FEATURES

FREQUENCY (Hz)

0.1

HARMONIC DISTORTION (%)

0.2

0.4

10 1k 10k 100k

1010 TA02

0

100

0.3

V

OUT

= 10V

P-P

RL = 400Ω

LT1010

Fast ±150mA Power Buffer

U

DESCRIPTIO

■

20MHz Bandwidth

■

75V/µs Slew Rate

■

Drives ±10V into 75Ω

■

5mA Quiescent Current

■

Drives Capacitive Loads > 1µF

■

Current and Thermal Limit

■

Operates from Single Supply ≥ 4.5V

■

Very Low Distortion Operation

■

Available in 8-Pin miniDIP, Plastic TO-220

and Tiny 3mm × 3mm × 0.75mm 8-Pin DFN

Packages

U

APPLICATIO S

■

Boost Op Amp Output

■

Isolate Capacitive Loads

■

Drive Long Cables

■

Audio Amplifiers

■

Video Amplifiers

■

Power Small Motors

■

Operational Power Supply

■

FET Driver

The LT®1010 is a fast, unity-gain buffer that can increase

the output capability of existing IC op amps by more than

an order of magnitude. This easy-to-use part makes fast

amplifiers less sensitive to capacitive loading and reduces

thermal feedback in precision DC amplifiers.

Designed to be incorporated within the feedback loop, the

buffer can isolate almost any reactive load. Speed can be

improved with a single external resistor. Internal operating currents are essentially unaffected by the supply

voltage range. Single supply operation is also practical.

This monolithic IC is supplied in 8-pin miniDIP, plastic

TO-220 and 8-pin DFN packages. The low thermal resistance power package is an aid in reducing operating

junction temperatures.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

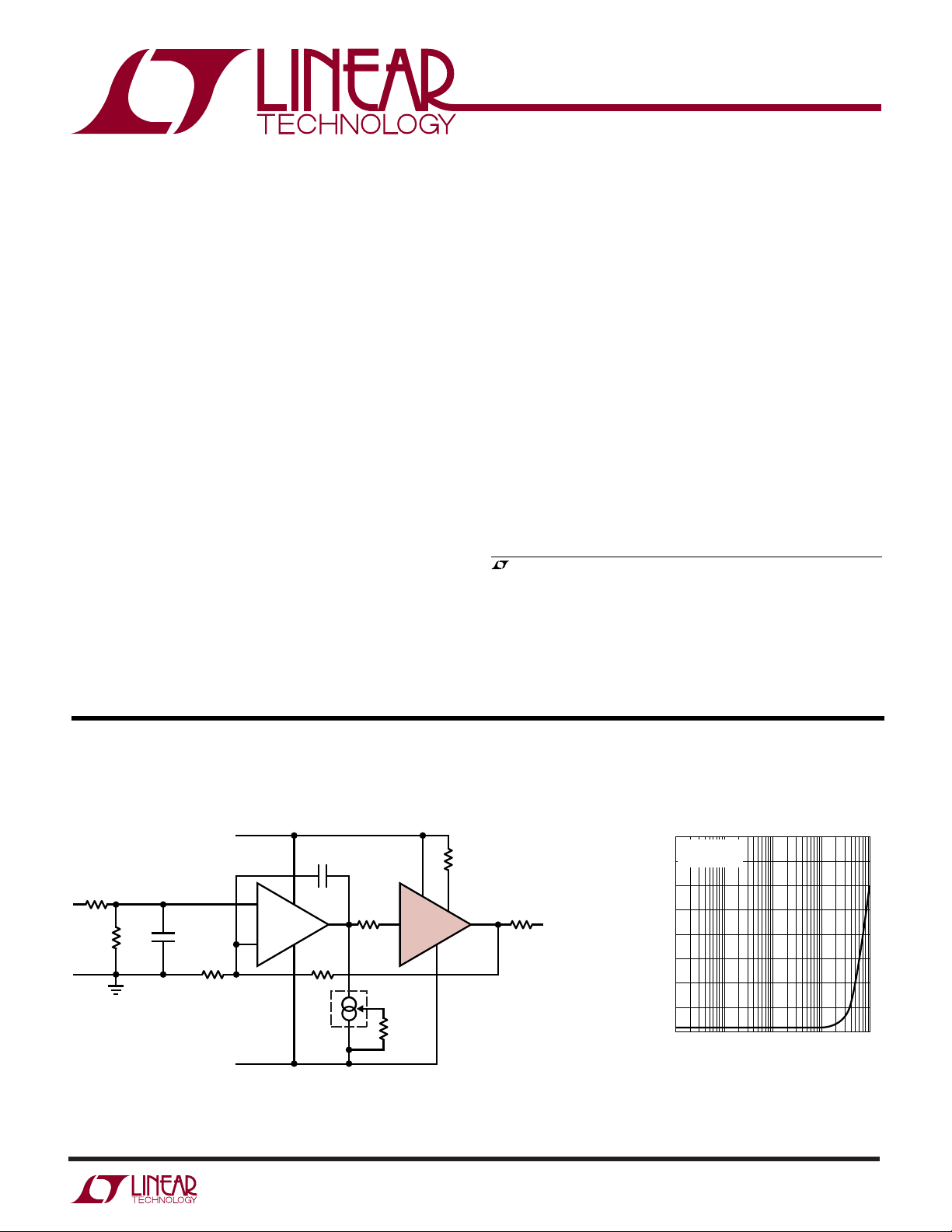

TYPICAL APPLICATIO

R1

1k

R2

1M

NOTE 1: ALL RESISTORS 1% METAL FILM

NOTE 2: SUPPLIES WELL BYPASSED AND LOW Z

C1

22pF

U

Very Low Distortion Buffered Preamplifier

+

V

18V

R3

1k

–18V

3

+

LT1056CN8 LT1010CT

2

–

+

V

C2

22pF

+

7

4

10k

LM334

O

I

SET

6

R4

= 2mA

100Ω

+

V

–

V

R6

V

IN OUT

R

SET

33.2Ω

1%

BOOST

–

V

1010 TA01

R7

50Ω

R8

100Ω

OUTPUT

1010fc

1

LT1010

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Total Supply Voltage .............................................. ± 22V

Continuous Output Current .............................. ±150mA

Input Current (Note 3) ....................................... ±40mA

Operating Junction Temperature Range

LT1010C ............................................... 0°C to 100°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

UU

W

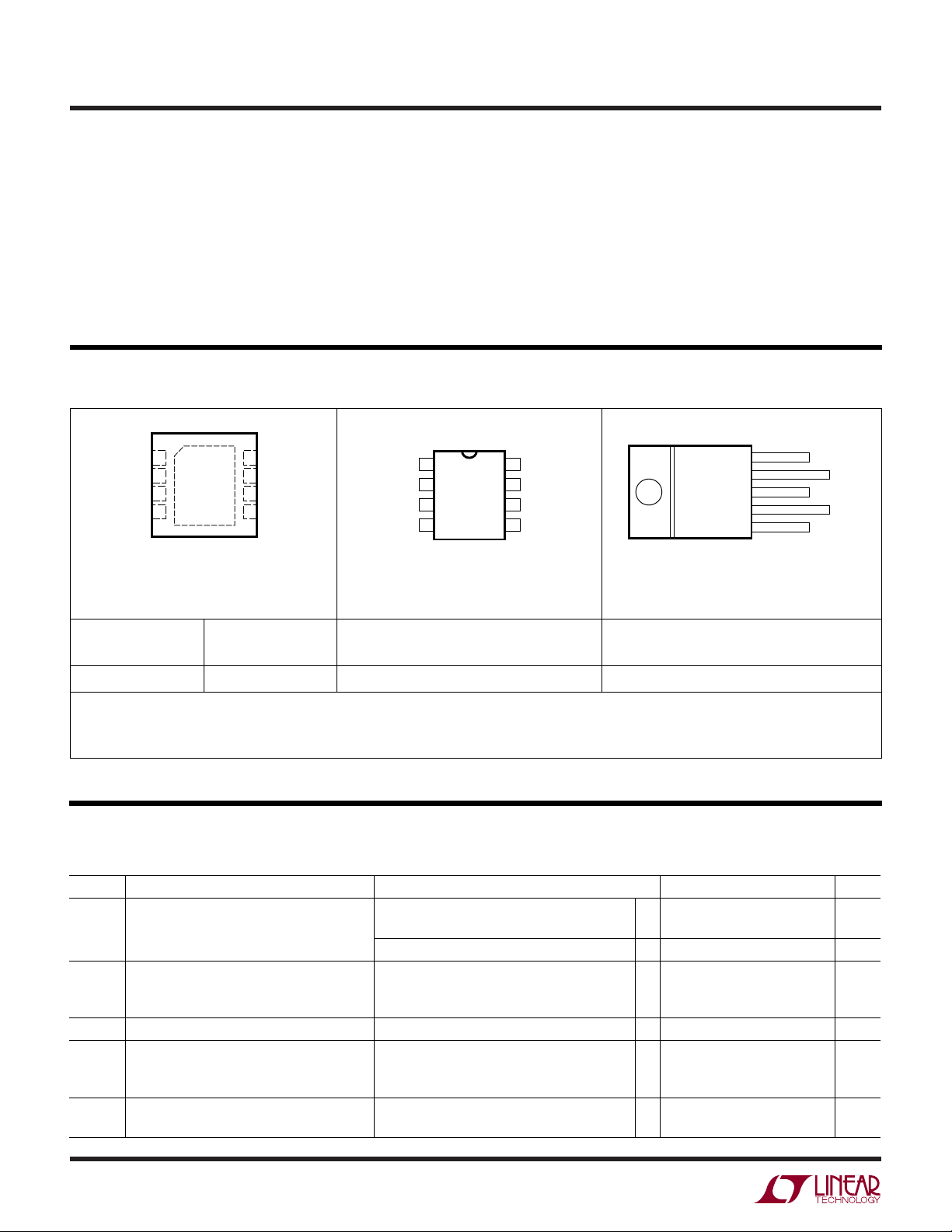

PACKAGE/ORDER I FOR ATIO

TOP VIEW

NC

V

+

1

2

3

4

N8 PACKAGE

8-LEAD PDIP

TOP VIEW

+

1V

BIAS

2

OUT

3

NC

4

8-LEAD (3mm × 3mm) PLASTIC DFN

T

JMAX

EXPOSED PAD (PIN 9) V

TO REDUCE THERMAL RESISTANCE (NOTE 7)

DD PACKAGE

= 100°C, θJC = 3°C/W, θJA = 40°C/W

–

CAN BE SOLDERED TO PCB

8

INPUT

NC

7

9

V

6

NC

5

–

BIAS

OUT

T

= 100°C, θJC = 45°C/W, θJA = 100°C/W

JMAX

U

UU

PRECO DITIO I G

100% Thermal Limit Burn In–LT1010CT

FRONT VIEW

8

INPUT

7

NC

–

6

V

5

NC

–

V

5-LEAD PLASTIC TO-220

T

= 125°C, θJC = 3°C/W, θJA = 50°C/W

JMAX

5

4

3

2

1

T PACKAGE

OUTPUT

BIAS

–

(TAB)

V

+

V

INPUT

ORDER PART

NUMBER

LT1010CDD LBWZ

DD PART

MARKING

ORDER PART

NUMBER

ORDER PART

NUMBER

LT1010CN8 LT1010CT

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● indicates specifications which apply over the full operating

= 25°C. (See Note 4. Typical values in curves.)

A

SYMBOL PARAMETER CONDITIONS (Note 4) MIN TYP MAX UNITS

V

OS

Output Offset Voltage (Note 4) 0 150 mV

●

–20 220 mV

VS = ± 15V, VIN = 0V 20 100 mV

I

B

A

V

R

OUT

Input Bias Current I

Large-Signal Voltage Gain

Output Resistance I

= 0mA 0 250 µA

OUT

≤ 150mA 0 500 µA

I

OUT

= ±1mA 5 10 Ω

OUT

I

= ±150mA 5 10 Ω

OUT

●

●

●

0 800 µA

0.995 1.00 V/V

12 Ω

Slew Rate VS = ±15V, VIN = ±10V, 75 V/µs

= ±8V, RL = 100Ω

V

OUT

1010fc

2

LT1010

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● indicates specifications which apply over the full operating

= 25°C. (See Note 4. Typical values in curves.)

A

SYMBOL PARAMETER CONDITIONS (Note 4) MIN TYP MAX UNITS

+

V

SOS

V

SOS

R

SAT

V

BIAS

I

S

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: For case temperatures above 25°C, dissipation must be derated

based on a thermal resistance of 25°C/W for the T package, 130°C/W for

the N8 package and 40°C/W for the DD package for

above 25°C. See Applications Information.

Note 3: In current limit or thermal limit, input current increases sharply

with input-output differentials greater than 8V; so input current must be

limited. Input current also rises rapidly for input voltages 8V above V

0.5V below V

Note 4: Specifications apply for 4.5V ≤ V

–

+ 0.5V ≤ VIN ≤ V+ – 1.5V and I

V

Temperature range is 0°C ≤ T

Positive Saturation Offset I

–

Negative Saturation Offset I

Saturation Resistance I

Bias Terminal Voltage R

Supply Current I

–

.

≤ 40V,

S

= 0, unless otherwise stated.

OUT

≤ 100°C, TC ≤ 100°C.

J

ambient

= 0 (Note 5) 1.0 V

OUT

= 0 (Note 5) 0.2 V

OUT

= ±150mA (Note 5) 22 Ω

OUT

= 20Ω (Note 6) 700 840 mV

BIAS

OUT

= 0, I

= 0 9 mA

BIAS

●

●

●

●

560 880 mV

●

1.1 V

0.3 V

28 Ω

10 mA

Note 5: The output saturation characteristics are measured with 100mV

output clipping. See Applications Information for determining available

output swing and input drive requirements for a given load.

Note 6: The output stage quiescent current can be increased by

connecting a resistor between the BIAS pin and V

+

. The increase is

equal to the bias terminal voltage divided by this resistance.

temperatures

Note 7: Thermal resistance varies depending upon the amount of PC board

metal attached to the pin (Pin 9) of the device. θ

is specified for a certain

JA

amount of 1oz copper metal trace connecting to Pin 9 as described in the

+

or

thermal resistance tables in the Applications Information section.

1010fc

3

LT1010

FREQUENCY (MHz)

25

5

10

PHASE LAG (DEGREES)

20

50

10 20

1010 G03

RL = 50Ω

R

L

= 200Ω

CL = 100pF

R

S

= 50Ω

R

BIAS

= 20Ω

T

J

= 25°C

UW

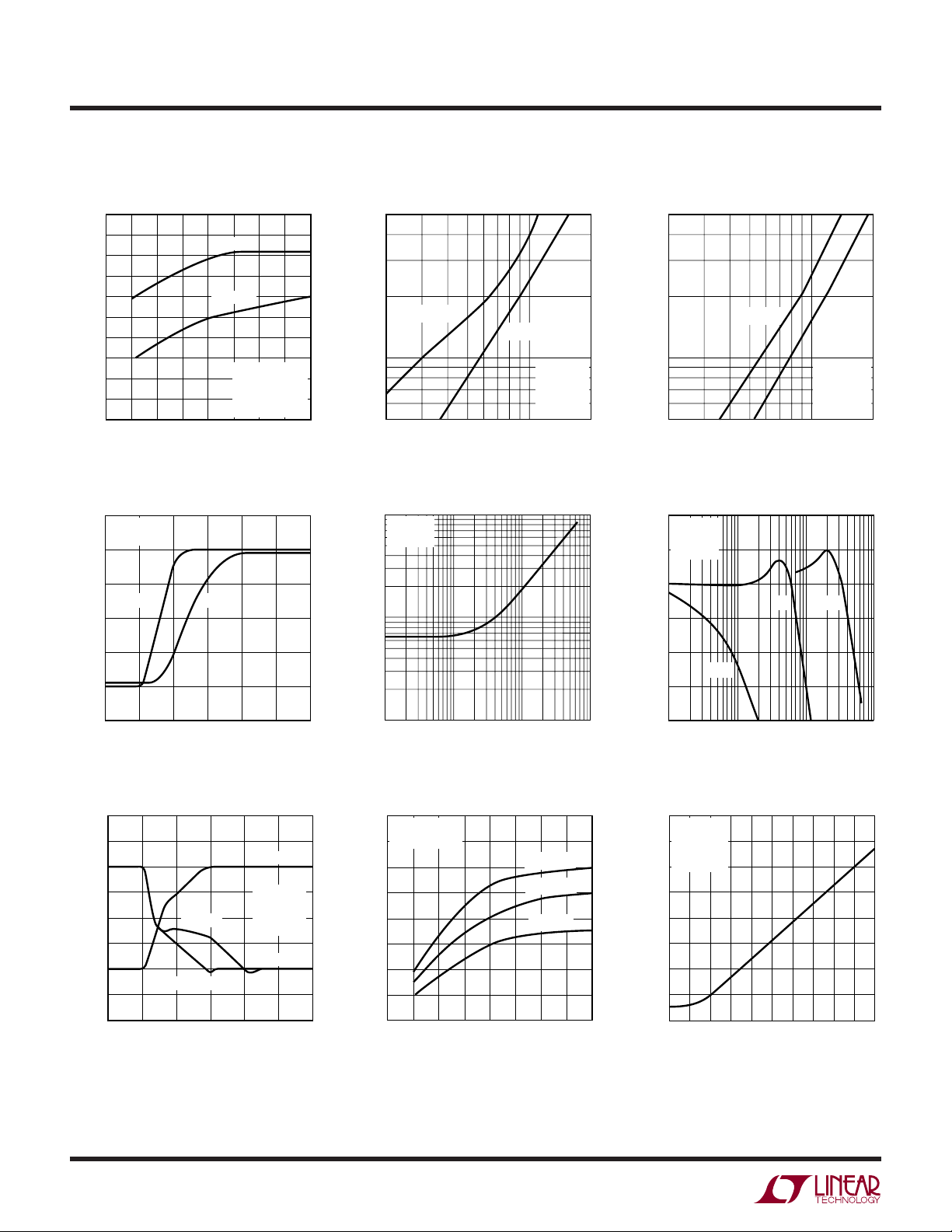

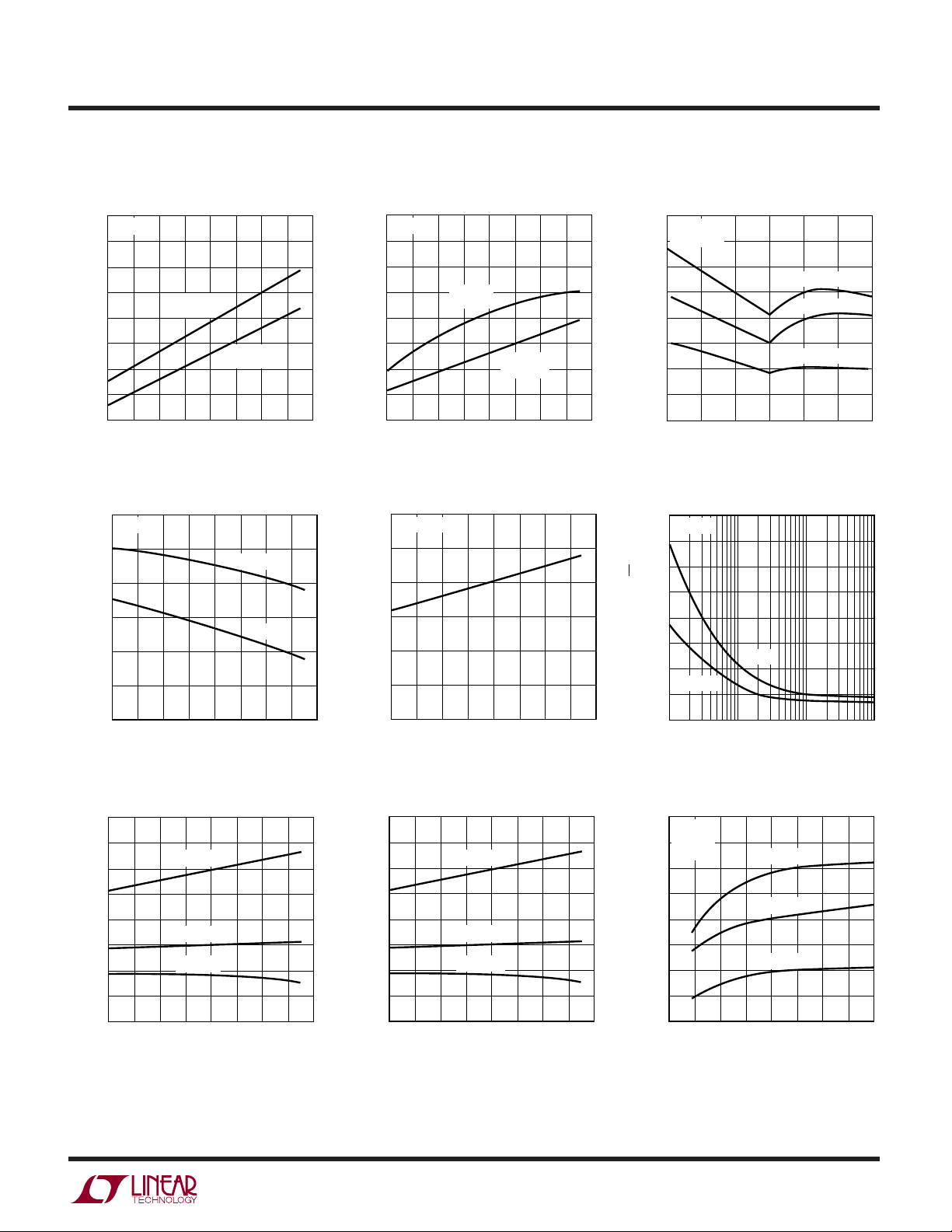

TYPICAL PERFOR A CE CHARACTERISTICS

Bandwidth Phase Lag Phase Lag

50

50

40

30

20

FREQUENCY (MHz)

10

0

0

QUIESCENT CURRENT (mA)

10

RL = 200Ω

RL = 50Ω

20

= 100mV

V

IN

CL 100pF

= –3dB

A

V

= 25°C

T

J

30

P-P

1010 G01

20

RL = 50Ω

10

PHASE LAG (DEGREES)

5

40

25

Small-Step Response Output Impedance

150

RL = 100Ω

= 25°C

T

J

100

50

INPUT OUTPUT

0

–50

VOLTAGE CHANGE (mV)

–100

100

I

= 0

BIAS

= 25°C

T

J

10

OUTPUT IMPEDANCE (Ω)

R

= 200Ω

L

FREQUENCY (MHz)

CL = 100pF

= 50Ω

R

S

= 0

I

BIAS

= 25°C

T

J

10 20

1010 G02

Capacitive Loading

10

RS = 50Ω

= 0

I

BIAS

= 25°C

T

J

0

–10

VOLTAGE GAIN (dB)

0.1µF

100pF3nF

–150

0

Slew Response

20

15

10

5

0

–5

OUTPUT VOLTAGE (V)

–10

–15

–20

–50

4

10 20

TIME (ns)

= 0

I

BIAS

R

= 20Ω

BIAS

0 50 150

100

TIME (ns)

1010 G04

POSITIVE

VS = ±15V

= 100Ω

R

L

= 25°C

T

J

f ≤ 1MHz

NEGATIVE

200

1010 G07

30

250

1

0.1

Negative Slew Rate

400

VS = ±15V

≥ –10V

0 ≥ V

IN

300

200

SLEW RATE (V/µs)

100

0

0

10

QUIESCENT CURRENT (mA)

1 10 100

FREQUENCY (MHz)

20

1010 G05

RL = 200Ω

RL = 100Ω

RL = 50Ω

30

1010 G08

–20

0.1

1 10 100

FREQUENCY (MHz)

1010 G06

Supply Current

80

VS = ±15V

= ±10V

V

IN

= 0

I

L

= 25°C

T

C

60

40

SUPPLY CURRENT (mA)

20

40

0

123 5

0

FREQUENCY (MHz)

4

1010 G09

1010fc

UW

FREQUENCY (Hz)

10

100

NOISE VOLTAGE (nV/√Hz)

150

200

100 1k 10k

1010 G15

50

0

TJ = 25°C

RS = 1k

RS = 50Ω

TYPICAL PERFOR A CE CHARACTERISTICS

Output Offset Voltage Input Bias Current Input Bias Current

200

VIN = 0

200

VIN = 0

200

VS = ±15V

= 75Ω

R

L

LT1010

150

100

OFFSET VOLTAGE (mV)

50

0

–50

0

V+ = 38V

–

= –2V

V

+

V

–

V

50

TEMPERATURE (°C)

= 2V

= –38V

100

150

1010 G10

150

100

BIAS CURRENT (µA)

50

0

–50

Voltage Gain Output Resistance

1.000

0.999

GAIN (V/V)

0.998

I

OUT

= 0

VS = 40V

VS = 4.5V

12

I

≤ 150mA

OUT

10

8

6

4

OUTPUT RESISTANCE (Ω)

2

V+ = 38V

–

= –2V

V

0

50

TEMPERATURE (°C)

+

V

–

V

= 2V

= –38V

100

1010 G10

150

150

100

BIAS CURRENT (µA)

50

0

–100 –50 50

–150

OUTPUT CURRENT (mA)

Output Noise Voltage

0

TJ = 125°C

TJ = 25°C

TJ = –55°C

100

150

1010 G12

0.997

–50

Positive Saturation Voltage

4

3

2

1

SATURATION VOLTAGE (V)

0

–50

050

TEMPERATURE (°C)

IL = 150mA

IL = 50mA

IL = 5mA

0

50

TEMPERATURE (°C)

100

100

1010 G13

1010 G16

150

150

0

–50

050

TEMPERATURE (°C)

100

150

1010 G14

Negative Saturation Voltage Supply Current

4

3

2

1

SATURATION VOLTAGE (V)

0

–50

IL = –150mA

IL = –50mA

IL = –5mA

0

TEMPERATURE (°C)

50

100

150

1010 G16

7

VIN = 0

I

OUT

I

BIAS

6

5

SUPPLY CURRENT (mA)

4

3

0

= 0

= 0

10

TOTAL SUPPLY VOLTAGE (V)

TJ = –55°C

TJ = 25°C

TJ = 125°C

20

30

40

1010 G18

1010fc

5

LT1010

TEMPERATURE (°C)

–50

0

OUTPUT CURRENT (A)

0.2

0.5

0

50

1010 G24

0.1

0.4

0.3

100

150

VS = ±15V

V

OUT

= 0

SINK

SOURCE

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Bias Terminal Voltage Total Harmonic Distortion Total Harmonic Distortion

1.0

0.9

VS = ±20V

0.4

0.3

RL = 50Ω

f = 10kHz

= ±15V

V

S

= 25°C

T

C

0.8

0.6

I

BIAS

V

S

V

OUT

= 25°C

T

C

= 0

= ±15V

= ±10V

0.8

R

0.7

0.6

BIAS TERMINAL VOLTAGE (V)

0.5

–50

BIAS

0

TEMPERATURE (°C)

= 20Ω

R

= 100Ω

BIAS

50

100

150

1010 G19

0.2

0.1

HARMONIC DISTORTION (%)

0

0.1

I

= 0 R

BIAS

1 10 100

OUTPUT VOLTAGE (V

Shorted Input Characteristics Peak Power Capability

50

VS = ±15V

= 0

V

OUT

= 25°C

T

J

25

0

INUPT CURRENT (mA)

–25

–50

–10 –5 5

–15

0

INPUT VOLTAGE (V)

10

15

1010 G22

10

TC = 85°C

8

6

4

PEAK POWER (W)

2

0

1

PULSE WIDTH (ms)

= 50Ω

BIAS

)

P-P

1010 G20

TO-220

10 100

1010 G23

0.4

0.2

HARMONIC DISTORTION (%)

0

1

RL = 50Ω

RL = 100Ω

10 100 1000

FREQUENCY (kHz)

Peak Output Current

1010 G21

6

1010fc

WUUU

V

VV R

RR

OUT

SOS L

SAT L

+

+

+

=

+

(– )

APPLICATIO S I FOR ATIO

LT1010

General

These notes briefly describe the LT1010 and how it is

1

used; a detailed explanation is given elsewhere

. Emphasis here will be on practical suggestions that have resulted

from working extensively with the part over a wide range

of conditions. A number of applications are also outlined

that demonstrate the usefulness of the buffer beyond that

of driving a heavy load.

Design Concept

The schematic below describes the basic elements of the

buffer design. The op amp drives the output sink transistor, Q3, such that the collector current of the output

follower, Q2, never drops below the quiescent value (determined by I

and the area ratio of D1 and D2). As a result,

1

the high frequency response is essentially that of a simple

follower even when Q3 is supplying the load current. The

internal feedback loop is isolated from the effects of

capacitive loading by a small resistor in the output lead.

+

V

D1

–

A1

I

1

D2

BIAS

I

+

Q2

R1

Q3

2

INPUT

Q1

OUTPUT

–

V

1010 AI01

idealized buffer with the unloaded gain specified for the

LT1010. Otherwise, it has zero offset voltage, bias current

and output resistance. Its output also saturates to the

internal supply terminals2.

+

V

+

V

A1

V

SOS

R′

R′ R′ = R

V

SOS

–

R

OUT

OUTPUTINPUT

– R

SAT

OUT

–

1010 AI02

I

B

V

OS

+

Loaded voltage gain can be determined from the unloaded

gain, A

tance, R

, the output resistance, R

V

, using:

L

AR

A

VL

VL

=

RR

+

OUT L

, and the load resis-

OUT

Maximum positive output swing is given by:

The input swing required for this output is:

R

OUT

R

L

⎞

+ ∆1–

VV

OS OS

⎟

⎠

+

VV

=+

IN OUT

⎛

+

⎜

⎝

The scheme is not perfect in that the rate of rise of sink

current is noticeably less than for source current. This can

be mitigated by connecting a resistor between the bias

terminal and V+, raising quiescent current. A feature of the

final design is that the output resistance is largely independent of the follower quiescent current or the output load

current. The output will also swing to the negative rail,

which is particularly useful with single supply operation.

Equivalent Circuit

Below 1MHz, the LT1010 is quite accurately represented

by the equivalent circuit shown here for both small- and

large-signal operation. The internal element, A1, is an

where ∆VOS is the 100mV clipping specified for the

saturation measurements. Negative output swing and

input drive requirements are similarly determined.

Supply Bypass

The buffer is no more sensitive to supply bypassing than

slower op amps as far as stability is concerned. The 0.1µF

disc ceramic capacitors usually recommended for op

amps are certainly adequate for low frequency work. As

always, keeping the capacitor leads short and using a

1

R. J. Widlar, “Unique IC Buffer Enhances Op Amp Designs; Tames Fast Amplifiers,”

Linear Technology Corp. TP-1

2

See electrical characteristics section for guaranteed limits.

, April, 1984.

1010fc

7

LT1010

∆ =

+

I

VV

RR

OUT

OS OS

OUT OUT

12

12

–

WUUU

APPLICATIO S I FOR ATIO

ground plane is prudent, especially when operating at high

frequencies.

The buffer slew rate can be reduced by inadequate supply

bypass. With output current changes much above

100mA/µs, using 10µF solid tantalum capacitors on both

supplies is good practice, although bypassing from the

positive to the negative supply may suffice.

When used in conjunction with an op amp and heavily

loaded (resistive or capacitive), the buffer can couple into

supply leads common to the op amp causing stability

problems with the overall loop and extended settling time.

Adequate bypassing can usually be provided by 10µF solid

tantalum capacitors. Alternately, smaller capacitors could

be used with decoupling resistors. Sometimes the op amp

has much better high frequency rejection on one supply,

so bypass requirements are less on this supply.

Power Dissipation

In many applications the LT1010 will require heat sinking. Thermal resistance, junction to still air is 100°C/W

for the TO-220 package and 130°C/W for the miniDIP

package. Circulating air, a heat sink or mounting the

package to a printed circuit board will reduce thermal

resistance.

In DC circuits, buffer dissipation is easily computed. In AC

circuits, signal waveshape and the nature of the load

determine dissipation. Peak dissipation can be several

times average with reactive loads. It is particularly important to determine dissipation when driving large load

capacitance.

without limiting. Because of this, it is capable of power

dissipation in excess of its continuous ratings.

Normally, thermal overload protection will limit dissipation and prevent damage. However, with more than 30V

across the conducting output transistor, thermal limiting

is not quick enough to ensure protection in current limit.

The thermal protection is effective with 40V across the

conducting output transistor as long as the load current is

otherwise limited to 150mA.

Drive Impedance

When driving capacitive loads, the LT1010 likes to be

driven from a low source impedance at high frequencies.

Certain low power op amps (e.g., the LM10) are marginal

in this respect. Some care may be required to avoid

oscillations, especially at low temperatures.

Bypassing the buffer input with more than 200pF will solve

the problem. Raising the operating current also works.

Parallel Operation

Parallel operation provides reduced output impedance,

more drive capability and increased frequency response

under load. Any number of buffers can be directly paralleled as long as the increased dissipation in individual

units caused by mismatches of output resistance and

offset voltage is taken into account.

When the inputs and outputs of two buffers are connected

together, a current, ∆I

, flows between the outputs:

OUT

With AC loading, power is divided between the two output

transistors. This reduces the effective thermal resistance,

junction to case to 15°C/W for the TO-220 package as long

as the peak rating of neither output transistor is exceeded.

The typical curves indicate the peak dissipation capabilities of one output transistor.

Overload Protection

The LT1010 has both instantaneous current limit and

thermal overload protection. Foldback current limiting has

not been used, enabling the buffer to drive complex loads

8

where VOS and R

resistance of the respective buffers.

Normally, the negative supply current of one unit will

increase and the other decrease, with the positive supply

current staying the same. The worst-case (V

increase in standby dissipation can be assumed to be

∆I

Offset voltage is specified worst case over a range of

supply voltages, input voltage and temperature. It would

, where VT is the total supply voltage.

OUTVT

are the offset voltage and output

OUT

→ V+)

IN

1010fc

WUUU

A2

LT1010

R

F

2k

R

S

2k

V

IN

C

F

1nF

C

L

1010 AI06

V

OUT

–

+

A1

LT118A

APPLICATIO S I FOR ATIO

LT1010

be unrealistic to use these worst-case numbers above

because paralleled units are operating under identical

conditions. The offset voltage specified for V

V

= 0V and TA = 25°C will suffice for a worst-case

IN

= ±15V,

S

condition.

+

V

I

S

IS – ∆I

A1

LT1010

OUT

–

V

V

IN

A2

LT1010

1010 AI03

I

S

IS + ∆I

OUT

V

OUT

∆I

OUT

Output load current will be divided based on the output

resistance of the individual buffers. Therefore, the available output current will not quite be doubled unless output

resistances are matched. As for offset voltage, the 25°C

limits should be used for worst-case calculations.

At lower frequencies, the buffer is within the feedback loop

so that its offset voltage and gain errors are negligible. At

higher frequencies, feedback is through C

, so that phase

F

shift from the load capacitance acting against the buffer

output resistance does not cause loop instability.

Stability depends upon the RFCF time constant or the

closed-loop bandwidth. With an 80kHz bandwidth, ringing is negligible for C

= 0.33µF. The pulse response is shown in the graph.

C

L

5

0

–5

5

OUTPUT VOLTAGE (V)

0

–5

0

= 0.068µF and damps rapidly for

L

Pulse Response

CL = 0.068µF

CL = 0.33µF

50

100

TIME (µs)

150

200

1010 AI05

Parallel operation is not thermally unstable. Should one

unit get hotter than its mates, its share of the output and

its standby dissipation will decrease.

As a practical matter, parallel connection needs only some

increased attention to heat sinking. In some applications,

Small-signal bandwidth is reduced by CF, but considerable isolation can be obtained without reducing it below

the power bandwidth. Often, a bandwidth reduction is

desirable to filter high frequency noise or unwanted

signals.

a few ohms equalization resistance in each output may be

wise. Only the most demanding applications should require matching, and then just of output resistance at 25°C.

Isolating Capacitive Loads

The inverting amplifier below shows the recommended

method of isolating capacitive loads. Noninverting amplifiers are handled similarly.

R

S

V

IN

C

F

100pF

–

A1

LT1007

+

R

F

20k

A2

LT1010

C

L

1010 AI04

The follower configuration is unique in that capacitive

load isolation is obtained without a reduction in smallsignal bandwidth, although the output impedance of the

V

OUT

buffer comes into play at high frequencies. The precision

unity-gain buffer above has a 10MHz bandwidth without

capacitive loading, yet it is stable for all load capacitance

to over 0.3µF, again determined by R

FCF

.

1010fc

9

LT1010

A2

LT1010

R1

100Ω

R2

800Ω

C1

15pF

V

IN

1010 AI09

V

OUT

–

+

A1

HA2625

A2

LT1010

R1

400Ω

R2

1.6k

INPUT

1010 AI10

OUTPUT

–

+

A1

HA2625

WUUU

APPLICATIO S I FOR ATIO

This is a good example of how fast op amps can be made

quite easy to use by employing an output buffer.

Integrator

A lowpass amplifier can be formed just by using large C

F

in the inverter described earlier, as long as the increasing

closed-loop output impedance above the cutoff frequency

is not a problem and the op amp is capable of supplying

the required current at the summing junction.

C

I

I

IN

R

20k

F

–

LT1012

+

A1

C

F

500pF

A2

LT1010

1010 AI07

V

OUT

If the integrating capacitor must be driven from the buffer

output, the circuit above can be used to provide capacitive

load isolation. As before, the stability with large capacitive

loads is determined by R

FCF

.

Wideband Amplifiers

This simple circuit provides an adjustable gain video

amplifier that will drive 1V

into 75Ω. The differential

P-P

pair provides gain with the LT1010 serving as an output

8.2k

+

22µF

15V

25Ω

BIAS

22µF

TYPICAL SPECIFICATIONS

INTO 75Ω

1V

P-P

AT A = 2

0.5dB TO 10MHz

3dB DOWN AT 16MHz

AT A = 10

0.5dB TO 4MHz

+

–3dB = 8MHz

stage. Feedback is arranged in the conventional manner,

although the 68µF-0.01µF combination limits DC gain to

unity for all gain settings. For applications sensitive to

NTSC requirements, dropping the 25Ω output stage bias

value will aid performance.

This shows the buffer being used with a wideband amplifier that is not unity-gain stable. In this case, C1 cannot be

used to isolate large capacitive loads. Instead, it has an

optimum value for a limited range of load capacitances.

The buffer can cause stability problems in circuits like

this. With the TO-220 packages, behavior can be improved by raising the quiescent current with a 20Ω

+

resistor from the bias terminal to V

. Alternately, devices

in the miniDIP can be operated in parallel.

It is possible to improve capacitive load stability by

operating the buffer class A at high frequencies. This is

done by using quiescent current boost and bypassing the

bias terminal to V

–

with more than 0.02µF.

10

–15V

Q2Q1INPUT

5.1k

Q1, Q2: 2N3866

LT1010

–15V

PEAKING

5pF to 25pF

0.01µF

+

900Ω

1k

GAIN SET

68µF

1010 AI08

OUTPUT

(75Ω)

Putting the buffer outside the feedback loop as shown

here will give capacitive load isolation, with large output

capacitors only reducing bandwidth. Buffer offset, referred to the op amp input, is divided by the gain. If the

load resistance is known, gain error is determined by the

output resistance tolerance. Distortion is low.

1010fc

WUUU

APPLICATIO S I FOR ATIO

LT1010

R3

800Ω

INPUT

–

HA2625

C1

20pF

A1

A2

LT1010

R4

39Ω

OUTPUT 1

+

R2

R1

200Ω

50Ω

OTHER

SLAVES

A3

LT1010

R5

39Ω

OUTPUT 2

1010 AI11

The 50Ω video line splitter here puts feedback on one

buffer with the others slaved. Offset and gain accuracy of

slaves depend on their matching with master.

When driving long cables, including a resistor in series

with the output should be considered. Although it reduces

gain, it does isolate the feedback amplifier from the effects

of unterminated lines which present a resonant load.

When working with wideband amplifiers, special attention should

always

be paid to supply bypassing, stray

capacitance and keeping leads short. Direct grounding of

test probes, rather than the usual ground lead, is absolutely necessary for reasonable results.

The LT1010 has slew limitations that are not obvious from

standard specifications. Negative slew is subject to

glitching, but this can be minimized with quiescent

current boost. The appearance is always worse with fast

rise signal generators than in practical applications.

Track and Hold

The 5MHz track and hold shown here has a 400kHz power

bandwidth driving ±10V. A buffered input follower drives

the hold capacitor, C4, through Q1, a low resistance FET

switch. The positive hold command is supplied by TTL

logic with Q3 level shifting to the switch driver, Q2. The

output is buffered by A3.

When the gate is driven to V– for HOLD, it pulls charge out

of the hold capacitor. A compensating charge is put into

the hold capacitor through C3. The step into hold is made

independent of the input level with R7 and adjusted to zero

with R10.

Since internal dissipation can be quite high when driving

fast signals into a capacitive load, using a buffer in a power

package is recommended. Raising buffer quiescent current to 40mA with R3 improves frequency response.

This circuit is equally useful as a fast acquisition sample

and hold. An LT1056 might be used for A3 to reduce drift

in hold because its lower slew rate is not usually a problem

in this application.

Current Sources

A standard op amp voltage to current converter with a

buffer to increase output current is shown here. As usual,

INPUT

+

V

A2

R2

2k

D1

HP2810

R6

1k

R3

20Ω

Q1

2N5432

SD

R4

2k

Q2

2N2222

–

V

C4

1nF

*2N2369 EMITTER BASE JUNCTION

C3

100pF

C5

10pF

200k

–

A3

LT118A

OUTPUT

+

+

A4

LT118A

–

R8

5k

R9

10k

R7

R10

50k

1010 AI12

R11

6.2k

D2*

6V

1010fc

R1

2k

+

LT118A

–

HOLD

A1

C1

50pF

R5

1k

C2

150pF

Q3

2N2907

LT1010

11

LT1010

WUUU

APPLICATIO S I FOR ATIO

excellent matching of the feedback resistors is required to

get high output resistance. Output is bidirectional.

R1

100k

0.01%

V1

–

A1

LT1012

R3

100k

0.01%

V2

+

R2

100k

0.01%

R4

100k

0.01%

A2

LT1010

I

OUT

R4

10Ω

0.1%

R2(V2 – V1)

=

R1R4

1010 AI13

I

OUT

This circuit uses an instrumentation amplifier to eliminate

the matched resistors. The input is not high impedance

and must be driven from a low impedance source like an

op amp. Reversal of output sense can be obtained by

grounding Pin 7 of the LM163 and driving Pin 5.

A2

LT1010

R1

V

IN

7

6

A1

LM163

×10

5

10Ω

0.1%

–

2

3

+

I

OUT

=

V

10R1

I

OUT

1010AI14

IN

Output resistances of several megohms can be obtained

with both circuits. This is impressive considering the

±150mA output capability. High frequency output characteristics will depend on the bandwidth and slew rate of the

amplifiers. Both these circuits have an equivalent output

capacitance of about 30nF.

A2

LT1010

R2

2k

A3

LT118A

–

+

99.8k

0.1%

R3

2Ω

R4

2k

0.1%

R7

10mA/V

OUTPUT

R5

2k

0.1%

R6

99.8k

0.1%

V

I

1010 AI15

V

1V/V

V

–

+

D1

1N457

R1

2k

A1

LT118A

C2

10pF

C1

1nF

D2

1N457

enables the current regulator to get control of the output

current from the buffer current limit within a microsecond

for an instantaneous short.

In the voltage regulation mode, A1 and A2 act as a fast

voltage follower using the capacitive load isolation technique described earlier. Load transient recovery as well as

capacitive load stability are determined by C1. Recovery

from short circuit is clean.

Bidirectional current limit can be obtained by adding

another op amp connected as a complement to A3.

Supply Splitter

Dual supply op amps and comparators can be operated

from a single supply by creating an artificial ground at half

the supply voltage. The supply splitter shown here can

source or sink 150mA.

The output capacitor, C2, can be made as large as necessary to absorb current transients. An input capacitor is

also used on the buffer to avoid high frequency instability

that can be caused by high source impedance.

Voltage/Current Regulator

This circuit regulates the output voltage at VV until the

load current reaches a value programmed by VI. For

heavier loads, it is a precision current regulator.

With output currents below the current limit, the current

regulator is disconnected from the loop by D1 with D2

keeping its output out of saturation. This output clamp

12

C1

1nF

R1

10k

R2

10k

A1

LT1010

C3

0.1µF

C2

0.01µF

1010 AI16

+

V

+

/2

V

1010fc

A2

LT1010

1k

10k

–5V

5V

3

BA

OUTPUT

6

4

–5V

5V

7

0.1µF

2

Q2

2N2222

INPUT

Q1

2N5486

–

+

2000pF 0.1µF

1010 AI18

0.01µF

10M

100Ω

A1

LTC1050

10M

WUUU

APPLICATIO S I FOR ATIO

High Current Booster

The circuit below uses a discrete stage to get 3A output

capacity. The configuration shown provides a clean, quick

way to increase LT1010 output power. It is useful for high

current loads such as linear actuator coils in disk drives.

The 33Ω resistors sense the LT1010’s supply current

with the grounded 100Ω resistor supplying a load for the

LT1010. The voltage drop across the 33Ω resistors

biases Q1 and Q2. Another 100Ω value closes a local

feedback loop, stabilizing the output stage. Feedback to

the LT1056 control amplifier is via the 10k value. Q3 and

Q4, sensing across the 0.18Ω units, furnish current

limiting at about 3.3A.

15pF

10k

15V

+

–15V

33Ω

LT1010

33Ω

2N3906

100Ω

2N3904

22µF

+

68pF

10k

INPUT

–

LT1056

+

HEAT SINK OUTPUT TRANSISTORS

22µF

Wideband FET Input Stabilized Buffer

The figure below shows a highly stable unity-gain buffer

with good speed and high input impedance. Q1 and Q2

constitute a simple, high speed FET input buffer. Q1

functions as a source follower with the Q2 current source

load setting the drain-source channel current. The LT1010

buffer provides output drive capability for cables or

whatever load is required. Normally, this open-loop configuration would be quite drifty because there is no DC

®

feedback. The LTC

stabilize the circuit. It does this by comparing the filtered

circuit output to a similarly filtered version of the input

1050 contributes this function to

Q3

MJE2955

MJE3055

Q4

0.18Ω

1k

Q1

100Ω

Q2

1k

0.18Ω

1010 AI17

OUTPUT

LT1010

signal. The amplified difference between these signals is

used to set Q2’s bias, and hence, Q1’s channel current.

This forces Q1’s V

to whatever voltage is required to

GS

match the circuit’s input and output potentials. The 2000pF

capacitor at A1 provides stable loop compensation. The

RC network in A1’s output prevents it from seeing high

speed edges coupled through Q2’s collector-base junction. A2’s output is also fed back to the shield around Q1’s

gate lead, bootstrapping the circuit’s effective input capacitance down to less than 1pF.

Gain-Trimmable Wideband FET Amplifier

A potential difficulty with the previous circuit is that the

gain is not quite unity. The figure labeled A on the next

page maintains high speed and low bias while achieving

a true unity-gain transfer function.

This circuit is somewhat similar except that the Q2-Q3

stage takes gain. A2 DC stabilizes the input-output path

and A1 provides drive capability. Feedback is to Q2’s

emitter from A1’s output. The 1k adjustment allows the

gain to be precisely set to unity. With the LT1010, output

stage slew and full power bandwidth (1V

) are 100V/µs

P-P

and 10MHz respectively. – 3dB bandwidth exceeds 35MHz.

At A = 10 (e.g., 1k adjustment set at 50Ω), full power

bandwidth stays at 10MHz while the –3dB point falls to

22MHz.

With the optional discrete stage, slew exceeds 1000V/µs

and full power bandwidth (1V

) is 18MHz. – 3dB band-

P-P

width is 58MHz. At A = 10, full power is available to

10MHz, with the – 3dB point at 36MHz.

1010fc

13

LT1010

WUUU

APPLICATIO S I FOR ATIO

Figures A and B show response with both output stages.

The LT1010 is used in Figure A (Trace A = input, Trace B

= output). Figure B uses the discrete stage and is slightly

faster. Either stage provides more than adequate performance for driving video cable or data converters and the

LT1012 maintains DC stability under all conditions.

Gain-Trimmable Wideband FET Amplifier

15V

1k

470Ω

Q2

2N3904

5.6k

Q3

2N3906

AB

3k

INPUT

0.01µF

Q1

2N5486

1k

GAIN

ADJ

50Ω300Ω2k10k10M

Thermal Considerations for the MiniDIP Package

The miniDIP package requires special thermal considerations since it is not designed to dissipate much power. Be

aware that for applications requiring large output currents, another package should be used.

10pF

15V

A2

LT1010

1k

10M

OUTPUT

3k

2N3904

3Ω

BA

3Ω

A = 0.2V/DIV

B = 0.2V/DIV

–15V

0.002µF

A1

LT1012

+

–

0.1µF

0.1µF

1k

1010 AI19

(A) (B)

A = 0.2V/DIV

B = 0.2V/DIV

10ns/DIV 10ns/DIV

1010 AI20

2N3906

3k

–15V

1010 AI21

14

Figure A. Waveforms Using LT1010 Figure B. Waveforms Using Discrete Stage

1010fc

WUUU

APPLICATIO S I FOR ATIO

LT1010

Typical thermal calculations for the miniDIP package are

detailed in the following paragraphs.

For 4.8mA supply current (typical at 50°C, 30V supply

voltage—see supply current graphs) to the LT1010 at

± 15V, P

The rise in junction is then:

This means that the junction temperature in 50°C ambient

air without driving any current into a load is:

Using the LT1010 to drive 8V DC into a 200Ω load using

± 15V power supplies dissipates PD in the LT1010 where:

This causes the LT1010 junction temperature to rise

another (0.280W)(0.130°C/W) = 36.4°C.

This heats the junction to 68.7°C + 36.4°C = 105.1°C.

Caution: This exceeds the maximum operating temperature of the device.

An example of 1MHz operation further shows the limitations of the N (or miniDIP) package. For ±15V operation:

This power dissipation causes the junction to heat from

50°C (ambient in this example) to 50°C + (0.3W)

(130°C/W) = 89°C. Driving 2V

200Ω load causes an additional

= power dissipated in the part is equal to:

D

(30V)(0.0048A) = 0.144W

(0.144W)(130°C/W—This is θJA for the N package)

= 18.7°C.

18.7°C + 50°C = 68.7°C

+

–

VV V

()

P

=

D

15 8 8

()()

=

at IL = 0 at 1MHz* = (10mA)(30V) = 0.30W

P

D

⎛

P

=

D

⎜

⎝

OUT OUT

()

R

L

–

VVV

Ω

200

⎞

V

2

200

15 2 0 130•– .

()

⎟

Ω

⎠

=

0 280

.

RMS

=

W

of 1MHz signal into a

W

to be dissipated, resulting in another (0.130W)

(0.130°C/W) = 16.9°C rise in junction temperature to

89°C + 16.9°C = 105.9°C.

Caution: This exceeds the maximum operating temperature of the device.

Thermal Resistance of DFN Package

For surface mount devices, heat sinking is accomplished

by using the heat spreading capabilities of the PC board

and its copper traces. Copper board stiffeners and plated

through-holes can also be used to spread the heat generated by power devices.

The following table lists thermal resistance for several

different board sizes and copper areas. All measurements

were taken in still air on 3/32" FR-4 board with one ounce

copper.

Table 1. DFN Measured Thermal Resistance

COPPER AREA

TOPSIDE BACKSIDE BOARD AREA (JUNCTION-TO-AMBIENT)

2500 sq mm 2500 sq mm 2500 sq mm 40°C/W

1000 sq mm 2500 sq mm 2500 sq mm 45°C/W

225 sq mm 2500 sq mm 2500 sq mm 50°C/W

100 sq mm 2500 sq mm 2500 sq mm 62°C/W

For the DFN package, the thermal resistance junction-tocase (θJC), measured at the exposed pad on the back of the

die, is 16°C/W.

Continuous operation at the maximum supply voltage and

maximum load current is not practical due to thermal

limitations. Transient operation at the maximum supply is

possible. The approximate thermal time constant for a

2500sq mm 3/32" FR-4 board with maximum topside and

backside area for one ounce copper is 3 seconds. This time

constant will increase as more thermal mass is added (i.e.

vias, larger board, and other components).

For an application with transient high power peaks, average power dissipation can be used for junction temperature calculations as long as the pulse period is significantly

less than the thermal time constant of the device and

board.

THERMAL RESISTANCE

*See Supply Current vs Frequency graph.

1010fc

15

LT1010

WW

SCHE ATIC DIAGRA

Q5

Q3

Q2

Q1

R1

4k

R2

1k

(Excluding protection circuits)

R6

15Ω

R7

300Ω

R5

1.5k

R3

1k

Q7Q6

R4

1k

Q8

Q12

R8

1k

Q10Q9

Q14

C1

30pF

+

V

R10

200Ω

R11

200Ω

Q21

Q15

Q13Q4

R9

Q16

4k

R13

200Ω

Q18Q11

BIAS

Q19Q17

Q20

R12

R14

3k

Q22

7Ω

1010 SD

OUTPUT

INPUT

–

V

U

UW

DEFI ITIO OF TER S

Output Offset Voltage: The output voltage measured with

the input grounded (split supply operation).

Input Bias Current: The current out of the input terminal.

Large-Signal Voltage Gain: The ratio of the output volt-

age change to the input voltage change over the specified

input voltage range.*

Output Resistance: The ratio of the change in output

voltage to the change in load current producing it.*

Output Saturation Voltage: The voltage between the output and the supply rail at the limit of the output swing

toward that rail.

Saturation Offset Voltage: The output saturation voltage

with no load.

Saturation Resistance: The ratio of the change in output

saturation voltage to the change in current producing it,

going from no load to full load.*

Slew Rate: The average time rate of change of output

voltage over the specified output range with an input step

between the specified limits.

Bias Terminal Voltage: The voltage between the bias

+

terminal and V

.

Supply Current: The current at either supply terminal with

no output loading.

*Pulse measurements (~1ms) as required to minimize thermal effects.

16

1010fc

PACKAGE DESCRIPTIO

LT1010

U

DD Package

8-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1698)

0.675 ±0.05

3.5 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1

TOP MARK

(NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-1)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON TOP AND BOTTOM OF PACKAGE

0.50

BSC

2.38 ±0.05

(2 SIDES)

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

0.00 – 0.05

1.65 ± 0.10

(2 SIDES)

R = 0.115

TYP

0.25 ± 0.05

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

0.38 ± 0.10

85

14

0.50 BSC

(DD) DFN 1203

1010fc

17

LT1010

PACKAGE DESCRIPTIO

U

N8 Package

8-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

.255 ± .015*

(6.477 ± 0.381)

.400*

(10.160)

MAX

87 6

5

12

.300 – .325

(7.620 – 8.255)

.065

(1.651)

.008 – .015

(0.203 – 0.381)

+.035

.325

–.015

+0.889

8.255

()

–0.381

NOTE:

1. DIMENSIONS ARE

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .010 INCH (0.254mm)

INCHES

MILLIMETERS

TYP

.045 – .065

(1.143 – 1.651)

.100

(2.54)

BSC

3

4

.130 ± .005

(3.302 ± 0.127)

.120

(3.048)

MIN

.018 ± .003

(0.457 ± 0.076)

.020

(0.508)

MIN

N8 1002

18

1010fc

PACKAGE DESCRIPTIO

LT1010

U

T Package

5-Lead Plastic TO-220 (Standard)

(Reference LTC DWG # 05-08-1421)

.390 – .415

(9.906 – 10.541)

.460 – .500

(11.684 – 12.700)

.067

BSC

(1.70)

(3.734 – 3.937)

.230 – .270

(5.842 – 6.858)

.330 – .370

(8.382 – 9.398)

.028 – .038

(0.711 – 0.965)

.147 – .155

DIA

.570 – .620

(14.478 – 15.748)

SEATING PLANE

.260 – .320

(6.60 – 8.13)

.700 – .728

(17.78 – 18.491)

.152 – .202

(3.861 – 5.131)

(3.429 – 4.191)

.165 – .180

(4.191 – 4.572)

.135 – .165

.620

(15.75)

TYP

.045 – .055

(1.143 – 1.397)

.095 – .115

(2.413 – 2.921)

.155 – .195*

(3.937 – 4.953)

.013 – .023

(0.330 – 0.584)

* MEASURED AT THE SEATING PLANE

T5 (TO-220) 0801

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1010fc

19

LT1010

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1206 250mA, 60MHz Current Feedback Amplifier 900V/µs, Excellent Video Characteristics

LT1210 1.1A, 35MHz Current Feedback Amplifier 900V/µs Slew Rate, Stable with Large Capacitive Loads

LT1795 Dual 500mA, 50MHz CFA 500mA I

LT1886 Dual 700MHz, 200mA Op Amp DSL Driver

ADSL Driver

OUT

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

1010fc

LT/LWI 0806 REV C • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 1991

Loading...

Loading...