Page 1

e/eM Style Standalone

Keypad Installation/

Programming

Manual

This manual applies to these models: 212e, 212eM, 242e, and

242eM.

This equipment is designed to be installed and serviced by security

and lock industry professionals.

Put Service Company Contact Information Here:

Company Name:

Service Number:

Contents

Section 1: Features and Product Description

Section 2: Specifications

Section 3: U.L. Requirements

Section 4: Mounting

Section 5: Wiring

Section 6: Testing t he Keypad

Section 7: Programming

Section 8: Troubleshooting

Section 9: Programming Mode Loopback

Section 10: Warranty

Manual Revision Date: 12/10/04 Firmware Version: 1.0b

Document # 6104401, Rev. 1.0, D1e 1

Page 2

e/eM Style Standalone Installation/Programming Manual

1. Features and Product

Description

1.1 Features

• Flush Mount

• Indoor and Outdoor Use

• Keypad Programmable

• Access Control Functionality*

• Individually Control up to 4 Devices*

• Illuminated Backlit Keys (e keypad only)

• Durable Metal Braille Keys (eM keypad only)

• Keypress Feedback via Built-In Sounder

• Bi-Color Red/Green LED Indicates Relay Status

• Yellow LED Indicates Program Mode

• 120 Users

• Panic and Duress Options

• Single Use Codes

• Lockout Users

• Two-Man Rule Option

• 10 to 30 Volt DC Operation

• 12 to 24 Volt AC Operation

• 2AmpMainRelay

• Remote Trigger Input (REX)

*242 only

1.1.1 Access Control Function (242 factory settings)

• RequesttoExitInput

• Door Monitoring Input

• Relay Outputs

- Lock Release

- Forced Door

- Propped Door

- Alarm Shunt

• Keypad Programmable

2 Document # 6104401, Rev. 1.0, D1e

Page 3

e/eM Style Standalone Installation/Programming Manual

1.1.2 Output Functionality Options (242 field programma-

ble settings)

• Request To Exit and Door Monitor Inputs

• Four Independently Programmable Outputs

• All Outputs Assignable by Code

• Outputs Programmable For Latched or Timed Operation

• Keypad Programmable

1.2 Product Description and Naming Convention

IEI keypads and other standalone devices use an alpha-numeric

model number convention to identify functionality and style. The

numeric component identifies functionality. The alpha component

identifies style.

Examples:

1.2.1 Functionality

The 242 keypad features the most flexibility and options available

in a self-contained unit. It can perform access control functions,

and also its four relay outputs can be assigned independently for

timed operation or to latch. The 242 keypad can provide individual

control of up to four devices, and is perfect for controlling electronic locking devices, security systems, CCTV systems, automatic

operators, or machinery.

The 212 keypad features a single-relay output to control any device

requiring an on/off switch. The output is timed or latched and operated by a user’s PIN code. Additionally, the 212 keypad provides basic keyless entry by controlling a door locking device where security

is not an issue.

Document # 6104401, Rev. 1.0, D1e 3

Page 4

e/eM Style Standalone Installation/Programming Manual

1.2.2 Style

e keypads: Flush mount backlit keypad.

eM keypads: Flush mount durable metal keypad.

All keypads: Designed for both indoor and outdoor flush mount

applications. The electronics for each keypad are conformal coated

in the manufacturing process in order to provide this level of application flexibility. Installation is easy. All keypads mount to any

standard single-gang electrical box or directly to any wall.

NOTE: This manual covers both 212 and 242 models. All features referring to the additional relays and outputs are

available only on the 242 model.

4 Document # 6104401, Rev. 1.0, D1e

Page 5

e/eM Style Standalone Installation/Programming Manual

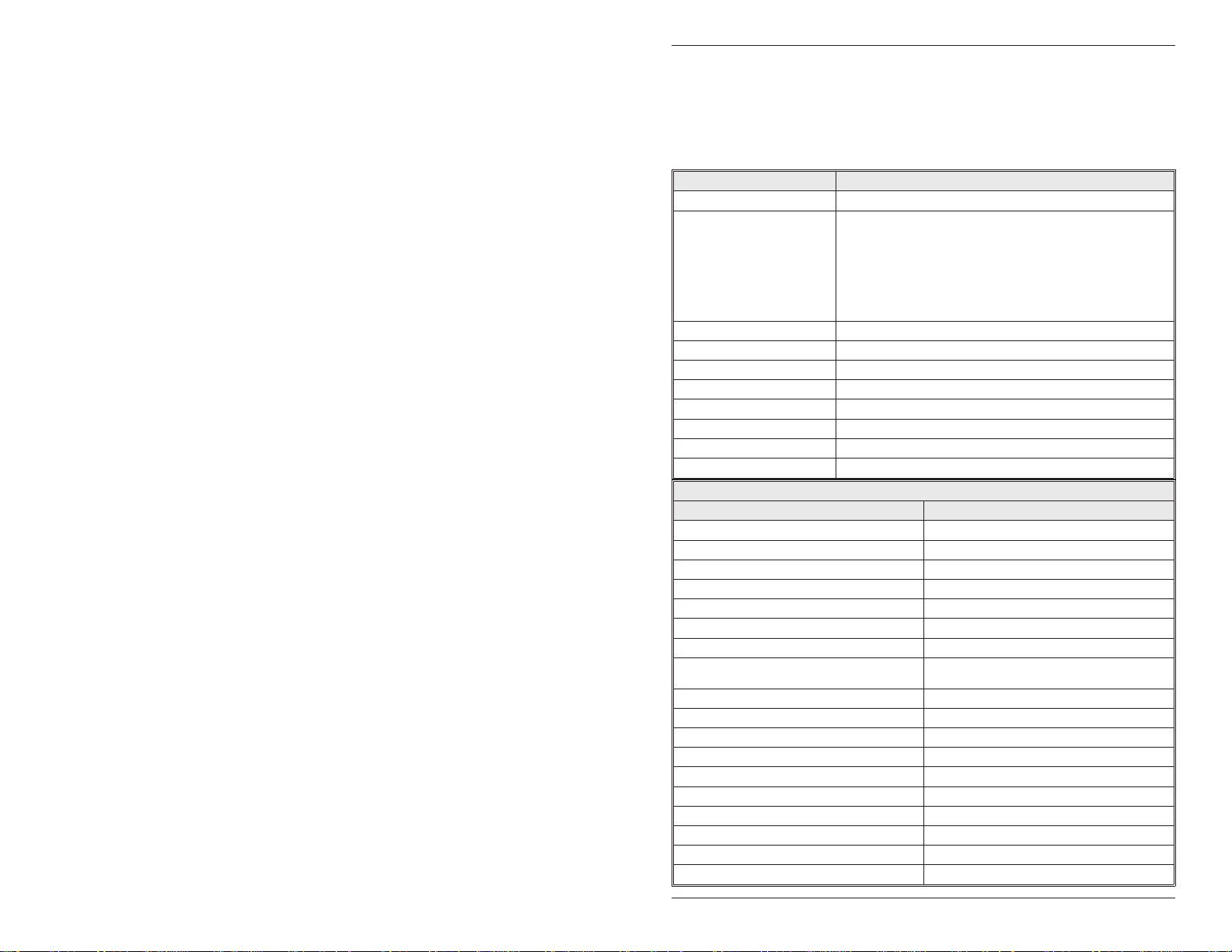

2. Specifications

Parameter Range/Description

Voltage 10-30 VDC, 12-24 VAC (Auto-Adjusting)

e:

75mA@10VDC,

100mA@30VDC,

125mA@12VAC, and

Current

Environment Indoor and Outdoor

Temperature Tolerance -20 °F to 130 °F (-28 °C to 54 °C)

Dimensions 4.5" H x 2.75" W x 0.60" D

Main Relay (Form C) Contact Rating: 2A @ 30VAC/DC

Aux Relay (Form C) Contact Rating: 1A @ 24V AC/DC

REX Input Normally Open Dry Contact

Door Position Input Normally Closed Dry Contact

LEDs Bi-Color Red/Green Yellow

Parameter Default Setting

Master Code 1234

Lock Output Relay 1 (Main Relay) (212 and 242)

Alarm Shunt Relay 2 (242)

Propped Door Relay 3 (242)

Forced Door Relay 4 (242)

Audio Alerts Not Assigned (212 and 242)

REX Triggers Lock Output

REX Operation

Error Lockout Enabled

Error Lockout Threshold 3 Attempts

Error Lockout Duration 10 Seconds

Lock Output Time 5 Seconds

Propped Door Time 30 Seconds

Forced Door Time 10 Seconds

Visual Keypress Feedback Enabled

Audio Keypress Feedback Enabled

Auto-Entry Disabled

User Lockout Enabled

200mA@24VAC

eM:

46mA@10VDC; 49mA@12VAC;

60mA@24VAC; 68mA@30VDC

Add 20 mA for each energized aux relay

Default Settings

Always Triggers (regardless of

Door Loop)

Document # 6104401, Rev. 1.0, D1e 5

Page 6

e/eM Style Standalone Installation/Programming Manual

3. U.L. Requirements

NOTE:Thissectionappliestothe 212e and 242e keypads only.

The 212eM and 242eM keypads are not U.L. Listed.

The 212e/242e keypad is a U.L. Listed access control unit. This section contains information regarding all the requirements necessary

to meet U.L. requirements.

This system must be installed in accordance with the National Electrical code (NFPA70), local codes, and the authorities having jurisdiction. In addition, a ll wires and cables used must be stranded

andshieldedU.L.Listedand/orrecognizedwire.

All interconnecting devices (that is, door contacts, REX, locking devices, etc.) must be U.L. Listed. A U.L. Listed access control power

limited power supply must be used to power the keypad.

A minimum of three user codes must be programmed into the keypad for controlling access.

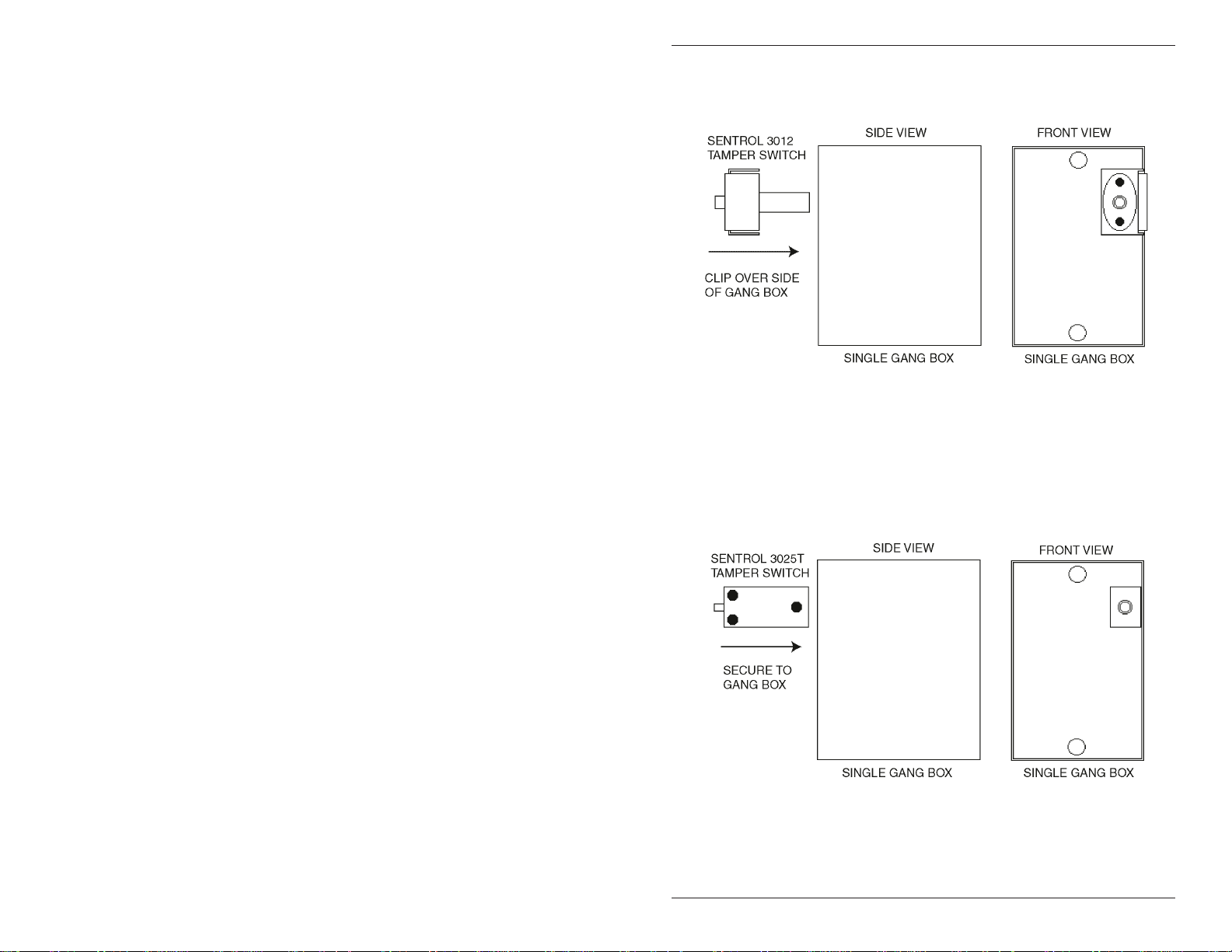

3.1 Tamper Requirements

To meet U.L. requirements, a U.L. Listed tamper switch must be installed in the single gang box used for mounting the keypad. The

tamper switch must activate if the keypad is removed from the box

and must disconnect power from the lock. The lock must be a failsecure device, meaning the lock remains locked when power is removed. In addition, o nce the tamper device is activated, it must be

configured so that it can only be reset from within the protected

area. Only a Sentrol 3012 or Sentrol 3025T tamper switch can be

used. The d iagrams on the next page show the suggested mounting location for each device.

6 Document # 6104401, Rev. 1.0, D1e

Page 7

e/eM Style Standalone Installation/Programming Manual

Figure 1 Mounting a Sentrol 3012 Tamper Switch

Figure 2 Mounting a Sentrol 3025T Tamper Switch

Document # 6104401, Rev. 1.0, D1e 7

Page 8

e/eM Style Standalone Installation/Programming Manual

4. Mounting

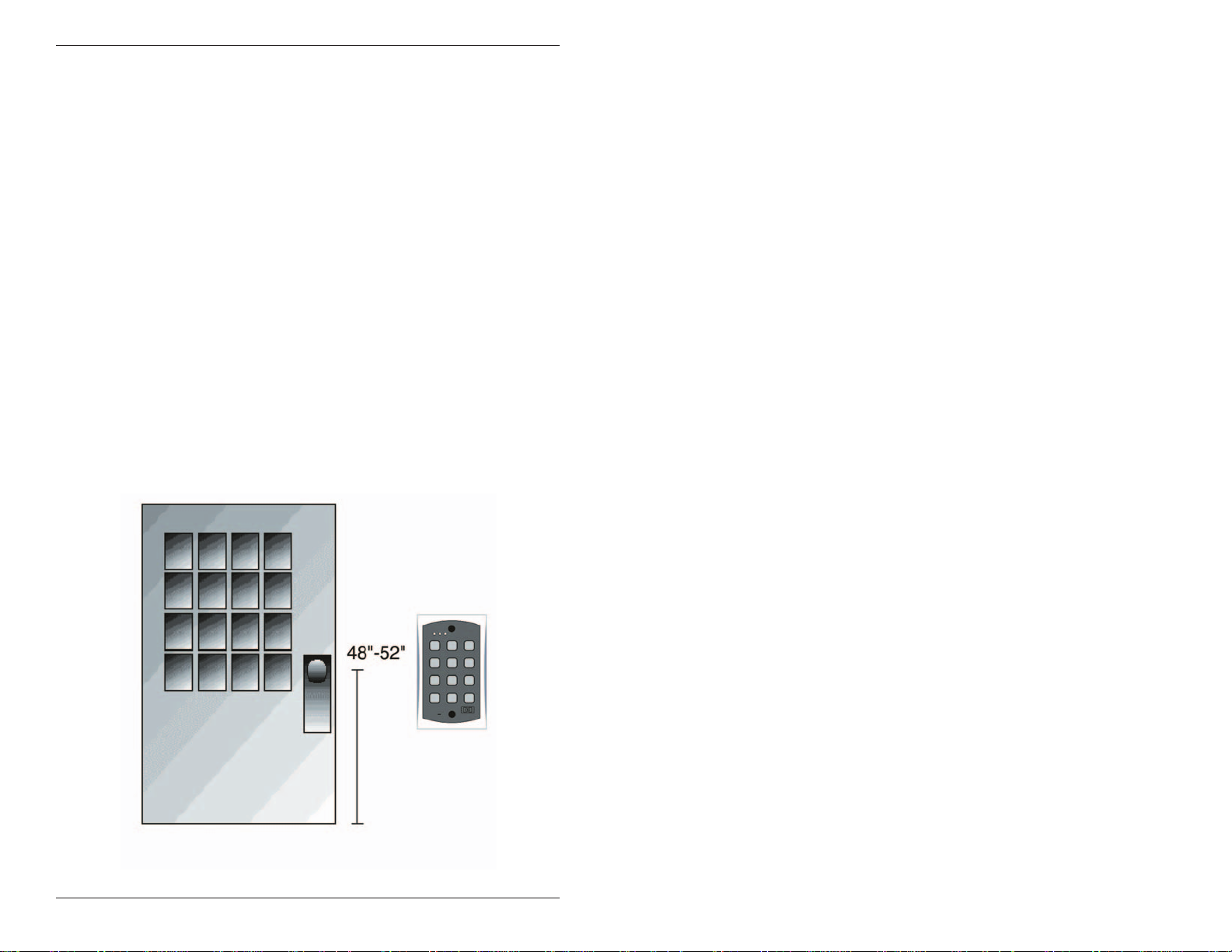

The keypad is designed to be flush mounted using a standard single-gang electrical box. In addition, it can be flush mounted directly to the wall surface by cutting a hole in the wall. To properly

size the mounting and wire access hole, use the installation template on the last page in this manual and on the unit’s container.

Mounting height can vary depending on requirements. An appropriate range is typically between 48 and 52 inches on center off the

floor.

For outdoor installations, use a weatherproof backbox and seal the

wire entry locations with silicone and provide a drain hole. In addition,usetheanti-oxidantgreasepackforthewireharnessconnectors.

Figure 3 Keypad Mounting Height

8 Document # 6104401, Rev. 1.0, D1e

Page 9

e/eM Style Standalone Installation/Programming Manual

5. Wiring

Figure 4 Keypad Connector and Wire Harness

5.1 Wire Harness Configuration

Pin Wire Color Signal Name

1Red V+

2Black V-

3 White/Black Not Used

4 White/Yellow Not Used

5 Brown Remote Trigger (REX)

6 White/Orange Loop Common

7 White Door Loop Monitor

8 Green

9 Blue Main Relay - Common

10 Gray

NOTE: For wiring the accessory relay boa rd, see sections 5.6 and 5.7.

Document # 6104401, Rev. 1.0, D1e 9

Main Relay - Normally

Open

Main Relay - Normally

Closed

Page 10

e/eM Style Standalone Installation/Programming Manual

5.2 Wiring the Keypad to a Maglock (Fail-Safe)

Use the following steps to connect the keypad to a Maglock (FailSafe):

1. Connect the red wire (V+) to the blue wire (common), and

then connect them to the positive on the power supply.

2. Connect the gray wire (normally closed) to the positive on

the maglock.

3. Connect the black wire (V-) to the negative on the Maglock,

and then connect them to the negative on the power supply.

Figure 5 Wiring the Keypad to a Maglock (Fail-Safe)

5.3 Wiring the Keypad to an Electric Strike

(Fail-Secure)

Use the following steps to connect the keypad to an electric strike

(fail-secure) (seeFigure6forreference):

1. Connect the red wire (V+) to the blue wire (common), and

then connect them to the positive on the power supply.

2. Connect the green wire (normally open) to the positive on

the strike.

3. Connect the black wire (V-) to the negative on the strike, and

then connect them to the negative on the power supply.

10 Document # 6104401, Rev. 1.0, D1e

Page 11

e/eM Style Standalone Installation/Programming Manual

Figure 6 Wiring the Keypad to Electric Strike

5.4 Shunting a Normally Closed Zone

Use the following steps to employ the keypad to shunt a normally

closed zone:

1. Connect the blue wire (common) to the common connection

on the door position switch.

2. Connect the green wire (normally open) to the normally

closed connection on the door position switch.

Figure 7 Shunting a Normally Closed Zone

Document # 6104401, Rev. 1.0, D1e 11

Page 12

e/eM Style Standalone Installation/Programming Manual

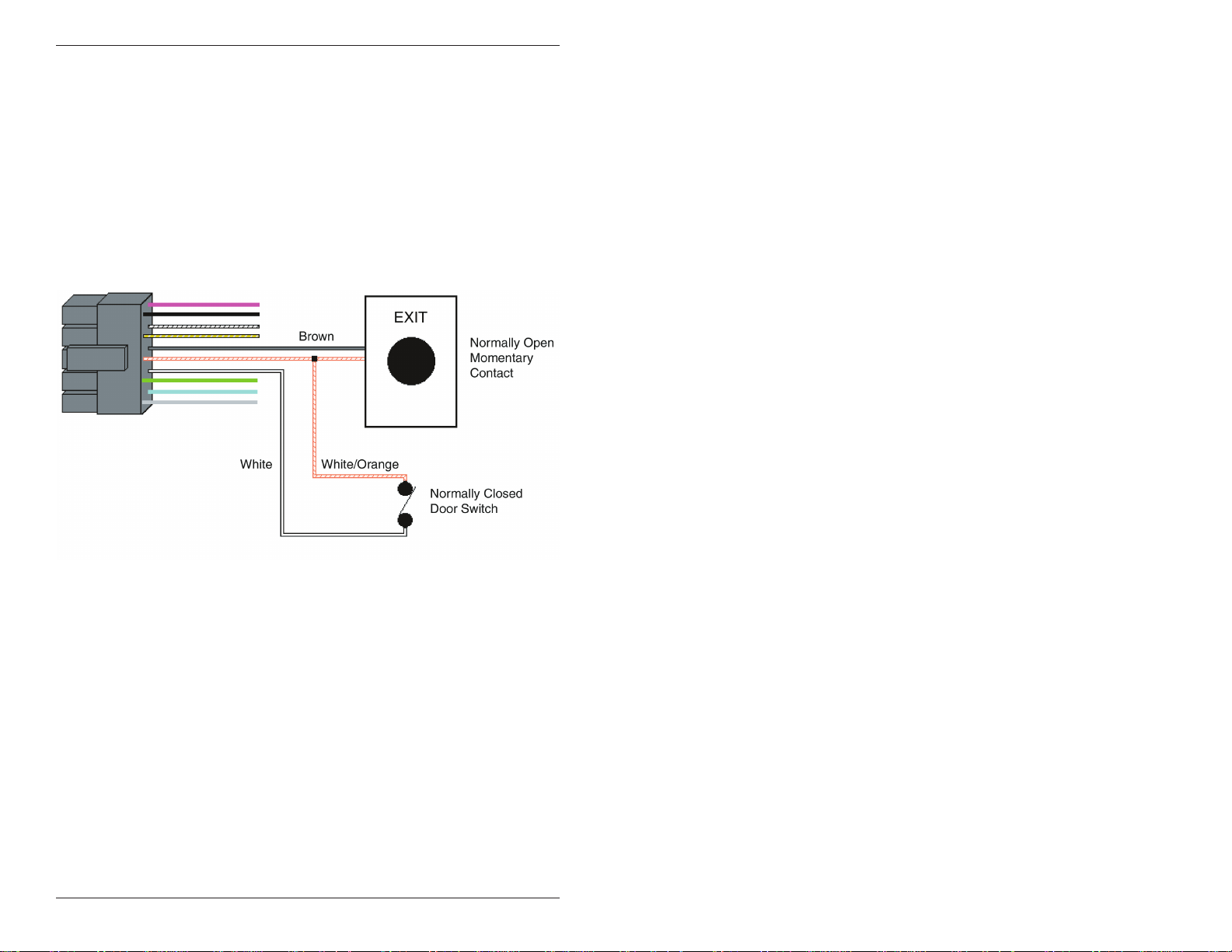

5.5 Wiring Remote Trigger as Request to Exit

(REX) Button and Door Contacts

Use the following steps to connect the keypad to a normally open

REX device and normally closed door switch:

1. Connect the brown wire (REX Input) to the normally open

connection the REX device.

2. Connect the white/orange (loop common) to the common on

theREXdeviceandthecommonthedoorswitch.

3. Connect the white wire (door loop) to the normally closed

connection on the door switch.

Figure 8 Wiring a REX Button and Door Contacts

NOTE: By default, the REX function operates the virtual lock output only, but this can be changed using command 49. In addition,

the door loop does not need to be closed for the REX function to

operate, by default, but setting option 8 to 0 under command 30

programs the REX function to operate only when the door loop is

closed. This prevents the REX from re-triggering when the door is

open.

12 Document # 6104401, Rev. 1.0, D1e

Page 13

e/eM Style Standalone Installation/Programming Manual

5.6 Wiring an Accessory Relay Board (242 only)

Theaccessoryrelayboardcontainsphysicaloutputs2,3,and4

shown in the table below.

Physical Output Relay Connector

2K2P1

3K3P2

4K4P3

Use the wire harnesses supplied with the relay board to connect to

therelays.Thewirecolorsareshowninthetablebelow.

Wire Color Relay Connection

Gray Normally Closed

Blue Common

Green Normally Open

Figure 9 Wiring an Accessory Relay Board

5.7 Wiring an Integrated Access Control

System Using the Accessory Relay Board

Physicaloutputs2,3,and4aredefaulted to the alarm shunt,

propped door, and forced door virtual outputs, respectively. Use

the following steps to wire the alarm shunt, propped door alarm,

and forced door alarm.

Document # 6104401, Rev. 1.0, D1e 13

Page 14

e/eM Style Standalone Installation/Programming Manual

NOTE: You MUST wire a normally closed door switch, as shown

in Figure 6, for these functions to work properly.

1. (Wiring the alarm shunt) Using P1 (K2), connect the blue

wire (common) to common on the door switch. Connect the

green wire (normally open) to the normally closed contact on

the door switch.

2. (Wiring the propped door alarm) Using P2 (K3), connect the

green wire (normally open) to the positive on the alarm

device.Connectthebluewire(common)tothepositiveon

thepowersupply.Connectthenegativeonthealarmdevice

to the negative on the power supply.

3. (Wiring the forced door alarm)UsingP3(K4),connectthe

green wire (normally open) to the positive on the alarm

device.Connectthebluewire(common)tothepositiveon

thepowersupply.Connectthenegativeonthealarmdevice

to the negative on the power supply.

Figure 10 Wiring an Integrated Accessory Relay Board

14 Document # 6104401, Rev. 1.0, D1e

Page 15

e/eM Style Standalone Installation/Programming Manual

There are two options for plugging the relay board onto the keypad, depending on the installation. For flush mount applications,

plug the relay board onto P3 horizontally, as shown in Option 1 below. If the keypad is mounted using a surface mount backbox, use

the right angle connector included in the backbox. First insert the

right angle connector into S3 on the relay board; then plug the connector onto P3 on the keypad. This is shown in Option 2 below.

Use the included tie wrap to bundle all the wires together from the

keypad wire harness and relay board.

NOTE: The IEI backbox is not U.L. listed

Figure 11 Plugging on Relay Board - Option 1

Figure 12 Plugging on Relay Board - Option 2

Document # 6104401, Rev. 1.0, D1e 15

Page 16

e/eM Style Standalone Installation/Programming Manual

6. Testing the Keypad

After installing the keypad, IEI recommends that you perform the

keypad self-test once a year, to ensure that the keypad works properly.

1. To perform the self-test, with the unit powered up, press the

following keys on the keypad:

7890#123456*

• If all 12 keypresses are accepted, the keypad enters self-test

mode.

• The LEDs alternate green, yellow, and red followed by the

sounder beeping three times.

2. Verify that the master code works correctly. (The master c ode

accesses program mode and activates the main relay to verify

that the locking device is workin g.)

The default master code is 1234.

(If the default is not working, refer to section 9.)

16 Document # 6104401, Rev. 1.0, D1e

Page 17

e/eM Style Standalone Installation/Programming Manual

7. Programming

To program the keypad, you must first enter program mode by

pressing 99 # Master Code *. The default Master Code is 1234.

NOTE: If auto-entry is enabled, the * (asterisk) key is not used to

enter Program mode. To change the Master Code, enter:

1 # new Master Code * new Master Code *

(To exit Program Mode, press *.)

7.1 Programming Order

To ensure that the keypad is programmed properly in the initial

installation, program the keypad in the following order:

• Step 1: Assigning Virtual Outputs to Physical Outputs

• Step 2: Programming Output Time Durations

• Step 3: Programming Users

• Step 4: Programming Keypad Options

7.2 Assigning Virtual Outputs to Physical

Outputs

ThekeypadisequippedwithelevenVirtualOutputsandsixPhysical Outputs. Virtual Outputs are functions that you can assign to operate any Physical Output. Physical Outputs include the main relay,

the three relays on the aux relay board, and the two audio alerts.

The 242 model has six physical outputs (four relays and two audio

alerts). The 212 model has three physical outputs (a main relay

and two audio alerts).

• Using command 10, you can assign any Virtual Output to

any Physical Output or disable a Physical Output.

• Each Physical Output can only h ave one Virtual Output

assigned to it.

Document # 6104401, Rev. 1.0, D1e 17

Page 18

e/eM Style Standalone Installation/Programming Manual

Command/Action Keys to Enter/Details

Command 10.

Assign Virtual

Outputs to Physical

10#virtualoutput#physicaloutput#*

*

Outputs

Virtual Output List Physical Output List

0 - No mapping 1 - Relay 1 (Main Relay)

(physical output unused)

1-Lock 2-Relay2(K2)

2 - Alarm Shunt 3 - Relay 3 (K3)

3 - Propped Door 4 - Relay 4 (K4)

4-ForcedDoor 9-AudioAlert#1

5 - OUT2 10 - Audio Alert #2

6-OUT3

7-OUT4

8-OUT5

13 - Duress

14 - Panic

15 - Keypad Active

* Audio alerts are described in section 7.2.2.

Defaults—The

keypad comes

programmed with

the following default

output assignments:

The Lock Output is assigned to Relay 1, the

Alarm Shunt Output to Relay 2, the Propped

Door Output to Relay 3, and the Forced

Door Output to Relay 4.

7.2.1 Virtual Outputs

Virtual Output Description/Details

Lock This output is used for your locking device.

This is used to shunt out an existing alarm

Alarm Shunt

Propped Door

18 Document # 6104401, Rev. 1.0, D1e

panel. It activates with the lock output and

de-energizes one second after the lock time

expires.

This output activates after entering a valid

user code only if the door position switch is

left open longer than the programmed

propped door time.

Page 19

e/eM Style Standalone Installation/Programming Manual

Virtual Output Description/Details

This output activates if the door position

Forced Door

OUT2, OUT3, OUT4,

OUT5

Duress

Panic

Keypad Active

switch is opened without entering a valid

user code.

These four independently controlled outputs

are activated by user codes programmed to

activate multiple outputs and the REX

function. See programming commands 59

and 49 in the Programming section.

The duress output is activated when a

duress user enters their code. See Duress

User in the Programming section.

Panicisactivatedbypressingthe* and #

keys at the same time. This is used in case

of emergency to activate an auxiliary device

andshouldnotbeusedtogainaccess.

The Keypad Active output is activated when

any key is pressed. Do not use this output

to gain access.

7.2.2 Audio Alerts

Audio Alerts are produced by the local sounder on the keypad

and can be used as a local propped door alarm or forced door

alarm to free up the other relays for other functions.

• Alert #1 is a constant quick beep (¼ second on and ¼ second off).

• Alert #2 is a short beep (100 ms) every two seconds.

• Alert #1 takes priority over Alert #2.

7.2.3 Programming REX Outputs

For wiring information, see section 5.5.

49#outputlist#0#**

(Use this command to program which outputs the REX operates.

1=LOCK,2=OUT2,3=OUT3,

4=OUT4,and5=OUT4.)

Document # 6104401, Rev. 1.0, D1e 19

Page 20

e/eM Style Standalone Installation/Programming Manual

7.3 Programming Output Time Durations

Command/Action Keys to Enter/Details

Command 11. Set

LOCK Time Duration

Command 12. Set

OUT2 Time Duration

Command 13. Set

OUT3 Time Duration

Command 14. Set

OUT4 Time Duration

Command 15. Set

OUT5 Time Duration

Options:

ttt

(Example:)

pre

(Example:)

Command 44. Set

Propped Door Time

Options:

time

11 # time # 0 # * * (time = 1 to 255

seconds)

12 # ttt # pre # * *

13 # ttt # pre # * *

14 # ttt # pre # * *

15 # ttt # pre # **

number of time units to operate OUTn when

valid PIN entered (1 through 255)

12#1#10#(for ten seconds)

number of seconds in each time unit

(prescaler)

12#15#1#(for fifteen seconds)

44 # time # 0 # * *

Propped Door Time - rounded down to

nearest 10’s of seconds; entered as 00, 10

through 990, defaults to 30 seconds;

entering a time of zero disables the propped

door function

Command 45. Set

Forced Door Time

Options:

time

20 Document # 6104401, Rev. 1.0, D1e

45 # time # 0 # * *

Forced Door Time - rounded down to

nearest 10’s of seconds; entered as 00, 10

through 990, defaults to 10 seconds;

entering a time of zero latches the virtual

forced door that can be cleared with any

valid PIN or by entering program mode

Page 21

e/eM Style Standalone Installation/Programming Manual

Command/Action Keys to Enter/Details

Command 32.

Change Keypad

Parameters

Parameter Value

0 - duress output duration 1 through 255 (defaults to 5)

1 - panic output duration 1 through 255 (defaults to 5)

2 - error lockout threshold 1 through 50 (defaults to 3)

3 - error lockout duration 1 through 255 (defaults to 10)

32 # parameter # values # * *

7.4 Programming Users

Command/Action Keys to Enter/Details

User #1 is the master code; it can access all

commands in program mode. The default

Master Code

Supervisor Code

Add Standard User

(short version)

Add User with

Specific Unlock Time

Delete User user location # * *

code is 1234. The master code can be

programmed with command 50 or command

60 as a standard user only.

User #2, when programmed, is the supervisor

code. The supervisor can access program

mode, but is limited to adding and deleting

users, as well as enabling or disabling users.

The supervisor code can not change, delete,

or disable the master code or supervisor code

itself.

user location # code * code *

unlock time # user location # c ode * code *

(This command is used to program a user

with a specific unlock. This user activates the

virtual lock output.)

Document # 6104401, Rev. 1.0, D1e 21

Page 22

e/eM Style Standalone Installation/Programming Manual

Command/Action Keys to Enter/Details

Command 60.

Add/Modify Enhanced

User

Toggle User A toggle user latches the virtual lock output.

Standard User

Lockout User

Single Use Code

Emergency User

60 # type # location # code * code *

(codes can be from 1 to 10 digits in length)

User Types

0 - Toggle User

1-StandardUser

3 - Lockout User

5 - Single Use Code

7 - Emergency User

8-DuressUser

9 - Two-Part User Type A

10 - Two-Part User Type B

Activates the virtual lock output using the lock

duration programmed with command 11.

This user type locks out users in user locations

higher than the lockout user when the lockout

user code is entered. For example, if the lockout

user is programmed for user 20, any user in

location 21 to 120 is locked out and their codes

no longer work to gain access. A lockout is

removed by entering the same lockout code. If

another lockout code in another user location is

entered, the lockout user location level is set to

the new lockout user location. The master code

and emergency users can not be locked out.

The current lockout is cleared when program

mode is entered. “Lockout activated” is indicated

by two double beeps. “Lockout canceled” is

indicated by one double beep.

“Access denied due to lockout” is indicated by 1

long beep followed by 3 short beeps.

“User lockout” can be enabled or disabled with

command 30.

This code can only be entered once to gain

access using the lock virtual output. Once used,

this code is no longer active. A single use code

can be verified by entering 5 # code *. If the

code is a single use code, the green LED flashes

for ½ a second. An “invalid code” is indicated by

3 quick beeps.

This user type is a standard user that can not be

locked out by a lockout user.

22 Document # 6104401, Rev. 1.0, D1e

Page 23

e/eM Style Standalone Installation/Programming Manual

Command/Action Keys to Enter/Details

Entering a duress code activates the lock and

Duress User

Two-Part Users A

and B

duress virtual outputs. This allows you to trigger

another device silently, such as an alarm, and

still gain access in case of an emergency.

When the two-part user option is enabled, two

codes are required to gain access. A “Two-Part

Type A” and “Two-Part Type B” user must enter

their code (not necessarily in that order). After

the first code is entered, the LED alternates

between red and green, indicating another code

is required. The second code must be entered

within 15 seconds of the first code. When two

codes of the same type are entered, a type

mismatch is indicated by 5 beeps. When

Two-Part User is disabled, all Type A and B user

codes are converted to standard user codes.

Two-Part users activate the virtual lock output.

Two-Part Users can be enabled or disabled with

command 30.

Command 56.

Enable/Disable User

Options: 1 = Disable

Command 59.

Program users to

operate virtual outputs

OUT2, OUT3, OUT4,

and OUT5 as well as

the virtual lock output.

56 # enable/disable # user location # * *

0 = Enable

The master code and supervisor code

cannot be disabled.

59 # output list # location # code * code *

(Use this command to operate multiple outputs

and the virtual lock output using a single code.

This is useful when you want to operate a

separate device while unlocking the door and

still use some of the access control features

such as alarm shunt, propped door, forced door

and REX.

The output list is specified by entering the

output(s) you want the code to operate.

1 = LOCK, 2 = OUT2, 3 = OUT3,

4=OUT4,and5=OUT5.

Document # 6104401, Rev. 1.0, D1e 23

Page 24

e/eM Style Standalone Installation/Programming Manual

7.5 Programming Keypad Options

Command/Action Keys to Enter/Details

Command 30.

Enable/Disable keypad

options

Option Set/Clear

0 - audio keypress feedback 0=disabled, 1=ENABLED

1 - visual keypress feedback 0=disabled, 1=ENABLED

2 - auto-entry enable 0=DISABLED, 1=enabled

3 - error lockout 0=disabled, 1=ENABLED

4 - user lockout 0=disabled, 1=ENABLED

5 - two-part users 0=disabled, 1=ENABLED

6 - keypad illumination 0=disabled, 1=ENABLED

7 - keypad dimming 0=disabled, 1=ENABLED

8 - REX operation 0=only when door loop closed

Defaults are in bold. Options 6 and 7 available only in e keypads.

Auto-entry

Error Lockout

Keypad Illumination Keypad backlighting can be enabled or disabled.

Keypad Dimming

Command 40. Reset

defaults only.

Command 46. Erase

Users and Reset

Default Settings.

30 # option # enable/disable # * *

1=always

When auto-entry is enabled, users with codes

the same length as the master code do not have

to press the * key after entering their code. If

you have a code greater than the master code,

you can use Auto-Entry Suspend. Just enter the

# key prior to your code followed by the * key.

Example:

# 23456 * if the master code is four digits.

When enabled, the keypad keeps track of the

number of consecutive invalid codes entered,

including attempts to access program mode.

When the threshold is reached, the yellow LED

turns on solid and the keypad no longer

responds to key presses for the programmed

time duration. The count is reset by entering a

valid code, including entering program mode.

The error lockout threshold and duration is

programmed with command 32.

When enabled, the backlighting illumination level

decreases 15 seconds after the last key press.

When disabled, the backlighting remains at full

illumination at all times.

40 # 00000 # 00000 # ** (master code, all

keypad options and parameters)

46 # 00000 # 00000 # **

24 Document # 6104401, Rev. 1.0, D1e

Page 25

e/eM Style Standalone Installation/Programming Manual

8. Troubleshooting

Refer to this section if the keypad is not operating correctly as described in this manual.

Problem Solution

The keypad is designed to monitor the input

The LEDs are slowly

cycling from right to

left and backlighting is

off.

The LEDs are rapidly

cycling from left to

right and the keypad

has lost all operation.

Themastercodedoes

not work.

No LEDs are lit on the

keypad

If the keypad still does not work after troubleshooting, please call

IEI’s technical support department at 1-800-343-9502 (outside MA)

or 1-800-733-9502 (inside MA). Operating hours are Monday

through Friday from 8:00 A.M. to 7:00 P.M. Eastern Standard Time.

voltage and this is an indication of under-voltage.

The under-voltage threshold is set to 8.5VDC,

and when the voltage drops below this limit, the

low voltage warning starts and backlighting is

turned off. To solve, raise the voltage to between

12-24V.

The keypad is designed to monitor the input

voltage, and this is an indication of over-voltage.

The over- voltage threshold is set to 36VDC, and

when the voltage rises above this limit, the

over-voltage warning starts and the keypad loses

all operation. To solve, lower the voltage to

between 12-24V.

Perform the programming mode loopback and

reset the master code using the programming

command.

Power is not reaching the keypad. Using a

voltmeter, confirm that there is voltage at the

keypad on the red and black wires. If there is no

voltage at the keypad, verify that there is voltage

at the power supply. If there is no voltage at the

power supply, call the manufacturer of the power

supply. If there is voltage at the power supply

but not at the keypad, verify there is no break in

the wires, then check continuity in the whole

length of the wire run. To verify that the keypad

is working, you can power the keypad with a

12-Volt Battery.

Document # 6104401, Rev. 1.0, D1e 25

Page 26

e/eM Style Standalone Installation/Programming Manual

9. Programming Mode

Loopback

If the Master Code is either not working or forgotten, power

down the system, connect the wire harness as shown in Figure 13

below, and then power the system up again. Next, change your

Master Code and power down the system and restore the wire

harness to its original configuration and power the system back

up.

Figure 13 Programming Mode Loopback Standalone

First, disconnect power from the system. Next, connect the

White/Yellow wire to the Brown (REX) wire and the White (Door

Loop) wire as shown in Figure 13, and then power up the keypad

again.

26 Document # 6104401, Rev. 1.0, D1e

Page 27

10. Warranty

International Electronics Inc. (IEI) warrants its products to be free

from defects in material and workmanship when they have been

installed in accordance with the manufacturer’s instructions and

have not been modified or tampered with. IEI does not assume

any responsibility for damage or injury to person or property due

to improper care, storage, handling, abuse, misuse, normal wear

and tear, or an act of God.

IEI’s sole responsibility is limited to the repair (at IEI’s option) or

the replacement of the defective product or part when sent to IEI’s

facility (freight and insurance charges prepaid) after obtaining

IEI’s Return Material Authorization. IEI will not be liable to the

purchaser or any one else for incidental or consequential damages

arising from any defect in, or malfunction of, its products.

Except as stated above, IEI makes no warranties, either expressed

or implied, as to any matter whatsoever, including, and without

limitation to, the condition of its products, their merchantability, or

fitness for any particular purpose.

Warranty Periods Are:

1Year PowerKey

2 Years Door Gard & Secured Series

Products

2 Years LS Series

2 Years Glass Break

5Years eandeMStyleKeypads

Allproductshavedatecodelabelingtodeterminethewarrantyperiod.A

90-day grace period is added to all products to account for shelf life.

Page 28

Loading...

Loading...