Page 1

Optical Air Eliminator (US Patent #7000628)

Rened Fuels Applications (A8981 & A8981A)

Installation

and Parts

Liquid ControLs Group

An IDEX Fluid & Metering Business

Installation: M300-20

Page 2

Table of Contents

Introduction

Specications ................................................. 3

General Information ....................................... 3

How Optical Air Eliminators Work .................. 4

Installation

New Installations ............................................ 6

Retrot Installations ....................................... 6

Dimensional Drawing ..................................... 8

Wiring ............................................................. 9

Maintenance

Disassembly ..................................................11

Reassembly ................................................. 13

Troubleshooting ........................................... 14

Bill of Materials

Exploded View ............................................. 15

Bill of Materials ............................................. 15

! WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualied personnel trained in the proper application, installation, and maintenance

of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury, or death

from re and/or explosion, or other hazards that may be associated with this type of equipment.

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our web site, www.lcmeter.com. It

is the responsibility of the local distributor to provide the most current version of LC manuals, instructions, and specication sheets in the required language of the country, or the language of the end user to which the products are shipping . If

there are questions about the language of any LC manuals, instructions, or specication sheets, please contact your local

distributor.

2

Page 3

Optical Air Eliminators (A8981 & A8981A)

Specications

Environmental Rating

NEMA 4X

Safety

Designed to meet Class I, Division 2 requirements

Materials of Construction

Class1

Body: Aluminum

Solenoid: Brass

Class2

Body: Anodized Aluminum

Solenoid: Stainless Steel

Pressure Rating

Maximum non-shock working pressure

• 150PSI (10.3BAR)

Maximum differential pressure

• 100PSI (6.9BAR)

Temperature Rating

-40° to 160°F (-40° to 71°C)

Products

Class1 Rened Fuels

Gasoline, Gasohol, Diesel fuel, and Fuel Oil

Class2Aviation

Av-Gas and Jet Fuel

Solenoid (S3)

Voltage: +12 (± 2)VDC

Optional: +24 (± 4)VDC

Current: 1A maximum

Optical Sensor

Voltage: +10 to +28VDC

Current: 0.5A maximum

General Information

The Liquid Controls Optical Air Eliminator is designed for

use with LectroCount® Electronic Registers. An optical

sensor, installed in the wall of the air eliminator housing,

is used to monitor the liquid level. The presence or absence of liquid at the sensor level activates or deactivates

a solenoid valve located at the top of the air eliminator to

vent air or vapor from the system.

The optical air eliminator is designed to work with Liquid

Controls M5, M7, M10, M15, and M25 meters, for applications measuring rened petroleum products. Designed

with the same mounting dimensions as Liquid Controls

mechanical air eliminators, the optical air eliminator does

not require plumbing changes to retrot to existing meter

installations; however, electronic registers do require CPU

board part number 81920 for LCR and LCR-II; CPU board

part number 81924 for LC³. The optical air eliminator also

requires the use of a solenoid-operated control valve such

as the E-7 or A2848-11 on the outlet side of the meter.

Class 2

The Liquid Controls Optical Air Eliminator can be manufactured for Class 2 aviation applications. The Class 2 optical

air eliminator (Part #A8981A) is made with an anodized

aluminum housing and a stainless steel solenoid valve.

3

Page 4

Introduction

Solenoid Valve - OPEN

Vent

Optical Sensor

Control Valve - OPEN

Liquid Level

Solenoid Valve - OPEN

Vent

Optical Sensor

Control Valve - CLOSED

Liquid Level

How the Optical Air Eliminator Works

A solenoid valve, located at the top of the air eliminator,

is either open or closed. When the liquid level is below

the optical sensor (Figure 1), and a delivery is initiated,

the solenoid valve opens and vents air and vapor to

atmospheric pressure. At the same time, a solenoid-actuated control valve (A2982-11 or A2848-11) closes at the

meter outlet.

When liquid rises to the optical sensor level as the air is

exhausted (Figure 2), the optical air eliminator solenoid

valve closes and prevents continued venting to atmospheric pressure. At the same instant, the control valve

at the meter outlet opens so that a delivery may begin or

continue. This functionality ensures that only liquid passes

through the meter for measurement.

As long as a delivery is active and the liquid level remains

at or above the optical sensor, the optical air eliminator

solenoid valve remains closed and the control valve remains open. If the liquid level should drop below the optical

sensor, the optical air eliminator solenoid valve opens and

the control valve closes. When the delivery is complete,

the control valve closes and the printer prints a delivery

ticket. The optical air eliminator solenoid valve is not active between deliveries and remains OFF or closed.

Figure 1: Liquid Level below Optical Sensor

Figure 2: Liquid Level at or above Optical Sensor

4

Page 5

Introduction

How the Optical Air Eliminator Works

The gures to the left show a cutaway view of the vent port

through the solenoid valve. This port has been designed

to optimize the venting of air and vapor from the optical

air eliminator.

When the liquid level is below the sensor, the S3 solenoid

valve is open and allows air and vapor to vent through the

solenoid valve as shown in Figure 4. When the liquid level

is at or above the optical sensor, the S3 solenoid valve

closes the vent path as shown in Figure 5.

Figure 4: Solenoid and Port Open

Figure 5: Solenoid and Port Closed

The diagram in Figure 6 shows the LectroCount register

logic for a preset delivery. In order to function properly, the

optical air eliminator must be used in conjunction with a

solenoid-actuated control valve at the meter outlet, such

as the A2982-11 or A2848-11.

Figure 6: Optical Air Eliminator operating sequence.

5

Page 6

Installation

½" NPT Port

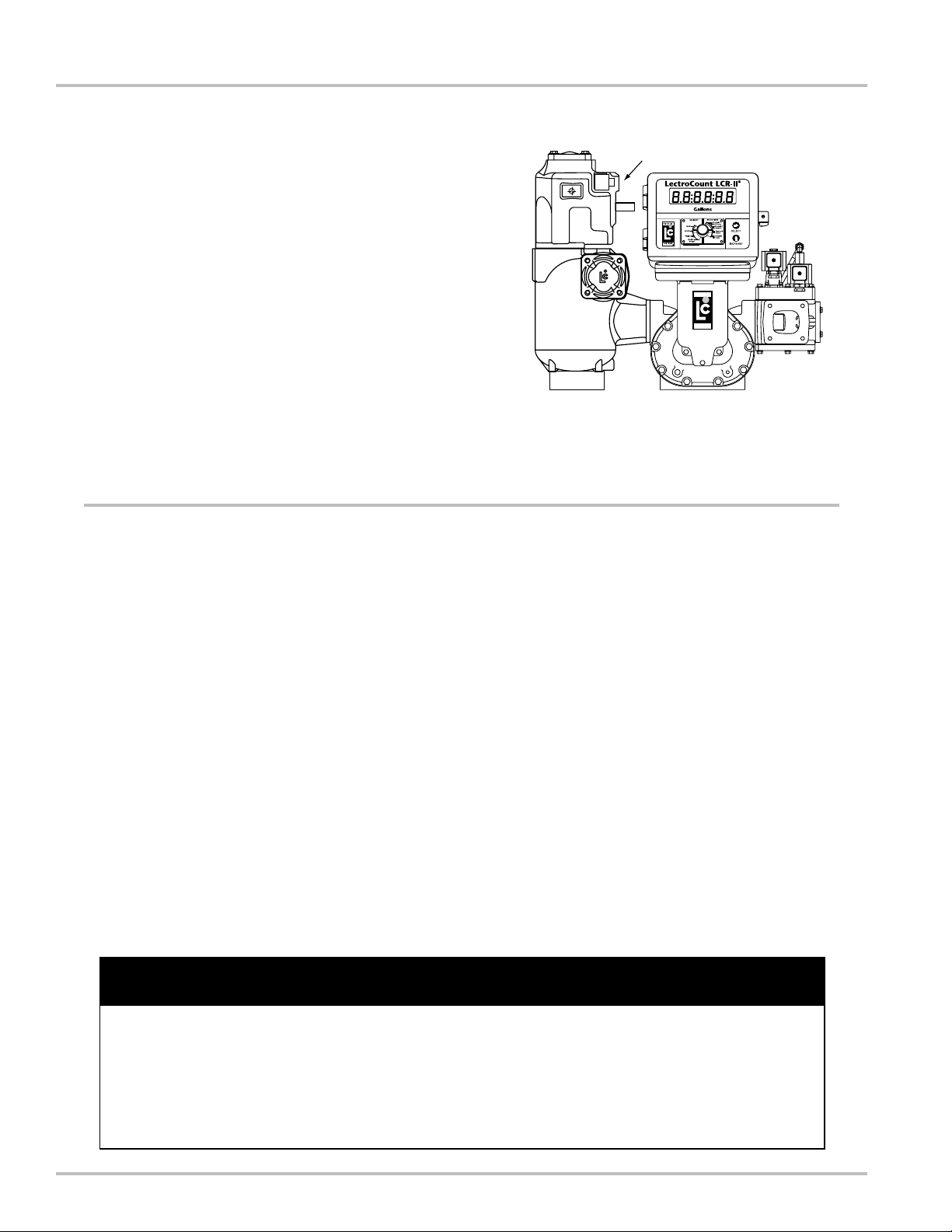

New Installations

When ordered with a new meter, the optical air eliminator is supplied mounted atop a strainer on the inlet side

of the meter. An example is the meter with high-capacity

strainer, two-stage valve, and LectroCount LCR-II® Electronic Register shown in the gure to the right.

A vent line must be connected from the output port of the

optical air eliminator. This connection is ½” NPT. The vent

line must be connected to an appropriate receptacle such

as an overow tank on a truck.

The optical air eliminator solenoid valve and optical sensor are supplied pre-wired to the LectroCount Electronic

Register.

Figure 7: New Assembly

Retrot Installations

Depending on the existing conguration, adding an optical

air eliminator valve may require modication of the vent

piping, modication or change of the outlet valve, and

modication or change of the register.

The optical air eliminator requires the following components to operate:

• LectroCount LCR/LCR-II Electronic Register with

internal CPU board Part Number 81920 or LC³ with

CPU board Part Number 81924.

• Electronically-controlled outlet valve such as the

A2982-11 or A2848-11.

Refer to the manuals accompanying these items for proper

installation and conguration.

! WARNING

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST BE RELIEVED

AND ALL LIQUID DRAINED FROM THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the meter and liquid source.

Failure to follow this warning could result in property damage, personal injury, or death from re and/or explosion, or

other hazards that may be associated with this type of equipment.

6

Page 7

Figure 8: Remove old Air Eliminator

Installation

Retrot Installations

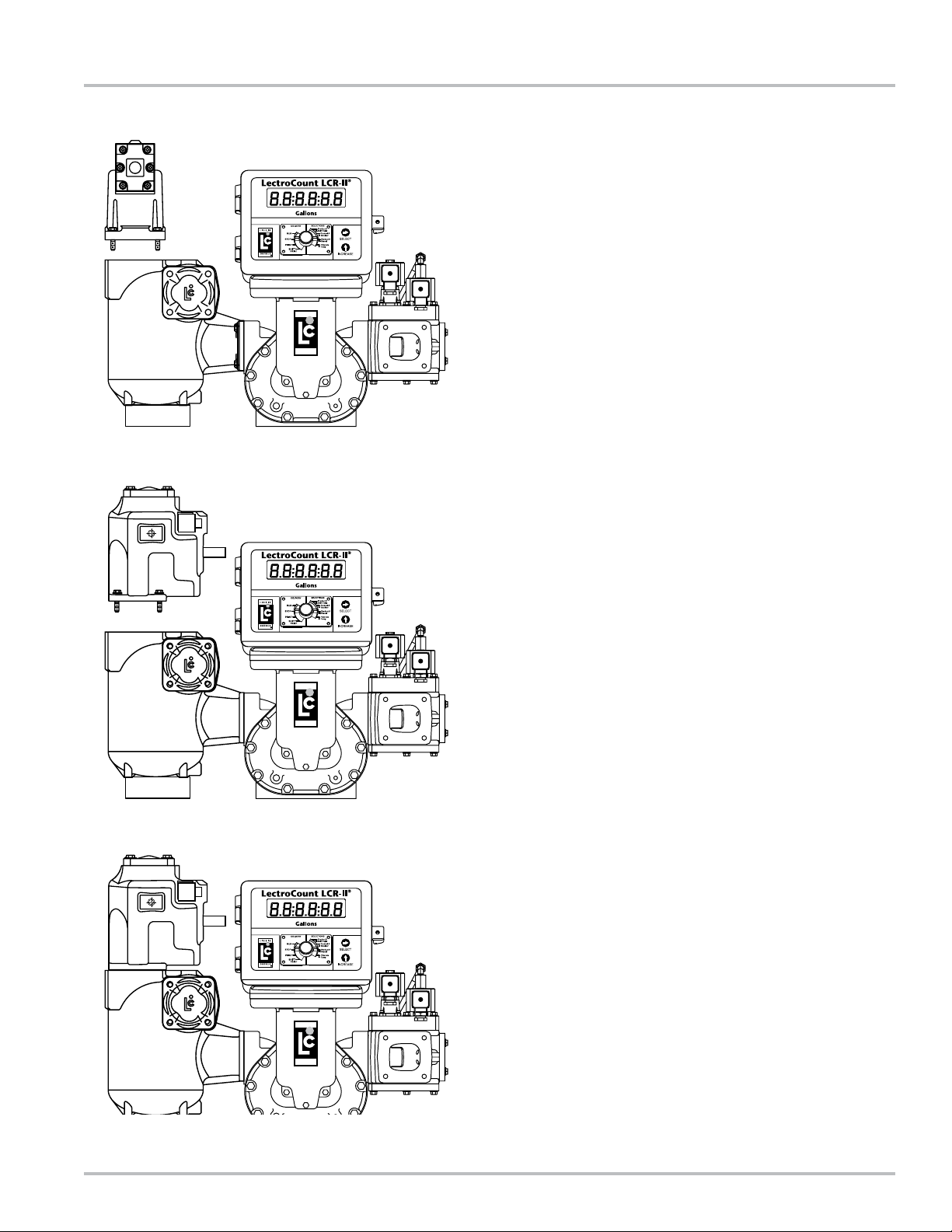

These retrot instructions will show a system using a

Hi-Cap strainer/air eliminator; however, the optical air

eliminator may also be installed on other LC strainer assemblies used for rened petroleum products.

Step 1 - Remove Old Air Eliminator and Baffel Cup

After the internal pressure has been relieved from the system

and the assembly drained of liquid, remove the four bolts

and washers used to fasten the old air eliminator to the top

of the strainer. Inspect the O-ring and replace if necessary.

Step 2 - Mount the Optical Air Eliminator

Depending on the strainer being used, the optical air eliminator may be fastened to the strainer/air eliminator in any of four

90° rotational increments. Select the most suitable orientation

for ease of nal installation of wiring and vent piping.

Figure 9: Orient the Optical Air Eliminator

Fasten the optical air eliminator to the strainer using the

four bolts and washers. Tighten the bolts to a torque of 27

lbf-ft (37 Nm).

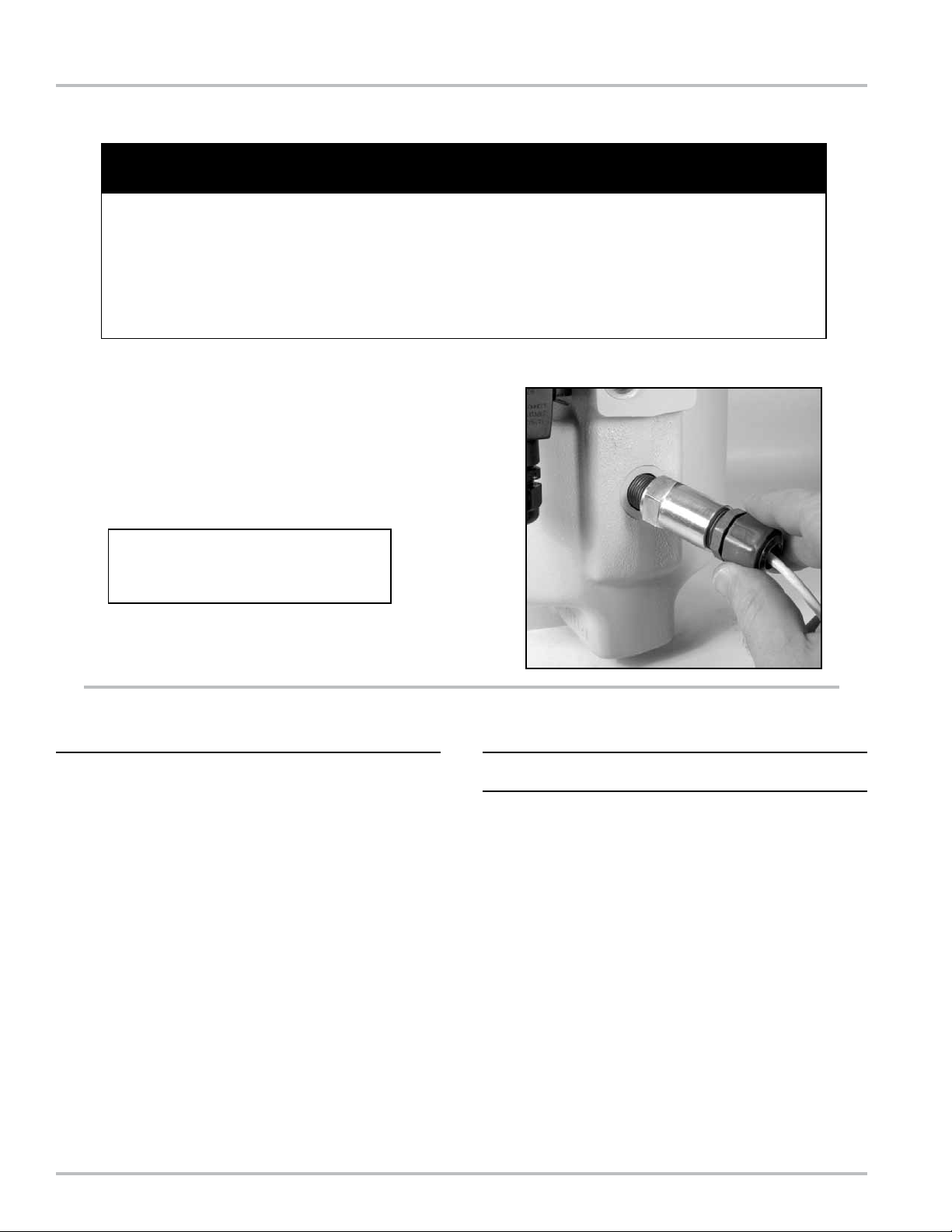

Step 3 - Connect the Vent Piping/Tubing

This connection is ½” NPT. Remove the pipe thread protector

and then connect the piping/tubing to the vent port. This piping typically connects directly to an overow tank on a truck.

Step 4 - Wire the Solenoid and Sensor to the Register

Wiring instructions begin on Page 9.

Figure 10: Fasten the Optical Air Eliminator

7

Page 8

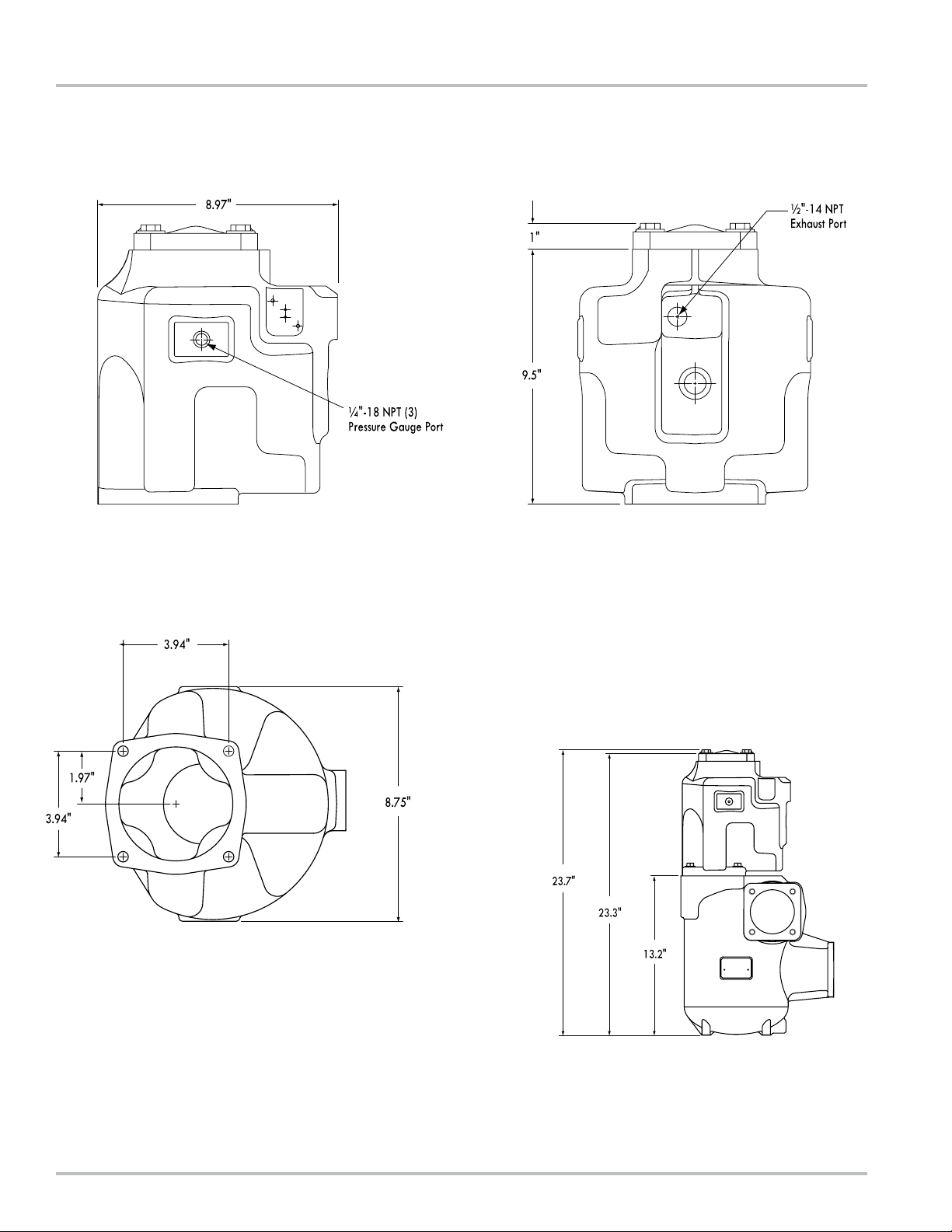

Dimensions

Front Side

Bottom

optical air eliminator with

igh capacity Strainer

h

Dimensionsshownarenotforconstructionuse.

ConsultfactorywhencertiedEngineeringDrawingsarerequired.

8

Page 9

Installation

Wiring

The optical air eliminator requires a LectroCount LCR/

LCR-II Electronic Register with CPU board part number

81920 (LC³ with 81924). If the LectroCount does not

contain an 81920 CPU board (LC³ with 81924), this board

must be ordered as a replacement to the existing CPU

board.

The 81920 CPU board has an additional connector, connector J15, not present on other board models. On the

LC³ 81924 CPU board it is connector J11.

To make the connection to a LectroCount Register, the

optical sensor comes supplied with a 24” cable. The cable

is potted in the optical sensor assembly at one end. A

threaded cord grip is included to fasten the other end of

the cable into the back of the LectroCount Register. The

solenoid requires a 12 AWG, two-wire, braided cable,

approximately 24 to 36” in length.

Step 1 - Remove Cable Plug

Loosen and remove the screw from the cover of the S3

solenoid valve cable plug. Remove the cable plug from the

solenoid valve coil. Remove the cover from the cable plug

housing and then remove the terminal block. Be sure to note

its orientation in the housing. Leave the at gasket in place

on the coil.

Step 2 - Connect Cable to Cable Plug

Route one end of the cable through the conduit tting and

into the cable plug housing. Connect the cable wires to the

terminal block. Connect the BLACK wire to Terminal 2 and

the RED wire to Terminal 1. These indicators are marked on

the terminal block.

! Caution

Incorrect wiring can damage the optical sensor.

! WARNING

For North American Installations, the installation must be fully in accordance with the National Electrical Code (US) or the Canadian Electrical Code respectively to maintain the hazardous location

ratings on the product. This may involve using rigid conduit for all connections.

9

Page 10

Installation

Wiring

Step 3 - Reassemble Cable Plug

Reinstall the terminal block into the cable plug housing in

the same orientation you found it. Tighten the strain relief

strap inside the cable plug using the two screws. Tighten the

cable gland on the bottom of the cable plug so that it seals

around the cable.

Reconnect the cable plug to the coil. Place the cover over

the cable plug and fasten with the screw to a torque of 8.8

in-lbs (1 Nm).

Step 4 - Connect to LectroCount Electronic Register

Route the cables from the optical sensor and solenoid valve

to the back of the LectroCount register. Connect these to two

open ports on the back of the register using the appropriate

connectors.

ConnectthewirestoterminalblockJ15ontheLectro-

LCR-II

CountCPUboard.RefertoFigure11aforadditional

clarication.

LCR-II Connections

Optical Sensor Connection

Wire Color J15 Pin Connection

Red 56

White 55

Black 54

S3 Solenoid Connection

Terminal J15 Pin Connection

1 (Red) 52

2 (Black) 53

LC³

ConnectthewirestoterminalblockJ11ontheLec-

troCountCPUboard.RefertoFigure11bforadditional

clarication.

LC3 Connections

Optical Sensor Connection

Wire Color J11 Pin Connection

Red 33

White 34

Black 35

S3 Solenoid Connection

Terminal J11 Pin Connection

1 (Red) 31

2 (Black) 32

Figure 11a: LCR-II to Optical Air Eliminator Wiring

Figure 11b: LC³ to Optical Air Eliminator Wiring

10

Page 11

Maintenance

! WARNING

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST BE RELIEVED

AND ALL LIQUID DRAINED FROM THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the meter and liquid source.

Failure to follow this warning could result in property damage, personal injury, or death from re and/or explosion, or

other hazards that may be associated with this type of equipment.

Disassembling

Tools required:

• Flat blade screwdriver

• 14mm box end or open end wrench

The optical air eliminator consists of a housing, optical

sensor, and control solenoid valve. Of these three components, only the solenoid valve is serviceable; however,

if any part of the solenoid is damaged, a new solenoid

assembly (Part Number 502011) must be ordered. The

optical sensor contains no serviceable parts because the

internal components are potted. If the optical sensor fails,

the complete assembly must be replaced (Part Number

81947).

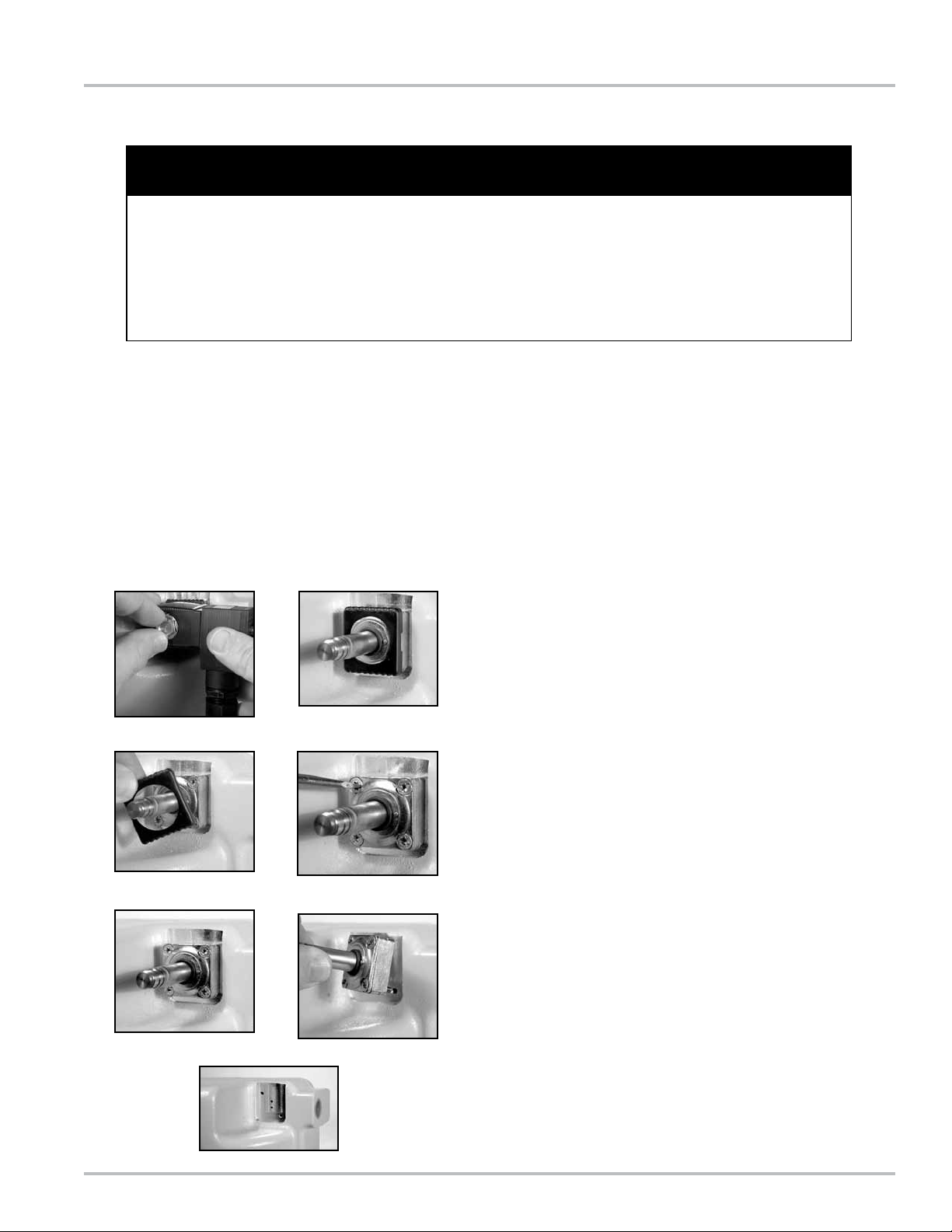

Step 1

Loosen the thin hex nut holding the solenoid in place using a

14mm wrench. Remove the nut and coil off of the armature

guide post.

Step 2

Remove the plastic bonnet from the armature guide post.

This should be easy to remove without tools.

Step 3

Using a screwdriver, loosen the upper left and lower right

screws of the valve body. These are the only two screws

which hold the valve body in place. The upper right and

lower left screws fasten the armature guide post and valve

body together. Remove the valve body from the optical air

eliminator housing.

11

Page 12

Maintenance

Disassembling

Step 4

Place the valve body on a at surface. Using a at blade

screwdriver, remove the two screws which hold the armature

guide post and valve body together. Lift the armature guide

post off of the valve body. The internal components consist

of a plunger and a spring. Inspect the spring for damage.

Step 5

The armature guide post is composed of four components:

two O-rings, the guide post, and the ange. Inspect these

components for damage.

Step 6

The valve body has two O-rings found on the face which

faces the housing. These two O-rings are identical. Inspect

these for damage. Inspect the ports for blockage.

O-rings

O-rings

12

Page 13

Maintenance

Reassembling

Step 1

Place the spring inside the plunger and insert the plunger,

spring end rst, into the armature guide post. Place the armature guide post assembly on the valve body.

Fasten the armature guide post to the valve body using the

two screws removed earlier. Two holes of the valve body are

threaded and two are not. Make sure the screws are being

inserted into the threaded holes.

Note that the valve body has a number stamped into it. This

will be used to set the proper orientation of the solenoid

valve body with respect to the optical air eliminator housing

assembly.

Number Stamp

Position solenoid valve body

with number stamp in this

location

Step 2

Align the solenoid valve body so that the stamped number on

the valve body faces the housing assembly as shown in the

picture to the left. The valve body can physically be fastened

to the housing assembly in one of two orientations. Only one

orientation is correct.

IMPORTANT!

Ifthestampednumbersfaceawayfromthehousing,

theopticalaireliminatorwillnotfunctionproperly.The

portwillbeblockedandtheaireliminatorwillfail.

With the valve body in the proper orientation, fasten it to the

housing using the two screws removed earlier. Tighten to a

torque of 15 to 18 in-lbs (1.7 to 2.0 Nm).

13

Step 3

Place the plastic bonnet over the valve body and snap in

place.

Step 4

Place the coil over the armature guide post and fasten with

the thin hex nut. Tighten the nut with a 14mm wrench to a

torque of 4.5 in-lbs (0.5 Nm).

Page 14

Maintenance

! WARNING

Before disassembly of any meter or accessory component, ALL INTERNAL PRESSURES MUST BE RELIEVED

AND ALL LIQUID DRAINED FROM THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

Pressure must be 0 (zero) psi. Close all liquid and vapor lines between the meter and liquid source.

Failure to follow this warning could result in property damage, personal injury, or death from re and/or explosion, or

other hazards that may be associated with this type of equipment.

Optical Sensor

If the optical sensor ever needs replacement, use a 1”

open end wrench to remove the optical sensor from the

housing. When installing a new optical sensor, care should

be taken not to exceed a torque of 75 in-lbs (8.5 Nm).

Excessive torque may damage the sensor.

Alightcoatingofgreaseoranti-seize

lubricantshouldbeappliedtothethreads

ofthesensorpriortoassembly.

Troubleshooting

PROBLEM

Excessiveliquidowingoutofventtospittank.

Scenario 1: Solenoid not closing.

• Check S3 solenoid wiring.

• Measure resistance across S3 solenoid. Value should

read approximately 15 ω. If not, replace S3 solenoid.

• Inspect S3 solenoid for blockage. Refer to disassembly instructions.

• LectroCount CPU failure. Replace CPU board.

Scenario 2: Optical Sensor not functioning.

• Check optical sensor wiring.

• Measure resistance between the RED and WHITE

wires. Value should be approximately 10kω. If not,

replace optical sensor.

• LectroCount CPU failure. Replace CPU board.

PROBLEM

Noliquidowingthroughmeterduringdelivery.

Scenario 1: Liquid level not rising in optical air eliminator.

• Check S3 solenoid. It may not be opening to allow

air/vapor to vent.

• Check S3 solenoid wiring.

• Measure resistance across S3 solenoid. Value should

read approximately 15 ω. If not, replace S3 solenoid.

• Inspect S3 solenoid for blockage. Refer to disassembly instructions.

• LectroCount CPU failure. Replace CPU board.

Scenario 2: Meter outlet valve not opening

• Check wiring of the outlet valve S1 solenoid.

• Measure resistance across S1 solenoid. Value

should read approximately 15ω. If not, replace S1

solenoid.

• Inspect S1 solenoid for blockage. Refer to the manual

which accompanies the valve.

• LectroCount CPU failure. Replace CPU board.

14

Page 15

Bill of Materials - Exploded View

Model Number: A8981 & A8981A

Italicized part numbers indicate A8981A (Class 2) parts. If there is no italicized number, the

listed part number applies to A8981 & A8981A

15

Page 16

Liqui d c onT roL S

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

Liqui d c onT roL S e uro pe/ SAm pi

Via Amerigo Vespucci 1

55011 Altopascio (Lucca), Italy

+39 0583 24751

ideX FLu id And me Ter ing pv T. LTd.

Survey No. 256, Alindra

Savli GIDC, Manjusar

Dist. Vadodara 391 770

Gujarat, India

+91 265 2631855

Liqui d c onT roL S S pon SLe r

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

TopTe ch SySTe mS

1124 Florida Central Parkway

Longwood, FL 32750

(407) 332-1774

Nateus Business Park

Nieuwe Weg 1-Haven 1053

B-2070 Zwijndrecht (Antwerp), Belguim

+32 (0)3 250 60 60

FAu re her mAn

Route de Bonnetable

B.P. 20154

72406 La Ferté-Bernard Cedex, France

+33 (0)2 43 60 28 60

6961 Brookhollow West Drive

Houston, TX 77040

(713) 623-0808

corke n

3805 Northwest 36th St.

Oklahoma City, OK 73112

(405) 946-5576

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2008 Liquid Controls

Pub. No. 500333

(2/12)

Loading...

Loading...