Page 1

INSTALLATION & O PERAT IO N

MANUAL

AN25

Totalizer / Rate I n d i cato r

DOC#: MN-AN25.doc

Page 2

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

2

Temperature:

Input Voltage:

110VAC or 12-16.5VDC 100mA MAX

Display:

LCD, 8 Digit .3” characters

Accuracy:

Totalizer + 1 Count

Enclosure:

Pan el moun t, ¼ DIN molded plastic

SPECIFICATIONS

Operating 0 to 70°C

Storage -20 to 85°C

Observe Polarity

Signal Input: Frequency 0-10KHz

Amplitude 50mV – 35V sine or square wave

Sensitivity field adjustable

Impedance 10K

Totalizer – 8 Digit

Rate I ndicator – 5 Digit

Leading zero blanking on rate function

Totalizer has bat tery backup

Totalizer r eset external l y initiat ed

Engineering units – Input factoring .00000001 – 1.9999

DOC#: MN-AN25

Rate I ndicator + 1%

Analog Outputs .3% F/S

Analog Output: 4mA @ 0Hz, 20mA @ desired full scale frequency

0V @ 0Hz, 5V or 10V @ desired full scale frequency

Full scale range 100Hz-10KHz

Response time 95% of change in 1 second

Linearity .3% F/S

Tempco < 2% of reading over entire temperature range

4-20mA Maximum load resistance 500 Ohms

Voltage Output minimum load resistance 250 Ohms

AN25-L: Loop powered by a 4-20mA loop input

Minimum voltage 6.5V + (.02 x RL)

Maximum Voltage 28V + (.004 x RL)

(Same temperature, Displ ay and accuracy specifications appl y)

Page 3

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

3

DOC#: MN-AN25

INTRODUCTION

General

The Model AN25 Tot alizer and Rate Indicat or i s comprised of compact, convenient and precision electronics

designed to interface with any frequency generating device such as a turbine flowmeter. The Model AN25 provides

flow totalization and rate in any engineering unit. Total and rate are displayed simultaneously via two 8 digit liquid

crystal displ ays. A backup battery is incorp or ated in the Totalize r displ ay circuitry to retain the total until Reset.

Reset i s accomplish ed externall y by a magnetic field.

Negatives previously associat ed with LCD’s – poor cold temper ature per formances, condensation which is a by

product of heaters and display ghosting – have all been erad i cated by incorpor ating a l ow t emperat ure coefficient

LCD (-35

In addition to totalization and rate in dication, the Model AN25 (Analog) provides an interface 4-20mA output and an

interface voltage output of 0-5V or 0-10V, selectable. The AN2 5 (Analog) lin ear ly converts a frequency to

equ i valent anal og outputs of 4-20mA and 0-5V or 0-10V. When incorporated wit h a turbine flowm eter, interface

outputs of 4-20mA and 0-5 V or 0-10V proportion al to flow are obtainable.

An input supply voltage of 110VAC or 12VDC is standard.

The Model AN25 -L is a Loop Powered Totalizer & Rate Indicator which accepts a 4-20mA Loop Powered Input.

Model AN25-L provides the same totali zation and rate i ndication as t he Model AN25.

Theory of Operation

Model AN25 amplifies and shapes the incoming pulses generated by the turbine's response to flow. The amplified

pu l se train is factored by a phase l ocked loop (PLL). The fact or ed pulse train is then scaled & divid ed to produce a

totalized display in the desired engineering unit. For rate, the divided pulse train is combined with a crystal

timebase for ab solute accuracy. This configurati on permits the calib r ation factor to be universal for both total and

rate indicat ion.

Model AN25-L Loop Powered Totalizer & Rate Indicator accepts a 4-20mA loop input. An analog to frequency

converter is incorporated in the circuitry to establish a calibrated 10KHz full scale frequency pulse. This pulse is

then scaled and divided by the same circuitry as the standard AN25 to provide totalization and rate indication in

engineering units.

Calibration

Field calibration for Totalization and Rate i s accomplish ed by inco r porating a calibration factor based on the turbine

K-Factor. Divider switches provide divisional increments of .00000001 – 1.9999. The calibration factor is entered

via 4 BCD switches, a divider switch, an d a ‘0-1’ switch.

Calibration of the analog control outputs is established by installation of a F/S frequency jumper in conjunction with

the zero and span adjustments. 0-5 or 0-10VDC output is selected by installation of a jumper. 4-20mA and 0-5/

0-10V calibrations are i ndependent of each other and i ndependent of the cal ibration factor en tered for total and r ate

indication.

o

C).

Page 4

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

4

DOC#: MN-AN25

INSTALLATION

Inspection

All units are completely assembled , inspected and tested at the factory prior to shipment. U pon recei pt of the unit,

a visual inspection should be conducted to detect any damage that may have occurred during shipment. Report

any discrepancy to th e factory immediatel y.

Physical

All Model AN25 units are enclosed in a ¼ DIN, molded plastic housing. The housing has a snap on the front

Bezel, removable mounting clips, and a plug-in wiring terminal on the back.

Refer to dimensional requirements for dimensions, bezel size, and depth needed for mounting the instrument in a

user panel. Be sure to provide additional space for cabling and connections behind the instrument. Additionally,

all wirin g to the back of t he instrum ent sh ould have sufficien t service loops to allow for the easy removal of the

instrument from the panel.

Electrical

An input supply voltage of 110VAC or 12VDC is stand ar d for the Model AN25. Be sure to observe correct polarity

when making field terminations.

Model AN25-L requires a minimum loop voltage of 6.5V + (.02 x RL). Maximum voltage is 28V + (.004 x RL).

Signal

The standard signal cable is a 2 wire shielded cable with a MS3102 connector termination which is the industry

standard interface for 2 pole pickup coils. The shielding is singly ended and should not be altered.

Page 5

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

5

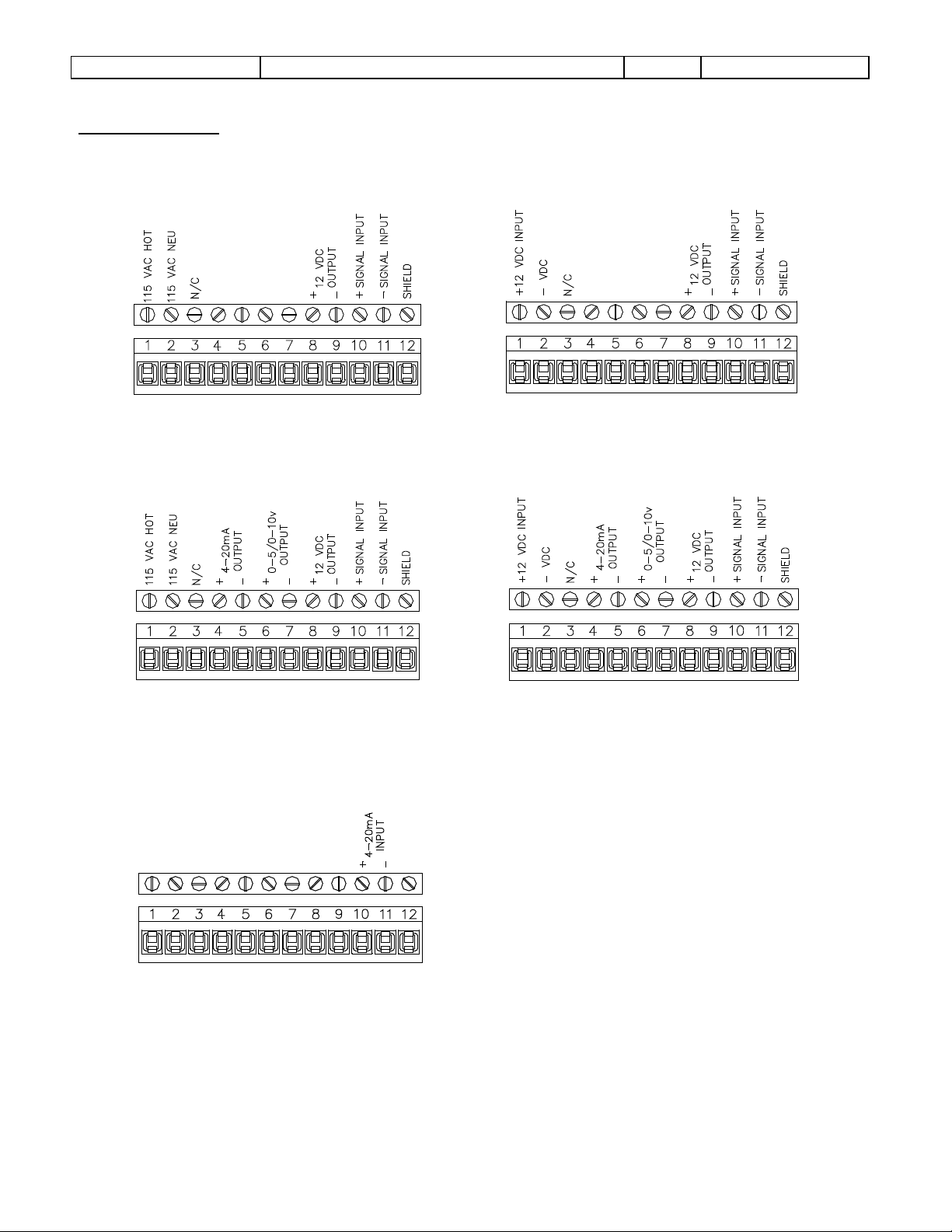

For 115VAC

For +12VDC

For 115VAC wit h A nalog Output

For +12VDC with A nalog Output

Field Terminations

MODEL AN25

MODEL AN25-L

DOC#: MN-AN25

Page 6

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

6

Engineering Units

K-Factor

F x T x C.F.

D

F x C.F. x 60

D

(Rate is per mi nute)

DOC#: MN-AN25

CALIBRATION

Sensitivity

The sensitivity adjust R6 is located on the Power Supply and Input Amplifier P.C.B. The amplitude of the signal

gen er ated by t he turbine is proport i onal to the rate of flow, therefore, sensitivit y should be adjusted at the lowest

usable flow rate. Rotate R6 co mpletely counter-clockwise, then slowly rotate R6 clockwise unti l the di splay correctly

responds, then increase R6 slightly clockwise.

Calibrati on Factor for Total & Rate

The calibration factor is d er ived from the turbines K-Factor (Pulses per gallon or other desired engineering unit ) .

The K-Factor i s listed on the calibration d ata sheet for the specific turbine being used .

C.F. =

Example # 1: K-Factor = 250 Pulses per gallon

Desired Engineering Units = gallons

C.F. = 1/250 = .00400

On the factoring P.C.B.

Set S6 #3 ‘ON’ (↓ Position) for ÷ 100 (Moves decimal point right 2 places)

Set S2 @ 4, S3, S4, S5 @ 0 (Enters .4000)

Set S1 in ‘0’ Position (0.4000)

The electronic accuracy can be verified by injecting a stable frequency @ TB1-10, 11 and

inco r poratin g the foll owing formulas:

Total =

Rate =

Where F = Frequency in Hz

T = Time (Duration) of test in seconds

C.F. = Calibration Factor as entered in S1-S5

D = Divisor as entered in S6

Example #2: F = 500 Hz T = 2 min (120 sec) C.F. = .4000 D = 100

Total = 500 x 120 x 4000

100

= 60,000 x 4000

100

= 24000/100 = 240 in 2 minutes

Rate = 500 x .4000 x 60

100

= 120 per minute

Page 7

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

7

Units p er Gallon

Pu l ses per G al lon

41, 381,600 x .1256

10

41, 381,600 x 1.2566

100

DOC#: MN-AN25

Calibration ‘0-1’ Function

The ‘0-1 ’ funct i on provid es enhanced accuracy when totalization encompasses a large quantity for an extended

period of time such as SCF produced in a 24 hour period.

The ‘0-1’ function should be incorporated only when both conditions listed below are met:

1) C.F.’s 1

2) C.F.’s 5

st

digit right of decimal is 1

th

digit right of decimal is n ot 0

Example #3 Assume a t urbine has a K -Factor of 79.58 pulses per SCF and the customer product demand is

520,000 SCF a day

C.F. = 1/79.58

= .0125659 = .12566 ÷ 10 Note: Both conditions are met

Without the ‘0-1’ function: S6 #2 ‘ON’ (÷ 10)

S2@1, S3@2, S4@5, S5@6

S1 in ‘0’ Position

A usage of 520,000 SCF = 41,381,600 total pulses (520,000 x 79.58) and using the C.F. of S1-

S6 the displayed quantity is 519,752 SCF ( ) rather than 520,000 for a

difference of 248 SCF.

With the ‘0-1’ function: Set S6 #2 ‘ON’ (↓ Position) for ÷ 100 (moves decimal right 2 places)

Set S2@2, S3@5, S4@6, S5@6 (.2566)

Set S1 in ‘1’ Position (1.2566)

as stated above the 24 hr usage is 520,000 SCF. The displayed quantity is now 520,001 SCF

( ) for a difference of 1 SCF.

Change of Calibr ation Engineeri ng Uni ts

Assume that liters rather than gallons is the desired engineering unit.

Example # 4 K-Factor = 250 pulses per gallon

Liters = 3.785 per gallon

C.F. = 3.785 / 250

C.F. = .01514 for display of liters

On the Factoring P.C.B.:

Set S6 #2 ‘ON’ (↓ Position) M oves decim al point r i ght 1 place

Set S2@1, S3@5, S4@1, S5@4 (.1514)

Set S1 in ‘0’ Position (0.1514)

Note: The ‘0-1’ functi on was not incorporated because onl y 1 of the 2 conditions was met

C.F.’s 1

C.F.’s 5

C.F. =

st

digit right of decimal is 1

th

digit right of decimal is 0

Page 8

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

8

Actual Quantity

Displayed Quant ity

DOC#: MN-AN25

Example #5: The Engineering Unit is pounds in 10

th

s CO2

K-Factor = 250 pulses per gallon

Pounds of CO

In or der to establish 10

= 8.470 per gallon

2

th

s, increase lbs./gal. by a factor of 10

C.F. = 84.7/250

C.F. = .3388

On the Factoring P.C.B.:

Set S6 #1 ‘ON’ (↓ Position) ÷ 1 does not move d ecimal poin t

Set S2@3, S3@3, S4@8, S5@8

Set S1 in ‘0’ Position

If the gallons per unit volume such as 7.48 gallons per FT

3

is known, but not the unit volume per gallon as

required to calculate the calibration factor; take th e r eciprocal of gallons per un it volum e to derive the unit

volume per gal l on.

7.48 gallons per FT

Example #6: The engineering unit is ACF (FT

3

1/7.48 = .13369 FT3 per gallon

3

)

K-Factor = 250 pulses per gallon

ACF = .13369 per gallon

C.F. = .13369 / 250

C.F. - .0005348

On the Factoring P.C.B.:

Set S6 #4 ‘ON’ (↓ Position) M oves decim al point r i ght 3 places

Set S2@5, S3@3, S4@4, S5@8

Set S1 in ‘0’ Position

Example #7: Desired Eng ineering Unit is ACF x 10

K-Factor = 250 pulses per gallon

ACF = .13369 per gallon

In or der to establish x 10, decrease A CF/gal by a factor of 10

C.F. = .013369 / 250 = .00005348

On the factoring P.C.B.:

Set S6 #5 ‘ON’ (↓ Position) M oves decim al point r i ght 4 places

Set S2@5, S3@3, S4@4, S5@8 (.5348)

Set S1 in ‘0’ Position (0.5348)

Field Corre ction of Calibration Factor

To adjust th e calibrat i on factor t o r efl ect the turbine’s actual response t o the operating conditions, incorp or ate the

following formula:

New C.F =

x Present C.F.

Page 9

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

9

DOC#: MN-AN25

Example #8: Actual = 50

Displayed = 52

C.F. = .4000

New C.F. = 50/52 x .4000

= .9615 x .4000

= .3846

On the factoring P.C.B.:

Set S2@3, S3@8, S4@4, S5@6

In the above example, .96 denotes that the meter is operating 4% fast. Multiplying by the present C.F.

(.4000) by the Displayed:Actu al Ratio (.96) effectively reduces the error by decreasing the C.F. by 4%.

Example #9: Actual = 52

Displayed = 50

C.F. = .4000

New C.F. = 52/50 x .4000

= 1.04 x .4000

= .4160

On the Factoring P.C.B.:

Set S2@4, S3@1, S4@6, S5@0

In the above example, 1.04 denotes that the meter is operating 4% slow. Multiplying the present C.F.

(.4000) by the Displayed:Actual Ratio (1.04) effectively reduces the error by increasing the C.F. 4%.

Rate Display Conside r ations

The displayed rate is limited to a maximum of 30,000. This characteristic must be considered when determining

the displayed engineering unit. Note that if the desired rate displayed is other than ‘Per Minute’, the calibration

factor is only correct for the rate displayed.

Example #10: A 1 ” turbi ne meter has a maximum fl ow rat e of 60 GPM and a K-Factor of 970 pulses per gallon in

Liquid Oxygen. The desired engineering unit is SCFH.

Given: 1 gallon O

= 115 SCF

2

1) Determine maximum flow rate; does it exce ed 30,000?

60 GPM x 115 SCF = 6900 SCFM

6900 SCFM x 60 = 414,000 SCFH

414,000 exceeds 30,000. Therefore, direct SCFH units are not permissible and some factor of

SCFH must be determined.

2) Determine what factor of SCFH is permissible –

4140 is the largest SCFH factor under 30,000; 1/100 of the actual SCFH flow rate.

3) Determine the cal i bration factor for SCFH x 100 K-Factor = 9 70 Pulses per gallon

SCF O

= 115 per gallon

2

A) I n order t o establish x 10 0 decrease SCF/G al by a factor of 1 00 (115/100 = 1.15)

B) In order to establish per hour increase SCF/Gal by a factor of 60 (1.15 x 60 = 69)

C.F. = 69/970

= .07113

On the Factoring P.C.B.:

Set S6 #2 ‘ON’ (↓ Position) for ÷ 10 (moves decimal point right 1 place)

Set S2@7, S3@1, S4@1, S5@3 (.7113)

Set S1 in ‘0’ Position (.07113)

Page 10

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

10

DOC#: MN-AN25

Page 11

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

11

DOC#: MN-AN25

Page 12

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

12

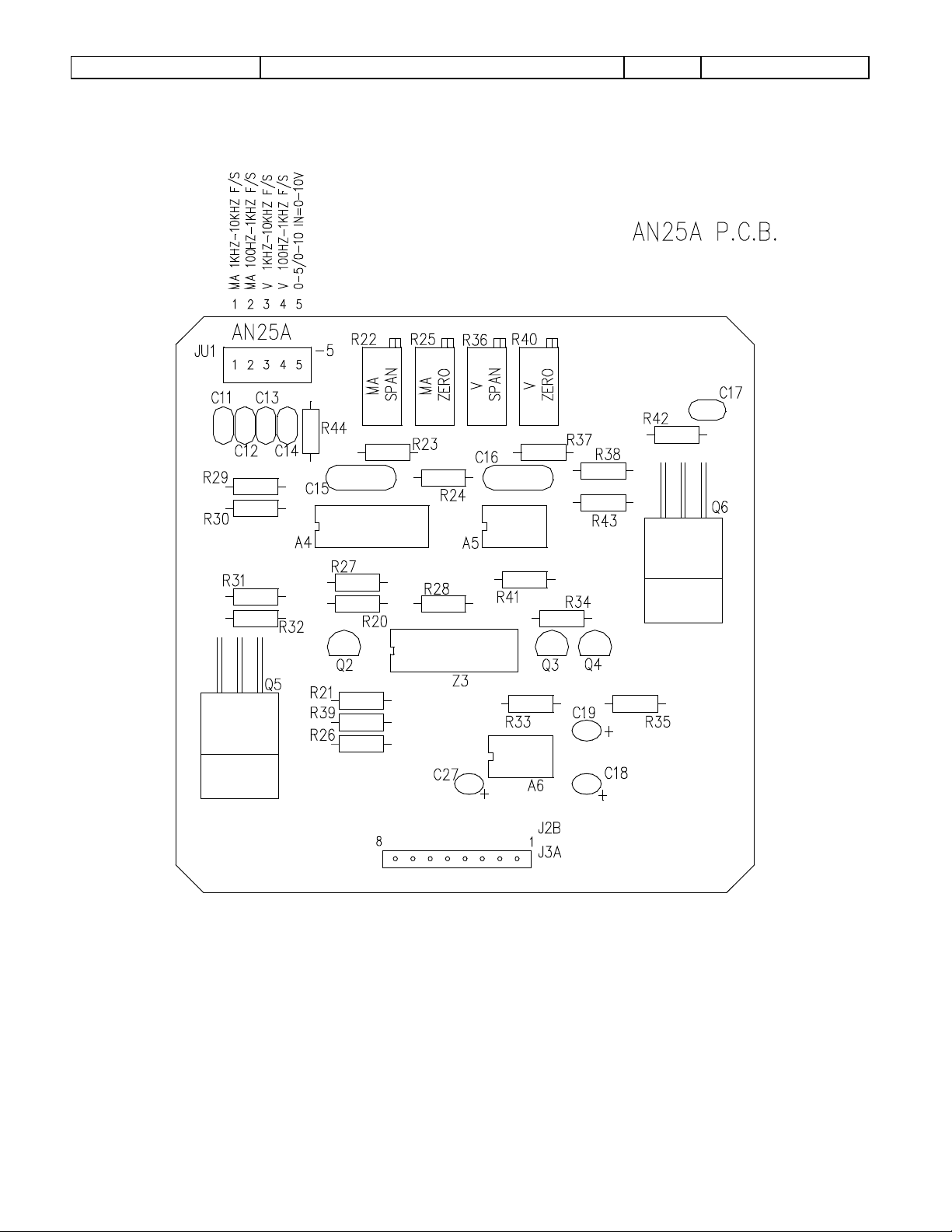

Calibration of Analog Outputs

DOC#: MN-AN25

REQUIRE D EQUIPMENT: Power Supply 110 VAC or 12-16.5 VDC

2 Digital Mu ltimeters (DMM)

Frequency Generator

Frequency Counter

NOTE: All test eq uipment power cords should be equipped with 2 prong “cheater” plugs.

a) Connect power supply Positive (HOT) & Negative (NEU) leads to TB1-1 ,2 respectively.

b) Connect #1 DMM Positive lead TB1-4. Connect #1 DMM Negative lead to 250 Ω resistor; Conn ect other end

of resistor to TB1-5. Set DMM function to mA DC.

c) Connect #2 DMM Positive & Negative leads t o TB1-6, 7 respectively. Set DMM function t o Volts DC .

d) Connect frequency generator P ositive & Negative leads to TB1-1 0, 11 respectively. Set output to si newave

and amplitude to zero.

e) Set “Sensitivity” adjust R1 fully clockwise

f) Install jumpers at JU1 or JU2 and JU3 or JU4 for desired frequency range.

g) Select desired voltage output level. Install JU5 for 0-10V; omit for 0-5V.

h) Turn Power Supply & Frequency Generator “ON”

i) Adjust “ZERO” (R25) for 4.00mA #1 DMM indication.

j) Adjust “ZERO” (R40) for .000VDC #2 DMM indication.

k) Adjust signal amplitude of frequency generator to 50mV & frequency to maximum desired point (full scale

frequency)

l) Adjust “SPAN” (R22) for 20.00mA #1 DMM indication.

m) Adjust “SPAN” (R36) for 5.00V or 10.00VDC #2 DMM indication.

n) Reduce signal amplitude of frequency generator to zero. Adjust “ZERO” (R25) for 4.00mA #1 DMM indication,

if necessary. Adjust “ZERO” (R40) for .000VDC #2 DMM indication, if necessary.

o) Adjust signal amplitude of frequency generator to 50mV. Adjust “SPAN” (R22) for 20.00mA #1 DMM

indication, if necessary. Adjust “SPAN” (R36) for 5.00V or 10.00VDC #2 DMM indication, if necessary.

p) Ad j ust frequency of freq uency g enerator to exactly 50% of maximum frequency point in step K. #1 DMM

should indicate 12.00mA +/- .06mA; #2 DMM should indicate 2.50V or 5.00V +/- .02V.

To check for linearity @ any frequency point:

Volt age output:

F/F Max X Full Scale Output = Volts

Example: Assume maximum frequency point = 2KHz & full scale output = 10v. Check for linearity

@ 750Hz point

750/2000 X 10 = 3.75V #1 DMM should indicate 3.75V +/- .03V

mA output:

(F/F Max X 16) + 4 = mA

Example: Assume maximum frequency point = 2KHz

Check for linearity @ 750Hz point

(750/2000 X16) + 4 = mA

(.375 X 16) + 4 = mA

6 + 4 = 10mA #1 should indicate 10.00mA +/- .06

Page 13

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

13

DOC#: MN-AN25

Page 14

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

14

AN25: ¼” DIN Dim ensional Information

DOC#: MN-AN25

Page 15

Sponsler Co., Inc. AN25 Totalizer/Rate Indicator

pg.

15

DOC#: MN-AN25

Page 16

© 2009

Pub. No. MN-AN25-mA

(9/2009)

Loading...

Loading...