查询LT3150CGN供应商

Low Input Voltage, Very Low Dropout

FEATURES

■

Fast Transient Response Optimized with

Ceramic Output Capacitors

■

FET R

■

±1% Reference Tolerance Over Temperature

■

Multifunction LDO Shutdown Pin with Latchoff

■

Fixed Frequency 1.4MHz Boost Converter Generates

Defines Dropout Voltage

DS(ON)

MOSFET Gate Drive

■

Internally Compensated Boost Converter Uses Tiny

Capacitors and Inductor

■

Independent Boost Converter Shutdown Control

Permits LDO Output Voltage Supply Sequencing

■

16-Lead SSOP Package

U

APPLICATIO S

■

Microprocessor, ASIC and I/O Supplies

■

Very Low Dropout Input-to-Output Conversion

■

Logic Termination Supplies

, LTC and LT are registered trademarks of Linear Technology Corporation.

LT3150

Fast Transient Response,

Linear Regulator Controller

U

DESCRIPTIO

The LT®3150 drives a low cost external N-channel MOSFET

as a source follower to produce a fast transient response,

very low dropout voltage linear regulator. Selection of the

N-channel MOSFET R

300mV for low VIN to low V

The LT3150 includes a fixed frequency boost regulator

that generates gate drive for the N-channel MOSFET. The

internally compensated current mode PWM architecture

combined with the 1.4MHz switching frequency permits

the use of tiny, low cost capacitors and inductors.

The LT3150’s transient load performance is optimized

with ceramic output capacitors. A precision 1.21V reference accommodates low voltage supplies.

Protection includes a high side current limit amplifier that

activates a fault timer circuit. A multifunction shutdown

pin provides either current limit time-out with latchoff,

overvoltage protection or thermal shutdown. Independent

shutdown control of the boost converter provides on/off

and sequencing control of the LDO output voltage.

allows dropout voltages below

DS(ON)

applications.

OUT

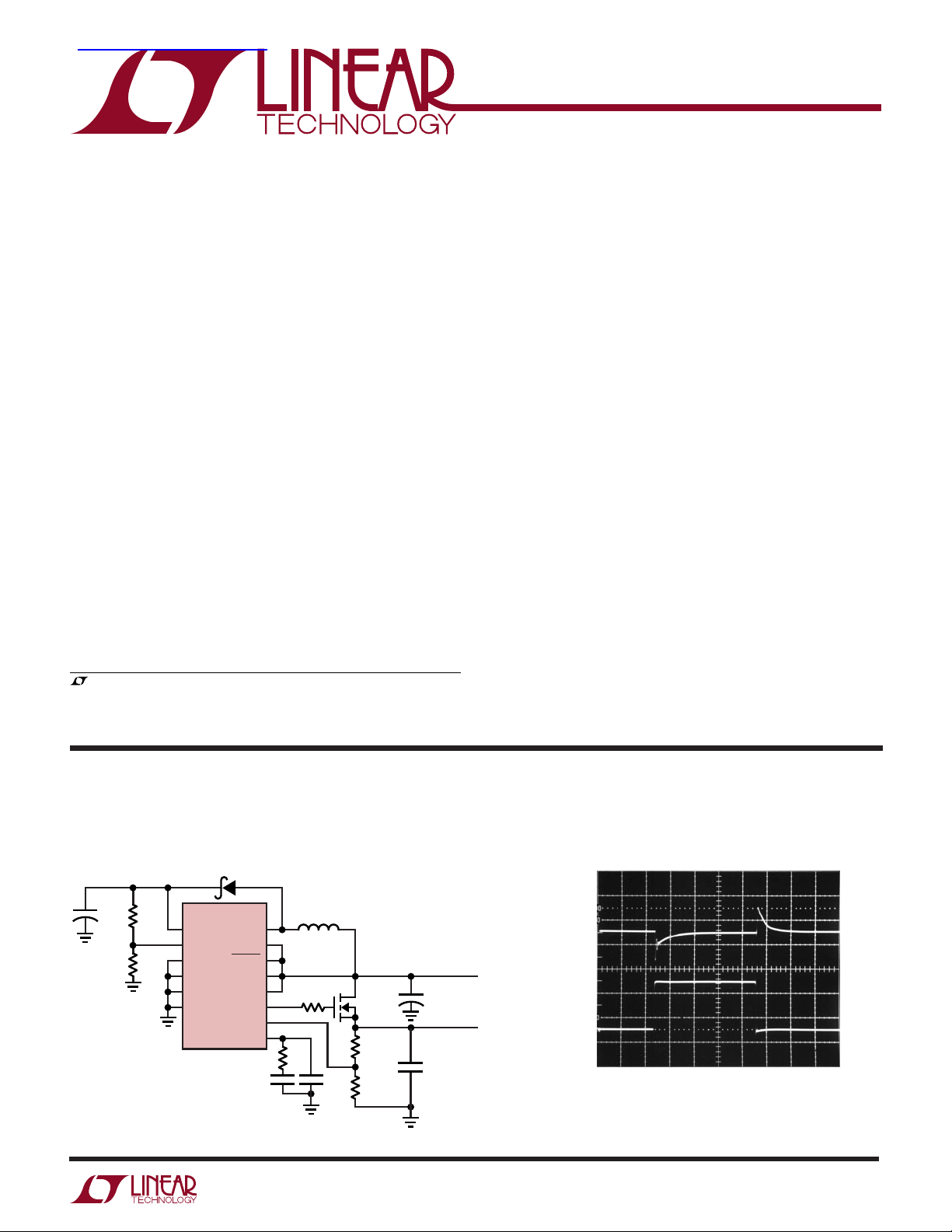

TYPICAL APPLICATIO

1.8V to 1.5V, 4A Very Low Dropout Linear Regulator

(Typical Dropout Voltage = 65mV at I

MBR0520L

+

C1

6.19k

4.7µF

1%

1.37k

1%

C

: PANASONIC SP SERIES EEFUE0E221R 20%

IN

C1: AVX TAJA475M020R 20V 20%

L1: MURATA LQH32CN100K11 OR SUMIDA CDRH3D16100

LT3150

V

IN2

FB1

SHDN2

SWGND

GND

GND

SW

V

IN1

SHDN1

I

POS

I

NEG

GATE

FB2

COMP

6800pF 50pF

L1

10µH

5.1Ω

1.5k

U

OUT

Si4410

243Ω

1%

1020Ω

1%

= 4A)

+

C

IN

220µF

2.5V

×2

2.2µF ×10

X5R CERAMIC

0805 CASE

3150 TA01

V

IN

1.8V

V

OUT

1.5V

4A

50mV/DIV

2A/DIV

Transient Response for

0.1A to 4A Output Load Step

20µs/DIV

3150 TA02

3150f

1

LT3150

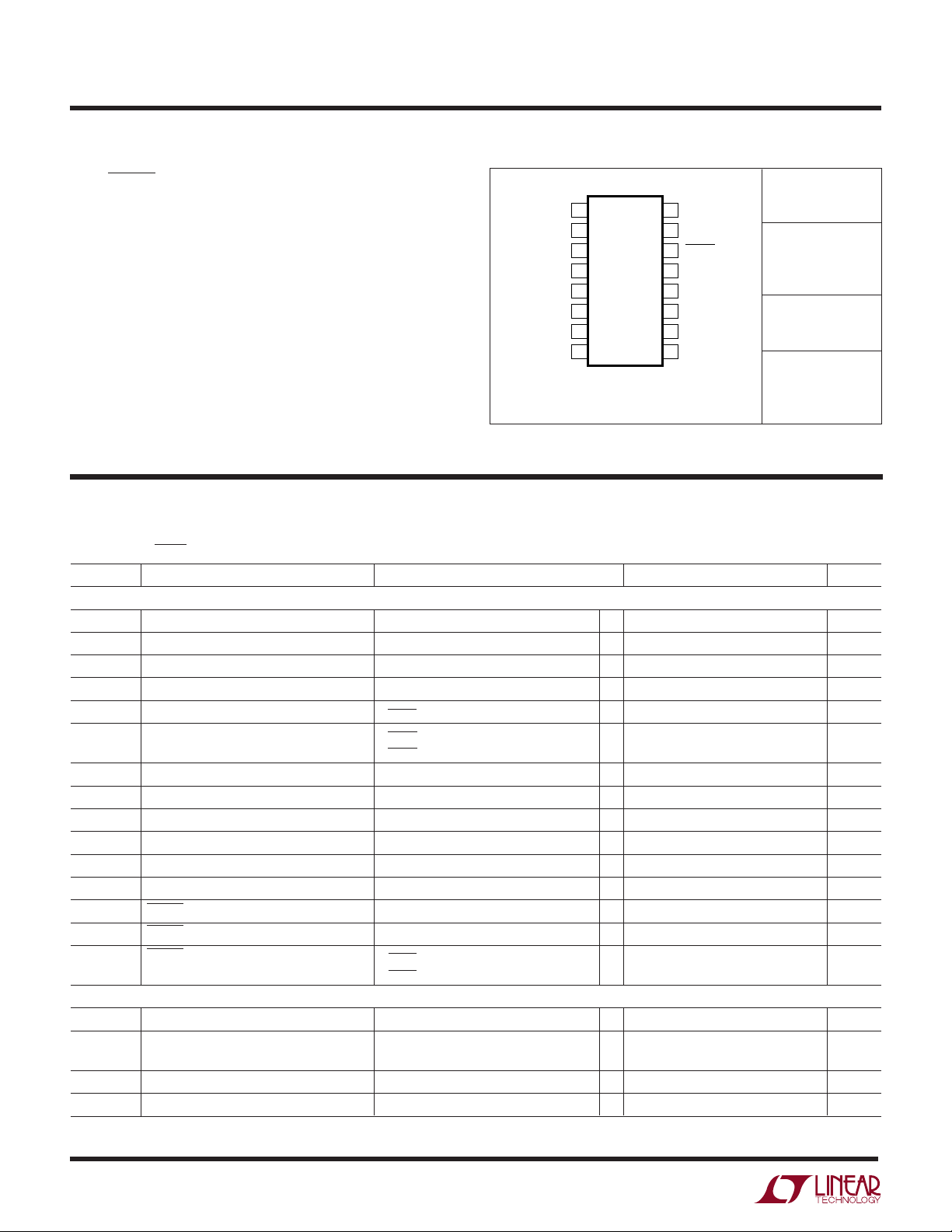

PACKAGE/ORDER I FOR ATIO

UU

W

GN PACKAGE

16-LEAD PLASTIC SSOP

1

2

3

4

5

6

7

8

TOP VIEW

16

15

14

13

12

11

10

9

SW

SWGND

V

IN1

SHDN2

V

IN2

GND

NC

FB2

FB1

GND

SHDN1

I

POS

I

NEG

GATE

NC

COMP

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

V

, SHDN1 Voltage .............................................. 10V

IN1

SW Voltage .............................................. –0.4V to 36V

FB1 Voltage ................................................ V

Current into FB1, FB2 Pin .................................... ±1mA

V

, I

, I

IN2

POS

....................................................... 22V

NEG

SHDN2.................................................................... V

Operating Ambient Temperature Range..... 0°C to 70°C

Junction Temperature (Note 2)........................... 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= 1.5V, V

IN1

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Boost Switching Regulator

V

FB1

I

Q1

Linear Regulator Controller

I

Q2

V

FB2

2

= V

, V

SHDN1

V

IN1

V

IN1

FB1 Reference Voltage ● 1.20 1.23 1.255 V

FB1 Input Bias Current Current Flows into Pin ● 27 80 nA

V

IN1

V

IN1

FB1 Reference Line Regulation 1.5V ≤ V

Switching Frequency ● 1 1.4 1.9 MHz

Maximum Duty Cycle ● 82 86 %

Switch Current Limit (Note 3) 550 800 mA

Switch V

Switch Leakage Current VSW = 5V 0.01 1 µA

SHDN1 Input Voltage High 1 V

SHDN1 Input Voltage Low 0.3 V

SHDN1 Input Bias Current V

V

IN2

FB2 Reference Voltage 1.203 1.210 1.217 V

FB2 Line Regulation 10V ≤ V

FB2 Input Bias Current FB2 = V

IN1

Minimum Operating Voltage 0.9 1.1 V

Maximum Operating Voltage 10 V

Quiescent Current V

Quiescent Current in Shutdown V

CESAT

Quiescent Current ● 51219 mA

= 12V, GATE = 6V, I

IN2

ORDER PART

NUMBER

+ 0.3V

IN1

LT3150CGN

IN2

GN PART

MARKING

3150

T

= 125°C, θJA = 130°C/W, θJC = 40°C/W

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

= I

POS

SHDN1

SHDN1

V

SHDN1

ISW = 300mA 300 350 mV

SHDN1

V

SHDN1

= 5V, V

NEG

= 1.5V 3 4.5 mA

= 0V, V

= 0V, V

IN1

= 3V, Current Flows into Pin 25 50 µA

= 0V, Current Flows into Pin 0.01 0.1 µA

IN2

FB2,

= 2V 0.01 0.5 µA

IN1

= 5V 0.01 1.0 µA

IN1

≤ 10V 0.02 0.2 %/V

≤ 20V ● 0.01 0.03 %/V

Current Flows out of Pin ● –0.6 –4 µA

= 0.75V unless otherwise noted.

SHDN2

● 1.198 1.210 1.222 V

3150f

LT3150

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= 1.5V, V

IN1

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

A

VOL

V

OL

V

OH

= V

, V

SHDN1

Large-Signal Voltage Gain V

GATE Output Swing Low (Note 4) I

GATE Output Swing High I

I

POS

Current Limit Threshold Voltage 42 50 58 mV

Current Limit Threshold Voltage 3V ≤ I

Line Regulation

SHDN2 Sink Current Current Flows Into Pin ● 2.5 5.0 8.0 µA

SHDN2 Source Current Current Flows Out of Pin ● –8 –15 –23 µA

SHDN2 Low Clamp Voltage ● 0.1 0.25 V

SHDN2 High Clamp Voltage ● 1.50 1.85 2.20 V

SHDN2 Threshold Voltage ● 1.18 1.21 1.240 V

SHDN2 Threshold Hysteresis ● 50 100 150 mV

IN1

+ I

Supply Current 3V ≤ I

NEG

= 12V, GATE = 6V, I

IN2

= I

POS

GATE

GATE

GATE

= 5V, V

NEG

= 3V to 10V ● 69 84 dB

= 0mA ● 2.5 3 V

= 0mA ● V

≤ 20V ● 0.3 0.625 1 mA

POS

≤ 20V ● –0.20 –0.50 %/V

POS

= 0.75V unless otherwise noted.

SHDN2

IN2

● 37 50 63 mV

– 1.6 V

– 1 V

IN2

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: T

dissipation P

is calculated from the ambient temperature TA and power

J

according to the following formula:

D

TJ = TA + (PD • 130°C/W)

Note 3: Switch current limit is guaranteed by design and/or correlation to

static test.

Note 4: The V

OUT

.

3V – V

of the external MOSFET must be greater than

GS(th)

3150f

3

LT3150

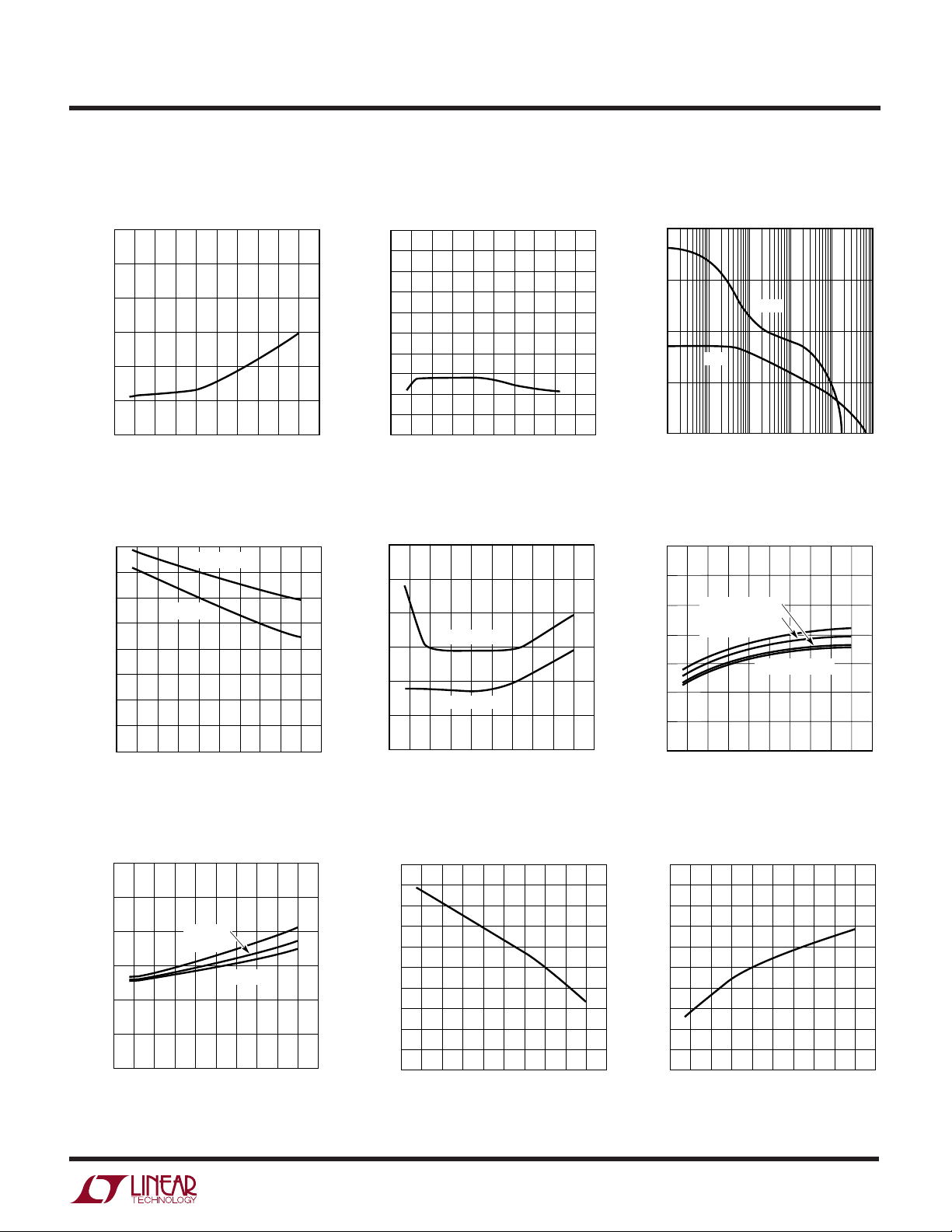

TEMPERATURE (°C)

–50

FB1 REFERENCE VOLTAGE (V)

3150 G05

1.25

1.24

1.23

1.22

1.21

1.20

VOLTAGE

–25 0 25 50 75 100

UW

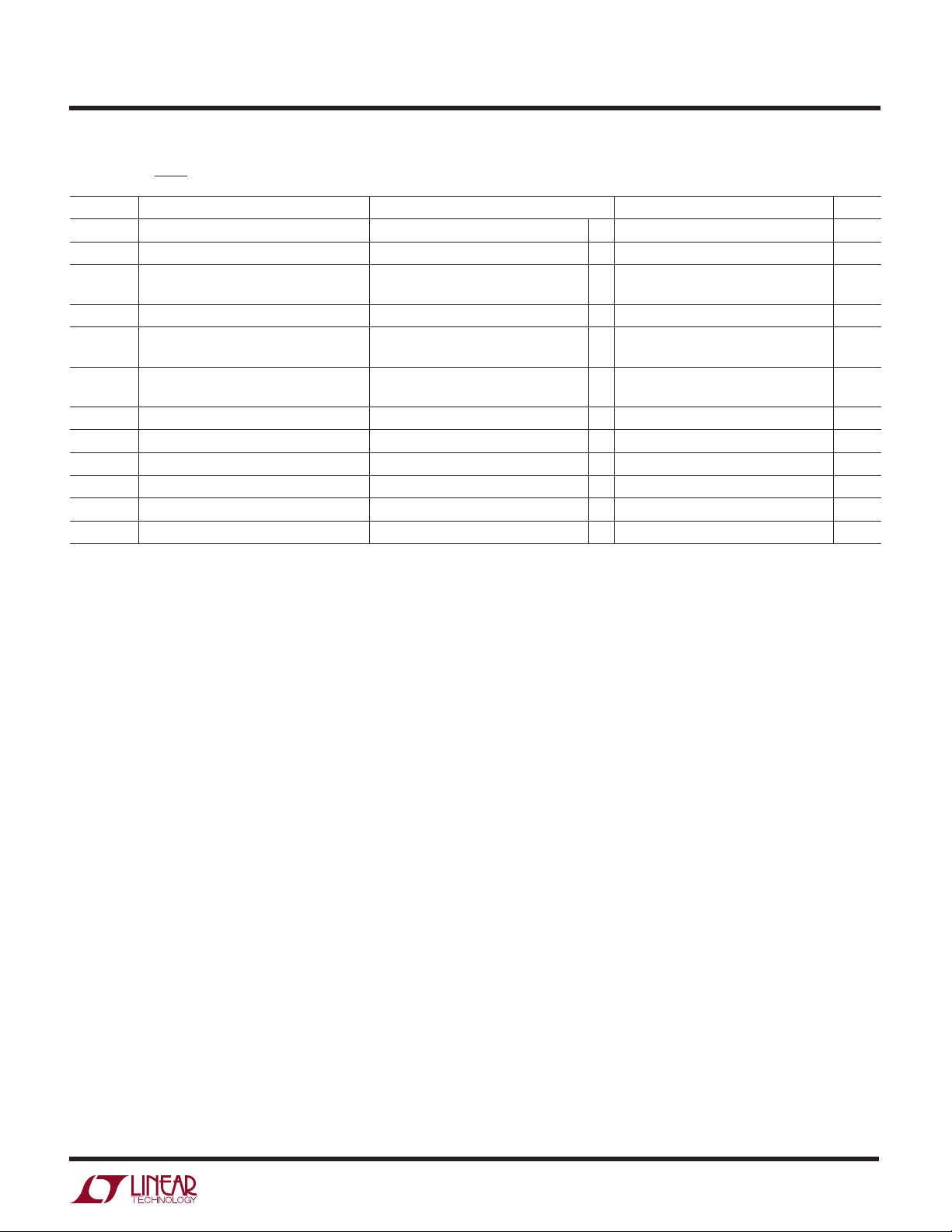

TYPICAL PERFOR A CE CHARACTERISTICS

Boost Switching Regulator

Switch V

700

TA = 25°C

600

500

400

(mV)

300

CESAT

V

200

100

0

0 100 200 300 400 500 600 700

vs Switch Current

CESAT

SWITCH CURRENT (mA)

Switch Current Limit vs Duty Cycle

1000

900

800

700

600

500

400

SWITCH CURRENT LIMIT (mA)

300

200

10 20 30 40 50 60 70 80

Linear Regulator Controller

3150 G01

DUTY CYCLE (%)

Oscillator Frequency

vs Temperature

2.00

1.75

1.50

1.25

1.00

0.75

0.50

SWITCHING FREQUENCY (MHz)

0.25

70°C

25°C

–40°C

VIN = 5V

VIN = 1.5V

0

–50 –25 0 25 50 75 100

TEMPERATURE (°C)

3150 G04

SHDN1 Input Bias Current

vs V

50

TA = 25°C

40

30

20

10

SHDN1 INPUT BIAS CURRENT (µA)

0

012345

3150 G02

FB1 Reference Voltage

vs Temperature

SHDN1

SHDN1 PIN VOLTAGE (V)

3150 G03

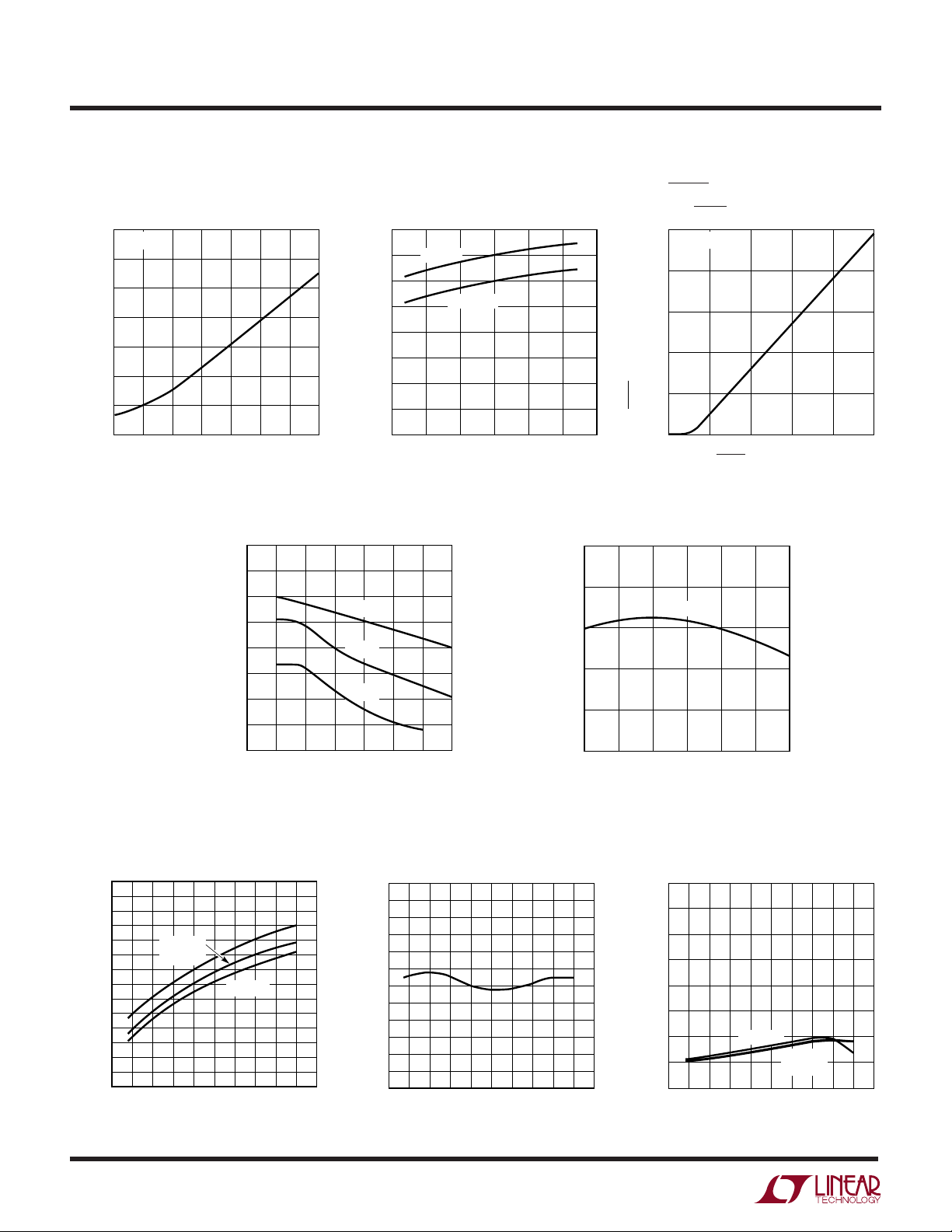

V

IN2

vs Temperature

19

18

17

16

15

14

13

12

11

10

9

QUIESCENT CURRENT (mA)

8

IN2

V

7

6

5

–50 0

–75

4

Quiescent Current

= 12V

V

IN

V

= 20V

IN

VIN = 8V

–25

50 150

75

25

TEMPERATURE (°C)

100

125

3150 G06

1.222

1.220

1.218

1.216

1.214

1.212

1.210

1.208

1.206

1.204

FB2 REFERENCE VOLTAGE (V)

1.202

1.200

175

1.198

–75

FB2 Reference Voltage

vs Temperature

–25

–50 150

0

TEMPERATURE (°C)

75

100

25

50

125

3150 G07

175

FB2 Input Bias Current

vs Temperature

4.0

3.5

3.0

2.5

2.0

1.5

1.0

FB2 INPUT BIAS CURRENT (µA)

0.5

0

–50 150

–75

VIN = 20V

–25

0

25

TEMPERATURE (°C)

V

= 12V

IN

= 8V

V

IN

75

100

125

50

175

3150 G08

3150f

FREQUENCY (Hz)

50

100

ERROR AMPLIFIER GAIN (dB) AND PHASE (DEG)

150

200

1k 100k 1M 100M

3150 G11

0

10k

10M

PHASE

GAIN

TEMPERATURE (°C)

–75

300

I

POS

+ I

NEG

SUPPLY CURRENT (µA)

400

600

700

800

1000

–50

50

100

3150 G14

500

900

25

150

175

–25

0

75 125

I

POS

= I

NEG

= 3V

I

POS

= I

NEG

= 5V

I

POS

= I

NEG

= 12V

I

POS

= I

NEG

= 20V

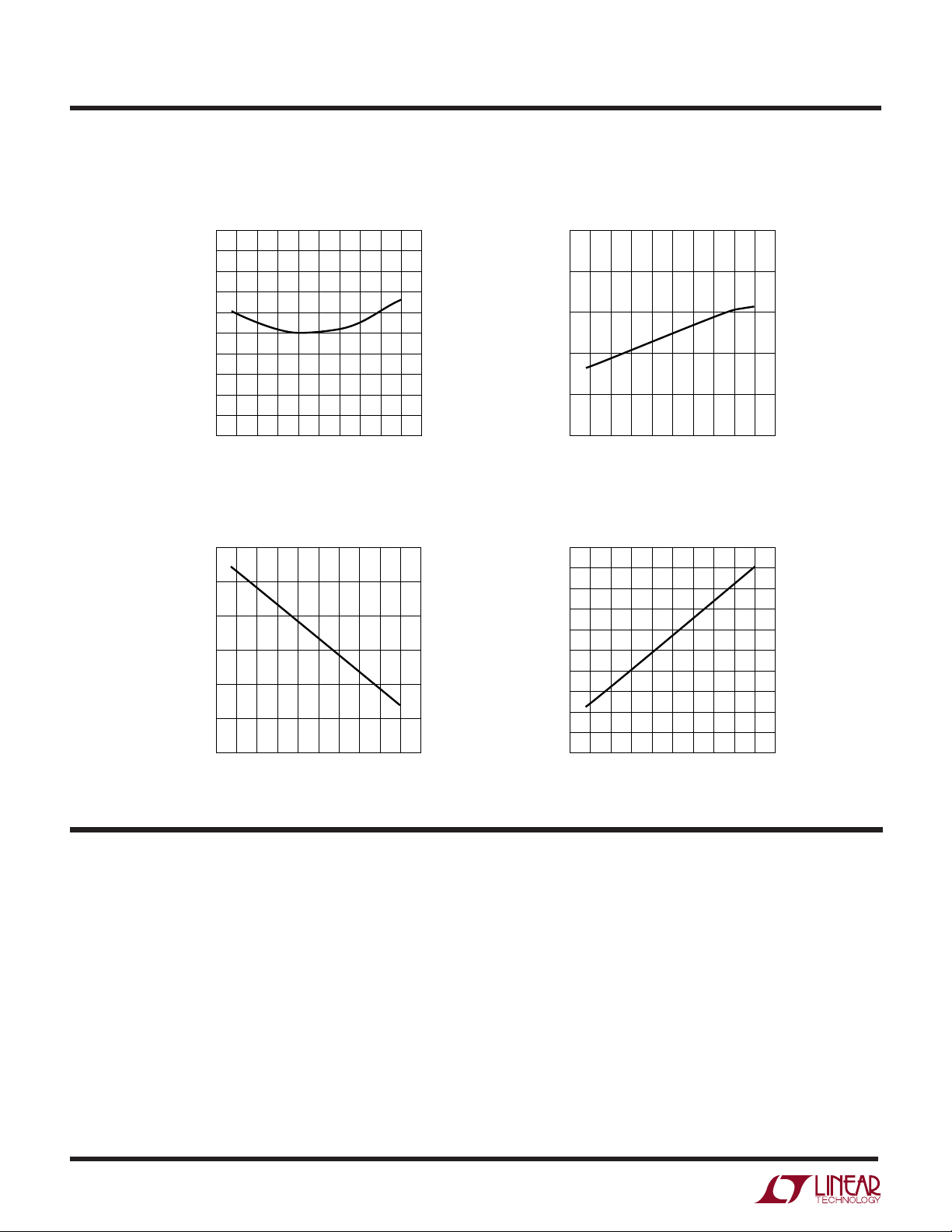

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT3150

Linear Regulator Controller

FB2 Line Regulation

vs Temperature

0.030

0.025

0.020

0.015

0.010

FB2 LINE REGULATION (%/V)

0.005

0

–25 25 75 125

TEMPERATURE (°C)

Gate Output Swing Low

vs Temperature

3.00

2.75

2.50

2.25

2.00

1.75

1.50

GATE OUTPUT SWING LOW (V)

1.25

1.00

–50 150

–75

I

LOAD

NO LOAD

–25

0

25

TEMPERATURE (°C)

= 50mA

75

50

100

125

3150 G09

3150 G12

175–50–75 0 50 100 150

175

Error Amplifier Large-Signal

Voltage Gain vs Temperature

120

115

110

105

100

95

90

85

80

LARGE-SIGNAL VOLTAGE GAIN (dB)

75

70

–25

–50 150

–75

0

25

50

TEMPERATURE (°C)

Gate Output Swing High (V

V

) vs Temperature

GATE

3.0

2.5

2.0

I

= 50mA

1.5

1.0

GATE OUTPUT SWING HIGH (V)

0.5

0

LOAD

NO LOAD

–25 25 75 125

TEMPERATURE (°C)

Gain and Phase vs Frequency

75

100

125

175

3150 G10

I

+ I

IN2

–

POS

Supply Current

NEG

vs Temperature

175–50–75 0 50 100 150

3150 G13

Current Limit Threshold Voltage

vs Temperature

65

60

I

55

50

45

40

CURRENT LIMIT THRESHOLD VOLTAGE (mV)

35

–25 25 75 125

= 5V

POS

= 3V

I

POS

TEMPERATURE (°C)

I

POS

= 20V

3150 G15

Current Limit Threshold Voltage

Line Regulation vs Temperature

0

–0.1

–0.2

–0.3

–0.4

CURRENT LIMIT THRESHOLD

VOLTAGE LINE REGULATION (%/V)

175–50–75 0 50 100 150

–0.5

–25

0

–50 150

–75

25

50

TEMPERATURE (°C)

75

100

125

175

3150 G16

SHDN2 Sink Current

vs Temperature

7.5

7.0

6.5

6.0

5.5

5.0

4.5

4.0

SHDN2 SINK CURRENT (µA)

3.5

3.0

2.5

–25

–50 150

–75

0

25

TEMPERATURE (°C)

75

100

125

50

175

3150 G17

3150f

5

LT3150

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Linear Regulator Controller

SHDN2 Source Current

vs Temperature

–10

–11

–12

–13

–14

–15

–16

–17

–18

SHDN2 SOURCE CURRENT (µA)

–19

–20

–25

–50 150

–75

0

25

50

TEMPERATURE (°C)

SHDN2 High Clamp Voltage

vs Temperature

2.1

2.0

1.9

1.8

1.7

1.6

SHDN2 HIGH CLAMP VOLTAGE (V)

1.5

–25 25 75 125

TEMPERATURE (°C)

SHDN2 Low Clamp Voltage

vs Temperature

0.25

0.20

0.15

0.10

0.05

SHDN2 LOW CLAMP VOLTAGE (V)

75

100

125

175

3150 G18

0

–25

–50 150

–75

0

TEMPERATURE (°C)

75

25

50

100

125

175

3150 G19

SHDN2 Hysteresis vs Temperature

150

140

130

120

110

100

90

80

SHDN2 HYSTERESIS (mV)

70

60

3150 G20

175–50–75 0 50 100 150

50

–25

–50 150

–75

0

TEMPERATURE (°C)

75

25

100

50

125

175

3150 G21

U

UU

PI FU CTIO S

SW (Pin 1): Boost Converter Switch Pin. Connect inductor/diode here. Minimize trace area at this pin to keep EMI

down.

SWGND (Pin 2): Switch Ground. Tie directly to the local

ground plane and the GNDs at Pins 6 and 15.

V

(Pin 3): Boost Converter Input Supply Pin. Must be

IN1

locally bypassed.

SHDN2 (Pin 4): This is a multifunction shutdown pin that

provides GATE drive latchoff capability. A 15µA current

source, that turns on when current limit is activated,

6

charges a capacitor placed in series with SHDN2 to GND

and performs a current limit time-out function. The pin is

also the input to a comparator referenced to V

When the pin pulls above V

, the comparator latches the

REF

(1.21V).

REF

gate drive to the external MOSFET off. The comparator

typically has 100mV of hysteresis and the SHDN2 pin can

be pulled low to reset the latchoff function. This pin

provides overvoltage protection or thermal shutdown

protection when driven from various resistor divider

schemes.

3150f

LT3150

U

UU

PI FU CTIO S

V

(Pin 5): This is the input supply for the linear regulator

IN2

control circuitry and provides sufficient gate drive compliance for the external N-channel MOSFET. The maximum

operating V

set by V

(worst-case V

GND (Pin 6): Analog Ground. This pin is also the negative

sense terminal for the internal 1.21V reference. Connect the

LDO regulator external feedback divider network and frequency compensation components that terminate to GND

directly to this pin for best regulation and performance. Also,

tie this pin directly to SWGND (Pin 2) and GND (Pin 15).

NC (Pins 7, 10): No Connect.

FB2 (Pin 8): This is the inverting input of the error amplifier

for the linear regulator. The noninverting input is tied to the

internal 1.21V reference. Input bias current for this pin is

typically 0.6µA flowing out of the pin. Tie this pin to a

resistor divider network to set output voltage. Tie the top

of the external resistor divider directly to the output load

for best regulation performance.

COMP (Pin 9): This is the high impedance gain node of the

error amplifier and is used for external frequency compensation. The transconductance of the error amplifier is 15

millimhos and open-loop voltage gain is typically 84dB.

Frequency compensation is generally performed with a

series RC + C network to ground.

GATE (Pin 11): This is the output of the error amplifier

that drives N-channel MOSFETs with up to 5000pF of

“effective” gate capacitance. The typical open-loop output impedance is 2Ω. When using low input capacitance

MOSFETs (< 1500pF), a small gate resistor of 2Ω to 10Ω

dampens high frequency ringing created by an LC resonance due to the MOSFET gate’s lead inductance and

input capacitance. The GATE pin delivers up to 50mA for

a few hundred nanoseconds when slewing the gate of the

N-channel MOSFET in response to output load current

transients.

is 20V and the minimum operating V

IN2

+ (VGS of the MOSFET at max I

OUT

to GATE output swing).

IN2

OUT

is

IN2

) + 1.6V

I

(Pin 12): This is the negative sense terminal of the

NEG

current limit amplifier. A small sense resistor is connected

in series with the drain of the external MOSFET and is

connected between the I

POS

and I

pins. A 50mV

NEG

threshold voltage in conjunction with the sense resistor

value sets the current limit level. The current sense resistor can be a low value shunt or can be made from a piece

of PC board trace. If the current limit amplifier is not used,

tie the I

is to ground the I

NEG

pin to I

to defeat current limit. An alternative

POS

pin. This action disables the current

NEG

limit amplifier and additional internal circuitry activates

the timer circuit on the SHDN2 pin if the GATE pin swings

to the VIN rail. This option provides the user with a

No R

I

POS

TM

SENSE

current limit function.

(Pin 13): This is the positive sense terminal of the

current limit amplifier. Tie this pin directly to the main

input voltage from which the output voltage is regulated.

SHDN1 (Pin 14): Boost Regulator Shutdown Pin. Tie to 1V

or more to enable device. Ground to shut down. This pin

must not float for proper operation. Connect SHDN1

externally as it does not incorporate an internal pull-up or

pull-down.

GND (Pin 15): Boost Converter Analog Ground. This pin

is also the negative sense terminal for the FB1 1.23V

reference. Connect the external feedback divider network, which sets the V

supply voltage and terminates

IN2

to GND, directly to this pin for best regulation and

performance. Also, tie this pin directly to SWGND (Pin 2)

and GND (Pin 6).

FB1 (Pin 16): Boost Regulator Feedback Pin. Reference

voltage is 1.23V. Connect resistive divider tap here.

Minimize trace area at FB1. Set V

V

= 1.23V(1 + R1/R2).

OUT

No R

is a trademark of Linear Technology Corporation.

SENSE

OUT

= V

IN2

according to

3150f

7

LT3150

W

BLOCK DIAGRA S

Boost Switching Regulator

V

IN2

R1

(EXTERNAL)

R2

(EXTERNAL)

V

OUT

V

3

IN1

FB1

16

FB1

GND

15

SHDN2

R7

(EXTERNAL)

FB2

R8

(EXTERNAL)

V

GND

FB2

4

IN2

5

6

8

V

IN1

Q2

x10

R6

40k

R3

30k

R4

140k

+

A1

–

gm = 77µmhos

R

C

100k

C

40pF

C

RAMP

GENERATOR

1.4MHz

OSCILLATOR

Σ

SHDN1

14

COMPARATOR

–

A2

+

SHUTDOWN

FF

RQ

S

I

LIM1

DRIVER

SW

1

Q3

+

0.15Ω

–

2

SWGND

3150 BD1

R5

40k

Q1

Linear Regulator Controller

V

TH1

SW1

I

1

15µA

NORMALLY

OPEN

OR1

50mV

+

–

+

I

AMP

LIM2

D1

–

I

I

POS

13

NEG

12

+

COMP1

–

100mV

HYSTERESIS

D2

–

COMP2

+

SW2

I

2

5µA

NORMALLY

CLOSED

R10

OR2

Q9

5k

+

V

START-UP V

REF

1.21V

100µA

COMP3

+

ERROR AMP

–

I

3

Q5Q4

R9

50k

Q7

Q6

TH2

1V

–

+

–

GATE

11

COMP

9

Q8

3150 BD02

8

3150f

WUUU

APPLICATIO S I FOR ATIO

LT3150

INTRODUCTION

With each new generation of computing systems, total

power increases while system voltages fall. CPU core,

logic and termination supplies below 1.8V are now common. Power supplies must not only regulate low output

voltages, but must also operate from low input voltages.

A low voltage, very low dropout linear regulator is an

attractive conversion option for applications with output

current in the range of several amperes. Component count

and cost are low in comparison with switching regulator

solutions and with low input-to-output differential voltages, efficiencies are comparable.

In addition to low input-to-output voltage conversion,

these systems require stringent output voltage regulation.

The output voltage specification includes input voltage

change, output load current change, temperature change

and output load current transient response. Total tolerances as low as ±2% are now required. For a 1.5V output

voltage, this amounts to a mere ±30mV. Transient load

current response is the most critical component as output

current can cycle from zero to amps in tens of nanoseconds. These requirements mandate the need for a very

accurate, very high speed regulator.

Historically employed solutions include monolithic

3-terminal linear regulators, PNP transistors driven by

low cost control circuits and simple buck converter

switching regulators. The 3-terminal regulator provides

high integration, the PNP driven regulator provides low

dropout performance and the switching regulator provides high electrical efficiency.

However, these solutions manifest a common trait of

transient response measured in many microseconds. This

fact translates to a regulator output decoupling capacitor

scheme requiring several hundred microfarads of very low

ESR bulk capacitance using multiple capacitors in parallel.

This required bulk capacitance is in addition to the ceramic

decoupling capacitor network that handles the transient

load response during the first few hundred nanoseconds

as well as providing high frequency noise immunity. The

combined cost of all capacitors is a significant percentage

of the total power supply cost.

The LT3150 controller IC is a unique, easy-to-use device

that drives an external N-channel MOSFET as a source

follower and realizes an extremely low dropout, ultrafast

transient response regulator. The circuit achieves superior regulator bandwidth and transient load performance

by eliminating expensive special polymer, tantalum or

bulk electrolytic capacitors in the most demanding applications. Performance is optimized around the latest generation of low cost, low ESR, readily available ceramic

capacitors. Users benefit directly by saving significant

cost as all bulk capacitance is removed. Additional savings

include insertion cost, purchasing/inventory cost and

board space.

The precision-trimmed adjustable voltage LT3150 accommodates most power supply voltages. Proper selection of the N-channel MOSFET R

dropout voltage performance. Transient load step performance is optimized for ceramic output capacitor networks

allowing the regulator to respond to transient load changes

in a few hundred nanoseconds. The output capacitor

network typically consists of multiple 1µF to 10µF ceramic

capacitors in parallel depending on the power supply

requirements. The LT3150 also incorporates current limiting, on/off control for power supply sequencing and

overvoltage protection or thermal shutdown with simple

external components.

The LT3150 combines the benefits of low input voltage

operation, very low dropout voltage performance, precision regulation and fast transient response. With low

input/output differential voltage applications becoming

the norm, an LT3150-based solution is a practical alternative to switching regulators providing comparable efficiency performance at an appreciable cost savings.

BLOCK DIAGRAM OPERATION

Gate drive for the external N-channel MOSFET in the linear

regulator loop is provided by a current mode, internally

compensated, fixed frequency step-up switching regulator. Referring to the Block Diagram, Q1 and Q2 form a

bandgap reference core whose loop is closed around the

output of the regulator. The voltage drop across R5 and R6

allows user-settable

DS(ON)

3150f

9

LT3150

WUUU

APPLICATIO S I FOR ATIO

is low enough such that Q1 and Q2 do not saturate, even

when V

above 1.23V, causing VC (the error amplifier’s output) to

decrease. Comparator A2’s output stays high, keeping

switch Q3 in the off state. As increased output loading

causes the FB1 voltage to decrease, A1’s output increases.

Switch current is regulated directly on a cycle-by-cycle

basis by the VC node. The flip flop is set at the beginning

of each switch cycle, turning on the switch. When the

summation of a signal representing switch current and a

ramp generator (introduced to avoid subharmonic oscillations at duty factors greater than 50%) exceeds the V

signal, comparator A2 changes state, resetting the flip flop

and turning off the switch. More power is delivered to the

output as switch current is increased. The output voltage,

attenuated by external resistor divider R1 and R2, appears

at the FB1 pin, closing the overall loop. Frequency compensation is provided internally by RC and CC. Transient

response can be optimized by the addition of a phase lead

capacitor CPL in parallel with R1 in applications where

large value or low ESR output capacitors are used.

As the load current is decreased, the switch turns on for a

shorter period each cycle. If the load current is further

decreased, the converter will skip cycles to maintain

output voltage regulation.

The linear regulator controller section of the LT3150 Block

Diagram consists of a simple feedback control loop and

multiple protection functions. Examining the Block Diagram for the LT3150, a start-up circuit provides controlled

start-up, including the precision-trimmed bandgap reference, and establishes all internal current and voltage

biasing.

Reference voltage accuracy at the FB2 pin is specified as

±0.6% at room temperature and as ±1% over the full

operating temperature range. This places the LT3150

among a select group of regulators with a very tightly

specified reference voltage tolerance. The 1.21V reference

is tied to the noninverting input of the main error amplifier

in the feedback control loop.

The error amplifier consists of a single high gain gm stage

with a transconductance equal to 15 millimhos. The

inverting terminal is brought out as the FB2 pin. The g

stage provides differential-to-single ended conversion at

is 1V. When there is no load, FB1 rises slightly

IN1

C

m

the COMP pin. The output impedance of the gm stage is

about 1MΩ and thus, 84dB of typical DC error amplifier

open-loop gain is realized along with a typical 75MHz

uncompensated unity-gain crossover frequency. Note

that the overall feedback loop’s DC gain decreases from

the gain provided by the error amplifier by the attenuation

factor in the resistor divider network which sets the DC

output voltage. External access to the high impedance

gain node of the error amplifier permits typical loop

compensation to be accomplished with a series RC + C

network to ground.

A high speed, high current output stage buffers the COMP

node and drives up to 5000pF of “effective” MOSFET gate

capacitance with almost no change in load transient performance. The output stage delivers up to 50mA peak

when slewing the MOSFET gate in response to load

current transients. The typical output impedance of the

GATE pin is typically 2Ω. This pushes the pole due to the

error amplifier output impedance and the MOSFET input

capacitance well beyond the loop crossover frequency.

the capacitance of the MOSFET used is less than 1500pF,

it may be necessary to add a small value series gate

resistor of 2Ω to 10Ω. This gate resistor helps damp the

LC resonance created by the MOSFET gate’s lead inductance and input capacitance. In addition, the pole formed

by this resistance and the MOSFET input capacitance can

be fine tuned.

Because the MOSFET pass transistor is connected as a

source follower, the power path gain is much more predictable than designs that employ a discrete PNP transistor as

the pass device. This is due to the significant production

variations encountered with PNP Beta. MOSFETs are also

very high speed devices which enhance the ability to produce a stable wide bandwidth control loop. An additional

advantage of the follower topology is inherently good line

rejection. Input supply disturbances do not propagate

through to the output. The feedback loop for a regulator

circuit is completed by providing an error signal to the FB2

pin. A resistor divider network senses the output voltage

and sets the regulated DC bias point. In general, the LT3150

regulator feedback loop permits a loop crossover frequency

on the order of 1MHz while maintaining good phase and gain

margins. This unity-gain frequency is a factor of 20 to 30

times the bandwidth of currently implemented regulator

If

3150f

10

WUUU

APPLICATIO S I FOR ATIO

LT3150

solutions for microprocessor power supplies. This significant performance benefit is what permits the elimination

of all bulk output capacitance.

Several other unique features are included in the design

that increase its functionality and robustness. These functions comprise the remainder of the Block Diagram.

A high side sense, current limit amplifier provides active

current limiting for the regulator. The current limit amplifier uses an external low value shunt resistor connected in

series with the external MOSFET’s drain. This resistor can

be a discrete shunt resistor or can be manufactured from

a Kelvin-sensed section of “free” PC board trace. All load

current flows through the MOSFET drain and thus, through

the sense resistor. The advantage of using high side

current sensing in this topology is that the MOSFET’s gain

and the main feedback loop’s gain remain unaffected. The

sense resistor develops a voltage equal to I

The current limit amplifier’s 50mV threshold voltage is a

good compromise between power dissipation in the sense

resistor, dropout voltage impact and noise immunity.

Current limit activates when the sense resistor voltage

equals the 50mV threshold.

Two events occur when current limit activates: the first is

that the current limit amplifier drives Q5 in the Block

Diagram and clamps the positive swing of the COMP node

in the main error amplifier to a voltage that provides an

output load current of 50mV/R

ues as long as the output current overload persists. The

second event is that a timer circuit activates at the SHDN2

pin. This pin is normally held low by a 5µA active pull-down

that limits to ≈ 100mV above ground. When current limit

activates, the 5µA pull-down turns off and a 15µA pull-up

current source turns on. Placing a capacitor in series with

the SHDN2 pin to ground generates a programmable time

ramp voltage.

The SHDN2 pin is also the positive input of COMP1. The

negative input is tied to the internal 1.21V reference.

When the SHDN2 pin ramps above V

drives Q7 and Q8. This action pulls the COMP and GATE

pins low and latches the external MOSFET drive off. This

condition reduces the MOSFET power dissipation to zero.

The time period until the latched-off condition occurs is

typically equal to C

(1.11V)/15µA. For example, a

SHDN2

. This action contin-

SENSE

REF

OUT(RSENSE

, the comparator

).

1µF capacitor on the SHDN2 pin yields a 74ms ramp time.

In short, this unique circuit block performs a current limit

time-out function that latches off the regulator drive after

a predefined time period. The time-out period selected is

a function of system requirements including start-up and

safe operating area. The SHDN2 pin is internally clamped

to typically 1.85V by Q9 and R10. The comparator tied to

the SHDN2 pin has 100mV of typical hysteresis to provide

noise immunity. The hysteresis is especially useful when

using the SHDN2 pin for thermal shutdown.

Restoring normal operation after the load current fault is

cleared is accomplished in two ways. One option is to

recycle the V

external bleed path for the SHDN2 pin capacitor is provided. The second option is to provide an active reset

circuit that pulls the SHDN2 pin below V

SHDN2 pin below V

source and reactivates the 5µA pull-down. If the SHDN2

pin is held below V

lator continues to operate in current limit into a short. This

action requires being able to sink 15µA from the SHDN2

pin at less than 1V. The 5µA pull-down current source and

the 15µA pull-up current source are designed low enough

in value so that an external resistor divider network can

drive the SHDN2 pin to provide overvoltage protection or

to provide thermal shutdown with the use of a thermistor

in the divider network. Diode-ORing these functions together is simple to accomplish and provides multiple

functionality for one pin.

If the current limit amplifier is not used, two choices

present themselves. The simplest choice is to tie the I

pin directly to the I

and provides the simplest, no frills circuit. Applications in

which the current limit amplifier is not used are where

extremely low dropout voltages must be achieved and the

50mV threshold voltage cannot be tolerated.

However, a second available choice permits a user to provide short-circuit protection with no external sensing. This

technique is activated by grounding the I

disables the current limit amplifier because Schottky diode

D1 clamps the amplifier’s output and prevents Q5 from

pulling down the COMP node. In addition, Schottky diode

D2 turns off pull-down transistor Q4. Q4 is normally on and

LT3150 supply voltage as long as an

IN2

. Pulling the

REF

turns off the 15µA pull-up current

REF

during a fault condition, the regu-

REF

pin. This action defeats current limit

POS

pin. This action

NEG

NEG

3150f

11

LT3150

WUUU

APPLICATIO S I FOR ATIO

holds internal comparator COMP3’s output low. This

comparator circuit, now enabled, monitors the GATE pin

and detects saturation at the positive rail. When a saturated

condition is detected, COMP3 activates the shutdown timer.

Once the time-out period occurs, the output is shut down

and latched off. The operation of resetting the latch remains

the same. Note that this technique does not limit the FET

current during the time-out period. The output current is

only limited by the input power supply and the input/output impedance. Setting the timer to a short period in this

mode of operation keeps the external MOSFET within its

SOA (safe operating area) boundary and keeps the

MOSFET’s temperature rise under control.

Unique circuit design incorporated into the LT3150 alleviates all concerns about power supply sequencing. The

issue of power supply sequencing is an important topic as

the typical LT3150 application has two separate power

supply inputs, V

IN1

and V

. If the V

IN2

supply

IN2

voltage is

slow in ramping up or is held off by SHDN1, insufficient

MOSFET gate drive exists and therefore, the output

voltage does not come up. This statement is true as long

as the V

input voltage is lower than the threshold of the

IN1

external MOSFET. Prior to the boost converter powering

up, V

through the boost inductor. If V

equals V

IN2

– VF due to the DC path present

IN1

is high enough, the

IN1

MOSFET turns on and pulls the output voltage up. If this

situation exists and the output must be held off, then

pulling the SHDN2 pin high actively holds the output off.

Pull the SHDN2 pin low to allow start-up, as the SHDN2

high logic state is a latched condition.

If V

is present, but the V

IN2

I

pin is slow in ramping, then the feedback loop wants

POS

to drive the GATE pin to the positive V

in a large current as the V

supply voltage tied to the

IN1

rail. This results

IN2

supply ramps up. However,

IN1

undervoltage lockout circuit COMP2, which monitors the

I

supply voltage, holds Q6 on and pulls the COMP pin

POS

low until the I

voltage increases to greater than the

POS

internal 1.21 reference voltage. The undervoltage lockout

circuit then smoothly releases the COMP pin and allows

the output voltage to come up in dropout from the input

supply voltage. An additional benefit derived from the

speed of the LT3150 feedback loop is that turn-on

overshoot is virtually nonexistent in a properly compensated system.

BOOST REGULATOR COMPONENT SELECTION

Diode

Linear Technology recommends the use of a Schottky

diode with the LT3150. For input supply voltages less than

2V, the Motorola MBR0520 or equivalent is a good choice

due to its small size, low cost and low forward voltage. The

average diode current equals the V

supply current of

IN2

12mA typically. The peak diode current equals the peak

switch current, which in these low input-to-output voltage

applications ranges from 100mA to 200mA.

The diode’s forward voltage during its conduction period

directly affects the duty cycle of the boost converter. These

low input-to-output voltage applications require the boost

converter to operate at duty cycles close to the maximum

and the difference of a few hundred millivolts in the diode

forward voltage results in a duty cycle difference of several

percent. For supply voltages greater than 2V, a 1N4148 is

suitable and lowers cost.

Inductor

Use inductors with a saturation current rating (where

inductance is approximately 70% of zero current inductance) of 0.2A or greater. Also, choose an inductor with a

DCR of 2.5Ω or less. The inductor’s DCR also affects the

boost converter’s duty cycle. A larger DCR value increases

the required duty cycle. An inductance value between

4.7µH and 10µH works well in most applications.

Table 1 lists several 10µH inductors that work with the

LT3150, although this is by no means an exhaustive list.

Many magnetic vendors have components suitable for use

in this boost application.

Input Capacitor

The input bypass capacitors serve as the reservoir capacitor for the boost regulator, the linear regulator and whatever other system circuitry the input supply powers.

Therefore, the input capacitor network is most likely

distributed along the input supply PCB plane.

However, the switching of current at high speed by the

boost regulator mandates a local bypass capacitor at the

V

pin. Place this input capacitor physically close to the

IN1

3150f

12

LT3150

WUUU

APPLICATIO S I FOR ATIO

Table 1. Inductor Vendors

VENDOR PHONE URL PART NUMBER INDUCTANCE DCR I

Murata (404) 436-1300 www.murata.com LQH31CN100K03K 10µH 1.3Ω 0.23A

LQH32CN100K23K 10µH 0.44Ω 0.3A

Panasonic (800) 344-2112 www.panasonic.com ELJPC100KF 10µH 2.2Ω 0.21A

Sumida (847) 956-0666 www.sumida.com CDRH3D16100 10µH 0.21Ω 0.55A

Taiyo Yuden (800) 348-2496 www.t-yuden.com LQLB2016T100M 10µH 0.5Ω 0.155A

LQLB2518T100M 10µH 0.25Ω 0.165A

Toko (847) 297-0070 www.toko.com LLM3225-100K 10µH 1.7Ω 0.22A

V

pin. ESR is not critical and in most cases, an inexpen-

IN1

sive tantalum or ceramic capacitor with a value from 1µF

to 4.7µF is appropriate.

The boost regulator output capacitor also serves as the

V

input bypass capacitor. Place this capacitor physi-

IN2

cally close to the V

pin. This capacitor supplies the

IN2

instantaneous current to slew the external MOSFET’s

Output Capacitor

The output capacitor choice is far more important. The

gate capacitance quickly during an output load current

transient.

capacitor’s characteristics determines output voltage ripple.

The output capacitor must have enough capacitance to

LINEAR REGULATOR COMPONENT SELECTION

satisfy the load under transient conditions and it must

shunt the switched component of current coming through

the diode. Output voltage ripple results because this

switched current passes through the capacitor’s finite

output impedance. The capacitor must have low impedance at the 1.4MHz switching frequency of the LT3150. At

this frequency, the capacitor’s equivalent series resistance (ESR) usually dominates the impedance. Choosing

a capacitor with lower ESR results in lower output voltage

ripple.

However, consider loop stability when choosing the output capacitor because the LT3150 is internally compensated and no access is provided to this internal

compensation. Small, low cost tantalum capacitors have

some ESR. This ESR enhances stability due to the addition

of a zero in the regulator feedback loop. Ceramic capacitors are very popular, having attractive characteristics

such as near-zero ESR, small size and low cost. Replacing

the tantalum output capacitor with a ceramic unit decreases the phase margin, in some cases to unacceptable

levels. The addition of a phase lead capacitor and an

isolating resistor in the feedback divider network can be

used to stabilize the feedback loop, but the added component count and cost makes the use of a tantalum output

capacitor the simpler and preferred choice.

Output Capacitors

The LT3150 linear regulator is stable with a wide range of

output capacitors (assuming the feedback loop is properly frequency compensated). However, using multiple,

low value, very low ESR ceramic capacitors (1µF to 4.7µF)

in parallel optimizes the load transient response of an

LT3150 feedback loop. As is discussed in the Frequency

Compensation section, the output capacitor value is critical because it sets the location of a pole in the feedback

loop that determines the unity-gain crossover frequency.

Therefore, the characteristics of ceramic capacitors warrant some discussion.

Manufacturers make ceramic capacitors with a variety of

dielectrics, each with different behavior across temperature and applied voltage. The most common dielectrics

are Z5U, Y5V, X5R and X7R. The Z5U and Y5V dielectrics

provide high C-V products in a small package at low cost,

but exhibit very strong voltage and temperature coefficients. The X5R and X7R dielectrics yield highly stable

characteristics and are more suitable for use as the output

capacitor at fractionally increased cost. The X5R and X7R

dielectrics both exhibit excellent voltage coefficient char

teristics. The X7R type works over a larger temperature

range and exhibits better temperature stability whereas

X5R is less expensive and is available in higher values.

SAT

ac-

3150f

13

LT3150

WUUU

APPLICATIO S I FOR ATIO

Figures 1 and 2 show voltage coefficient and temperature

coefficient comparisons between Y5V and X5R material.

With the critical pole in the LT3150 feedback loop being set

by the absolute value of the output capacitor, it is obvious

why Linear Technology strongly recommends the use of

ceramic capacitors with X5R or X7R dielectric material.

MOSFET Selection

MOSFET selection criteria include threshold voltage

V

tance R

package thermal resistance R

, maximum continuous drain current ID, on-resis-

GS(TH)

, maximum drain-to-source voltage VDS and

DS(ON)

.

TH(JA)

Linear Technology recommends the use of a logic-level

threshold MOSFET in LT3150 applications. The VGS range,

as defined by the threshold voltage and the load current

range, fits well within the boost regulator’s capability and

the output swing range of the error amplifier. The MOSFET’s

continuous drain current rating must equal or exceed the

maximum load current and the maximum drain-to-source

voltage must exceed the maximum input voltage.

The most critical specification is the MOSFET R

Calculate the required R

MOSFET R

DS(ON)

≤

from the following formula:

DS(ON)

VV

IN MIN OUT MIN

–

() ()

I

•3

OUT MAX

()

DS(ON)

.

The additional factor of three in the equation’s denominator accounts for production variation, the temperature

coefficient of R

, voltage dips in VIN during transient

DS(ON)

output load steps and other operating point characteris-

tics. Although the factor of three is slightly conservative,

this imposes no cost penalty. As an example, consider the

1.8V to 1.5V at 4A application on the front page. Assuming

the 1.8V input and the 1.5V output each have a ±5%

tolerance,

(. • . )–(. • . )

R

DS(ON)

095 18 095 15

=≤Ω

A Siliconix Si4410 MOSFET with an R

close match. Although the Si4410’s 30V maximum V

VV

•

34

A

DS(ON)

.

23 8

m

of 20mΩ is a

DS

and 8A maximum ID ratings exceed the application’s

requirements, the Si4410’s low cost makes it an excellent

choice.

As the final criteria, consider the thermal resistance R

TH(JA)

of the MOSFET’s package. The temperature rise in the

MOSFET must be kept under control and within the

manufacturer’s maximum junction temperature specification. The power dissipated in the MOSFET is calculated by:

P

In the design example, P

1.2W. The Si4410’s R

MOSFET

= (V

IN

– V

) • I

OUT

TH(JA)

OUT

MOSFET

= (1.8V – 1.5V) • 4A =

is 50°C/W for its S0-8 pack-

age, which translates to a 60°C temperature rise above

ambient. MOSFET manufacturers have significantly lowered the thermal resistance of modern devices with improved packages. These packages provide exposed

backsides that directly transfer heat to the PCB board.

These packages enable LT3150 applications with much

higher output currents while keeping the MOSFET temperature in control.

20

0

–20

–40

–60

CHANGE IN VALUE (%)

–80

–100

0

Figure 1. Ceramic Capacitor DC Bias Characteristics

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

X5R

Y5V

26

4

8

DC BIAS VOLTAGE (V)

14

12

10

3150 F01

14

40

20

0

–20

–40

–60

CHANGE IN VALUE (%)

–80

–100

–50

16

Figure 2. Ceramic Capacitor Temperature Characteristics

–25 0

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

X5R

Y5V

50 100 125

25 75

TEMPERATURE (°C)

3150 F02

3150f

WUUU

APPLICATIO S I FOR ATIO

LT3150

Frequency Compensation

Frequency compensation is the most critical step in designing an LT3150 application circuit. Frequency compensation stabilizes the feedback loop under all line, load and

temperature conditions and determines the transient load

step performance.

To start the frequency compensation process, gather the

following application information. Determine the output

voltage, the minimum and maximum output currents, the

transconductance (gfs) of the selected MOSFET at the

minimum and maximum output currents and the output

capacitor type (ceramic, tantalum, electrolytic).

Frequency compensation is accomplished with a passive

network tied from the LT3150’s COMP pin to ground. The

LT3150 generally employs a Type-2 frequency compensation method. The “Type-2” method uses two poles and one

zero. The output capacitor type determines how the zero

in the feedback loop is set. Ceramic capacitors typically

have very low ESR (equivalent series resistance) and

therefore the COMP pin network sets the “zero” location.

Tantalum and electrolytic capacitors typically have sufficient ESR such that the “zero” formed by the ESR and the

capacitance value is used. Using tantalum or electrolytic

capacitors in LT3150 applications is somewhat more

challenging because the user must choose capacitors with

the proper ESR plus capacitance value to place the zero at

the correct spot in the frequency response.

Refer to the simplified LT3150 block diagram shown in

Figure 3 during the frequency compensation discussion

that follows.

Figure 4 illustrates the typical bode plot and the pole/zero

locations with the use of low ESR ceramic output

capacitors.

Figure 5 illustrates the typical bode plot and the pole/zero

locations with the use of tantalum or electrolytic output

capacitors.

In both output capacitor cases, the location of the first

pole, P1, is set by the error amplifier COMP pin’s openloop output impedance, RO, and compensation capacitor,

C1. The low frequency gain is set by g

• RO • (V

m1

REF/VOUT

)

In the case of low ESR ceramic capacitors, R1 in series

with C1 in the COMP pin network sets the zero, Z1. With

tantalum or electrolytic capacitors, the ESR in series with

the output capacitor CO sets Z1. Z1’s location establishes

the mid-band gain or “shelf” gain. For a given value of

output capacitance, the “shelf” gain determines the

regulator’s transient response to an output load step,

especially the output voltage’s peak overshoot and undershoot. For a given output load current change, a corresponding delta in the MOSFET’s VGS occurs. This ∆V

GS

divided by the “shelf gain” sets how much the FB2 must

change and thus, results in output voltage perturbation.

Higher “shelf” gain results in lower transient response

peak deviations. Higher shelf gain also translates to a

g

= 0.015

m1

V

REF

FB2

+

–

Figure 3. Simplified Block Diagram for Frequency Compensation

R

1M

COMP

+

O

R1

C1

C2

–

R

F1

V

R

REF

F2

=

V

RF1 + R

OUT

F2

R

F2

V

R

IN

G

Q1

V

OUT

R

ESR

I

LOAD

C

O

3150 F03

3150f

15

LT3150

WUUU

APPLICATIO S I FOR ATIO

P1 = 1/(2 • π • R

AVOL = g

GAIN (dB)

I

fX = gm1 • R1 • •

• C1)

O

• RO • (V

m1

Z1 = 1/(2 • π • R1 • C1)

LOAD(MIN)

FREQUENCY (Hz)

MANY HIGH ORDER POLES AND

REF/VOUT

P2 = g

m

AV1 = gm1 • R1 • (V

ZEROS PAST UNITY-GAIN f

V

gm(Q1)

REF

2 • π • C

V

OUT

)

P2 IS A FUNCTION

OF LOAD CURRENT

(Q1)/(2 • π • CO)

I

LOAD(MAX)

3150 F04

X

O

REF/VOUT

)

Figure 4. Typical Bode Plot for

Low ESR Ceramic Output Capacitors

higher unity gain bandwidth crossover frequency, fX. f

X

must be set to a value that provides adequate phase and

gain margin and this criteria limits the shelf gain value. If

higher shelf gain is required for a given application, then

increase output capacitance.

In both output capacitor cases, the location of the second

pole, P2, is set by the MOSFET’s transconductance, gm(Q1),

and the value of the output capacitor, CO. The output load

current sets the transconductance of the MOSFET. P2

moves as a function of load current and consequently, so

does the unity-gain crossover frequency, fX. Figures 4 and

5 depict this behavior. At very low output currents, P2’s

location moves to a very low frequency. Therefore, set Z1

at a low enough frequency to provide adequate phase boost.

A temptation is to set Z1’s value equal to P2’s value at

minimum output load current. The bode plot then exhibits

a single pole response at minimum output current. However, this either makes the “shelf gain” and fX too high for

stability or it makes the small signal settling time very long.

Set Z1 above the minimum value for P2 so that at small

output load currents, the second pole P2 occurs and then

Z1 provides phase boost prior to crossing unity gain.

At the highest load current levels, several poles and zeros

exist just beyond the unity-gain crossover frequency.

Sometimes, the gain peaks back above unity and a high

frequency, low level oscillation appears. A high frequency

P1 = 1/(2 • π • R

AVOL = g

GAIN (dB)

I

• C1)

O

• RO • (V

m1

Z1 = 1/(2 • π • ESR • C

LOAD(MIN)

FREQUENCY (Hz)

MANY HIGH ORDER POLES AND

f

X

REF/VOUT

P2 = g

m

AV1 = AVOL • (P1/P2)

ZEROS PAST UNITY-GAIN f

g

m1

=

2 • π • C1

)

P2 IS A FUNCTION

OF LOAD CURRENT

)

O

(Q1)/(2 • π • CO)

• CO)/(gm(Q1) • C1)

= (g

m1

I

LOAD(MAX)

3150 F05

X

Figure 5. Typical Bode Plot for Tantalum

or Electrolytic Output Capacitors

pole is necessary to roll off the response. In the case of

ceramic output capacitors, capacitor C2 in Figure 4 sets

this pole in combination with R1. In the case of electrolytic

or tantalum output capacitors, some small ceramic capacitors in parallel with the main output capacitors usually

provide the desired response.

Finally, look for very high frequency gate oscillations in the

range of 2MHz to 10MHz. Small MOSFETs with low gate

capacitance are most susceptible to this issue. This oscillation is typically caused by the MOSFET’s “effective” gate

capacitance and the MOSFET’s parasitic source inductance resonating. The MOSFET’s source inductance is the

sum of the device’s bond wire plus package lead inductance and the PCB trace inductance between the MOSFET’s

source and the actual output capacitors. Although the

MOSFET’s internal inductance is fixed, proper PCB layout

techniques minimize the external inductance. Minimize

the distance between the MOSFET’s source and the output

decoupling capacitors and run wide planes if possible.

Connect the top of the feedback divider at the point closest

to the actual load rather than the MOSFET source. If high

frequency oscillations persist, a small value resistor in the

range of 1Ω to 50Ω in series with the gate of the MOSFET

typically eliminates this ringing. The inclusion of a gate

resistor may permit the high frequency pole discussed in

the preceding paragraph to be eliminated or fine tuned.

16

3150f

U

TYPICAL APPLICATIO S

LT3150

Setting the Linear Regulator Output Voltage

V

OUT

R2

FB2

R1

= 1.21V(1 + R2/R1)

V

OUT

3150 TA03

Setting Current Limit

I

POS

I

NEG

GATE

= 50mV/R

*I

LIM

R

SENSE

R

SENSE

ACTIVATING CURRENT LIMIT ALSO ACTIVATES

THE SHDN2 PIN TIMER

SENSE

= DISCRETE SHUNT RESISTOR OR

= KELVIN-SENSED PC BOARD TRACE

V

IN1

R

*

SENSE

Q2

V

OUT

3150 TA05

Using No R

I

SHDN2 V

POS

C

T

I

NEG

GATE

Current Limit

SENSE

MBR0520L

C1

10µF

D1

IN1

Q1

V

OUT

3150 TA04

Current Limit with Foldback Limiting Example

I

POS

I

NEG

GATE

SET R5 << R6

50mV

= –

I

OUT

R4

R5

D1

1N4148

D2

1N4148

R6

R6

(V

()

R5 + R6

IN1

3150 TA06

– V

R4

R4

Q3

OUT

V

IN1

I

OUT

V

OUT

– 2VF)

R5

()

R5 + R6

Shutdown Time-Out with Reset

R1

100k

Q1

VN2222L

RESET

0V TO 5V

*C1 = 15µA(t)/1.11V

t = SHUTDOWN LATCHOFF TIME

Shutdown Time-Out with Reset

R2

100k

RESET

0V TO 5V

*C2 = 15µA(t)/1.11V

t = SHUTDOWN LATCH-OFF TIME

Q2

2N3904

R3

100k

SHDN2

C1*

3150 TA07

SHDN2

C2*

3150 TA09

Basic Thermal Shutdown

V

IN1

RT1

10k

NTC

SHDN2

R4*

RT1 = DALE NTHS-1206N02

THERMALLY MOUNT RT1

IN CLOSE PROXIMITY

TO THE EXTERNAL

N-CHANNEL MOSFET

*CHOOSE R4 BASED ON

V

IN1

SHUTDOWN TEMPERATURE

Overvoltage Protection

V

V

= 1.21(R6/R5) + 5µA(R6)

OUT(uth)

= 1.11(R6/R5) – 15µA(R6)

V

OUT(lth)

AND REQUIRED THERMAL

3150 TA08

OUT

R6

SHDN2

R5

3150 TA10

3150f

17

LT3150

TYPICAL APPLICATIO S

1.5V to 1.2V, 4A Very Low Dropout Linear Regulator

U

MBR0520L

1.5k

10µH

5.1Ω

L1

V

IN

1.5V

V

OUT

1.2V

4A

50pF

Si4410

+

3150 TA11

C

IN

220µF

2.5V

×2

2.2µF ×10

X5R CERAMIC

0805 CASE

+

C1

4.7µF

5.9k

1%

1.37k

1%

CIN: PANASONIC SP SERIES EEFUE0E221R 20%

C1: AVX TAJA475M020R 20V 20%

L1: MURATA LQH32CN100K11 OR SUMIDA CDRH3D16100

LT3150

V

IN2

FB1

SHDN2

SWGND

GND

GND

SW

V

SHDN1

I

POS

I

NEG

GATE

FB2

COMP

6800pF

IN1

2.5V to 1.8V, 1.7A Low Dropout Linear Regulator

MBR0520L

1.5k

10µH

5.1Ω

L1

V

IN

2.5V

V

OUT

1.8V

1.7A

3150f

50pF

Si4410

499Ω

1%

1020Ω

1%

+

3150 TA11a

C

IN

220µF

4V

×2

2.2µF ×6

X5R CERAMIC

0805 CASE

+

C1

4.7µF

6.65k

1%

1.37k

1%

LT3150

V

IN2

FB1

SHDN2

SWGND

GND

GND

CIN: PANASONIC SP SERIES EEFUE0G221R 20%

C1: AVX TAJA475M020R 20V 20%

L1: MURATA LQH32CN100K11 OR SUMIDA CDRH3D16100

SW

V

IN1

SHDN1

I

POS

I

NEG

GATE

FB2

COMP

6800pF

18

PACKAGE DESCRIPTIO

LT3150

U

GN Package

16-Lead Plastic SSOP (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1641)

.045 ±.005

.254 MIN

RECOMMENDED SOLDER PAD LAYOUT

.007 – .0098

(0.178 – 0.249)

.016 – .050

NOTE:

1. CONTROLLING DIMENSION: INCHES

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.150 – .165

.0250 TYP.0165 ±.0015

.015

(0.38 ± 0.10)

0° – 8° TYP

± .004

.189 – .196*

(4.801 – 4.978)

16

15

14

12 11 10

13

.229 – .244

(5.817 – 6.198)

12

×

°

45

.053 – .068

(1.351 – 1.727)

.008 – .012

(0.203 – 0.305)

4

3

5

9

678

(0.102 – 0.249)

.0250

(0.635)

BSC

.009

(0.229)

REF

.150 – .157**

(3.810 – 3.988)

.004 – .0098

GN16 (SSOP) 0502

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3150f

19

LT3150

TYPICAL APPLICATIO

U

1.8V to 1.5V, 4A Very Low Dropout Linear Regulator with No R

MBR0520L

+

CIN: PANASONIC SP SERIES EEFUE0E221R 20%

C1: AVX TAJA475M020R 20V 20%

L1: MURATA LQH32CN100K11 OR SUMIDA CDRH3D16100

C1

4.7µF

6.19k

1%

1.37k

1%

SHDN2

0.01µF

LT3150

V

IN2

FB1

SHDN2

SWGND

GND

GND

SW

V

IN1

SHDN1

I

POS

I

NEG

GATE

FB2

COMP

6800pF

SHDN1

10µF

1.5k

50pF

Current Limiting and Shutdown

SENSE

L1

10µH

10k

BAT54

5.1Ω

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1573 UltraFast Transient Response Low Dropout VIN: 2.8V to 10V, V

Regulator PNP Driver, Up to 5A I

LT1575/LT1577 UltraFast Transient Response Low Dropout VIN: 1.5V to 22V, V

Regulator MOSFET Driver, Up to 10A LT1577 is Dual Version, N8, S8 Packages

LT1761 100mA, Low Noise Micropower, LDO VIN: 1.8V to 20V, V

LT1762 150mA, Low Noise Micropower, LDO VIN: 1.8V to 20V, V

LT1763 500mA, Low Noise Micropower, LDO VIN: 1.8V to 20V, V

LT1764/LT1764A 3A, Low Noise, Fast Transient Response, LDO VIN: 2.7V to 20V, V

LT1962 300mA, Low Noise Micropower, LDO VIN: 1.8V to 20V, V

LT1963/LT1963A 1.5A, Low Noise, Fast Transient Response, LDO VIN: 2.1V to 20V, V

LTC3411 1.25A(I

), 4MHz, Synchronous Step-Down 95% Efficiency, VIN: 2.5V to 5.5V, I

OUT

DC/DC Converter I

LTC3412 2.5A(I

), 4MHz, Synchronous Step-Down 95% Efficiency, VIN: 2.5V to 5.5V, I

OUT

DC/DC Converter I

: 200µA, Requires External PNP Transistor, S8 Package

SD

I

: <1µA, Low Noise <20µV

SD

Capacitors, ThinSOT Package

: <1µA, Low Noise <20µV

I

SD

I

: <1µA, Low Noise <20µV

SD

: <1µA,Low Noise <40µV

I

SD

Capacitors, DD, TO220-5 Packages

: <1µA, Low Noise <20µV

I

SD

I

: <1µA, Low Noise <40µV

SD

Capacitors, DD, T0220-5, SOT-223, S8 Packages

: <1µA, MS and DFN Packages

SD

: <1µA, TSSOP16E Package

SD

V

IN

: 1.25A, V

: 2.5A, V

1.8V

V

OUT

1.5V

4A

REF

REF

: 0.8V,

: 0.8V,

C

IN

+

Si4410

243Ω

1%

1020Ω

1%

: 1.265V, Dropout Voltage: 0.35V, IQ: 1.7mA,

OUT

: 1.21V, Dropout Voltage: 0.15V, IQ: 12mA,

OUT

: 1.22V, Dropout Voltage: 0.30V, IQ: 20µA,

OUT

: 1.22V, Dropout Voltage: 0.30V, IQ: 25µA,

OUT

: 1.22V, Dropout Voltage: 0.30V, IQ: 30µA,

OUT

: 1.21V, Dropout Voltage: 0.34V, IQ: 1mA,

OUT

: 1.22V, Dropout Voltage: 0.27V, IQ: 30µA,

OUT

: 1.21V, Dropout Voltage: 0.34V, IQ: 1mA,

OUT

220µF

2.5V

×2

2.2µF ×10

X5R CERAMIC

0805 CASE

3150 TA11a

, Stable with 1µF Ceramic

RMS P-P

, MS8 Package

RMS P-P

, S8 Package

RMS P-P

, “A” Version Stable with Ceramic

RMS P-P

, MS8 Package

RMS P-P

, “A” Version Stable with Ceramic

RMS P-P

OUT

OUT

20

Linear T echnology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3150f

LT/TP 1003 1K • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 2002

Loading...

Loading...