Page 1

SECURED SERIES

™

HUB

PLUS

CONTROL MODULE/

MODEM COMPATIBLE

FEATURES, PROGRAMMING AND WIRING GUIDE

500 USERS

1000 TRANSACTION BUFFERED AUDIT TRAIL

SUPPORTS TWO FRONT-ENDS FOR IN/OUT OPERATION

PROGRAMMABLE FROM KEYPAD ON HUB, OR P.C.

PRINT LIVE AUDIT TRAIL

EIGHT TIME ZONES (PROGRAMMABLE WITH P.C. SOFTWARE)

SIXTEEN HOLIDAY TIME ZONES (PROGRAMMABLE WITH P.C. SOFTWARE)

AUTO UNLOCK TIME ZONES

FIRST IN AUTO-UNLOCK

REMOTE ACCESSIBLE VIA MODEM

FORCED DOOR ALARM RELAY/TIMER

PROPPED DOOR RELAY/TIMER

ALARM ZONE SHUNTING RELAY

TIMED EGRESS INPUT

NON-VOLATILE EEPROM MEMORY

“DURESS CODE” CAPABLE WITH KEYPAD

The Secured Series System by IEI is a two part, single door, access control system. When used with

a locking device, it can control access to that particular door. A one door system would consist of one HUB

control module, and up to two front end readers. The door may require a reader on the inside as well as

the outside of the door (for logging of in and out transactions),but the HUB control module can only control

one door.

The HUB is where all memory is stored, and all outputs originate. The HUB control module reads data

sent to it from the front end, determines if access should be granted or not, and energizes the proper outputs. All relay outputs are located internal to the HUB controller, as well as communication ports for networking, an internal clock, a keypad for programming, and memory chips to store user information and

transaction log data.

If you wish, you can run communication wires from HUB to HUB for the purpose of sending data,

ie.,user codes, card or touch chip number information from one stand-alone HUB to the next. This is

referred to as networking. Networking will also allow you to transfer data from any HUB in the system to a

serial printer, for example sending the transaction log information, or the list of code, card or chip numbers.

You can also run a network cable from the HUB designated as “Door #1” to a personal computer. This

will allow the owner to easily manipulate important information from HUB to HUB or simply program in and

out information pertaining to the system from one location, the computer. With a computer networked into

the system the owner can now view the list of people by name when looking at the transaction log, and

also assign time zones and holidays limiting certain users to a timed schedule. The personal computer

makes programming easier than from the HUB keypad. This will also require the IEI Secured Series

Software, Model # PCSFTWR. Up to eight HUB controllers may be networked into the system, or on one

personal computer or serial printer.

The HUB control module comes equipped with an infra-red transmitter mounted just to the left of the

red/green bi-color light. You can see the window that the data is transferred out of just above the numbered digits on the HUB keypad. IEI’s hand held IR-printer, (model# IR-PRINT) will allow you to retrieve

the transaction log or user list from the front of each HUB. WIRELESS! Using the IR port disables the use

of the system with a personal computer, or serial printer.

Page 2

Table Of Contents

What is a Front End?...............................................................................

Location of HUB.......................................................................................

What you need to know about installing a HUB...................................

Parts Checklist.........................................................................................

Testing the system..................................................................................

Wiring the Front End...............................................................................

Propped Door Relay................................................................................

Forced Door Relay...................................................................................

Alarm Shunt Relay...................................................................................

Auto Re-Lock...........................................................................................

Request to Exit Switch............................................................................

Networking...............................................................................................

Transferring of HUB control data...........................................................

DC wiring diagrams.................................................................................

AC wiring diagrams.................................................................................

Printing features and programming......................................................

Setting up printer to receive data..........................................................

Modem wiring and programming...........................................................

Programming............................................................................................

Troubleshooting guide............................................................................

Programming Options Chart..................................................................

Accessories.............................................................................................

Product specifications............................................................................

2

PG. 3

PG. 3

PG. 3

PG. 4

PG. 5

PG. 6

PG. 7

PG. 8

PG. 9

PG. 9

PG. 10

PG. 11

PG. 12

PG. 13

PG. 15

PG. 16

PG. 20

PG. 21

PG. 24

PG. 29

PG. 31

PG. 32

PG. 33

Page 3

What is a “FRONT END”?

A front end is the device which you choose to place outside the door. IEI manufactures several to

choose from, keypads, magnetic card readers, proximity card readers, touch chip readers. No programming is done from the front end, only at the HUB controller.

Location of HUBS

Once you have established which type of device you need, and how many doors will be equipped

with electronic access, a location must be found for the HUB controllers. Whether you have a one

door system or an eight, IEI recommends that the HUB or HUBs be located in a secure but convenient location. If you are planning a system with two or more HUBs, IEI recommends that you place

all the HUB controllers in the same location if possible.

What you need to know about installing a HUB

The HUB controller can be mounted in a standard size, single-gang electrical box. If you find

space in a single-gang box insufficient for all the wiring, try a double-gang electrical box with a mud

ring. Arecommendation for systems that have two or more HUBs, is to purchase a can or cabinet.

Mounting at your work bench consists of cutting a 2¾ inch by 2 inch hole in cabinet door for each

HUB. The HUB controllers should be far enough apart to fit a small flat-head screwdriver in between

units, in order to access the screw terminal block at each HUB control. With the HUB controllers

mounted in door of cabinet, you can program from the keypads, all located in a single location.

Open door of cabinet and look at the back of the HUB controllers, all the wiring is now accessible,

easy to work with, easy to install, easy for troubleshooting, and makes for a clean job.

IEI manufactures a one HUB cabinet with a 12VDC power supply all mounted at the factory,

model #PSW/ENC-12V. A 12 x 14 cabinet will house four (4) HUB controls, but power supplies

must be in another cabinet.

3

Power for the Secured Series access control system can be from 12 volts AC/DC, up to 24 volts

AC/DC. Choosing the correct power supply for your application is important! One HUB controller will

power one or two front ends, but will only be capable of controlling one locking device. To calculate

current draw requirements for the Secured Series system,determine what front end you will be using

and view chart on current draw on page 32. Add current draw from front end to 125 milliamps.

Multiply this total by the number of doors in your system. Locking devices must also be taken into

consideration when using the same power supply to power your locks. Adding the current draw for

the locking devices to your total will give you the total current draw on your power supply.

Power for HUB controller

Page 4

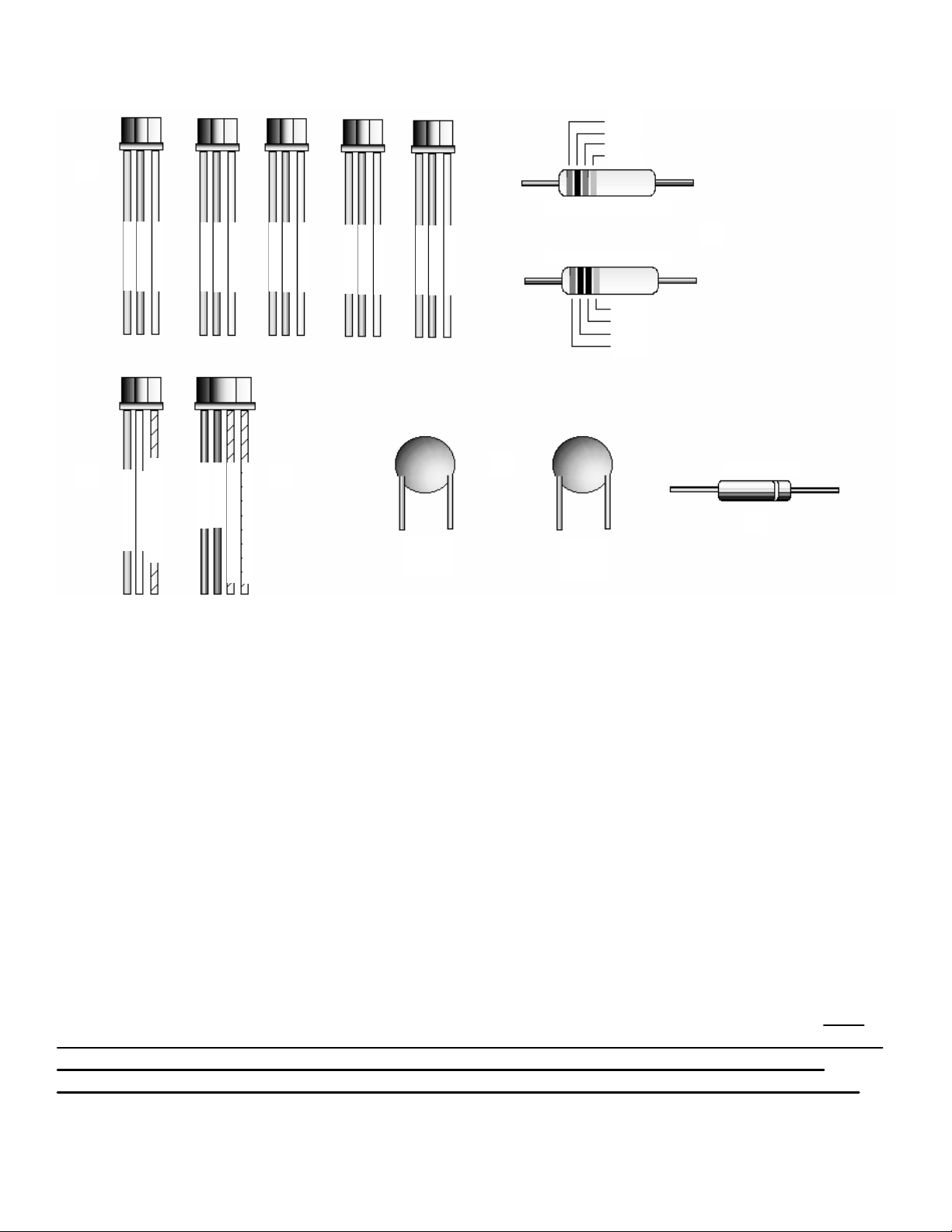

PARTS CHECK LIST

Additional parts included with the HUB

plus

Control Module are as follows:

5 ea. Three conductor harness with blue, green, and gray wires. 1 ea. will be used for the

Propped door, Forced door, and the Alarm shunt relay. The remaining 2 will be used when networking HUBs together, or when connecting HUB to a serial printer or personal computer.

2 ea. 1/4 watt resistors. One 10 ohm resistor, marked with a brown, black, and black stripe and

one 100 ohm resistor with a brown, black, and brown stripe. These are to be used when using AC

as a power source. Use the 10 ohm resistor with 12VAC, and the 100 ohm resistor with 24VAC.

2 ea. Metal Oxide Varistors. These are used when using AC or DC as a power source. One will

be connected at V+ and V- on the terminal strip of the HUB control module, and the other will be

connected across the terminals on the locking device. No polarity need be observed.

1 ea. 1N4004 Diode. This component is wired across the locking device terminals when using DC

as a power source. Silver band towards positive side of lock

1 ea. Three conductor harness with brown, white, and white\orange wires. This harness is to be

connected to a request to exit switch (normally open), and a door contact (normally closed). If no

door contacts are to be used, then the white wire and the white\orange wire must be shorted

together

, otherwise the request to exit switch will not engage the locking device when

pressed, and the transaction log will display “Door

Ajar” when a valid entry has occurred.

1 ea. Four conductor harness with black, red, white\black, and white\yellow wires. This harness is

used to connect the HUB to the front end.

g

r

e

e

n

b

l

u

e

g

r

a

y

g

r

e

e

n

b

l

u

e

g

r

a

y

g

r

e

e

n

b

l

u

e

g

r

a

y

g

r

e

e

n

b

l

u

e

g

r

a

y

g

r

e

e

n

b

l

u

e

g

r

a

y

b

r

o

w

n

w

h

i

t

e

w

h

t

/

o

r

g

b

l

a

c

k

r

e

d

w

h

t

/

b

l

a

c

k

w

h

t

/

y

e

l

metal

oxide

varistor

metal

oxide

varistor

10 ohm 1/4 watt resistor

100 ohm 1/4 watt resistor

1N4004 diode

4

Brown

Black

Brown

Gold

Gold

Black

Black

Brown

A.

B.

E. F.

C.

D.

A.

B.

C.

D.

E.

F.

Page 5

SECURED SERIES DEFA ULTS

Door-Gard Secured Series keypads are designed for easy inst allation in a minimum amount of time. The following default s have

been factory programmed.

Master Code (user 1) 1234

*

Main Relay will energize for 5 secs.

Keypress Feedback O n

Propped door relay will energize af ter 30 secs.

Forced door relay will energize for 10 secs.

Printer Output Port RS-232 Port (Port A on Hub Control Module #1)

If default s must be changed or additional functions are desired, please refer to PROGRAMMING FROM THE HUB (see p a g e

24).

LED INDICATO R S

The following is a list of the LED operations on the Hub Control Module

Yellow LED

Slow blink Program mode active/T ransaction log almost full indicator

Rapid blink Program mode verify

S teady Program mode error

V ery rapid blink Memory (EEProm) erase in progress

Bi-color LED

Solid red Main relay not energized

Solid green Main relay energized

Rapid green blink User dump or log dump in progress

Slow green/yellow blink User dat a being sent (yellow LED also blinks slow)

Slow red/green blink Unit is in receive mode or user dat a is being received

Slow green blink Unit is in A u t o L o c k \ U n l o c k m o d e

TESTING THE SYSTEM

Testing The Hub Control Module

1. Connect the positive (+) lead of your power supply to the screw terminal (TS1) +V input on the Hub Control Module.

2. Connect the negative (-) lead of your power supply to the screw terminal (TS1) -V input on the Hub Control Module.

3. T urn on your power supply.

4. The bi-color (red and green) LED on the face of the Hub Control Module should be red.

5. Press 7890#123456*. If all 12 keypresses are verified, the Hub Control Module will enter self test mode. The bi-color LED

should now turn green. The red LED flashes alternately with the yellow LED and then both will turn of f. The sounder will

then beep 3 times, p ause, then beep once more. If this does not happen, try to enter self test mode again by pressing

7890#123456

*.

6. Enter the master code of 1234*. The red LED will turn of f and the green LED will turn on for 5 seconds while the main relay

energizes. Refer to programming section (see p age 24) to program your system.

Testing The Front End Module

1. Power down your Hub Control Module when connecting any Front End Module.

2. Refer to appropriate Front End Module wiring diagram (see p age 6) for proper connection to Hub Control Module.

3. T urn on your power supply.

4. Once the Front End is properly powered a red LED (except for the Ruggedized) will illuminate on the front of the unit.

5. If the Front End Module has a keyp ad, then press 7890#123456*. If all 12 keypresses have been verified, the Front End

Module will enter self test mode. See the following for proper self test mode Front End indicators:

Indoor/Weather Resist ant Keyp ads- LED s will sequence across and then the yellow LED will flash until a key is

pressed.

Mullion Keyp ad- LED s will sequence across and then the far left green LED will flash until a key is pressed.

Card Reader/Keypad- LED s will sequence across, sounder beeps twice and then the yellow LED will flash until a key is

pressed.

Ruggedized Keypad- The sounder will beep twice. Press any key to exit self test mode.

W eather Proof Keyp ad- The LED will alternately flash and then turn of f, af ter which, the sounder will beep twice. Press

any key to exit self test mode.

6. Enter the master code of 1234*(except on the Card, Proximity, or Touch Reader). The red LED (except for the Ruggedized )

will turn green and the main relay on the Hub Control will energize. Refer to programming section (see p age 24) to program

your system.

5

Page 6

Voltmeter

Electrical

Tape

Electrical

Tape

Front

End

Insulator

BLACK

RED

BLACK/WHITE

BLACK\YELLOW

Drain

Wire

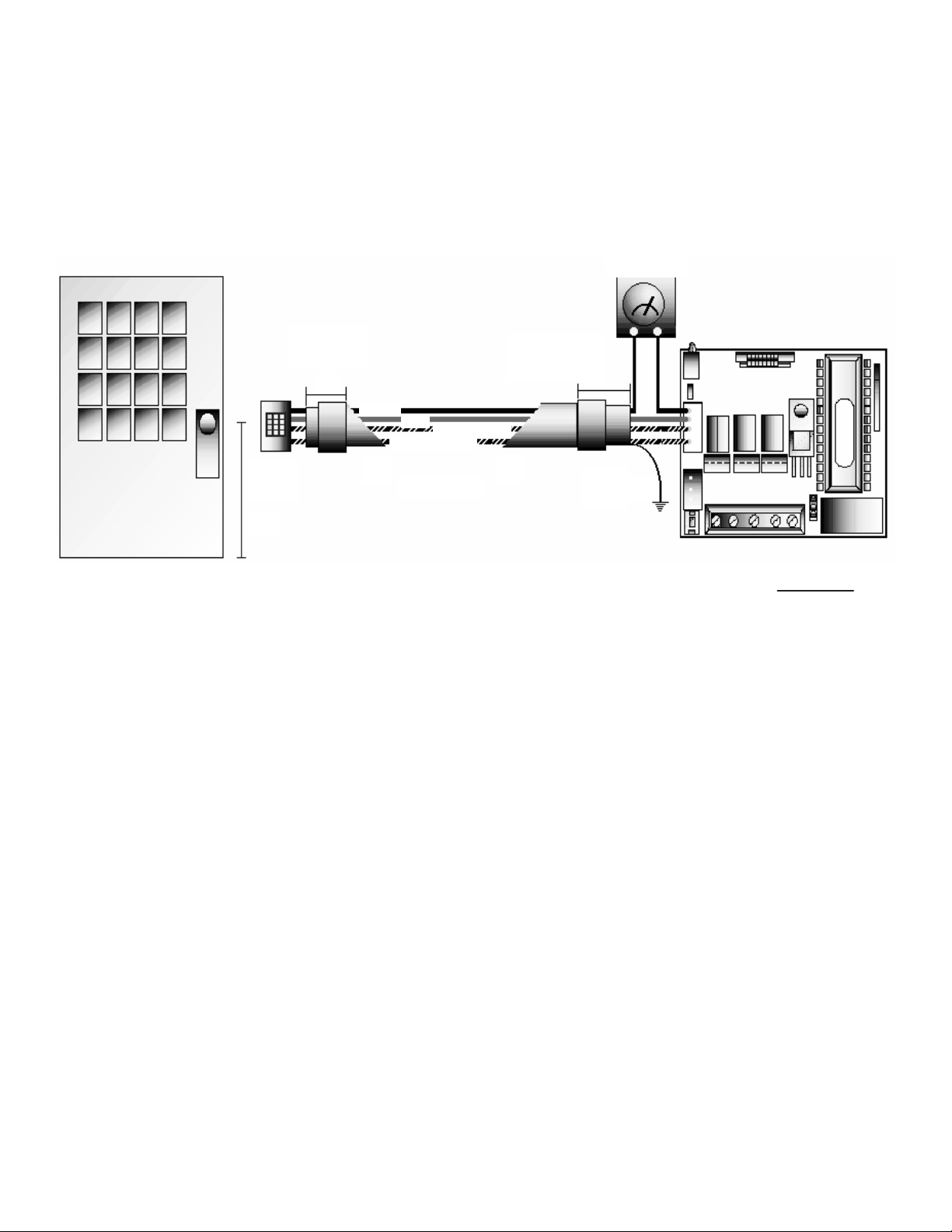

WIRING THE FRONT END

A front end is the device which you choose to place outside the door. IEI manufactures several

to choose from; keypads, magnetic card readers, proximity card readers, and touch chip readers.

No programming is done at the front end.

Choosing the correct front end for the application is important. IEI manufactures light traffic and

heavy traffic devices. If you are not sure which front end to utilize, please call us at 1-800-343-9502.

TESTING THE FRONT END FOR GROUND POTENTIAL DIFFERENCES

Wiring the front end to the HUB control unit requires a four conductor,stranded and shielded

cable to be wired between two units. Maximum lengths are as follows:

At the HUB, connect the four conductor cable to the four pin connector on the Hub control relay

board, as shown in the diagram above. The drain wire at the HUB controller must be attached to

ground, also the foil shield should be cut back with the insulator and taped with electrical tape.

Ground is the V- terminal on TS1 if the power supply is grounded. At the front end, the drain wire

and foil shield is cut back with the insulator and taped with electrical tape. The four conductor harness connects into the four pin connector in the front end. Both wire harnesses are connected to

each other color to color.

22 AWG stranded : 250 feet

20 AWG stranded : 500 feet

18 AWG stranded : 1000 feet

48”

If the front end reader is mounted to the metal frame of the building, a ground potential test

should be run. This test is important because a ground potential difference between the power supply ground and the ground on the metal frame of a building can render the system inoperable. The

front end should first be installed and the power supply grounded and turned off. Now set up a

meter to read DC voltage. At HUB control separate the black wire of the four conductor cable from

the wire running to the front end and attach the meter in series with the two wires per diagram

above. If the meter shows more than one volt then the front end must either be insulated from the

frame or the ground wire of the reader must be removed. Setup meter to read AC voltage and

repeat test. On the front end you will find the grounding wire screwed to the case at one end and

plugged into the circuit board on the other end. If you have any questions about this procedure

please call IEI technical support, 1-800-343-9502.

6

Page 7

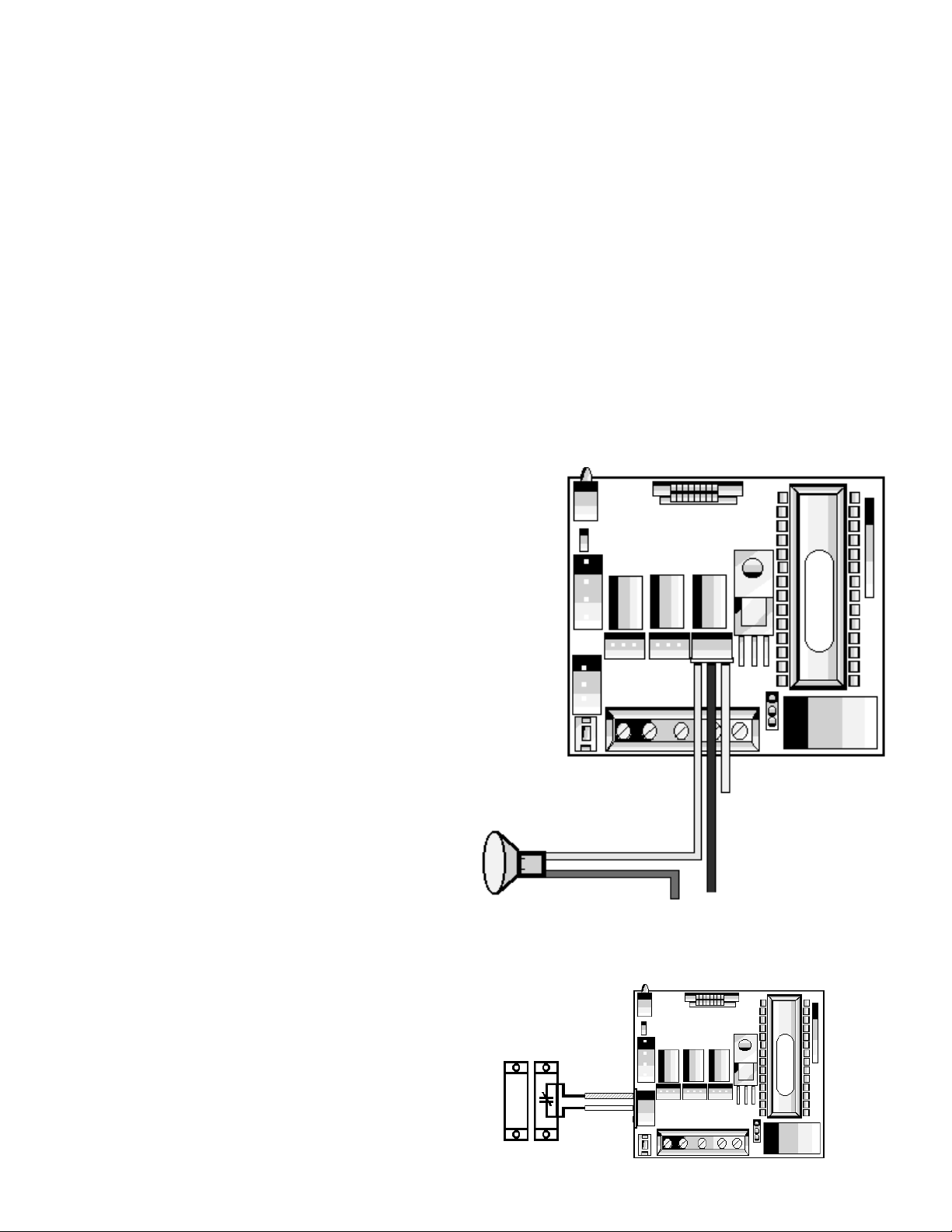

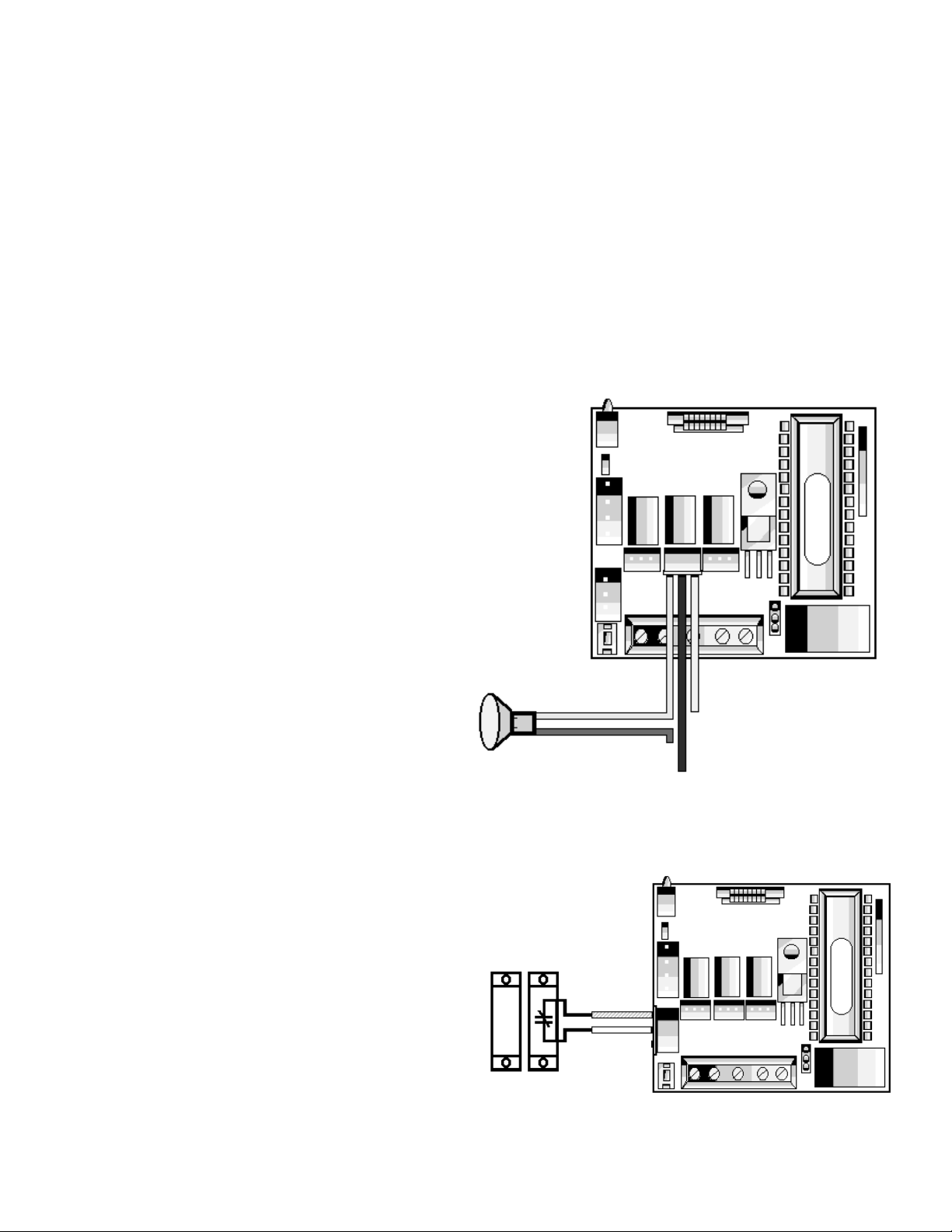

Propped Door Relay

This output is utilized to inform personnel that the door is being held, or propped open, after a

valid entry. To accomplish this, the Hub

plus

Control Module comes equipped with a relay and an

internal timer circuit that is designated for this purpose. The relay is rated to handle one (1) amp of

current at either 12 volts or 24 volts, type AC or DC, and turns on or off one leg of power to a warning device. Warning device not included with IEI equipment.

1. Connect the three conductor harness with the green,

blue, and gray wire to the propped door relay jack as

shown in diagram A.

2. Connect green wire to V+ on sounder.

3. Connect blue wire to V+ from power supply.

4. Connect V- from power supply to V- on sounder.

5. Gray wire is not used.

DIAGRAM A

HUB

PLUS

CONTROL RELAY BOARD

V-

V+

V+

GREEN (NO)

BLUE (C)

GRAY (NC) NOT USED

Programming the Propped Door Relay

To program how long the door can be propped open

before the alarm is tripped, Program as follows:

1. Enter programming mode. Press 99 # (master code) *

2. Verify HUB is in programming, yellow light should be

flashing slowly.

To

Power Supply

To incorporate this feature into your system, simply locate one of the five connectors, each one

with three (3) wires, green, blue, and gray, located in the box with the Hub

plus

Control Module. With

the HUB powered down, unlatch the keypad from the plastic housing and slide the two (2) printed

circuit boards out of housing. With the circuit boards out, you can now separate the two (2) boards,

exposing the connectors as shown in Diagram A. If the propped door relay is energized, the event

will be logged in the transaction buffer.

3. Press 44 # (time) # 0 # **, time represents how

long the relay stays de-energized, 10 to 900 seconds

4. Press * to exit program mode, yellow light

should not be flashing.

Propped door time must be programmed in intervals of 10 seconds, ie. 10, 30, 60,... up to 900

seconds.

NOTE: This feature requires that you utilize the

door contact (input) per diagram B.

door contact

white wire

with orange

stripe

white wire

DIAGRAM B.

Propped

Door

Relay

Wiring the Propped Door Relay

7

Page 8

Forced Door Relay

Forced

Door

Relay

This output is utilized to inform personnel that the door had been opened without authorization. To

accomplish this, the Hub

plus

Control Module comes equipped with a relay and an internal timer circuit that is designated for this purpose. The relay is rated to handle one (1) amp of current at either

12 volts or 24 volts, type AC or DC, and turns on or off one leg of power to a warning device.

Warning device not included with IEI equipment.

To incorporate this feature into your system, simply locate one of the five connectors, each one

with three (3) wires, green, blue, and gray, located in the box with the Hub

plus

Control Module. With

the HUB powered down, unlatch the keypad from the plastic housing and slide the two (2) printed

circuit boards out of housing. With the circuit boards out, you can now separate the two (2) boards,

exposing the connectors as shown in Diagram A. If the forced door relay is energized, the event will

be logged in the transaction buffer.

Wiring the Forced Door Relay

1. Connect the three conductor harness with the green, blue,

and gray wire to the forced door relay jack as shown in diagram A.

2. Connect green wire to V+ on siren.

3. Connect blue wire to V+ from power supply.

4. Connect V- from power supply to V- on sounder.

5. Gray wire is not used.

HUB

PLUS

CONTROL RELAY BOARD

DIAGRAM A.

To

Power Supply

V+

V+

V-

GRAY (NC) NOT USED

GREEN (NO)

BLUE (C)

Programming the Forced Door Relay

To program the time forced door output stays

energized, Program as follows:

1. Enter programming mode. Press 99 # (master

code) *

2. Verify HUB is in programming, yellow light

should be flashing slowly.

3. Press 45 # (time) # 0 # * *, time represents how

long the relay stays energized, 10 to 900 seconds,

or you may press 00 for a latched output, requiring a valid code to reset output.

4. Press * to exit program mode, yellow light

should not be flashing.

white wire

with orange

stripe

white wire

NOTE: This feature requires that you utilize the

door contact (input) per diagram B.

DIAGRAM B.

door contact

8

Page 9

Alarm Shunt Relay

Alarm

Shunt

Relay

green

blue

gray (not used)

door contact

DIAGRAM A

DIAGRAM B.

HUB

PLUS

CONTROL RELAY BOARD

The shunt relay may be necessary to use when a security

system or other type of system has already been in existence.

The shunt relay would keep the alarm from activating when

the door is opened. No programming required, the HUB controller will activate the shunt relay automatically with any valid

access or egress.

To incorporate this feature into your system, simply locate

one of the five connectors, each one with three (3) wires,

green, blue, and gray, located in the box with the Hub

plus

Control Module. With the HUB powered down, unlatch the

keypad from the plastic housing and slide the two (2) printed

circuit boards out of housing. With the circuit boards out, you

can now separate the two (2) boards, exposing the connectors as shown in diagram A.

Wiring the Alarm Shunt Relay

1. Connect the three conductor harness with the green, blue,

and gray wire to the alarm shunt relay jack as shown in diagram A.

2. Connect green wire to “Common” side of door contact.

3. Connect blue wire to “Normally Open” side of door contact.

4. Make a parallel connection to the green and blue wires,(as

shown in diagram A.), and run the leads to the alarm panel.

NOTE: This feature requires that you utilize the door contact (input) per diagram B.

door contact

white wire with

orange stripe

white wire

Auto Re-Lock

Auto Re-Lock solves the problem of people

“tailgating” in behind those using valid access

protocol, allowing the programmer the opportunity to set a long door open time. This feature

over-rides the main relay timer, resetting the

door open time as soon as the HUB sees the

door open. In many situations, you will find yourself programming a long door open time, this

allows people carrying packages enough time to

get from the front end (reader) to the door and

open it before the timer runs out. Other people may only require a few seconds to do the same task,

without an auto re-lock, the door would be left unlocked long enough for people to tailgate in behind

you. No programming is necessary, after a valid access or egress, the HUB control monitoring the

door contact sees the door switch open and drops the main relay immediately, disengaging the lock

which you will notice always locking behind you, whether you take three seconds to get to the door

or ten seconds.NOTE: This feature requires that you utilize the door contact (input) per dia-

gram B.

To alarm panel

To alarm panel

9

Page 10

Each HUB control module may

be wired to monitor a remote

switching device, and is meant to

be installed on the safe side of a

door. This is a momentary input

that will engage the main relay for

the same amount of time that the

master code is set for. This input

requires a momentary closure

between two wires at the HUB

enabling you the freedom to use

several devices in a parallel circuit.

This function can be stored in the

transaction log for future viewing. A

remote button may be placed at a

receptionist desk, press to exit

switch on the inside of a door, or a

passive infra red detector, allowing

free and convenient egress. You

may opt to install a second front

end. This would be for higher security where personnel may need to

be monitored entering and exiting a

building or a room. A remote button

can still be used to open a door

even if you have used a second

front end on the door. Their is no

programming required, just wire

according to one of the two

Diagram A.

Diagram B.

REQUEST TO EXIT SWITCH

following wiring diagrams which applies to your application. Locate the cable harness

with the brown, white, and white and orange stripe wires. This three wire harness is

in the box that the HUB came in. Plug the harness into the white connector next to

the program switch (sw1). If you do not wish to install the door contacts per dia-

gram A, then you must twist the white wire and the white and orange striped

wires together, see diagram B.

Door Contact

Brown

White

White\Orange

Normally

Open

Switch

Normally

Open

Switch

Brown

White

White\Orange

10

Page 11

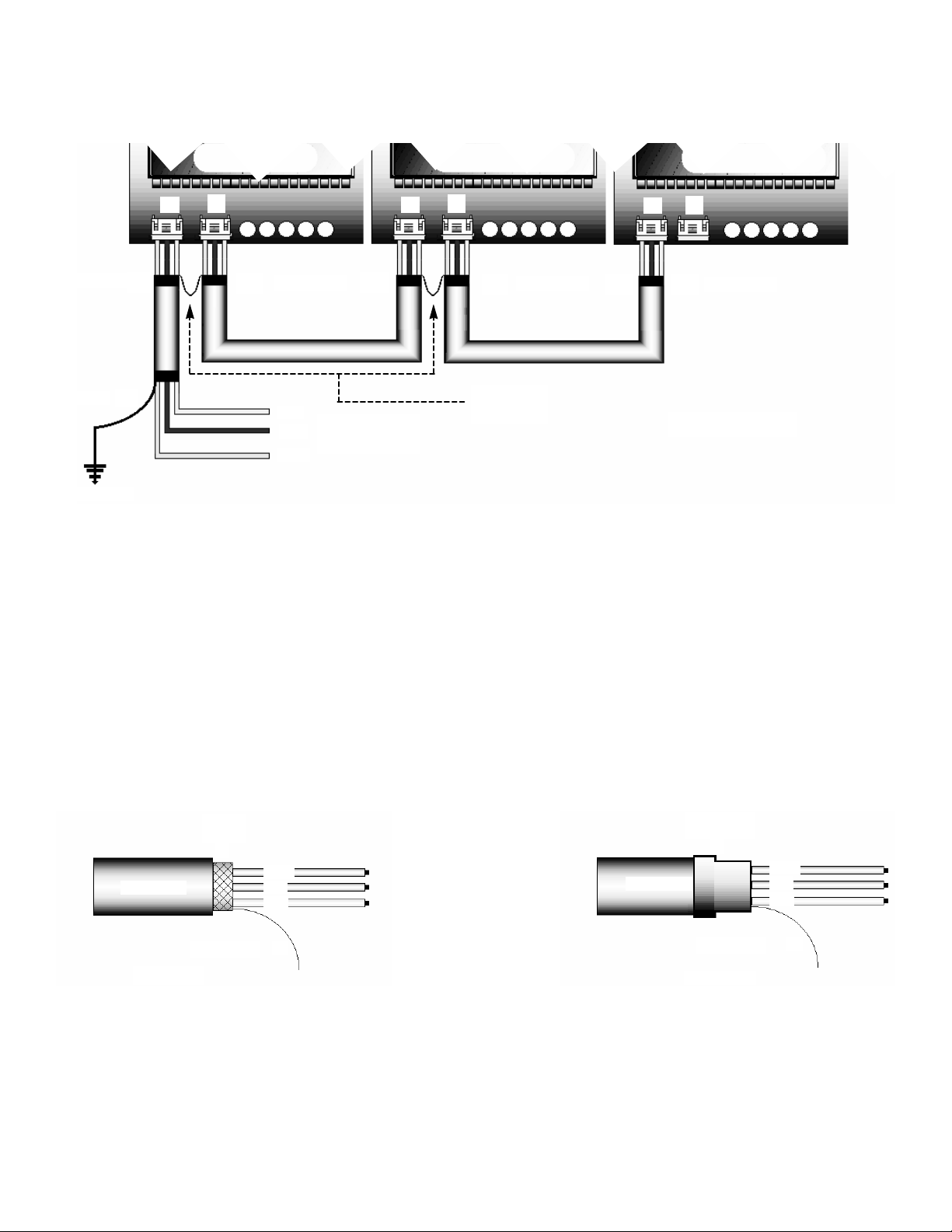

NETWORKING

USING SHIELDED CABLES

A

C

A

C

A

C

blue

green

gray

drain wire

earth ground

electrical tape

electrical tape

electrical tape

electrical tape

to serial printer

or computer

GROUNDING THE NETWORK CABLE SHIELD

Once you have run the network cable it will need to have the shields grounded. Under the insulator there is a foil shield that protects the wire from any data, RF, or AC that might be induced on the

lines (see diagram B.). After you you strip back the insulator, remove the exposed shield, leaving

only the wires. You will have exposed the wires with individual insulators and a bare wire called a

“drain wire”, they will be used so do not cut them. Tape over the exposed foil with electrical tape to

prevent it from shorting to any wires accidentally not covered properly during installation,(see diagram C.) The shield is now grounded!

DIAGRAM B.

DIAGRAM C.

The network cable provides the data buss that information can be transferred along. This cable is

run between HUBs and will enable the user to transfer all, or selected user information from one

programmed HUB to another. It can also be connected to a personal computer, or a serial printer.

To wire, locate two of the three conductor harness with the green, blue, and gray wire. Now, at

the HUB designated as door #1, locate the two white male connectors ( on the buffer board ), called

port “A” and port “C”(see diagram A.). Insert one three conductor harness into each port on all the

HUBs you wish to network. The wires extending from port “A” of HUB #1 will be wired to a personal

computer or a serial printer. The wires from port “C” of HUB #1 will go to HUB#2 port “A”. Connect

the harnesses between port “C” of HUB #2 to port “A” of HUB #3 color to color.(see diagram A.) If

the cable exits a cabinet, or must be run more than a few feet, then you must protect the data with a

shielded cable. The shield must be connected to ground at one end, the other end is to be “floating”, or un-grounded.

INSULATOR

FOIL

SHIELD

DRAIN WIRE

green

blue

gray

INSULATOR

ELECTRICAL

TAPE

DRAIN WIRE

green

blue

gray

Diagram A.

11

Drain wires

connected

Page 12

TRANSFERRING OF HUB CONTROL D ATA

Before a Hub Control can receive dat a it must be put into a receive mode. While a Hub control is waiting to receive or is receiv ing dat a, the green and red LED s will alternately blink. The receiving Hub will remain in receive mode until a key is pressed; at

which time it will return to normal operations. No transactions can be processed from a front end while a Hub is in receive mode.

SET HUB TO RECEIVE DATA

At receiving Hub:

1. Enter programming mode Press 99 # (master code) *(yellow LED flashes slowly)

2. Set Hub to receive Press 29 # 0 # 0 #

* *

SET HUB TO SEND DATA

When data is sent a range of user numbers may be specified or you may copy all of the Hub data at once. While a Hub Control

is sending dat a the green LED will blink slowly . When the transfer is complete, the sending Hub will return to programming

mode.

At sending Hub:

To send all of the Hub dat a at once:

1. Enter programming mode Press 99 # (master code) *(yellow LED flashes slowly)

2. Set Hub to send dat a Press 21 # 0 # 0 #

* *

This new command will copy all system p arameters (relay time, propped door time, etc.) to the receiving Hub along with the pro grammed users. The time and date must still be programmed at the receiving Hub. This procedure will copy the door number from

the sending Hub to the receiving Hub. The door number must be reprogrammed at the receiving Hub af ter the transfer has been

completed.

To send a group of user numbers:

1. Enter programming mode Press 99 # (master code) *(yellow LED flashes slowly)

2. Set Hub to send dat a Press 20 # (FFF) # (LLL) #

* *

FFF = First user number to transfer

LLL = Last user number to transfer

12

WIRING OF COMMUNICATION PORTS

Page 13

Power

Supply

V+

V-

V+ V- NC C NO

V+ V- NC C NO

TS-1

TS-1

P5

Jumper

P5 Jumper

Relay

Relay

1. Determine what voltage you will be using to power hubs.

2. When using 12-15 VDC, place P5 jumper in position 1.

3. When using 15-24 VDC, place P5 jumper in position 2.

Position 1

Position 2

12-15 VDC 15-24 VDC

4. Connect V+ from power supply to V+ on TS-1.

5. Connect V- from power supply to V- on TS-1.

6. With power on, the red led will turn on.

7. Enter “1234*”, the red led will turn off, and the green led will turn on for 5 seconds.

After 5 seconds the green led will turn off and the red led will turn on, signifying an

armed status. Relay will “click” upon entering “1234*”.

8. Turn power off and proceed with wiring locking devices.

P5 Jumper

Grounding the power supply

Any time you network HUBs together, care must be taken to insure that the power

supplies are grounded properly. If you are installing more than one power supply for a

system, all power supplies must be tied to a common ground by running a common

line between the supply ground lug terminals. If the supplies do not have ground

lugs, run a wire between the DC negative terminals on the output from the units.

13

DC Power Requirements / Wiring Diagrams

HUB #1 HUB #2

Page 14

V+

V-

V+ V- NC C NO

TS-1

P5

Jumper

Relay

1. Determine what voltage you will be using to power hub

2. When using 12-15 VDC, place P5 jumper in position 1.

3. When using 15-24 VDC, place P5 jumper in position 2.

Position 1

Position 2

12-15 VDC

15-24 VDC

4. Connect V+ from power supply to V+ on TS-1.

5. Connect a jumper wire from V+ to C on TS-1.

6. Connect V+ from strike to NO on TS-1.

7. Connect diode across locking device terminals; Striped end on V+ at lock, and the

other end to V- on

locking device.

8. Connect V- from strike to V- on TS-1.

9. Connect V- from power supply to V- on TS-1.

10. With power on, the red led will turn on.

11. Enter “1234*”, the red led will turn off, and the green led will turn on for 5 seconds.

After 5 seconds the green led will turn off and the red led will turn on, signifying an

armed status. Relay will “click” upon entering “1234*”.

P5 Jumper

Power

Supply

Strike*

Diode

Grounding the power supply

Any time you network HUBs together, care must be taken to insure that the power

supplies are grounded properly. If you are installing more than one power supply for a

system, all power supplies must be tied to a common ground by running a common

line between the supply ground lug terminals. If the supplies do not have ground

lugs, run a wire between the DC negative terminals on the output from the units.

14

*NOTE: When wiring a magnetic

lock, use diagram above with the

following exception:

6. Connect V+ from magnetic

lock to NC on TS-1.

DC Power Requirements / Wiring Diagrams

Page 15

Transformers can have AC or DC power as an output. The output from a transformer, whether

AC or DC, is unfiltered, unregulated and has certain limitations. Many electrical environments are

susceptible to having transients, electrical spikes, and surges. Such noisy electrical systems can

induce a glitch in the program of the HUB controller. Some situations to look for are listed below.

Do not use transformer power in a system that networks HUBs together

, or on a system

that will be used with a personal computer. Using transformer power alone without a filter/regula-

tor circuit card will be acceptable in some locations. Make sure to follow the wiring diagram above

for this application. IEI has provided two M.O.V.’s and two different value resistors to use in this

application. The hardware packet will provide the two resistors and the M.O.V.. One ten ohm resistor

with brown, black, black color bands will be used for 12 volt AC application only, and one 100 ohm

resistor with the brown, black, brown color bands will be used for 24 volt AC applications only. These

are provided to add protection to the HUB systems, since transformers usually have little if any transient protection. If the bands are hard to see, please meter the resistors for the correct value.

The HUB controller needs to be set up for the voltage you decide to use. Find P5 pin rail and

select the proper pins to short together with the jumper (See diagram B.). You will find P5 is shown

in diagram A. next to the terminal strip.

Resistor

Door

Strike

Metal

Oxide

Varistor

Transformer

Buildings that utilize back-up electrical generators. (Hospitals, Nursing Homes, etc.)

When using power that also feeds the motor controller of a gate, or an overhead door.

In a building with heavy machinery like elevators, and other large three-phase motors,

welders, large industrial refrigerators, an AC units with large condensers.

When using a proximity reader as a front end, you must

use a filtered and regulated

12V DC power supply.

Diagram B.

3

2

1

12-24VAC

P5

Diagram A.

TS1

15

Metal

Oxide

Varistor

AC Power Requirements / Wiring Diagrams

Page 16

Printing Features and Programming

Hub Control Front V iew

The following connections are

shown for most st andard serial

printers. Refer to your printer

manual for exact connections.

Location of InfraRed (IR) LED.

W ireless handheld printer must

be held near LED for proper

printing.

A

C

DB-9

Signal ground

Data out

Data in

DB-25

Signal ground

Data out

Data in

Pin

5

3

2

Pin

7

2

3

Wire

Green

Blue

Gray

Wire

Green

Blue

Gray

Ground

Hub Control

Communication Board

PROGRAMMING THE HUB CONTROL UNITS TO PRINT

Before the HUB can send data, you must program the following commands at each HUB.

• Enter programming mode at HUB by pressing 99 # master code *, the yellow light should be flashing.

• Press 43 # 0 # 01 up to 08 # ** sets door number

• Press 42 # mmddyy # day # ** sets the month day and year, day is 1 for

Sunday, 2 is for Monday...

• Press 41 # hhmm # 0 # ** sets the clock in military time ( 24 hour configuration).

• Press 31 # 3 # 0 # ** sets printer output for Infra-red port

• Press 31 # 3 # 1 # ** sets printer output for RS-232 Port A (System Default)

The printing feature offers the ability of retrieving reports from the system. Each HUB controller is

capable of sending the data stored in memory to three different types of equipment. The reports can be

sent to a personal computer, a hard wired serial printer, or the IEI infra-red printer model # IR-PRINT. Both

the serial and infra-red printers will require the user to go to each HUB in the system and use the keypad in

order to select the report desired. The Print Live feature allows you to view the transaction log as the

events occur with a serial printer. This feature can not be used with the infra-red printer. The print live command sends only the transaction log to a serial printer and will only be able to accommodate one HUB per

system. Each HUB is capable of storing up to one thousand transactions in memory. As the system is

being used the buffer takes and holds all the data in a “first in/first out” type of memory. This means that

when the buffer is full of transactions it will “bump” the oldest transaction out of the system.

16

Door #01

9/14/96

1 17:50 user 002 in

2 17:49 user 010 out

3 17:48 user 052 print

4 17:46 access denied

5 17:30 forced door

Page 17

The HUB can indicate that the buffer is 80% at capacity with a warning light. If the log almost full

warning is programmed “ON” and the transaction log has 799 transactions stored, the yellow light

on the HUB will flash once every ten seconds. The warning will continue until the log is erased,

dumped, or the self test sequence is entered at HUB. To program the log almost full warning follow

the programming steps below:

• At HUB press 99 # master code *, HUB should now be in programming mode, ( slow

flashing yellow light).

• Now press 31 # 11 # 1 # **

• Asolid yellow light indicates the command did not take, start over or call technical support

• Now exit programming mode by pressing the * button. The yellow light should not be flashing.

• Pressing 31 # 11 # 0 # **will disable feature.

PRINT LIVE

Print live is a feature that can be programmed into a HUB enabling the unit to transmit the log

data directly to a serial printer. The report that is generated by using the system also gets stored

into the memory buffer for future viewing. Print live can be programmed into any HUB in a network.

If more than one HUB tries to print at once, the data will be garbled at the printer, although the data

will still be available from the transaction buffer. This function is not capable of being used with the

infra-red printer. To program the HUB to print live follow the programming steps below:

• At HUB press 99 # master code *, HUB should now be in programming mode, ( slow flashing

yellow light).

• Now press 31 # 10 # 1 # **.

• Asolid yellow light indicates the command did not take, try again before calling technical sup-

port.

• Now exit programming mode by pressing the * button, The yellow light should not be flashing.

• • Pressing 31 # 10 # 0 # ** will disable function.

SELECTING THE INFORMATION THAT WILL SHOW IN THE LOG

Not every transaction will be necessary for viewing by the user. In this case IEI has provided

a way of ignoring the un-desired transactions. Certain transactions may be ignored by programming

those events out of the logs criteria. To program the HUB to ignore those transactions which are not

needed follow the programming steps below :

•At HUB press 99 # master code *, HUB should now be in programming mode, ( slow flashing

yellow light).

•Now press 73 # event # 0/1 # ** Asolid yellow light indicates the command did not take, start

over or call technical support.

•Now exit programming mode by pressing the * button, The yellow light should not be flashing.

Where the 0/1 is shown in the programming process is the on off directive for the HUB. This

means that if you press a “0” at this point that transaction will not be logged, or if you press a “1”

the transaction will be restored and the log will retain the event. The “event” is a two digit number

that represents a specific transaction. A list of the events that are logged are listed on the next

page.

17

Log Almost Full Warning

Page 18

01 - access denied 16 - print

02 - program denied 17 - in ( user xxx entered )

03 - program mode 18 - out (user xxx egresses )

04 - request to exit (Rex) 19 - bad time zone ( valid user tried to

05 - door ajar get access outside time zone)

06 - door closed 20 - toggle on

07 - forced door 21 - toggle off

08 - log erased 22 - first in / auto-unlock

09 - duress 23 - relock

All transactions are programmed at the factory to be logged. When a HUB is defaulted back to

its factory settings, the user may wish to program the events that should not be logged back out.

LOGGING “ACCESS DENIED”

When someone tries to gain access and has not been programmed for access at that door, the

log records the event as “access denied”. The person may have pressed the wrong code by accident or swiped the wrong card. You may or may not wish to know this type of information so IEI

have made provisions allowing this type of transaction to also be ignored. To program the HUB for

this option follow the steps below:

• Enter programming mode at HUB by pressing 99 # master code *, the yellow light should be

flashing slow.

• Press 31 # 06 # 0 # ** to ignore the transaction .

OR, press 31 # 06 # 1 # ** to log this type of transaction Asolid yellow light indicates the com-

mand did not take, start over or call technical support.

• Press * in order to exit program mode, yellow light should not be flashing.

PRINT LIST OF USERS

Both the serial printer and the infra red printer can be used to retrieve a list containing all the

user access information. This is done at each HUB controller and can only show the information

from that specific HUB. The HUB unit is a stand alone device so each unit can have different user

information stored.Each HUB control can store up to 500 different codes in memory, or the data off

499 cards with one master code, or the data off 499 touch chips with one master code. The user

data is stored into a register that is numbered. Register one is referred to as user one, register two

is referred to as user two and so on. The user data is stored into any of the 500 registers and does

not need to be placed in any special order.

You can store codes or cards in the first five registers and then skip some registers leaving them

empty, then continue programming from registers out of sequence. This is an important fact to

know because the report will tell you the location of a particular persons data. The printed list will

have the register number printed first and then the data off the card, touch chip, or code. The next

line will print the next register that holds information with that users data. To keep a log, simply

print the list and write the persons name next to the data. Now maintaining the system will be possible. To retrieve the list follow the steps on the next page.

18

Page 19

• Enter programming mode at HUB by pressing 99 # master code *, yellow light should now be

flashing slowly.

• Press 25 # 0 # 0 # **

•If you are using the infra red printer you will need to hold the printer up to the infra-red port on

the HUB. Hold the printer about one or two inches away from port steadily until report is

completed. The list is numbered showing if any data was missed.

•The lights on the front of the HUB will be flashing indicating the list is being sent to the printer.

• When the list is completed press the * button to exit program mode.

TRANSACTION LOG

The transaction log may be sent to the printer, serial or infra red, with one of two different

methods. You can program a “dump code” in each HUB enabling the user to simply press in the

special code, or place HUB into programming mode and the press in the command to send that log

to the printer manually.

PROGRAM DUMP CODE OR CARD

• Enter programming mode at HUB by pressing 99 # master code *, the yellow light should be

flashing slow.

• Press 50 # 2 # user number # code * code *

• OR press 50 # 2 # user number # ** and swipe card or touch chip.

• Press * to exit program mode.

DUMP TRANSACTION LOG

• Enter programming mode at HUB by pressing 99 # master code *, the yellow light should be

flashing slow.

• Press 70 # 0 # 0 # ** the data should be transmitting and the lights should be flashing.

• Press * to exit program mode after transactions are retrieved.

ERASE ENTIRE TRANSACTION LOG

The log should be erased after being retrieved to prevent reports from conflicting. To do this

follow the programming steps listed below:

• Enter programming mode at HUB by pressing 99 # master code *, the yellow

light should be flashing slow.

• Press 76 # 00000 # 00000# **

• Press * to exit programming mode

The 76 command will be logged in the transaction buffer to give the user a reference as

to when the log was erased.

19

Page 20

programmed users

001 S F 1234 ----

002 S R 543 ----

003 S T ---- 500019

004 S L 23 ----

005 B F 444 006155

006 E F 99999 006132

Door #01

9/14/94

1 17:50 user 002 in

2 17:50 user 010 out

3 17:48 user 052 print

4 17:46 access denied

5 17:30 forced door

6 17:23 program mode

User Number

T

ime

The printout is read backwards, with the

most recent transaction printed first.

Door Number

Date

Card Number

Code Number

User Type 1

S = Single PIN

B = Both code and

card

E = Either code or

card

User Type 2

R =Relockbbbbbbbbbbbbb

F = Users that follow mas -

ter code for main relay

time

T = Users programmed for

toggle of main relay

L = Users programmed to

initiate log dump.

Resulting

Transaction

User 002 in = User 2 entering door

User 010 out = User 10 exiting door

User 052 print = User 52 entered

log dump command

access denied = invalid access

attempted

program mode = program mode

entered

T

ransaction Number

Each time a transaction is

sent to the buf fer log it is

given a sequential number.

If the printed numbers are

not sequential, a transaction

has been missed.

Sample of Printed User Table

Sample of Transaction Log

---- = No Code/Card

NOTE: If you are using the wireless handheld printer make sure that you

hold the printer in place while the green LED is blinking rapidly, otherwise

you may miss some transactions. This would be indicated by the fact that

you have skipped some transaction numbers in the printout.

The HUB transmits standard serial data. Diagram on page 15 shows how to wire most

serial printers. If the green and red lights are flashing alternately, the HUB is sending

data. Note the specifications listed below and check with the manufacturer of that printer

for any dip switch settings that may need to be set.

The HUB provides data in, data out, and signal ground.

Speed: 1200 Baud Rate

Data Bits: 8

Stop Bits: 1

Parity: None

Characters per second (CPS): 120

Printer S

pecifications

Setting up printer to receive data

20

Page 21

1. To set up the system for this operation you must first install the security chip in the HUB designated as door # 1. The security chip is located in the P.C. Software kit, packaged in a small static

sensitive box. Locate and install in accordance to the installation guide provided in the software kit.

2. At HUB #1, the erase all memory command needs to be programmed. This is to reset the factory settings and ensures that the program is running after the security chip was installed. This will

clear any “glitches” in the system, caused by static that may have been induced when handling circuit boards.

• Place HUB control in program mode by pressing 99 # (master code) *, at HUB

keypad

• Verify HUB is in program mode, yellow light should be flashing slowly.

Press 46 # 00000 # 00000 # **, when the yellow light is flashing at the slow rate

once again, the command is complete

• Press * to exit program mode.

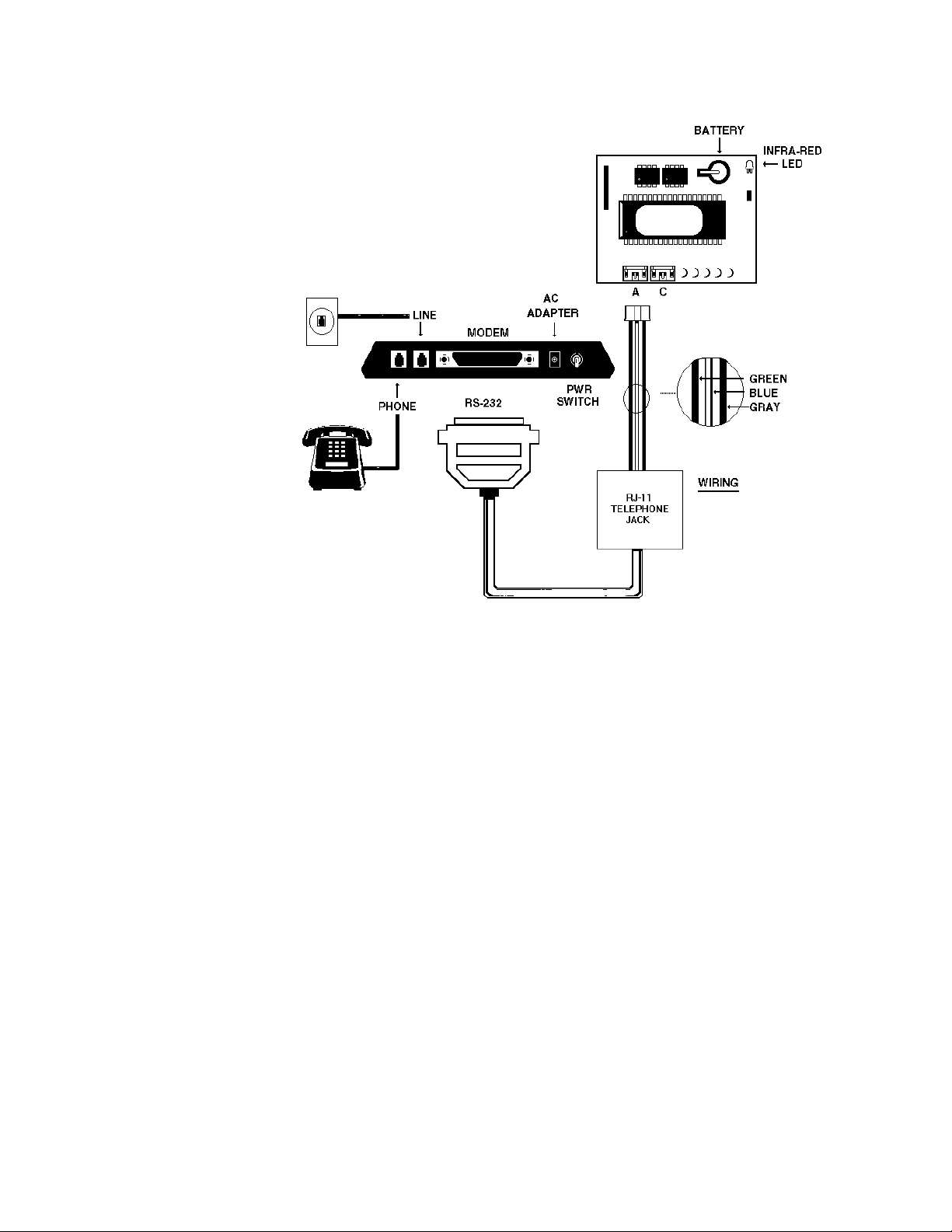

The HUB

PLUS

system

can be accessed from a

remote site. This enables

you to manipulate any of

the data in the system as if

you were on the site with

your personal computer,

via modem. This will

require two IEI modem

kits, model #SS-MODEM-

144. One is to be located

at the jobsite, with the

HUB controllers, and the

other modem kit is to be

located at the remote site,

with the computer. You will

also need one IEI 3.0 version P.C. Software kit

model #PCSFTWR. Both

the remote location with

the computer , and the job

site, with the HUB controllers, need to have phone lines available to work.

SECURITY

CHIP

21

Remote Access From A Modem

Modem Wiring And Programming At Job Site

Diagram A.

Page 22

3. Once the security chip is installed, you must program each hub with a door number. If you do not do

this, the software will not be able to locate the HUB controllers, and the software will not show the doors

as being on-line. Program each HUB as follows:

• Place HUB control in program mode by pressing 99 # (master code) *, at HUB keypad.

• Verify HUB is in program mode, yellow light should be flashing slowly.

• Press 43 # 0 # (door number in two digits) # * *

• Press * to exit program mode, yellow light will stop flashing.

• Do these programming steps to assign door numbers to all the HUBs in the system.

• Make sure that each HUB has a different door number.

• The HUB control that is to be assigned “door one” must

be the one with the security

chip and physically located first in the network. This is the HUB that you will now hookup to the modem.

4. To hook-up the modem at the job site, use the diagram on page 21.

Connect the three conductor harness with the green, blue, and gray wire to the RJ-11 telephone jack as

shown in the diagram on page 21. Connect the three conductor cable to port “A” of HUB controller #1.

Connect the the telephone cable (included) to the RJ-11 telephone jack. Connect the other end of the telephone cable to the RS-232 jack. Connect the RS-232 jack to the modem. Connect telephone into jack

marked “phone”, and connect outside line into jack marked “line”. NOTE: You will find that a cable in the

modem kit will not be used at the job site.

5. HUB #1 must be programmed with two commands that will enable and setup the unit to communicate

with the modem.

• Place HUB control #1 in program mode by pressing 99 # (master code) *, at HUB key

pad.

• Verify HUB is in program mode, yellow light should be flashing slowly.

• Press 31 # 8 # 1 # ** remote access enabled

• Press 35 # 1 # 0 # ** select modem string

• Press * to exit program mode

6. At HUB #1 run self test, this will setup a communication link hub #1 and modem. This is NOT

done

with the HUB in program mode.

• Press 7 8 9 0 # 1 2 3 4 5 6 *

The self test command will run a simple diagnostics test. This checks the communication between the

two circuit boards of the HUB, it will also test the keypad as well. On the HUB, you should see the lights

cycling between the different colors and ending with the sounder beeping.

22

Page 23

Secured Series Hub Control w/ Modem

Off-site/Remote Location Configuration

DB-9

DB-25

To Comm. Port.

Use

DB-25 or DB-9

Connector

At the remote site, you will need the second modem kit. You will also need the diskette from the P.C.

Software Kit, one of the two RJ-11 phone jacks, one of the two straight cords, and the two connectors.

Both the 25 pin and the 9 pin connector are labeled “ to P.C.”.

To setup the computer, follow the instructions with the P.C. Software on how to guide you thru the

Comm. Port Test. This will require you to plug-in the DB-25 or the DB-9 connector into either communication port one or two, located in the back of the computer. Then plug the telephone cable into the RJ-11

jack, and proceed to the Comm. Port test.

Once the test is complete, follow diagram above to complete hook-up.

23

Remote Site Wiring To P.C.

Page 24

PROGRAMMING FROM THE HUB

Each secured series HUB control module, with a reader, represents a stand alone system, and can be

programmed at the HUB controller. This programming guide had been broken up into boxes in order to

allow you the opportunity to find the section that pertains to your application. This section is for programming on the HUB’s keypad, located at the front of the HUB control unit.

Much of the programming had been covered and explained in the section pertaining to that specific

feature. Programming with the IEI software is covered in a different instruction that is provided with the IEI

software kit.

The first step in programming is always to place the HUB into program mode. When the HUB is in program mode, the yellow light will be flashing at a slow rate. When the yellow light stops flashing the HUB is

no longer in program mode. If the programming is not taken or not entered correctly, the yellow light stays

on solid, indicating to you to re-try the process. If the HUB will not go into program mode refer to the troubleshooting guide.

In order to place the HUB into programming mode you need to know the master code. The master

code is the code that is stored in register one. To place the HUB into programming mode press 99 # and

the master code followed by the * button, now the yellow light should be flashing. The factory default code

is 1234*. This code is also referred to as user one.

The master code should not be programmed as a card, or touch chip, because that will keep you from

using “user one” for programming since you cannot program from the front ends. The master code also

sets the door open time for all the other users, and the request to exit time. The master code cannot be

set for a latched output.

Each code programmed may consist of a different quantity of digits. A code may consist of only two

digits, or up to six digits in length. If you try to put a code into memory that had been previously entered

into a different register the yellow light will stop flashing and stay solid, indicating the action was impossible

to accomplish. Try a different code. Repeating digits in the same code is acceptable.

Changing the main relay time will allow users the proper amount of time to get from the front end to the

door before the main relay re-locks the door. Setting the main relay time for the master code, or user one,

will simultaneously set the time for users in register two thru register five hundred. The factory default relay

time is five seconds. To change this or the codes follow the steps listed below.

CHANGE MAIN RELAY TIME

Time can be set in one second increments from one second to ninety seconds, all other users will follow this time with only one exception, latching users, covered next.

• Press 99# master code *, yellow light flashing indicating HUB is in program mode.

• Enter in new time in seconds followed by #, next press 1#, representing user one, then the master

code *, you should see the yellow light flashing fast, verify code by pressing the master code in a

second time followed by a *, yellow light should now be flashing slow.

• Press * to exit programming.

24

Page 25

ADDING NEW OR CHANGING EXISTING CODES/CARDS/TOUCH CHIPS

• Enter program mode at the HUB, press 99# master code *, the yellow light should be flashing

slowly. 1234* is the factory set master code.

• Press the register number that represents the user to be added, or changed. Follow with a #

key. 2, would be user two, 500, would be user five hundred.

• CODE: Now press the two to six digit code and *, the yellow light should be flashing fast indi-

cating to you to verify the new code by pressing the same code and * a second time. The yellow light will

be flashing slow if the code is accepted.

• CARD/ T

OUCH CHIP: Press ** and go to reader and swipe card, or Press * if you wish to exit

program mode or continue to add or change codes.

SEQUENTIALLY ADDING CARDS/TOUCH CHIPS

If you are going to add several cards or touch chips into memory you will want to batch load them.

Sequentially adding IEI MAG stripe cards, and proximity cards are easy to keep in order because the code

is written on the front of each card. The touch chips are not in any order when received, so care should be

taken to print the user log before handing out the chips. This gives you the opportunity to log which chip

was given to which person.

To program several users from the front end, follow the program instructions below :

• Enter program mode at HUB by pressing 99 # master code *, yellow light should be flashing slow

• Press 53 # 1 # starting user number # ** at HUB, the starting user number is never 1, that is the

master code.

• Swipe first card/touch chip. On the card reader the red light should flash green indicating the card

was accepted. On the touch chip reader the sounder should beep indicating it was accepted.

• Continue to enter users or Press * to exit program at HUB

PROGRAMMING CARD READER KEYPAD

The CR/KP 500w (card reader keypad) can be programmed to accept code only users, card only

users, or combination code and card users. The users cannot share codes, or cards when programming for

card/code users. When a combination code/card user uses the device they may swipe the magnetic card

first, or press in the code first.

Once a code/card user has either swiped the card or pressed in the code they should see the yellow

light on the reader come on solid, indicating that the HUB is looking for the second half of the transaction

before granting access. Once access is granted the red light should turn green and the door should

release. To program this front end for card and code follow the programming instructions below.

• Enter program mode at HUB by pressing 99 # master code *, the yellow light should be flashing

slow.

• Press at the HUB 52 # 1 # user number # new code * new code * and then go to reader and

swipe the card. The red light should flash to green and back to red three times at reader indicating

the transaction is complete.

• Repeat the last step for each card/code user to be entered, their are no provisions made for

entering a batch of users in this style of device.

• Press * to exit program mode

To enter just a code, or just a card follow the programming steps described in the section titled “ADDING OR CHANGING

CODES OR CARDS”

25

Page 26

PROGRAMMING A USER TO LATCH THE MAIN RELAY

A latching code, card, or touch chip, may be programmed allowing a user the ability to bypass

the door for an indefinite amount of time. When the user then enters that code, card, or touch chip, the

HUB latches the relay on. Using any latching code, card, or touch chip a second time (either at the HUB or

the front end), and the relay latches to the opposite position.

When a user that is programmed to latch resets the main relay, the timed, or toggle users can then

resume standard operation. When a user latches the main relay on/off the event is stored in the transaction

log. The record will show “TGL ON” “TGL OFF”, also the time, date, door number, and user. To program a

user as a latching, or toggled output, follow the programming steps listed below.

• Enter program mode at the HUB by pressing 99 # master code *, the yellow light should be flash

ing slow.

• FOR A CODE, at HUB enter the time as 00 # user number # code * code *

• FOR

A CARD, OR TOUCH CHIP, at HUB enter the time as 00 # user number # **, and swipe card

or touch chip at reader.

• FOR

A CARD READER KEYPAD, at HUB enter the time as 00 # user number # code * code *, then

go to reader and swipe card.

• Press * at HUB to exit program mode.

T

O DELETE USERS

In order to delete a user from the system the register that the user information is stored in must be

known. If you dump the user list in accordance with the instructions on page 18, you can find this information and continue with the programming steps. If the system is not equipped with the means to print this

list, then the programmer should have filled out a chart as to the location, or register, the users are located

in. To delete a user follow the programming instructions below.

• Enter the program mode at the HUB by pressing 99 # master code *, the yellow light should be

flashing slow

• Press the user number and # **Press * at HUB to exit program mode.

PROGRAMMING A DURESS CODE

When utilized, a user may press the # key within three seconds of a valid code activating the duress

feature. Programming this option will enable any code programmed into a specific HUB to activate a

relay output. This can be used to activate a silent alarm during a hold up, or hostage style situation. This

feature is not available with card readers or touch readers. The output will activate the propped door relay

for five seconds.

When programmed for duress, the door ajar output will be disabled at that HUB. To wire output use

diagram “A” on page 7. Connect propped door relay to an auto-dialer. Duress is added to the transaction

log when enabled, and the “door closed” subtracted from the transaction log. Duress will not operate if a

Relock code is entered prior to the # key. To program this feature follow the instructions below.

• Enter programming mode at HUB by pressing 99 # master code *, yellow light should be flashing

slow

• Press 31 # 9 # 1 # **, to activate

• Press 31 # 9 # 0 # **, to disable

• Press * to exit program mode

26

Page 27

KEYPRESS FEEDBACK

Keypress feedback is a feature used to enable a sounder to beep once on each key press at HUB keypad, KP-500r, KP-500wp, KP-500i, or KP-500w. The output is factory set “on”, and helps the user to determine if the digit was pressed hard enough to be acknowledged. To enable/disable this feature, follow the

programming steps below.

• Enter program mode at HUB by pressing 99 # master code *, yellow light should be flashing slow

• Press 30 # 0 # 1 # ** to enable

• Press 30 # 0 # 0 # ** to disable

• Press * to exit program mode

RESET MASTER CODE AND SYSTEM DEFAULTS

Programming this command at the HUB will not erase the user data stored in registers two thru five

hundred. This can be useful if the HUB has a glitch in the program and is not running correctly, or if you

simply wish to reset system defaults in order to understand what has been programmed earlier. To program

this command follow the program steps below.

• Enter program mode at HUB by pressing 99 # master code *, the yellow light should now be flashing

slow

• Press 46 # 0 # 0 # **

• Press * to exit program mode

ERASE ENTIRE KEYPAD MEMORY AND RESET FACTORY DEFAULT

Programming this command will erase the entire HUB memory including any user information. This

would be used if the programmer needed to erase a specific user and could not retrieve the user log. To

program this command follow the program steps below.

• Enter program mode at HUB by pressing 99 # master code *, the yellow light should be flashing

slow

• Press 46 # 00000 # 00000 # **

• Press * to exit program mode

AUT

O-UNLOCK AUTO- RELOCK TIME ZONES

The HUB control module is capable of being programmed with up to eight time zones. A time zone is a

window that you can issue to a specific user that would limit the hours access would be granted. This is

possible because each HUB control is equipped with a twenty four hour clock, keeping track of the time of

day. The HUB is also capable of telling what day it is and the date. An “auto - unlock” time zone is a variation of a standard time zone. This type of time zone will unlock the door when programmed to do so, and

re-lock again after the time zone ends. The eight time zones per HUB can be assigned to be Auto - Unlock

time zones thru programming.

27

Page 28

The HUB control is factory programmed with time zone eight assigned as “auto - unlock” , open at

0900, re-lock at 1700, Monday through Friday. In order to change the time, days, or exclude holidays the

P.C. software will be required. If the HUB is pre-programmed prior to installation, or the P.C. is unavailable,

auto - unlock can still be re-assigned to existing pre-programmed zones, or turned off the time zones from

the front of the HUB.

When the HUB activates the auto - unlock time zone, the green light on the HUB and front end will flicker off and back on. Every 900 milliseconds the green light will turn off for 100 milliseconds . This will help

the users distinguish between a toggled/latched door (solid green), and the auto - unlock time zone being

active.

“First in auto - unlock”

is a command that programs the HUB to hold the door locked until someone is

granted access during that auto - unlock zone. This means that the door will not unlock automatically at the

set time but rather hold the door locked until the next access is granted during that specific window.

RELOCK CODE can be programmed in order to give the operator the ability to clear a toggled relay,

and will also re-lock an active auto - unlock situation. If the relock code is used to relock an auto - unlocked

door, the unlock feature will activate the next time the window opens. This feature is entered into the transaction log when used. The relock code will not allow access.

PROGRAMMING TIME ZONE FEA

TURES

• Press 99 # master code * to enter program mode at HUB

• Press 31 # 05 # 1 # ** Auto -unlock enabled

• Press 31 # 05 # 0 # ** Auto - unlock disabled

• Press 31 # 04 # 1 # ** Time zone enabled

• Press 31 # 04 # 0 # ** Time zone disabled

• Press 31 # 07 # 1 # ** First in auto - unlock enabled

• Press 31 # 07 # 0 # ** First in auto - unlock disabled

• Press 33 # time zone (1 to 8) # 1 # ** Auto- unlock time zone turned on

• Press 33 # time zone (1 to 8) # 0 # ** Auto - unlock time zone turned off

• Press 50 # 3 # user number # ** Assign RELOCK code active.

28

Page 29

TROUBLESHOOTING GUIDE

Red light turns green when access is accepted, but door does not open.

Check power supply voltage and verify the correct position of the P5 jumper.

While monitoring voltage at HUB V+ and V- terminal with meter, enter a valid code and insure

that voltage remains constant while locking device attempts to unlock and relock. If the voltage

varies 1/4 volt or more during this test, this is a problem and must be corrected. There are several

things to look for.

If you press 99 # (master code) * and the HUB does not go into program mode, it is possible

that the master code you are trying was changed or is not the master code. To get the HUB into program mode press SW1 momentarily. Do this with the power on. This micro switch is located on the

relay board next to the V+ terminal of TS1. If you need to pull the two circuit boards out of the plastic housing care must be taken. Handle the boards by the edges, the solder points can be shorted

together by fingers causing damage.

The yellow light should now be flashing slow, indicating that the HUB is in programming mode.

To program a new master code press 1# new code * new code *, the code can be one to six digits

and repeated numbers are ok. Press * to drop out of programming.

1. Verify that the power supply is rated sufficiently for all the equipment being powered.

2. Verify that the locking device, if on the same power supply , is set up for the voltage being

used. Example: If a lock draws 300ma at 24VDC, the same lock may draw 600ma at 12VDC,

especially if the unit requires that jumpers be placed in a different configuration. Place meter

across the lock power wires at lock and ensure lock is receiving the proper voltage.

3. If the resistor and M.O.V. have been installed, verify that the resistor value is correct according to specs : 10 ohms at 12VAC and 100 ohms at 24VAC.

Hub not entering program mode

The following problems will occur when the data lines of the four-conductor harness

(black/white and black/yellow) are reversed:

FRONT END

SYMPTOM

KP500R HUB: Red LED on

Front End: No Response

Keypress feedback still operates via sonalert

CR/KP500W HUB: Red LED on

Front End: No Response

Keypress feedback still operates via sonalert

Swipe good magcard: HUB: No change

Front End: Green LED flashes

29

Page 30

Swipe bad magcard: HUB: No change

Front End: Red LED flashes

CR500W HUB: Red LED on

Front End: No Response

Swipe good magcard: HUB: No change

Front End: Green LED flashes

Swipe bad magcard: HUB: No change

Front End: Red LED flashes

KP500I HUB: Red LED on

Front End: No Response

Keypress feedback still operates via sonalert, but not with yellow LED

KP500M HUB: Red LED on

Front End: No Response

Keypress feedback still operates via YELLOW led

TCH500W HUB: Red LED on

Front End: No Response

PRX500W HUB: Red LED on

Front End: Sonalert beeps twice

Good proxcard is swiped: HUB: No change

Front End: LED blinks from green to red

The following problems will occur when the power lines of the four-conductor harness (black and

red) are reversed:

FRONT END

SYMPTOM

All Front Ends HUB: Operates

Front End: No response

30

Page 31

PROGRAMMING OPTIONS CHART

If the pre-programmed default values must be changed or additional functions are desired,

the following options may be programmed once you have entered the programming mode.

To enter programming mode Press 99 # (master code) *yellow LED flashes slowly

1. Change master code/set main relay time Press (time) # 1 # (new code) *(new code)

*

Code only operation Note 10

Example: Master code of 4321/relay time of 10 seconds Press 10 # 1 # 4321 * 4321 *

2. Add/change user: code only Press (user number) # (new code) *(new code)

*

3. Add/change user: mag or prox card only Press (user number) # **(Swipe mag or proximity card)

4. Add/change user: code and magnetic card Press (user number) # (new code) *(new code) *(Swipe magnetic

card)

5. Add/change user to toggle main relay: code onl y Press (00) # (user number) # (new code) *(new code) *

6. Add/change user to toggle main relay: card onl y Press (00) # (user number) # **(Swipe mag or proximity card)

7. Add/change user to toggle main relay: Press (00) # (user number) # (new code)

*

magnetic card and code (new code) * (Swipe magnetic card)

8. Delete users Press (user number) #

**

9. Set Hub to send data Press 20 # FFF # LLL # **(refer to p age 12)

10 . Copy all Hub dat a to another Hub Press 21 # 0 # 0 #

**

(refer to p age 12)

11 . Print a list of user codes/cards Press 25 # 0 # 0 # **(refer to p age 17)

12 . Set Hub to receive dat a Press 29 # 0 # 0 #

**

(refer to p age12 )

13 . Set/Clear S tandared Option (0-2) Press 30 # option # s/c # * *

14 . Set/Clear System Option (0-11) Press 31 # option # s/c # * *

15 . Set printer output to InfraRed (IR) Port Press 31 # 3 # 0 #

**

(refer to Printing section p age 15)

16 . Set printer output to RS-232 Port A Press 31 # 3 # 1 #

**

(refer to Printing section p age 15)

17. To enable the auto unlock/lock time zone Press 31 # 5 # 1 #

**

18. To disable the auto unlock/lock time zone Press 31 # 5 # 0 #

**

19. To prevent access denied from being printed Press 31 # 6 # 0 #

**

20. To allow access denied to be printed Press 31 # 6 # 1 #

**

21 . Set time registers in real time clock Press 41 # HHMM # 0 #

**

(refer to Printing section p age 15)

22 . Set date registers in real time clock Press 4 2 # MMDDYY # Day of Week #

**

(refer to p age15)

23 . Set door number Press 43 # 0 # NN #

**

(refer to Printing section p age 15)

24. Set propped door tim e Press 44 # (time) # 0 #

**

25. Set forced door relay tim e Press 45 # (time) # 0 #

**

26. Reset master code and system default s Press 46 # 0 # 0 #

**

27. Erase entire keypad memory/reset default s Press 46 # 00000 # 00000 #

**

28. Assign dump code Press 50 # 2 # (user number) # code *code

*

29 . Assign dump card Press 50 # 2 # (user number) # **(Swipe mag or proximity card)

30. Add user for magnetic card or code operation Press 52 # 1 # (user number) # code *code

*

(Swipe magnetic card)

31. Sequentially add users: card onl y Press 53 # 1 # (st arting user number) # **(Swipe first mag or

3 2 . Print audit trail transaction log Press 70 # 0 # 0 #

**

(refer to Printing section p age 18)

33. Se t /Clear Event Logging Press 73 # event # s/c * *

34 . Delete audit trail transaction log Press 76 # 00000 # 00000 #

**

(refer to Printing section pg. 18)

Command 30 - Standard Options ( 30 # option # 0/1 # * * )

00 - keypress feedback (0= of f, 1=on)

01 - heavy duty mode (unused)

02 - auto entry (unused)