Lincoln POWER-MASTER III 84981, POWER-MASTER III 84982, POWER-MASTER III 84985, POWER-MASTER III 84983, POWER-MASTER III 84984 Owner's/operator's Manual

Page 1

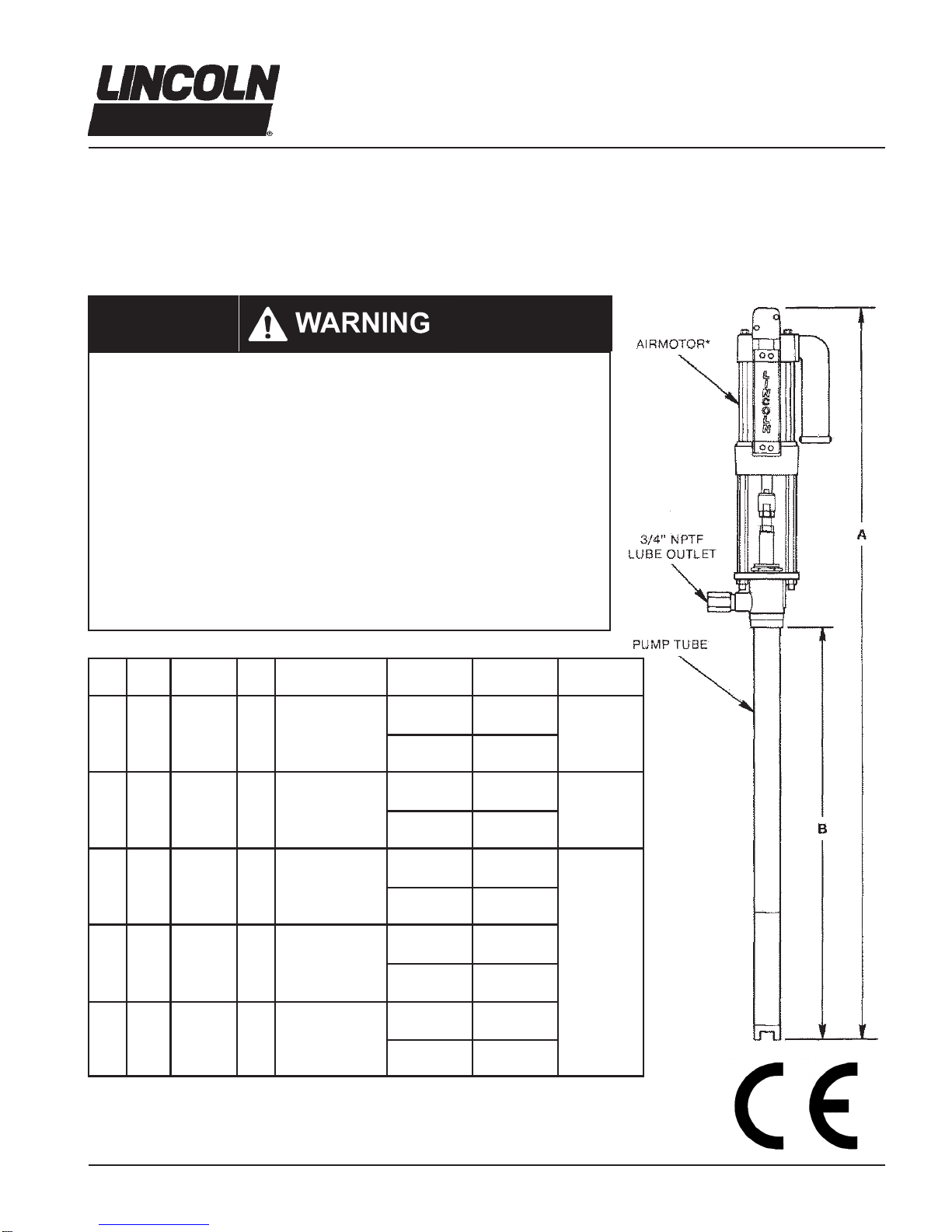

Models 84981, 84982, 84983, 84984, 84985

POWER-MASTER III DRUM PUMPS

Ball Type Foot Valve

OWNER/OPERATOR MANUAL

It is the responsibility of the Owner/Operator to properly use and maintain this equipment.

The Instructions and Warnings contained in this manual shall be read and understood by the Owner/Operator prior to operating

this equipment

It is the responsibility of the Owner/Operator to maintain the legibility of all Warning and Instruction labels

The Owner/Operator shall retain this manual for future reference to important Warnings, Operating and Maintenance

Instructions.

DO NOT operate these pumps with 10” airmotor.

DO NOT exceed the stated maximum working pressure of the airmotor or the

lowest rated component in your system.

DO NOT alter or modify any part of this equipment.

DO NOT operate this equipment with combustible gas.

DO NOT attempt to repair or disassemble the equipment while the system is

pressurized.

TIGHTEN all uid connections securely before using this equipment.

ALWAYS read and follow the uid manufacturer’s recommendations regarding

uid compatibility, and the use of protective clothing and equipment.

CHECK all equipment regularly and repair or replace worn or damaged parts

immediately.

IMPORTANT: Failure to heed these warnings including misuse, over pressurizing, modifying parts, using incompatible chemicals and uids, or using worn or

damaged parts, may result in equipment damage and/or serious personal injury,

re, explosion, or property damage.

MODEL CHART

PUMP PUMP MAXIMUM DELIVERY MAXIMUM AIR DIMENSION "A" DIMENSION "B"

TUBE MODEL AIRMOTOR* RATIO PRESSURE PRESSURE in. (cm.) in. (cm.)

2061 84808 42:1 4200 psi (294 bar) 100 psi (7 bar) 60 (152.4)

2021 84806 24:1 2400 psi (168 bar)

84985 2001 84804 12:1 2400 psi (168 bar) 200 psi (14 bar) 60-7/8 (154.6)

2052 84803 6:1 1200 psi (84 bar)

2065 84808 42:1 4200 psi (294 bar) 100 psi (7 bar) 53-3/8 (135.6)

2025 84806 24:1 2400 psi (168 bar)

84984 2005 84804 12:1 2400 psi (168 bar) 200 psi (14 bar) 54-1 /4 (137.8)

2055 84803 6:1 1200 psi (84 bar)

2061-7 84808 42:1 4200 psi (294 bar) 100 psi (7 bar) 60 (152.4)

2021-7 84806 24:1 2400 psi (168 bar)

84983 2001-7 84804 12:1 2400 psi (168 bar) 200 psi (14 bar) 60-7/8 (154.6)

2052-7 84803 6:1 1200 psi (84 bar)

2061-8 84808 42:1 4200 psi (294 bar) 100 psi (7 bar) 60 (152.4)

2021-8 84806 24:1 2400 psi (168 bar)

84982 2001-8 84804 12:1 2400 psi (168 bar) 200 psi (14 bar) 60-7/8 (154.6)

2052 -8 84803 6:1 1200 psi (84 bar)

2061-9 84808 42:1 4200 psi (294 bar) 100 psi (7 bar) 60 (152.4)

2021-9 84806 24:1 2400 psi (168 bar)

84981 2001-9 84804 12:1 2400 psi (168 bar) 200 psi (14 bar) 60-7/8 (154.6)

2052-9 84803 6:1 1200 psi (84 bar)

* Refer to Airmotor Owner/Operator Manual, Section AS Page 78.

34 (86.4)

273/8 (69.5)

34 (86.4)

©

© Indicates change

MAY - 2007

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Form 403663

Section

- A50

Page

- 80A

Page 2

Models 84981, 84982, 84983, 84984, 84985

POWER-MASTER III DRUM PUMPS

Ball Type Foot Valve

ATTACHING AIRMOTOR TO

PUMPTUBE

1. Tightly attach tie rods to the airmotor

(use short threaded end of the tie rods).

2. Mount airmotor on top of the pump tube

outlet and tightly connect Coupling Nut

(Item 2) to airmotor piston rod.

3. Hand tighten tie rods to the pumptube

with four nuts supplied with airmotor.

4. Slowly cycle the pump several times,

using just enough air pressure to operate

the pump without stalling.

5. Stop the pump on an “up” stroke and

tighten the four nuts to securely fasten

the airmotor to the pumptube.

OPERATING PRECAUTIONS

Use Lincoln replacement parts to assure •

compatible pressure rating

HEED ALL WARNINGS•

Be sure material hoses and other •

components are able to withstand uid

pressures developed by this pump

Do not operate pump continuously at •

speeds in excess of 75 cycles per

minute.

Disconnect air line from pump air motor •

when system sits idle for long periods of

time.

SERVICING Before servicing or •

cleaning pump, or removing uid hose or

gun from a unit that has been used, be

sure to disconnect air lines and carefully

bleed pressure off of the system.

PREVENT STATIC SPARKING. If static

sparking occurs, re or explosion could

result. Pump, dispensing valve, and con-

tainers must be grounded when handling

ammable uids such as petroleum products, paints, lacquers, etc. and wherever

discharge of static electricity is hazard.

Check continuity (a good static wire •

connection) with an ohmmeter Place

one probe on one hose tting and the

other probe on other hose tting, conti-

nuity or proper grounding through hose

is good when a reading is obtained on

the ohmmeter

PREVENT FIRES. When pumping, •

ushing or recirculating volatile solvents, the area must be adequately

ventilated.

Keep solvents away from heat, sparks •

and open ames. Keep containers

closed when not in use.

Page Number - 2

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

DO NOT allow pump to operate when

out of material.

PUMP PRIMING

To begin operation, the pump has to

be primed with the pumped material.

The Power-Master III pump is a double

acting (pumps material on ‘up’& “down”

stroke.) positive displacement recipro-

cating pump and as such intakes material only on the “up” stroke.

To prime pump, open output line (material

valve) and slowly open air supply valve

until pump starts. Allow pump to cycle

very slowly until all air is pushed out of

lines and material lls up pump and lines.

Close output line (material shut-off valve)

- pump should stall against pressure

Note: Pumps are factory tested with light

oil and some of it is left in to protect pump

parts during storage and transportation.

To prevent contamination of material to be

pumped, ush pump before using.

Form 403663

Page 3

Models 84981, 84982, 84983, 84984, 84985

POWER-MASTER III DRUM PUMPS

Ball Type Foot Valve

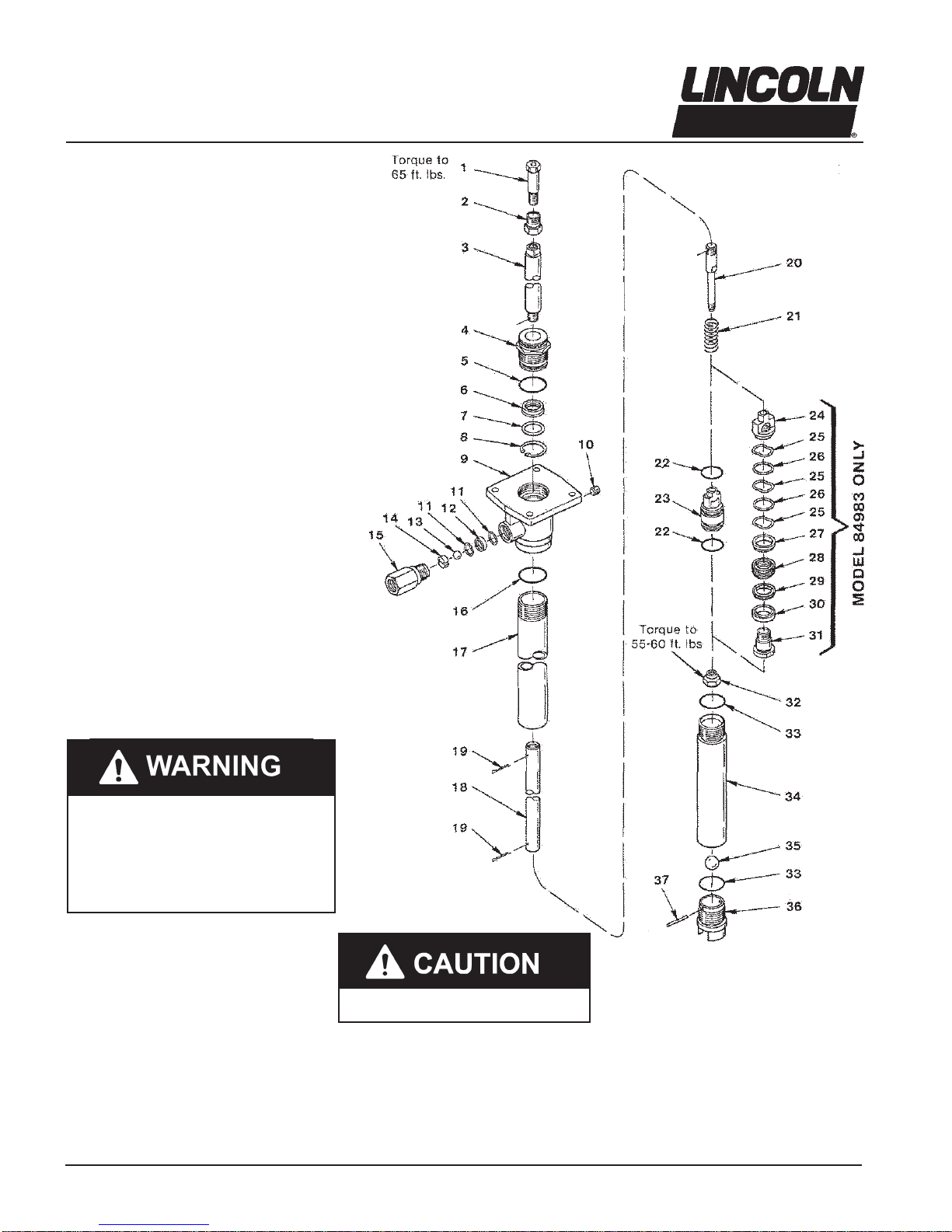

DISASSEMBLY

Tools Required

2-1/8” Dia Strap Wrench 7/8” Hex Wrench 2-1/4” Hex Wrench

1-3/8” Hex Wrench

Retaining Ring Pliers (Internal) 5/8” Hex Wrench

1” Hex Wrench

Procedure

1. Remove Foot Valve Body (Item 36) from Bushing Tube

(Item 34).

2. Slide Retaining Pin (Item 37) from Foot Valve Body (Item

36) and remove Ball (Item 35).

3 Unscrew Bushing Tube (Item 34) and slide off of Piston

(Item 23).

4. Remove Bolt Connector (Item 1) from Plunger (Item 3)

5. Pull Piston (Item 23) to remove Plunger (Item 3), Connect-

ing Rod (Item 18) and Piston Assembly from Pump Tube

(Item 17).

6. Remove Pump Tube (Item 17) from Outlet Body (Item 9).

7. Remove O-ring (Item 16) from Outlet Body (Item 9).

8. Remove Gland Nut (Item 4) from Outlet Body (Item 9).

9. Remove Outlet Body (Item 15) from Outlet Body (Item 9).

10. Remove Ball (Item 13), Check Seat (Item 12) and Gaskets

(Item 11) from Outlet Body (Item 9).

11. Remove Retaining Ring (Item 8), Packing Washer (Item 7)

and U-cup (Item 6) from Gland Nut (Item 4).

12. Remove Piston Check (Item 32) from Piston Rod (Item

20).

13 Remove Piston (Item 23) and Spring (Item 21) from Piston

Rod (Item 20).

14. Remove Cotter Pins (Item 19) from Connecting Rod (Item

18).

15. Remove Piston Rod (Item 20) and Plunger (Item 3) from

Connecting Rod (Item 18).

16. To re-assemble pump, reverse disassembly procedure.

(Refer to illustration for torque specications.)

TROUBLESHOOTING

Problem Possible Cause Solution

Pump does not operate. Restricted or inadequate air supply. Check air supply pressure and air hose

diameter (see Airmotor manual for

minimum air supply hose diameter)

Obstructed material output, Check output line for restrictions.

Erratic or accelerated operation. Pump is not primed. Prime pump (see "Pump Priming"

Instructions).

Insufcient material supply Rell material supply.

Material is too heavy for priming. Lower output with material valve. Increase

pressure to pressure primer (if in use).

Check for inlet restrictions.

Pump operates on "down" stroke only Worn or damaged Piston O-rings (Item 22) Check and replace if needed.

(missing "up" stroke) or Piston Check (Items 23 & 32).

Pump operates on "up" stroke only Worn or damaged Inlet Check (Items 35 Check and replace if needed.

(missing "down" stroke). & 36).

Insufcient material supply. Pump is not Check inlet for restrictions Lower output

intaking enough material to dispense on with material valve.

both strokes.

Pump is operating but not dispensing Inlet Check (Items 35 & 36) is not seating Check and replace if needed.

material. or is damaged

ACCESSORIES AND PACKING KITS

86214 Gland Protection Sleeve - To increase life of gland

seal.

86213 Lube Cup - For solvent, to prevent material from drying

on pump rod.

84502 Teon Packing Kit - For Models 84981, 84982, 84984

& 84985.

86221 Viton Packing Kit - For Models 84981, 84982, 84984

& 84985.

16177 Foot Valve Adapter - Converts pump inlet to 1-1/2”

NPTF Female

84112 Pump Piston Replacement - With Leather V-packings

(standard on Model 84983).

PUMP REPAIR KITS:

86219 - Includes soft parts for Models 84983”, 84984 & 84985

86220 - Includes soft parts for Models 84981 & 84982.

86222 - Piston rebuild kit for Model 84983*.

* Model 84983 requires Kits 86219 & 86222 for rebuild.

Form 403663

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Page Number - 3

Page 4

Models 84981, 84982, 84983, 84984, 84985

POWER-MASTER III DRUM PUMPS

Ball Type Foot Valve

SPECIFICATIONS

Pump stroke - 6 in (152 mm)

Output per cycle- 11.9 cu m. (195 cc)

Max. recommended speed (continuous) - 75 cycles min

Approx. cycles per gallon (liter) - 20 (5)

Output at 75 cycles/min. - 3.9 gpm (14 6 liter/min.)

ITEM PART NUMBER

NO. DESCRIPTION QTY. Model 84981 Model 84982 Model 84983 Model 84984 Model 84985

1 Bolt Connector 1 236225 236225 236225 236225 236225

2 Coupling Nut 1 237051 237051 237051 237051 237051

3 Plunger 1 242840 242839 242839 242839 242839

4 Gland Nut 1 242844 242843 242843 242843 242843

5 O-ring 1 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

6 U-cup Packing 1 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

7 Packing Washer 1 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

8 Retaining Ring 1 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

9 Outlet Body 1 242223 242223 242216 242216 242216

10 Pipe plug 1 ---- ---- 67359 67359 67359

11 Gasket 2 ---- ---- (Note #1) (Note #1) (Note #1)

12 Outlet Check 1 ---- ---- 11948 11948 11948

13 Ball 1 ---- ---- 66285 66285 66285

14 Ball Stop 1 ---- ---- 57036 57036 57036

15 Outlet Body 1 ---- 12017 12017 12017

16 O-ring 1 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

17 Pump Tube 1 242228 242228 242232 242235 242232

18 Connecting Rod 1 242243 242243 242245 242244 242245

19 Cotter Pin 2 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

20 Piston Rod 1 16445-9 16445-8 16445 16445 16445

21 Spring 1 55292 55292 55262 55262 55262

22 O-ring 2 (Note #2) (Note #2) ---- (Note #1) (Note #1)

23 Piston 1 14611-9 92136-8 ---- 92136 92136

24 Piston Rod Guide 1 ---- ---- 14994 ---- ---

25 Wave Washer 3 ---- ---- (Note #3) ---- ---

26 Washer 2 ---- ---- (Note #3) ---- ---

27 Male Adapter 1 ---- ---- 14993 ---- ---

28 Leather V-packing 4 ---- ---- (Note #3) ---- ---

29 Teon V-packing 1 ---- ---- (Note #3) ---- ---

30 Female Adapter 1 ---- ---- 14861 ---- ---

31 Piston Nut 1 --__ ---- 14859 ---- ---

32 Piston Check 1 16103-9 16103-8 16103 16103 16103

33 O-ring 2 (Note #2) (Note #2) (Note #1) (Note #1) (Note #1)

34 Bushing Tube 1 242215 242220 242221 242221 242221

35 Ball 1 68785 68649 66203 66203 66203

36 Foot Valve Body 1 13222-9 13222-9 13222 13222 13222

NOTES:

1. Included in 86219 Pump Repair Kit.

37 Retaining Pin 1 13226-9 13226-9 13226-9 13226-9 13226-9

2. Included m 86220 Pump Repair Kit.

Wetted part materials:

84985-Steel, Brass, Copper, Polyurethane, Nitrile

84984-Steel. Brass, Copper, Polyurethane, Nitrile

84983-Steel, Brass, Copper, Polyurethane, Leather, Teon,

Nitrile

84982- Chrome Plated Steel, Stainless Steel, Brass, Polyurethane, Nitrile

84981- Stainless Steel, Polyurethane, Nitrile, Teon

PARTS LIST

3. Included in 86222 Piston Repair Kit.

Page Number - 4

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Form 403663

Page 5

Models 84981, 84982, 84983, 84984, 84985

POWER-MASTER III DRUM PUMPS

Ball Type Foot Valve

Declaration by the manufacturer as dened by Machinery Directive 89/392EEC Annex IIB

Herewith we declare that the supplied model of PowerMaster Pumps 84981, 84982, 84983, 84984 and 84985

Is intended to be incorpoated into machinery covered by this directive and must not be put into service until the machiner into

shich it is to be incorpoated has been declared in conformity with the provisions of the directive 91/386/EEC.

Applied harmonized standards in particular:

EN 292 Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principles and

specications

EN 809 Pumps and pump units for liquids - Common safety requirements

EN 983 Safety of machinery - Safety requirements for uid power systems and their components - Pneumatics

EN 1050 Safety of machinery - Principles for risk assessment

Paul Conley, Cheif Engineer 5/20/07

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Form 403663

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Phone +49.6227.33.0

Fax +49.6227.33.259

Europe/Africa:

Germany

Asia/Pacic:

51 Changi Business Park

Central 2

#09-06 The Signature

Singapore 486066

Phone +65.6588.0188

Fax +65.6588.3438

© Copyright 2007

Printed in USA

Web site:

www.lincolnindustrial.com

Page Number - 5

Loading...

Loading...