Linear Technology LTC1622 Datasheet

FEATURES

LTC1622

Low Input Voltage

Current Mode Step-Down

DC/DC Controller

U

DESCRIPTIO

■

High Efficiency

■

Constant Frequency 550kHz Operation

■

VIN Range: 2V to 10V

■

Multiampere Output Currents

■

OPTI-LOOPTM Compensation Minimizes C

■

Selectable, Burst Mode Operation

■

Low Dropout Operation: 100% Duty Cycle

■

Synchronizable up to 750kHz

■

Current Mode Operation for Excellent Line and Load

OUT

Transient Response

■

Low Quiescent Current: 350µA

■

Shutdown Mode Draws Only 15µA Supply Current

■

±1.9% Reference Accuracy

■

Available in 8-Lead MSOP

U

APPLICATIO S

■

1- or 2-Cell Li-Ion Powered Applications

■

Cellular Telephones

■

Wireless Modems

■

Portable Computers

■

Distributed 3.3V, 2.5V or 1.8V Power Systems

■

Scanners

■

Battery-Powered Equipment

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode and OPTI-LOOP are a trademarks of Linear Technology Corporation.

The LTC®1622 is a constant frequency current mode stepdown DC/DC controller providing excellent AC and DC load

and line regulation. The device incorporates an accurate

undervoltage feature that shuts the LTC1622 down when

the input voltage falls below 2V.

The LTC1622 boasts a ±1.9% output voltage accuracy and

consumes only 350µA of quiescent current. For applica-

tions where efficiency is a prime consideration and the

load current varies from light to heavy, the LTC1622 can

be configured for Burst ModeTM operation. Burst Mode

operation enhances low current efficiency and extends

battery run time. Burst Mode operation is inhibited during

synchronization or when the SYNC/MODE pin is pulled low

to reduce noise and possible RF interference.

High constant operating frequency of 550kHz allows the

use of a small inductor. The device can also be synchronized up to 750kHz for special applications. The high

frequency operation and the available 8-lead MSOP package create a high performance solution in an extremely

small amount of PCB area.

To further maximize the life of the battery source, the

P-channel MOSFET is turned on continuously in dropout

(100% duty cycle). In shutdown, the device draws a mere

15µA.

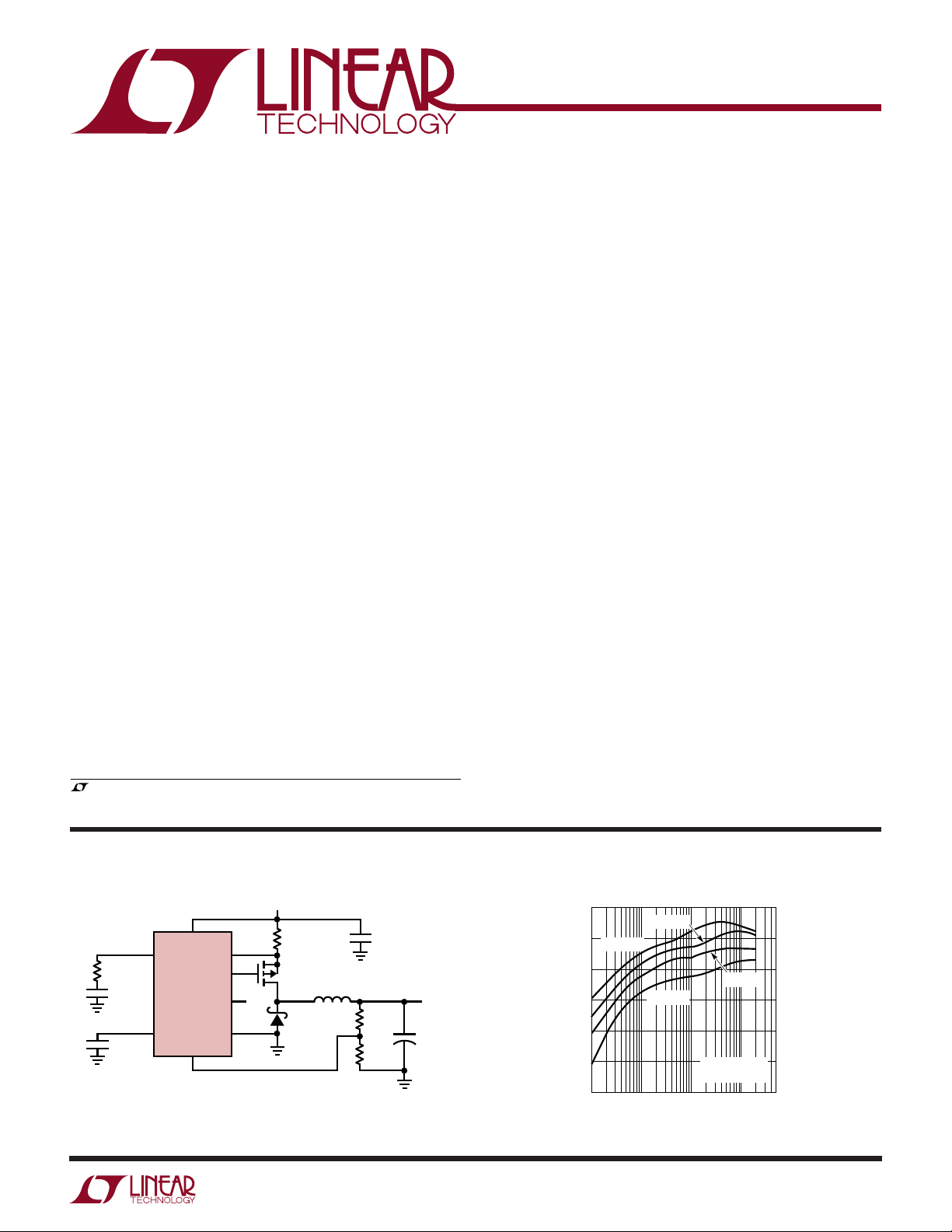

TYPICAL APPLICATIO

V

IN

2.5V TO 8.5V

8

V

IN

2

I

4

TH

LTC1622

SYNC/MODE

RUN/SS

V

3

R1

10k

C3

220pF

470pF

C1: TAIYO YUDEN CERAMIC EMK325BJ106MNT

C2: SANYO POSCAP 6TPA47M

D1: INTERNATIONAL RECTIFIER IR10BQ015

SENSE

FB

PDRV

GND

1

–

7

5

6

Figure 1. High Efficiency Step-Down Converter

R2

0.03Ω

Si3443DV

L1: MURATA LQN6C-4R7

R2: DALE WSL-1206 0-03Ω

U

4.7µH

D1

IR10BQ015

Efficiency vs Load Current with

Burst Mode Operation Enabled

100

C1

10µF

10V

L1

R3

159k

R4

75k

V

OUT

2.5V

1.5A

+

C2

47µF

6V

1622 F01a

90

80

70

EFFICIENCY (%)

60

50

40

1 100 1000 5000

VIN = 3.3V

10

VIN = 4.2V

VIN = 8.4V

V

OUT

R

SENSE

LOAD CURRENT (mA)

VIN = 6V

= 2.5V

= 0.03Ω

1622 F01b

1

LTC1622

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

Input Supply Voltage (VIN).........................–0.3V to 10V

RUN/SS Voltage .......................................–0.3V to 2.4V

SYNC/MODE Voltage ................................. –0.3V to V

SENSE– Voltage .......................................... 2.4V to V

IN

IN

PDRV Peak Output Current (<10µs) ......................... 1A

Storage Ambient Temperature Range ... –65°C to 150°C

U

W

U

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

LTC1622CMS8

MS8 PART MARKING

LTDB

–

SENSE

1

2

I

TH

3

V

FB

4

RUN/SS

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 125°C, θJA = 250°C/W

JMAX

TOP VIEW

8

V

IN

7

PDRV

6

GND

5

SYNC/MODE

Operating Temperature Range

Commercial ............................................ 0°C to 70°C

Industrial ........................................... –45°C to 85°C

Junction Temperature (Note 2)............................. 125°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART

SENSE

I

V

RUN/SS

TOP VIEW

–

1

2

TH

3

FB

4

S8 PACKAGE

8-LEAD PLASTIC SO

T

= 125°C, θJA = 150°C/ W

JMAX

V

8

IN

PDRV

7

GND

6

SYNC/MODE

5

NUMBER

LTC1622CS8

LTC1622IS8

S8 PART MARKING

1622

1622I

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 4.2V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

VFB

V

FB

V

OVL

∆V

OSENSE

V

LOADREG

I

S

V

RUN/SS

I

RUN/SS

f

OSC

V

SYNC/MODE

V

UVLO

Feedback Current (Note 3) VFB = 0.8V 10 70 nA

Regulated Feedback Voltage (Note 3) Commercial Grade ● 0.785 0.8 0.815 V

(Note 3) Industrial Grade

Output Overvoltage Lockout Referenced to Nominal V

Reference Voltage Line Regulation VIN = 4.2V to 8.5V (Note 3) 0.04 0.08 %/V

Output Voltage Load Regulation Measured in Servo Loop; V

Measured in Servo Loop; V

Input DC Supply Current (Note 4)

Burst Mode Inhibited V

Sleep Mode V

Shutdown V

Shutdown V

RUN/SS Threshold Commercial Grade ● 0.4 0.7 0.9 V

Soft-Start Current Source V

Oscillator Frequency VFB = 0.8V 475 550 625 kHz

SYNC/MODE Threshold V

Undervoltage Lockout VIN Ramping Down ● 1.55 1.92 2.3 V

= 2.3V 450 µA

IN

= 0V, V

ITH

RUN/SS

RUN/SS

Industrial Grade

RUN/SS

V

FB

SYNC/MODE

Ramping Up 1.97 2.36 V

V

IN

SYNC/MODE

= 0V 15 30 µA

= 0V, VIN = V

= 0V 1 2.5 5 µA

= 0V 75 110 140 kHz

Ramping Down 1 1.5 V

OUT

= 0.2V to 0.625V 0.3 0.5 %

ITH

= 0.9V to 0.625V – 0.3 –0.5 %

ITH

= 2.4V 350 400 µA

– 0.1V 4 10 µA

UVLO

● 0.780 0.8 0.820 V

4 7.5 10.5 %

● 0.3 0.7 1.0 V

2

LTC1622

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 4.2V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

PDRV t

r

PDRV t

f

∆V

SENSE(MAX)

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: T

dissipation P

Gate Drive Rise Time C

Gate Drive Fall Time C

= 3000pF 80 140 ns

LOAD

= 3000pF 100 140 ns

LOAD

Maximum Current Sense Voltage ● 80 110 140 mV

Note 3: The LTC1622 is tested in a feedback loop that servos V

= 0.8V).

ITH

is calculated from the ambient temperature TA and power

J

according to the following formula:

D

feedback point for the error amplifier (V

Note 4: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

to the

FB

LTC1622CS8; TJ = TA + (PD • 150°C/W),

LTC1622CMS8; TJ = TA + (PD • 250°C/W)

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

Shutdown Current

vs Supply Voltage

45

40

35

30

25

20

15

SHUTDOWN CURRENT (µA)

10

5

0

23

45

67

SUPPLY VOLTAGE (V)

89

1622 G01

RUN/SS Current vs Supply Voltage

3.50

3.00

2.50

2.00

SOFT-START CURRENT (µA)

1.50

10

1.00

3579

2

46 10

SUPPLY VOLTAGE (V)

8

1622 G02

Maximum Current Sense Voltage

vs Duty Cycle

110

VIN = 4.2V

100

90

80

70

60

TRIP VOLTAGE (mV)

50

40

30

20 30

40 50

DUTY CYCLE (%)

UNSYNC

60 70

80 90

100

1622 G03

Normalized Oscillator Frequency

vs Temperature

10.0

VIN = 4.2V

7.5

5.0

2.5

0

–2.5

–5.0

NORMALIZED FREQUENCY (%)

–7.5

–10.0

–55 –35

–15 5

25 45 65

TEMPERATURE (°C)

85 105

1622 G04

125

Reference Voltage

vs Temperature

0.810

VIN = 4.2V

0.805

0.800

0.795

0.790

0.785

REFERENCE VOLTAGE (V)

0.780

0.775

–55 –35

–15 5

TEMPERATURE (°C)

25 45 65

85 105

1622 G05

125

Undervoltage Lockout Voltage

vs Temperature

2.10

2.05

2.00

1.95

1.90

1.85

1.80

UNDERVOLTAGE LOCKOUT VOLTAGE (V)

1.75

–55 –35

–15 5

25 45 65

TEMPERATURE (°C)

85 105

125

1622 G06

3

LTC1622

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

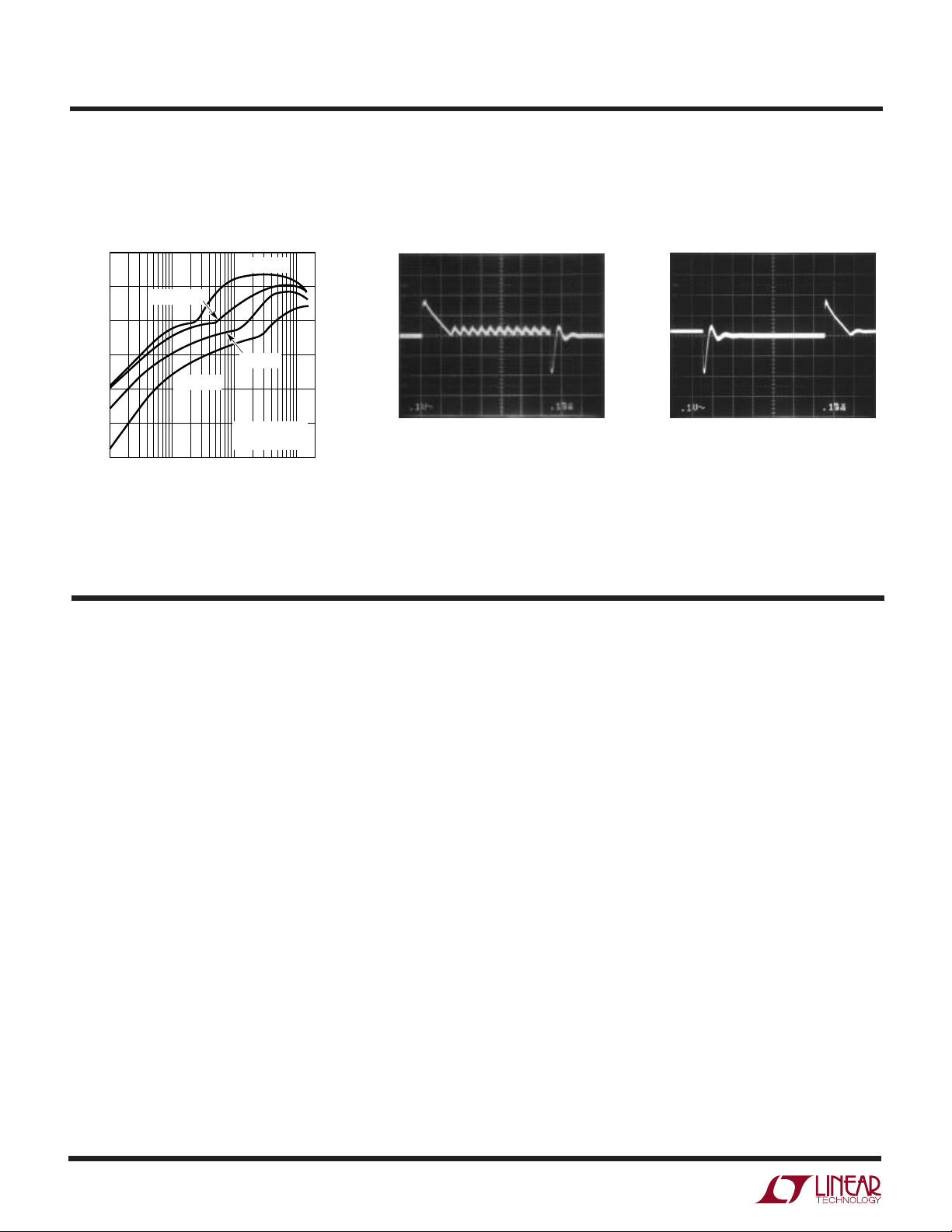

Efficiency vs Load Current for

Figure 1 with Burst Mode

Operation Defeated

100

90

80

VIN = 4.2V

VIN = 3.3V

Load Step Transient Response

Burst Enabled

Load Step Transient Response

Burst Inhibited

70

EFFICIENCY (%)

60

50

40

1

VIN = 6V

VIN = 8.4V

V

OUT

R

SENSE

10 100

LOAD CURRENT (mA)

= 2.5V

= 0.03Ω

1000

1622 G07

100mV/DIV

I

= 50mA TO 1.2A

LOAD

VIN = 4.2V

UUU

PIN FUNCTIONS

SENSE– (Pin 1): The Negative Input to the Current Comparator.

ITH (Pin 2): Error Amplifier Compensation Point. The

current comparator threshold increases with this control

voltage. Nominal voltage range for this pin is 0V to 1.2V.

VFB (Pin 3): Receives the feedback voltage from an external resistive divider across the output capacitor.

100mV/DIV

I

= 50mA TO 1.2A

LOAD

1622 G08

VIN = 4.2V

1622 G09

SYNC/MODE (Pin 5): This pin performs three functions.

Greater than 2V on this pin allows Burst Mode operation

at low load currents, while grounding or applying a clock

signal on this pin defeats Burst Mode operation. An

external clock between 625kHz and 750kHz applied to this

pin forces the LTC1622 to operate at the external clock

frequency.

Do not attempt to synchronize below 625kHz

.

Pin 5 has an internal 1µA pull-up current source.

RUN/SS (Pin 4): Combination of Soft-Start and Run

Control Inputs. A capacitor to ground at this pin sets the

ramp time to full output current. The time is approximately

0.45s/µF. Forcing this pin below 0.4V causes all circuitry

to be shut down.

4

GND (Pin 6): Ground Pin.

PDRV (PIN 7): Gate Drive for the External P-Channel

MOSFET. This pin swings from 0V to VIN.

VIN (Pin 8): Main Supply Pin. Must be closely decoupled

to ground Pin 6.

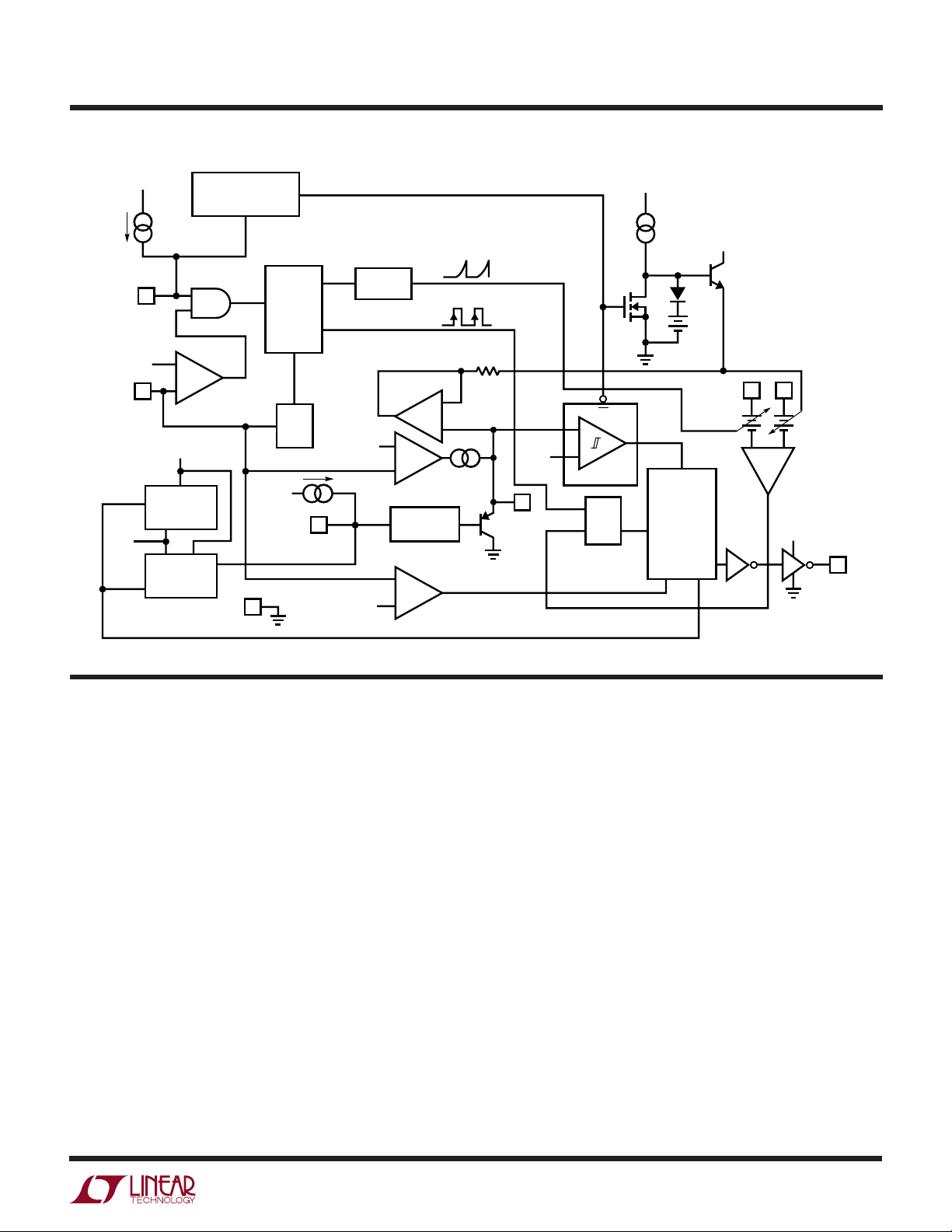

LTC1622

UU

W

FUNCTIONAL DIAGRA

V

SYNC/

MODE

V

FB

V

REF

0.8V

IN

1µA

5

0.3V

3

REFERENCE

TRIP = 1.97V

SHUTDOWN

–

+

V

IN

0.8V

UVLO

BURST DEFEAT

X

6

GND

Y

OSC

FREQ

SHIFT

V

IN

RUN/SS

4

V

REF

Y = “0” ONLY WHEN X IS A CONSTANT “1”

OTHERWISE Y = “1”

SLOPE

COMP

–

0.8V

V

2.5µA

+ 60mV

REF

+

+

EA

–

g

= 0.5m

m

RUN/

SOFT-START

+

OV

–

Ω

2

I

TH

0.12V

EN

–

+

BURST

S

RQ

R

S1

V

CC

SLEEP

SWITCHING

BLANKING

LOGIC

AND

CIRCUIT

0.36V

SENSE

1622 BD

–

1

+

ICOMP

V

8

IN

–

V

IN

PDRV

7

U

OPERATIO

Main Control Loop

The LTC1622 is a constant frequency current mode switching regulator. During normal operation, the external

P-channel power MOSFET is turned on each cycle when

the oscillator sets the RS latch (RS1) and turned off when

the current comparator (I

inductor current at which I

controlled by the voltage on the ITH pin, which is the output

of the error amplifier EA. An external resistive divider

connected between V

an output feedback voltage VFB. When the load current

increases, it causes a slight decrease in VFB relative to the

0.8V reference, which in turn causes the ITH voltage to

increase until the average inductor current matches the

new load current.

The main control loop is shut down by pulling the RUN/SS

pin low. Releasing RUN/SS allows an internal 2.5µA

(Refer to Functional Diagram)

) resets the latch. The peak

COMP

resets the RS latch is

COMP

and ground allows EA to receive

OUT

current source to charge up the soft-start capacitor CSS.

When CSS reaches 0.7V, the main control loop is enabled

with the ITH voltage clamped at approximately 5% of its

maximum value. As CSS continues to charge, ITH is gradually released allowing normal operation to resume.

Comparator OV guards against transient overshoots

>7.5% by turning off the P-channel power MOSFET and

keeping it off until the fault is removed.

Burst Mode Operation

The LTC1622 can be enabled to go into Burst Mode

operation at low load currents simply by leaving the SYNC/

MODE pin open or connecting it to a voltage of at least 2V.

In this mode, the peak current of the inductor is set as if

V

= 0.36V (at low duty cycles) even though the voltage

ITH

at the ITH pin is at lower value. If the inductor’s average

current is greater than the load requirement, the voltage at

5

Loading...

Loading...