Page 1

Link Lite 305

Black Max

User Requirements

Installation Information

Operating Instructions

Black Max

LINK ELECTRIC & SAFETY CONTROL COMPANY

444 McNALLY DRIVE, NASHVILLE TN 37211

PH (615)-833-4168 FAX (615)-834-1984

MANUAL

INCLUDES

SECTIONS

1,3, &4

Page 2

Link Lite Black Max Section 1 - User Requirements

1. IMPORTANT REQUIREMENTS

AND RESPONSIBILITIES THAT

THE USER/EMPLOYER MUST

MEET WHEN USING LINK LITE

BLACK MAX LIGHT CURTAINS

The Link Lite Black Max light curtain is a

presence sensing device whose most

common use is to enhance protection of

personnel from point of operation hazards

on industrial machinery. A light curtain

performs the simple function of a light

activated switch that can be used to

provide a signal as to whether something

or someone is in the sensing field between

its transmitter and receiver units. It

cannot, as a stand alone component,

provide personnel safety enhancement or

other function. Only when a light curtain

is properly applied, installed, adjusted, and

used as a component of a production

system whose other components also meet

the requirements for use of a light curtain

does it act, in conjunction with other

components of the system, to enhance

personnel safety. Because only the user

/employer has continuous knowledge and

control over all elements of production

system design and use (and attendant

hazards), both OSHA regulations and

ANSI standards assign the employer the

responsibility for providing and insuring

the use of properly applied and adjusted

point of operation safeguarding.

1.1. Machine and Machine Control

Construction Requirements

All light curtains depend on the electrical,

mechanical, pneumatic, and/or hydraulic

control components and drive systems of

the machine to stop hazardous motion

when the light curtain gives a stop signal

to the machine control. If machine control

components or drive systems fail to

function properly, the machine may fail to

stop, or may not stop quickly, even though

the Black Max is functioning properly.

Install Black Max light curtains for

safeguarding only on machines or

production systems that meet the

following requirements.

The machine construction must comply

1.

with any applicable OSHA or ANSI

standards for such a machine.

The machine design and construction

2.

must allow hazardous action to be stopped

quickly at any time or position within its

cycle.

WARNING!

on full revolution mechanical power presses

or any other machinery that can only be

stopped at the end of a complete cycle.

Serious injury may result, because the

machine cannot immediately respond to a

stop signal.

Do not install the Black Max

It is the user's/employer's responsibility to

read, understand, and enforce the

following requirements when using a Link

Lite Black Max as a safeguarding device.

Link Electric and Safety Control Co. takes

no responsibility where its light curtains

are improperly installed, adjusted, or used,

and where machines on which its light

curtains are used are not properly

maintained.

The machine action must be

3.

electrically controllable.

The electrical, pneumatic, and/or

4.

hydraulic control system that governs

machine action must be designed and

constructed so that de-energization of

electrical components or loss of pressure

results in stopping the machine action.

1-1

Page 3

Link Lite Black Max Section 1 - User Requirements

Machine controls must be designed for

5.

"Control Reliability", i.e., so that a single

failure in electrical, pneumatic, or

hydraulic components does not prevent the

normal stopping of machine action when

required but does prevent initiation of

further machine action.

WARNING!

designed to stop hazardous machine action

if a component fails, the control may not

stop the machine action when the Link Lite

Black Max sends a stop signal, with

possible consequent serious injury or death

to personnel.

The machine must require manual

6.

initiation of action after power is turned

on, after changes in operating modes, and

each time a stop signal is applied to the

control.

Where presence sensing devices such

7.

as the Black Max are used to safeguard

part revolution mechanical power presses,

the control system must include a brake

monitor"! See 1910.217(b)(14) of

OSHA's General Industry Standards.

NOTE!

provide assistance upon request in

evaluating your machine tool as to

compliance with control requirements.

Link Systems can provide control systems

for part revolution mechanical power

presses and mechanical press brakes, and

interface systems for many hydraulic

presses and press brakes that meet OSHA

and ANSI requirements for the use of the

Link Lite Black Max as safeguarding

device. Link Electric and Safety Control

Co. assumes no responsibility when the

Black Max is used on machines with

controls that do not comply with the above

requirements or where controls not

If machine controls are not

Link Systems' engineers will

supplied by Link fail in such a manner as

to not stop the machine action when the

Black Max provides a stop signal to the

controls.

1.2. Installation

It is the user's/employer's responsibility to

properly install (or have installed) the Link

Lite Black Max, using qualified installers.

Proper installation of any necessary

supplemental barriers or safety devices, or

alternative safeguarding methods is the

responsibility of the user/employer.

1.3. Use Requirements

1.3.1. Safeguarding Configuration

It is the user's/employer's responsibility to

perform a hazard analysis for every job

performed by a machine or production

system using a Black Max light curtain as

a safety component. The user/employer

must determine and implement a

safeguarding configuration of Black Max

units, any necessary supplemental barriers,

and/or alternative safeguarding

components to enhance personnel safety

on every job performed.

1.3.2. Training

It is the employer's responsibility to train

all setup personnel, operators, maintenance

personnel, and supervisors in all aspects of

the safe setup and use of the production

system for every job performed on the

machine. Training must include the

following items.

The required safeguarding

1.

configuration for each job.

1-2

Page 4

Link Lite Black Max Section 1 - User Requirements

The specific duties and actions to be

2.

performed by setup and operator personnel

for each job relative to both production

and safety. These work practices must be

in conformance with any OSHA or ANSI

standards that apply.

The machine manufacturer's operating

3.

instructions.

Instructions to never use the machine

4.

in such a manner or for any job that will

exceed any rated capacity for the machine.

All operating instructions and warnings

5.

in the Link Lite Black Max Technical

Manual including the "Safety System

Setup" and "Operator Safety System

Checkout" prescribed in section 4 of this

manual.

Instructions to never operate the

6.

machine or production process if the

checkouts required in item 5 of this list

reveals that any safeguarding component

is not properly set up and functional, or

that the machine is not working properly.

Instructions to never remove, bypass,

7.

or rewire the Link Lite Black Max or

other safety devices, controls, or

guards on the machine.

WARNING!

the correct setup and use of the production

system, including the safety components

can lead to unsafe production systems and

work practices with consequent severe

injury or death to personnel.

NOTE!

barrier would keep a person from reading

(or listening) and understanding warnings

and training instructions, the employer

Failure to train personnel in

Where illiteracy or a language

must read or provide translation of these

instructions to the person. The employer

must ascertain that the instructions are

understood.

1.3.3. Supervision

OSHA requires the employer not only to

provide but to "insure" the use of properly

applied and adjusted point of operation

safeguarding. Supervisors must

understand and enforce all items covered

in the preceding Training section for the

safe setup and operation of the machine.

1.4. Maintenance

OSHA requires the employer to establish

and follow a maintenance program for

industrial machinery. No presence sensing

device, including the Black Max, will

protect personnel from abnormal

hazardous machine action(s) that result

from failure, wear, or misadjustment of

mechanical, hydraulic, pneumatic or

electrical drive components of the machine

upon which it is installed. Inspection and

preventative maintenance of drive systems

that govern machine action is necessary to

reduce risks of abnormal machine

action(s) that cannot be stopped by the

machine control (and hence the stop signal

from the Black Max). Maintenance must

also be performed as required to keep

stopping time of machine action less than

the stopping time that the safety distance,

Ds, explained in the Installation and

Operating Instruction sections of this

manual is based upon. Maintenance

personnel must always follow any OSHA

required lockout procedures when working

on the machine and never work on the

machine while production is being run.

1-3

Page 5

Link Lite Black Max Section 1 - User Requirements

WARNING!

machines, or improper repairs or

adjustments to machines on which the Link

Lite Black Max is used as a safeguarding

component, may result in abnormal,

uncontrollable machine action(s) that cause

serious injury or death even though the

Black Max is functioning properly.

Where a production system uses auxiliary

equipment for scrap chopping, material

feeding, part removal, part transfer, or

other purposes, and where any hazard to

personnel posed by auxiliary equipment is

also to be safeguarded by the Link Lite

Black Max, maintenance of this equipment

for the purposes of safety is also a must.

Failure to maintain

1-4

Page 6

Link Lite Black Max Section 3 - Installation

jury

3 INSTALLATION

3.1 General Requirements

Both OSHA and ANSI standards make it

the user/employer's responsibility to see that

safety components of the production system

are installed, adjusted, and used properly to

enhance personnel protection. One or more

installers, chosen from qualified employees

or contracted from outside sources, may be

used to install the Black Max and any

necessary auxiliary or supplemental

safeguarding. Each installer must be

qualified to do the task assigned to him in

accordance with the requirements of this

manual and standards or regulatory

agencies.

WARNING!!

Max must be installed by qualified

persons. If the Black Max is not

properly installed, it will not afford the

protection intended from hazardous

machine action which can cause

serious in

The Link Lite Black

or death.

3.2.1

Summary of Black Ma x Installa-

tion Requirements

Installation of the Link Lite Black Max

must include the following procedures and

requirements. These procedures and

requirements are discussed in more detail in

sections 3.3 through 3.8. The installer(s) of

the Black Max must:

1.

Calculate, or obtain from other

persons qualified to calculate, the Safety

Distance, D

at which the sensing field of

s

the Black Max(s) must be located from the

nearest hazard to prevent a person from

reaching the hazard before the machine can

stop.

2.

Determine the mounting location and

orientation of the Black Max(s) with

consideration of the safety distance and

other operational and safety requirements

and mount the Black Max transmitter and

receiver units.

3.

Electrically interface the Black

Max(s) to power and the machine control(s).

Summary of Installation Requirements

3.2

Installation procedures and requirements for

the Link Lite Black Max and any necessary

supplemental safeguarding components are

summarized in this section to provide an

overview of the tasks that installers must

perform.

INSTALLERS!

Read this manual

completely through before beginning the

installation of a Link Lite Black Max on any

machine as a safety device.

4.

5.

Set the Black Max(s) power level.

Align the Black Max(s) transmit-

ter(s) and receiver(s).

6.

Perform a checkout sequence to

verify proper operation of the Black Max(s),

machine control, and machine.

3.2.2

Summary of Suppleme ntal Guard

Requirements

When barriers are necessary (or used by

design of the safety system) to supplement

protection provided by the sensing field

provided by Black Max units, the designated employees or outside contractor(s)

3-1

Page 7

Link Lite Black Max Section 3 - Installation

k

selected by the user/employer to install the

barriers must:

1.

Determine where barriers are

necessary and the location and size of

barriers.

2.

Design and fabricate (or have fabricated) the necessary barriers.

3.

Mount the barriers and confirm their

effectiveness and that pinch points or other

hazards are not created between barriers and

moving machine parts.

Supplemental guard requirements are discussed in more detail in section 3.9.

3.3

Calculating the Required Black

Max Safety Distance.

Every machine requires a period of time

(stopping time) to stop hazardous action

after a stop signal is applied to its control

system because of reaction times in control

components, valves, and actuators and

because of inertial effects of moving

machine parts. All light curtains also have a

reaction time to detect an object in their

sensing field and send a stop signal. The

Link Lite Black Max must be installed to

provide an OSHA and ANSI required

minimum safety distance, D

, between its

s

primary sensing field and the nearest point

of operation hazard, or other moving

machine hazard to be safeguarded. This

safety distance must be calculated by a

formula specified by OSHA and ANSI

standards. The safety distance is intended

to prevent injury by requiring a longer time

for a person to reach the hazardous area

after interrupting the presence sensing field

than the time it takes to stop the machine

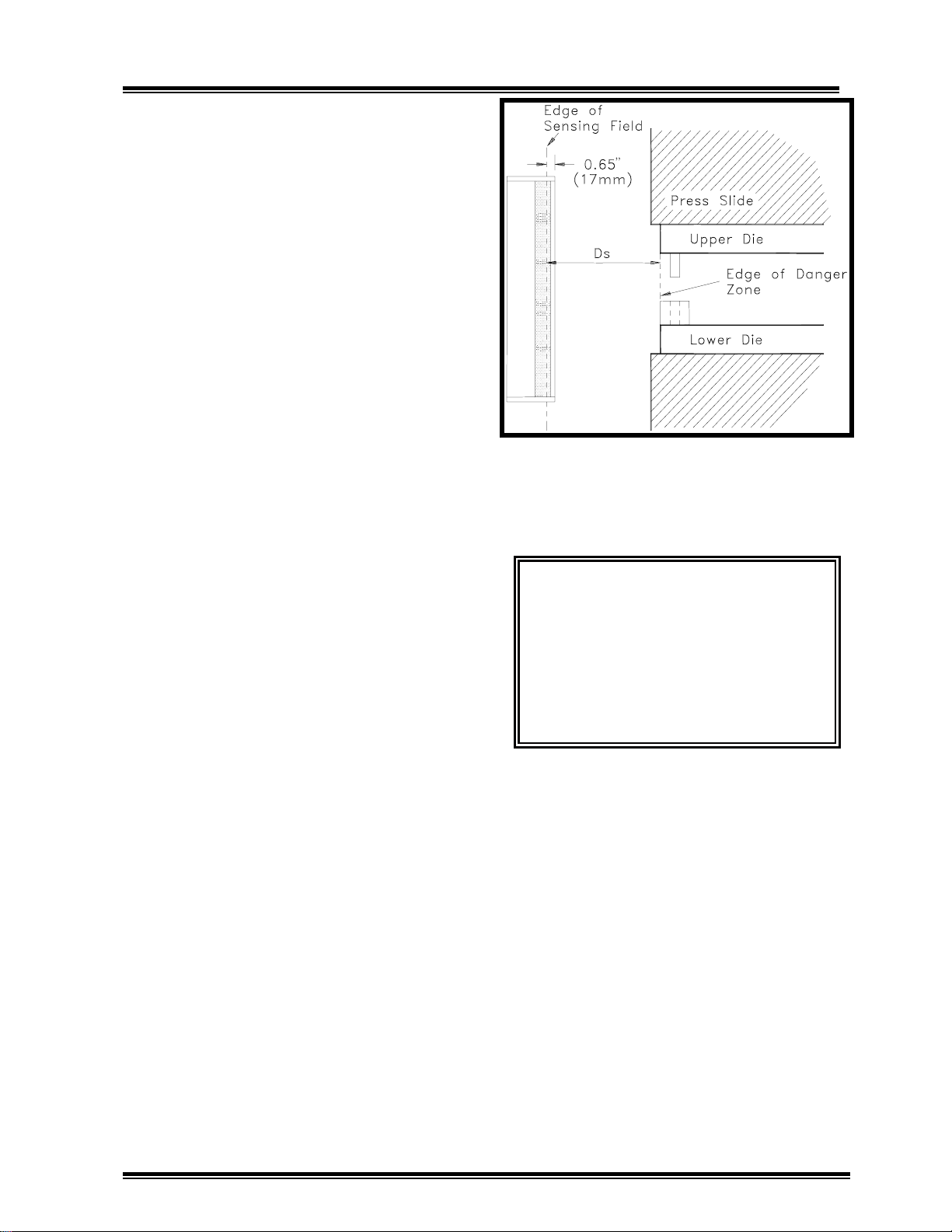

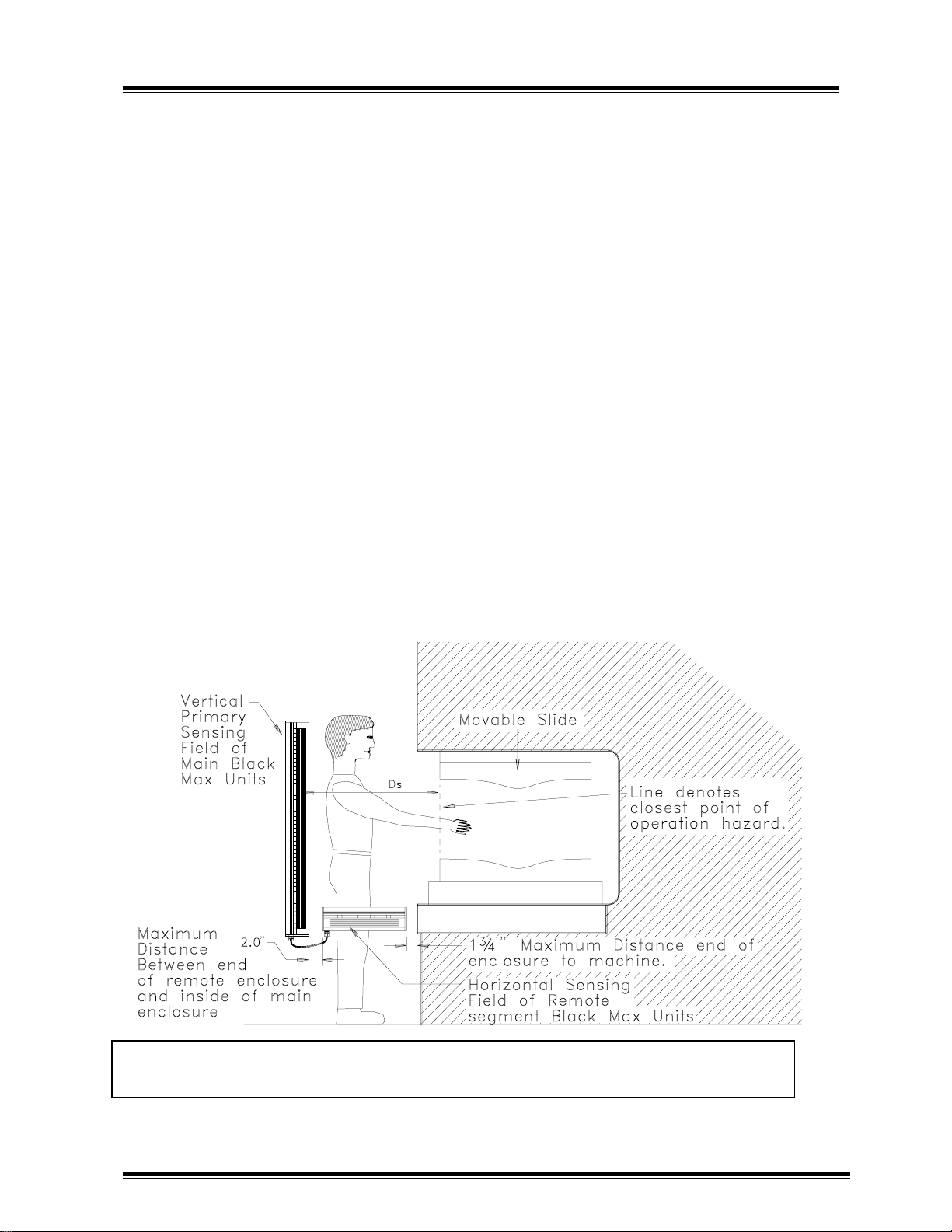

action that poses the hazard. Figure 3.1

depicts one application of the safety

distance.

Figure 3.1: Minimum Safety Distance

WARNING!!

The Link Lite Blac

Max must be installed at a distance

greater than or equal to the safety

distance, D

.Failure to do so can

s

result in serious injury to personnel

because it may be possible to reach

into the hazardous area before the

machine can stop.

The Minimum safety distance in the most

recent ANSI standards is calculated by the

formula:

D

= K (Ts+Tc+Tr+Tbm) + D

S

pf

Where:

D

= the required minimum safety dis-

s

tance

K = 63 in/sec (the average handspeed

constant)

3-2

Page 8

Link Lite Black Max Section 3 - Installation

Ts = the stop time (in seconds) of the

machine measured from the control

output stop signal to the actuator(s)

(valves, etc.) that govern machine

motion till the machine actually

stops.

T

= the response time (in seconds) of the

c

machine control to a stop signal from

the presence sensing device (Black

Max).

NOTE!

If the Link Lite Black Max output

contacts are connected to the emergency

stop circuit of relay controls, most control

designs will cause the Black Max contacts

to directly remove power from the actuators that cause motion without waiting for

other control elements to de-energize. This

means that T

=0 in the case of these

c

controls. If the machine is a part revolution mechanical power press and is

equipped with Link Electric and Safety

Control Co.'s SS501 controls or OmniLink

5000 controls, use T

=0.005 seconds (5

c

milliseconds).

presses. See ANSI B11.1 1988 sections

6.3.2(15) and 4.11 and OSHA's CFR

1910.217 sections (c)(5) and (b)(14).

Where time based monitors with the ability

to set predetermined stop time limits are

provided on machines, T

is determined by

bm

the relation:

T

= Brake Monitor Time Setting-T

bm

s

Where Ts is the actual machine stop time

already described.

NOTE!

On machines where stopping time

performance monitors are not required, a

marginal amount of stopping time to allow

for some normal wear or degradation of

machine stopping mechanisms without

violating safety distance must be substituted for T

. Link recommends that a

bm

value from 10% to 20% of the actual

machine stopping time T

.2T

, be used in place of Tbm. Periodic

s

, i.e. from .1Ts to

s

measurement of actual stopping time must

be performed to prevent stopping time

increase beyond the allowed margin.

T

= the response time of the presence

r

sensing device (Response time for

Black Max units is less than 20 ms see unit label for specific time).

T

= the additional amount of time over

bm

the actual average stopping time

allowed by a brake monitor (stopping performance monitor) to permit

some normal wear of friction brakes

and other components before the

safety distance, Ds, is violated and

the brake monitor prevents

successive strokes.

NOTE!

Stopping performance monitors

(brake monitors) are required on part

revolution presses when light curtains are

used for safeguarding mechanical power

D

= the added safety distance required to

pf

compensate for the possibility that

fingers or hand could penetrate

beyond the plane of the light curtain

sensing field plane before the profile

of the finger/hand/arm is large

enough to be detected by the sensing

field.

All presence sensing devices have a limited

object sensitivity, i.e., it takes a certain size

object to be detected at all points in the

sensing field. Penetration depth depends

on the minimum object sensitivity, M.O.S.,

of the light curtain. M.O.S. is defined as

the smallest object profile that will be

detected at all points in the active sensing

field of the light curtain. The penetration

depth factor, in inches, is described by the

3-3

Page 9

Link Lite Black Max Section 3 - Installation

following formula. Use this formula only

for M.O.S. less than 2.75 inches.

D

= 3.4 (M.O.S. - .276)

pf

Figure 3.2 illustrates the penetration depth

factor in graphical form

Figure 3.2:

penetration depth factor, D

Graphical Representation of

, vs. minimum

pf

object sensitivity.

The minimum object sensitivity in inches

for Link Lite Black Max light curtains is

specified on a label on both transmitter and

receiver enclosures. Standard range units

(to 50') for primary point of operation

guarding have a M.O.S. of .95 inches.

Long range units (to 100') for primary point

of operation guard-ing have a M.O.S. of

1.25 inches. Perimeter guarding models

and supplemental remote extension guarding units may have larger M.O.S.. Always

determine M.O.S. from the labels on the

actual units used. Always verify that both

receiver and transmitter units have the

same M.O.S. stated on their labels before

installing.

PLEASE NOTE!

When individual

channels are to be blanked (turned off) to

allow fixtures or obstructions that extend

into the primary Black Max sensing field,

additional safety distance may be necessary

to account for the increase in M.O.S. due to

blanking. Blanking is possible on Black

Max units with .95" M.O.S. and 1.25"

M.O.S.. Each contiguous (side by side)

channel blanked increases the M.O.S. by

.75".

When the Link Lite Black Max is used on

machines such as power presses, press

brakes, and other machines that have slides

used to impart motion and force to tooling,

the stop time must be measured at approximately midstroke in the closing (hazardous) portion of the stroke. The best

stopping performance of a machine will be

attained when all machine adjustments that

affect stopping time are adjusted within the

machine manufacturer's specifications. It

is the user/employer responsibility to

always maintain mechanisms that affect

stopping time in good repair and adjustment where safety devices like the Black

Max depend on the stopping action of the

machine to protect personnel.

Where a time-base brake monitor is used

on a press or other machine that is to have

a Black Max installed for point-of-operation safeguarding, the stopping time, T

can be determined by use of the brake

monitor. On time base brake monitors

equipped with stop time display, stop the

machine at approximately the mid point of

the die closing portion of the stroke and

read the stopping time displayed. For a

time based brake monitor with no direct

display of stopping time but that has a dial

or other method of setting allowable stop

time, make repeated machine stops near

midstroke, adjusting the time setting each

time until the lowest time setting that

results in the brake monitor allowing a

successive stroke without resetting is

found. This is the stop time, T

, that must

s

be used.

,

s

3-4

Page 10

Link Lite Black Max Section 3 - Installation

When no stopping performance monitor is

used on a machine (you must use one when

required by OSHA or ANSI standards) and

there is no statutory or standards requirement to use a stopping performance

monitor, a stop time measurement device

can be used to measure T

. These are

s

portable devices that usually attach to the

moving slide of the machine to detect when

the slide is stopped after another mechanism of the device gives a stop signal.

3.4

Mounting Considerations and

Requirements

Any installation of Link Lite Black Max

light curtains as a safety component of a

production or other system must include

determination of mounting locations and

orientations of the components of the

Black Max(s) that meet both the safety and

operational requirements of the production

system. General mounting requirements of

various Black Max components are

provided in the following subsections. Any

special requirements must be determined

by the user/employer and must not violate

the general requirements.

Any location and orientation of the

1.

main Black Max transmitter and receiver

units must place the sensing field at a

distance from the hazard greater than or

equal to the safety distance required in

section 3.3 of this manual, i.e. so, that

hands or fingers are D

from the hazard

s

when the sensing field is interrupted by any

part of the body.

Locate the main Black Max transmitter

2.

and receiver units at the same height and

orient at the same angle. The numbers

beside the acrylic lens on the front of the

transmitter unit and the receiver unit

designate the transmitter and sensor

channels. Each transmitter channel number

must be directly across from each similarly

numbered receiver channel. See Figures

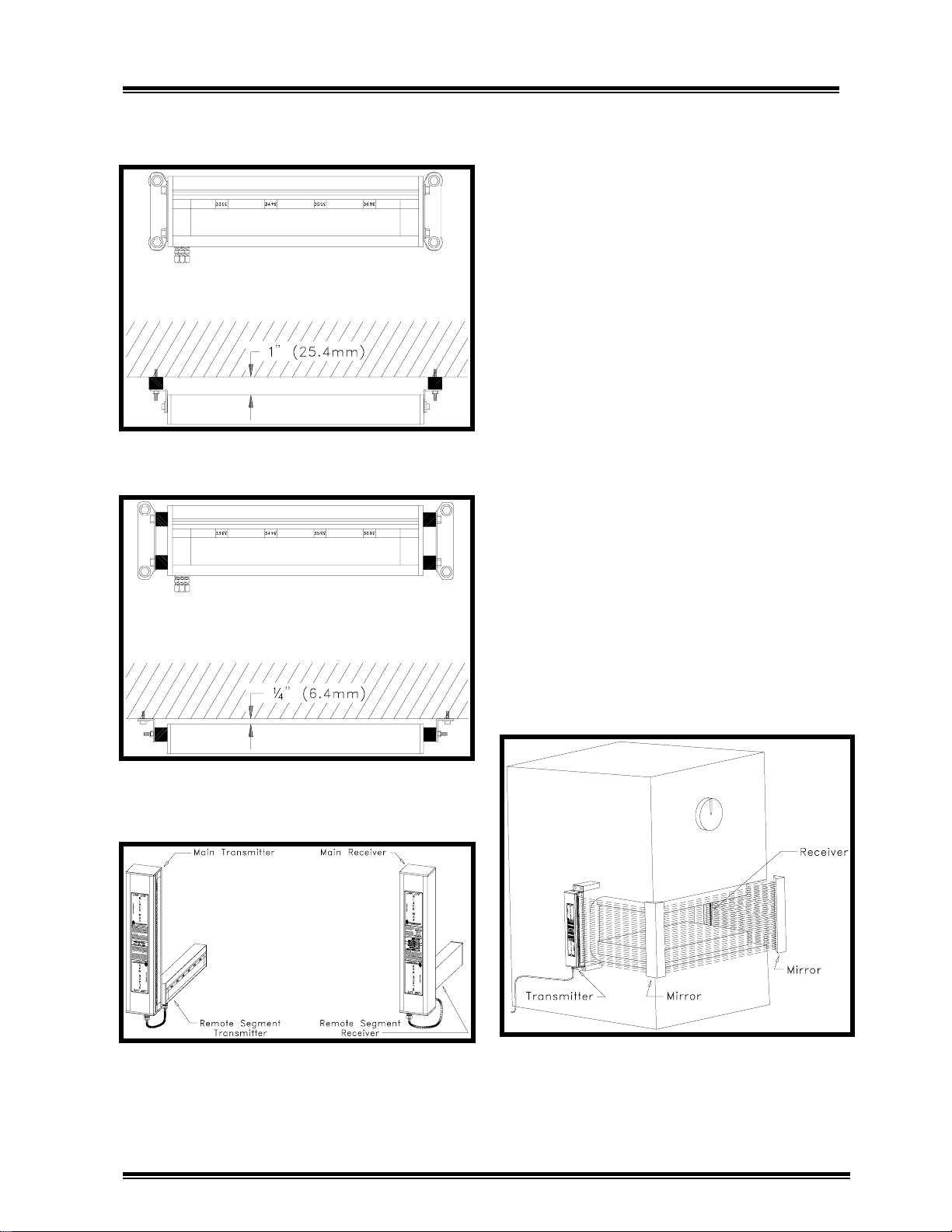

3.3.a and 3.3b.

3.4.1

Black Max Main Transmitter and

Receiver Units.

All Black Max installations will have main

transmitter and receiver units that must be

located and oriented to create a primary

sensing field whose function is to detect a

person's hand or other body part and to

provide a stop signal to the machine

control to prevent or stop hazardous

machine action(s) when the hand or other

body part is detected. The main Link Lite

Black Max transmitter and receiver units

may be mounted vertically, horizontally, or

at an angle as long as the following general

requirements are met.

Figure 3.3a:

Front view of transmitter and

receiver units mounted at a common height.

Figure 3.3b:

Top view of transmitter and

receiver units.

3-5

Page 11

Link Lite Black Max Section 3 - Installation

The mounting location or method must

3.

leave access for work pieces, tool changes,

and other operational requirements.

The main transmitter and receiver must

4.

be mounted so that the indicator lights and

warning messages on their enclosure doors

are clearly visible to operators and supervisors and so that the enclosure door can be

opened.

5.

may be mounted directly to the machine, on

brackets attached to the machine, or on floor

stands as long as safety distance and

operational requirements are met.

Mounting brackets must be sturdy to

provide a rigid mounting support that is not

easily knocked out of alignment. When

prefabricated brackets are not provided, the

installer must design and make suitable

mounting brackets.

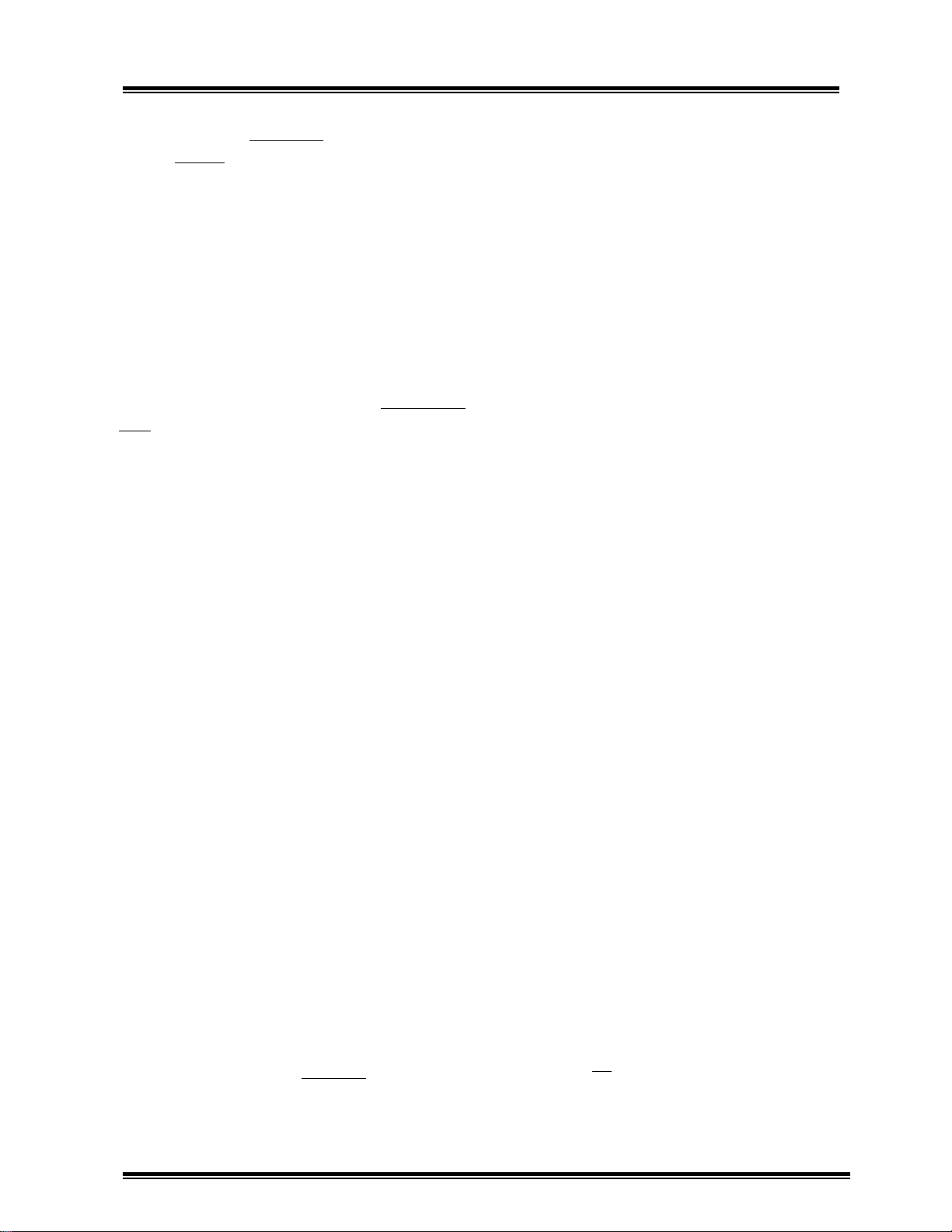

6.

be installed on two or more machines that

are arranged in a row, alternate the transmitter and receiver units (as to which unit

is mounted on the left and which on the

right side of the machine) on each adjacent

machine as shown in Figure 3.4 to reduce

the possibility of crosstalk. Crosstalk

occurs when light pulses from transmitter

unit mounted on one machine are "seen"

not only by the intended receiver unit, but

also by receiver units on other machines.

For many infrared light curtains on the

market today this creates a danger to

operators because their receiver units

accept crosstalk pulses just as they accept

pulses from the correct transmitter. An

operator may have a hand or arm in a light

curtain sensing field, blocking light pulses

from the transmitter on his machine, and a

transmitter on another machine can pass

over or under his arm, "fooling" the receiver into not providing a stop signal to

The main transmitter and receiver

When Black Max light curtains are to

the machine control as required. The

Black Max is designed to detect crosstalk

from other light curtains and to provide a

stop signal if it occurs. It is important to

install Black Max light curtains in such a

manner as to avoid nuisance machine stops

caused by crosstalk.

Figure 3.4:

crosstalk.

The scheme shown in Figure 3.4 should

also be followed when infrared light

curtains other than the Black Max are used

on adjacent machines.

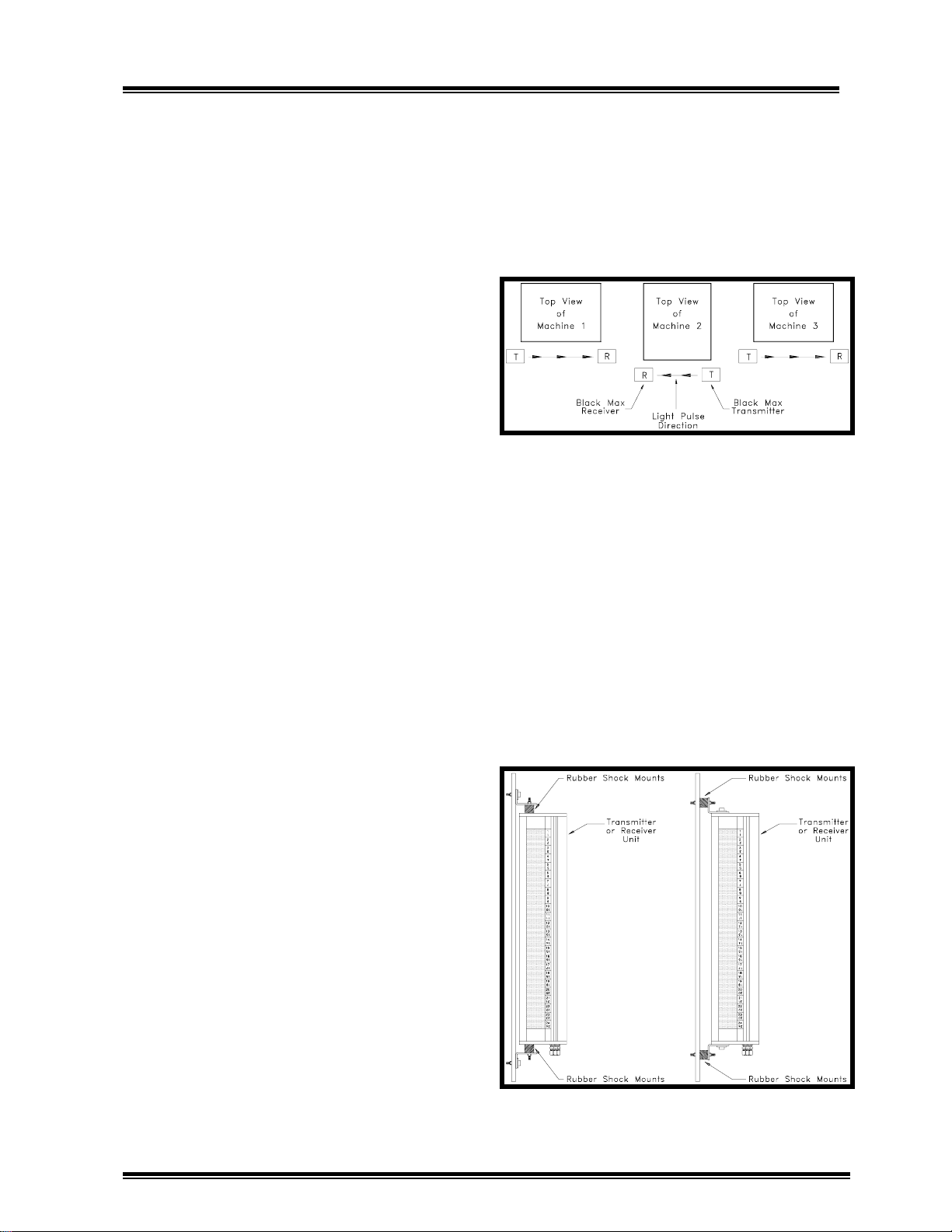

Mount the Black Max main transmitter

7.

and receiver units on the rubber shock

mounts provided in the shipment box using

one of the two mounting methods shown in

Figure 3.5.

Figure 3.5:

Mounting scheme to minimize

Use of rubber shock mounts.

3-6

Page 12

Link Lite Black Max Section 3 - Installation

p

The Black Max transmitter and receiver

8.

each have four mounting holes, two in each

end mounting flange. See Figure ---, page

---, for mounting hole dimensions and

patterns for various length units.

3.4.2 Black Max Remote Segment

Transmitter and Receiver Units.

Black Max remote segment transmitter and

receiver units are housed in separate

enclosures from the main Black Max

transmitter and receiver. When electrically

connected to the main transmitter and receiver units, they provide additional

channels of emitters and receptors which are

sequenced by the logic electronics in the

main transmitter and receiver, respectively. Remote segment units will be part

of the installation only when the

user/employer has purchased them as

components of the safety system to supplement the protection provided by the main

transmitter and receiver units.

Since the remote segments are in separate

enclosures from the main Black Max units,

they can be used to create "L" shaped or

other sensing field shapes when combined

with the main transmitter and receiver

units. When safety distance requirements,

machine configuration, or operational

requirements place the primary sensing

field between the main transmitter and

receiver at a location that allows a person

to pass completely through the primary

sensing field toward the hazard, horizontally oriented remote segment Black Max

units can be used to detect a person standing inside the sensing field as shown in

Figure 3.6.

Figure 3.6:

erson inside the main sensing field.

Horizontally mounted remote segment Black Max units to detect a

3-7

Page 13

Link Lite Black Max Section 3 - Installation

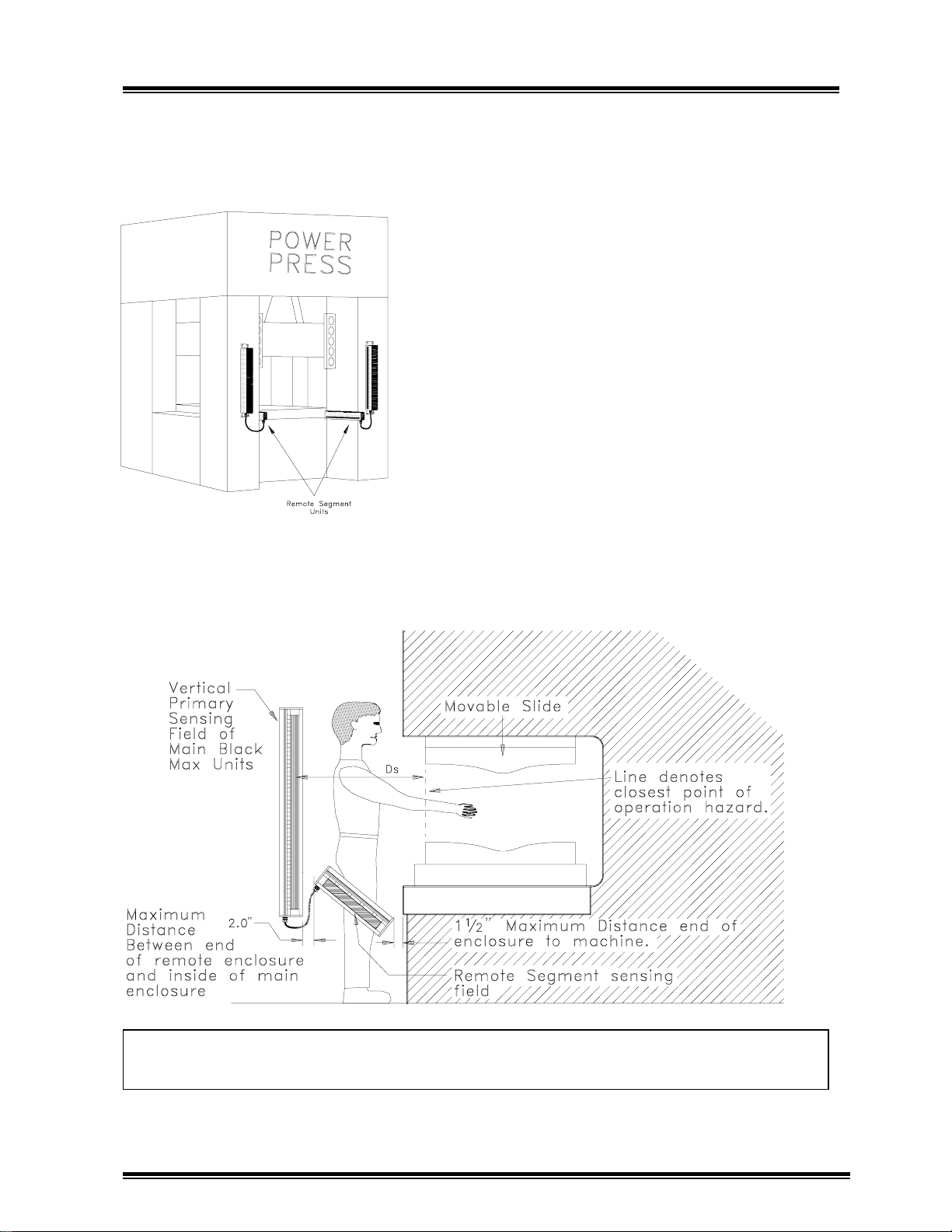

Figure 3.7. Shows remote segment units

mounted on a straight side press with

columns extended beyond the bed and

slide.

Figure 3.7:

units mounted between columns of straight

side power press to detect a person standing

inside the primary sensing field.

Remote segment Black Max

The mounting requirements for remote

segment Black Max units are generally the

same as for main transmitter and receiver

units except that when used for

supplemental guarding between the main

sensing field and the hazard, there is no

safety distance, D

location of remote segment units.

NOTE!

any manner intended to extend and be part

of the main sensing field, safety distance

requirements will then apply to the remote

segment units.

If remote segment units are used in

, requirement for the

s

Figure 3.8:

between the primary sensing field and the hazard.

Remote segment Black Max units oriented at an angle to sense a person

3-8

Page 14

Link Lite Black Max Section 3 - Installation

Also, the mounting arrangement is somewhat different for the remote segement units

as shown in Figures 3.9a and 3.9b.

Figure 3.9a:

Black Max unit mounting.

Example of remote segment

Black Max remote segment transmitter and

receiver units must always be mounted on

the same side of the machine, respectively,

as the main transmitter and receiver units as

shown in Figure 3.10

3.4.3 Use of Mirrors for Multi-Sided

Point of Operation or Perimeter

Safeguarding Applications

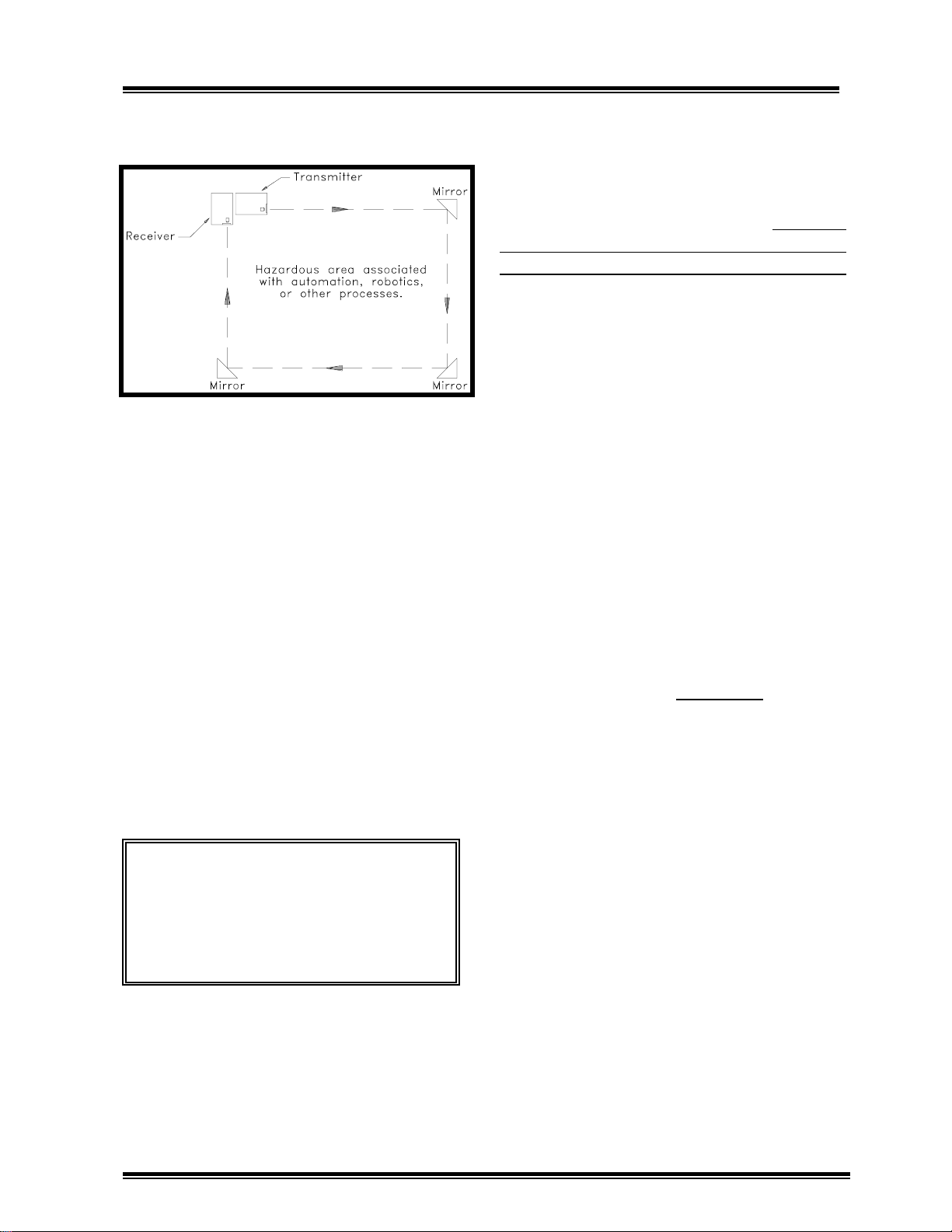

In some safeguarding applications mirrors

may be used to "bend" the sensing field

provided by main Black Max units to

provide two or more sided safeguarding for

point of operation or perimeter safeguarding. Mirrors for this purpose can be

purchased from Link Systems. Since even

the finest quality mirrors do not reflect

100% of incident light and some diffusion

of light occurs, the maximum sensing field

distance between transmitter and receiver

will be reduced by about 10% per mirror

used. Figure 3.11 illustrates a three sided

point of operation safeguarding application.

Figure 3.9b:

Black Max unit mounting.

Figure 3.10:

transmitter and receiver units on the same

respective sides.

Alternate remote segment

Mount main and remote

NOTE!

maintained on all sides of sensing field.

Figure 3.11:

of operation guarding on C frame press.

Safety Distance, D

Example of three sided point

, must be

s

3-9

Page 15

Link Lite Black Max Section 3 - Installation

g

Figure 3.12 Illustrates a four sided perimeter guarding application.

Figure 3.12:

perimeter guarding application.

3.5 Electrical Wiring to I nterface Link

Lite Black Max Units to Power and

the Machine Control.

When all Link Lite Black Max transmitter

and receiver units have been mounted, you

are ready to make electrical connections to

interface the Black Max(s) to power and

the machine control. Also, if remote

segment Black Max units are used, you

must connect the remote segment transmitter unit to the main transmitter unit and the

remote segment receiver unit to the main

receiver unit with the cables provided.

Top view of four sided

accommodate a 1/2" conduit fitting. Run a

1/2" conduit from the machine control

enclosure to each main Black Max transmitter unit. Similarly, run a 1/2" conduit

from the machine control enclosure to each

main Black Max receiver unit.

required for the transmitter and receiver

should be pulled through the 1/2" conduit.

Use of flexible conduit with integral armor

and ground wire, such as Seal Tite, is

preferable. When such flexible conduit is

used, it is also desirable to route it in such

a way as to leave slack that will allow the

Black Max units to be moved further away

from the machine if future setups necessitate moving the transmitter(s) and receiver(s) to meet safety distance requirements.

There are also two holes that are sized for

3/4" fittings, one in both ends of the main

transmitter and receiver units. These holes

are closed with screw in type plugs. They

should only be used for cable connections

between main transmitter and receiver

units and remote segment receiver and

transmitter units.

plugged openings for conduit between the

main Black Max units and the control

enclosure. Use the open 7/8" hole only.

DO NOT

All wires

use the

WARNING!

shock hazards lock all power to the

machine off before beginning the

wiring procedures for the Link Lite

Black Max. In the U.S., follow OSHA

Lockout re

3.5.1 Conduit Requirement s

The main Black Max transmitter and

receiver units both have a 7/8" hole to

To prevent electrical

ulations.

3.5.2 Power Connections

Both the transmitter and receiver units of

the Black Max must be supplied with 115

VAC (Nominal) power. Generally, this

power should be supplied from a transformer with 115 VAC secondary in the

machine control. Pull a "hot" wire, a

neutral wire, and a ground wire through the

conduit from the control enclosure to the

Black Max main transmitter unit. Refer to

Figure 3.13 for the location of the combination three connection power terminal and

plug in connector.

3-10

Page 16

Link Lite Black Max Section 3 - Installation

Figure 3.13:

Location of transmitter power connector.

3-11

Page 17

Link Lite Black Max Section 3 - Installation

g

Unplug the terminal/connector from its

socket and turn the three wire clamp

screws counterclockwise so that the power

wires can be inserted into the wire clamping slots. Strip the three power wires about

1/4" from their ends, insert them into the

wire clamping slots, and tighten the

clamping screws in the following order.

"Hot"

Neutral

Ground

When finished connecting the wires, plug

the terminal/connector back into its socket.

Three power wires must also be pulled

through the conduit from the machine

control to the main Black Max unit. The

location of the three connection power

terminal/connector is shown in Figure 3.14

for the receiver unit. Connect the power

wires to the receiver to the power terminal/connector by following the same

procedures outlined for transmitter power

connections.

3.5.3

Link Lite Black Max(s) must be wired into

the machine control circuit in such a

manner that their stop signal to the control

results in the control immediately initiating

machine stopping action.

Control Connections

WARNING!

Link Lite Black Max(s) to the machine

control can cause the Black Max to be

ineffective as a safety device with

possible consequent injury to personnel

by the machine hazard intended to be

safe

uarded.

wire connects to

terminal marked L1

wire connects to terminal

marked L2

wire connects to terminal

marked GND

Improper connection of

All control wiring connections to the Link

Lite Black Max are made to the eight

position terminal/connector located on the

relay board in the main Black Max receiver

enclosure, accessible by opening the door

to the receiver enclosure as shown in

Figure 3.14. Run wires through the 1/2"

flexible conduit from the machine control

enclosure to the main Black Max receiver

unit to interconnect the light curtain to the

control.

Two normally open (N.O.) and one normally closed (N.C.) contact paths are

supplied in the Link Lite Black Max

receiver unit for interconnection to

machine control circuits. Two separate

relay contacts whose operation is checked

by Black Max logic circuits are used in

each path as shown in Figure 3.14. The

interconnection of the Black Max(s) to the

control circuit depends on the design and

configuration of the machine control

circuit. When the Black Max is used with

a machine control supplied by Link

Systems, schematics will be provided that

show the connections that must be made

between the Black Max light curtain and

the control. Wire as shown in the schematic. Do not deviate from the schematic

unless Link gives written approval of an

alternative wiring scheme.

When interconnecting Black Max units to

controls not supplied by Link, at least one

of the normally open contact paths must be

used to provide the stop signal to the

machine control in such a manner that the

control immediately initiates machine

stopping action. In some cases use of both

normally open contact paths of the Black

Max may be necessary. The normally

closed contact path between terminals 3

and 4 must never be used to provide the

stop signal to the press control. Link

provides these terminals for use in addition

to normally open contact

3-12

Page 18

Link Lite Black Max Section 3 - Installation

Figure 3.14:

Power and relay connections for Black Max receiver.

3-13

Page 19

Link Lite Black Max Section 3 - Installation

p

paths in special interfaces between the

Black Max and the machine controls

designed by Link Systems.

WARNING!

closed contact path only to provide a

stop signal to the machine control. A

loose connection or broken wire would

result in no stop signal being supplied

to the control by the Black Max even

though the Black Max itself was

operating properly.

Link Systems will evaluate existing

machine controls as to their suitability for

use with the Link Lite Black Max upon

customer request and provision of schematics, and will mark schematics for interconnection with the Black Max when such

controls are suitable for use with the Black

Max.

WARNING!

provides machine controls or marks

existing machine control schematics for

interconnection with Black Max units,

always wire as shown by Link on

schematics. Improper connection of

Black Max units to the machine control

may result in failure of the machine to

stop even though the Black Max

component is functioning properly with

possible serious injury or death to

ersonnel.

Never use the normally

When Link Systems

mechanical power presses, hydraulic power

presses, power press brakes, etc., OSHA

and ANSI allow presence sensing devices

such as the Link Lite Black Max to be

interconnected or interfaced with the

machine control so that the protective

function is bypassed (muted) during the

non-hazardous portion of the stroking cycle

only. Never simply use unmonitored limit

switch contacts to mute the Black Max in

the non-hazardous part of a machine cycle.

Interfacing to maintain "control reliability"

in the event of a component fault in the

muting circuit is necessary.

Some machine controls are designed to

require cycling of light curtain output

relays on each cycle of the machine even if

the sensing field is not interrupted.

Terminals 1 and 2 on the eight position

terminal/connector provide an input to

cycle the output relays. To activate the

relay cycle circuit a jumper must be removed on the receiver logic board in the

receiver unit. See Figure 3.15. When the

jumper is removed, a voltage must be

supplied between terminals 1 and 2 to

energize the output relays in each receiver

unit (but only when the Black Max transmitter and receiver are properly aligned

and no obstruction is in the sensing field).

Switching this voltage off at least 35

milliseconds will cause relays LC1 and

LC2 to de-energize. If both relays switch

off and the voltage is switched back onto

terminals 1 and 2, the relays will again

energize. This relay cycle is normally done

during the non-hazardous portion of the

machine stroke when the Black Max is

muted to avoid stopping the machine when

the relays are de-energized.

In some cases, Link Systems may have to

provide an interface circuit to accomplish

proper interconnection of the Link Lite

Black Max with a customers existing

control circuit.

On linearly stroking machines such as

As shipped, a voltage of 12VDC to 30VDC

may be used for the relay cycle input to

terminals 1 and 2 when the jumper is

removed. Removing jumpers J2 and J3 on

the receiver Relay Board as

3-14

Page 20

Link Lite Black Max Section 3 - Installation

y

Figure 3.15:

Location of rela

check con-figuration jumpers.

3-15

Page 21

Link Lite Black Max Section 3 - Installation

g

shown in Figure 3.15 will configure the

relay cycle circuit for 115VAC input

voltage between terminals 1 and 2.

Some machines use programmable logic

controllers (PLCs) as the machine control.

The Black Max must never be connected to

only the inputs of a single PLC controller.

Always contact Link before

Lite Black Max as a protective device on a

machine with a PLC control. Most PLC

controls do not meet OSHA's control

reliability requirement for use of a presence

sensing device.

WARNING!

Black Max on a machine controlled by

a PLC without first consulting Link

Systems as to whether the Black Max

should be used and how it should be

connected to the control. Failure of the

PLC control could cause the machine to

fail to stop even though the Black Max

is functioning properly if the control

system is not designed to provide a stop

signal to the machine in the event of

a component failure or program fault.

Serious injury or death may result from

the hazard intended to be safe

3.5.4

Connections between main Black Max

transmitter and receiver units and remote

segment units are accomplished by a cable

that terminates inside the main and remote

units in a ribbon cable plug-in connector.

The cable enters each unit enclosure

through a water and oil tight screw on

fitting. See Figures 3.16 and 3.17. The

remote segment unit may be connected to

either end of the main unit by removing the

Connections Between Main Black

Max Units and Remote Segments

Units

Never use a Link Lite

using a Link

uarded.

screw-in plug in the large hole in the end

cap, running the ribbon cable through the

hole, and screwing the cable fitting into the

hole. Always leave the screw-in plug in

place on the unused end of the main

transmitter or receiver unit to retain the

NEMA 4 performance of the enclosure. In

some cases, two remote segment units may

be used, one off of either end of the main

transmitter or receiver enclosure. This is

illustrated in Figure 3.18.

3.6

Setting The Black Max Transmit-

ter Power Level

After mounting and electrically connecting

the Black Max transmitter and receiver

units, the transmitter power must be set for

the separation distance between the transmitter and receiver. Using more power

than necessary to transmit between transmitter and receiver is undesirable because

of the possibility that the excess light

energy can be detected by other Black Max

receiver units on other machines. This

cross talk would result in nuisance stops on

the other machines. Also, the life of the

infrared light emitting diodes in the transmitter is somewhat dependent on power

level. These components will have prolonged life at lower power levels.

To set the transmitter power level, open the

door of the main transmitter enclosure,

locate the small 4 position DIP switch on

the outside edge of the transmitter logic

board, and adjust the switch positions

according to the power level table located

on the inside of the transmitter door. The

location of the 4 position switch and power

level table are shown in figure 3.19.

Always adjust the power level correctly for

the separation distance between the Black

Max transmitter and receiver.

3-16

Page 22

Link Lite Black Max Section 3 - Installation

g

Figure 3.16:

Use of remote se

ment at bottom of main transmitter.

3-17

Page 23

Link Lite Black Max Section 3 - Installation

Figure 3.17:

Remote segment unit used at top of main transmitter.

3-18

Page 24

Link Lite Black Max Section 3 - Installation

g

Figure 3.18:

Use of two remote se

ment units with main transmitter.

3-19

Page 25

Link Lite Black Max Section 3 - Installation

p

Figure 3.19

: Location of the transmitter

ower level switch and power level table.

3-20

Page 26

Link Lite Black Max Section 3 - Installation

NOTE!

Max light curtain is designed to supply a

stop signal when far too much light is

received from the transmitter.

3.7

After setting the proper transmitter power

level, make sure that both the Black Max

transmitter and receiver enclosure doors are

closed and screwed shut. If the mounting

instructions in section 3.4 have been correctly followed, the acrylic lens on the

transmitter and receiver units should face

each other, the channel numbers beside the

acrylic lens on the transmitter and receiver

units should be directly across from each

other, the receiver and transmitter should be

mounted at the same height from the floor

and in the same plane. Final alignment must

now be done. Each transmitter channel of

the Black Max sends out a focused cone of

infrared light at a diverging angle rather like

a sharply focused flashlight. This beam of

light from a transmitter channel must fall

upon the similarly numbered receiver

channel. Also, each receiver channel has a

lens to provide a limited cone of view. Each

receiver channel must "look" at the

transmitter channel with similar number.

Figures 3.20 and 3.21 illustrate correct and

incorrect alignment from front and top

views, respectively.

The receiver unit of the Black

Aligning The Black M ax Trans-

mitter(s) and Receiver(s)

Figure 3.20b:

receiver in alignment from front view.

Figure 3.21a:

receiver out of alignment from top view.

Black Max transmitter and

Black Max transmitter and

Figure 3.20a:

receiver out of alignment from front view.

Black Max transmitter and

Figure 3.21b:

receiver in of alignment from top view.

Figure 3.22 illustrates alignment of transmitter and receiver from the side view. If

Black Max units are not aligned properly,

the receiver will not see the transmitter

light, and a continuous stop signal will be

3-21

Black Max transmitter and

Page 27

Link Lite Black Max Section 3 - Installation

sent by the Black Max receiver unit to the

machine control.

Figure 3.22a:

of alignment from side view.

Transmitter and receiver out

receiver units. Verify that power is on the

transmitter by observing that the green

"POWER" LED in the front center of the

transmitter unit is on. Verify that power is

on the receiver by observing that either the

green "CLEAR" LEDS or the red "STOP

SIGNAL" LEDS in the front center of the

receiver unit are on. Don't start the

machine for this alignment procedure.

Leave all motors off.

Check to make sure that no grease or

2.

dirt covers the red acrylic lens in the front

of the transmitter and receiver units and

that no obstruction is between the transmitter and receiver. Also, check the front of

the main receiver unit to make sure that the

amber colored "NO BLANKING" light is

on and that the RUN-PROGRAM -SELECT switch is in the "RUN" position. If

not, use the key for the RUN PROGRAM - SELECT switch to obtain

these conditions.

Figure 3.22b:

alignment from side view.

To align the Black Max transmitter and

receiver units perform the following steps.

Turn on the main disconnect switch to

1.

the machine control to supply power to the

Link Lite Black Max transmitter and

Transmitter and receiver in

Observe the green "CLEAR" and red

3.

"STOP SIGNAL" lights on the door of the

main receiver unit. If the transmitter and

receiver are aligned to where some part of

the cone of light from each emitter in the

transmitter falls upon its similarly numbered phototransitor channel on the receiver and, if the receiver is aligned well

enough that some sector of its cone of

vision can see the light from the emitter,

the "CLEAR" lights will be on. If not, the

"STOP SIGNAL" lights will be on. Even if

the "CLEAR" lights are on, indicating at

least rough alignment, perform the following steps to achieve best alignment. Best

alignment results when the cone of transmitted light and the cone of receiver vision

are centered on each other.

The L shaped mounting "ears" for the

4.

Link Lite Black Max units are designed to

allow easy alignment if the mounting

3-22

Page 28

Link Lite Black Max Section 3 - Installation

j

brackets (or surface) to which the transmitter and receiver are to be mounted are in

reasonable alignment. The two mounting

holes in the "ears" that bolt to the mounting

surface are slotted to allow the transmitter

and receiver units to be aligned lengthwise

as shown in Figure 3.20b. The front

mounting hole on the section of the

mounting ear that attaches to the transmitter and receiver unit is slotted (the rear hole

is not) to allow pivoting motion to align the

transmitter and receiver in the direction

shown in Figure 3.21b. To achieve best

alignment, first loosen the bolts on the

mounting ears of transmitter and receiver

units that attach the ears to the mounting

brackets or other mounting surface and use

a carpenters level to get them plumb as

shown in Figure 3.20b. When plumb,

tighten mounting ear bolts to the bracket or

surface.

connect the mounting ears to the transmitter unit to lock the transmitter into angular

alignment.

Loosen the bolts that connect the

7.

mounting ears to the receiver unit and

repeat the procedure of step 6 with the

receiver to bring the receiver into angular

alignment.

NOTE

that have remote segment units, first align

main receiver and transmitter units and

then remote segment receiver and transmitter units. Until both main and remote

segment units are roughly aligned, the

green "CLEAR" lights on the main receiver

door won't come on.

3.8 Functional Checkout of the Link

! When aligning Black Max units

Lite Black Max Installation and

Machine.

Now loosen the mounting ear bolts that

5.

connect the mounting ears to the transmitter and receiver units and pivot transmitter

and receiver back and forth until the green

"CLEAR" light comes on the door of the

receiver unit. Tighten the bolts that hold

the mounting ears to the receiver unit only,

making certain that the green "CLEAR"

light stays on as you do so.

Pivot the transmitter clockwise just till

6.

one or more of the red LEDS behind the

acrylic lens on the front of the receiver

come on, indicating that these channels

have lost alignment. Then pivot the

transmitter counterclockwise. The red

channel LEDS should first turn off as the

transmitter is rotated back into alignment,

then turn back on as alignment is lost in the

counterclockwise direction. Again pivot

the transmitter clockwise until the transmitter is located at an angle halfway between

the clockwise and counterclockwise loss of

alignment angles. Tighten the bolts that

When the installation steps described in

sections 3.3 through 3.7 have been successfully completed, a functional checkout of

the operation of the machine and the Link

Lite Black Max(s) must be performed

before placing the machine into production, or before beginning installation of

supplementary barriers if necessary.

WARNING!

of the Link Lite Black Max Installation

and the machine on which it is installed

must be performed to verify that the

Black Max is wired into the machine

control to provide on immediate

initiation of stopping action and that

the machine is functioning correctly.

Serious injury or death can result from

hazardous machine action if there are

installation errors or machine

misad

ustments or malfunctions.

The functional checkout

3-23

Page 29

Link Lite Black Max Section 3 - Installation

Perform the following checkout steps:

Turn on power to the Link Lite Black

1.

Max units by turning the main disconnect

to the machine control to the on position.

Do not turn on machine motor(s). Verify

that there are no obstructions between

transmitter and receiver units.

Look at the door of the main Black Max

2.

receiver unit and verify that the green

"CLEAR" lights are on, that the amber "NO

BLANKING" light is on, and that the RUN

- PROGRAM - SELECT switch is in the

RUN position. If not, use the key for the

RUN - PROGRAM -SELECT switch to

obtain these conditions.

Both the main transmitter and receiver

3.

units have a label that states their minimum

object sensitivity (M.O.S.). Check these

labels to verify that both transmitter and

receiver have the same M.O.S.. If a

different M.O.S. is stated on the receiver

and transmitter, a different model number

transmitter and receiver have inadvertently

been installed. find the transmitter or

receiver that corresponds with the intended

model number and exchange to correct this

situation. When you have determined the

M.O.S. of the installed units, obtain a test

bar or strip that has a width equal to the

M.O.S. of the installed Black Max system.

NOTE!

used as supplementary safeguarding, the

M.O.S. of these units will usually be

different than the main units. Check the

labels on these units for M.O.S..

Place the test bar or strip obtained in

4.

item 3 immediately in front of the top

channel of the main receiver unit and

slowly lower the bar or strip through the

sensing field to the bottom channel,

observing to confirm that each channel

If remote segment units are also

indicator light behind the acrylic receiver

lens lights as its channel is blocked, and

that the red "STOP SIGNAL" lights on the

receiver door stay continuously on as the

bar or strip is lowered from top to bottom.

Repeat step 4 with the bar or strip

5.

placed immediately next to the main

transmitter unit and lowered from top to

bottom.

Repeat step 4 with the bar or strip

6.

halfway between the transmitter and

receiver units and lowered from top to

bottom.

If remote segment transmitter and

7.

receiver units are installed, block each

channel of the remote segment unit and

confirm that its channel indicator light

located behind the acrylic lens on the

remote segment receiver unit comes on and

that the red "STOP SIGNAL" lights on the

door of the receiver come on.

If any of the results in the test per-

8.

formed in the preceding steps are not as

specified, go to the troubleshooting section

of this manual or contact Link Systems to

correct the problem. Do not start the

machine until the problem is corrected. If

the preceding tests were successful, start

the machine and, with no obstruction

between the Black Max transmitter and

receiver units operate the machine in all

modes to confirm normal operation. If the

green "CLEAR" lights on the main receiver

unit door are on but the machine won't

operate, incorrect wiring from the Black

Max to the machine control is indicated. If

the machine operates properly proceed to

the next step.

3-24

Page 30

Link Lite Black Max Section 3 - Installation

Take the test bar or strip used in steps 4

9.

through 6 and insert it into the sensing field

between the transmitter and receiver. The

machine stopping action should immediately be initiated when the sensing field is

interrupted. An exception to this occurs

when the Black Max is muted during a part

of a machine cycle that is not hazardous.

The interruption of the sensing field should

then only stop the machine action during

the hazardous portion of the cycle check to

see that the machine does stop in all

hazardous parts of the stroke. Repeat this

test several times, making sure that the

machine stops properly and that the safety

distance requirement of section 3.3 is met

for the stopping time encountered under

the conditions of this test. If the machine

that the Black max is installed on has

multiple operating modes (such as Inch,

Single Stroke, and Continuous on a

mechanical power press) repeat this test in

all modes to verify the intended stopping

action. If the stopping mechanisms of the

machine seem to be working improperly or

erratically, notify the user/employer and

request that a maintenance person qualified

to adjust or repair the stopping mechanisms

be assigned to do so. Don't proceed to the

next step until the problem is corrected.

If all requirements of the preceding

10.

checkout steps are met, the installation of

the Link Lite Black Max components of the

safety system is complete. If the installer(s) of the Black Max components has

been contracted or assigned the responsibility to provide any other necessary

supplemental guarding components of the

safety system, proceed to section 3.9. If

someone else is to install other components

of the safety system that may be required,

the Black Max installer(s) should notify the

user/employer that his phase of the

installation is complete.

3.9

Supplemental Guard Installation

Requirements

Although a safety system design for an

industrial machine that uses only light

curtains, such as the Link Lite Black Max

units in addition to the machine components involved in stopping hazardous

action can often be accomplished, it is

sometimes necessary to make and install

barriers to supplement the safeguarding

function intended to be performed by the

Black Max sensing field(s) to comply with

OSHA and ANSI standards. Often, the

requirement and physical configuration for

barriers can only be determined after the

Black Max installation. The safety distance requirement, configuration of the

machine, size, and location of the light

curtain and tooling can all be factors which

affect the specific application. There are

two areas of concern that must be considered when determining whether supplemental guards or barriers are required.

Any light curtain, including the Black

1.

Max, only protects people who reach

through its sensing field as they approach

the hazard to be safeguarded. Therefore,

once the Black Max units have been

installed, if it is possible to enter the

hazardous area over, under, or around the

Black Max(s) sensing field(s) from any

normal position associated with the tasks

of operators or other personnel, barriers

must be installed to cause the only path to

the hazard to be through the Black Max(s)

sensing field(s).

The Black Max will not protect people

2.

if the required safety distance discussed in

section 3.3 places the main transmitter and

receiver far enough away from the hazard

that a person can assume any normal

position between the Black Max sensing

field and the hazard, i.e., so that he can

3-25

Page 31

Link Lite Black Max Section 3 - Installation

g

have a body part in the hazardous area

without being detected. If remote segment

Black Max units are not used to detect a

person standing between the primary

sensing field created by the main transmitter and receiver and the hazard (see section

3.4.2), then barriers must be installed to

keep someone from passing completely

through the Black Max sensing field

toward the hazard.

WARNING!

supplemental barriers, when required,

may result in serious injury to someone

reaching the hazard through an opening

or area not sensed by the Black Max

li

ht curtain(s).

Barriers installed to prevent people from

reaching over, under, or around the Black

Max(s) sensing field(s) must meet several

OSHA construction requirements. These

are:

The guard should prevent reaching

1.

over, under, or around the guard and into

Failure to install

the point of operation, except through the

Black Max(s) sensing field(s).

Openings in the guard must meet the

2.

requirements of OSHA Table 0-10.

The barrier must be installed so that it

3.

doesn't create hazards (such as pinch

points) between the guard and moving

machine parts.

Unless the barrier is interlocked with

4.

the machine control to prevent hazardous

action of the machine when it is not in

place, it should use fasteners that require

tools to remove.

Barriers to prevent someone from assuming

a position between a Black Max sensing

field and the hazard without being detected

must be installed to prevent a persons body

from passing completely through the Black

Max sensing field as he approaches the

hazard.

Figures 3.23 through 3.26 give general

illustrations of the use of supplemental

barriers.

Table 0-10

Distance of Opening Maximum Width

to Nearest Hazard of Opening

½” to 1 ½” ¼”

1 ½” to 2 ½” 3/8”

2 ½” to 3 ½” ½”

3 ½” to 5 ½” 5/8”

5 ½” to 6 ½” ¾”

6 ½” to 7 ½” 7/8”

7 ½” to 12 ½” 1 ¼”

12 ½” to 15 ½” 1 ½”

15 ½” to 17 ½” 1 7/8”

17 ½” to 31 ½” 2 1/8”

3-26

Page 32

Link Lite Black Max Section 3 - Installation

Figure 3.23:

the top of a Black Max sensing field or through the openings of a C frame machine.

Illustration of barriers installed to prevent someone from reaching over

3-27

Page 33

Link Lite Black Max Section 3 - Installation

g

p

p

Figure 3.24:

between li

Figure 3.25:

ht curtain and hazard.

A Black Max with supplemental barrier to prevent standing

Exam

le of a Black Max on a press brake with supplemental barriers.

Figure 3.26:

rotect inside primary sensing field, and barriers to prevent entry from the side.

Use of Black Max remote segment units in the horizontal position to

3-28

Page 34

Link Lite Black Max Section 4 - Operating Instructions

Link Lite Black Max light curtain

4 OPERATING INSTRUCTIONS,

REQUIREMENTS, AND PRECAUTIONS

IMPORTANT!

operators, supervisors, maintenance

personnel, and other persons associated

with the care and use of machines or

production systems using Link Lite Black

Max light curtains as safety components

must read (or be provided with the knowledge of) the material in this

Instructions, Requirements and Precautions

section to enhance safety to the fullest

possible extent. OSHA and ANSI standards make it the employer's responsibility

to train all employees associated with the

setup, operation, and maintenance of the

machine, and to provide supervision to

ensure that employees follow proper setup

and operation procedures.

All

setup personnel,

Operating

1.

presence sensing devices are designed and

manufactured to comply with OSHA and

ANSI standards for construction of point of

operation devices. Properly installed,

located, adjusted and used presence

sensing devices enhance personnel safety

by preventing normal initiation of hazardous machine action or by stopping normal

hazardous action in progress if the operator's (or other's) hand or other body part are

in the sensing field (the plane directly

between the Black Max transmitter and

receiver units as shown in Figure 4.1).

4.1 Safeguarding System L imitations

and Requirements

Link Lite Black Max light curtains are not

the safety system, but rather are a component of the machine safety system. Light

curtains send a stop signal to the control of

a machine when someone of something

blocks their sensing field light. They

depend on other electrical, pneumatic,

mechanical, and/or hydraulic components

of the machine drive system to actually

stop hazardous action when you are in the

sensing field. In some cases, supplemental

barriers or safety devices may be required

in addition to light curtains to protect you

from the machine or production system

hazard(s). Light curtains must be properly

installed, located, and used in conjunction

with any other necessary safety components to protect you, in accordance with the

following requirements.

Figure 4.1:

location between main Black Max

transmitter and receiver units when no

blanking is used.

WARNING!

device, including the Link-Lite Black

Max, will protect you from abnormal

hazardous machine action(s) caused by

failure, wear, or misadjustment of

mechanical, hydraulic, pneumatic, or

electrical components of the machine

upon which it is installed. Serious

injury or death may result from such

failures.

Proper machine preventative maintenance

must be performed to reduce the risk of

accidents that result from failure, wear, or

misadjustment of machine components.

Illustration of sensing field

No presence sensing

4-1

Page 35

Link Lite Black Max Section 4 - Operating Instructions

p

g

The main Black Max sensing field must

2.

be located far enough away from the

hazardous area that machine action will be

stopped before a persons hand that passes

through the light curtain sensing field can

reach the closest hazard. This safety

distance is required by both OSHA and

ANSI. The minimum safety distance, DS, is

determined by a formula which is explained in section 3.3 of the installation

section of this manual.

It must never be assumed that the original

installation of a Black Max light curtain will

always result in maintaining D

setups and under all operating conditions.

For several reasons, safety distance must be

verified for each setup under actual

operating conditions.

for all

S

Figure 4.2:

Illustration of Minimum Safety

Distance Measurement

First, D

depends on the stopping time, TS,

S

of the machine, which can vary depending

on many factors, including position in

stroke, cycle rate, air or hydraulic pressure,

speed of moving parts (stroking speed),

temperature of hydraulic fluid, weight of

tooling attached to moving machine parts,

and counterbalance adjustment. On

machines equipped with friction clutches

and brakes, clutch and brake wear over a

period of time can cause the stopping time

to increase. Some hydraulically operated

machines have adjustments that can affect

stopping time.

Second, the size and location of the tooling

used in a machine often varies for each

machine setup, bringing the hazardous

point of operation closer or farther away

from the Black Max sensing field on

different setups and thus affecting D

. For

S

this reason the person(s) assigned to set the

machine up for different production jobs

must verify the safety distance for each

setup. See Figure 4.2

WARNING!

The Link Lite Black Max

sensing field must be located at a

distance greater than or equal to the

safety distance, D

. Failure to do so

S

can result in serious injury to personnel

because it is possible to reach into the

hazardous area before the machine can

sto

.

Light curtains, including the Black

3.

Max, only protect people who reach

through their sensing field as they approach the hazard to be safeguarded.

WARNING!

The Black Max light

curtain will not protect you if you

reach over, under, or around its sensing

field and into the hazard. Serious

injury may result if you can enter the

hazard other than through the Black

Max sensin

field.

Depending on the safety system design and

the machine or production system configuration, supplemental barriers may be

4-2

Page 36

Link Lite Black Max Section 4 - Operating Instructions

p

required to prevent someone from reaching

the hazardous area from any normal

position associated with the employer

defined tasks of operators or other personnel other than through the Black Max

sensing field. These barriers must be

provided and used

supplement the Black Max safeguarding

component.

. The required safety distance of item 2

4

may place the main Black Max sensing

field far enough away from the hazard that

a person can assume a normal working

position between the sensing field and the

hazard. A person in such a position can

reach into, or enter into, the hazardous area

without being detected by the main Black

Max sensing field, and the Black Max will

provide no protection if hazardous machine

action is started.

A physical barrier to prevent persons from

standing inside the main Black Max

sensing field or Black Max remote extension units oriented horizontally and

extending outward from the machine to

detect persons inside the main sensing field

and prevent normal machine action must be

used if every person operating or helping

with the production system doesn't have his

own set of active operator controls, located

on the other side of the main Black Max

sensing field, from the hazard. These

operator controls must be designed to be

operated concurrently with all other

operator controls to initiate machine

action.

WARNING!

Max will not protect a person in a

position between the sensing field and

the hazard. Serious injury or death

may be inflicted by the hazard if

machine or production system action is

started while a person is in such a

position.

when necessary to

The Link Lite Black

Any task associated with a machine or

5.

production system using a Black Max as a

safeguarding component that requires a

person to enter into the hazardous area so

that he is not protected by the Black Max

or other safeguarding components must be

done in accordance with OSHA's lockout/tagout regulations, CFR1910.147,

where all hazardous energy is locked out

on the machine or production system by

each person involved in the task. For

example, tool or die repairs or adjustments

in the machine and repair or adjustment of

parts transfer or other feeding systems

located in the hazardous area may cause

the person(s) doing these tasks to assume

positions or locations that aren't protected

by production mode safeguarding.

WARNING!

production system corrective measures

or tasks that cause persons to enter the

hazardous area and assume positions or

locations so that they aren't protected

by the Black Max or other

safeguarding components must be

performed in accordance with OSHA's

CFR1910.147 lockout procedures.

Serious injury or death may result from

the machine or production system if

lockout

OSHA and ANSI standards permit

6.

"muting" (bypassing the presence sensing

device stop signal) in the non-hazardous

portion of the cycle - such as the die

opening portion of the cycle - on linearly