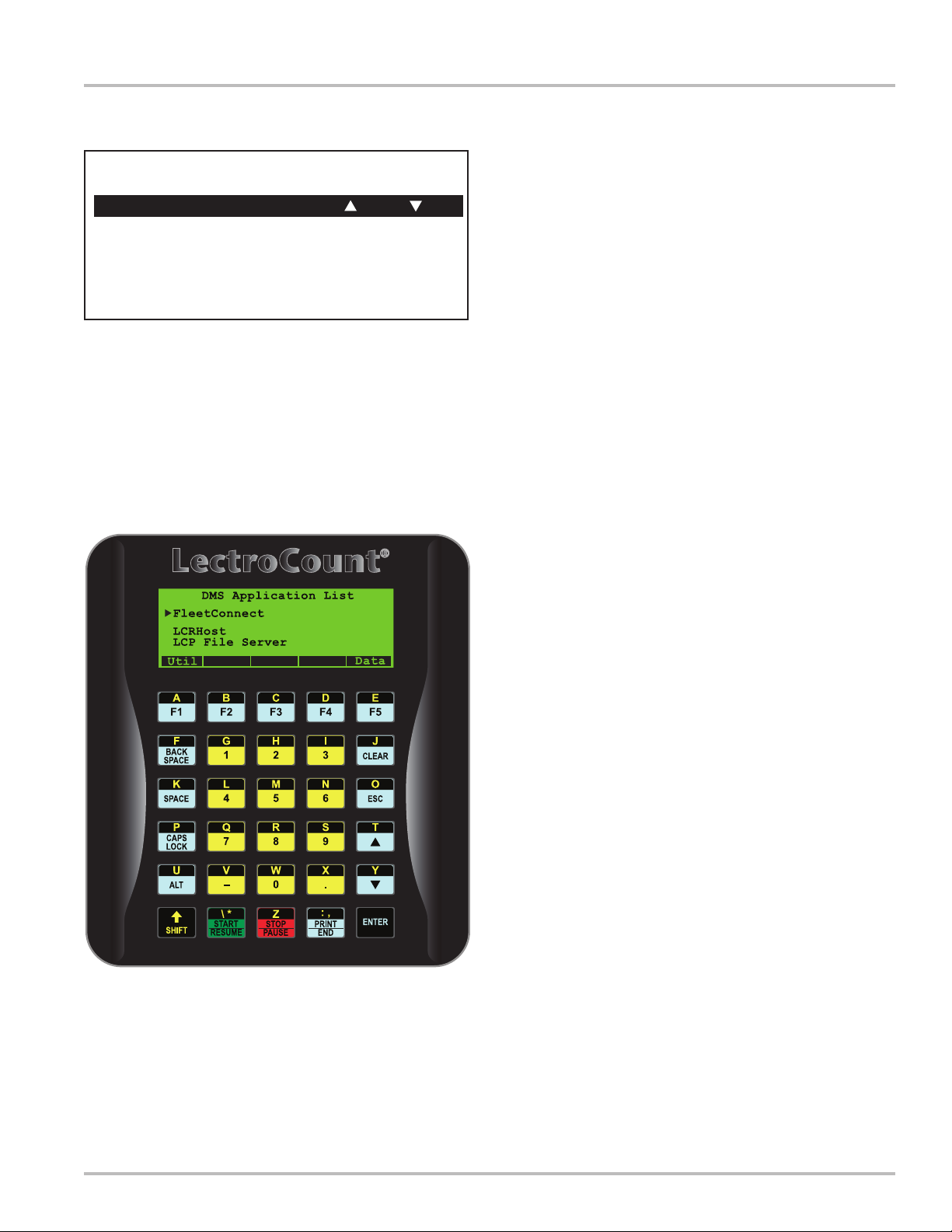

Data Application List

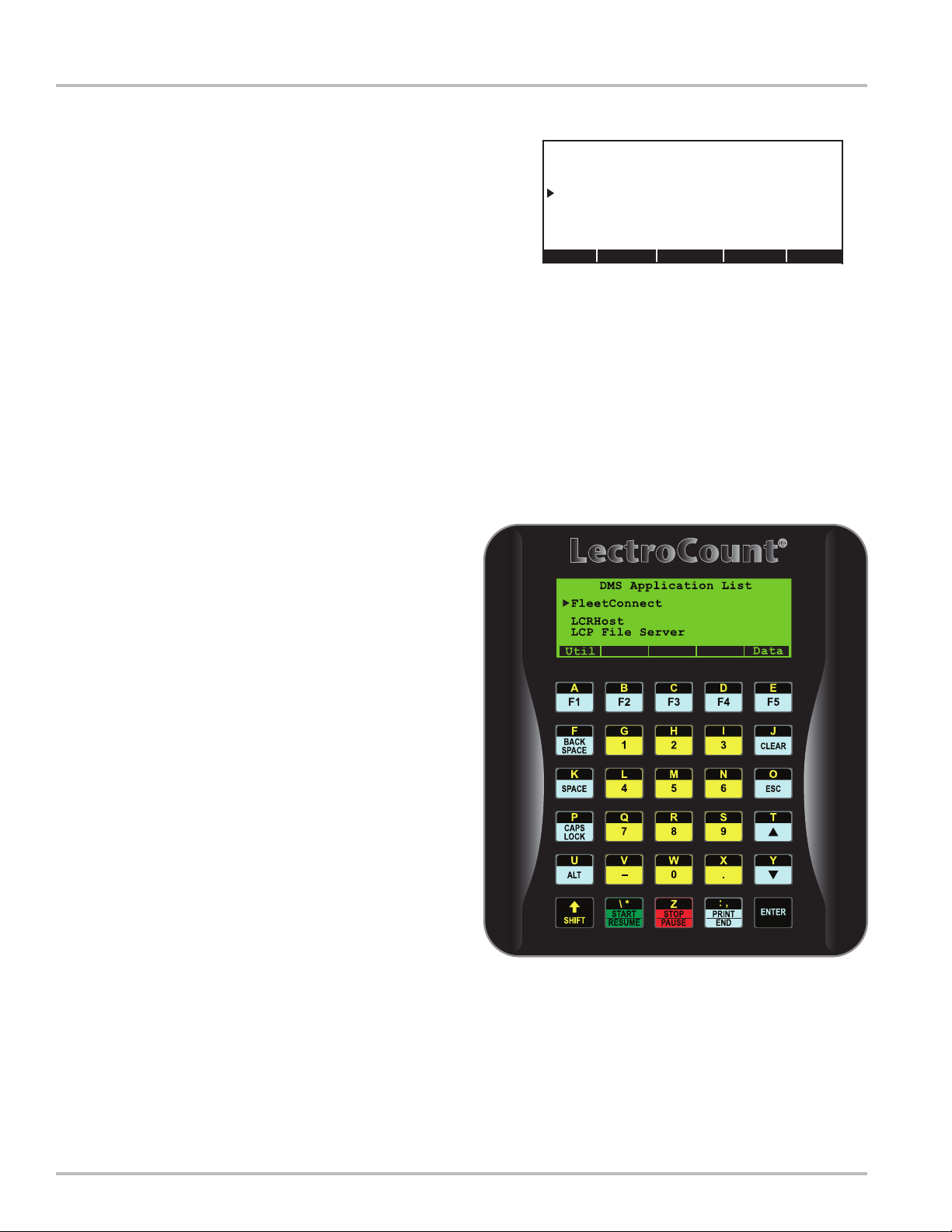

Screen 3: Data Management System

This screen is the main launch point for other applications

in the system. To access this screen, press ALT and ESC

simultaneously from any other application. This screen

must be accessed in order to navigate between available

applications. There is no direct link between LCRHost,

LCP File Server, and DMS i1000 Delivery. They must

all be accessed from this screen.

DMS i1000 Delivery

Application providing the operator ability to select

customers from a customized list, make deliveries, record

and track deliveries, review shift information, and transfer

completed delivery information to a DMS i1000 ofce

program using the USB ash memory.

The DMS i1000 Delivery application is not covered in

this publication. Refer to Operator’s Manual: 500344, for

detailed information on DMS i1000 Delivery Application.

LCRHost

Application provides operator ability to setup an LCR

Network, congure and calibrate a LectroCount register

and meter, and make deliveries.

DMS i1000 Application

List

DMS i1000 Delivery

LCRHost

LCP File Server

NOTE: PgUp (F2) and PgDn (F4) are activated only

if more applications are available than appear on the

screen.

The LCRHost application description begins on page

19.

LCP File Server

Provides operator ability to access hard drive of the DMS

i1000 interface from other computer systems.

The LCP File Server application description begins on

page 65.

Press Util (F1) to return to Screen 2a on page 12.

Press Data (F5) to advance to Screen 5 on page 17.

16

Page 17

Database Management

Send Transactions to Ofce

Retrieve Database from Ofce

USB Done

Database Management

Database Management

Screen 4: Database Management

Database Management screen is used to transfer

completed transaction les to an ofce computer and to

retrieve an updated database from an ofce computer.

Send Transactions to Ofce display is used to transfer

completed transaction les to an ofce computer. This

is typically done at the end of a shift or often as required.

When ENTER is pressed, appearance of the screens will

depend on the LectroCount DMS i1000 conguration.

To ensure system recognizes the USB memory device,

press USB (F3). This locates the USB memory device.

Once communication with USB memory device is

established, proceed with Send Transactions to Ofce

as described above.

Locating USB Drive...

USB Done

Database Management

Send Transactions to Ofce

Retrieve Database from Ofce

Send Mechanism

Radio

USB Memory Device

When ENTER is pressed, the system will transfer the

transaction le (CompTran.trn) to the USB ash memory.

A status indicator will appear and indicate progress of

le transfer. As this le is sent, the transaction records

are also automatically appended to an archive file

(CompTran.tra) in the DMS i1000. This archive le will

increase in size indenitely until deleted by the operator

via the LCR File Server application. When le transfer is

complete, the display will indicate:

“The transactions were successfully sent.

Press ENTER to proceed”.

Press ENTER to close this window.

Retrieve Database from Ofce display functions in

a similar fashion as Send Transactions to Office

display.

Move pointer to Retrieve Database from Ofce and

press ENTER. This will copy all les from the USB ash

memory with the extension “.slf” to DMS i1000 internal

ash memory. A transfer status indicator will display

progress of the le download. When complete, press

Done (F5) to return to Screen 3 on page 16.

17

Page 18

18

Page 19

LCRHost Application

19

Page 20

Main Menu

Screen 1: Program Initialization

When the LCRHost application is initialized at startup, screen to the right appears. This screen contains

information about the operating software. The rst line

contains program name and revision.

LCRHost v1.02

Welcome to LCRHost!

The message shown in lines 4-7 which appear after the

introduction lines, will then appear under the following

condition:

LCRHost detects that the LCRConfg.slf le does not

exist.

If system was already congured, the display will advance

to Screen 19a: Preset and Delivery (1/7) on page 54.

If communication cannot be established with the LCR,

then display will show Screen 20: Device Not Found

on page 59.

If this is the initial set and conguration of the system,

press Main (F5) to advance to Screen 2 shown below.

Screen 2: Main Menu

Main Menu is the launch point for system setup, calibration,

and conguration. Items appearing on the Main Menu are

typically used for initial setup and conguration of the

system but may be reset should the system or application

change.

By default, the pointer position will be the rst available

function on the screen. To move pointer from Setup

Network to another line, use up or down arrow of the

DMS i1000 Lap Pad. The up arrow is on shares T key

and down arrow shares Y key.

To set up your network, go to

the Main Menu by pressing the

F5/Main key.

Main

LCRHost v1.02

MAIN MENU

Setup Network

System Parameters

Congure LCR #xxx

Save Conguration

Load Conguration

Dlvy LCR#

Setup Network

Advances display to Screen 3 on page 21.

System Parameters

Advances display to Screen 6a on page 26.

Congure LCR#

Advances display to Screen 7 on page 28.

Save Conguration

Advances display to Screen 14 on page 51.

Load Conguration

Advances display to Screen 15 on page 52.

Dlvy appears above function key F1. Press Dlvy (F1) to

advance to Screen 19a on page 54.

LCR# appears above function key F4. Press LCR# (F4)

to open a list box window with options for selecting an

LCR to communicate with.

Press Esc to exit list box window. Move pointer to Setup

Network and press ENTER to advance to Screen 3 on

page 21.

20

Page 21

SETUP NETWORK

Steps to create a new network.

F3/New: Create a new network.

Edit Port eld if necessary.

F1/Next:Setup device database.

F1/Next:Setup network devices.

New Main

SETUP NETWORK

(1/3)

Network #:

Name:

Port:

COM2 at 19200 Baud

Next New Del Main

SETUP NETWORK

(1/3)

Network #:

Network Number

1 :1-METER SYSTEM

2 :2-METER SYSTEM

3 :3-METER SYSTEM

Setup Network

Screen 3: Setup Network

If no network les have been set up, the screen to the

right will be displayed. This display is not editable, but

indicates the steps to be taken to set up a new network.

Press New (F3) to create a new network. This advances

the display to Screen 4a shown below.

NOTE: The default values for each of the SETUP

NETWORK elds will effectively communicate with a

LectroCount register.

Screen 4a: Setup Network (1/3)

The SETUP NETWORK screens allow a new installation

to dene the network. There are two editable items on this

rst of these screens. The rst eld, Network #, opens

a list box window with a default set of network identiers.

If this is a single meter network, select 1 |1-METER

SYSTEM. This populates Network # and Name elds

for this screen.

If a different Network # and Name are required, a new

network can be established. Initiated by pressing New

(F3).

New opens a eld edit window. Network Number can

have a numeric value from 1 to 65535. Enter a number

and press ENTER to accept the value. For example, enter

1 as the Network Number and press ENTER.

Move pointer to Name and press ENTER to open a eld

edit window. Network Name is an optional eld and can

be a maximum length of 14 alpha-numeric characters.

Enter desired Network Name and press ENTER to accept

the value. For example, enter TRUCK 2112 then press

ENTER.

SETUP NETWORK

(1/3)

Network #:

Name:

Single Meter

Network Name

|1-METER SYSTEM|

Home <-- Ins --> End

If more than one network is required for the application,

press New (F3) to enter next Network Number.

To delete a Network #, select that network number from

the list box window, press ENTER, and then press Del

1

(F4) to delete that network from the program.

When task is complete, press Port (F2) to advance to

Screen 5: Setup Network Port on page 24.

21

Page 22

Setup Network

Screen 4b: Setup Network (2/3)

This screen is used to establish communication with

LectroCount Registers (LCRs). By default, all LCRs are

shipped with a node address of 250. This information

will be helpful when establishing communication with

new LCRs.

Based on examples provided, one network has been

dened and this is Network # 1. Move pointer to Device

and select New (F3) The device number can be between

1 and 249. Enter the number “1” and press ENTER to

accept.

Next, move pointer to Name and press New (F3) to open

a eld edit window. This eld can be from 0 to 16 alpha-

numeric characters in length. Enter a suitable name for

the device number 1. For example, type in “LCR1” and

press ENTER to accept.

SETUP NETWORK

Network:

1|1-METER SYSTEM

(2/3)

Device:

Name:

METER-1

1

Next Prev New Del

SETUP NETWORK

Network:

1|1-METER SYSTEM

(2/3)

New Device Number

|1_ |

Home <-- Ins --> End

SETUP NETWORK

Network:

1|1-METER SYSTEM

(2/3)

Device:

Name:

METER-1

1

Next Prev New Del

SETUP NETWORK

Network:

1|1-METER SYSTEM

(2/3)

Device Name

|METER-1 |

Home <-- Ins --> End

22

Page 23

SETUP NETWORK

Network:

1|1-METER SYSTEM

(3/3)

======SEARCH FOR DEVICES======

First Device:

Last Device:

Prev Addr Srch Setup

SETUP NETWORK

Network:

1|1-METER SYSTEM

(3/3)

Set Up LCR Devices

No

Yes

Setup Network Devices

Screen 4c: Setup Network (3/3)

Move pointer to Last Device and enter Setup (F5) this

allows automatic selection of an active LCR device.

Under Set Up LCR Devices, move pointer to Yes then

press ENTER. This will display The setup process has

completed successfully.

1

1

When a new device is found, enter a name for it and

continue with setup.

To remove a device from the network conguration, select

device and press Del (F4). This deletes the selected

device. Deleting a device connected to the network

will cause it’s node address to be reset to 250. When

programming of network devices is complete, press Exit

(F5) to return to Screen 4a on page 21. Then press Main

(F5) to return to Screen 2 on page 20.

Move pointer to System Parameters and press ENTER

to advance to Screen 6a on page 26.

SETUP NETWORK

Network:

1|1-METER SYSTEM

(3/3)

Finding active device

Last Device:

Prev Addr Srch Setup

LCRHost: 31025

The setup process has

completed successfully.

Press ENTER to proceed.

Last Device:

Prev Addr Srch Setup

NOTE: It will be assumed the operator can now

readily navigate list box windows and eld edit

windows. Therefore, these windows will no

longer be shown for remainder of this manual.

23

Page 24

Setup Network

Screen 5: Setup Network Port

Setting up network port sets up communication parameters

between LectroCount DMS i1000 and LectroCount

electronic register.

Port is used to select the port and interrupt request line

used by the active network. Press ENTER to open a list

box window for Communications Port. The following

options will be available:

COM1

COM2

COM3

COM4

Use Base Address of UART

A standard DMS i1000 Module is wired to communicate

with the LCR network on COM2, IRQ3, at a baud rate of

19200, therefore select COM2 and press ENTER. This will

open another list box window. The new list box window is

for selecting the IRQ used by the port. This list box window

contains interrupt request (IRQ) values between 2 and 15.

Select IRQ “3” and press ENTER to accept the COM and

IRQ choices and return to SETUP NETWORK PORT.

The changes for Port are now displayed on the screen.

Move pointer to Bits/Second (baud rate) and press

ENTER. This opens the Bits/Second list box window.

This value is the baud rate used to communicate with the

network of LectroCount registers. The following options

are available:

2400

4800

9600

19200

57600

It is recommended to use a baud rate of 19200. Select

19200 and press ENTER to accept the value. If there is

no printer connected to the system, a baud rate of 57600

can be selected.

SETUP NETWORK PORT

Port:

Bits/Second (Baud):

Tx Enable Bit:

Maximum Retries:

Timeout (ms):

Baud Synchronization :

COM2 using IRQ 3

19200

RTS

1

100

Yes

Exit

SETUP NETWORK PORT

Communications Port

COM1

COM2

COM3

COM4

Use Base Address of UART

IRQ

3

4

5

6

7

8

Home PgUp Find PdDn End

SETUP NETWORK PORT

Bits/Second

2400

4800

9600

19200

57600

24

Page 25

Transmit Enable Bit

!RTS

!RTS!DTR!

DTR

None

RTS

RTSDTR

Home PgUp Find

SETUP NETWORK PORT

Port:

Bits/Second (Baud):

COM1 using IRQ 3

19200

Maximum Retries:

|1_ |

Home <-- Ins --> End

SETUP NETWORK PORT

Port:

Bits/Second (Baud):

COM1 using IRQ 3

57600

Timeout:

|250_|

Home <-- Ins --> End

Setup Network

Screen 5: Setup Network Port

Continued

Move pointer to Tx Enable Bit and press ENTER to open

Transmit Enable Bit list box window. The Transmit

Enable Bit is used in an RS-485 network when data is to

be transmitted to a LectroCount register. The following

options are available:

!DTR

!RTS

!RTS!DTR

DTR

None

RTS

RTSDTR

For a standard DMS i1000 Module, select RTS and press

ENTER to accept the value.

Move pointer to Maximum Retries and press ENTER to

open a eld edit window.

Maximum Retries represents number of times system

attempts to communicate with a LectroCount register

should rst attempt fail. The maximum number of retries

can have a value between 0 and 255. Enter desired

number of retries and press ENTER to accept the value.

Move pointer to Timeout and press ENTER to open a

eld edit window. Timeout value is the length of time (in

milliseconds) a single communication is attempted before

returning a communication failure. The timeout value may

be between 100 and 9999 ms. Enter desired value and

press ENTER to accept. The recommended value is 100.

SETUP NETWORK PORT

Port:

COM1 using IRQ 3

Bits/Second (Baud):

Tx Enable Bit:

Baud Synchronization

No

Yes

19200

RTS

Move pointer to Baud Synchronization and press

ENTER to open a list box window and chose Yes or No. If

Yes is selected, the system will try all available baud rates

should the baud rate set earlier result in a communication

error. Select Yes and press ENTER to accept.

NOTE: Care should be taken when setting the Maximum

Retries and Timeout values. If an LCR is not present in

the network, it will take:

5 x (R + 1) x T = milliseconds

before it is determined an LCR is not present. 5 is the

number of baud rates if Baud Synchronization is set to

Yes, R is the number of Maximum Retries and T is the

Timeout value in milliseconds. If the number of retries

is 3 and the timeout value is 500, then the time before an

error is returned is:

5 x (3 + 1) x 500 = 10,000 or 10 seconds.

Press Exit (F5) to exit SETUP NETWORK PORT and

return to SETUP NETWORK. Then press Dev (F1) to

advance to Screen 5: SETUP NETWORK DEVICES on

page 24.

25

Page 26

System Parameters

Screen 6a: System Parameters (1/2)

System Parameters screens are used to set up user

interface and system information.

Move pointer to Language and press ENTER to open a

list box window of languages. Select desired language

to be used by LCRhost and displayed on the DMS i1000

Lap Pad. Language options currently include English.

Move pointer to LCRHost Password and press ENTER

to open a eld edit window. Enter an alpha-numeric code

up to 10 characters in length. Once LCRHost Password

is entered, the operator is required to enter this code in

effort to access the Main Menu from delivery screens.

NOTE: If password protection of Main Menu is not

desired, leave this eld blank.

The elds are for setting date and time of LCRHost

processor (not the LCR). Date and time are eld edit

windows. Enter current date and time for each eld.

Date/Time Master designates which device will have the

master copy of the date and time. When a new delivery

is started, date and time from the master device will

be sent to a slave device. Move pointer to Date/Time

Master and press ENTER to open a list box window with

the options:

SYSTEM PARAMETERS

Language:

(1/2)

English

LCRHost Password:

Host Date:

Host Time:

Date/Time Master:

01/16/06

16:00:23

Host

Next Vers Main

HOST

LCR

None

If HOST is selected, date and time are maintained in the

LCRHost processor. When a delivery is started, HOST

date and time will be sent to the LCR. If LCR is selected,

date and time are maintained in the active LCR to be

retrieved and set in the LCRHost processor at start of

each delivery.

If None is selected, then date and time will not be

synchronized between LCRHost processor and active

LCR. Date and time information appearing on delivery

ticket will be from the LCR.

Press Next (F1) to advance to Screen 6b on page 27.

Press Vers (F4) to open DMS i1000 About Display shown

on the bottom of page 12.

26

Page 27

SYSTEM PARAMETERS

Startup Caps Lock:

Startup Insert Flag:

(2/2)

Off

Off

Prev Main

LCRHost (DMS i1000) v1.02

MAIN MENU

Setup Network

System Parameters

Congure LCR # 1

Save Conguration

Load Conguration

Dlvy LCR#

System Parameters

Screen 6b: System Parameters (2/2)

Startup Caps Lock is used to designate whether the

DMS i1000 Lap Pad should boot with caps lock on or off.

Pressing ENTER opens a list box window with options

Yes or No.

Startup Insert Flag is used to designate whether the DMS

i1000 Lap Pad should boot with the system set to insert

or overwrite. Pressing ENTER opens a list box window

with the options Yes or No.

When programming of this screen is complete, press Main

(F5) to return to the MAIN MENU (shown to the right),

move pointer to Congure LCR# 1, and press ENTER

to advance to Screen 7 on page 28.

27

Page 28

Congure LCR

Screen 7: Congure LCR

Network and LCR Device must be assigned rst.

Congure LCR is similar to Main Menu as a launching

point for several other sub-menus. Within Congure

LCR are:

General Setup

Advances display to Screen 8a on page 29.

1CONFIGURE LCR

General Setup

System Calibration

Product Calibration

Diagnostics

Security

System Calibration

Advances display to Screen 9a on page 32.

Product Calibration

Advances display to Screen 10a on page 37.

Diagnostics

Advances display to Screen 11a on page 48.

Security

Advances display to Screen 12 on page 49.

Pressing Stat (F3) advances display to Screen 21 on

page 60.

Pressing LCR# (F4) allows the operator to select the

LectroCount register to be congured.

Pressing Main (F5) returns display to Screen 2 on page

20.

Ensure pointer is on General Setup and press ENTER

to advance to Screen 8a on page 29.

Status LCR# Main

28

Page 29

GENERAL SETUP

(1/5) 1

Unit ID:

Presets Allowed:

Net

Date Format:

Date:

Time:

MM/DD/YY

01/11/05

11:27:36

Next Cnfg Main

General Setup

Screen 8a: General Setup (1/5)

General Setup screens are used to set up system

information, deliveries, and ticket printing.

Unit ID is an alpha-numeric identier up to 10 characters

in length used to identify the active LectroCount register.

Press ENTER to open a eld edit window and enter

desired value. Press ENTER to accept.

Presets Allowed denes presets an operator can set

while making deliveries. Preset deliveries allow an

operator the ability to enter a preset volume for delivery.

Upon reaching the preset volume, LectroCount will

typically close a security valve (if equipped) and print a

delivery ticket.

There are four options for Presets Allowed.

BOTH - for both net and gross presets

GROSS - for gross (non-compensated) presets only

NET - for net (temperature compensated) presets

or

NONE - for no presets allowed

Move pointer to desired option and press ENTER to

accept.

NOTE: If the preset feature is used, ensure the S1 CLOSE

eld on page 38 is set for a preset value to work properly.

Date Format is used to determine the format date

displayed and printed. Press ENTER to open a list box

window with the options: DD/MM/YY (Day/Month/Year)

and MM/DD/YY (Month/Day/Year). Select desired format

and press ENTER to select.

Date and Time are elds where current date and time

are entered for the LCR (not for LCRHost). Open the

eld edit window for each and enter current date and

time. Three characters used as a separator are period (.),

forward slash (/), and colon (:). Press ENTER to accept

each value.

Pressing Next (F1) advances display to Screen 8b on

page 30.

Pressing Cnfg (F4) returns display to Screen 7 on page

28.

Pressing Main (F5) returns display to Screen 2 on page

20.

29

Page 30

General Setup

Screen 8b: General Setup (2/5)

Sale # is used to track number of transactions LectroCount

processes. This number will increment each time a

delivery is started.

Press ENTER to open a eld edit window to enter starting

number for Sale # and press ENTER to accept. The

LectroCount will use this as the starting value for Sale #

and increment by 1 each time a delivery is started. Once

a Sale # reaches 999999, it will return the count to zero

and resume counting from 1.

GENERAL SETUP

(2/5) 1

Sale #:

Ticket #:

Print Gross & Parameter?

Volume Corrected Message?

Pulse Output Edge:

Falling

Yes

Yes

Next Prev Cnfg Main

1

1

Ticket # is similar to Sale # however, Ticket # will

increment each time LectroCount prints a ticket.

If multiple or duplicate tickets are used for transactions,

the ticket number will increment more than the Sale #.

Press ENTER to open a eld edit window and enter

starting number for Ticket # and press ENTER to accept.

LectroCount will use this as the starting value for Ticket #

and increment by 1 each time a delivery ticket is printed.

Once Ticket # reaches 999999, it will return the count to

one and resume counting from 1.

NOTE: If 0 is entered for Ticket #, the Ticket # will not

print on the delivery ticket and it will not increment.

Print Gross & Param? is used to enable or disable

printing of gross volume and compensation parameter

on the delivery ticket if the product is temperature

compensated. In many applications this is required.

Check local Weights & Measures requirements.

Press ENTER to open a list box window. Select No if it is

NOT desired to print the gross volume and compensation

parameter on the ticket. Select Yes if it IS desired to

print the gross volume and compensation parameter on

the ticket.

Volume Corrected Message? is used to enable or disable

printing of the base temperature of net deliveries on the

delivery ticket. In many applications, this is required.

Check local Weights & Measurements requirements.

There are two options for Vol Corrected Msg?. Select

No if the volume corrected message is NOT printed on the

delivery ticket. Select Yes to have the volume corrected

message printed on the delivery ticket. If Yes is selected,

the LectroCount will print a message on the delivery ticket

indicating the delivery volume has been corrected to a

specied base temperature.

If base temperature is in °C, the message will read:

TEMPERATURE VOLUME CORRECTED TO 15 °C

If the base temperature is in °F, the message will read:

TEMPERATURE VOLUME CORRECTED TO 60 °F

NOTE: The base temperature for Linear C and Linear F

can be set to a value other than their default values.

All LectroCount registers feature a calibrated pulse output

which cycles once per least signicant unit of delivery.

The Pulse Out Edge eld allows the LectroCount to

synchronize the calibrated pulse output waveform with the

requirements of an external counter. Depending on the

manufacturer, some counters may increment on the rising

pulse edge of the waveform, some on the falling pulse

edge. Refer to the manufacturer’s manual to determine

the specic requirements.

The List Box Window has two options. Select Rising for

the rising edge of the pulse output. Select Falling for the

falling edge of the pulse output.

Press Next (F1) to advance to Screen 8c on page 31.

30

Page 31

(3/5) 1GENERAL SETUP

Header Text

1:

2:

3:

4:

5:

Next Prev Cnfg Main

(4/5) 1GENERAL SETUP

Header Text

6:

7:

8:

9:

10:

Next Prev Cnfg Main

General Setup

Screen 8c: General Setup (3/5)

The next three consecutive screens all deal with header

information to be printed on a delivery ticket. The header

lines are edited individually. Press ENTER to open a eld

edit window for each line. Enter alpha-numeric information

up to 35 characters in length per line. Any or all of these

elds may be left blank.

NOTE: Since display is set to 30 character width, header

text information may scroll off the screen. This will be

indicated by ›› at the end of the header text line. All

information will, however, print on the delivery ticket.

Screen 8d: General Setup (4/5)

Header lines 6 through 10. Refer to description above.

(5/5) 1GENERAL SETUP

Header Text

11:

12:

Prev Cnfg Main

Screen 8e: General Setup (5/5)

Header lines 11 and 12 print conditionally. Header line

11 prints only if Aux1 is set to ON DURING DELIVERY.

Similarly, Header line 12 prints only if Aux2 is set to ON

DURING DELIVERY. For example, if an additive injector

is activated by Aux1, it may be desirable to note this on

the ticket by adding a header line such as “Prist added

to this delivery”.

Press Cnfg (F4) to return to Screen 7 on page 28. Move

the pointer to System Calibration and press ENTER to

advance to Screen 9a on page 32.

31

Page 32

System Calibration

Screen 9a: System Calibration (1/5)

System Calibration screens cover configuration and

calibration of the metering system.

Meter ID is an alpha-numeric value used to uniquely

identify a Meter attached to a LectroCount register. It is

important a unique number is selected and recommended

the meter serial number be entered. This number will

print on all calibration and diagnostic tickets for future

reference.

Press ENTER to open a eld edit window and enter a

unique identier up to 10 alpha-numeric characters in

length. Press ENTER to accept this value.

Flow Direction is used to set direction of ow through

the meter. If the LectroCount display counts in reverse

(decreasing numbers) after unit is installed, it will be

necessary to select opposite Flow Direction.

Ticket Required is used to select whether a delivery

ticket will be required for each delivery. Most Weights

& Measures governed truck applications will require a

ticket.

There are two options for Ticket Required?. If No is

selected, the system will NOT require a ticket to be printed

after each delivery. If Yes is selected, the LectroCount

will not allow deliveries to be made unless a ticket is in the

printer and the printer is operational. It will also require a

ticket be printed before another delivery can be started.

SYSTEM CALIBRATION

Meter ID:

Flow Direction:

Ticket Required?

Printer

Epson OldFontA

dP Shutdown Value:

(1/5) 1

4545

->

Yes

xx.x

Next Cnfg Main

dP Shutdown Value represents differential pressure

that will cause current active delivery to shutdown. This

function is only active when the following conditions

exist:

1. A Differential Pressure device is installed.

2. LectroCount Register has SR214 software installed.

3. Value is set to a number other than “0”

When these three conditions exist, reaching or exceeding

the dP Shutdown Value will end the delivery. Press

ENTER to open a eld edit window and enter a value

between 0 and 59.9.

Press Next (F1) to advance to Screen 9b on page 33.

Move pointer to desired option and press ENTER to

accept.

NOTE: Selecting No will still allow a ticket to be printed

if a printer is connected, loaded with paper, and ready

to print.

Printer is used to select printer model to communicate

with the LectroCount. Selecting a wrong printer model

may result in miscommunication between LectroCount

and printer.

There are six options for the Printer. Use the following

guide to select the correct option:

BLASTER (select for use with Cognitive Solutions

Thermal Printer).

EPSON NewFontA (select for use with EPSON TM-

T88iii)

EPSON NewFontB (select for use with EPSON 200 Roll

and EPSON 220 Roll)

EPSON OldFontA (select for use with EPSON 290 Slip

and EPSON 295 Slip)

EPSON OldFontB (select for use with EPSON 300

Roll)

Okidata ML184T (select for use with Okidata ML184T)

32

Page 33

SYSTEM CALIBRATION

Units of Measure:

Flow Rate Base:

Decimals:

Residual Processing

(2/5) 1

Gallons

Per Minute

Hundreths

Truncate

Next Prev Cnfg Main

System Calibration

Screen 9b: System Calibration (2/5)

Units of Measure is used to dene base unit of measure

for delivery quantities. Press ENTER to open a list box

window with the options:

Gallons

Litres

Cubic M

LBS

KGS

Barrels

Other

Move pointer to selection and press ENTER.

Flow Rate Base is used to dene rate base used by ow

rate eld. Press ENTER to open a list box window with

the options:

Per Hour

Per Minute

Per Second

Move pointer to desired option and press ENTER.

Decimals is used to dene the number of digits maintained

to right of decimal point in quantity elds. Press ENTER

to open a list box window with the options:

Hundredths = 2 decimal places (e.g. 120.22)

Tenths = 1 decimal place (e.g. 120.2)

Whole = 0 decimal places (e.g. 120)

Move pointer to desired option and press ENTER.

Residual Processing is used to dene what happens

with residual amounts. Press ENTER to open a list box

window with the options:

Round

Truncate

Selecting Round causes quantity residuals to be rounded

in the displayed values. Selecting Truncate causes

quantity residuals to be truncated from the display values.

For example, if actual quantity registered is 100.26 and

Decimals is set to Tenths, the Round value would be

100.3, and Truncated value would be 100.2.

Press Next (F1) to advance to Screen 9c on page 34.

33

Page 34

System Calibration

Screen 9c: System Calibration (3/5)

The rst three items on this screen are used to dene

parameters of an odometer sensing device (if installed

as part of the LCR).

The elds of Pulses/Distance, Calibrated Distance, and

Odometer are used to calibrate an odometer pulser if an

odometer input is being used with an LCR.

NOTE: LectroCount LCR-II does not have an odometer

input option. If the register is required to maintain an

odometer reading, use LectroCount LCR.

Pulses/Distance represents number of pulses from an

odometer pulser the LectroCount LCR counts per unit of

distance (miles or kilometers). For initial calibration of the

odometer, enter 4000 as a starting point. The frequency

of the odometer pulser must be no more than 25 pulses

per second or inaccuracies will result.

SYSTEM CALIBRATION

Pulses/Distance:

Calibrated Distance:

Odometer:

Password Usage:

Customer Usage:

(3/5) 1

2.000000

--------

0.0

Delivery

Delivery

Next Prev Cnfg Main

Customer Usage allows operator to specify when

customer number will be required on the front panel of

the LCR-II. Press ENTER to open a list box window with

the options:

Delivery

None

If odometer feature is not being used, this number must

be set to 2.

If LCR odometer input terminals are being used for

optional START/STOP feature, Pulses/Distance must

be set to “0”.

Calibrated Distance is used to calibrate the odometer.

To begin odometer calibration, enter “0” for Calibrated

Distance. Drive vehicle a known distance (minimum of 5

miles recommended) using truck’s odometer for reference.

Enter actual distance traveled in the Calibrated Distance

eld. This will automatically adjust Pulses/Distance to

reect corrected number.

Odometer represents truck’s odometer once odometer

function has been calibrated.

Enter truck’s current odometer reading in Odometer eld

edit window. Press ENTER to accept value.

NOTE: The next two elds will only be displayed when a

LectroCount register has software SR216 installed.

Password Usage is used to determine when a password

will be required on front panel of the LCR-II. Press ENTER

to open a list box window with the options:

Select None to indicate customer number will not be

required and will be set to 0 for each delivery.

Select Delivery to indicate customer number will be

required for each delivery.

Press Next (F1) to advance to Screen 9d on page 35.

Delivery

None

Shift

Select None to indicate password eld will not be used.

Select Delivery to specify password will need to be

entered before each delivery.

Select Shift to specify password will need to be entered

before each shift.

34

Page 35

SYSTEM CALIBRATION

Temperature:

Offset:

Temperature Unit:

(4/5) 1

80.54

.30

Deg. F

System Calibration

Screen 9d: System Calibration (4/5)

Tempera t u r e displays current reading from the

temperature probe with the offset applied. If LectroCount

is not equipped with a temperature probe, the display will

show dashes. This eld allows entry from a Weights &

Measures calibrated thermometer.

RTD Slope:

RTD Offset:

0.025000

0.000

Next Prev Cnfg Main

To calibrate temperature probe, run enough product

through the meter to allow temperature to stabilize.

Compare Temperature reading with current Weights &

Measures thermometer reading. If the readings do not

match, enter the Weights & Measures reading in the eld

edit window for Temperature. This value will overwrite

the previous value and the Offset eld will be recalculated

by the LectroCount.

Offset adjustments are limited to ±0.3°C (±0.54°F).

Adjustments greater than these offset values require

replacement of the RTD Probe.

Offset represents the difference between the ofcial

Weights & Measures temperature reading and the

LectroCount probe’s temperature reading. The offset

is automatically calculated if an entry is made in the

Temperature eld. If a temperature probe is not present,

this eld will show dashes.

If a Weights & Measures temperature reading was not

entered in Temperature, subtract Temperature value

from Weights & Measures temperature reading. Enter this

value in the eld edit window for Offset. If the difference

is a negative number, enter “-” before the value.

Offset adjustments are limited to ±0.3°C (±0.54°F).

Adjustments greater than these offset values require

replacement of the RTD Probe.

Temperature Unit is used to dene the temperature

unit to be used for the application. The two options for

Temperature Unit are Deg. C (degrees Celsius) and Deg.

F (degrees Fahrenheit). Move pointer to desired option

and press ENTER to accept.

RTD Slope and RTD Offset are used for factory calibration

of the LectroCount and are not editable.

RTD Slope indicates slope used to calculate the raw

temperature value from the raw ADC value.

RTD Offset indicates offset used to calculate the raw

temperature value from the ADC value.

Press Next (F1) to advance to Screen 9e on page 36.

35

Page 36

System Calibration

Screen 9e: System Calibration (5/5)

These calibration information elds are for metrology use

and are not editable.

Calib Date displays date and time when the red selector

switch on the LectroCount register was last moved from

the calibration position to SHIFT PRINT position.

Calib Number displays number of times the red selector

switch of the LectroCount has been switched from the

calibration position to SHIFT PRINT position.

Calib Event displays number of times a calibration event

has occurred.

Cong Event displays number of times a conguration

event has occurred.

For more information on Calib Event and Cong Event,

refer to page 64.

Press Cnfg (F4) to return to the Screen 7 on page 28.

From there, move pointer to Product Calibration and

press ENTER to advance to Screen 10a on page 37.

SYSTEM CALIBRATION

Calib Date:

01/11/05 11:50:25

(5/5) 1

Calib Number:

Calib Event:

Cong Event:

24

29

Prev Cnfg Main

1

36

Page 37

PRODUCT CALIBRATION

Product #: X

Units: Gallons

(1/6) 1

Product Code:

Name:

Product Type:

Gasoline

Next Cnfg Main

Product Calibration

Screen 10a: Product Calibration (1/6)

Product Calibration screens are used to calibrate the

metering system for product(s) which will be measured.

Product # is used to select product number to be

calibrated. The product number will correspond to one of

the product types/calibrations set up in the LectroCount.

At least one product must be calibrated to allow for

deliveries. Press ENTER to open a list box window with

options: 1, 2, 3, or 4.

Product Code will correspond to the Product Number.

The Product Code can also be entered in the Preset

and Delivery menu. Press ENTER to open a eld edit

window. Enter a alphanumeric product code up to ve

characters in length.

Name contains a description of the product that will appear

on the delivery ticket. Press ENTER to open a eld

edit window and enter an alphanumeric name up to 18

characters in length. Ensure product Name is descriptive

of the Product Type and Product Code.

Product Type is used to specify type of product to be

delivered. Press ENTER to open a list box window with

the following eight options:

Ammonia

Aviation

Distillate

Gasoline

Methanol

LPG

Lube Oil

(blank)

Move pointer to desired Product Type and press ENTER

to accept. If (blank) is selected, it indicates there is no

product type associated with the product being calibrated

and delivered.

Press Next (F1) to advance to Screen 10b on page 38.

37

Page 38

Product Calibration

Screen 10b: Product Calibration (2/6)

If temperature volume compensation is being used for

deliveries, the type of temperature volume compensation

must be selected for the Product #. It is necessary

to make a selection for proper Net (temperature

compensated) calculations.

Move pointer to Comp Type and press ENTER to open

a list box window with the following options:

None

Linear F

Linear C

Table 24

Table 54

Table 6B

Table 54B

Table 54C

Table 54D

NH3

Move pointer to desired option and press ENTER to

accept.

NOTE: If None is selected, deliveries can only be made

in gross (non-compensated) quantities.

PRODUCT CALIBRATION

Product #: 1

Units: Gallons

(2/6) 1

Comp Type:

Comp Parameter:

Base Temperature:

S1 Close:

10.0

Next Prev Cnfg Main

window and enter a number in this eld based on the

following guideline:

Selection Range

Linear F -130.0 to 212.0

Linear C -90.0 to 100.0

S1 Close represents the number of measurement units

remaining on a preset delivery before the valve is placed

in a bypass, trickle, or dwell mode. This eld is only used

when a two-stage valve is used in the application and

is connected to the LectroCount register. An S1 Close

value must be set for each product if presetting is being

employed.

Refer to Compensation Types and Parameters table on

page 39 to assist in making the correct selection.

Comp Parameter is the coefcient of expansion per

degree, the base temperature density, the API gravity,

or the base temperature specic gravity that will be used

with the Comp Type selected. Press ENTER to open a

eld edit window and enter a value based on the following

guideline:

Selection Range

None 0.0

Linear F 0.0000 to 0.0025 (per °F)

Linear C 0.000 to 0.005 (per °C)

Table 24 0.500 to 0.550 (SGU)

Table 54 0.500 to 0.600 (KG/Litre)

Table 6B 0.0 to 85.0 (°API)

Table 54B 653.0 to 1075.0 (KG/M³)

Table 54C 0.000486 to 0.001674 (per °C)

Table 54D 800.0 to 1164.0 (°API)

NH3 N/A

If Comp Type selection is either Linear C, or Linear F,

then Base Temp is used to set the base temperature for

temperature compensated deliveries.

If Linear C is selected for Comp Type, the Base Temp

value will default to 15.0 (for 15 °C). If Comp Type is

set to Linear F, the Base Temp default value is 60.0 (for

60°F).

When the S1 Close value is reached, Solenoid 1 is

deactivated and Solenoid 2 is activated.

For example: If value entered is 10 and the preset delivery

is set to 100, then S1 will close and S2 will open when the

register reaches 90. This reduces the delivery ow rate,

slowing down the ow of product through the meter.

Press ENTER to open eld edit window and enter a value

between 0.0 and 99999.0. It is recommended not to use

a value smaller than 10% of preset volume.

Press Next (F1) to advance to Screen 10c on page 40.

To change this value, press ENTER to open a eld edit

38

Page 39

Compensation Types and Parameters

Product Calibration

Product VCF Type

General

General

LPG

USA

LPG

Europe & Canada

Refined Petroleum Products

Europe & Canada

Refined Petroleum Products

USA

General

Lube Oil

Europe & Canada

Ammonia

Canada

Linear Linear 0 to 0.003 ºC 15 -90 N/A +100

Linear Linear 0 to 0.005 ºF 60 -130 N/A +212

API Table 24 Specic Gravity 0.5 to 0.550 ºF 60 -50 -50 +140

API Table 54

API Table 54B

API Table 6B API Gravity 0 to 85 ºF 60 -50 -40 +200

API Table 54C Coefcient

API Table 54B

NH3 N/A N/A ºC 15 -30 -30 +40

Parameter

Coefcient

Density

kg/L

Density

kg/m3

Density

kg/m3

Range

0.5 to 0.600 ºC 15 -46 -46 +60

653.0 to 1075.0 ºC 15 -50 -40 +95

0.000486 to

0.001674

800 to 1164 ºC 15 -50 -40 +95

ºCelsius/

ºFahrenheit

ºC 15 -50 -40 +95

Tbase Tmin Thold Tmax

Thold is the temperature below which no additional

compensation correction is applied.

Tmin and Tmax are the limits beyond which a diagnostic

of TEMP OUT OF RANGE will be triggered.

39

Page 40

Product Calibration

Screen 10c: Product Calibration (3/6)

Linearization Mode is used either to enable multi-point

linearization in the LectroCount, or to disable linearization

so base calibration can be set up. Press ENTER to open

a list box window with the two options:

PRODUCT CALIBRATION

Product #: 1

Units: Gallons

Linearization Mode:

(3/6) 1

Setup

Setup

Applied

Select Setup for single-point calibration. Select Applied

for multi-point calibration.

NOTE: Always perform initial calibration in Setup.

Single-point and Multi-point Calibration are covered on

Pages 44-47.

Pulses/Unit represents number of pulse edges counted

by the LectroCount per unit of measure. This number

is also known as the product’s K-factor. This number

is used to scale Prover Quantity. Only gross volume

applies. Press ENTER to open a eld edit window and

enter a value based on the following guideline:

Decimal Setting Range

Whole 2.0 to 20000.0

Tenths 20.0 to 20000.0

Hundreths 20.00 to 20000.0

Since this will change during calibration, leave the default

value of 0 and proceed to rest of editable elds in Product

Calibration.

Prover Quantity displays amount of product measured

during the last prover run. When this value is overwritten

with actual Prover Volume read during a calibration run, a

new Pulses/Unit will be recalculated automatically. This

eld should only be edited during meter calibration.

Pulses/Unit:

Prover Quantity:

492.506104

---------

Next Prev Cnfg Main

NOTE: If this is the initial calibration for the meter, enter

the rest of the Product Calibration data before entering

this eld.

Press Next (F1) to advance to Screen 10d on page 44.

40

Page 41

PRODUCT CALIBRATION

Product #: 1

Units: Gallons

Gross Quantity:

Gross Preset:

(4/6) 1

48.8

0.0

Product Calibration

Screen 10d: Product Calibration (4/6)

Gross Quantity is a read-only eld. The gross quantity of

uid measured by the meter during a product calibration

prover run is represented here. This is covered in detail

in the sections on Single-Point Calibration and Multi-Point

Calibration.

Temperature:

Net Quantity:

80.5

47.1

Next Prev Cnfg Main

Gross Preset can be used to set a prover run volume.

This represents a volume of liquid to be run through the

meter during a proving run. This is covered in detail in

the sections on Single-Point and Multi-Point Calibration.

Temperature displays current temperature reading of the

probe. This eld is not editable.

Net Quantity represents temperature compensated

quantity of current delivery. This eld is not editable.

Press Next (F1) to advance to Screen 10e on page 42.

41

Page 42

Product Calibration

Screen 10e: Product Calibration (5/6)

Aux Multiplier is used to convert quantity delivered to

an alternate volume or inferred mass. In order for this to