Page 1

Back Check Valves

A2885 & A2883 (LPG)

A2882 (Rened Fuels)

Installation & Parts

Liquid ControLs Group

An IDEX Fluid & Metering Business

Installation: M400-50

Page 2

TABLE OF CONTENTS

INTRODUCTION

Safety Procedures ................................................... 2

General Information ................................................. 3

A2885 & A2883 (LPG)

New Installations ...................................................... 3

Retrot Installations and Maintenance .................... 4

Disassembly .....................................................................4

Reassembly .....................................................................4

A2882 (REFINED FUELS)

New Installations ...................................................... 5

Retrot Installations and Maintenance .................... 5

Disassembly .....................................................................5

Reassembly .....................................................................5

BILL OF MATERIALS

A2885 & A2883 (LPG) .............................................. 6

A2882 (Rened Fuels) ............................................. 7

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our web site, www.lcmeter.com. It is the

responsibility of the local distributor to provide the most current version of LC manuals, instructions, and specication sheets in

the required language of the country, or the language of the end user to which the products are shipping. If there are questions

about the language of any LC manuals, instructions, or specication sheets, please contact your local distributor.

Be Prepared

! WARNING

• Before using this product, read and understand the instructions.

• All work must be performed by qualied personnel trained in the proper application, installation, and maintenance

of equipment and/or systems in accordance with all applicable codes and ordinances.

• When handling electronic components and boards, always use proper Electrostatic Discharge (ESD) equipment

and follow the proper procedures

• Make sure that all necessary safety precautions have been taken.

• Provide for proper ventilation, temperature control, re prevention, evacuation, and re management.

• Provide easy access to the appropriate re extinguishers for your product.

• Consult with your local re department, state, and local codes to ensure adequate preparation.

• Read this manual as well as all the literature provided in your owner’s packet.

• Save these instructions for future reference.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury, or

death from re and/or explosion, or other hazards that may be associated with this type of equipment.

Safely Evacuate

Piping System

! WARNING

Before disassembly of any meter or accessory component:

ALL INTERNAL PRESSURES MUST BE RELIEVED AND ALL LIQUID DRAINED FROM

THE SYSTEM IN ACCORDANCE WITH ALL APPLICABLE PROCEDURES.

-Pressure must be 0 (zero) psi.

-Close all liquid and vapor lines between the meter and liquid source.

For Safety Rules Regarding LPG, refer to NFPA Pamphlet 58 and local authorities.

Failure to follow this warning could result in property damage, personal injury, or death from re and/or explosion, or other

hazards that may be associated with this type of equipment.

2

Page 3

INTRODUCTION / A2885 & A2883 (LPG)

Observe National and

Local Codes

Power, input, and output (I/O) wiring must be in accordance with the area classication for which it is used (Class I, Div 2).

For North America, installations must be per the U. S. National Electrical Code, NFPA 70, or the Canadian Electrical Code

in order to maintain Class I, Division 2 ratings. This may require using connections or other adaptations in accordance

with the requirements of the authority having jurisdiction.

WARNING: Explosion Hazard -

Substitution of components may impair suitability for Class I, Division 2 applications.

WARNING: Explosion Hazard -

When in hazardous locations, turn power OFF before replacing or wiring modules.

WARNING: Explosion Hazard -

Do NOT disconnect equipment unless power has been switched OFF or the area is known to be Non-Hazardous.

! WARNING

General Information

Liquid Controls soft seat Back Check Valves are designed to prevent reverse ow of product through the meter.

This assures that the meter and all components downstream remain full of the liquid being measured. The A2885

and A2883 for LPG are installed on the inlet side of the strainer assembly on the meter. The A2885 and A2883 are

applicable for MA-5 and MA-7 meters. The A2882 for Rened Petroleum products is installed on the outlet side of the

meter. The A2882 is applicable for M-5, M-7, and M-10 Meters.

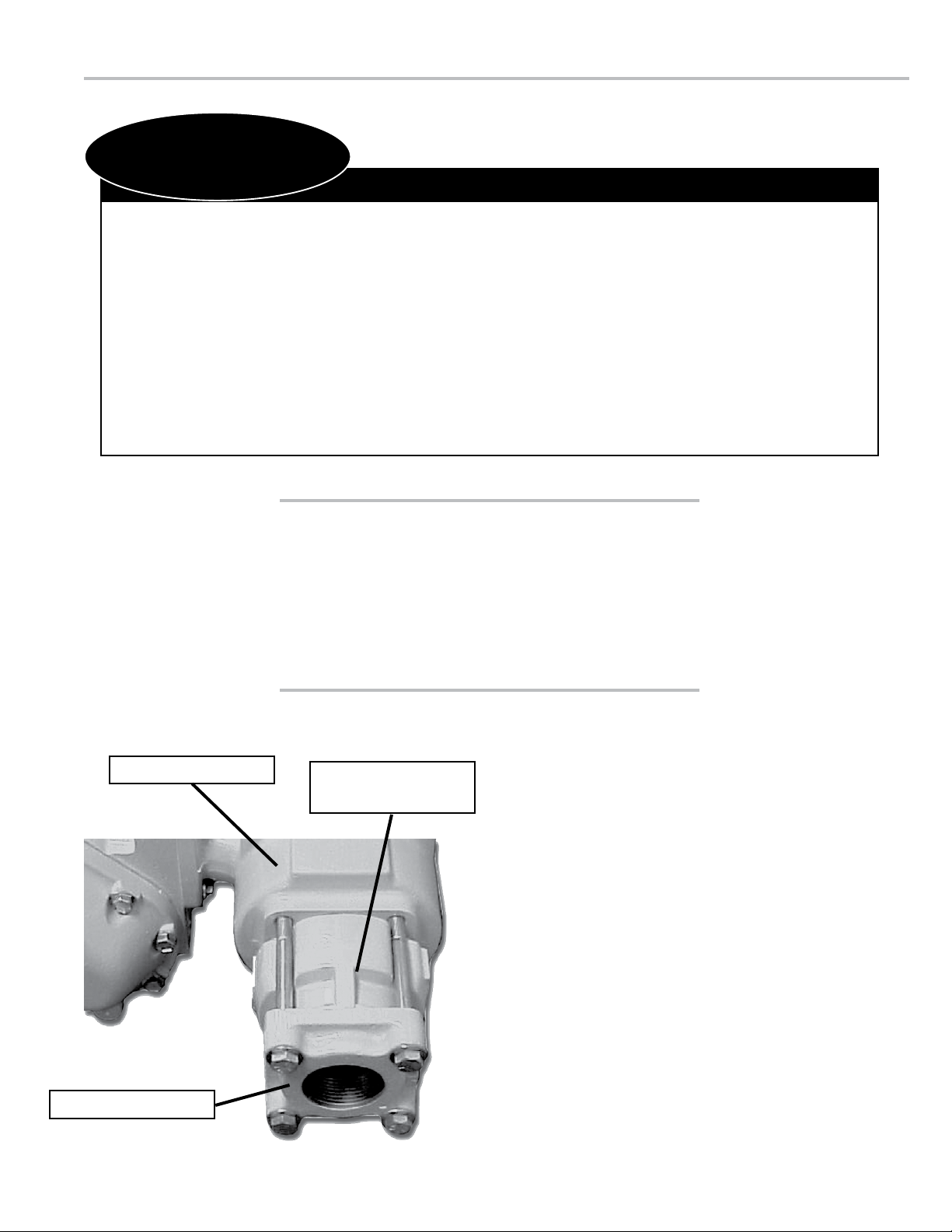

Strainer Assembly

A2885 or A2883

Back Check Valve

A2885 & A2883 Back Check Valves

NEW INSTALLATIONS

When ordered with a new metering system, the A2885

or A2883 Back Check Valve is supplied mounted to the

inlet side of the strainer housing as shown to the right.

To complete the A2885 or A2883 Back Check Valve

portion of the installation, a liquid line must be connected

to the ange on the inlet side of the valve. The ange

connection is 2” NPT.

2" NPT Flange (Inlet)

3

Page 4

A2885 & A2883 (LPG)

A2885 & A2883 Back Check Valves

RETROFIT INSTALLATIONS

Depending on the existing conguration, adding an

A2885 or A2883 Back Check Valve may require

modication of the inlet piping.

After the internal pressure is relieved from the system,

the inlet line can be disconnected from the inlet side of

the strainer assembly. The valve and ange assembly

can then be connected to the inlet side of the strainer.

Use the four bolts and washers provided to fasten the

valve/ange assembly to the strainer as shown on Page

3. Tighten the bolts in a crossing pattern as shown to the

right. Once the valve/ange assembly is secure, the inlet

line may be reconnected to the ange. The ange tting

is 2” NPT.

Item Numbers

Refer to the illustrated parts breakdown on Page 6 for Item Numbers referenced in these

instructions. Item Numbers appear in circles in the drawing.

Bolt Tightening Pattern

DISASSEMBLY

1. Remove the valve from the line by removing the four

screws (Item 3) and washers (Item 4) that hold it in place.

2. Using a tire valve stem changer, remove the relief valve

(Item 920) from the valve stem (Item 265).

3. From the inlet side of the valve, unscrew the valve stem

(Item 265) from the valve nut (Item 875).

4. Remove the valve nut (Item 875) by pressing down on

the spring holder (Item 382). The spring should be held

down with a press. Lift the valve nut out of position. The

spring holder and lock washer can now be removed from

the housing.

5. Remove the O-Ring retainer (Item 452), O-Ring (Item

470), piston (Item 133), O-Ring (Item 471), and spacer

(Item 472), lifting by the threaded end of the valve stem

(Item 265).

6. Remove the O-Ring retainer (Item 452) and O-Ring (Item

471) from the stem.

7. Remove the O-Ring (Item 471) and the piston (Item 133)

from the stem.

8. Replace components if necessary and reassemble. The

bushing (Item 485) is pressed in place and need not be

removed.

REASSEMBLY

1. Place the piston (Item 133) on the valve stem (Item 265),

with the raised rim pointing upwards.

2. Place the spacer (Item 472) and O-Ring (Item 471) on

the piston (Item 133)

3. Place the O-Ring (Item 470) on the retainer (Item 452)

and place it over the piston (Item 133) with the O-Ring

downward.

4. Place a self locking nut (Item 875) on the valve stem and

tighten. Place a second self locking nut (Item 875) on the

valve stem and tighten.

5. Insert this assembly into the housing (Item 110) from the

outlet side.

6. Place the compression spring (Item 595) over the valve

stem (Item 265).

7. Insert the Teon bearing (Item 486) into the valve spring

holder (Item 382).

8. Place the spring holder (Item 382) on the housing (Item

110) and compress the spring inward. A press should be

used to overcome the force of the spring.

9. Secure the spring holder with the spiral retaining ring

(Item 393).

10. Screw the pressure relief valve (Item 920) into the valve

stem (Item 265) using a tire valve stem changer.

11. Place the O-Ring (Item 473) in the groove on the outlet

side of the housing assembly (Item 110).

The back check valve is now ready to be reinstalled using the

four screws (Item 3) and washers (item 4).

4

Page 5

A2882 (REFINED FUELS)

Meter Outlet

2882 Back Check Valve

Item Numbers

Refer to the illustrated parts breakdown on Page 7 for Item

Numbers referenced in these instructions. Item Numbers appear

in circles in the drawing.

A2882 Back Check Valves

NEW INSTALLATIONS

When ordered with a new metering system, the A2882

Back Check Valve is supplied mounted to the outlet

side of the meter as shown to the right. To complete the

A2882 Back Check Valve portion of the installation, a

liquid line must be connected to the ange on the outlet

side of the valve. The ange connection is 2” NPT.

RETROFIT INSTALLATIONS

Depending on the existing conguration, adding an

A2882 Back Check Valve may require modication of the

outlet piping.

After the internal pressure is relieved from the

system (see warning on Page 2), the outlet line can

be disconnected from the output side of the meter

assembly. The valve and ange assembly can then be

connected to the outlet side of the meter.

Use the four bolts and washers provided to fasten the

valve/ange assembly to the meter. Tighten the bolts

in a crossing pattern (as shown on Page 4). Once the

valve/ange assembly is secure, the outlet line may be

reconnected to the ange. The ange tting is 2” NPT.

DISASSEMBLY

1. Remove the valve from the line by removing the four

screws (Item 3) and washers (Item 4) that hold it in place.

2. Using a tire valve stem changer, remove the relief valve

(Item 920) from the valve stem (Item 265).

3. From the inlet side of the valve, unscrew the valve stem

(Item 265) from the valve nut (Item 875).

4. Remove the valve nut (Item 875) by pressing down on

the spring holder (Item 382). The spring should be held

down with a press. Lift the valve nut out of position. The

spring holder and lock washer can now be removed from

the housing.

5. Remove the O-Ring retainer (Item 452), O-Ring (Item

470), piston (Item 133), O-Ring (Item 471) and spacer

(Item 472), lifting by the threaded end of the valve stem

(Item 265).

6. Remove the O-Ring retainer (Item 452) and O-Ring (Item

470) from the stem.

7. Remove the O-Ring (Item 471) and the piston (Item 133)

from the stem.

8. Replace components if necessary and reassemble. The

bushing (Item 485) is pressed in place and need not be

removed.

REASSEMBLY

1. Place the piston (Item 133) on the valve stem (Item 265),

with the raised rim pointing upwards.

2. Place the spacer (Item 472) and O-Ring (Item 471) on

the piston (Item 133)

3. Place the O-Ring (Item 470) on the retainer (Item 452)

and place it over the piston (Item 133) with the O-Ring

downward.

4. Place washer (705) over the valve stem and secure it

with self locking nut (875)

5. Insert this assembly into the housing (Item 110) from the

outlet side.

6. Place the compression spring (Item 595) over the valve

stem (Item 265).

7. Insert the Teon bearing (Item 486) into the valve spring

holder (Item 382).

8. Place the spring holder (Item 382) on the housing (Item

110) and compress the spring inward. A press should be

used to overcome the force of the spring.

9. Secure the spring holder with the spiral retaining ring

(Item 393).

10. Screw the pressure relief valve (Item 920) into the valve

stem (Item 265) using a tire valve stem changer.

The back check valve is now ready to be reinstalled using the

four screws (Item 3) and washers (item 4).

5

Page 6

BILL OF MATERIALS - A2885 & A2883 (LPG)

Model A2885 (For LPG)

Used on meters sold AFTER December 19, 1991 beginning

with Serial No. 225233

48863 2” Check Valve Assembly

Item Description Part Number

486 Bearing N/S*

473 Buna-N O-Ring 06854

393 Spiral Retaining Spring 09137

382 Valve Spring Holder 48337

595 Compression Spring 09138

875 Self Locking Nut (2) 09143

452 O-Ring Retainer 47974

470 Buna-N O-Ring 09131

471 Buna-N O-Ring 09140

472 Spacer 47295

133 Piston 47975

265 Valve Stem N/S

485 Bushing 07867

110 Check Valve Housing 47973

920 Valve Core N/S

N/S = Not for Sale

Model A2883 (For LPG)

Used on meters sold BEFORE December 19, 1991 ending with

Serial No. 225232

48190 2” Check Valve Assembly

Item Description Part Number

486 Bearing N/S

473 Buna-N O-Ring 06854

393 Spiral Retaining Spring 09137

382 Valve Spring Holder 48337

595 Compression Spring 09138

875 Self Locking Nut (2) 09143

452 O-Ring Retainer 47974

470 Buna-N O-Ring 09131

471 Buna-N O-Ring 09140

472 Spacer 47295

133 Piston 47975

265 Valve Stem N/S

485 Bushing 07867

110 Check Valve Housing 47994

920 Valve Core N/S

Mounting Screws & Bolts

(A2885 & A2883)

6

Page 7

BILL OF MATERIALS - A2882 (REFINED FUELS)

Model A2882 (For Rened Fuels)

48189 2” Check Valve Assembly

Item Description Part Number

393 Spiral Retaining Spring 09137

486 Bearing 07801

382 Valve Spring Holder 48337

595 Compression Spring N/S

875 Self Locking Nut (2) 09143

705 Flat Washer 40241

452 O-Ring Retainer 47974

470 Viton O-Ring 09025

471 Viton O-Ring 09139

472 Spacer 47295

133 Piston 47975

110 Check Valve Housing N/S

485 Bushing 07867

265 Valve Stem N/S

920 Valve Core N/S

420 Buna-N O-Ring 06854

Mounting Screws & Bolts

(A2882)

7

Page 8

Liquid conTroLS

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

Liquid conTroLS europe/SAmp i

Via Amerigo Vespucci 1

55011 Altopascio (Lucca), Italy

+39 0583 24751

Liquid conTroLS indiA

808 VCCI Complex

GIDC Makarpura

Vadodara-390 101

Gujarat, India

+91 265 2631855

Liquid conTroLS SponSLer

105 Albrecht Drive

Lake Bluff, IL 60044

(847) 295-1050

TopTech SyS Te mS

1124 Florida Central Parkway

Longwood, FL 32750

(407) 332-1774

Nateus Business Park

Nieuwe Weg 1-Haven 1053

B-2070 Zwijndrecht (Antwerp), Belguim

+32 (0)3 250 60 60

FAu re h er mA n

Route de Bonnetable

B.P. 20154

72406 La Ferté-Bernard Cedex, France

+33 (0)2 43 60 28 60

6961 Brookhollow West Drive

Houston, TX 77040

(713) 623-0808

corken

3805 Northwest 36th St.

Oklahoma City, OK 73112

(405) 946-5576

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2004 Liquid Controls

Pub. No. 500320

(10/04)

Loading...

Loading...