Page 1

Rev: 03.18.2014

Page 1

Trailer Axle Owners Manual FULL

Page 2

TABLE OF CONTENTS

Introduction 3

Safety Information 3

Break-in Period for Electric Drum Brakes 4

Hubs/Drums/Bearings 4

Hub Removal 4

Brake Drum Inspection 5

Bearing Inspection 5

Bearing Lubrication - Oil 6

Bearing Lubrication - Grease 6

Seal Inspection and Replacement 7

Bearing Adjustment/Hub Replacement 7

Electric Brakes 8

How to Use Lippert Electric Brakes Properly 9

General Maintenance - Electric Brakes 9

Brake Adjustment 9

Lubricate Brakes 10

Clean and Inspect Brakes 10

Magnets 10

Shoes and Linings 11

Axle and Suspension Installation 11

Suspension Systems 11

Double-Eye Leaf Springs 12

Torsion Suspension System 13

Inspection 14

Suspension Replacement 14

Wheels 15

Wheel Selection 15

Torque Requirements 16

Tires 17

Introduction to Troubleshooting 18

Troubleshooting 18

Measuring Voltage 18

Troubleshooting Chart 19

Measuring Amperage 20

Amperage Chart 21

Maintenance Schedule 22

Wiring Diagram 23

Pigtail and Coupler Wiring Color Codes 24

3,500LB AXLE WHEEL END COMPONENTS 25

5,200LB AXLE WHEEL END COMPONENTS 30

6,000LB AXLE WHEEL END COMPONENTS 34

7,000LB AXLE WHEEL END COMPONENTS 37

Storage 41

Storage Preparation 41

Extended Storage Inspection Procedures 41

Trip Preparation Checklist 42

Rev: 03.18.2014

Page 2

Trailer Axle Owners Manual FULL

Page 3

Introduction

Combining years of experience in the trailer frame and recreational vehicle industry with the newest

and most innovative technology, Lippert Components, Inc. introduces it’s newest addition, The Axle and

Running Gear Division.

The following publication is designed to give the customer an easy-to-understand operation and service

manual to provide useful and important information. The quality of the Lippert name and the finest

materials utilized in the production of the Axles and Running Gear provide you with hubs, brakes, drums

and spindles that make trailering and braking the finest in the industry.

Quality comes threefold in Lippert Components, Inc.

1. The finest quality materials.

2. The latest technology and design.

3. The quality standards maintained from materials to final assembly.

All three points provide the customer with the best product they can possibly buy and the satisfaction of

knowing they can trust the equipment on which they have spent their hard-earned money.

Lippert Components, Inc. thanks you for purchasing our Axles and Running Gear. When you speak of

Lippert Components, Inc., our quality stands beside you.

Safety Information

The “WARNING” symbol above is a sign that a service or maintenance procedure has a safety risk involved

and may cause serious injury or death if not performed safely and within the parameters set forth in this

manual.

Always wear eye protection when performing service or maintenance to the vehicle. Other safety

equipment to consider would be hearing protection, gloves and possibly a full face shield, depending on

the nature of the service.

This manual provides general service and maintenance procedures. Many variables can change the

circumstances of the service procedure, i.e., the degree of difficulty involved in the service operation and the

ability level of the individual performing the operation. This manual cannot begin to plot out procedures

for every possibility, but will provide the general instructions for effectively servicing the vehicle. In the

event the skill level required or the procedure to difficult, a certified technician should be consulted before

performing the necessary service. Failure to correctly service the vehicle may result in voiding the warranty,

inflicting injury or even death.

The owner’s manual for your unit may have more procedures for service and maintenance.

Rev: 03.18.2014

Page 3

Trailer Axle Owners Manual FULL

Page 4

Break-in Period for Electric Drum Brakes

The break-in period is a typical phenomenon with drum brakes and especially electric drum brakes. Electric

drum brakes will require a break-in period to achieve full performance. This break-in period applies for new

axles and any time new brake shoes and/or magnets are installed as part of regular maintenance.

Lippert Components has found through extensive brake testing that the break-in period for our drum

brakes can range from 20 to 50 brake applications.

Brakes can be seated in by applying approximately 8-10 volts to the trailer brakes at an initial speed of 40

mph and allowing the truck/trailer combination to slow down to 20 or 25 mph. For best results do not use

truck brakes during this procedure. The trailer brakes will seat in faster by using them to stop both the truck

and trailer. The easiest method is to apply the trailer brakes using the manual activation lever located on the

in-cab brake controller. Care must be taken to not overheat the lining material, therefore brake applications

conducted at one mile intervals will suffice. The driver should feel a noticeable difference in the brake

performance during this period, sometimes in as few as 10 applications. After 50 applications, the brake

lining material will be fully cured from the heat and develop close to 100% contact with the brake drum

surface.

This break in period not only seats the shoe lining material but also seats in the brake electromagnets.

During the break-in period, the linings will wear at a faster rate than they do after they are seated in.

NOTE: Brakes should be manually adjusted after the first 200 miles of operation and periodically thereafter,

approx. 3,000 mile intervals.

Hubs/Drums/Bearings

Hub Removal

To remove the hub assembly for inspection, maintenance or service, follow the six (6) steps below:

Lift unit by the frame and never the axle or suspension. Do not go under unit unless it is properly

supported by jack stands. Unsupported units can fall causing death or serious injury.

1. Lift trailer and support it per manufacturer’s requirements.

2. Remove the wheel.

3. Remove the grease cap by prying the edge out of the hub. If equipped with oil lubrication, unscrew oil

cap using a 2½” socket. Let oil drain into pan.

4. Pull the cotter pin from the castle nut and remove the outer spindle nut.

5. Remove the spindle washer.

6. Pull the hub off the spindle. Do not let the outer bearing cone fall free of the assembly. The inner

bearing cone will be contained by the seal and will not fall out.

NOTE: Brakes may need to be adjusted or backed off to remove drum from spindle.

NOTE: A gear puller may be necessary to remove hub from spindle.

Rev: 03.18.2014

Page 4

Trailer Axle Owners Manual FULL

Page 5

Brake Drum Inspection

The brake shoes contact the drum surface and the magnet contacts the armature. These surfaces are

subject to wear and should be inspected periodically.

The drum surface should be re-machined if wear is more than .030” or out of round by more than .015”. The

drum should be replaced if scoring or wear is greater than .090”.

The inner surface of the brake drum that contacts the brake magnet is the armature surface. If the armature

surface is scored or worn unevenly, it should not be machined more than .030”. The magnets should be

replaced whenever the armature surface is refaced and vice versa.

NOTE: Ensure that the wheel bearing cavities are clean and free of contamination before reinstalling

bearing and seals. Resurfacing procedures can produce metal chips and dust that can contaminate

the wheel bearings and cause failure.

Drum Maximum Re-bore Diameter

7" 7.09"

10" 10.09"

12" 12.09"

Bearing Inspection

Wash all grease and oil from the bearing cone using a suitable solvent. Dry the bearing with a clean, lint-free

cloth and inspect each roller completely. If any pitting, spalling, or corrosion is present, then the bearing

must be replaced. The bearing cup inside the hub must be inspected.

NOTE: Bearings must always be replaced in sets of one cone and one cup.

Always wear eye protection when servicing the axle, brakes, hubs, springs and wheels. Failure to wear

eye protection may result in serious injury.

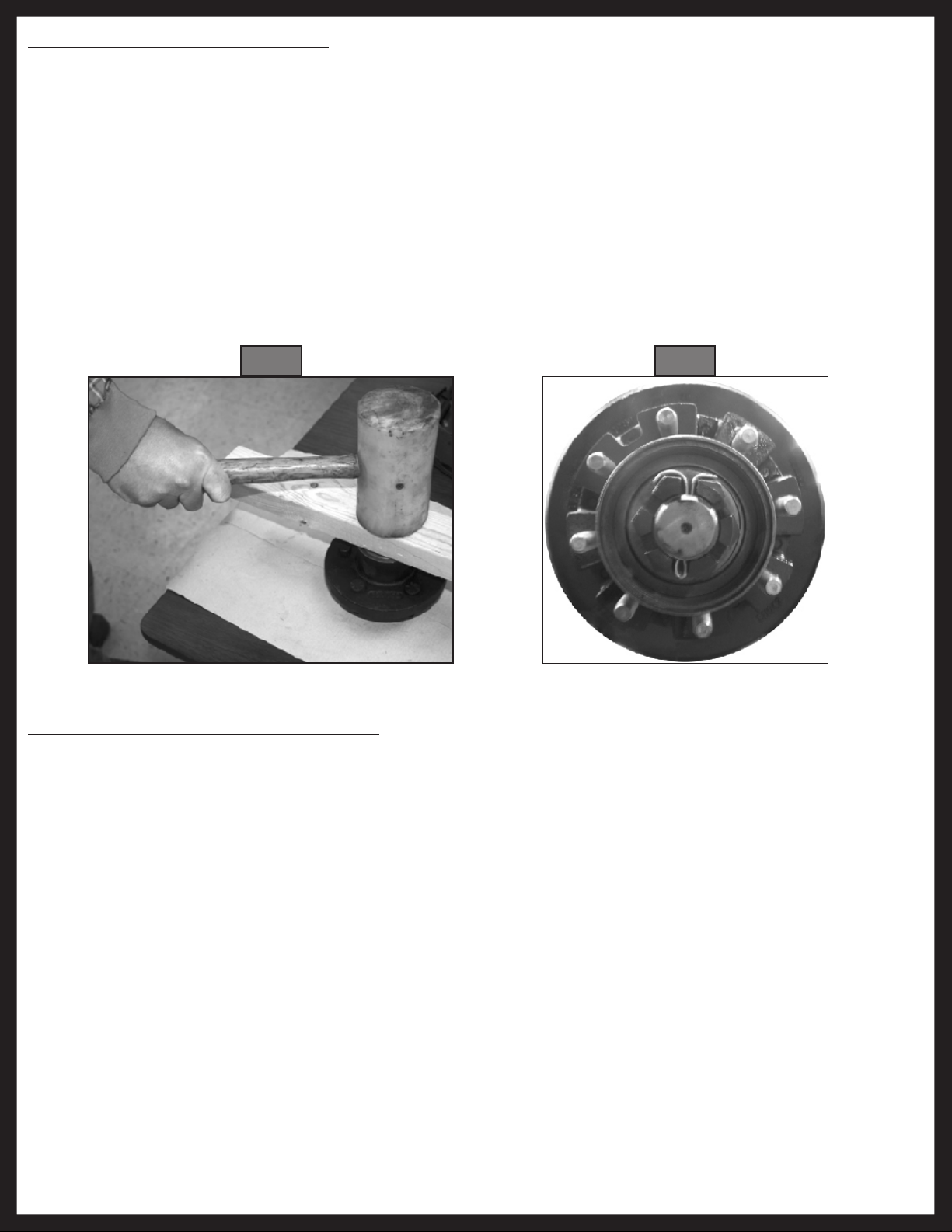

Follow the procedure below to replace the bearing cup:

1. Place hub on a flat surface with bearing cup on the bottom.

2. With brass drift punch, lightly tap around the small end of the cup to push it out.

3. Clean the hub bore. Replace the cup by tapping it back in with the brass drift punch. Cup should be

seated against the retaining shoulder in the hub.

Consult Bearing Replacement Chart for proper replacement bearings.

NOTE: Replacing the bearing cup is a very precise process. The cup must be perfectly seated when

replaced. If the cup is not seated correctly, damage to the assembly may not be covered by the

warranty. Consult Lippert Components, Inc. prior to replacing bearing and bearing cup. The trailer

should be taken to a certified service center for this work to be done.

Do not mix Lithium, calcium, sodium or barium complex greases. Chemical compatibility problems may

occur. If you are changing from one chemical grease to another, be sure all old grease is removed prior to

applying new grease. If the old grease is not removed completely, chemical compatability may result in

component failure or damage.

Rev: 03.18.2014

Page 5

Trailer Axle Owners Manual FULL

Page 6

Bearing Lubrication - Oil

If your axles are equipped with oil lubricated hubs, then your lubrication procedure is to periodically fill the

hub with a high quality hypoid gear oil to the level indicated on the clear plastic oil cap. The oil can be filled

through the rubber plug hole in the cap.

Bearing Lubrication - Grease

Bearing grease should be replaced every 12,000 miles or 12 months, whichever comes first. Remove all

old grease from wheel hub and bearings first. Bearings should be packed by machine if possible. Packing

bearings by machine is preferable; however, packing by hand is a viable alternative.

Follow these procedures to repack bearings by hand:

1. Place grease into the palm of your hand (Fig. 1).

2. Press widest end of bearing into the outer edge of the grease pile, forcing grease into the inner area of

the bearing between two adjacent rollers (Fig. 2).

3. Repeat this process while turning bearing from roller to roller until all rollers are coated.

4. Apply a light coat of grease into the bearing cup surface.

5. Reassemble bearing into cup.

Fig. 1

Fig. 2

Recommended Wheel Bearing Grease Specifications

Thickener Type Lithium Complex

Dropping Point 230°C (446°F) Minimum

Consistency NLGI No. 2

Additives EP, Corrosion, & Oxidation Inhibitors

Base Oil Solvent Refined Petroleum Oil

Base Oil Viscosity @40°C (104°F) 150cSt (695 SUS) Minimum

Viscosity Index 80 Minimum

Pour Point -10°C (14°F) Minimum

Rev: 03.18.2014

Approved Sources

Mobil Oil Mobilgrease HP

Exxon/Standard Ronex MP

Kendal Refining Co. Kendall L-427

Ashland Oil Co. Valvoline Val-plex EP Grease

Pennzoil Prod. Co. Premium Wheel Bearing Grease 707L

Page 6

Trailer Axle Owners Manual FULL

Page 7

Seal Inspection and Replacement

Always check the seal to make sure that it is not damaged, nicked, cracked or torn and is in good working

order. If there is any question of condition, replace the seal.

Procedure to replace seal:

1. Pull seal from the hub with a seal puller. Never push the seal out with the bearing. The bearing may get

damaged.

2. Apply a PERMATEX sealant to the outside of the new seal.

NOTE: Do not use PERMATEX on rubber encased seals.

3. Tap the new seal into place using a clean, hardwood block (Fig. 3).

NOTE: When installing a new oil seal, be sure side marked “AIR SIDE” is away from bearing cone.

Fig. 3 Fig. 4

Bearing Adjustment/Hub Replacement

To adjust bearings or replace removed hub, follow procedures below:

1. Place hub, bearing, washers and castle nut back on axle spindle in the reverse order from which they

were removed. Castle nut should be torqued to 50 ft.-lb. Hub will rotate during this process.

2. Loosen castle nut to back off the torque.

3. Tighten castle nut finger tight until snug.

4. Insert cotter pin. If cotter pin does not line up with hole, back castle nut up slightly until pin can be

inserted (Fig. 4).

5. Bend cotter pin over to lock nut in place. Nut should be free to move with only the cotter pin keeping

it in place.

Rev: 03.18.2014

Page 7

Trailer Axle Owners Manual FULL

Page 8

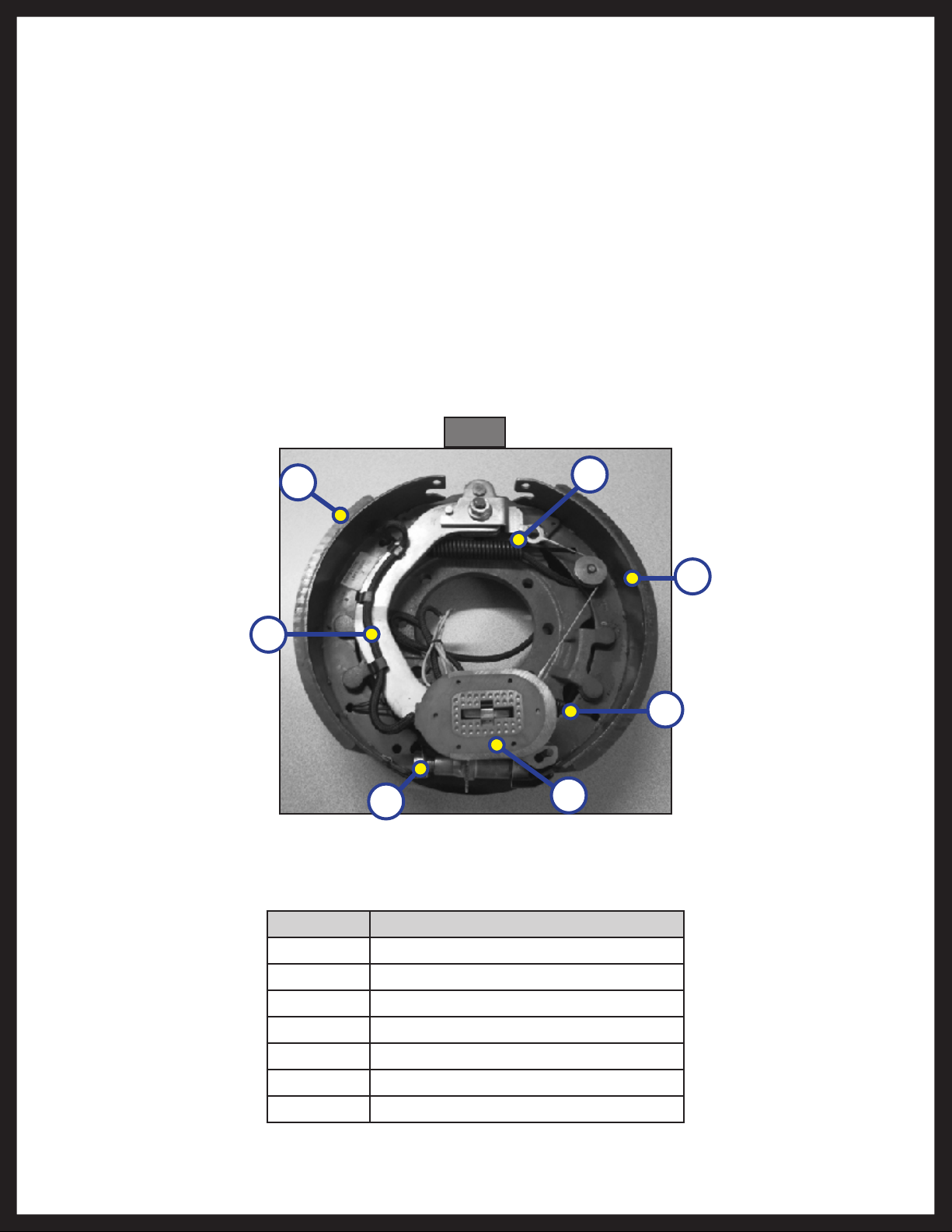

Electric Brakes

The basic structure of the Electric Brakes on your trailer will resemble the brakes on your car or tow vehicle,

with one major difference; your trailer implements an Electric Actuation system and your tow vehicle utilizes

a hydraulic system. The Electric Braking System operates in the following order of steps: (Refer to the Electric

Braking System Diagram and the brake diagram below to follow along.)

6. Electric current is supplied to the trailer’s braking system when the tow vehicle’s brakes are applied.

7. From the tow vehicle’s battery, the electricity flows to the brake’s electromagnet.

8. When energized the magnets are attracted to the rotating surface of the drums.

9. This moves the actuating levers in the direction the drums are turning.

10. The actuating cam at the end of the shoe forces the primary shoe out to the drum surface.

11. The force of the primary shoe actuates the secondary shoe to contact the drum.

12. The force applied to the brake drum can be increased by elevating the current flow to the magnet.

Fig. 5

A

B

C

Callout Description

A Primary Shoe

G

F

E

D

Rev: 03.18.2014

B Actuating Lever

C Adjuster

D Magnet

E Adjusting Spring

F Secondary Shoe

G Retracting Spring

Page 8

Trailer Axle Owners Manual FULL

Page 9

How to Use Lippert Electric Brakes Properly

The Lippert Components, Inc. Electric Braking System is synchronized with the tow vehicle brakes. Never

attempt to stop the combined load of the tow vehicle and the trailer by using either the tow vehicle brakes

or the trailer brakes only. They are designed to work together.

Small manual adjustments may occasionally be necessary to accommodate changing loads and driving

conditions. Synchronization of tow vehicle to trailer braking can only be accomplished by road testing.

Locking up, excessive grab, or delayed application is quite often due to the lack of synchronization between

the tow vehicle and the trailer being towed. High voltage (2V+), Low voltage (2V-) or improperly adjusted

brakes are the most common causes of these problems and can be easily remedied.

Prior to any adjustments, your trailer brakes should be burnished-in by applying the brakes 20-30 times

with a 20 m.p.h. decrease in speed, e.g. 40 m.p.h. to 20 m.p.h. Allow ample time for brakes to cool between

application. This allows the brake shoes and magnets to begin seating to the brake drum.

Trailer Wire Gauge Chart

Wire Gauge and Type Number of Axles Length of Run

16 Ga Stranded Copper 1 N/A

14 Ga Stranded Copper 2

12 Ga Stranded Copper 2 or 3

Under 30ft. (9.1m) from

hitch to center of axles

Over 30ft. (9.1m) from

hitch to center of axles

General Maintenance - Electric Brakes

Brake Adjustment

Prior to testing or adjusting brakes, be sure area is clear of any persons and vehicles. Failure to perform

test in a clear area may result in death or serious injury.

Lippert Components, Inc. Electric Brakes are automatic adjust only. If manual adjusting is needed, the

following 6-step procedure can be utilized. The brakes should be adjusted in the following manner:

1. Jack up trailer and secure on adequate capacity jack stands. Follow trailer manufacturer’s

recommendations for lifting and supporting the unit. Make sure the wheel and drum rotates freely.

Lift unit by frame and never the axle or suspension. Do not go under unit unless it is properly supported

by jack stands. Unsupported units can fall causing death or serious injury.

2. Remove the adjusting hole cover from the adjusting slot on the bottom of the brake backing plate.

3. With a screwdriver or standard adjusting tool, rotate the starwheel of the adjuster assembly to expand

the brake shoes. Adjust the brake shoes out until the pressure of the linings against the drum makes

the wheel very difficult to turn.

4. Then rotate the starwheel in the opposite direction until the wheel turns freely with a slight lining drag.

NOTE: A second screwdriver will be needed to push the auto adjusting lever away from the adjuster

starwheel so that the starwheel can be rotated backwards.

5. Replace the adjusting hole cover and lower the wheel to the ground.

6. Repeat the above procedure on all brakes. For best results, the brakes should all be set at the same

clearance.

Rev: 03.18.2014

Page 9

Trailer Axle Owners Manual FULL

Page 10

Lubricate Brakes

Prior to reassembling the brake drum assembly, remember to apply a light film of white grease or an antiseize compound on the brake anchor pin, the actuating arm bushing and pin, and the areas on the backing

plate that are in contact with the brake shoes and magnet lever arm. In addition apply a light film of grease

on the actuating block mounted on the actuating arm.

Clean and Inspect Brakes

In the event the braking system encounters symptoms of improper application or failure, immediate

inspection and service must be implemented. During normal use, servicing the braking system once a year

is considered normal. Increased usage will require service on a regulated schedule based on 3000-6000 mile

increments. As magnets and shoes become worn, they need to be changed to maintain maximum braking

capability.

Be sure, when disassembling brakes for cleaning, to clean the backing plate, magnet arm, magnet and

shoes. Also, make sure that any and all parts removed for cleaning are placed back into the same brake drum

assembly. This is also an excellent time to check for parts that have become loose or worn.

Potential Asbestos Dust Hazard.

Older brake linings have the potential to contain asbestos dust, which has been linked to serious or fatal

illnesses. Certain precautions must be taken when servicing brakes:

1. Avoid creating and/or breathing any brake dust.

2. Do not machine, file, or grind the brake linings.

3. Remove with a damp brush or cloth. Dry brushing or compressed air will cause the dust particles to

become airborne.

Magnets

This electric braking system utilizes an electromagnet to actuate the brake shoes. These high-quality

magnets provide superior force and friction to safely and effectively stop the trailer. These magnets should

be inspected and serviced on the same schedule as the rest of the axle system, at least once a year for

normal use and more often if the trailer is used extensively. Abnormal or uneven wear is a sign that the

magnet needs to be replaced. Check the surface of the magnet with a straight edge to check for uneven

wear. The surface of the magnet should be completely flat.

If the magnet’s coil is exposed in any way, even if normal wear is evident, the magnets should be replaced

immediately. If the electromagnets are replaced, the drum armature surface should also be refaced. If

a magnet is replaced on one side of an axle, it is recommended that the magnet on the opposite brake

assembly also be replaced to ensure even braking capacity.

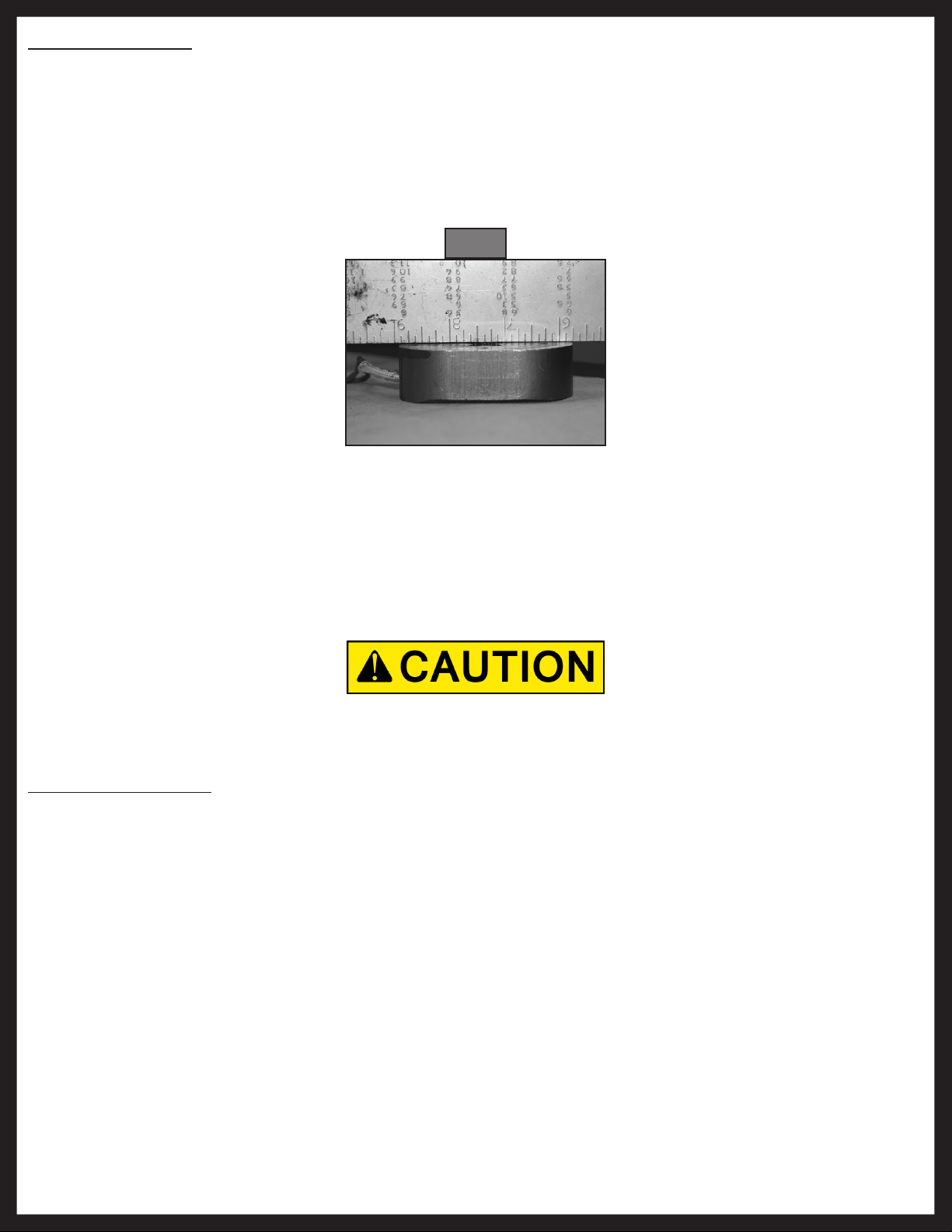

Figure 6 (Page 11) shows an Electro-Magnet with little or no wear. If there are any pronounced gaps on the

surface of the Electro-Magnet, the magnet should be replaced.

Rev: 03.18.2014

Page 10

Trailer Axle Owners Manual FULL

Page 11

Shoes and Linings

Linings should be replaced if the material is worn to ⁄” or less. Shoes should also be replaced if they

become contaminated with grease or oil or have become scored, pitted or gouged. Heat cracks are normal

and rarely require attention. When replacing shoes, both shoes on the same brake and the brakes on the

same axle should all be replaced at the same time, once again ensuring even braking capacity.

After replacing shoes and linings, your trailer brakes should be burnished-in by applying the brakes 20-30

times with a 20 m.p.h. decrease in speed, e.g. 40 m.p.h. to 20 m.p.h. Allow ample time for brakes to cool

between application. This allows the brake shoes and magnets to begin seating to the brake drum.

Fig. 6

Axle and Suspension Installation

The single most important portion of axle installation is parallel alignment of the trailer axle(s) to the tow

vehicle or drive axle(s). Parallel installation allows for correct and safe control, prolonged tread life and will

all but eliminate dog-tracking. Proper alignment is most readily achieved by measuring from the center of

the trailer king pin to the center of each end of the axles.

Lippert Components, Inc. tubular axles are made of high strength steel to prevent metal fatigue and provide

the best possible welding conditions. The round tubular axles allow for even and uniform structure.

Always wear eye protection when servicing the axle, brakes, hubs, springs and wheels. Failure to wear eye

protection may result in serious injury.

Suspension Systems

The suspension systems incorporated into Lippert Component, Inc. axles are designed to provide the

following benefits:

1. Attach the axle to the trailer.

2. Dampen the effects of road shock.

3. Provide stability to the trailer.

All Lippert suspension systems are available in single and multiple axle configurations. For specific or

custom applications, please contact Lippert Components, Inc. Axle Division.

Rev: 03.18.2014

Page 11

Trailer Axle Owners Manual FULL

Page 12

Double-Eye Leaf Springs

Double-eye leaf springs have eyes at either end of the spring assembly with nylon bushings to assist in

preventing wear. U-bolts hold the springs to the axle with a plate.

The articulation of this suspension occurs when the eyes rotate on the wear surfaces provided in eyes of the

springs and on the equalizers. This suspension is also available in single and multiple axle configurations.

In trailers with 2 or more axles, the additional movement is maintained by an equalizer. This feature allows

for even load handling from axle to axle.

Double-eye suspension systems are available on 8,000 lb. axles. Tandem and triple axle mounting kits are

available for both 33” and 35” axle spacing.

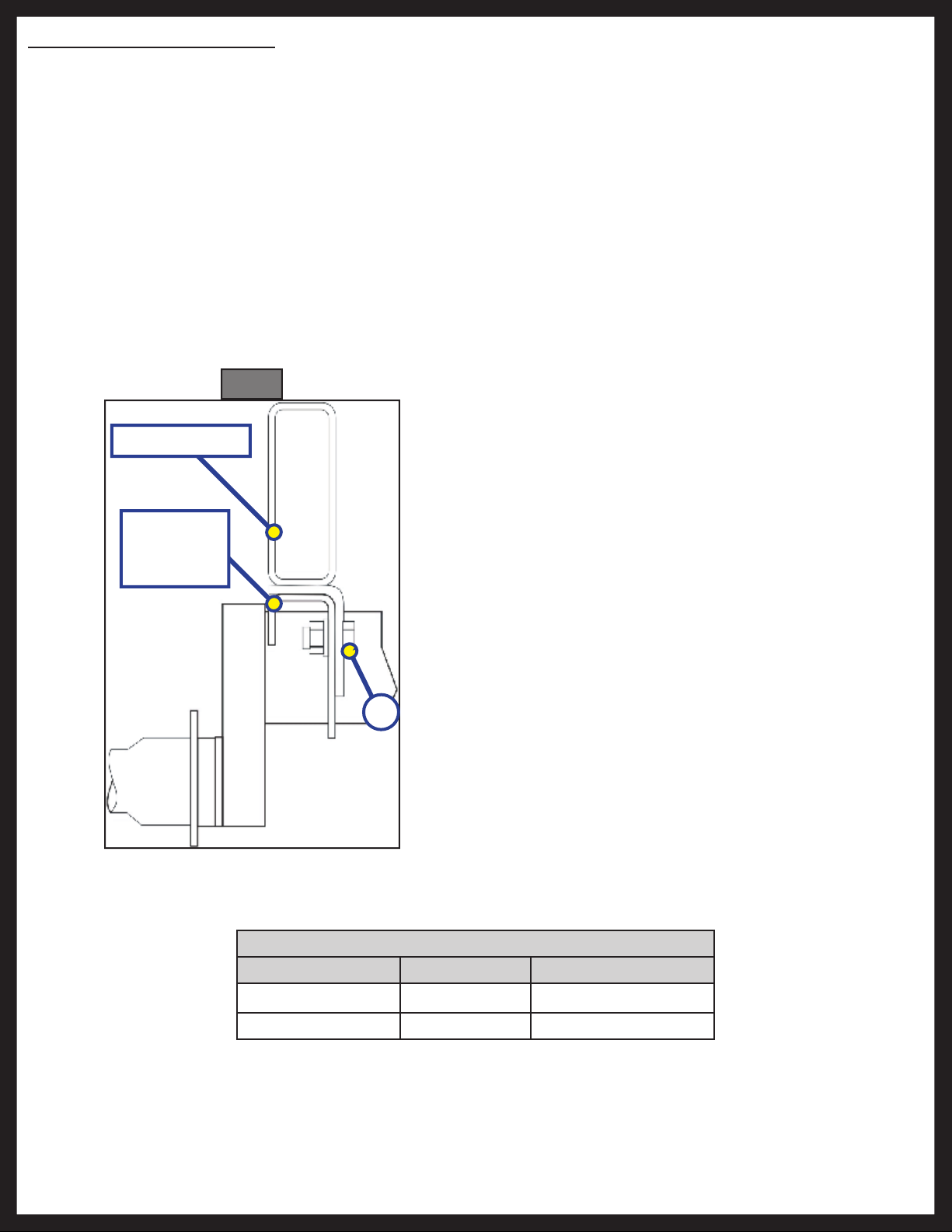

Front Hanger

Shackle Link Center Hanger

Fig. 7

Shackle Bolts

Tie Plate

Equalizer

Spring Axle Torque Specifications

Bolt Type Axle Capacity Maximum Torque

2K 25 ft-lb

Rear Hanger

Rev: 03.18.2014

U-Bolts

3.5K with ½ " 50 ft-lb

5.2K 65 ft-lb

6-8K 90 ft-lb

Minimum Torque Maximum Torque

Shackle Bolts 30 ft-lb 50 ft-lb

Page 12

Trailer Axle Owners Manual FULL

Page 13

Torsion Suspension System

1. The Lippert Components, Inc. Torsion Suspension system is designed to offer superior qualities over

leaf spring technology. The Lippert Components, Inc. Torsion Suspension system is bracketed to the

trailer’s frame and housed inside the trailer axle’s tube.

2. The spindle is connected to a swing arm, the swing arm is connected to a square inner bar that is

sheathed in rubber and as the swing arm rotates and experiences the torque and resistance of driving

conditions, the characteristics of the rubber absorb and distribute the load providing benefit over leaf

spring suspensions.

3. The Lippert Components, Inc. Torsion Suspension system requires very little attention in regards to

maintenance. Normal inspection of the entire Lippert Components, Inc. Trailer Axle system can be

applied to the Torsion Suspension system. See inspection procedures for system components in this

manual.

Fig. 8

Outside Frame

Outside

Bracket

Dimension

NOTE: For Torsion installation, mount axle bracket to

frame bracket (Fig. 8) and torque fasteners

as specified in the chart below.

NOTE: Washer(s) must be placed against the slotted

hole in the axle bracket (Fig. 8A).

NOTE: Low profile brackets have plain round holes.

A

Rev: 03.18.2014

Torsion Axle Torque Specifications

Axle Size Bolt Size Torque Range

#8 - #9 ½ " 70-90 ft-lb

#10 - #13 ⁄" 120-150 ft-lb

Page 13

Trailer Axle Owners Manual FULL

Page 14

Inspection

All the components of your suspension system should be visually inspected for signs of wear, damage or

loose fasteners at least every 6,000 miles. When replacing or tightening loose fasteners, consult the torque

specs on page 13 for correct torque values.

Worn spring eye bushings or sagging or broken springs should be replaced using the following method:

1. Support the trailer with the wheels just off the ground. Follow the trailer manufacturer’s

recommendations for lifting and supporting the unit.

2. After the unit is properly supported place a suitable block under the axle tube near the end to be

repaired. This block is to support the weight of the axle only so that suspension components can be

serviced or replaced.

3. Disassemble the U-bolts, nuts, and tie plates.

4. Remove the spring eye bolts and the spring.

5. If the spring eye bushings are to be replaced, press out the old bushing by hand or tapping out with a

punch.

6. Free-floating nylon bushing needs no lubrication. Press the new bushing into the spring eye by hand

or gently tapping it in with a bounce less rubber or plastic mallet.

7. Reinstall repaired or replaced components in reverse order.

NOTE: For multiple axle units, the weight of each axle must be supported as outlined in Step 2 before

disassembly of any component of the suspension system.

Lift unit by the frame and never the axle or suspension. Do not go under unit unless it is properly

supported by jack stands. Unsupported units can fall causing death or serious injury.

Always wear eye protection when servicing the axle, brakes, hubs, springs and wheels. Failure to wear

eye protection may result in serious injury.

If the equalizer or equalizer bushings must be replaced, follow the instructions above for lifting and

supporting the trailer unit and then proceed as follows:

1. With both axles blocked up, remove the spring eyebolt, keeper bolt, and equalizer bolt from the

equalizer to be repaired or replaced.

2. Press the old nylon bushing out of the equalizer.

3. Reassemble in reverse order.

Suspension Replacement

1. Make sure springs are on straight. Align spring eyes to front hanger. Insert spring eye bolts but do not

torque at this point.

2. Assemble springs into equalizer.

3. After leveling equalizer to frame, torque equalizer nuts and spring eye nuts to a minimum of 30 ft.-lb.

and a maximum of 50 ft-lb.

Rev: 03.18.2014

Page 14

Trailer Axle Owners Manual FULL

Page 15

Wheels

Wheel Selection

When specifying or replacing your trailer wheels it is important that the wheels, tires, and axle are properly

matched. The following characteristics are extremely important and should be thoroughly checked when

replacement wheels are considered:

1. Bolt Circle. Wheels have many bolt circle variations and some are so close that it could be possible to

attach an inappropriate wheel that does not match the axle hub.

2. Capacity. Wheel load capacity should match tire and trailer max. load ratings.

3. Offset. The relationship of the center line of the tire to the hub face of the axle should match any

replacement. Failure to match offset may result in reducing the carrying capacity of your axle.

4. Rim Contour. Replacement wheels should be direct replacements to match the rim contour.

Use only rim contours suggested by manufacturer. Failure to use correct rim contour may cause

dramatic separation of tire and wheel and could cause death or serious injury.

Attempting to modify or repair a wheel can cause unsafe conditions that may result in an explosion. Air

pressure on a weakened or cracked rim can cause death or serious injury.

Rev: 03.18.2014

Page 15

Trailer Axle Owners Manual FULL

Page 16

Torque Requirements

It is extremely important to apply and maintain proper wheel mounting torque on your trailer axle. Torque

wrenches assure the proper amount of torque is being applied to a fastener. Use no other method to torque

fasteners.

Proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/

or breaking or other possible hazardous breakage resulting in death or serious injury.

Be sure to use only the fasteners matched to the cone angle of your wheel (usually 60°or 90°). The proper

procedure for attaching your wheels is as follows:

1. Start all bolts or nuts by hand to prevent cross threading.

2. Tighten bolts or nuts in the following sequence (see Wheel Torque Requirement Chart below).

3. Tightening fasteners should be done in stages. Follow the recommended sequence (Fig. 9), tighten

fasteners per wheel torque requirements chart below.

4. Wheel nuts/bolts should be torqued before first road use and after each wheel removal. Check and

re-torque after the 10 and 25 miles and again at 50 miles. A periodic check during regular service is

recommended.

Wheel Torque Requirement Chart

Torque Sequence

Wheel Size Stud Size

1st Stage 2nd Stage 3rd Stage

14" 1/2" 20-25 ft-lbs 50-60 ft-lbs 90-120 ft-lbs

15" 1/2" 20-25 ft-lbs 50-60 ft-lbs 90-120 ft-lbs

16" 1/2" 20-25 ft-lbs 50-60 ft-lbs 90-120 ft-lbs

16.5" x 6.75" 1/2" 20-25 ft-lbs 50-60 ft-lbs 90-120 ft-lbs

16" 9/16" 20-25 ft-lbs 60-70 ft-lbs 120-130 ft-lbs

16.5" x 6.75" 9/16" 20-25 ft-lbs 60-70 ft-lbs 120-130 ft-lbs

16" Dual and 17.5" Cone Nut 5/8" 50-60 ft-lbs 100-120 ft-lbs 190-210 ft-lbs

16" Dual and 17.5" Flange Nut 5/8" 50-60 ft-lbs 150-200 ft-lbs 275-325 ft-lbs

14.5" Demount 5/8" Tighten sequentially to 85-95 ft-lbs

Fig. 9

1

1

6

4

3

6

3

1

3

2

Rev: 03.18.2014

8

4

5

2

Page 16

5

4

2

Trailer Axle Owners Manual FULL

7

5

Page 17

Tires

Prior to mounting tires onto wheels, be sure the rim size and contour are approved by the Tire and Rim

Association Yearbook or the tire manufacturers catalog. In addition, confirm that the tire will carry the rated

load. If the load is not evenly distributed on all tires, use the tire rated for the heaviest wheel position.

The Rubber Manufacturers Association or the tire manufacturers guidelines should be consulted for

mounting procedures.

Tire inflation pressure is the most important factor in tire life. Tire pressure should always be what is

recommended by the manufacturer for the load. Always check pressure cold before operation. DO NOT

bleed air from tires when they are hot. Check inflation pressure weekly during use to insure maximum tire

and tread life.

The following tire wear diagnostic chart will help you pinpoint the causes and solutions of tire wear

problems.

NOTE: Tire wear should be checked frequently because once a wear pattern becomes firmly established in a

tire it is difficult to stop, even if the underlying cause is corrected.

Problem Probable Cause Corrective Action

Center Wear Over-inflation

Edge Wear Under-inflation

Side Wear Loss of camber or overloading

Toe Wear Incorrect Toe-in

Cupping Out-of-balance

Adjust pressure to particular load

per tire catalog.

Adjust pressure to particular load

per tire catalog.

Make sure load does exceed

axle rating. Call Lippert Service &

Warranty to advise.

Call Lippert Service & Warranty to

advise.

Check bearing adjustment and

balance tires.

Flat Spots Wheel lockup and tire skidding

Rev: 03.18.2014

Page 17

Avoid sudden stop if possible and

adjust brakes.

Trailer Axle Owners Manual FULL

Page 18

Introduction to Troubleshooting

The following section is a guideline for ensuring operation of your braking system. The safety of you, those

traveling with you and those sharing the road paramount and it starts with the ability to safely stop the tow

vehicle and the towed vehicle.

Troubleshooting

Most brake malfunctions can be corrected by utilizing the Troubleshooting Chart on the next page.

Mechanical failure is the most common form of malfunction, however, if the brake system fails and it’s not

mechanical, it is usually electrical. A Voltmeter and Ammeter are essential tools to diagnose these problems.

Mechanical problems are mostly self-evident; something is bent or broken. Consult the troubleshooting

chart on Page 19 to determine the probable cause and corrective actions for a variety of issues with the

braking system.

Remember to use only Lippert Components, Inc. replacement parts on these systems. Consult the Limited

Warranty or call our Service Department for any other related issues.

Measuring Voltage

The Braking System voltage is measured at the two lead wires of the magnet on any brake. Use the pin

probes inserted through the insulation of the lead wires. To ensure that the battery is indicating a full

charge, the towing vehicle engine should be running with the trailer coupler connected when checking the

voltage.

Voltage in the system should begin at 0 volts and, as the brake pedal of the tow vehicle is applied, voltage

will gradually increase to about 12 volts. If the system does not indicate at least 12 volts, problems may

occur in the wiring of the system, the battery or alternator of the tow vehicle.

When the brakes are applied, a gradual increase in voltage is preferable to a quick increase to 12 volts. A

gradual increase in voltage ensures smooth and firm trailer braking. A quick increase in voltage will cause

the braking system to feel like the trailer is grabbing too quickly.

Taking a Voltage reading is usually done with probes inserted into the wire connector (Fig. 10).

Fig. 10

Rev: 03.18.2014

Page 18

Trailer Axle Owners Manual FULL

Page 19

Troubleshooting Chart

Problem Probable Cause Corrective Action

Open circuits Find and correct

No brakes

Weak brakes

Locking brakes

Intermittent brakes

Brakes pull to one

side

Short circuits Test and correct

Severe under-adjustment Adjust brakes

Grease or oil on magnets or linings Clean or replace

Corroded connections Clean and correct cause of corrosion

Worn linings or magnets Replace

Scored or grooved brake drums Machine or replace

Improper synchronization Correct

Under-adjustment Adjust brakes

Glazed Linings Re-burnish or replace

Under-adjustment Adjust

Improper synchronization Correct

Loose, bent or broken brake components Test and correct

Out-of-round brake drums Machine or replace

Insufficient wheel load Adjust system resistor and synchronize

Broken wires Test and correct

Loose connections Repair or replace

Faulty ground Find and repair

Wrong magnet lead wire color Adjust

Incorrect adjustment Correct

Grease or oil on linings or magnets Clean or replace

Broken wires Find and repair

Bad connections Find and repair

Harsh brakes

Under-adjustment Adjust

Improper synchronization Correct

Under-adjustment Adjust

Lack of lubrication Lubricate

Noisy brakes

Broken Replace component

Incorrect brake components Correct

Grease or oil on linings or magnets Clean or replace

Surging brakes

Out-of-round or cracked brake drums Machine or replace

Over-adjustment Readjust

Out-of-round brake drums Machine or replace

Incorrect brake components Replace

Dragging brakes

Loose, bent or broken brake components Replace

Faulty breakaway switch Repair or replace

Loose wheel bearing adjustment Adjust

Bent spindle Replace Axle

NOTE: If all trailer lights and brakes do not work, check your wiring plug connection and make sure the ball

is making solid contact with the coupler (that is how a trailer is grounded). Too much grease or not

using dielectric grease on the ball and coupler can cause this to happen.

Rev: 03.18.2014

Page 19

Trailer Axle Owners Manual FULL

Page 20

Measuring Amperage

The Braking System amperage is the amount of current flowing through the system when all magnets have

been energized. The amperage will change proportionately with the voltage. To ensure that the battery is

indicating a full charge, the towing vehicle engine should be running with the trailer coupler connected

when checking the voltage.

If a resistor is used in the brake system, it must be set at zero or bypassed completely to obtain the

maximum amperage reading. Individual amperage draw can be measured by inserting the ammeter in the

line at the magnet you want to check. Disconnect one of the magnet lead wire connectors and attach the

ammeter between the two wires. Consult Amperage Chart on the next page for normal amp readings.

Make sure that the wires are properly reconnected and sealed after testing is completed.

Testing for Amperage can be done with probes (Fig. 11) or alligator clips on the leads or an amp clamp

(Fig. 12).

Fig. 11 Fig. 12

Rev: 03.18.2014

Page 20

Trailer Axle Owners Manual FULL

Page 21

Amperage Chart

Amps/Magnet Two Brakes Four Brakes Six Brakes

3.0 6.0 12.0 18.0

Low or no voltage are the most common problem with the Braking System. Amperage at the brakes is also

a relatively common issue. Common causes of these conditions are:

1. Low quality electrical connections

2. Open circuits

3. Insufficient wire gauge

4. Broken wires

5. Blown fuses (fusing of brakes is not recommended)

6. Short circuits (indicated by high amperage)

Possible causes of shorts are:

1. Shorted magnet coils

2. Bare wires contacting a grounded object

Finding the cause of a short circuit in the system is done by isolating one section at a time. If the high

amperage reading drops to zero by unplugging the trailer, then the short is in the trailer. If the amperage

reading remains high with all the brake magnets disconnected, the short is in the trailer wiring.

All electrical troubleshooting procedures should start at the controller. Most complaints regarding brake

harshness or malfunction are traceable to improperly adjusted or nonfunctional controllers. See your

controller manufacturer’s data for proper adjustment and testing procedures. For best results, all the

connection points in the brake wiring should be sealed to prevent corrosion. Loose or corroded connectors

will cause an increase in resistance which reduces the voltage available for the brake magnets.

Rev: 03.18.2014

Page 21

Trailer Axle Owners Manual FULL

Page 22

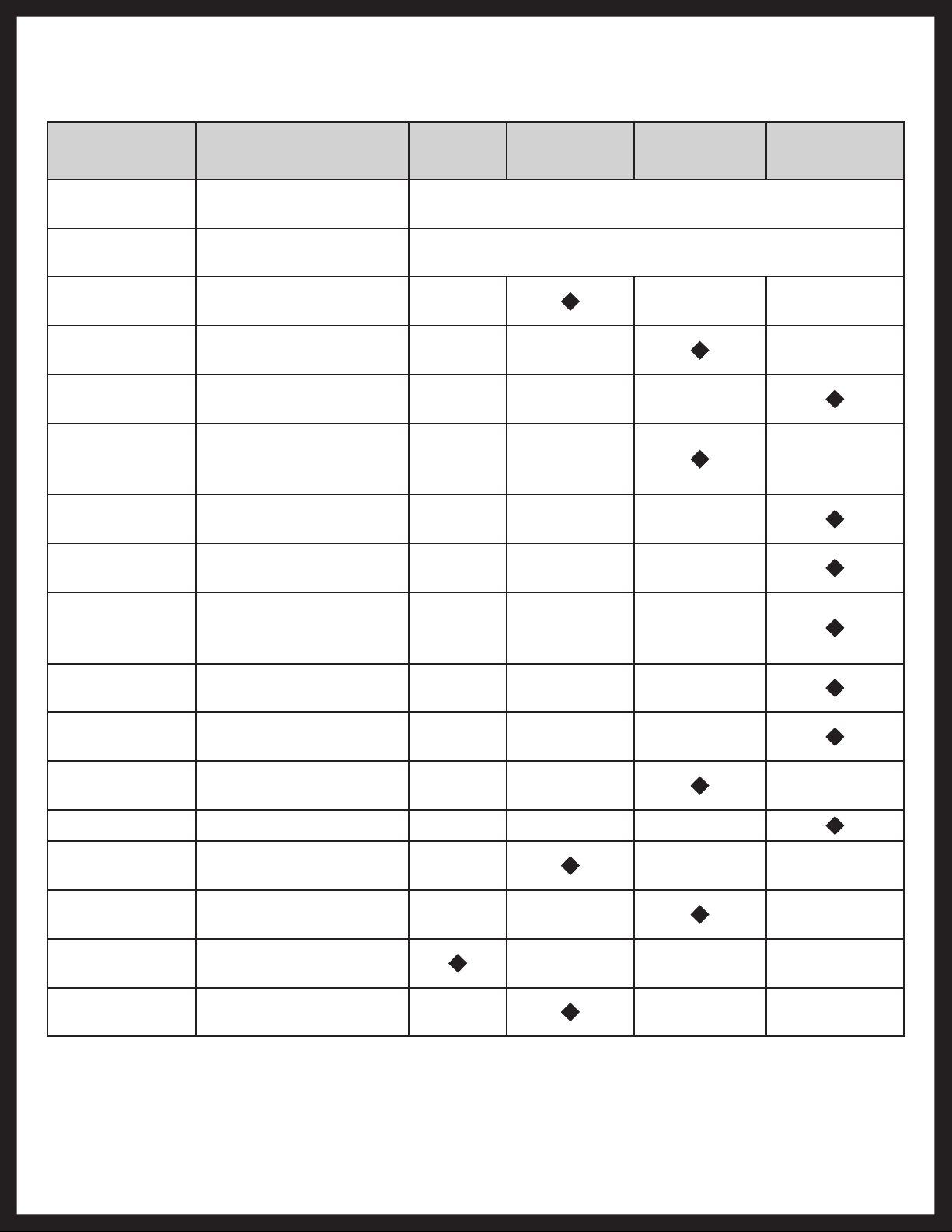

Maintenance Schedule

Item Function Required Weekly

Brakes

Breakaway

System

Brake

Adjustment

Brake

Magnets

Brake Linings

Brake

Controller

Trailer Brake

Wiring

Hub/Drum

Wheel

Bearing

Seals

Springs

Suspension

Parts

Test that they're

operational.

Check battery charge

and switch operation.

Adjust to proper

operating clearance.

Inspect for wear and

current draw.

Inspect for wear or

contamination.

Check for correct

amperage and

modulation.

Inspect wiring for

bare spots, fray, etc.

inspect for abnormal

wear or scoring.

Inspect for corrosion

or wear. Clean and

repack.

Inspect for leakage.

Replace if removed.

Inspect for wear, loss

of arch.

Inspect for bending,

loose fasteners, wear.

3 Months /

3,000 Miles

6 Months /

6,000 Miles

At Every Use

At Every Use

12 Months /

12,000 Miles

Hangers Inspect welds.

Wheel Nuts

and Bolts

Wheels

Tire Inflation

Pressure

Condition

Rev: 03.18.2014

Tire

Tighten to specified

torque values.

Inspect for cracks,

dents, or distortion.

Inflated tires to mfg's.

specifications.

Inspect for cuts, wear,

bulging, etc.

Page 22

Trailer Axle Owners Manual FULL

Page 23

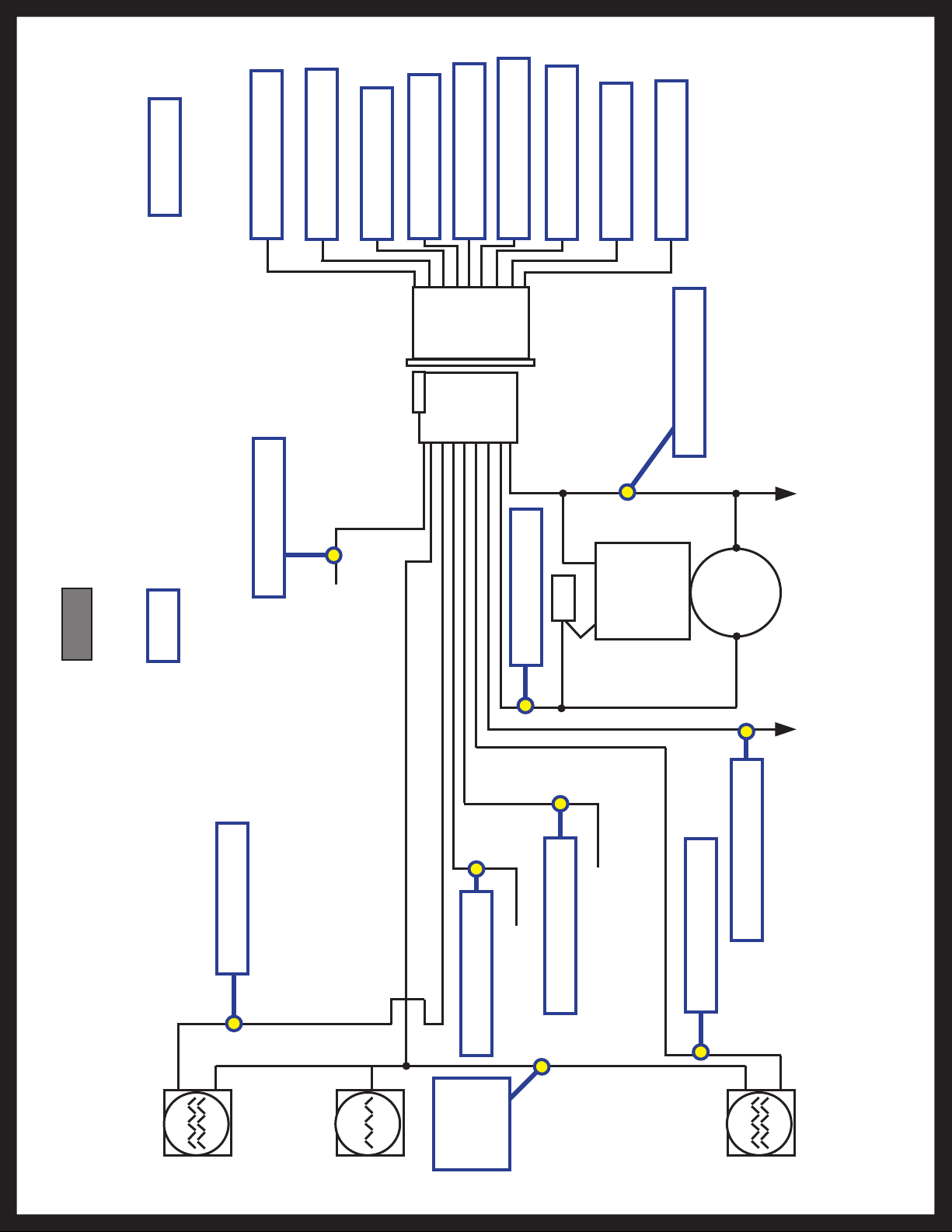

Wiring Diagram

Tow Vehicle

White - Terminal 1

Green - Terminal 3

Red - Terminal 5

Black - Terminal 4

Yellow - Terminal 7

Orange - Terminal 9

Brown - Terminal 6

Blue - Terminal 2

Gray - Terminal 8

White - Terminal 1

Fig. 13

Trailer

Gray - Terminal 8

Auxiliary Circuit

Red - Terminal 5

+ -

Blue - Terminal 2

Common

Ground

Electric

Brake

Auxiliary Circuit

Orange - Terminal 9

Rev: 03.18.2014

Stop and

Left Turn

Signal

License,

Tail and

Running

Lights

Black - Terminal 4

Battery Charge

3

Green -

Terminal

Page 23

Auxiliary Circuit

Yellow - Terminal 7

Brown - Terminal 6

Stop and

Right Turn

Signal

Trailer Axle Owners Manual FULL

Page 24

Pigtail and Coupler Wiring Color Codes

9-PIN COUPLER

STOP &

LH TURN

AUXILIARY

RED

ORANGE

TAIL LIGHTS

CLEARANCE &

GREEN

YELLOW

GROUND

WHITE

BLACK

AUXILIARY

BATTERY

BLUE

BRAKES

CHARGE

BROWN

STOP &

RH TURN

GRAY

AUXILIARY

BROWN - STOP & RH TURN

YELLOW - STOP & LH TURN

STOP &

RH TURN

CHARGE

BATTERY

WHITE - GROUND

GREEN - RUNNING LIGHTS

BLACK

TRAILER LIGHTS PIGTAIL - DOES NOT OPERATE BRAKES

GREEN

7-PIN COUPLER

TAIL LIGHTS

CLEARANCE &

YELLOW

BROWN

STOP &

RED

LH TURN

BRAKES

BLUE

WHITE

AUXILIARY

TRAILER BRAKE AND LIGHT COUPLER - OPERATES BRAKES

GROUND

Rev: 03.18.2014

Page 24

Trailer Axle Owners Manual FULL

Page 25

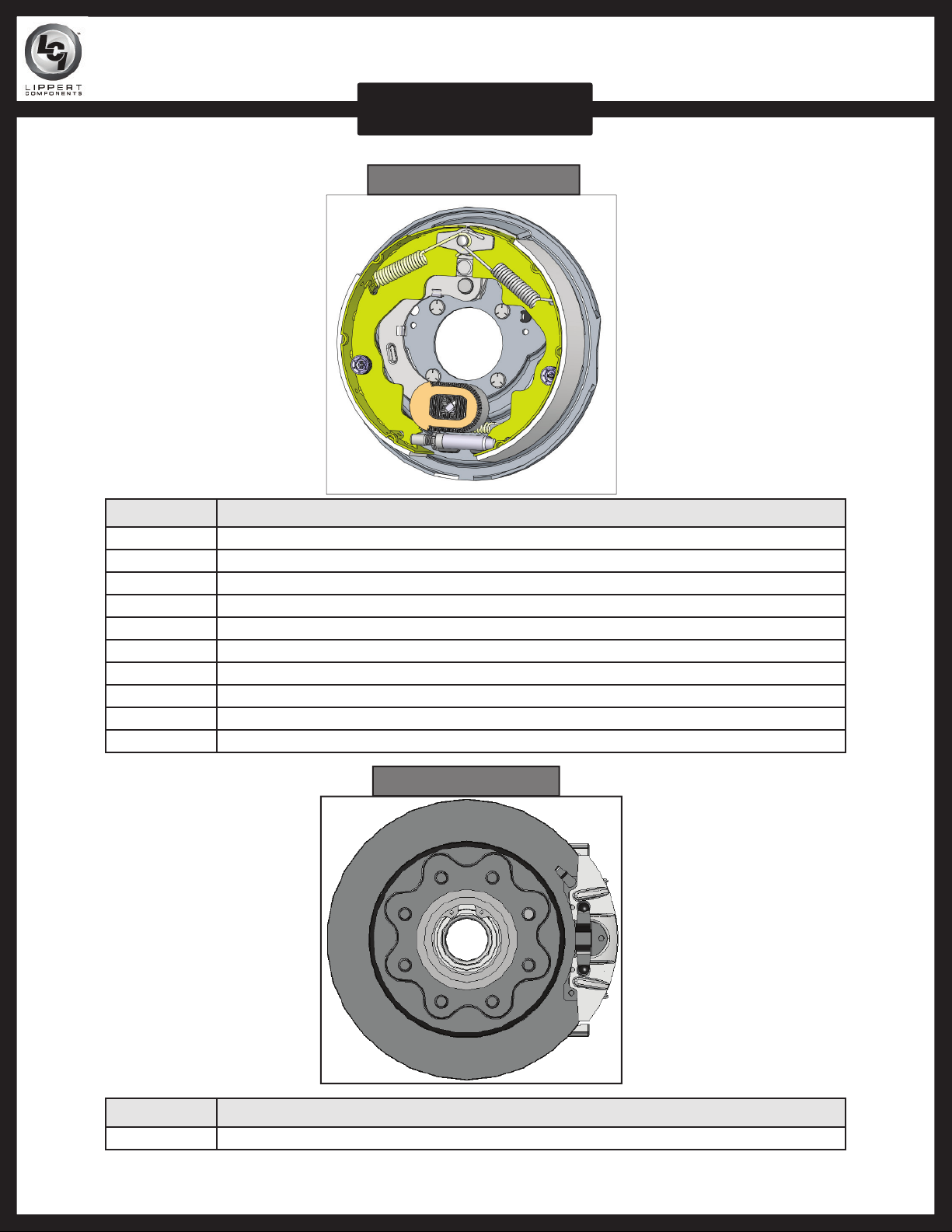

3,500-LB AXLE WHEEL END COMPONENTS

3,500-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

AXLES AND SUSPENSION

G

F

E

D

C

I

H

B

A

Callout Part # Description

A 122065 Rubber plug for lubed grease caps

B

C 122075 Cotter pin

D 122081 Spindle nut, 6 slot

E 119214 Spindle washer, round ID

E1 119215 Spindle washer, for spindle with D-flat

E2 119216 Spindle locking tang washer

Use E1 and E2 in place of C and E if spindle has no hole for cotter pin and has D-flat on all

122067 Dust cap, for 2" bore, super lube

122099 Dust cap, for 2" bore, non-lube

axles built prior to 2009.

Rev: 03.14.2014

F

122089 Outer bearing cone, L44649

125102 Outer bearing cup, L44610

G 126003 Brake hub; 545-1/2"

122092 Inner bearing cone, L68149

H

124296 Inner bearing cup, L68111

I 122087 Grease seal, double lip, 1.72" ID x 2.565" OD

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 25

3500 Axle Webpage

Page 26

3,500-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Electric Brake Assembly

Part # Description

122258 Electric Brake - 10" x 2.25" (Left Hand)

1222581 Electric Brake - 10" x 2.25" APG (Left Hand)

1222582 Electric Brake - 10" x 2.25" Long Lead (Left Hand)

1222583 Electric Brake - 10" x 2.25" Self-Adjusting (Left Hand)

139380 Electric Brake - 10" x 2.25" with Park (Left Hand)

122450 Electric Brake - 10" x 2.25" (Right Hand)

1224501 Electric Brake - 10" x 2.25" APG (Right Hand)

1224502 Electric Brake - 10" x 2.25" Long Lead (Right Hand)

12244503 Electric Brake - 10" x 2.25" Self-Adjusting (Right Hand)

139381 Electric Brake - 10" x 2.25" with Park (Right Hand)

Disc Brake Assembly

Rev: 03.14.2014

Part # Description

130033 Disc Brake; 545 - ½ " Studs

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 26

3500 Axle Webpage

Page 27

3,500-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Hydraulic Brake Assembly

Part # Description

132047 Hydraulic Brake - 10" x 2.25" (Right Hand)

132048 Hydraulic Brake - 10" x 2.25" (Left Hand)

179868 Hydraulic Brake - 10" x 2.25" Free Backing (Right Hand)

179869 Hydraulic Brake - 10" x 2.25" Free Backing (Left Hand)

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 27

3500 Axle Webpage

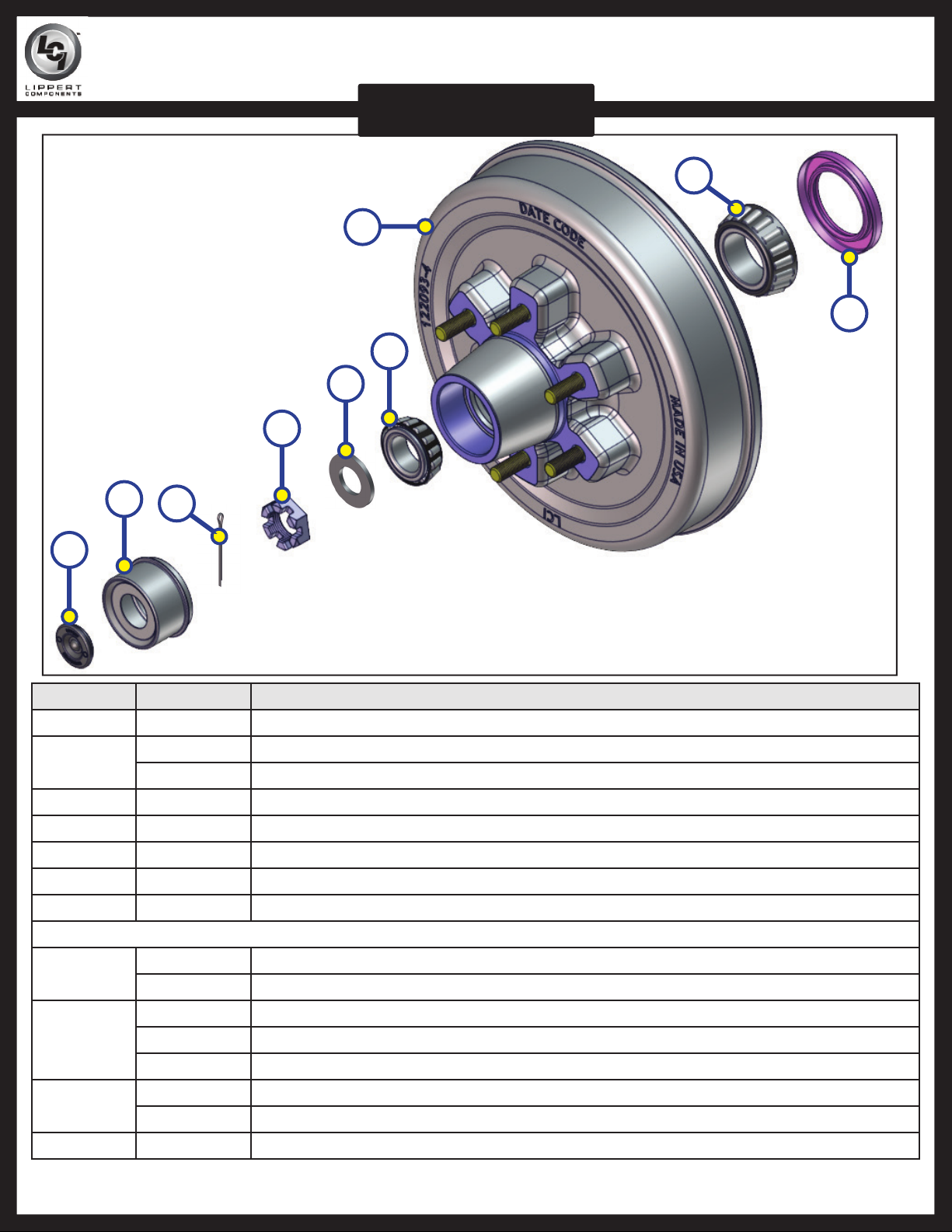

Page 28

3,500-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit (2 ⁄" Beam) Part #173229

B

C

A

D

F

G

H

I

J

Callout Part # Description Quantity

A 122073 U-Bolt; ½ - 20 x 5.1, 2.375 Tube Diameter Yellow Dich 4

B 122087 Seal; 1.666 x 2.565 x 5 (2,800 - 3,500) 2

C 122081 Castle Nut; 1 - 14 2

D 122079 Yellow Zinc Nut; .5 - 20 8

E 122084 Sealed Wire Connector 4

F 119216 Tang Washer; 1.58 x .033 2

G 122075 Cotter Pin; .120 x 1.75 2

H 119215 D-Flat Spindle Washer; 1 x 1.68 2

I 119214 Rounded Spindle Washer; 1 ID x 1.68 OD 2

J 122085 Washer; ⁄ - 20 Hex YZ or SZ 8

K 122086 Washer; ⁄ x ¾ x 11 GA Helical Lock ZInc 8

E

K

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 28

3500 Axle Webpage

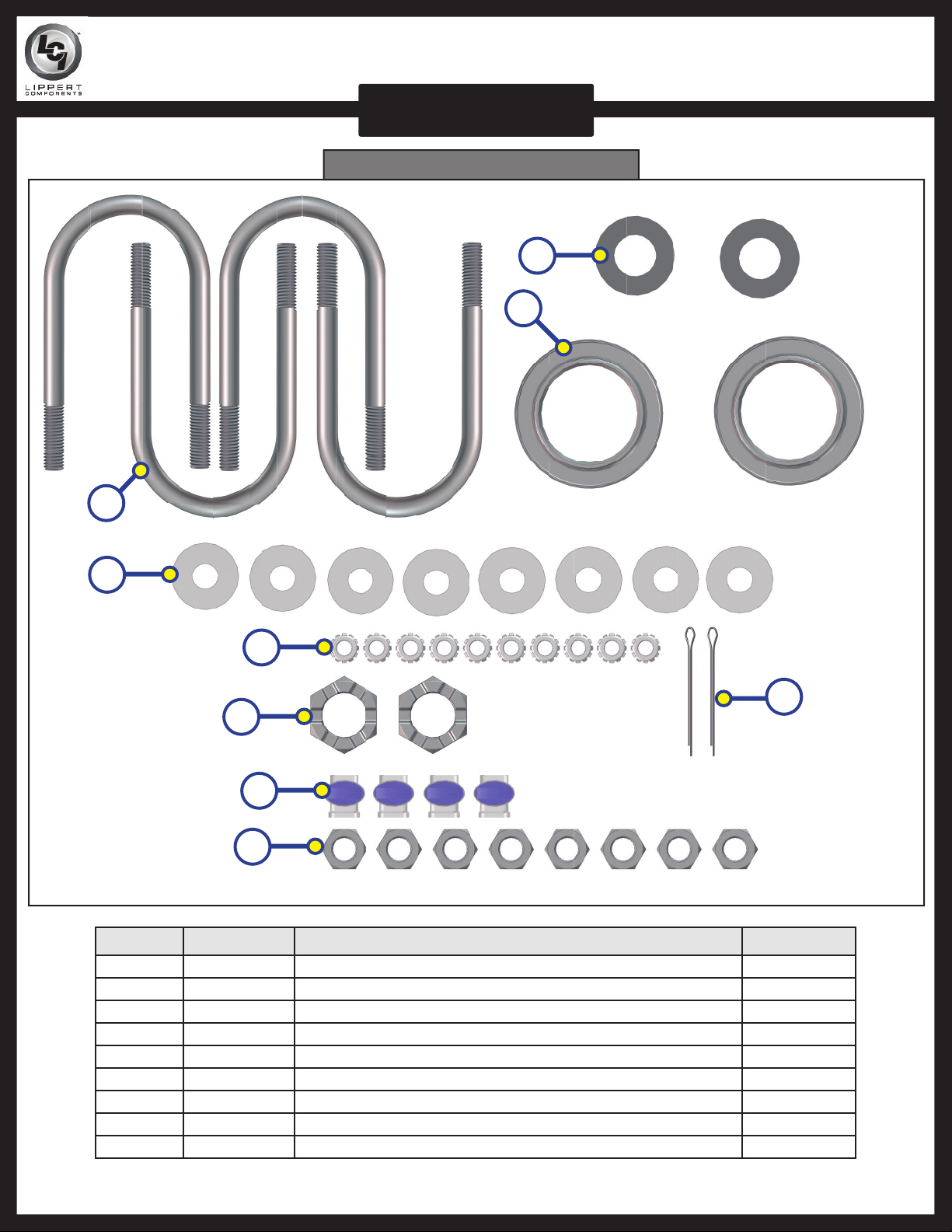

Page 29

3,500-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit (3" Tube) Part #260525

C

D

B

E

G

H

I

F

A

J

Rev: 03.14.2014

K

Callout Part # Description Quantity

A 2139541 U-Bolt; ⁄ - 18 x 6.625, 3" Tube YZ 4

B 122087 Seal; 1.666 x 2.565 x 5 (2,800 - 3,500) 2

C 119214 Round Spindle Washer; 1 ID x 1.68 OD 2

D 122081 Castle Nut; 1 - 14 2

E 122075 Cotter Pin; .120 x 1.75 2

F 122085 Nut; ⁄ - 20 Hex YZ or SZ 8

G 122086 Helical Lock Zinc Washer; ⁄ x ¾ x 11 GA 8

H 170997 Flat USS Hardened Washer; ⁄ 8

I 122084 Sealed Wire Connector 4

J 182274 Nut; ⁄- 18 Hex GR8 8

K 2139521 4 x 6.15 x .8 x .8 2

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 29

3500 Axle Webpage

Page 30

5,200-LB AXLE WHEEL END COMPONENTS

5,200-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

AXLES AND SUSPENSION

H

G

F

E

D

I

B

A

Callout Part # Description

A 122065 Rubber plug for lubed grease caps

B

C 122075 Cotter pin

D 122081 Spindle nut, 6 slot

E 179660 Spindle washer, round ID

E1 172888 Spindle washer, for spindle with D-flat

E2 119216 Spindle locking tang washer

Use E1 and E2 in place of C and E if spindle has no hole for cotter pin and has D-flat on all axles built prior to 2009

C

122064 Dust cap, for 2.5" bore, super lube

122071 Dust cap, for 2.5" bore, non-lube

F

G

H

I 122088 Grease seal, double lip, 2.25" ID x 3.376" OD

Rev: 03.14.2014

122091 Outer bearing cone, 15123

122996 Outer bearing cup, 15245

122094 Brake Hub; 655; ½ " studs

122095 Brake Hub; 865; ½ " studs

122096 Brake Hub; 865; ⁄" studs

122066 Inner bearing cone, 25580

124287 Inner bearing cup, 25520

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 30

5200 Axle Webpage

Page 31

5,200-LB AXLE WHEEL END COMPONENTS

NOTE: This diagram is

for reference only. The

parts specified here are

only available to the

OEM. Please use the parts

listing on the previous

page for replacement part

information.

AXLES AND SUSPENSION

H

G

I

F

E

D

B

C

A

Callout Part # Description

A 122065 Rubber plug for lubed grease caps

122064 Dust cap, for 2.5" bore, super lube

B

122071 Dust cap, for 2.5" bore, non-lube

C 122075 Cotter pin

D 122081 Spindle nut, 6 slot

E 119214 Spindle washer, round ID

E1 119215 Spindle washer, for spindle with D-flat

E2 119216 Spindle locking tang washer

Use E1 and E2 in place of C and E if spindle has no hole for cotter pin and has D-flat on all

axles built prior to 2009

Rev: 03.14.2014

F

122090 Outer bearing cone, L44649

124292 Outer bearing cup, L44610

G 122093 Brake Hub-drum, with cups and studs, 6 on 5.50" BC

122066 Inner bearing cone, 25580

H

124287 Inner bearing cup, 25520

I 122088 Grease seal, double lip, 2.25" ID x 3.376" OD

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 31

5200 Axle Webpage

Page 32

5,200-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Electric Brake Assembly

Part # Description

122259 Electric Brake - 12" x 2" (Left Hand)

1222592 Electric Brake - 12" x 2" Long Lead (Left Hand)

1222593 Electric Brake - 12" x 2" Self-Adjusting (Left Hand)

122451 Electric Brake - 12" x 2" (Right Hand)

1224512 Electric Brake - 12" x 2" Long Lead (Right Hand)

1224513 Electric Brake - 12" x 2" Self-Adjusting (Left Hand)

Disc Brake Assembly

Rev: 03.14.2014

Part # Description

130111 Disc Brake; 655 - ½ " Studs (5,200 - 6,000)

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 32

5200 Axle Webpage

Page 33

5,200-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit Part #232996

B

C

A

D

E

F

G

H

Callout Part # Description Quantity

A 2139541 U-Bolt; ⁄ - 18 x 6.625" for 3" Tube 4

B 119214 Round Spindle Washer - 1 ID x 1.68 OD 2

C 122088 Double Lip Grease Seal (5,200-7,000) 2

D 170997 Flat USS Hardened Washer - ⁄" 8

E 122077 Brake Nut Locking Keps Clear Dich 10

F 122081 Castle Nut - 1 - 14 2

G 122084 Sealed Wire Connector 4

H 182274 Hex Nut; ⁄" - 18 GR8 8

I 122075 Cotter Pin; .120" x 1.75" 2

I

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 33

5200 Axle Webpage

Page 34

6,000-LB AXLE WHEEL END COMPONENTS

6,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

AXLES AND SUSPENSION

H

G

F

E

D

I

B

A

Callout Part # Description

A 122065 Rubber plug for lubed grease caps

B

C 122075 Cotter pin

D 122081 Spindle nut, 6 slot

E 179660 Spindle washer, round ID

E1 172888 Spindle washer, for spindle with D-flat

E2 119216 Spindle locking tang washer

Use E1 and E2 in place of C and E if spindle has no hole for cotter pin and has D-flat on all axles built prior to 2009

C

122064 Dust cap, for 2.5" bore, super lube

122071 Dust cap, for 2.5" bore, non-lube

F

G

H

I 122088 Grease seal, double lip, 2.25" ID x 3.376" OD

Rev: 03.14.2014

122091 Outer bearing cone, 15123

122996 Outer bearing cup, 15245

122094 Brake Hub; 655; ½ " studs

122095 Brake Hub; 865; ½ " studs

122096 Brake Hub; 865; ⁄" studs

122066 Inner bearing cone, 25580

124287 Inner bearing cup, 25520

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 34

6000 Axle Webpage

Page 35

6,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Electric Brake Assembly

Part # Description

122259 Electric Brake; 12" x 2" (Left Hand)

1222592 Electric Brake; 12" x 2" Long Lead (Left Hand)

1222593 Electric Brake; 12" x 2" Self-Adjusting (Left Hand)

122451 Electric Brake; 12" x 2" (Right Hand)

1224512 Electric Brake; 12" x 2" Long Lead (Right Hand)

1224513 Electric Brake; 12" x 2" Self-Adjusting (Left Hand)

Disc Brake Assembly

Rev: 03.14.2014

Part # Description

130111 Disc Brake; 655; ½ " Studs (5,200 - 6,000)

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 35

6000 Axle Webpage

Page 36

6,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit Part #232996

B

C

A

D

E

I

F

G

H

Callout Part # Description Quantity

A 2139541 U-Bolt; ⁄" - 18 x 6.625" for 3" Tube 4

B 119214 Round Spindle Washer; 1 ID x 1.68 OD 2

C 122088 Double Lip Grease Seal (5,200-7,000) 2

D 170997 Flat USS Hardened Washer; ⁄" 8

E 122077 Brake Nut Locking Keps Clear Dich 10

F 122081 Castle Nut; 1 - 14 2

G 122084 Sealed Wire Connector 4

H 182274 Hex Nut; ⁄" - 18 GR8 8

I 122075 Cotter Pin; .120" x 1.75" 2

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 36

6000 Axle Webpage

Page 37

7,000-LB AXLE WHEEL END COMPONENTS

7,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

AXLES AND SUSPENSION

H

G

F

E

D

C

B

I

A

Callout Part # Description

A 122065 Rubber plug for lubed grease caps

B

C 122075 Cotter Pin

D 122081 Spindle Nut, 6 Slot

E 179660 Spindle washer, round ID

E1 172888 Spindle washer, for spindle with D-flat

E2 119216 Spindle locking tang washer

F

G

127300 Dust Cap, for 2.75" Bore, Super lube

127206 Dust Cap, for 2.75" Bore, Non-lube

Use E1 and E2 in place of C and E if spindle has no hole for cotter pin and has D-flat

127009 Outer Bearing Cone, 14125A

127012 Outer Bearing Cup, 14276

122096 Brake Hub; 865 - ½ "

134543 Brake Hub; 865 - ⁄"

Rev: 03.14.2014

H

122066 Inner Bearing Cone, 25580

124287 Inner Bearing Cup, 25520

I 122088 Grease Seal, Double Lip, 2.25" ID x 3.376" OD

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 37

7000 Axle Webpage

Page 38

7,000-LB AXLE WHEEL END COMPONENTS

Electric Brake Assembly

AXLES AND SUSPENSION

Part # Description

122259 Electric Brake; 12" x 2" (Left Hand)

1222592 Electric Brake; 12" x 2" Long Lead (Left Hand)

1222593 Electric Brake; 12" x 2" Self Adjusting (Left Hand)

122451 Electric Brake; 12" x 2" (Right Hand)

1224512 Electric Brake; 12" x 2" Long Lead (Right Hand)

1224513 Electric Brake; 12" x 2" Self Adjusting (Right Hand)

139383 Electric Brake; 12" x 2" (Left Hand)

139384 Electric Brake; 12" x 2" (Right Hand)

Hydraulic Brake Assembly

Part # Description

138754 Hydraulic Brake; 12" x 2" (Left Hand)

138755 Hydraulic Brake; 12" x 2" (Right Hand)

139419 Hydraulic Brake; 12" x 2" Free Backing (Left Hand)

139420 Hydraulic Brake; 12" x 2" Free Backing (Right Hand)

139429 Hydraulic Brake; 12" x 2" With Park (Left Hand)

139430 Hydraulic Brake; 12" x 2" With Park (Right Hand)

139516 Hydraulic Brake; 12" x 2" Free Backing With Park (Left Hand)

139517 Hydraulic Brake; 12" x 2" Free Backing With Park (Right Hand)

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 38

7000 Axle Webpage

Page 39

7,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit Part #232997

B

C

A

D

E

F

G

H

Callout Part # Description Quantity

A 1963511 U-Bolt; ⁄ - 18 x 7.25 for 3" Tube YZ 4

B 179660 Flat Hardened SAE Washer; 1.06 ID x 2.00 OD 2

C 122088 Double Lip Grease Seal (5,200-7,000) 2

D 170997 Flat USS Hardened Washer; ⁄" 8

E 122077 Brake Nut Locking Keps Clear Dich 10

F 122081 Castle Nut; 1 - 14 2

G 122084 Sealed Wire Connector 4

H 182274 Hex Nut; ⁄" - 18 GR8 8

I 122075 Cotter Pin; .120" x 1.75" 2

I

Rev: 03.14.2014

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 39

7000 Axle Webpage

Page 40

7,000-LB AXLE WHEEL END COMPONENTS

AXLES AND SUSPENSION

Axle U-Bolt Service Kit Part #309893 (Disc Brake Axle Application Only)

B

C

A

Rev: 03.14.2014

D

I

E

F

G

J

H

Callout Part # Description Quantity

A 1963511 U-Bolt - ⁄" - 18 Hex GR8 4

B 179660 Flat Hardened SAE Washer - 1.06 ID x 2.00 OD 2

C 122088 Double Lip Grease Seal (5,200-7,000) 2

D 170997 Flat USS Hardened Washer - ⁄" 8

E 119072 Flange Nut - ⁄" - 16 GR5 10

F 126030 Washer - .385" x .68" x .094" 10

G 182274 Hex Nut - ⁄" - 18 GR8 8

H 135835 Tap Bolt - ⁄" - 16 x 1 ½ GR5 ZN FTHD ST 10

I 122081 Castle Nut 1 - 14 2

J 122075 Cotter Pin - .120 x 1.75 2

Contact us: Lippert Components Inc. - www.lci1.com/customerservice - Phone: (574) 537-8900 - Email: warranty@lci1.com

Page 40

7000 Axle Webpage

Page 41

Storage

Storage Preparation

If your trailer is to be stored for an extended period of time the trailer will need to be prepared prior to going

into storage. Follow these guidelines to setup your trailer for storage:

1. If the trailer has an emergency breakaway battery remove it and store it inside, out of the weather.

Charge the battery at least every 90 days.

2. Jack up the trailer and place jack stands under the trailer frame so that the weight will be off the tires.

Follow trailer manufacturer’s guidelines to lift and support the trailer.

3. Lubricate mechanical moving parts such as the hitch, and suspension parts, that are exposed to the

weather.

4. In the case of boat trailer axles that are subject to repeated immersion, remove brake drums; clean, dry

and re-lubricate moving brake components; inspect bearings - clean and re-lubricate.

Lift unit by the frame and never the axle or suspension. Do not go under unit unless it is properly

supported by jack stands. Unsupported units can fall causing death or serious injury.

Extended Storage Inspection Procedures

Trailer should remain on jack stands during this procedure:

1. Remove all wheels and hubs or brake drums. Reinstall drum to same spindle and brake from which it

was removed.

2. Inspect suspension for wear.

3. Check tightness of hanger bolt, shackle bolt, and U-bolt nuts of the suspension for correct torque.

4. Check brake linings, brake drums and armature faces for excessive wear, scoring, damage or corrosion.

5. Check brake magnets with an ohmmeter. The magnets should check 3.2 ohms. If shorted or worn

excessively, they must be replaced.

6. Lubricate all brake moving parts using a high temperature brake lubricant.

7. Remove any rust from braking surface and armature surface of drums with fine emery paper or crocus

cloth. Be sure to protect bearings from contaminating dust.

8. Inspect oil or grease seals for wear or nicks. Replace if necessary.

9. Lubricate hub bearings.

10. Reinstall hubs and adjust bearings.

11. Mount and tighten wheels.

NOTE: Avoid getting any grease or oil on brake linings and pads or magnet surfaces.

Rev: 03.18.2014

Page 41

Axle Manual End

Page 42

Trip Preparation Checklist

The following checklist offers several guidelines to prolonging the quality of your running gear and will

provide trustworthy and safe trailering for years to come.

Using the following checklist before starting a trip with your trailer is highly recommended. Allow plenty of

time prior to any trip for any service or repairs that may need to be done before using the trailer.

1. Maintenance schedule should be current.

2. Inspect hitch for corrosion, lubrication and wear.

3. Inspect safety chains for rust and wear. Engage chains and breakaway switch actuating chain securely.

Breakaway battery should be fully charged.

4. Electronic coupler must be secure. Run check on all lights and break engagement and

synchronization.

5. Load trailer with 10% of total weight on the hitch end of trailer. Smaller trailers front end load should

be increased to 15%.

6. DO NOT OVERLOAD! Consult your trailers i.d. plate for gross vehicle weight restrictions.

7. Tires should be inflated to manufacturer’s specs. Inspect tires for any damage or wear.

8. Inspect lug nuts/bolts. All should be torqued to spec. (See Page 15 for specs).

9. Check torque of hanger bolt, shackle bolt, and U-bolt nuts on suspension.

10. Check that your trailer is towing level. Adjust hitch height if necessary to level trailer.

CUSTOMER SERVICE - TRAILER

PLANT #39

1701 CENTURY DR.

GOSHEN, IN 46528

PH: (574) 312-6425

FAX: (574) 534-7161

E-MAIL: trailerwarranty@lci1.com

WEBSITE: www.lci1.com

Lippert Components must be notified of all issues prior to work being performed. For the quickest and

most efficient response, Lippert Service & Warranty can be reached via e-mail at trailerwarranty@lci1.com.

Submissions should include full unit info including full VIN, Model, Date of Mfr, Date of Purchase and

Retail Owner name or by filling out the Repair Request Form. The Repair Request Form and other

service forms can be found online in addition to all owners manuals and informational publications.

See specific web addresses below.

Rev: 03.18.2014

ONLINE MANUALS, TECHNICAL INFORMATION & SERVICE FORMS

To find manuals, technical information, and service forms, please visit

www.lci1.com/customerservice

Page 42

Axle Manual End

Page 43

All information contained within may be distributed as a full document only, unless otherwise permitted by

explicit consent of Lippert Components Inc. to distribute individual parts.

All information contained within is subject to change without notice. New editions will be posted on www.lci1.

com and can be downloaded for free. Information contained within is considered factual until made obsolete

by a *NEW* revision.

Please recycle all obsolete materials.

For all concerns or questions, please contact

Lippert Components, Inc.

Ph: (574) 537-8900 Web: www.lci1.com Email: warranty@lci1.com

Rev: 03.18.2014

Page 43

Axle Manual End

Loading...

Loading...