Page 1

System 2500

Programmable Limit Switch /Die Protection Unit

Operator Manual

WARNING!!

THIS UNIT IS NOT INTENDED FOR APPLICATIONS REQUIRING

CONTROL RELIABILITY. DO NOT USE THE OUTPUT RELAYS OF

THE SYSTEM 2500 AS PRIMARY INPUTS TO A PRESS CONTROL.

Manual LS-013

Revision 07

Page 2

TABLE OF CONTENTS

Section 1 OVERVIEW OF THE SYSTEM 2500

1.1 Features ......................................................... 1-1

1.2 Components ...................................................... 1-2

1.3 Specifications .....................................................1-3

Section 2 OPERATION

2.1 Using the Operator Interface Terminal ................................. 2-1

2.1.1 Keyboard Use ............................................. 2-1

2.1.1.1 ANGLE/RPM Key .................................. 2-1

2.1.1.2 HELP Key ........................................ 2-2

2.1.1.3 CLEAR Key ....................................... 2-2

2.1.1.4 BRIGHT and DIM Keys ............................. 2-2

2.1.1.5 MAIN MENU Key .................................. 2-2

2.1.2 Mode Selector Keyswitch .................................... 2-2

2.2 Menu Selection Using the LCD ....................................... 2-3

2.2.1 Main Menu ............................................... 2-3

2.3 Programmable Limit Switch (PLS) Functions ............................ 2-4

2.4 OUTPUTS ....................................................... 2-4

2.4.1 SETPOINTS ..............................................2-5

2.4.1.1 Adding Setpoints ................................... 2-5

2.4.1.2 Erasing Setpoints ................................... 2-6

2.4.1.3 Editing Setpoints ................................... 2-6

2.4.1.4 Timed Outputs ..................................... 2-7

2.4.1.5 Speed Advanced Outputs ............................. 2-7

2.4.1.6 Incrementing Setpoints .............................. 2-8

2.4.2 VIEW STATUS ........................................... 2-8

2.4.3 COUNTED OUTPUTS ..................................... 2-8

2.4.3.1 Counted Outputs, VIEW SETUP ....................... 2-9

2.4.3.2 Counted Outputs, EDIT SETUP ....................... 2-9

2.4.3.3 CHANNELS ..................................... 2-10

2.4.3.4 COUNT ......................................... 2-11

2.4.3.5 ACTIVE COUNT ................................. 2-11

2.4.3.6 COUNT ANGLE .................................. 2-11

2.5 CONFIGURE .................................................... 2-12

2.5.1 Configure Access Code Screen and Menu ...................... 2-12

2.5.2 MOTION DETECTOR ..................................... 2-13

2.5.3 TOPSTOP ............................................... 2-14

2.5.4 TOPSTOP SPEED ADVANCE .............................. 2-15

System 2500 Operating & Installation Manual - Revision 07 i

Page 3

2.5.5 RESTRICTED CHANNELS ................................ 2-16

2.5.6 OFFSET ................................................ 2-17

2.5.7 PLS OUTPUT SPEED ADVANCE ........................... 2-17

2.6 COUNTERS .................................................... 2-18

2.6.1 PART Counter ........................................... 2-19

2.6.2 BATCH Counter .......................................... 2-19

2.6.3 QUALITY Counter ........................................ 2-20

2.6.4 STROKE Counter ......................................... 2-20

2.7 STORE/RECALL ................................................ 2-20

2.7.1 STORE ................................................. 2-21

2.7.1.1 Store Setup, USE THIS NAME ....................... 2-22

2.7.1.2 Store Setup, ENTER NEW NAME .................... 2-22

2.7.1.3 Memory Limits ...................................2-23

2.7.2 RECALL ................................................ 2-23

2.7.2.1 Recall Setup, ENTER SETUP NAME ................. 2-24

2.7.2.2 Recall Setup, VIEW NAMES ........................ 2-25

2.7.3 REMOVE ............................................... 2-25

2.8 DIE-PROT (Die Protection) ......................................... 2-26

2.8.1 DIE-PRO INPUTS ........................................ 2-26

2.8.1.1 EDIT INPUT MODE ............................... 2-27

2.8.1.2 VIEW STATUS ................................... 2-27

2.8.1.3 VIEW CHANGE .................................. 2-27

2.8.2 DIE-PRO ON/OFF ........................................ 2-28

2.8.2.1 Die Protection On/Off Status ......................... 2-28

2.8.2.2 Die Protection Lock Status ..........................2-29

2.8.3 TIMING CHANNELS ..................................... 2-30

2.8.3.1 SETPOINTS (for Timing Channels) ................... 2-30

2.8.3.2 VIEW STATUS (for Timing Channels) ................ 2-31

2.8.4 AUTO SS (Automatic Single Stroke) .......................... 2-31

2.8.4.1 Auto SS Programming Requirements ..................2-32

2.8.4.2 Auto SS Hardware Setup ............................ 2-33

2.8.4.3 Auto SS Status Screen and Menu .....................2-34

2.8.4.4 AUTO SS ON/OFF ................................ 2-35

2.8.4.5 MIN DELAY TIME ................................2-36

2.8.4.6 1ST STROKE TIME ............................... 2-36

2.8.4.7 MAX DELAY TIME ............................... 2-36

2.9 Die Protection Modes of Operation ................................... 2-37

2.9.1 STATIC ................................................. 2-37

2.9.2 CYCLIC ................................................ 2-39

2.9.3 TRACK ................................................. 2-41

2.9.4 TRANSFER ............................................. 2-41

2.9.5 IN POSITION ............................................ 2-42

2.9.6 1 PART ................................................. 2-43

System 2500 Operating & Installation Manual - Revision 07ii

Page 4

2.9.7 2 PART ................................................. 2-45

2.10 STOPS/FAULTS ................................................ 2-46

Section 3 OUTPUTS

3.1 Relay Outputs ..................................................... 3-1

3.2 DC Solid State Outputs ............................................. 3-1

3.3 AC Solid State Outputs ............................................. 3-1

Section 4 INSTALLATION

4.1 Component Mounting .............................................. 4-1

4.2 Wiring .......................................................... 4-4

4.3 Checkout and Start-up .............................................. 4-8

Section 5 ERROR CODES

5.1 Error Listing ...................................................... 5-1

System 2500 Operating & Installation Manual - Revision 07 iii

Page 5

Section 1 OVERVIEW OF THE SYSTEM 2500

1.1 Features

The System 2500 has 8 or 16 channel output capability for Programmable Limit Switch

functions.

Relay, solid state AC, and solid state DC outputs are available.

Multilevel programming security is provided so that fixed setpoints or special access can

be provided on the first 8 output channels.

Timed outputs up to 2 seconds in duration and speed advanced outputs are programmed

through the keyboard.

System 2500 PLS outputs 1 through 8 may be programmed so that they actuate only on

certain machine strokes.

The Die Protection function of the System 2500 has 8 inputs available to the operator for

use with die sensors and probes. These inputs may be used to monitor part ejection, stock

in place, material in position, stock buckling, end of stock, or other factors.

Each die protection input can be programmed for any of the following modes: Static,

Cyclic, Tracking, Transfer, In Position, Single Part detection or Two Part detection. A

special option of Cyclic mode enables the operator to activate a PLS output in the event

of die protection fault on this Cyclic input. This can be used for ejection of bad parts off

an assembly line or similar applications.

Eight internal timing channels are provided so that the operator can create timing

sequences for Cyclic, Transfer, In Position, and Part Detector modes.

The operator can select an output of either Emergency Stop (immediate stop) or Top Stop

for each die protection input monitored.

The System 2500 includes outputs for providing power to external die protection sensors

and also includes a separate power source for Link Model 3040 and 3080 parts detector

units.

As an option, the unit can be programmed to use the die protection inputs and the PLS

output relays in conjunction with an external control package to provide a complete

system for implementing the Automatic Single Stroke function.

System 2500 Operating & Installation Manual - Revision 07 1-1

Page 6

A stroke counter and presettable batch counter, parts counter, and quality check counter

are standard.

One hundred setups can be stored in nonvolatile memory and recalled by job number or

name. Each setup can contain as many as 60 setpoints or dwell times for PLS outputs

along with complete programming information for each die protection input.

A sturdy, compact single resolver unit is used by the System 2500 as position transducer.

Motion Detection to detect resolver de-coupling from the machine shaft is standard.

Programmable offset capability to align resolver zero with machine zero is standard.

The Operator Interface Terminal (OIT) includes user friendly keyboard programming

with LCD display menus and prompting.

The System 2500 PLS displays angle and speed in 1 degree and 1 rpm increments.

The System 2500 PLS can operate at speeds up to 2000 rpm with solid state outputs.

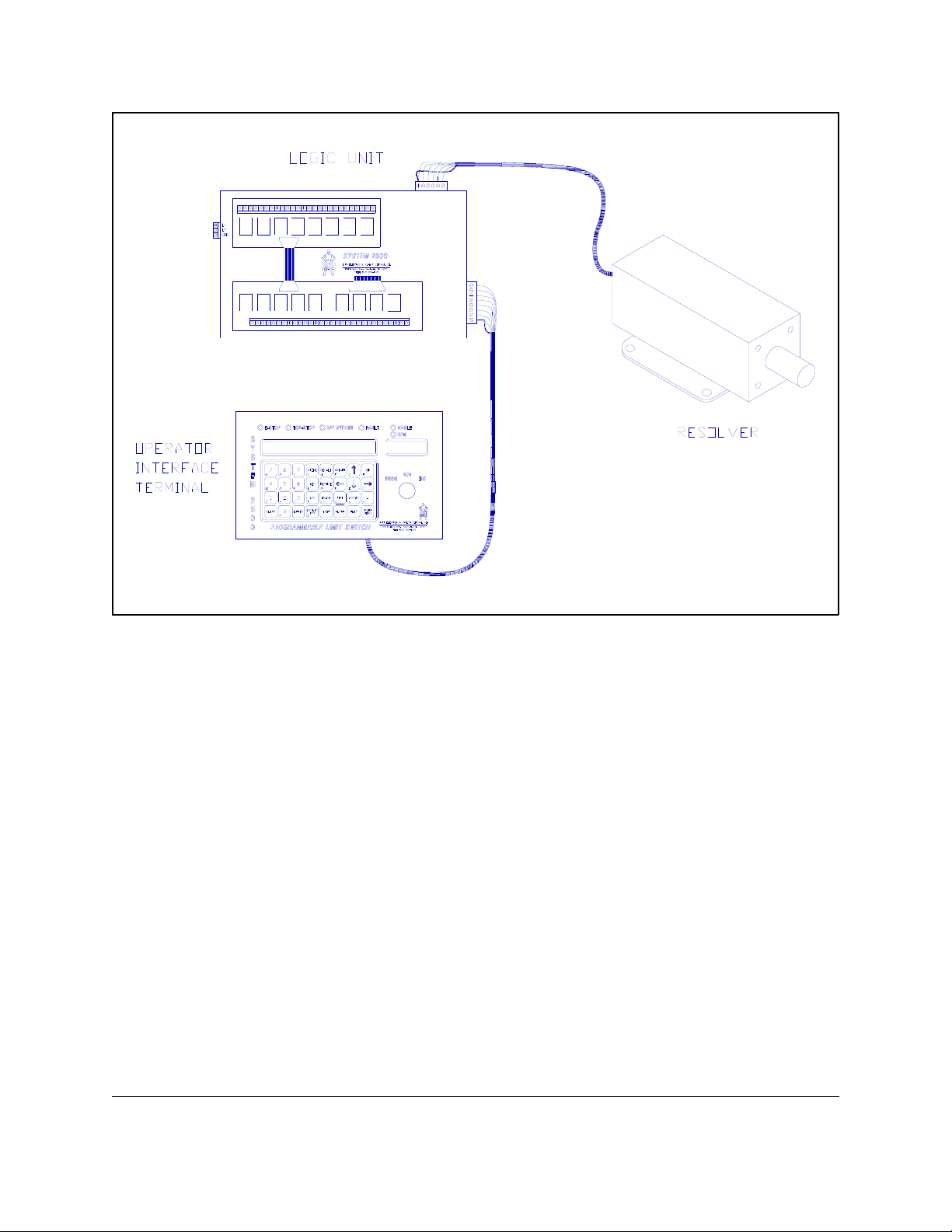

1.2 Components

The System 2500 consists of three major components interconnected by cabling (see Figure 1).

These components are:

C Logic Unit - This is the primary component of the system which contains the

power supply and most of the electronic circuitry. Connections are provided on

the Logic Unit for wiring both the outputs (such as limit switch relay contacts)

and inputs (such as the die protection sensors).

C Operator Interface Terminal (OIT) - This component is a panel mounted unit

consisting of a keyboard and two displays. The OIT allows the operator to

program the System 2500.

C Resolver Unit - This is the position transducer for the system. It mounts on the

machine and is coupled to the crankshaft. The Resolver Unit reads the crankshaft

position and provides it to the Logic Unit.

System 2500 Operating & Installation Manual - Revision 071-2

Page 7

Figure 1

System 2500 Components

1.3 Specifications

Input Ratings

Primary Input Power Requirements: 115VAC ± 15VAC, 60Hz, 1 Ampere

Run Signal Input (Terminals 34 & 35): 115VAC @ 10mA nominal

or 24VDC @ 2mA nominal

Die Protection Inputs and Auto SS Input: Inputs are active low (ground); to activate,

external circuit must sink 0.6mA (typical),

1.2mA (maximum)

Output Ratings

28VAC Output: 450mA maximum

+12VDC Output (for sensors): 100mA maximum

System 2500 Operating & Installation Manual - Revision 07 1-3

Page 8

Switching Output Ratings

Electromechanical Relay Outputs: 5.0 Amperes @ 120VAC or 24VDC

AC Solid State Relay Outputs: 1.5 Amperes @ 240VAC

DC Solid State Relay Outputs: 3.0 Amperes @ 60VDC

General

Response Time, Die Protection

(static type, time from input change to E-Stop

relay contacts open): 25mS (typical), 33mS (maximum)

Response Time, Die Protection

(cycling type, time from window position

passed to E-Stop relay contacts open): 20mS (typical), 28mS (maximum)

Pulse width recognized by N.O. die protection

input (low pulse): 1mS minimum

Pulse width recognized by N.C. die protection

input (high pulse): 9mS minimum

Maximum Operating Speed: 2000 SPM

Maximum Ambient Temperature: 45°C (113F°)

System 2500 Operating & Installation Manual - Revision 071-4

Page 9

Section 2 OPERATION

2.1 Using the Operator Interface Terminal

The OIT is the means by which the operator can control the operation of the System 2500. The

following features should be noted on the terminal:

C A large LCD (liquid crystal display) for messages

C Keyboard consisting of 32 keys

C A four digit LED display (red characters in the upper right hand corner)

C Mode Selector Keyswitch (lower right corner)

C Six individual status indicators: E-STOP, TOP-STOP, D/P BYPASS, FAULT,

ANGLE, and RPM

The operator should familiarize himself with these features since they will be referred to

frequently in the instructions following.

2.1.1 Keyboard Use

The leftmost portion of the keyboard is a set of numerical keys for entering data when

programming. The remaining keys are function keys which cause some action to occur when

pressed in the proper sequence. Some of the function keys are for general use and their functions

are always active. These are listed in the description following. The keyboard is illustrated on

the foldout in the back of this manual. This foldout should be referred to during the description

of keyboard use.

2.1.1.1 ANGLE/RPM Key

The four digit red display is intended to continuously display crankshaft angle or speed. The

angle is being displayed if the ANGLE light above the four digit red display is lit. The speed in

revolutions per minute (rpm) is being displayed if the RPM light above the four digit red display

is lit. The operator may alternate between angle and rpm by pressing the ANGLE/RPM key.

NOTE: The four digit display is also used to display error codes. When an error code is

being displayed, the angle and speed cannot be viewed. The error must first be cleared

with the CLEAR key.

System 2500 Operating & Installation Manual - Revision 07 2-1

Page 10

2.1.1.2 HELP Key

The operator may request a Help screen from the System 2500 PLS by pressing the HELP key.

The Help screens are intended to aid the operator by giving additional information and

explanation of the current stage of the program sequence. Some Help screens may be more than

two lines long. If the last character on the screen is a down arrow, more help information is

available. The operator may press the down arrow key to view the additional lines. The operator

may terminate a help screen and return to the program at any time by pressing the EXIT key. If

no help screen is available for the present program sequence, a message will inform the operator

that a help screen is not available.

2.1.1.3 CLEAR Key

The CLEAR key is used for two main functions. The first function is to remove any data input in

progress. If the operator keys in the wrong data but has not yet pressed the ENTER key, he may

press the CLEAR key to remove the entire data input. The correct data may then be keyed in.

The CLEAR key cannot remove any data once it has been en tered with the ENTER key.

The second function of the CLEAR key is to remove stops and faults. If a counter reaches its

programmed limit and stops the machine, the CLEAR key may be pressed to reset the counter

and allow the machine to be restarted. If a system fault occurs (such as a die protection fault),

once the cause of the fault has been corrected the error condition can be removed by pressing the

CLEAR key.

2.1.1.4 BRIGHT and DIM Keys

The intensity of the 80 character liquid crystal display can be varied by using the BRIGHT or

DIM keys. Pressing the BRIGHT key will increase the intensity of the display. If additional

brightness is required, the bright key must be released and pressed again. The DIM key is used to

decrease the brightn ess of the display.

2.1.1.5 MAIN MENU Key

If at any time during the programming procedure the MAIN MENU key is pressed (lower right

corner of keyboard) the Main Menu will be immediately displayed. This menu is the starting

point for all programming of the unit. (See Section 2.2 for more information on the menu

approach of the System 2500). NOTE: The MAIN MENU key will not cause the Main Menu to

display if there is a communication failure between the OIT and Logic Unit.

2.1.2 Mode Selector Keyswitch

System 2500 Operating & Installation Manual - Revision 072-2

Page 11

The Mode Selector is a three position keyswitch. The key may only be removed in the RUN

position. The operating conditions for the three positions are as follows:

C RUN - This is the normal operating mode of the System 2500. When the key is in

this position, the operator can only view limit switch setpoints or the die

protection input modes. He cannot add, erase, or edit PLS setpoints in this

position, nor can he edit the die protection setup. There is no E-Stop issued by the

System 2500 in this mode unless an error condition is present.

C PROG - This is the program mode of the System 2500. When the key is in this

position limit switch setpoints can be added, erased, or edited; Die-Protection can

be edited; and setups can be stored to memory or recalled from memory. An

E-Stop is always

motion while programming.

issued by the System 2500 in this mode to prevent machine

C INC - This is the increment mode of the System 2500. When the key is in this

position, PLS setpoints can be increased or decreased by one degree at a time. An

E-Stop is not issued by the System 2500. The increment mode allows the operator

to fine tune PLS setpoints while the machine is in operation.

2.2 Menu Selection Using the LCD

The LCD (liquid crystal display, in the center of the OIT) provides the operator with information

needed to program the unit. This is done by displaying a menu (list of choices) and allowing the

operator to select one of the menu items. On each menu one of the choices listed will be

blinking. The blinking effect is called the cursor

operator has selected. The cursor can be moved to a different choice on the menu using the

arrow keys (see the figure on the foldout in the back of the manual). Once the cursor is on the

item desired, the operator can press the ENTER key to get further information about that item.

The operator is not required to memorize any function names or keyboard entry sequences.

2.2.1 Main Menu

The main menu is the first list of options offered to the operator during programming of the

System 2500. There are five major functions from which to choose:

and is used to identify which item on the list the

C PLS - (Programmable Limit Switch) This is the function of the unit wherein the

output relays can be programmed to switch on or off at specified points of the

machine cycle.

C COUNTERS - There are three user presettable counters in the System 2500 which

System 2500 Operating & Installation Manual - Revision 07 2-3

Page 12

can be accessed by selecting this function. The total stroke count of the machine

as seen by the unit can also be displayed here.

C STORE/RECALL - With the System 2500 a particular setup (which includes both

limit switch and die protection settings) can be stored under a name or number

and recalled at a later time. This saves the operator from having to re-enter

different settings each time a die is changed.

C DIE-PROT - (Die Protection) In this function, inputs to the System 2500 which

are wired to appropriate die sensors can be programmed to detect fault conditions

related to the die and stop the machine before damage occurs.

C STOPS/FAULTS - This function allows the operator to view explanations of Top

Stop and Emergency Stop conditions when these conditions occur.

To select any of the above functions the operator must move the cursor to the desired function

using the arrow keys, then press the ENTER key.

2.3 Programmable Limit Switch (PLS) Functions

The Programmable Limit Switch functions are accessed by pressing the ENTER key while the

cursor is on PLS in the Main Menu. After pressing the ENTER key, the LCD will display the

PLS Menu. This menu has two options from which to choose:

C OUTPUTS - This choice will allow the operator to program the relay outputs of

the System 2500. Pressing the ENTER key with the cursor on OUTPUTS will

cause the Outputs Menu to be displayed. The options available from the Outputs

Menu are described in Section 2.4.

C CONFIGURE - This selection allows the operator to program certain information

that enables the System 2500 to operate properly with the machine on which it is

installed. This includes detecting motion of the machine crankshaft, setting the

resolver zero point when the crankshaft is at zero position, etc. Further

instructions for programming the configuration data are described in Section 2.5.

To select either of the above functions the operator must move the cursor to the desired function

using the arrow keys, then press the ENTER key.

2.4 OUTPUTS

The Outputs Menu gives the operator three choices for programming or monitoring the status of

System 2500 Operating & Installation Manual - Revision 072-4

Page 13

the output relays on the System 2500. These choices are as follows:

C SETPOINTS - This option allows the operator to program the output relays to turn

on or off at different points in the machine stroke (referred to as the 'setpoints' of

an output channel). This function is described in Section 2.4.1.

C VIEW STATUS - Choosing this option will produce a display which indicates the

on/off status of the output relays, in groups of 8. This function is described in

Section 2.4.2.

C COUNTED OUTPUTS - This menu option gives the operator an opportunity to

program any of outputs 1 through 8 so that they are tied to a counter. This means

that these outputs can be programmed to be active only on every other stroke, or

every third stroke, or every fourth stroke, etc. This is useful for operations which

should take place on a periodic basis but not on every stroke. The procedure for

setting up outputs in this way is described in Section 2.4.3.

To select any of the above functions the operator must move the cursor to the desired function

using the arrow keys, then press the ENTER key.

2.4.1 SETPOINTS

Selection of the SETPOINTS item from the Outputs Menu will allow the operator to view and

modify the setpoints of the individual limit switch channels. These setpoints are the crankshaft

angles at which the corresponding output relay will turn on or off. If the mode selector keyswitch

is in the RUN position, the setpoints can only be viewed. If the keyswitch is in the PROG

(Program) position, setpoints can be added, erased, or edited. If the keyswitch is in the INC

(Increment) position, individual setpoints can be incremented or decremented in one degree

increments.

The operator must enter the number of the channel he wishes to view by keying in a valid

channel number and pressing the ENTER key. Valid channel numbers are 1 thru 16. Once a

particular channel is displayed, the operator may view other channels by using the up and down

arrow keys.

If the channel contains more than two setpoint pairs, the operator can use the left and right arrow

keys to view the other setpoint pairs. When a channel contains no setpoints, a message stating

that no setpoints are programmed will be displayed and the channel output will always be off.

2.4.1.1 Adding Setpoints

To add a setpoint pair the operator must select the desired channel and press the ADD key.

System 2500 Operating & Installation Manual - Revision 07 2-5

Page 14

Setpoints can only be added when the mode keyswitch is in the PROG (Program) position. The

on and off points must then be entered as instructed. If incorrect data is keyed in, the CLEAR

key will remove the entire line and the correct data can then be entered. The CLEAR key cannot

be used once the ENTER key has been pressed to store the data. Once this has been done the

setpoints must be erased or edited.

If a channel is restricted no setpoints can be added. An 'R' will appear in the display beside the

channel number when this is the case. See Section 2.5.5 for more information on restricting

channels.

If necessary, more than one setpoint pair can be added on any channel to turn the output on and

off more than once in a machine stroke. When doing so, the setpoint pairs must be programmed

so that they switch on and off in alternating sequence; that is, the angles entered cannot be in

such an order so that two on points occur in succession followed by two off points. A warning

message will occur if programmi ng is attempted in this way.

Additionally, certain situations prevent the operator from programming more than one on/off pair

on a channel. Only one setpoint pair is allowed on an output which is to be speed advanced (see

Section 2.4.1.5). Attempting to add a second setpoint pair to a channel having advanced

setpoints will produce an error message. Also, if an output channel is being used as the special

assigned stop output for a Cyclic Die-Protection fault (see Section 2.9.2), or if the channel is tied

to the counter (Section 2.4.3), then only one setpoint pair can be programmed. A message will

be displayed signifying either of these last two conditions.

If the unit is programmed for Automatic Single Stroke operation, on/off setpoints cannot be

programmed on channels 7 or 8. During Auto Single Stroke the unit takes control of these

outputs and turns them on and off as required for proper operation (see Section 2.8.4).

WARNING: PLS OUTPUTS OF THE SYSTEM 2500 ARE NOT TO BE USED AS THE

PRIMARY INPUTS TO A PRESS CONTROL.

2.4.1.2 Erasing Setpoints

With the keyswitch in the PROG mode, setpoint pairs can be erased with the ERASE key. The

operator must select either the on or off setpoint of the pair to be erased. To select the setpoint

the operator must use the right or left arrow keys. When either the on or off setpoint of the pair

to be removed is blinking, the ERASE key must be pressed. A message will be displayed asking

the operator to confirm the pair to be erased. If the correct pair has been selected the operator

must again press the ERASE key. If the incorrect pair has been selected, the operator may press

any key other than the ERASE key to abort the erase operation.

If a channel is restricted no setpoints can be erased. An 'R' will appear in the display beside the

channel number when this is the case. See Section 2.5.5 for more information on restricting

System 2500 Operating & Installation Manual - Revision 072-6

Page 15

channels.

2.4.1.3 Editing Setpoints

To edit an on or off setpoint, the operator must first place the mode selector keyswitch in the

PROG mode. Then the setpoint to be modified must be selected with the right or left arrow keys.

When the setpoint to be modifi ed is b linking, the operator may key in the new setpoint value. If

a mistake is made in keying in the data, the CLEAR key may be pressed to clear the data. Also,

to discontinue editing without making any changes, the EXIT key can be pressed which will

redisplay the original setpoint value. Once the new setpoint is keyed in as desired the ENTER

key must be pressed. The operator is then asked to confirm the change by pressing the YES key.

If the operator does not want to confirm the change, he may press any key other than the YES key

and the entire data entry sequence will be canceled.

If the operator desires to modify a setpoint that is not speed advanced so that it will be speed

advanced, he must move the cursor to that setpoint and press the ADVAN key. Only one

setpoint pair can be programmed on a channel if one of the setpoints is to be advanced (see

Section 2.4.1.5 for information on Speed Advanced Outputs). A message will then be displayed

asking the operator to confirm that the setpoint should be changed to a speed advanced setpoint.

The YES key should be pressed to proceed with the change, or any other key to cancel the

change.

If a channel is restricted its setpoints cannot be edited. An 'R' will appear in the display beside

the channel number when this is the case. See Section 2.5.5 for more information on restricting

channels.

2.4.1.4 Timed Outputs

Channels 1 thru 8 can be programmed as timed outputs. A timed output will come on at the

angle of the on setpoint, and will turn off after the programmed dwell time. To add a timed

output, the operator must follow the steps of section 2.4.1.1, except the TIME key must be

pressed before entering the off setpoint. The dwell time must then be entered. Allowable dwell

times are from 2 to 2046 milliseconds (a millisecond is 1/1000 of a second). The System 2500

PLS will only store even number dwell times. If an odd dwell time is entered, it will be rounded

up to the next even number. A maximum of 5 timed outputs is allowed.

2.4.1.5 Speed Advanced Outputs

On PLS channels 1 thru 8, either the on or off setpoint or both setpoints of a setpoint pair can be

speed advanced. If a setpoint is advanced, its value is decreased as the machine speed is

increased. This means that the setpoint will occur earlier in the cycle to compensate for the

increased speed. To speed advance an output the operator must first determine the setpoints

System 2500 Operating & Installation Manual - Revision 07 2-7

Page 16

necessary for proper actuation of the output at maximum speed and at minimum speed (see

Section 2.5.7 for a description of this procedure). The setpoint value should be left programmed

at the correct setting for minimum

status, by pressing the ADVAN key while the cursor is on the setpoint. The screen will then ask

the operator to confirm that the setpoint is to be advanced. Pressing the YES key at this point

will program that setpoint as advanced and the 'A' label will appear beside the setpoint as an

indicator.

Configuration of the PLS Output Speed Advance is necessary for speed advanced outputs to

function properly (see Section 2.5.7). The System 2500 PLS will calculate a speed advance

constant from data entered for PLS Output Speed Advance in the configuration menu. The speed

advance constant will then be used to adjust the setpoint angle of advanced setpoints as machine

speed changes.

Note that once the data in the configuration menu is programmed, it should not be reprogrammed

if the operator later chooses to advance another setpoint. All future setpoints programmed as

advanced will use the speed advance constant already programmed. For later setpoints

programmed as advanced it will not be necessary to test at maximum speed. For these setpoints

it will only be necessary to enter the angle for proper operation at minimum speed and then edit

the setpoint to advanced.

speed. The setpoint should then be edited to 'Advanced'

If a channel is to be programmed with advanced setpoints and the correct setpoints are already

known, the setpoints can be directly programmed as advanced (rather than editing them to

advanced status after they have been programmed). To program a setpoint angle to be speed

advanced, the steps of section 2.4.1.1 must be followed to program the channel, except that the

ADVAN key must be pressed after the angle is keyed in and before the ENTER key is pressed.

Only one setpoint pair can be programmed on an output channel using Speed Advance.

2.4.1.6 Incrementing Setpoints

Individual on or off setpoints can be fine tuned by using the Increment mode. To use this mode

the keyswitch must be in the INC position. When in the increment mode, the System 2500 does

not generate an E-Stop. Since no E-Stop is generated, this mode allows adjustment of a setpoint

while the machine is running. To adjust a setpoint the operator must first select the channel and

then move the cursor to the on or off setpoint to be adjusted. When the desired setpoint is

blinking, the operator must press the up or down arrow keys to increase or decrease the setpoint

value, respectively. In many cases, the arrow key will have to be pressed more than once to

change the setpoint by one degree (the setpoint changes by only a fraction of a degree each time

the key is pressed).

2.4.2 VIEW STATUS

System 2500 Operating & Installation Manual - Revision 072-8

Page 17

If the VIEW STATUS item is selected from the Outputs Menu, the OUTPUT STATUS screen

will be displayed. This screen indicates for each of the first eight outputs whether the output is

on or off. This information can be useful when first setting up the unit on the machine or when

troubleshooting. On the far right of the display is the down arrow symbol, which indicates that

by pressing the DOWN arrow key the status for outputs 9 through 16 will be displayed.

Remember that outputs 9 through 16 can be programmed and the change in their on/off status

observed on this screen at any time, but for any external action to occur there must be a second

relay output board installed for relays 9 through 16.

2.4.3 COUNTED OUTPUTS

By pressing the ENTER key while the cursor is on COUNTED OUTPUTS in the Outputs Menu,

the operator can access a special function for PLS outputs 1 through 8 which allows them to be

tied to a counter. This is a separate counter for this function only and is not related to the Part,

Batch, Quality Check, or Stroke counters of the System 2500 (see Section 2.6). The purpose of

the Counted Outputs function is to allow a PLS output to be programmed in the fol lowing way:

1. The output is held off for a certain number of strokes regardless of its

programmed setpoints.

2. The output becomes active for one stroke so that its on/off setpoints cause the

output relay to switch.

3. The cycle of steps 1 and 2 is repeated.

The effect is that the output becomes active for one stroke every five strokes, or every eight

strokes, etc. depending on the count that the operator programs. This is useful for programming

some special action such as a scrap chopper which only becomes active after several machine

strokes have been made.

The first screen displayed for this function is the Counted Outputs Menu. It offers the following

choices:

C VIEW SETUP - Allows the operator to see which channels are tied to the counter

and the present stroke count.

C EDIT SETUP - Allows the operator to tie a PLS channel to the counter or remove

a channel from being tied to the counter. Also allows change of the present

counter value and which stroke count will activate the outputs.

To select either of the above functions the operator must move the cursor to the desired function

using the arrow keys, then press the ENTER key.

System 2500 Operating & Installation Manual - Revision 07 2-9

Page 18

2.4.3.1 Counted Outputs, VIEW SETUP

When VIEW SETUP is selected from the Counted Outputs Menu, the operator will see a list of

the outputs which are tied to the counter. Also shown is the stroke count on which these outputs

will be active and the current stroke count of the machine. (Remember that this is a special

cycling counter and is NOT the same as the Part, Batch, Quality Check, or Total Stroke counters

of the System 2500. See Section 2.6 for information regarding these counters). This information

is important since outputs tied to the counter will NOT be active on every stroke. The operator

or maintenance personnel may need to know why a certain PLS output is not on during its

programmed on portion of the stroke. By viewing this screen the operator will know when the

counter-tied outputs will be active.

2.4.3.2 Counted Outputs, EDIT SETUP

In order to program the necessary information to use the Counted Outputs function, the operator

must select EDIT SETUP from the Counted Outputs Menu. Prior to doing this, the keyswitch

must be placed in the PROG position. If EDIT SETUP is selected with the keyswitch in another

position an error message will appear. After EDIT SETUP is selected, the operator will be asked

to enter a special access code to proceed. This is the same code that is required to enter the

Configure Menu (see Section 2.5). The code is printed on the back page of this manual. It is

suggested that this code be given to qualified users only. If the keyswitch is turned to a position

other than PROG while the Counted Outputs setup is being edited, the error message will appear

and the operator will have to re-enter the access code. Through the keyswitch and access code

protection any undesired changes to this special function of the PLS outputs are prevented.

Once the access code has been properly entered the display will contain all the information

required for the Counted Outputs function. The following will be displayed:

C CHANNELS - A list of the PLS output channels which are presently tied to the

counter.

C COUNT - The present stroke count of the machine (as pertains to this function).

When this count is the same as the ACTIVE COUNT, the PLS outputs listed

beside CHANNELS will be active for one stroke.

C ACTIVE COUNT - The stroke count at which the PLS outputs tied to the counter

will become active. On this stroke count the PLS outputs listed beside

CHANNELS will follow the on/off setpoints that have been programmed for each

output. Until the count is reached, these outputs will always be off.

C COUNT ANGLE - The crankshaft angle at which the counter will count up, i.e.

the place in the stroke where the COUNT value on this screen will change.

System 2500 Operating & Installation Manual - Revision 072-10

Page 19

2.4.3.3 CHANNELS

If the operator wishes to tie a PLS output to the special counter, the ADD key must be pressed.

After this key is pressed, the display will prompt for entry of the channel to be added. PLS

channels 1 through 8 may be tied to the counter. Key in the desired channel number and press

ENTER. The display will then return to the Counted Outputs setup information screen with the

new PLS channel number added to the list.

Any channel to be tied to the counter can have only one setpoint pair programmed (one 'on'

setpoint and one 'off' setpoint). Additionally, the channel cannot be one that is already used as

the assigned output for a Die-Prot Cyclic fault. If the unit is set up for Auto Single Stroke

operation, outputs 7 and 8 cannot be tied to the counter. Attempting to add any channel

previously programmed as described here will cause an error message to appear.

To remove a PLS output from being tied to the counter, the operator must first press the

REMOVE key. The LCD will then request the number of the channel to be removed. Key in the

channel number and press ENTER. The display will then return to the Counted Outputs setup

information screen with this channel number deleted from the list. Remember that removing an

output from being tied to the counter means that the output will no longer be held off until the

active stroke, but will now be active on every stroke. If this is not desirable the operator may

turn the output off by erasing its setpoints (see Section 2.4.1.2).

Any channel that has been restricted previously cannot be tied to the counter nor removed from

being tied to the counter. Any unrestricted channel that has been tied to the counter can then be

restricted to prevent any further changes.

2.4.3.4 COUNT

When setting up outputs that are tied to the counter, the operator may find it necessary to adjust

the count that the machine is presently on to make the outputs become active on the proper

stroke. To do so the operator must use the arrow keys to move the cursor to the current count

value (upper right corner), then key in new value and press ENTER. For example, suppose the

press has a repeating five stroke sequence where certain PLS outputs are to become active on the

fifth stroke. If during setup of this function the press is mechanically two strokes away from the

stroke where the PLS outputs are to be active, then the operator should enter the number 3 for the

present COUNT.

2.4.3.5 ACTIVE COUNT

The ACTIVE COUNT is, as the name implies, the stroke count on which the PLS outputs tied to

the counter are to become active for one stroke. The ACTIVE COUNT is the maximum value

that the counter will reach; in other words, as the press strokes the COUNT will increase until the

ACTIVE COUNT value is reached and on the next stroke the COUNT will start over at 1. To

System 2500 Operating & Installation Manual - Revision 07 2-11

Page 20

change the ACTIVE COUNT, use the arrow keys to move the cursor to the ACTIVE COUNT

value then key in a new value and press ENTER. For example, if the outputs tied to the counter

should only be active every five strokes (make four strokes with these outputs OFF then one

stroke where the outputs switch normally), enter the number 5 for ACTIVE COUNT. If the

outputs should be active every eight strokes, enter the number 8 for ACTIVE COUNT. The

maximum ACTIVE COUNT value that can be entered is 255.

Remember also that the correct stroke in the cycle that the machine is presently on should be

entered beside COUNT on this screen (see Section 2.4.3.4). This must be done to insure that the

sequencing is correct.

2.4.3.6 COUNT ANGLE

The count angle is the crankshaft angle where the counter will change. To change the count

angle move the cursor to COUNT ANGLE using the arrow keys then key in a new angle (0 to

359 degrees) and press ENTER. In most cases this angle can be set at zero degrees (top of

stroke). However, if the die setup is such that a PLS output must be ON through zero degrees

during the active stroke, the count angle can be set to another value. The reason for this is that it

is not desirable to have the count angle change while the PLS outputs are programmed to be ON.

If this occurs, as soon as the count changes to the active count all PLS outputs tied to the counter

will immediately turn on. Likewise, when the count changes from the active count back to 1, all

PLS outputs tied to the counter will immediately turn off. It is more desirable to have the counter

change at a point in the stroke where all PLS outputs tied to the counter are programmed to be off

so that the change in count will not immediately affect those outputs.

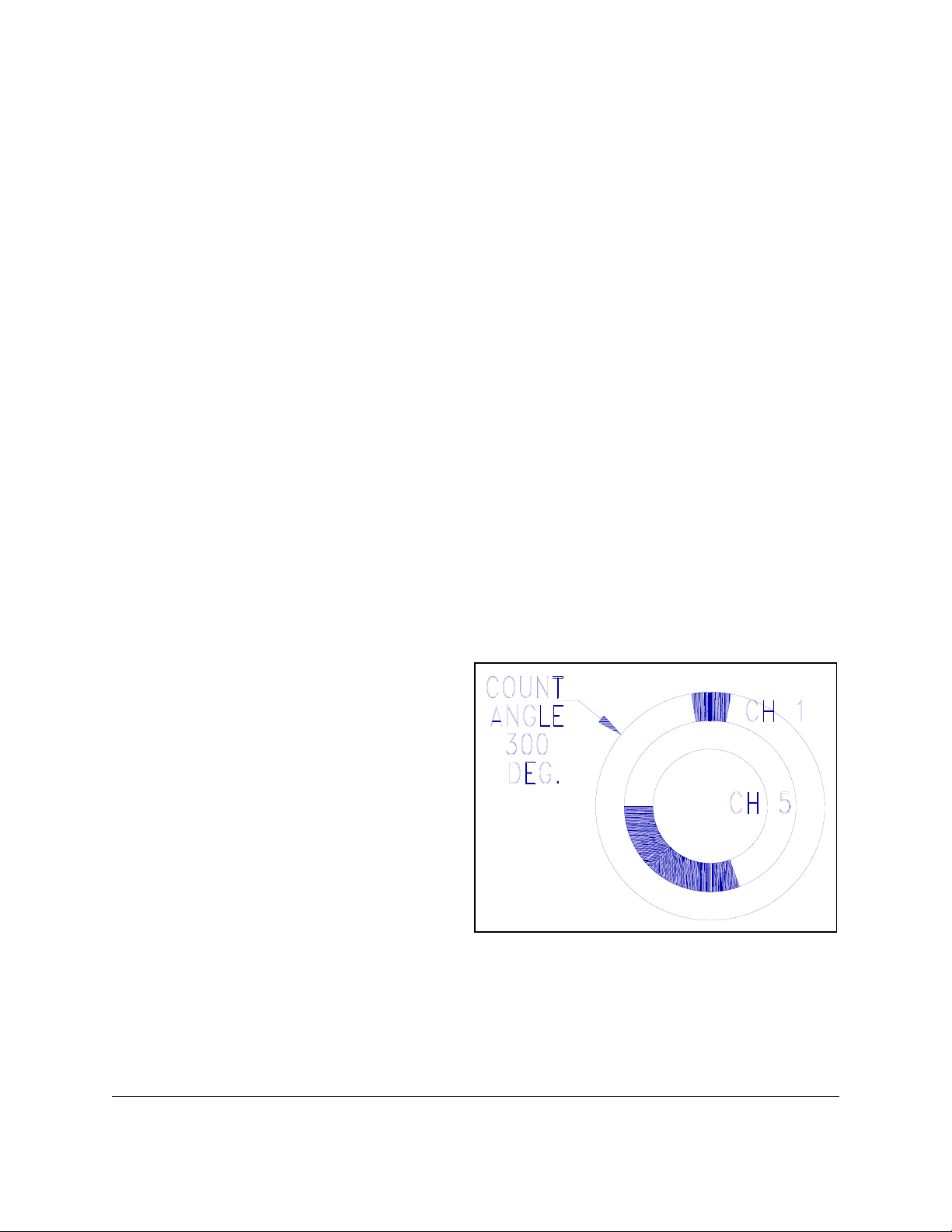

Example: (See Figure 2) PLS output

channels 1 and 5 are tied to the counter.

During the active stroke, channel 1 is to turn

on at 350 degrees and turn off at 10 degrees.

Channel 5 is to turn on at 160 degrees and

turn off at 270 degrees. In this case it would

be better to change the COUNT ANGLE

from 0 degrees to 300 degrees, since at this

point in the stroke channels 1 and 5 are both

off. In this way, the count will change to the

active count at 300 degrees; both output

channels can turn on and off properly at their

programmed setpoints; then when 300

degrees is reached again the counter will

recycle to 1 and the outputs will become

inactive.

System 2500 Operating & Installation Manual - Revision 072-12

Figure 2

Desired Location of Count Angle

Page 21

2.5 CONFIGURE

The Configure routines will allow the operator to program into the System 2500 important

information relating to the machine on which it is installed. The configuration routines can only

be entered with the mode selector keyswitch in the PROG position. Switching the keyswitch

from the PROG position will terminate the configuration routine (except for the special case of

setting TOPSTOP angle - see Section 2.5.3). To access these routines the operator must select

CONFIGURE from the PLS Menu.

2.5.1 Configure Access Code Screen and Menu

Selection of CONFIGURE will display a screen which will ask the operator to enter the

configuration access code. Failure to enter this code correctly will prohibit the operator from

entering the Configure Menu. The access code is printed on the last page of this manual. It is

suggested that the code be given to qualified users only. The Configure Menu allows the

operator to make modifications to the System 2500 PLS setup which can alter the operation of

the unit. Once the Configure Menu has been attained one of the following functions may be

selected:

C MOTION DETECTOR - Provides for entry of data for the internal motion

detector function which verifies that resolver is connected and operat ing p roperly.

C TOPSTOP - Allows entry of the crankshaft angle where a stop signal to the

machine should occur in order for the machine to come to a stop at the top of the

stroke.

C TOPSTOP ADVANCE - Allows entry of the information needed by the System

2500 to advance the TOPSTOP setpoint angle as the crankshaft speed increases.

C RESTRICTED CHANNELS - Allows the operator to add or remove restricted

channels.

C OFFSET - Selection of resolver zero point.

C PLS OUTPUT ADVANCE - Allows entry of the information needed by the

System 2500 to advance PLS setpoints as the crankshaft speed increases.

To select any of the above functions the operator must move the cursor to the desired function

using the arrow keys, then press the ENTER key.

2.5.2 MOTION DETECTOR

System 2500 Operating & Installation Manual - Revision 07 2-13

Page 22

The motion detector is used as a check by the System 2500 PLS to insure that the resolver is

properly wired, the input circuits are functioning, and the resolver is coupled to the machine

crankshaft. The operator must enter three values into the motion detector configuration. These

values are:

C THRESHOLD - This is the crankshaft speed at which the System 2500 will

recognize that the machine is in motion. The speed entered here should be 75% of

the machine's slowest operating speed.

C CLUTCH TIME - This is the time required after the machine control gives the run

signal before crankshaft motion begins (i.e., clutch engagement time). The range

of values that can be entered is 2 to 998 milliseconds. This time should be set to

as small a value as possible.

C MAX SPM - This the maximum machine speed in strokes per minute (SPM).

All data requested by the motion configuration must be entered for the unit to operate properly.

To enter or change any value move the cursor to the desired value, key in the new data and press

ENTER. The System 2500 will accept only even numbers for this data; entry of odd values will

be rounded up to the next even value. Note that if the value entered for MAX SPM is less than

the value entered for THRESHOLD, an error will be generated. To clear the error correct values

must first be entered and then the CLEAR key pressed. Additionally, an error will be generated

if the value entered for MAX SPM is less than the value entered for MINIMUM PRESS SPEED

in the Speed Advance data screen. In this case either the MAX SPM or MINIMUM PRESS

SPEED must be correc ted to i ts p rop er va lue before pressing t he C LEAR key.

The Motion Detector data is used in the following way: When the machine 'RUN' signal

becomes active (terminals 34 and 35) the System 2500 is alerted that the machine has been

commanded to stroke. The unit then expects machine motion (i.e., resolver motion) to occur

within the time limit programmed in CLUTCH TIME. Machine motion is recognized when the

machine crankshaft is turning faster than the speed programmed as THRESHOLD. If the System

2500 PLS does not detect motion at a speed greater than THRESHOLD within the time limit

programmed as CLUTCH TIME, it assumes that a fault has occurred and de-energizes the EStop relay. The MAX SPM data entered is used in other resolver related checks and also in

calculating Speed Advance constants (see Sections 2.5.4 and 2.5.7).

2.5.3 TOPSTOP

Certain functions of the System 2500 can be programmed so that stop conditions will allow the

machine to stop at the top of its stroke rather than cause an immediate stop. The System 2500

accomplishes this by opening the E-Stop relay at the proper angle in the stroke so that the

System 2500 Operating & Installation Manual - Revision 072-14

Page 23

machine will come to a stop at the top. This is called the 'stopping angle' in further text of this

manual. The Topstop selection from the Configure Menu (labeled TOPSTP) allows the operator

to program this angle so that an accurate top stop will occur.

The Topstop configuration display indicates on the top line the angle at which the E-Stop relay

will open when a top stop signal is generated. The bottom line allows the operator to enter a new

angle if required. This configuration step is unique in that the operator may move the keyswitch

to the RUN position so that the top stop accuracy can be tested. When the keyswitch is moved to

the RUN position, E-STOP can be cleared (if no errors exist) and the System 2500 will allow the

machine to run. In addition, the YES key on the OIT will become active as a way to initiate the

top stop. The operator can then make several strokes, press the YES key to cause a top stop, and

note where the machine stops. If the machine does not stop on top, the operator should return the

keyswitch to the PROG position whereupon the display will allow entry of a new stopping angle

(in RUN mode no configuration data can be entered). If the machine went over top, the operator

should enter a smaller angle value (earlier in stroke). If the machine stopped short of top, the

operator should enter a larger angle (later in stroke). After entering a new angle the keyswitch

can be returned to the RUN position to test the stopping point again. (Note that after switching

back to RUN mode it will be necessary to clear the E-Stop condition by pressing the CLEAR

key). By switching between Run and Program modes and entering data, the stopping angle can

be fine tuned to stop the machine on top.

On variable speed machines it will often be desirable to use the speed advance capability of the

System 2500 to automatically adjust the stopping angle as the speed changes. In order for the

Topstop Speed Advance function to work properly its configuration data must be programmed

(see Section 2.5.4). The top stop fine tuning procedure just described can be used to find the

stopping angle of the machine at various speeds so this information can be entered into the

Topstop Speed Advance configuration. Once the Topstop Speed Advance data has been

recorded, the stopping angle itself can then be programmed as 'Advanced' so that the stop signal

will automatically occur earlier in the stroke as the speed increases. If the stopping angle is to be

programmed as advanced, the angle should be left at the setting that was found while the

machine was set for its LOWEST operating speed. This angle should be keyed in on the Topstop

display as before except that the ADVAN key should be pressed before pressing the ENTER key.

The letter 'A' will appear beside the stopping angle to designate that the angle will be advanced.

The ADVAN key should NOT be pressed while different angles are being entered during the fine

tuning process (in other words, the 'A' should not be displayed during the fine tuning process).

If it is desired to return to the Configure Menu for additional programming, be sure that the

keyswitch is in the PROG position before pressing the EXIT key. If the keyswitch is in any

position other than PROG at any step of the Configure routines other than Topstop an error

message will appear. The operator will then have to move the selector switch back to PROG and

re-enter the access code to resume the configuration functions.

System 2500 Operating & Installation Manual - Revision 07 2-15

Page 24

2.5.4 TOPSTOP SPEED ADVANCE

For variable speed machines the operator may program the stopping angle to advance (occur

earlier in the stroke) as the speed increases. For functions which result in a top stop this will

insure that the machine will continue to stop on top as the machine speed increases. In order for

a speed advanced stopping angle to operate properly, the Topstop Speed Advance configuration

data must be programmed (found under the TOPSTP ADVAN selection of the Configuration

Menu). The data values required are the minimum press speed and the stopping angle of the

machine at four different machine speeds. (The stopping angle is the crankshaft angle where a

stop signal must be given in order for the machine to stop at the top of the stroke). This

information must be determined beforehand by the operator using the procedure to be described,

and then entered in the TOPSTP ADVAN selection of the Configure Menu. If the stopping angle

is not to be speed advanced, the operator may skip programming of the Topstop Speed Advance

data.

The stopping angles for the machine can be found using the Topstop function of the Configure

Menu (see Section 2.5.3 for instructions on using Topstop). The System 2500 performs the top

stop function by opening the E-Stop relay at the proper point in the stroke to top stop the press.

By adjusting the angle entered in the TOPSTOP data screen, the machine can be made to stop on

top at the particular press speed chosen. For determining the speed advance constants, the

machine must be run at four different speeds and the correct angle for initiating a top stop must

be found for each speed and then recorded. The four speeds are:

1. Minimum machine speed.

2. Minimum speed plus one-third of the difference between maximum speed and

minimum speed.

3. Minimum speed plus two-thirds of the difference between maximum speed and

minimum speed.

4. Maximum machine speed.

Once the correct angles for initiating a stop at these four speeds have been recorded, the operator

can return to the TOPSTP ADVAN selection of the Configuration Menu to enter the angles.

Choosing TOPSTP ADVAN from the Configure Menu gives the operator access to several data

screens on which the minimum press speed and stopping angles can be entered. The operator can

use the cursor to select a data value, then key in the proper value and press ENTER. When a

'down arrow' symbol is displayed as the last character on the bottom line of the display, this

indicates that another data line is available to the operator by pressing the down arrow key while

the cursor is on the bottom line. In the same way, an 'up arrow' symbol displayed as the last

character on the top line indicates that another data line is available by pressing the up arrow key

System 2500 Operating & Installation Manual - Revision 072-16

Page 25

while the cursor is on the top line. Using the arrow keys the operator can 'scroll' through all the

lines of data that must be entered. (The only exception to data entry is the MAX SPEED shown

on the first screen. MAX SPEED is for display only and cannot be entered on the Topstop Speed

Advance screen. To change the value of MAX SPEED the operator must go to the MOTION

DETECTOR data screen, Section 2.5.2).

All speed advance data must be entered for proper operation. The data must be entered correctly

or an error will be generated. This means that the minimum press speed obviously must be less

than the maximum speed, and for each increasing

decrease (must occur earlier in the stroke). After all data has been entered, programming of

Topstop Speed Advance is complete. Thereafter if the stopping angle has been programmed as

Advanced (see Section 2.5.3), the angle will be adjusted according to this data. As the speed

increases, when a top stop is required the E-Stop relay will actually open earlier in the stroke than

at the Topstop angle that is programmed. Since this function is for advancing

the angle entered for Topstop should be left programmed for proper operation at minimum

machine speed.

2.5.5 RESTRICTED CHANNELS

It may be desired to 'lock' the on/off setpoints on a PLS channel so that they cannot be changed.

In the System 2500 PLS this is called a restricted channel. Channels one thru eight can be

restricted channels. If a channel is restricted, its setpoints cannot be erased or edited nor can any

new setpoints be added. Additionally, a restricted channel cannot be changed with regard to

special functions as follows:

speed value the stop angle programmed must

the stopping angle,

1. Restricted channels cannot be tied to the counter. If a channel previously tied to

the counter is then restricted, it cannot be removed from being tied to the counter

unless the restricted status is removed (see Section 2.4.3.3).

2. Restricted channels cannot be assigned as the special fault output for the Cyclic

mode of Die Protection. If a channel previously assigned as the fault output is

then restricted, the fault output cannot be reassigned to another channel unless the

restricted status is removed from the previously assigned channel (see Section

2.9.2).

3. Channels 7 and 8 cannot be restricted if the unit is configured for Automatic

Single Stroke operation. These output channels are reserved for a special purpose

when Auto Single Stroke is used (see Section 2.8.4).

After selecting RESTRICTED CHANNELS from the Configure Menu, the LCD will display the

list of currently restricted channels. In order to restrict a PLS channel that is not on the list the

operator must press the ADD key, then the channel number desired (1-8), then the ENTER key.

System 2500 Operating & Installation Manual - Revision 07 2-17

Page 26

To remove a PLS channel from the list the operator must press the REMOVE key, then move the

cursor to the channel number desired using the arrow keys. The CLEAR key must then be

pressed to remove the restriction from the chosen channel.

2.5.6 OFFSET

The offset is a value that the System 2500 PLS will add to its resolver reading to make up for the

difference between machine zero position and resolver zero position. The offset value is limited

to + or - 10 degrees. If an offset of greater than + or - 10 degrees is necessary, mechanical

adjustments to the coupling of the resolver to the machine must be made. To adjust the offset the

operator is required to place the machine at its zero position (this position is usually top dead

center). The operator will be instructed to press the CLEAR key and then the '0' key. The

System 2500 PLS will calculate and display the necessary offset. If the offset is out of range, the

System 2500 PLS will retain the previous offset value.

2.5.7 PLS OUTPUT SPEED ADVANCE

In many applications it will be advantageous to have the on/off setpoints of a PLS channel to

advance (occur earlier in the stroke) as the speed increases. For example, an air blowoff for parts

may need to actuate earlier in the stroke as the machine speed increases. In order for setpoints

which are advanced in this way to operate properly, the PLS Output Speed Advance

configuration data must be programmed. The two data values required are the setpoint angle

which activates the desired output properly at minimum machine speed and the setpoint angle

which activates the output properly at maximum speed. This information must be determined

beforehand by the operator using the procedure to be described, and then entered in the PLS

Output Speed Advance selection of the Con figure Menu (labe led OU TPUT A DVAN). If no PLS

outputs are to be programmed as Advanced, it is not necessary to program the PLS Output Speed

Advance data.

For example, if the operator wishes to speed advance the 'On' setpoint of a PLS output, he must

first run the machine at maximum speed and adjust the 'On' setpoint of that output until the

desired action occurs at the proper point in the stroke. This adjustment can be made by stopping

the machine and editing the setpoint (see Section 2.4.1.3) or by using the Increment feature to

change the setpoint (see Section 2.4.1.6). Once the correct setpoint for maximum speed has been

found and recorded, repeat the test for minimum speed. Then leave the setpoint at the minimum

speed setting but edit the setpoint to be an Advanced setpoint (see Section 2.4.1.5). The operator

can now go to the PLS Output Speed Advance selection of the Configuration Menu to enter the

two recorded setpoint angles.

Choosing OUTPUT ADVAN from the Configure Menu gives the operator access to two data

screens on which the setpoints found for minimum and maximum press speed can be entered.

System 2500 Operating & Installation Manual - Revision 072-18

Page 27

The operator can use the cursor to select a data value, then key in the proper value and press

ENTER. When a 'down arrow' symbol is displayed as the last character on the bottom line of the

display, this indicates that another data line is available to the operator by pressing the down

arrow key while the cursor is on the bottom line. In the same way, an 'up arrow' symbol

displayed as the last character on the top line indicates that another data line is available by

pressing the up arrow key while the cursor is on the top line. Using the arrow keys the operator

can access both lines of data which must be entered. (NOTE: The MAX SPEED and MIN

SPEED shown on the top line of the first screen are for display only and cannot be entered on the

PLS Output Speed Advance screen. To change the value of MAX SPEED the operator must go

to the MOTION DETECTOR data screen, Section 2.5.2. To change the value of MIN SPEED

the operator must go to the TOPSTP ADVAN data screen, Section 2.5.4).

Both setpoint angles for Output Speed Advance must be entered for proper operation. The data

must be entered correctly or an error will be generated. This means that the angle entered for

maximum speed must be a smaller number than the angle entered for minimum speed (must

occur earlier in the stroke). After all data has been entered, programming of Output Speed

Advance is complete. Thereafter any PLS setpoint which is programmed as advanced (see

Sections 2.4.1.5) will be adjusted according to this data. For example, as the speed increases an

'on' setpoint will actually turn on earlier in the stroke than the angle that is programmed. Since

this function is for advancing

have its angle programmed for proper operation at minimum machine speed.

programmed setpoints, any setpoint to be speed advanced should

WARNING: PLS OUTPUTS OF THE SYSTEM 2500 ARE NOT TO BE USED AS THE

PRIMARY INPUTS TO A PRESS CONTROL.

2.6 COUNTERS

The System 2500 PLS has four counters: Part Counter, Batch Counter, Quality Check Counter,

and Stroke Counter. To access the counter routines the operator must select COUNTERS from

the Main Menu. From the Counter Menu the operator may select any of the four counters.

2.6.1 PART Counter

The part counter is used to count the number of parts of a run. From the part counter display the

operator can view the current part count, the part count limit and the part counter status (active or

inactive). If the part counter is inactive, the count will not change. If the part counter is active,

the count will increment in one of two ways:

1. If a Die Protection input is programmed to act as a Part Detector (either 1 Part or 2

System 2500 Operating & Installation Manual - Revision 07 2-19

Page 28

Part) and Die Protection is active (not bypassed) then the count will increment

whenever a part is seen by this input. (Remember that the part counter must still

be set active for counting to take place as noted earlier). If an input is

programmed as a Part Detector but Die Protection is bypassed, no counting will

take place.

2. If no Die Protection input is programmed as a Part Detector then the part counter

will increment at 270 degrees just as the stroke counter. In this mode the counter

acts as a presettable stroke counter which can stop the machine.

Once the counter reaches the parts count limit, the System 2500 PLS will generate a top stop for

the machine. (See Section 2.5.3 for description of the Topstop function). When the operator is

ready to restart the machine the top stop can be removed by pressing the CLEAR key. Clearing

the top stop also resets the part counter to zero.

If the keyswitch is in the PROG position, the counter operation can be programmed by the

operator. The part counter can be turned off (no counting whatsoever) by pressing the DOWN

arrow key, or turned on by pressing the UP arrow key. If the part counter is not being used, it

should be turned off. The counter can be reset to zero by pressing the '-' (dash) key. (Be careful

not to reset the counter accidentally!) Also, the Part Count Limit can be changed by keying in

the desired value and pressing the ENTER key. This limit is the count at which a top stop will be

issued to the machine. The maximum count limit is 999999.

2.6.2 BATCH Counter

The batch counter is used to count the number of strokes per batch. If a total part run is to

contain several batches (such as parts per box), the batch counter can be used to stop the process

after each batch limit has been reached.

The batch counter operates in exactly the same manner as the part counter. The counting

function is tied to the Part Detector portion of Die Protection in the same way that the part

counter is tied. All operations on the batch counter such as turning on, turning off, resetting, and

entry of the batch count limit are performed by the operator in the same way as for the part

counter. If the batch counter is not being used, it should be deactivated.

2.6.3 QUALITY Counter

The quality counter is used to count the number of strokes between quality control checks. The

quality counter operates in exactly the same manner as the part counter. The counting function is

tied to the Part Detector portion of Die Protection in the same way that the part counter is tied.

All operations on the quality counter such as turning on, turning off, resetting, and entry of the

System 2500 Operating & Installation Manual - Revision 072-20

Page 29

quality count limit are performed by the operator in the same way as for the part counter. If the

quality counter is not being used, it should be deactivated.

2.6.4 STROKE Counter

The stroke counter is used to record the total number of machine strokes since the System 2500

was connected to the machine. The stroke counter is incremented each time the machine passes

270 degrees. The stroke counter is always active. It cannot be reset by the user.

2.7 STORE/RECALL

In the System 2500, the information which includes PLS setpoints, restricted channels, and die

protection input program is called the current setup. This information determines how the

System 2500 will perform as the machine strokes. Programmed data such as PLS setpoints or die

protection input modes may have to change from job to job or as machine dies are changed.

Ordinarily, this would require having to manually change each separate PLS setpoint and

reprogram each die protection input individually. To avoid having to manually make each

separate change, the System 2500 allows the operator to store the current setup and assign it a

name so that it can be recalled in its entirety when needed later. This is done using the

Store/Recall Menu. This menu can be accessed by selecting STORE/RECALL from the Main

Menu. The mode selector keyswitch must be in the PROG position to access the store and recall

functions. If the keyswitch is in any other position an error message will be displayed.

When the Store/Recall Menu is displayed, the operator is presented with the following options:

C STORE - Allows the operator to store all the current setup information so that the

entire setup can be recalled at a later time.

C RECALL - Allows the operator to recall a setup that was stored at some previous

time.

C REMOVE - Allows the operator to remove a setup from backup memory that is

no longer needed or that has incorrect data programmed.

Any of these options can be chosen by using the arrow keys to move the cursor to the desired

option and pressing the ENTER key.

The Store/Recall Menu also displays the name of the current setup on the top line if the current

setup is one that is stored in backup memory. This means that when a setup is recalled from

System 2500 Operating & Installation Manual - Revision 07 2-21

Page 30

backup memory to be the current setup, the setup name will immediately appear on the

Store/Recall Menu. Similarly, if the current setup is stored into backup memory, the setup name

which the operator assigned will immediately appear on the Store/Recall Menu. In either case,

the name signifies that the current setup matches one stored in backup memory under that name.

If the current setup does not match one that is stored in backup memory, the message 'New data'

will be displayed. Similarly, if the current setup is edited (changed) in any way, the setup name

that appeared on the top line will be replaced with 'New data'. This signifies that the current

setup may no longer match the setup stored in backup memory since editing has been done.

2.7.1 STORE

If the operator desires to save the current setup, he may do so by selecting STORE from the

Store/Recall Menu. In order to store a setup, a name must first be given to the setup so that it can

be recalled by that name later. An illustration is shown in Figure 3. Prior to the store operation

(left side of figure) there are three setups in backup memory that have been previously stored.

Each of these setups has different PLS and Die-Prot information, and each has been given a name

(shown at the top of each page). The current setup has no name as of yet. The operator then

stores the current setup under the name 'BRACKET2'. After the store operation (right side of

figure), a copy of the current setup is in backup memory. The current setup is now called

Figure 3

Storing a Setup

'BRACKET2' to remind the operator of which setup information the System 2500 is using for

operation. This name will be displayed on the Store/Recall Menu until a new setup is recalled or

System 2500 Operating & Installation Manual - Revision 072-22

Page 31

the current setup is edited. Note that the current setup is not changed after the store; only a copy

of it has been saved in backup memory.

When STORE is selected from the Store/Recall Menu, the display will change to show the Store

Menu and will also show the last name used by the operator in a Store or Recall operation. The

STORE menu gives the operator two choices for entering the setup name:

C USE THIS NAME - Use the name which appears on the top line of the Store

Menu to store the current setup.

C ENTER NEW NAME - Enter a different name than the one displayed on the top

line for storing this setup.

2.7.1.1 Store Setup, USE THIS NAME

When the operator is first programming new information for a setup, frequent changes may have

to be made to the PLS setpoints or die protection information. If the setup is also stored in

backup memory after each change is made, the setup name must be re-entered each time the store

operation is performed. This can be time consuming, especially if the setup name is lengthy.

The USE THIS NAME selection from the Store Menu allows the operator to use the name

displayed on the top line of the menu to store the setup. This name will be the one that was used

by the operator the last time a store was done. Using this option allows the operator to more

quickly store the current setup without having to re-enter the setup name.

NOTE: Although setups are stored in the System 2500 PLS the operator is encouraged to

keep written records of stored setups. These records will be useful to recover setups

accidently lost by operator error or in the event of memory failure within the System 2500

PLS.

2.7.1.2 Store Setup, ENTER NEW NAME

Choosing the ENTER NEW NAME option from the Store Menu will allow the operator to enter

a name for the setup to be stored which has not been previously used. Ideally, this name should

correspond in some way to the job for which the setup is used, such as die number, customer

name, etc. The setup name can be up to 16 alphanumeric characters long. Alpha characters are

selected by first pressing the ALPHA key and then selecting the desired alpha character from the

lower left corner of a key. The ALPHA key must be pressed before selecting each alpha

character. When the ALPHA key is pressed, the blank line under the next character for the setup

name will be a double line rather than a single line to signify that an alpha character will be

entered. If a mistake is made while entering the setup name, the left arrow key can be pressed to

erase the last character entered. To erase the entire name and start over from the beginning, the

CLEAR key should be pressed.

System 2500 Operating & Installation Manual - Revision 07 2-23

Page 32

After the name has been keyed in, the operator must press the ENTER key. The System 2500

will then ask the operator to verify that he wishes to store the current setup using the name

displayed. By pressing the STORE key, a copy of the current setup will then be stored in backup

memory. Note that the current setup is not affected by the store operation, and that the PLS and

die protection information previously entered will still be in effect. After the store operation the

Store/Recall Menu will be displayed.

NOTE: Although setups are stored in the System 2500 PLS the operator is encouraged to

keep written records of stored setups. These records will be useful to recover setups

accidently lost by operator error or in the event of memory failure within the System 2500

PLS.

2.7.1.3 Memory Limits

The System 2500 PLS has memory capacity for one hundred setups to be stored. If the operator

attempts to store a setup after the backup memory is filled, the system will ask if he wishes to

store over a setup that is already in backup memory. If so, the operator may proceed by pressing

the YES key. The system will then allow the operator to store the current setup over the last

setup stored (the one indicated by the LAST NAME USED display) or to enter the name of a

different setup which is to be written over. In either case when the store operation is carried

through the old setup is lost from memory and the current setup takes its place.

2.7.2 RECALL

If the operator desires to recall a previously stored setup, he must select RECALL from the

Store/Recall Menu. Upon choosing RECALL, the display will indicate how many setups are

presently stored in backup memory. If no setups are stored, the display will indicate this and

obviously no setup can be recalled. If one or more setups are stored the operator must choose a

setup name for recall in one of two ways to be described later. Once the desired setup has been

chosen, the RECALL key is pressed and that setup in backup memory is copied over the current

setup.

An illustration is shown in Figure 4. Prior to the recall operation (left side of figure) there are

four setups in backup memory that have been previously stored. Each of these setups has

different PLS and Die-Prot information, and each has been given a name (shown at the top of

each page). The current setup now being run is called 'BRACKET2'. A change in jobs requires

that the System 2500 now run with PLS setpoints that are stored in the setup '06-21-90'. The