Lincoln 3270 Service Manual

PARTS & SERVICE MANUAL

Impinger 3270

Impinger 3270 CE

REV: 5/2/12

Lincoln Foodservice Products, LLC

1111 North Hadley Road

Fort Wayne, Indiana 46804

Telephone: 260.459.8200

Fax: 888.790.8193

Technical Support: 800.678.9511

lincolnfp.com

Table of Contents

MODEL NUMBER KEY............................................................................................................... 3

SEQUENCE OF OPERATION - DOMESTIC .............................................................................. 4

SEQUENCE OF OPERATION - INTERNATIONAL .................................................................... 5

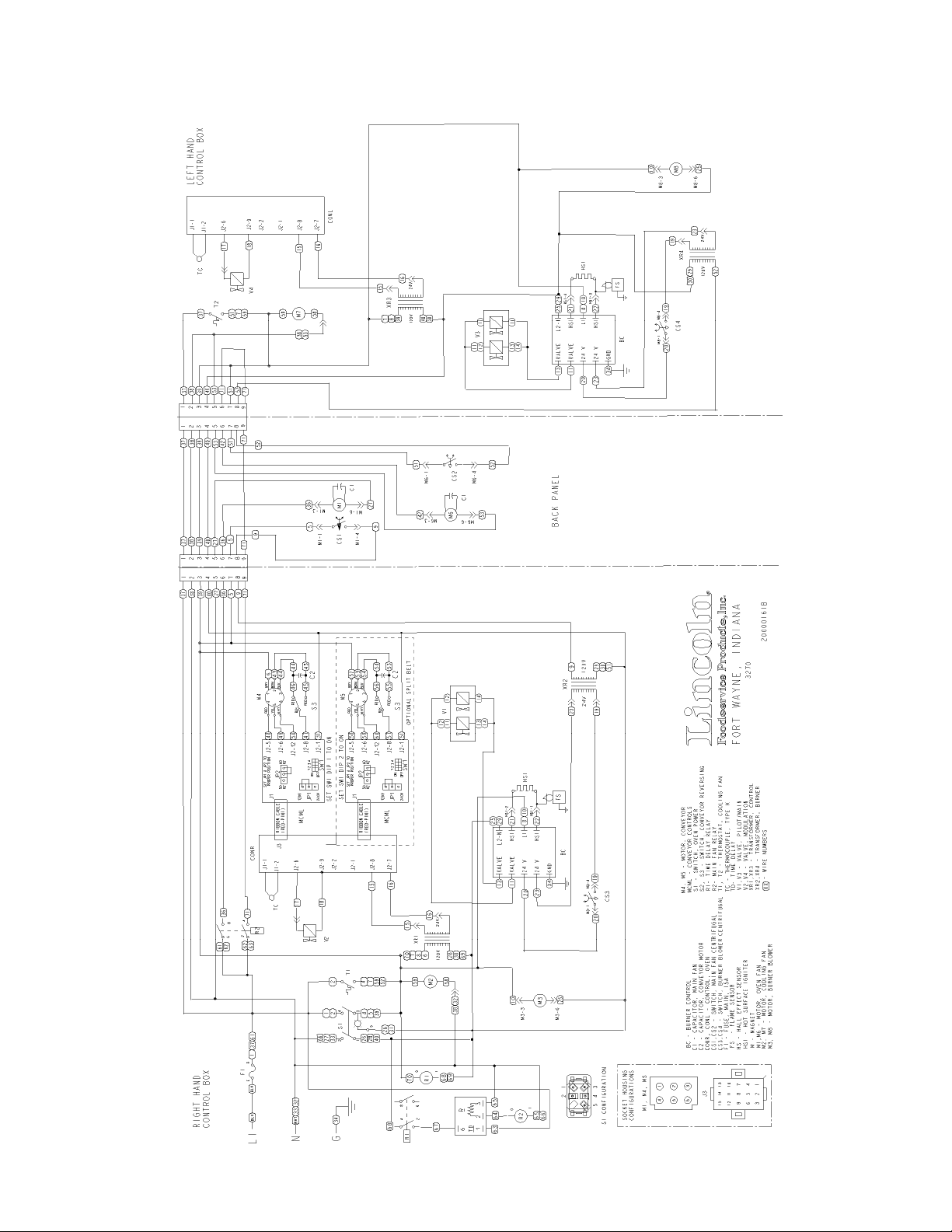

SCHEMATIC DIAGRAM - DOMESTIC ....................................................................................... 6

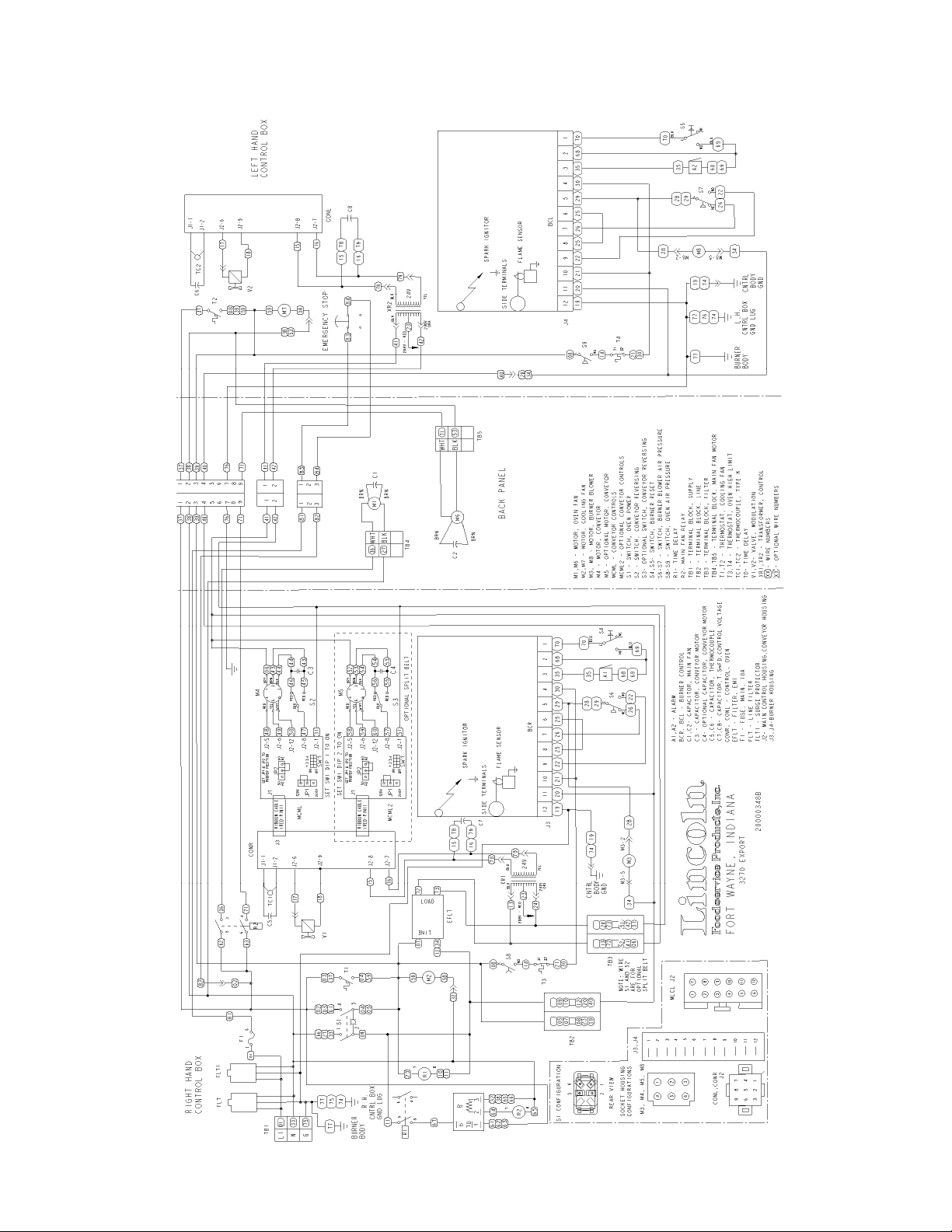

SCHEMATIC DIAGRAM - INTERNATIONAL ............................................................................. 7

TROUBLESHOOTING GUIDE - DOMESTIC .............................................................................. 8

TROUBLESHOOTING GUIDE - INTERNATIONAL .................................................................. 13

REMOVAL, INSTALLATION & ADJUSTMENTS ...................................................................... 18

OVEN CONTROL – PROGRAMMING...................................................................................... 25

GENERAL VIEW ....................................................................................................................... 27

CONTROL BOX, LEFT SIDE - DOMESTIC .............................................................................. 29

CONTROL BOX, RIGHT SIDE - DOMESTIC ........................................................................... 31

CONTROL BOX, LEFT SIDE - INTERNATIONAL .................................................................... 33

CONTROL BOX, RIGHT SIDE – INTERNATIONAL ................................................................. 35

REAR WALL MOTOR ASSEMBLY ........................................................................................... 37

CONVEYOR, FULL BELT ......................................................................................................... 39

CONVEYOR, SPLIT BELT ........................................................................................................ 41

2

Impinger 3270 Service Manual – Dom & Int’l

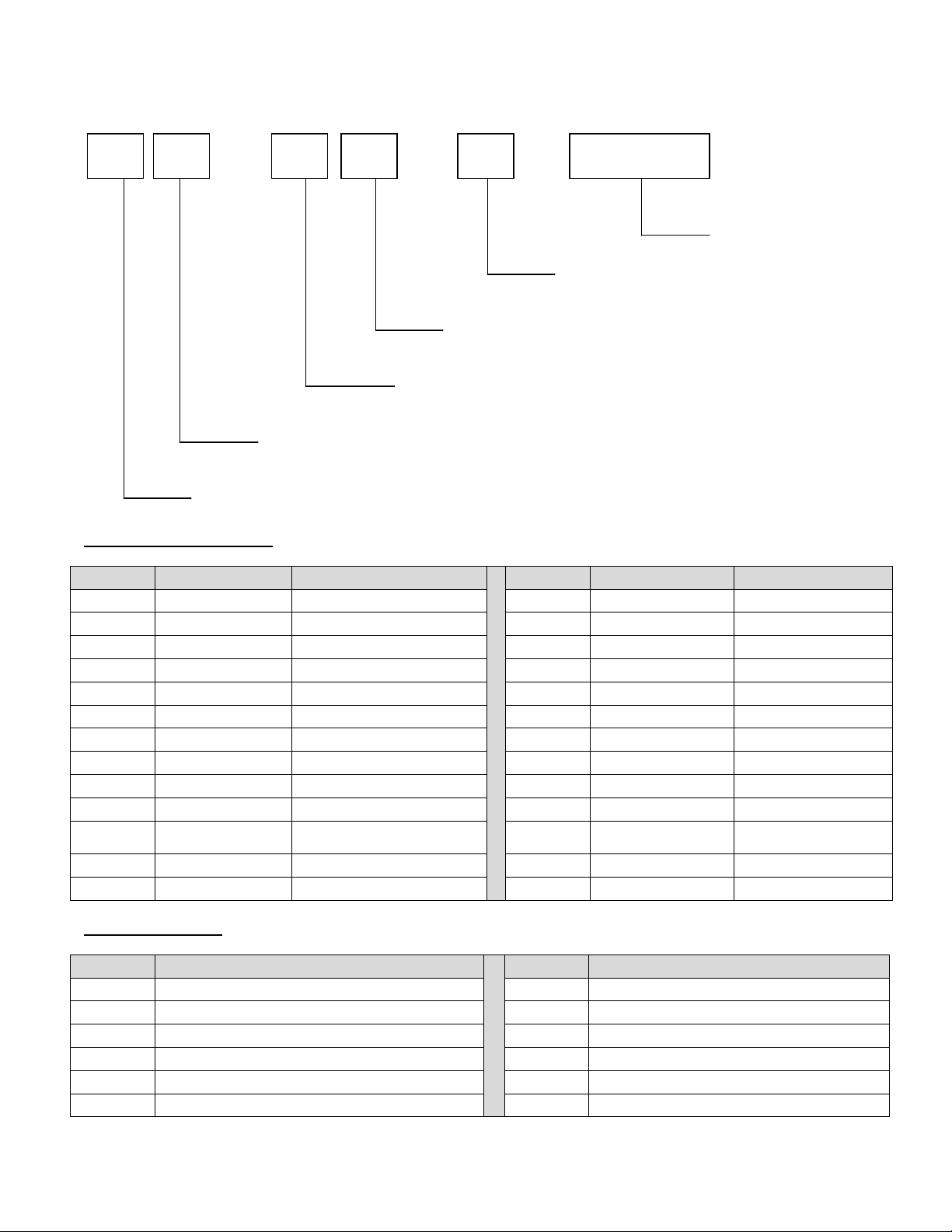

EXAMPLE: 3270-000-N-K1962 or 3270-000-NCE-K1962

32 70 - 0 00 - N - K1962

MODEL NUMBER KEY

Fuel Type / Agency Code (i.e. Natural / CE)

Custom Configuration Code (i.e. Solid Belt, General Market)

Language Code (i.e. English)

Oven Platform Size (cooking chamber width)

Oven Platform Size (belt width)

LANGUAGE CODE TABLE

CODE LANGUAGE COUNTRY CODE LANGUAGE COUNTRY

0 English Dom. & Int. Default N Finnish Finland

B French France/Luxembourg O Restricted ---

C German Germany P Norwegian Norway

D Italian Italy Q English Japan

E Spanish Spain R Swedish Sweden

F English UK/India/Africa/Hungary S English Australia

G Spanish Mexico/Latin America T Mandarin China

H Portuguese Portugal U Restricted ---

I Not Used --- V English Pacific Rim/Korea

J Danish Denmark W English Middle East

K

L Dutch Netherlands Y Not Used ---

M Greek Greece Z Not Used ---

Dutch &

French

Belgium X Not Used ---

FUEL TYPE TABLE

CODE TYPE CODE TYPE

N Natural Gas S 480V 3PH 60Hz

L LP Gas V 120/240V 3PH 60Hz

J 208V 1PH 60Hz B 230V 1PH 50Hz

M 220V 1PH 60Hz D 380/220V 1PH 50Hz

P 240V 1PH 60Hz G 415/240V 1PH 50Hz

R 208V 3PH 60Hz

Panel Setup Code

Impinger 3270 Service Manual – Dom & Int’l

3

SEQUENCE OF OPERATION - DOMESTIC

Model Gas Type Voltage Hz. Phase

3270 Natural Gas 120 VAC 60 Hz 1 Phase

3270 LP Gas 120 VAC 60 Hz 1 Phase

POWER SUPPLY

Electrical power to be supplied to the oven by a three conductor cordset.

Voltage from the black conductor to the white conductor to be 120VAC.

- White conductor is Neutral

- Green conductor is Ground

CONTROL BOX

AUTO COOL DOWN

When the temperature in either one of the control boxes reaches 120°F ± 3°F

(49°C ± 1.7°C), the cooling fan thermostats will switch power to the cooling fans.

The thermostats will interrupt power to the cooling fans when the temperature

falls to 100°F ± 3°F (37°C ± 1.7°C).

MAIN FAN CIRCUIT

120VAC is permanently supplied through a 15 amp fuse to the normally open

double pole power switch, to a normally open set of contacts on the main fan

relay and the normally open cooling fan thermostats. Closing the power switch

supplies 120VAC to the coil of the time delay relay. These normally open

contacts now close supplying 120VAC to the time delay which then supplies

120VAC to the main fan relay coil closing the normally open contacts, which then

supplies 120VAC to the main fan motors.

BURNER CIRCUIT

Closing the Oven Power Switch also supplies 120VAC to the burner blower

motors. NOTE: This oven utilizes two (2) complete Burner/Temperature Control

systems. The sequence of operations is the same for each system. 120VAC is

supplied, through the Centrifugal Switch of the Main Fan Motor (this switch

closes when the Main Fan reaches approximately 900 R.P.M.) to the primary of

Ignition Control Transformers. As the Burner Blower reaches approximately

1600 R.P.M., its internal centrifugal switch will close, supplying 24VAC to the

ignition control. The Ignition Control operates on both 24VAC and 120VAC.

When the control is energized by 24VAC, 120VAC is switched to the Hot Surface

Igniter for 45 seconds for Hot Surface Igniter warm up. The igniter glows red,

24VAC is switched to the MV/PV gas valve which opens, and ignition should now

occur. If ignition does not occur in 6 seconds, the control will lock out. To

recycle after lockout, turn off the main oven switch for 45 seconds and then turn

the switch back on.

TEMPERATURE CONTROL

When the Oven Power Switch closes, power is supplied to the Oven Control

Transformers which supply 24VAC to the oven controls (TWO CONTROLS –

one for the left side of oven, one for the right side of oven). The oven control is

set to a desired temperature. Thermocouples will provide varying millivolts to the

oven controllers. The oven controllers supply 3-24VDC to the modulating valve

to maintain desired temperature.

CONVEYOR DRIVE

Line voltage (120VAC) is supplied to the conveyor motor. The conveyor speed is

controlled by an increase or decrease in frequency for the conveyor controller.

Secondary voltage, 24VAC, is supplied to the oven control. Setting the oven

control to the desired time, outputs line voltage, through a reversing switch, to

the conveyor motor.

Speed is monitored via frequency output from the hall effect sensor.

NOTE: The conveyor control uses a hall effect sensor and magnet mounted in the conveyor motor that senses the

motor speed. Any change in motor load (± R.P.M.) is detected by the sensor and the frequency to the motor is

adjusted accordingly.

4

Impinger 3270 Service Manual – Dom & Int’l

SEQUENCE OF OPERATION - INTERNATIONAL

Model Gas Type Voltage Hz. Phase

3270 CE Natural Gas 230 VAC 50 Hz 1 Phase

3270 CE LP Gas 230 VAC 50 Hz 1 Phase

POWER SUPPLY

CONTROL BOX

AUTO COOL DOWN

Electrical power to be supplied to the oven by a three conductor service.

When the temperature in either one of the Control Boxes reaches 49°C ± 1.7°C,

(120°F ± 3°F) the Cooling Fan Thermostats will switch power to the Cooling

Fans. The thermostats will interrupt power to the Cooling Fans when the

temperature falls to 37°C ± 1.7°C (100°F ± 3°F).

MAIN FAN CIRCUIT

Power is permanently supplied through a 10 amp fuse, through the normally

closed emergency stop button, to the normally open double pole power switch, to

a normally open set of contacts on the main fan relay and the normally open

cooling fan thermostats. Closing the power switch supplies line voltage to the

coil of the time delay relay. These normally open contacts now close enabling

the time delay which then supplies line voltage to the main fan relay. As these

normally open contacts close, line voltage is supplied to the main fan motors.

BURNER CIRCUIT

Closing the oven power switch supplies line voltage, through the main fan air

pressure switch, through the normally closed oven cavity hi-limit thermostat, to

the ignition control. The combustion motor is now energized; the normally open

combustion air pressure switch closes upon sensing air. After a prepurge period

between 30 and 60 seconds, the spark and main gas valve are energized.

Ignition should now occur.

TEMPERATURE CONTROL

When the Oven Power Switch closes, power is supplied to the Oven Control

transformers which supply 24 VAC to the Oven Controls (TWO CONTROLS one

for the oven’s left side, one for the oven’s right side). The Oven Control is set to a

desired temperature. Thermocouples will provide varying millivolts to the Oven

Controllers. The Oven Controllers supply 3-24 VDC to the modulating valve to

maintain desired temperature.

CONVEYOR DRIVE

Line voltage is supplied to the conveyor motor. The Conveyor speed is controlled

by an increase or decrease in frequency from the Conveyor Controller.

Secondary voltage, 24VAC, is supplied to the oven control. Setting the oven

control to the desired time, outputs line voltage, through a reversing switch, to

the conveyor motor.

Speed is monitored via a frequency output from the hall effect sensor.

NOTE: The conveyor control uses a hall effect sensor and magnet mounted in the conveyor motor that senses the

motor speed. Any change in motor load (± R.P.M.) is detected by the sensor and the frequency to the motor is

adjusted accordingly.

Impinger 3270 Service Manual – Dom & Int’l

5

SCHEMATIC DIAGRAM - DOMESTIC

MODEL 3270 120V 60HZ 1PH NATURAL or LP GAS

6

Impinger 3270 Service Manual – Dom & Int’l

SCHEMATIC DIAGRAM - INTERNATIONAL

MODEL 3270 CE 230V 50HZ 1PH NATURAL or LP GAS

Impinger 3270 Service Manual – Dom & Int’l

7

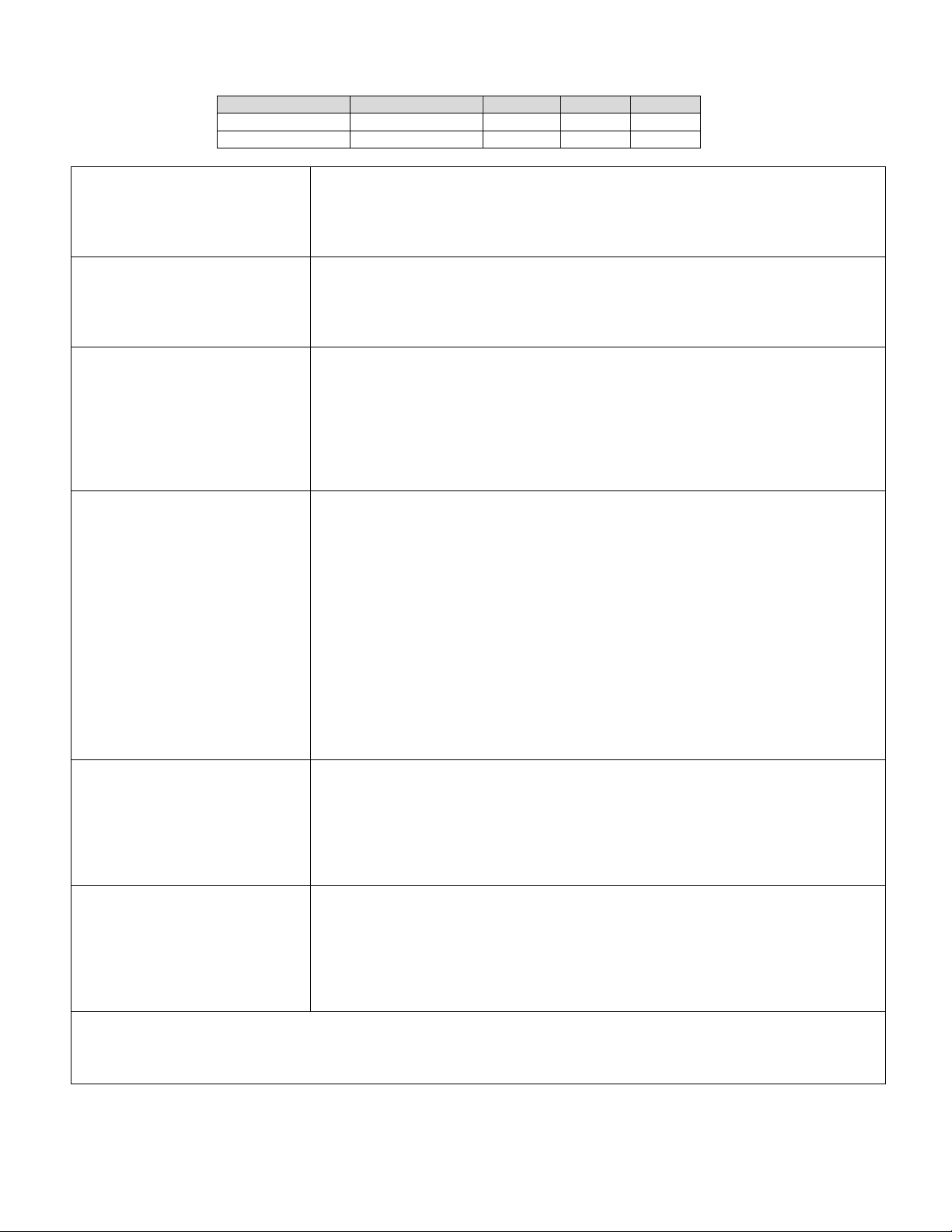

TROUBLESHOOTING GUIDE - DOMESTIC

SYMPTOM

POSSIBLE CAUSE

EVALUATION

Model Number Gas Type Voltage Hz. Phase

3270 Natural Gas 120 VAC 60 Hz 1 Phase

3270 LP Gas 120 VAC 60 Hz 1 Phase

Oven fan will not run

No control box cooling

Incoming Power Supply Check breakers, reset if required. Check power plug to be

sure it is firmly in receptacle. Measure the incoming power.

Call power company if needed.

Fuse, 15 Amp

Fuse Holder

Main Oven Switch

Time Delay Relay

Check, replace if necessary.

Check, replace if necessary.

Check continuity between switch terminals. Replace if

necessary.

Check for 120 VAC to the relay coil. If voltage is not

present, trace wiring back to the oven power switch. If

voltage is present, check to insure contacts are closing.

Time Delay

120 VAC is permanently supplied to the time delay. If no

voltage is present, trace wiring back to fuse and incoming

power. Neutral side of time delay coil is switched by the

time delay relay. When the time delay is enabled, it

supplies 120 VAC to coil of main fan relay.

Main Fan Relay

Check for 120 VAC to main fan relay coil. If no voltage is

present, trace back to time delay. If 120 VAC is supplied to

main fan relay coil, ensure the contacts of main fan relay

are closing by checking for 120 VAC on terminals #4 to a

neutral and #8 to a neutral (these are the terminal numbers

on the main fan relay). If contacts are not closing, replace

the relay. Each terminal supplies a main fan motor with

120 VAC.

Main Fan Motor

Check for 120 VAC at motor. If voltage is present and

motor doesn’t turn, WITH POWER OFF check for opens,

shorts, or grounds. Turn fan blade to check for locked

rotor. Replace as needed.

Capacitor

WARNING: Capacitor has a stored charge, discharge

before testing. Check for shorts or grounds, replace as

needed. Inspect for any visible damage. If the top of the

capacitor appears to be swollen, replace capacitor.

Incoming Power

Fuse, 15 Amp

Fuse Holder

Main Oven Switch

Cooling Fan(s)

Check main circuit breakers and reset, if required. Call

power company if needed.

Check, replace if necessary.

Check, replace if necessary.

Check continuity between switch terminals. Replace if

necessary.

120 VAC should now be at the fan motor. If voltage is

present and motor doesn’t turn, WITH POWER OFF, check

8

Impinger 3270 Service Manual – Dom & Int’l

motors for shorts or opens. Check for locked rotor.

Replace if necessary.

No automatic control box

cooling

Incoming Power Supply Check circuit breakers. Reset if required. Call power

Fuse, 15 Amp

Fuse Holder

Cooling Fan Thermostat Check the cooling fan thermostat. (Thermostat closes at

company if needed.

Check, replace if necessary.

Check, replace if necessary.

120°F and opens at 100°F.) With the cooling fan

thermostat preheated, check for continuity. If switch is

open, replace.

Cooling Fan(s)

120 VAC should be at the motor. If voltage is present,

WITH POWER OFF, check for locked rotor. Check motor

for shorts, opens, or grounds.

Oven will not heat

Gas Supply

Check manual gas valves and flexible gas line connection.

Also check for adequate gas supply.

NOTE: Natural Gas supply to oven – min. 7 in. W.C.

LP Gas supply to oven – min. 11 in. W.C.

Main Fan

If not operating, refer to “oven fan will not run”.

NOTE: These ovens utilize 2 complete burner/temperature control systems. Each system will follow the same

troubleshooting sequence.

Oven will not heat

Centrifugal Switch of

Main Fan Motor

Check for 120 VAC supplied to the centrifugal switch. If

voltage is not present, trace the wiring back to the oven

power switch. Check for 120 VAC out of the centrifugal

switch. If voltage is supplied to the centrifugal switch, and

motor is running but there is no voltage out of the

centrifugal switch, replace the fan motor.

(NOTE: See Schematic Diagram of proper wire numbers

on motors.)

Burner Blower Motor

If no 120 VAC to blower motor, trace wiring back to oven

power switch. Check for 120 VAC supply to the burner

blower motor, if 120 VAC is present and motor does not

turn, replace the motor.

Burner Transformer

Check for 120 VAC to primary of the 24 VAC ignition

control transformer. If voltage is not present, trace wiring

back to the centrifugal switch of main fan motor. If voltage

is present, check for 24 VAC at the secondary. If no

secondary voltage is present, replace the transformer.

Centrifugal Switch of

Burner Blower Motor

Check for 24 VAC supply to the centrifugal switch of burner

blower motor (see Schematic for proper wire numbers). If

no voltage is present, trace wiring back to the transformer.

If voltage is present, check for 24 VAC at the output of the

centrifugal switch. If there is no output and the burner

blower motor is running, replace the burner blower motor.

Ignition Control

Check for 24 VAC supply to the ignition control at terminals

marked 24V and 24V. If voltage is not present, trace wiring

back to the centrifugal switch of burner blower motor.

Check for 120VAC supply to the ignition control at

Impinger 3270 Service Manual – Dom & Int’l

9

Oven will not heat

(continued)

Hot Surface Igniter

(Located inside Burner

Assembly)

Flame will not stay on

NOTE: Flame should be lit at this time.

Low flame is on but no

Ignition Control

Gas Control Valves

Hot Surface Igniter

Power Supply

Oven Control

main flame

Thermocouple Probe

10

terminals L1 and L2. If no voltage is present, trace wiring

back to oven power switch. If the above checks are okay,

proceed. When 24 VAC is applied, the ignition control

should switch 120VAC to the hot surface igniter for 45

seconds. Check across the (2) terminals marked HIS. If

no voltage is present, replace the ignition control.

If 120VAC is present at HSI terminals, visually check to

see that the hot surface igniter is heating (igniter may be

viewed through port glass in end of burner tube). The

igniter should glow bright red. Check all connections to be

sure they are tight. If the igniter does not heat, replace.

After 45 seconds of hot surface igniter pre-heat, the ignition

control will switch 24 VAC to the gas control valves for 6

seconds. Check for 24 VAC output from the ignition

control and across terminals marked “valve” and “valve”. If

no voltage is present, replace the ignition control.

NOTE: The ignition control contains a safety lockout

circuit. If a flame is not detected within 6 seconds after the

gas control valve is energized, the ignition control will

lockout. To reset, turn the power switch “off”, wait 45

seconds and switch the system “on” to retry ignition.

Check for 24 VAC supplied to the pilot/main gas valves

(dual valve). If voltage is present, the valves should open.

Check the output gas pressure at the pressure tap located

on the burner manifold. Gas pressure should measure

approximately .6 in. W.C. If there is no gas pressure and

the voltage is supplied to valves, check piping for

obstructions.

The ignition control will keep the gas control valves

energized for 6 seconds. At the end of 6 seconds the hot

surface igniter must sense a flame or the ignition control

will go to into lockout. (The ignition control requires a

minimum of 0.8 micro-amps D.C.) If you detect a flame but

only for the 6 second trial, check the flame sensing

operation. Connect a digital multimeter (capable of

measuring D.C. micro-amps) between the “ground”

terminal on the ignition control and the ground lead.

NOTE: This is a current measurement and the meter must

be connected in series. NOTE: The D.C. micro-amp test

must be conducted in series. NOTE: The D.C. micro amp

test must be conducted with the oven in low flame (bypass)

operation. Set the temperature control to its lowest setting.

If there is sufficient micro-amp current and the 120VAC

polarity is correct but the flame will not stay lit, check for

proper ground connection for the ignition control. If ground

is good, replace the ignition control.

Adjust temperature to maximum setting and check for 3-24

VDC at terminals J2-6 & J2-9 on oven control. If 3-24 VDC

is present and unit is not heating, refer to “Modulating

Valve” for next check. If 3-24 VDC is not present, proceed.

WITH POWER ON AND THERMOCOUPLE LEADS

Impinger 3270 Service Manual – Dom & Int’l

Low flame is on but no

Thermal/Overload of Main

main flame (continued)

Modulating Valve

Intermittent heating

Fan and Burner Blower

Motors

Conveyor will not run

Power Supply

15 Amp Fuse

Fuse Holder

Main Fan Switch

Oven Control

Transformer

Switch, Conveyor

Reversing

Conveyor Motor

Conveyor Motor

Capacitor

Impinger 3270 Service Manual – Dom & Int’l

ATTACHED TO THE TEMPERATURE CONTROL

BOARD:

Measure the D.C. millivolt output of these leads. Refer to

thermocouple chart in “Removal and Installation” section of

service manual for proper readings. If these readings are

not achieved, replace the thermocouple. If these readings

are achieved with temperature at maximum setting, replace

the oven control.

With temperature at maximum setting, check for 3-24 VDC

at the modulating valve. If no voltage is present, trace

wiring back to the oven control terminals J2-6 & J2-9. If

voltage is present, check the output gas pressure at the

pressure tap located on the burner manifold. If voltage is

present and gas pressure is not exceeding .6 in. W.C. at

the burner manifold, replace modulating valve.

The main fan motors and the burner blower motors are

equipped with internal thermal protection and will cease to

operate if overheating occurs. As the motors overheat and

then cool, this will cause the units to cycle on and off

intermittently. Improper ventilation or improper

maintenance may cause this. Also, most of the problems

listed under “oven will not heat” can cause intermittent

failure.

Check incoming voltage supply at line 1 to neutral. There

should be a voltage reading of 120VAC. If not present,

check breakers.

Check and/or replace.

Check and/or replace.

Check continuity between switch terminals.

Check for supply voltage to primary of transformer. If no

voltage is present, trace wiring back to the main oven

switch. If voltage is present, check for 24VAC at

transformer secondary. If there is primary voltage but no

secondary voltage, replace transformer. If secondary

voltage is present, proceed.

Check for continuity between switch terminals. Replace

switch as needed.

Check for supply voltage to the motor. If no voltage is

present, trace wiring back to the reversing switch. If no

voltage at switch, replace conveyor control. If voltage is

present, check motor windings for opens or shorts.

WITH POWER OFF: Check the motor windings as follows:

Grey to Black – 38 ohm approx.

Grey to Brown – 38 ohm approx.

Brown to Black – 75 ohm approx.

If any of the above fail, replace motor.

Check for shorts or grounds. Replace capacitor as

needed.

WARNING: Capacitor has a stored charge. Discharge

before testing!

11

Conveyor will not run

(continued)

Conveyor runs but no

speed control

Conveyor Check for any mechanical problems in the conveyor

assembly. Check for damaged or torn belting. Check

conveyor shaft bearings for damage or excessive wear.

Repair or replace conveyor components as needed.

Oven Control

Check output voltage from oven control to hall effect sensor

(sensor is located in conveyor motor). Measure voltage at

the motor connector, red wire and yellow wire. Voltage

should be approx. 10VDC. If no voltage is present, trace

wiring back to the oven control. If there is no voltage

output present at the oven control, replace the oven

control.

Motor, Conveyor

If there is voltage supplied to the hall effect sensor, check

for frequency output from the hall effect sensor. Measure

frequency across the yellow and white wires at the motor

connector. Frequency readings should be between 25 –

500 Hz. If these readings are not achieved, replace the

conveyor motor. If these readings are achieved, proceed.

Oven Control

If the hall effect sensor readings are correct but there is no

speed indicated on the display, replace the oven control.

12

Impinger 3270 Service Manual – Dom & Int’l

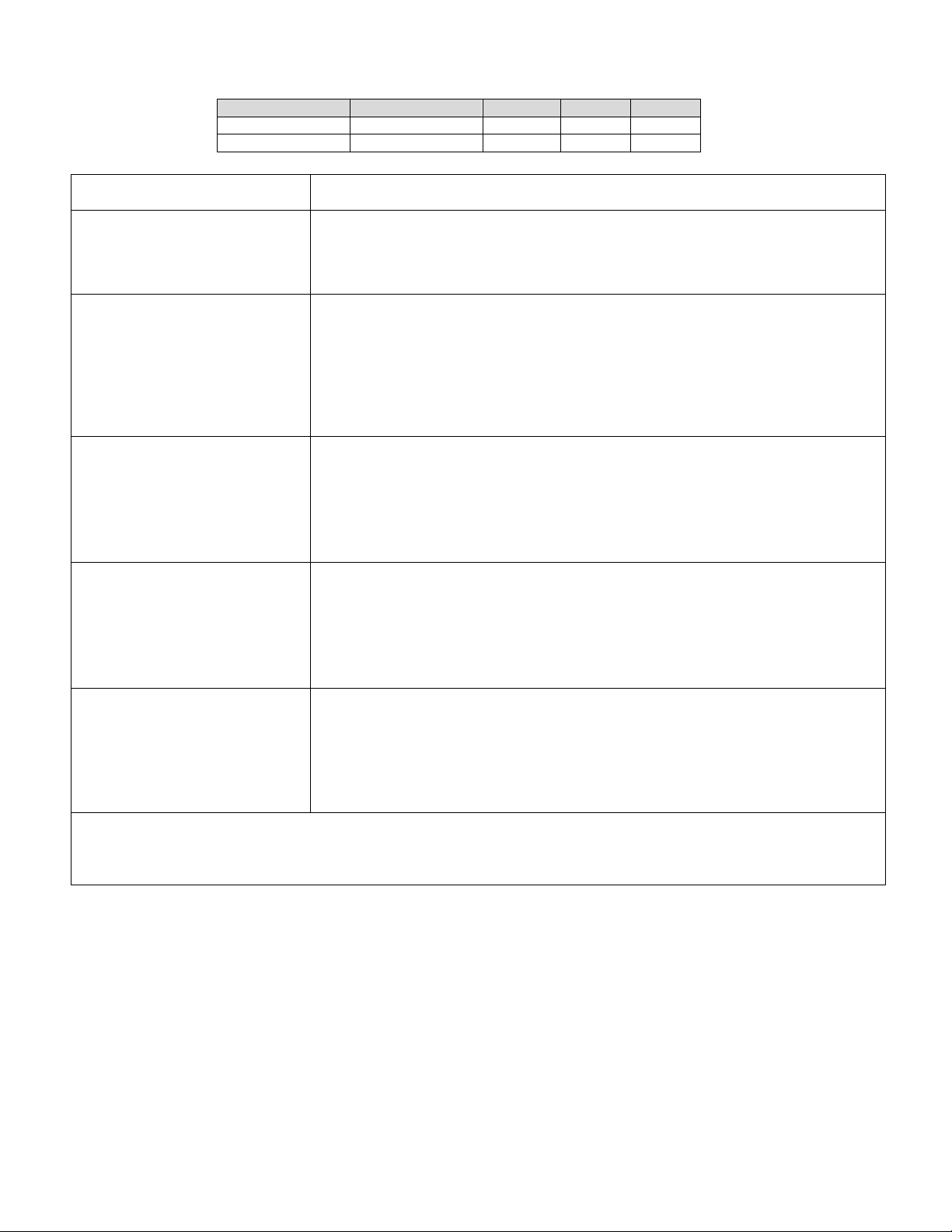

TROUBLESHOOTING GUIDE - INTERNATIONAL

SYMPTOM

POSSIBLE CAUSE

EVALUATION

Model Number Gas Type Voltage Hz. Phase

3270 CE Natural Gas 230 VAC 50 Hz 1 Phase

3270 CE LP Gas 230 VAC 50 Hz 1 Phase

Oven fan will not run

No control box cooling

Incoming Power Supply Check breakers, reset if required. Check power plug to be

sure it is firmly in receptacle. Measure the incoming power.

Call power company if needed.

Fuse, 10 Amp

Fuse Holder

Emergency Stop Button

Main Oven Switch

Time Delay Relay

Check, replace if necessary.

Check, replace if necessary.

This is a normally closed switch. Be sure button is re-set.

Check continuity between switch terminals. If switch is

open, replace Emergency stop button.

Check continuity between terminals. Replace if necessary.

Check for line voltage to the relay coil. If voltage is not

present, trace wiring back to the oven power switch. If

voltage is present, check to insure contacts are closing.

Replace as needed.

Time Delay

Line voltage is permanently supplied to terminal #1 of the

time delay. If no voltage present trace wiring back to fuse

and incoming power. Neutral side of time delay coil is

switched by the time delay relay. When the time delay is

enabled, line voltage is supplied to coil of main fan relay.

Main Fan Relay

Check for line voltage to main fan relay coil. If no voltage is

present, trace wiring back to time delay. If line voltage is

supplied to main fan relay coil, ensure the contacts of main

fan relay are closing by checking for output voltage from

relay contacts. If contacts are not closing, replace relay.

Each terminal supplies a main fan motor with line voltage.

Main Fan Motor

Check for line voltage at motor. If voltage is present and

motor doesn’t turn, WITH POWER OFF, check for opens,

shorts, or grounds. Turn fan blade to check for locked

rotor. Replace as needed.

Capacitor

WARNING: Capacitor has a stored charge, discharge

before testing. Check for shorts or grounds, replace as

needed. Inspect for any visible damage. If the top of the

capacitor appears to be swollen, replace capacitor.

Incoming Power

Fuse, 10 Amp

Fuse Holder

Main Oven Switch

Cooling Fan(s)

Check main circuit breakers and reset, if required. Call

power company if needed.

Check, replace if necessary.

Check, replace if necessary.

Check continuity between terminals. Replace if necessary.

Line voltage should now be at the fan motor. If voltage is

Impinger 3270 Service Manual – Dom & Int’l

13

Loading...

Loading...